A kind of preparation method of nanoporous silver powder

A nanoporous silver and powder technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve difficult large-scale production, low yield, complex electrochemical dealloying process of alloy strips, etc. problems, to achieve the effect of easy large-scale production, simple process and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

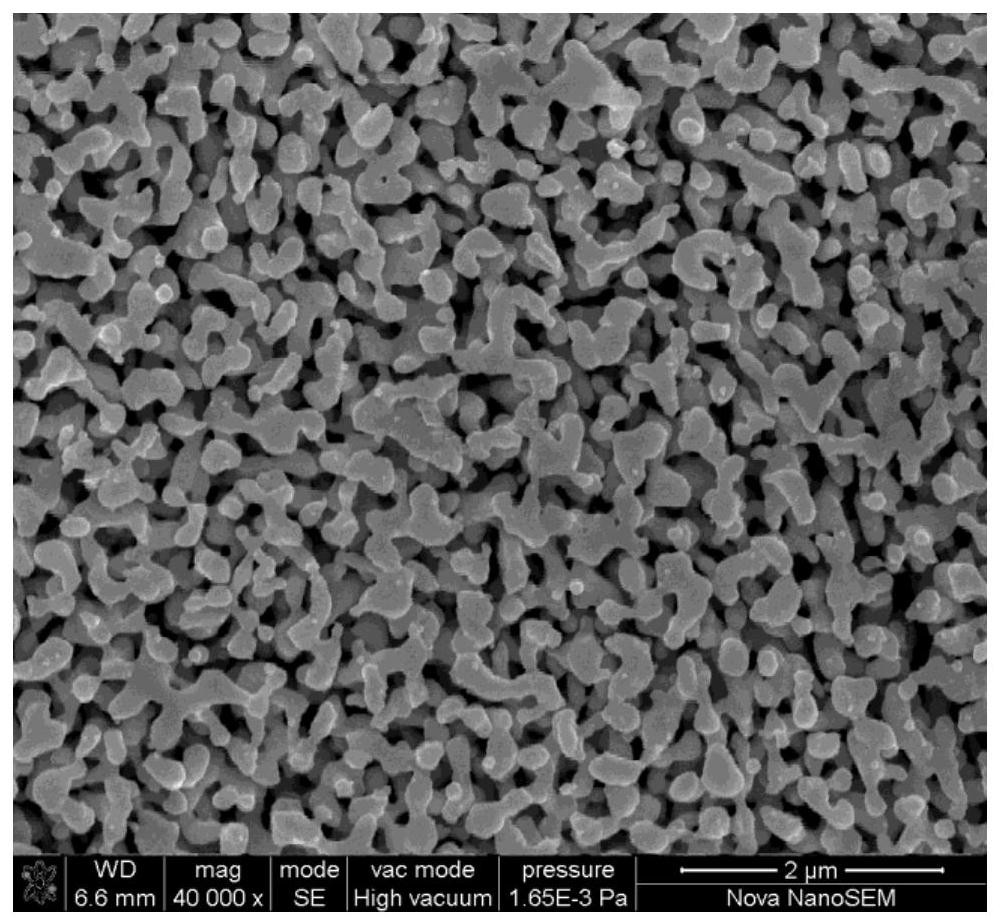

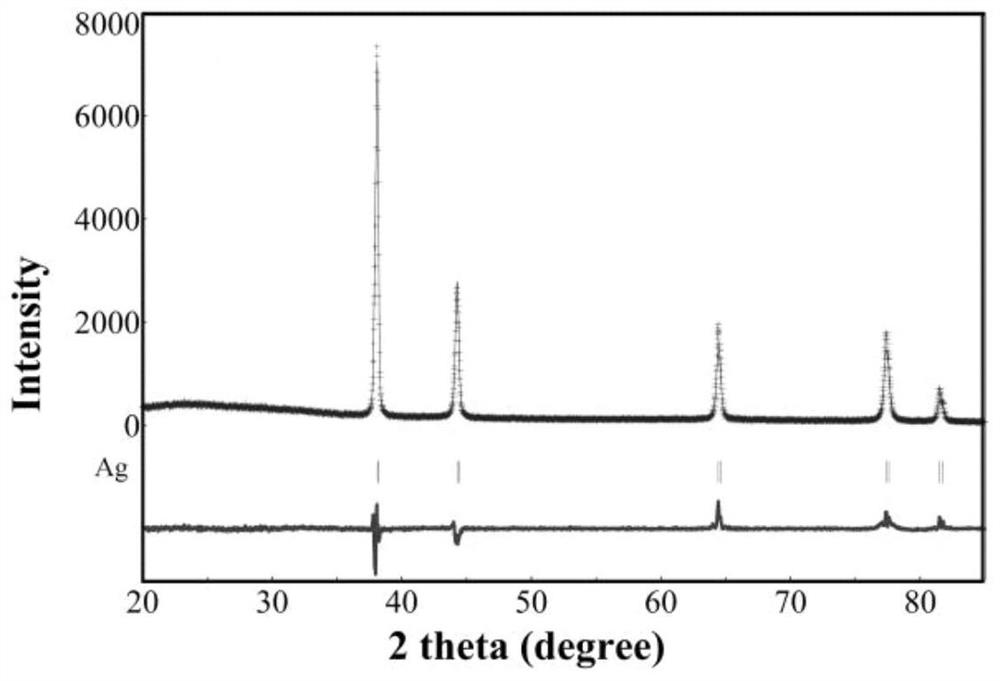

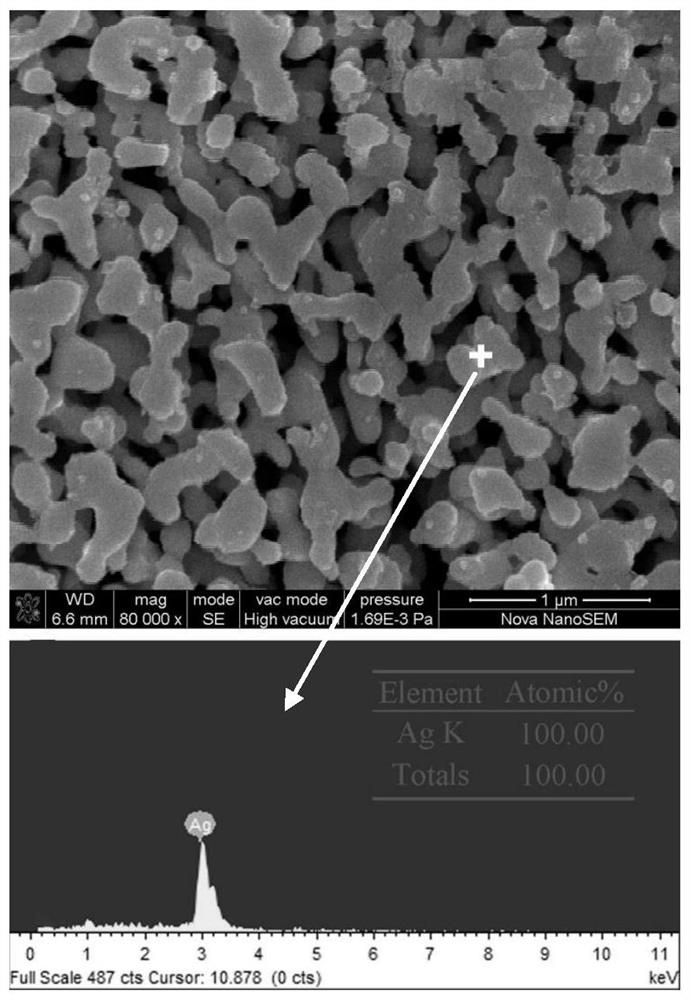

[0023] According to the atomic ratio of 1:4 and considering the burning loss of 2% zinc, silver flakes and zinc particles with a purity of not less than 99.5% are weighed and smelted into a silver-zinc alloy by vacuum induction melting; Mechanically pulverized into powder with a particle size of less than 200 mesh; pour the silver-zinc alloy powder into a 1 mol / L sulfuric acid solution, and corrode at 30 °C for 4 hours; pour the corroded solid product into a 12 mol / L hydrochloric acid solution, at 30 The post-dipping treatment is carried out under the condition of ℃ for 4 h; the post-dipping solid product is washed with distilled water and alcohol successively until neutral, and then vacuum dried to obtain the nanoporous silver. Depend on figure 1 , figure 2 and image 3 It can be seen that the obtained nanoporous silver powder is composed of a single Ag phase, has a uniform three-dimensional connected nanoporous structure, and the pore size is about 200 nm.

Embodiment 2

