Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

367 results about "Skin clean" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lotion Composition for Wet Wipes

InactiveUS20110268777A1Increasing perception of wetnessBiocideCosmetic preparationsMedicineSkin-cleaning wipe

A lotion composition for a skin cleaning wipe comprises a superwetter and a rheology modifier, adapted to provide an enhanced sensation of wetness with a reduced quantity of liquid. Complementary emollients, emulsifiers, and adjuncts and a method for increasing the wetness perception of a wet wipe are also described.

Owner:THE PROCTER & GAMBLE COMPANY

Moisturizing hyaluronic acid composition and preparation method and application thereof

ActiveCN106109265APrevent moisture from evaporatingHas deep water-locking abilityCosmetic preparationsMake-upSkin surfaceCleaning product

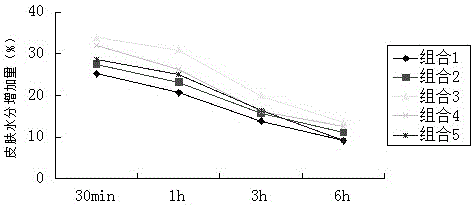

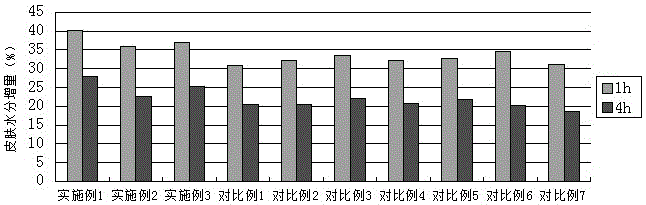

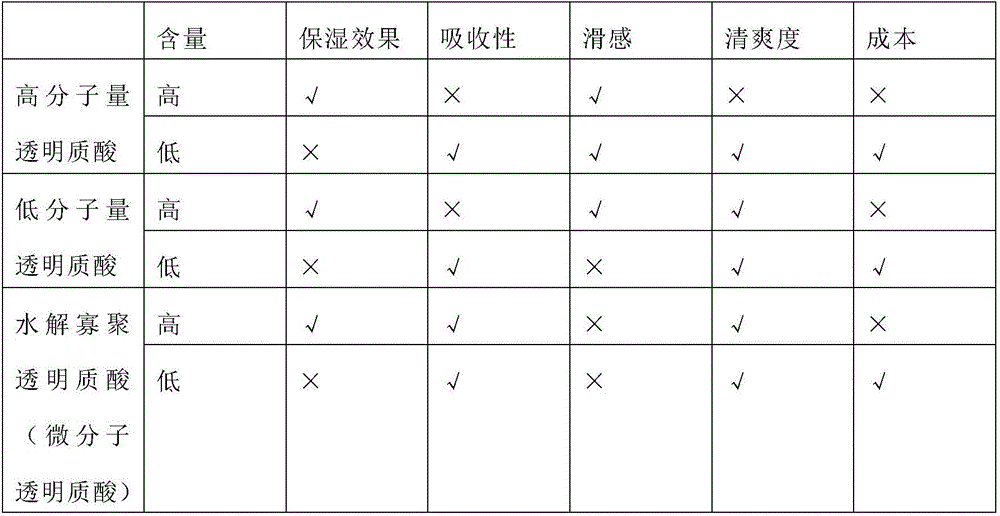

The invention relates to the technical field of hyaluronic acid, in particular to a moisturizing hyaluronic acid composition. The moisturizing hyaluronic acid composition comprises the following components in percentage by weight: 60-62% of hyaluronic acid with the molecular weight of 1100kDa or salt thereof, 18-20% of hyaluronic acid with the molecular weight of 400kDa or salt thereof and 18-20% of hyaluronic acid with the molecular weight of 6kDa or salt thereof. The moisturizing hyaluronic acid composition is applied to skin-cleaning, skin-caring and cosmetic products. Through reasonable combination of high-molecular weight, low-molecular weight and micro-molecular weight hyaluronic acids, the moisturizing hyaluronic acid composition has an all-layer three-dimensional moisturizing effect on the skin on a dermal layer, an epidermal layer, a corneum and the skin surface; the moisturizing hyaluronic acid composition is endowed with an instant and long-lasting moisturizing effect; in an aspect of skin touch, the sticky feeling of the high-molecular weight hyaluronic acid is significantly reduced and the silky feeling of the low-molecular weight hyaluronic acid is improved; the moisturizing hyaluronic acid composition can be applied to all types of cosmetics and cleaning products.

