Cellulose based gel polymer electrolyte and preparation method thereof, and lithium ion battery containing electrolyte

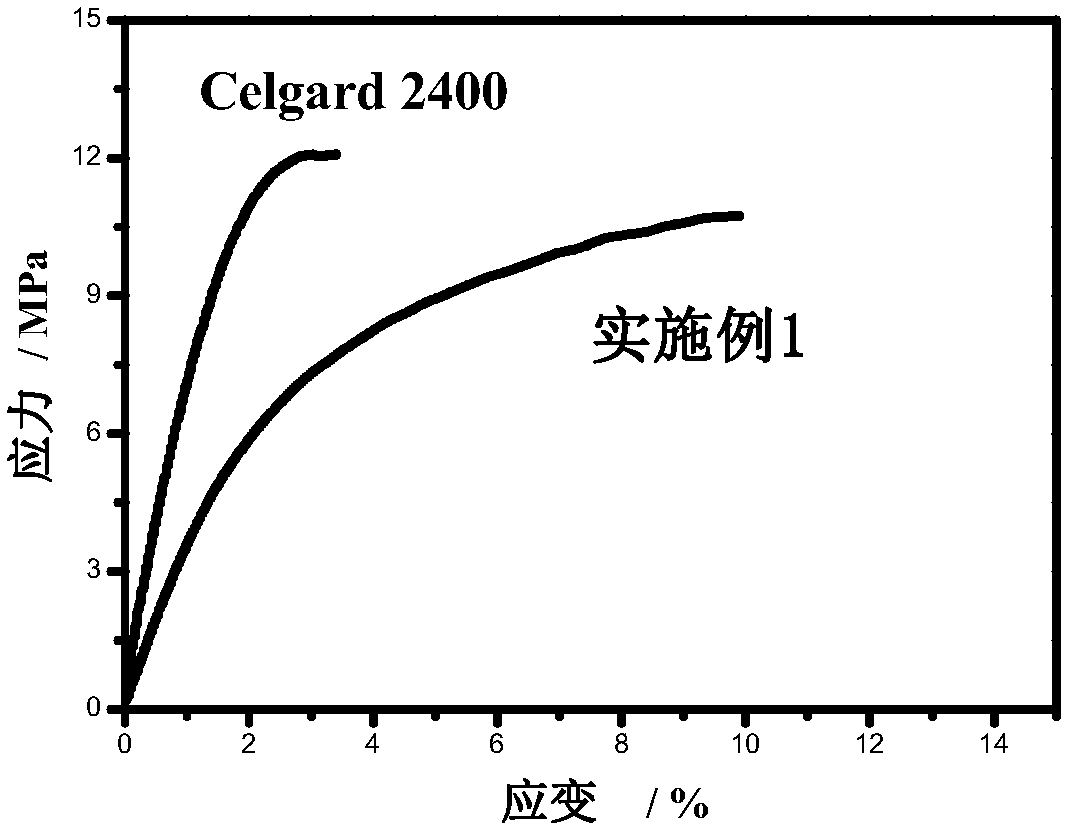

A cellulose and electrolyte technology, applied in the field of lithium-ion batteries, can solve the problems of difficult control of membrane structure uniformity, liquid absorption capacity to be improved, and low porosity, and achieve good dimensional and mechanical thermal stability, and electrochemical stability window The effect of wide and strong affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

