Method for extracting lithium from primary lithium-extraction solution of lithium ores

A lithium solution and lithium extraction technology, which is applied in the field of lithium extraction from lithium ore, can solve the problems of large material flow, high product cost, and low lithium recovery rate, and achieve the effects of low energy consumption, reliable operation, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] Step 1: 5000ml of the primary lithium extraction solution obtained from the treatment of lepidolite with sulfuric acid is not processed for future use.

[0074] Step 2: Make the flat nanofiltration membrane of aromatic polyamide into roll-type nanofiltration membrane element, and form a single-stage nanofiltration equipment with security filter, raw water pump, high-pressure pump, raw solution tank and product solution tank.

[0075] Step 3: Pass the primary lithium extraction solution through the nanofiltration equipment, under the operating pressure of 0.6MPa, separate and filter monovalent and multivalent cations, test the ICP of the monovalent and multivalent salt solutions obtained in this example, and analyze , It is estimated that the transmittance of Li and other ions is less than 1%, and effective separation of Li from Ca, Mg and Al cannot be achieved.

[0076] Step 4: Treat the concentrated solution with alkali, and Li, Ca, Mg and Al precipitate together and c...

Embodiment 2

[0078] Step 1: Add 5000ml of the primary lithium extraction solution obtained from lepidolite into 700g of calcium chloride, stir to dissolve the calcium chloride at room temperature, then let it stand for 24 hours for precipitation, and centrifuge at a speed of 5000 rpm for 4 minutes. , filtered to remove most of the CaSO 4 , to obtain a secondary lithium extraction solution with a pH value of 3;

[0079] Step 2: Make the flat nanofiltration membrane of aromatic polyamide into roll-type nanofiltration membrane element, and form a single-stage nanofiltration equipment with security filter, raw water pump, high-pressure pump, raw solution tank and product solution tank.

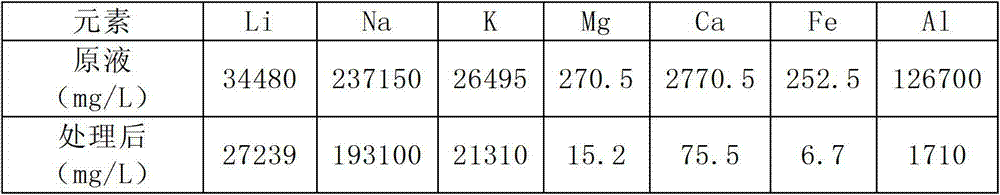

[0080] Step 3: The secondary lithium extraction solution is passed through nanofiltration equipment, and the monovalent and multivalent cations are separated and filtered under an operating pressure of 0.6 MPa to separate and obtain Li-containing monovalent cation chloride salt solution. The monovalent and mu...

Embodiment 3

[0085] Step 1: Add 8000ml of the primary lithium extraction solution obtained from spodumene to 1500g of barium chloride, stir and dissolve the barium chloride at room temperature, and then let it stand for 24 hours to precipitate, at a speed of 4000 rpm, 10 minutes at a time of rotation Centrifuge and filter to remove most of the BaSO 4 , to obtain a secondary lithium extraction solution with a pH value of 4;

[0086] Step 2: The tubular nanofiltration membrane of cellulose acetate is made into a tubular nanofiltration membrane element, and a two-stage nanofiltration equipment is composed of a security filter, a raw water pump, a high-pressure pump, a raw liquid tank and a liquid production tank.

[0087] Step 3: The secondary lithium extraction solution is passed through nanofiltration equipment, and the monovalent and multivalent cations are separated and filtered under an operating pressure of 0.8 MPa to separate and obtain Li-containing monovalent cation chloride salt sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com