Owner:BLOOMAGE BIOTECHNOLOGY CORP LTD +1

Skin cleansing composition

A composition containing, in a physiologically acceptable aqueous medium, (1) a surfactant system containing at least one anionic surfactant and at least one amphoteric surfactant, and (2) a thickening system containing at least two different anionic polymers each comprising at least one hydrophobic chain.

Owner:LOREAL SA

Composition For Skin Sanitization And Protection And Method Of Its Use

ActiveUS20110262558A1Prevent microbial infectionEradicate and reduce numberBiocideCosmetic preparationsAlpha hydroxyl acidMedicine

An improved composition for skin cleansing and protection is disclosed. The composition contains an effective amount of at least one alpha-hydroxyl acid or a pharmaceutically acceptable salt thereof, at least one base, one surfactant and one skin protectant. Various additives and excipients may be included in the formulation. The improved composition disclosed herein achieves a higher bacteria killing rate and shows longer action duration. The disclosed composition is capable of penetrating deep into the skin which allows for delivery of more anti-microbials to sites that are at a higher risk of being infected. Various modifications of the improved composition are also disclosed.

Owner:RN MEDICAL SOLUTIONS LLC

Wipe with an emulsion containing a thickening polymer and a hydrophobic modified inulin

The invention relates to an article, more particularly a wipe, having at least one water-insoluble substrate impregnated with a particular composition. The invention also relates to the composition itself and to the uses of the article in the cosmetic or dermatological field, in particular for cleaning and / or removing makeup from the skin. The article can in particular constitute a wipe which can be used especially for caring for the skin and / or hair and / or for cleaning and / or removing makeup from the skin.

Owner:LOREAL SA

Medical composite dressing for wound repair and preparation method thereof

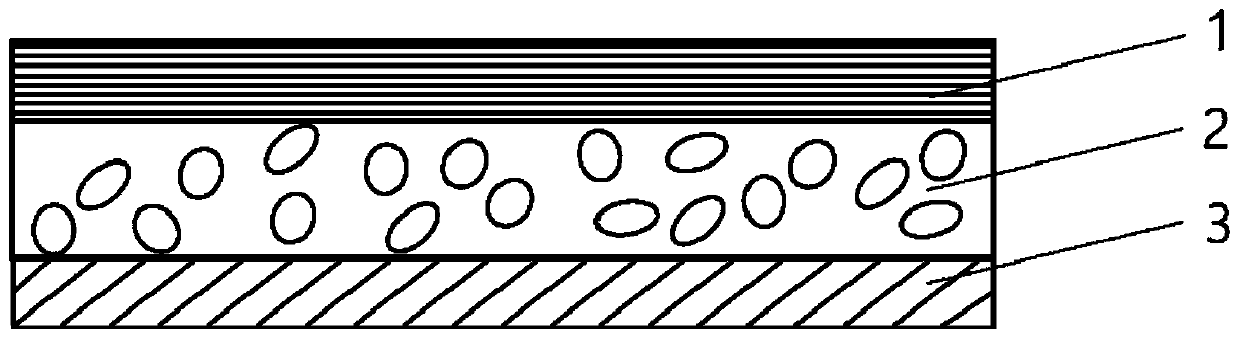

ActiveCN111529748AImprove water resistanceGood moisturizing effectLayered productsElectro-spinningCellulosePolymer science

The invention discloses a medical composite dressing for wound repair. The dressing comprises an inner layer which is in contact with a wound, a middle layer and an outer layer. The dressing is characterized in that: the inner layer is a chitosan / polyvinyl alcohol / oxidized sodium alginate blended nano-fiber antibacterial layer; the middle layer is an aerogel moisture absorption layer prepared by subjecting a sodium alginate / polyvinyl alcohol / sodium carboxymethyl cellulose nanofiber membrane to shearing and freeze-drying treatment; and the outer layer is a non-woven fabric breathable layer, andthe inner layer, the middle layer and the outer layer are compounded through medical glue. According to the composite dressing, the mechanical property of the dressing is improved by utilizing an electrostatic spinning technology. Meanwhile, the nanofiber membrane prepared according to the electrostatic spinning technology and the nanofiber membrane aerogel obtained through aftertreatment have high porosity and large surface area, the excellent breathability can be achieved while the high moisture absorption and moisture retention performance is guaranteed, exudate diffusion is reduced, the skin is kept clean, and the dressing can be widely applied to recovery treatment of various wounds.