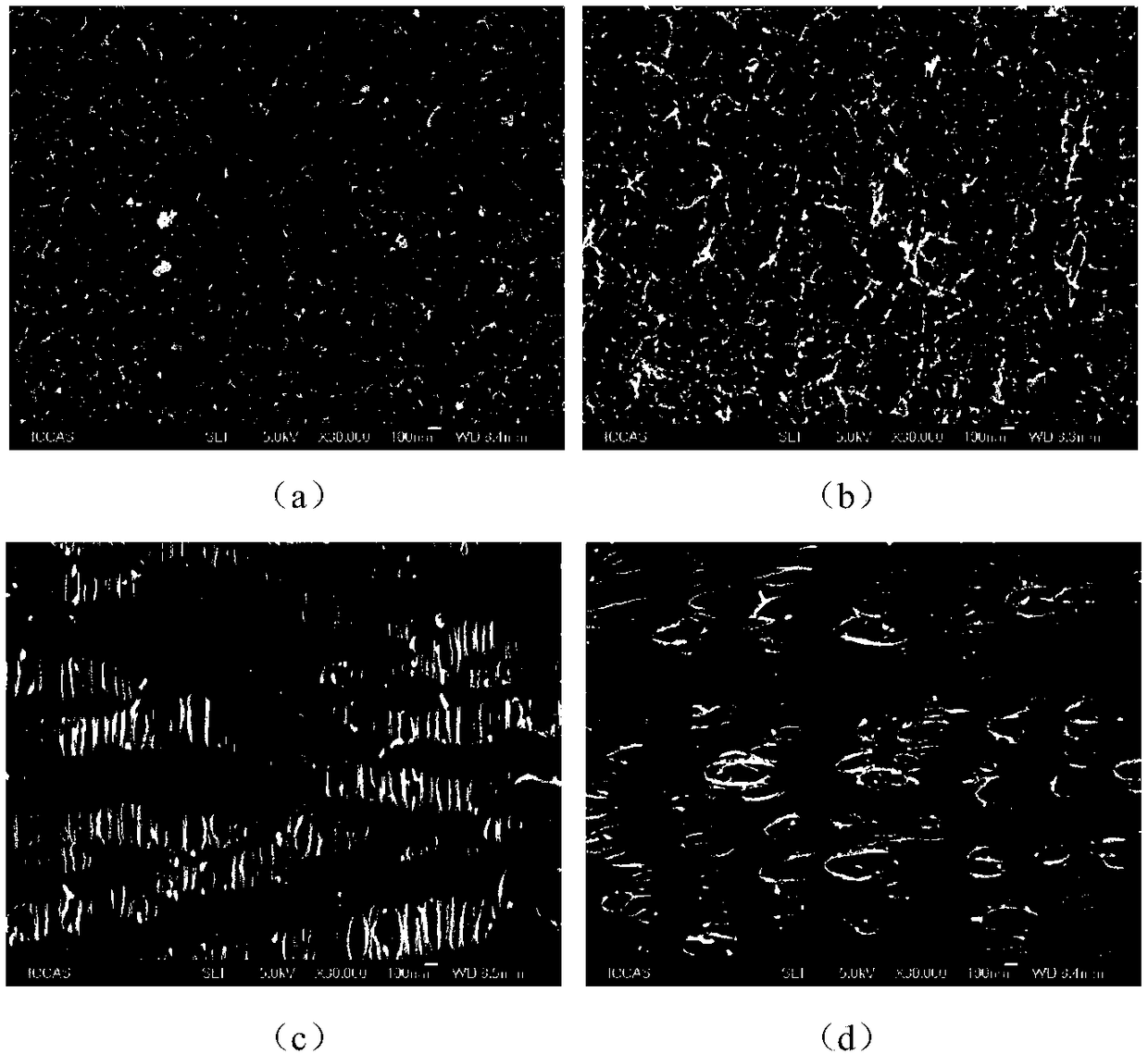

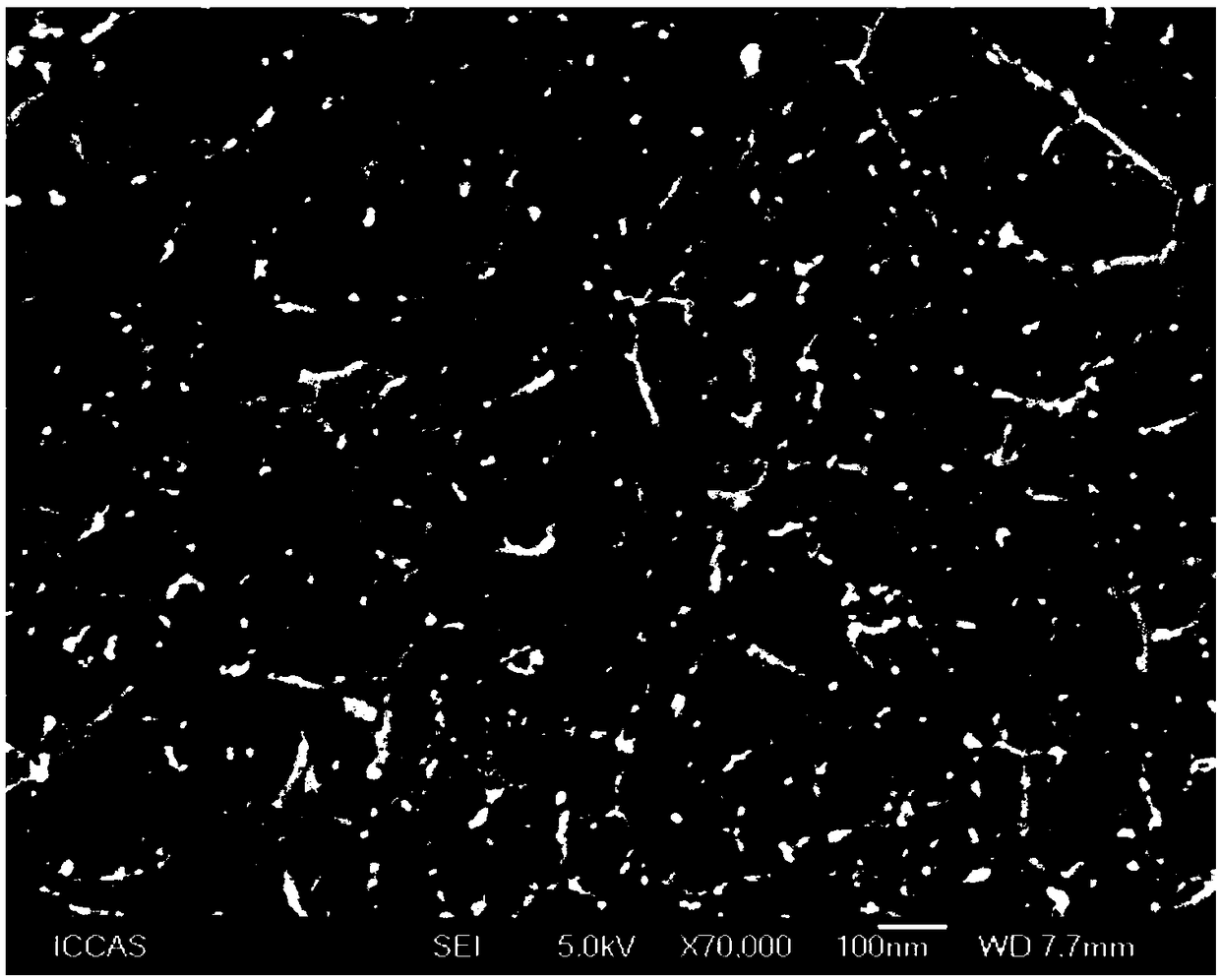

[0030]As mentioned above, the present invention discloses a cellulose-based gel polymer electrolyte and a preparation method thereof. The preparation method includes the following steps: (1) Using cellulose as a raw material, the “dissolution-regeneration” method is used to first prepare Obtain a regenerated cellulose gel film or a regenerated cellulose composite gel film; (2) the gel film is then freeze-dried, supercritically dried or directly dried to obtain a cellulose porous film or a cellulose composite porous film; ( 3) Soak the above-mentioned cellulose porous membrane or cellulose composite porous membrane in an organic electrolyte to absorb the organic electrolyte, and gel it to obtain a cellulose-based gel polymer electrolyte.

[0031] In the above-mentioned preparation method, step (1) specifically comprises the following steps:

[0032] (1a) cellulose is mixed with liquid A to obtain a transparent and uniform cellulose solution;

[0033] (1b) The cellulose solutio...

Embodiment 1

[0072] Add 4g of cotton pulp into a flask containing 96g of 1-allyl-3-methylimidazolium chloride (AmimCl) ionic liquid, heat in an oil bath at 80°C, and apply mechanical stirring under vacuum to dissolve for 2h, namely To obtain a transparent and uniform cellulose / AmimCl solution, cast the obtained cellulose / AmimCl solution on a glass plate to obtain a solution film with a thickness of 300 μm, then put the glass plate in 60% AmimCl ionic liquid / water solution, and take it out