Composition for preparing high-performance glass fiber by tank furnace production

A glass fiber and composition technology, applied in the field of special glass fiber components, can solve the problems of production constraints, production mode restrictions, and the inability to realize large-scale production of tank kilns, etc., and achieve the effect of excellent mechanical properties and close manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

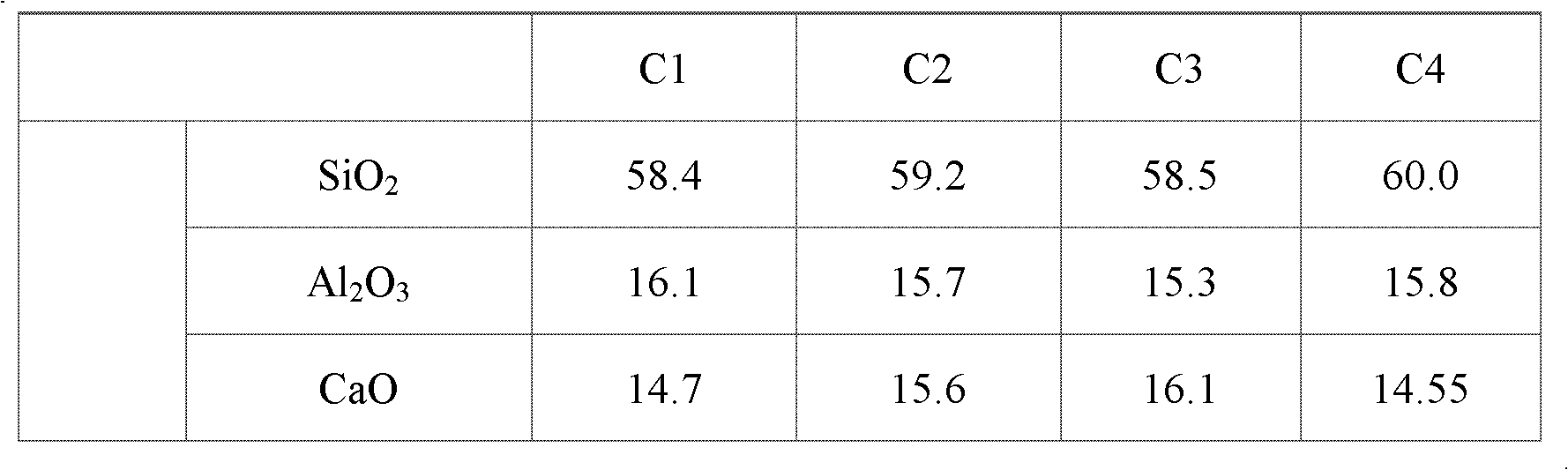

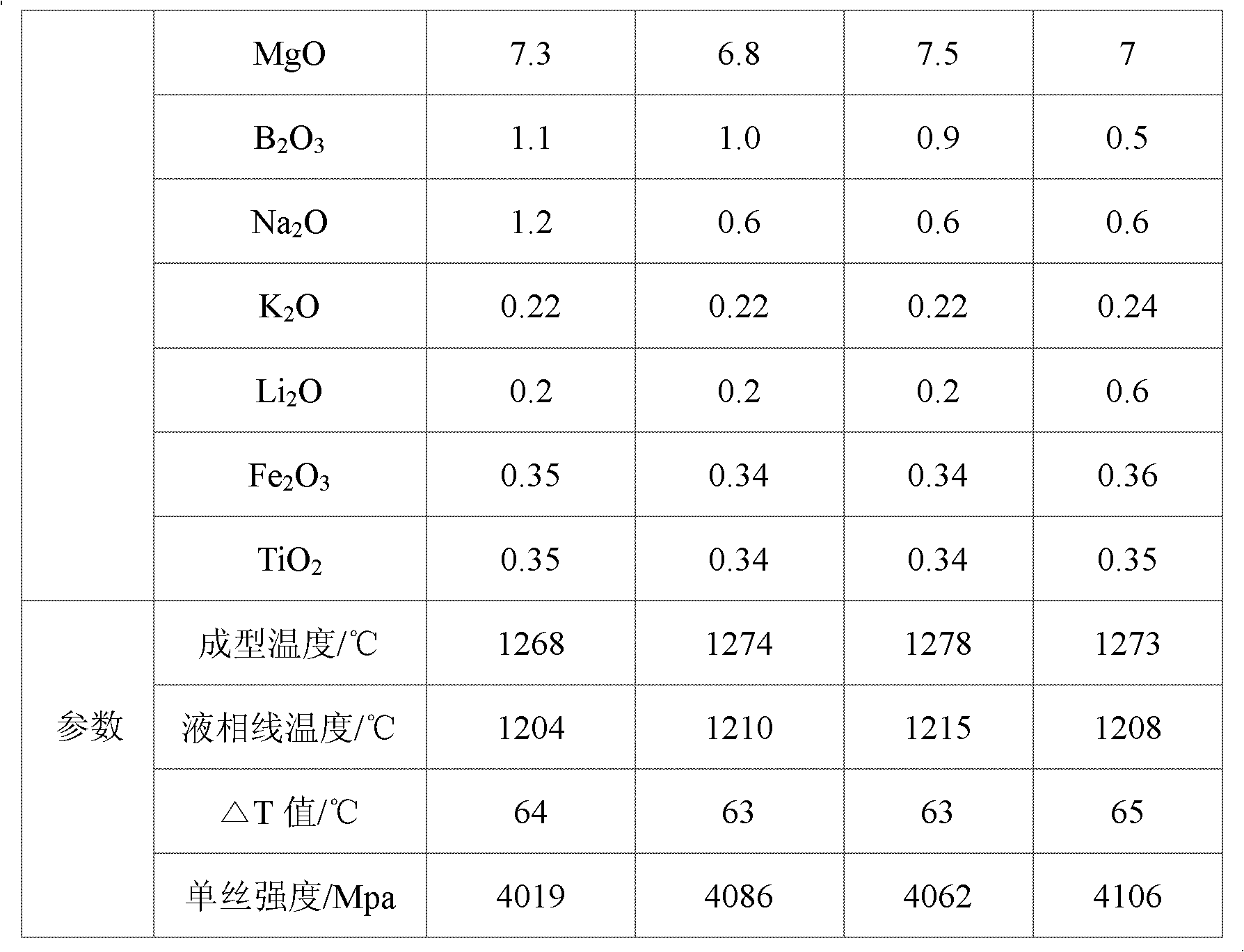

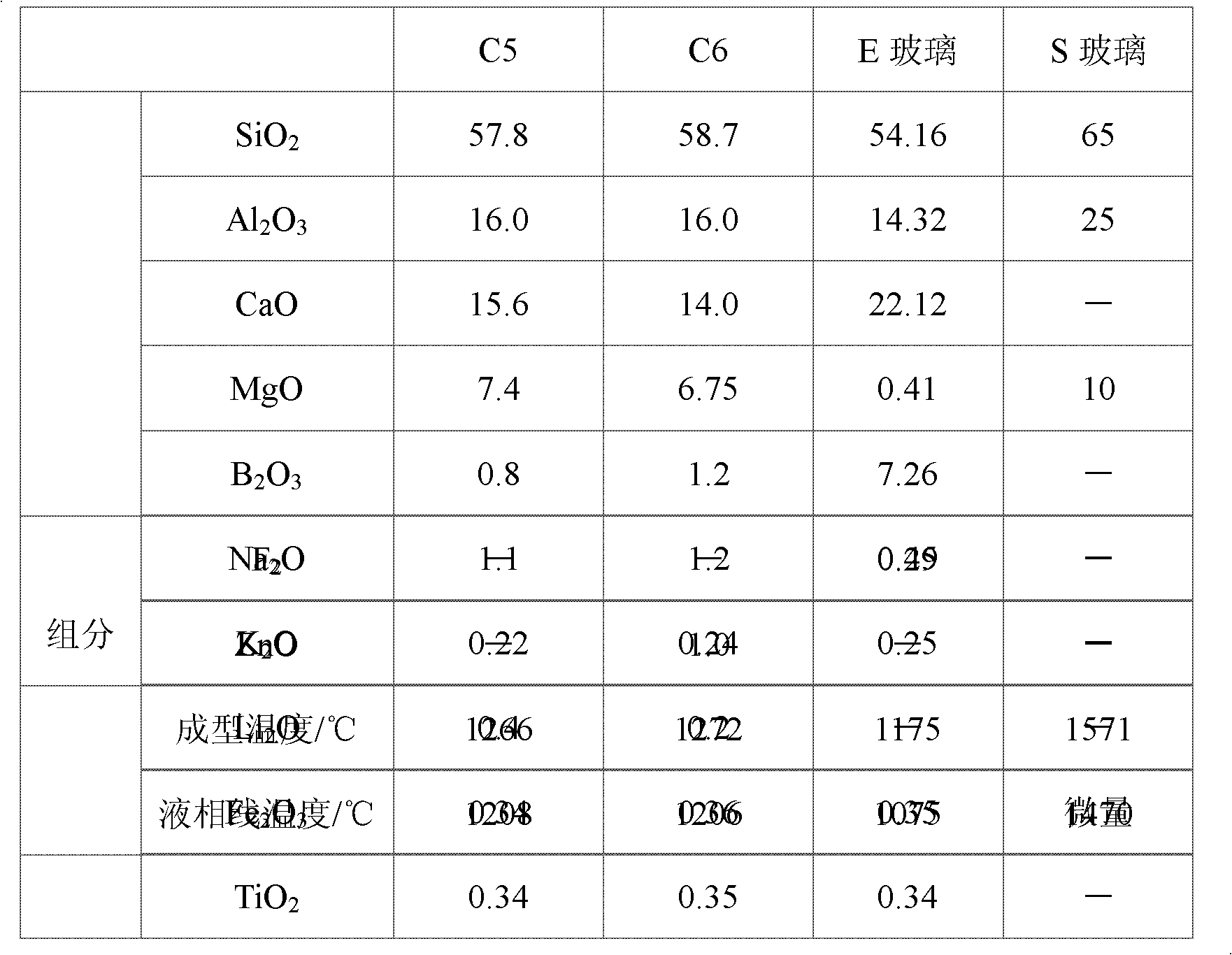

[0049] The technical solution of the present invention is specifically described below through examples, and the content of the present invention is not subject to any restriction by the following examples.

[0050] The present invention melts glass samples by means of a laboratory high-temperature electric furnace, and the raw materials used are basically natural mineral raw materials, such as the introduction of SiO 2 、Al 2 o 3 pyrophyllite or kaolin or quartz powder, calcined dolomite or dolomite introduced with CaO, MgO, calcined limestone or limestone introduced with CaO, introduced B 2 o 3 The boronite, the introduction of Li 2 O's spodumene, etc. The batch materials of each component are put into a platinum-rhodium alloy crucible and melted in a high-temperature electric furnace to form a glass sample. The ease of melting and refining of each glass formulation was studied by comparing different melting times and melting temperatures, and its forming temperature and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com