[0025] According to the atomic ratio of 1:4 and considering the burning loss of 2% zinc, silver flakes and zinc particles with a purity of not less than 99.5% are weighed and smelted into a silver-zinc alloy by vacuum induction melting; Mechanically pulverized into powder with a particle size of less than 200 mesh; pour the silver-zinc alloy powder into a 1 mol / L sulfuric acid solution, and corrode it at 30 °C for 8 hours; pour the corroded solid product into a 10 mol / L hydrochloric acid solution, at 30 The post-dipping treatment is carried out under the condition of ℃ for 8h; the post-dipping solid product is washed with distilled water and alcohol successively until neutral, and then vacuum dried to obtain the nanoporous silver powder.

Embodiment 3

[0027] According to the atomic ratio of 1:4 and considering the burning loss of 2% zinc, silver flakes and zinc particles with a purity of not less than 99.5% are weighed and smelted into a silver-zinc alloy by vacuum induction melting; Mechanically pulverized into powder with a particle size of less than 200 mesh; pour the silver-zinc alloy powder into a 1 mol / L sulfuric acid solution, and corrode it at 30 °C for 6 hours; pour the corroded solid product into a 15 mol / L hydrochloric acid solution, and at 30 The post-dipping treatment is carried out under the condition of ℃ for 4 h; the post-dipping solid product is washed with distilled water and alcohol successively until neutral, and then vacuum dried to obtain the nanoporous silver powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com