after standing for 1 hour. That is, the regenerated cellulose gel film is obtained, cellulose gel film for short. The obtained cellulose gel membrane is repeatedly washed with ethanol until the ionic liquid is completely washed out to obtain a cellulose ethanol gel membrane. The obtained cellulose ethanol gel membrane is dried by a supercritical carbon dioxide drying method to obtain a cellulose porous membrane. The prepared cellulose porous membrane can be further vacuum-dried at 50° C. for 48 h to comp...

Embodiment 2

[0074] 8g microcrystalline cellulose is added in the flask that 92g sodium hydroxide / urea aqueous solution (sodium hydroxide: 7%, urea: 12%) is housed, stirs and dissolves under the condition of-5 ℃, the solution that obtains is in 5000rpm / Centrifuge at a speed of 1 min to obtain a transparent and uniform cellulose solution. Cast the obtained cellulose solution on a glass plate to obtain a solution film with a thickness of 500 μm. Then put the glass plate into secondary water and take it out after standing for 1 hour to obtain regeneration. Cellulose hydrogel membrane, referred to as cellulose hydrogel membrane. The obtained cellulose hydrogel membrane was repeatedly washed with secondary water until the sodium hydroxide and urea were completely washed out to obtain a further optimized cellulose hydrogel membrane. The obtained cellulose hydrogel membrane is dried by a freeze-drying method to obtain a cellulose porous membrane. The prepared cellulose porous membrane can be fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com