Preparation method of nano-porous silver-based substrate with Raman signal enhancing function on surface

A nanoporous silver and Raman signal technology, applied in the direction of nanotechnology, Raman scattering, nanotechnology, etc. for materials and surface science, can solve the problems of unfavorable mass production, cumbersome process, and unfavorable environment, and achieve raw materials Cheap, easy to get raw materials, and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

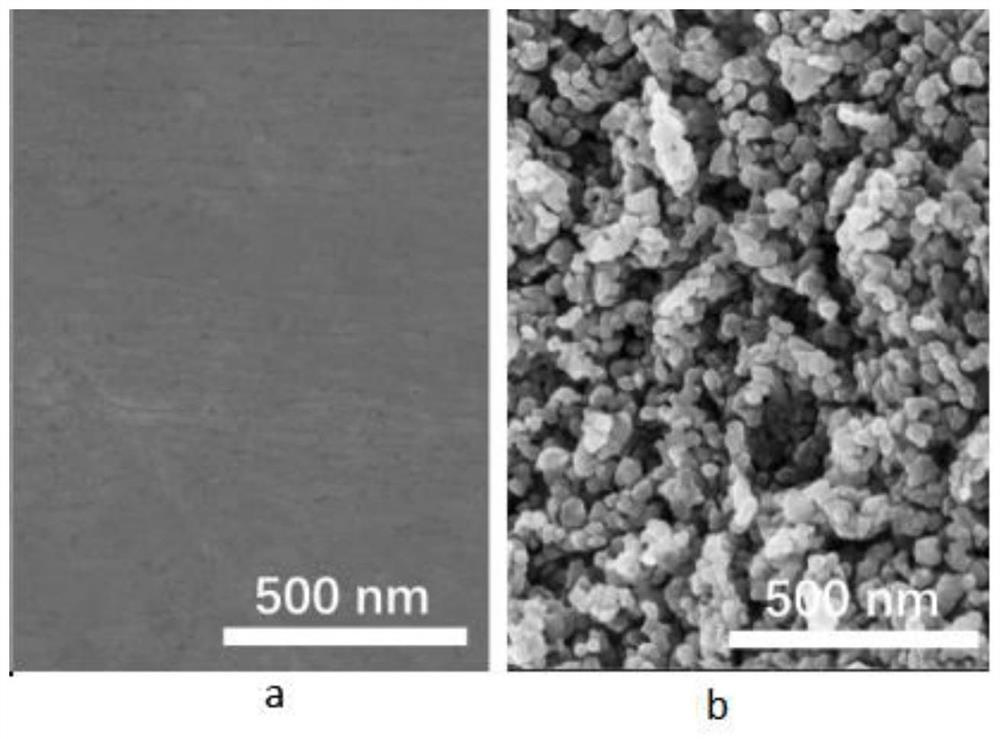

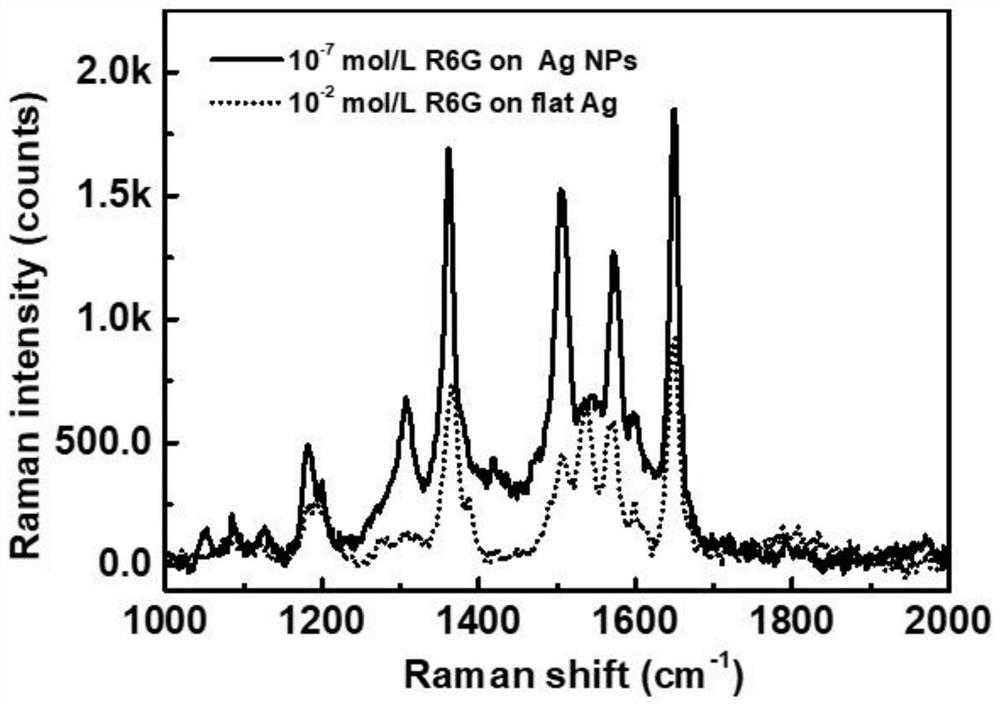

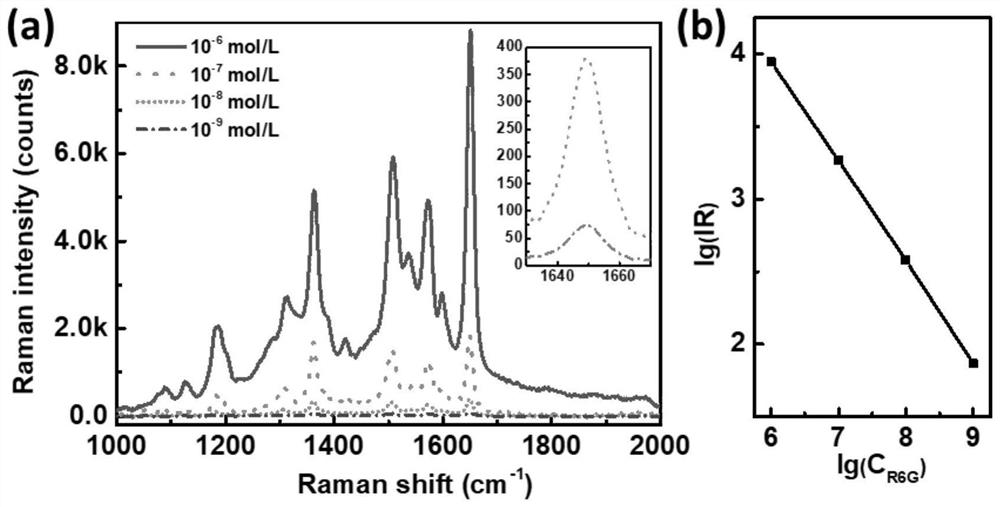

[0033] The preparation of the nanoporous silver-based substrate whose surface has the function of enhancing Raman signal comprises the following steps:

[0034] After the silver flakes (0.5cm×0.5cm×0.06cm) were ultrasonically treated with dilute hydrochloric acid and absolute ethanol, they were rinsed repeatedly with deionized water for 5 times to obtain clean and smooth silver flakes, which were then soaked in a pH 9 in the potassium hydroxide solution, at 273K, undergo linear sweep voltammetry (LSV) in situ electrochemical redox, take out the reacted silver flakes, wash them with acetone and distilled water, and dry them in a vacuum drying oven.

Embodiment 2

[0036] Preparation of nanoporous silver-based substrates with enhanced Raman signal function on the surface:

[0037] Silver foam (0.5cm × 0.5cm × 0.06cm) was ultrasonically treated with dilute hydrochloric acid and absolute ethanol, rinsed repeatedly with deionized water 10 times, and then soaked in a sodium hydroxide solution with a pH of 13. After linear sweep voltammetry (LSV) in-situ electrochemical redox at 373K, the foamed silver after the reaction was taken out, rinsed with acetone and distilled water, and then dried in a vacuum drying oven.

Embodiment 3

[0039] The preparation of the nanoporous silver-based substrate whose surface has the function of enhancing Raman signal comprises the following steps:

[0040] After the silver wire (Φ=1mm) was ultrasonically treated with dilute hydrochloric acid and absolute ethanol, it was rinsed repeatedly with deionized water 8 times, and then soaked in a sodium hydroxide solution with a pH of 11, and passed through LSV at 300K. In-situ electrochemical redox, take out the reacted silver wire, wash it with acetone and distilled water, and dry it in a vacuum drying oven.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com