Owner:DONGHUA UNIV

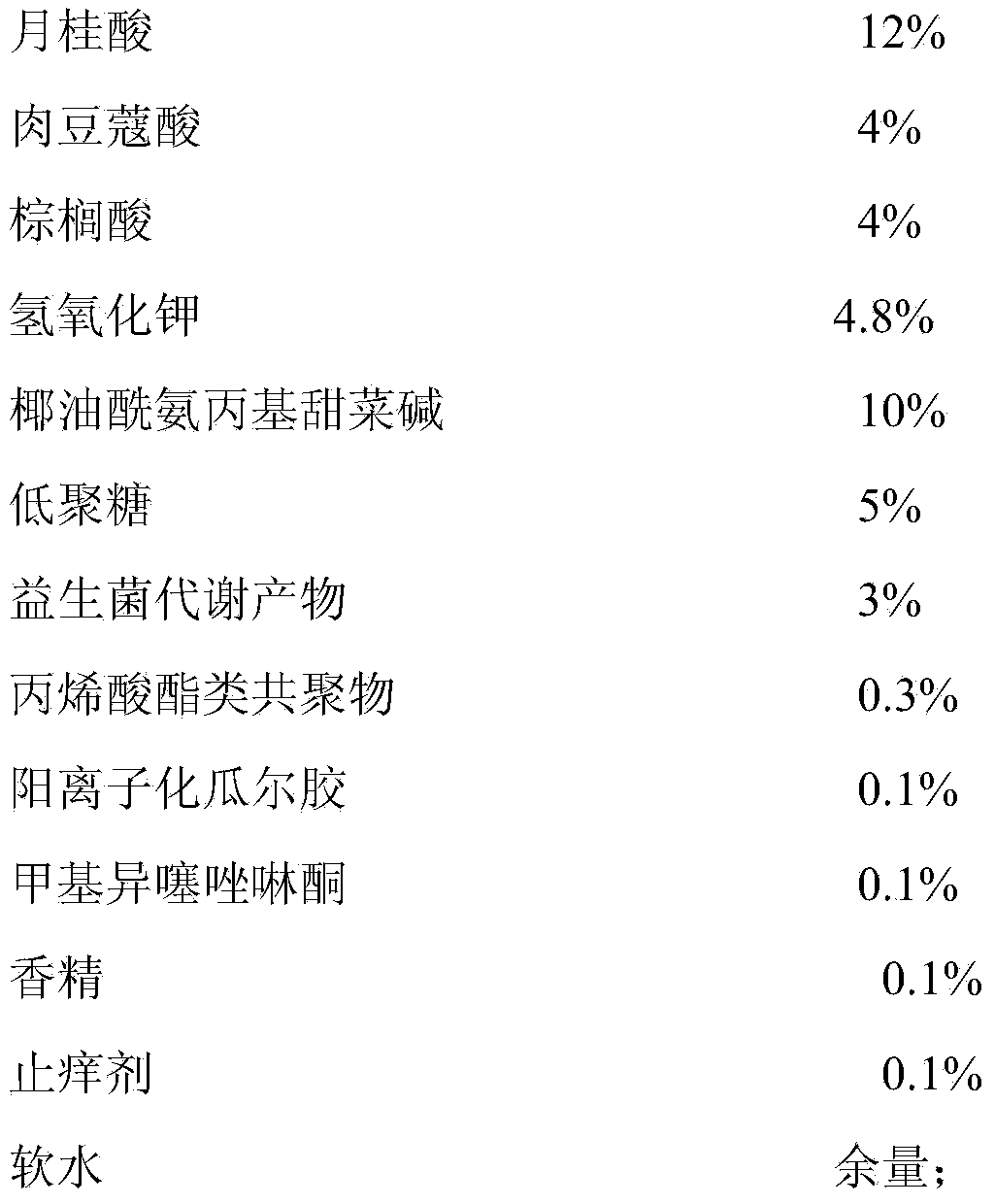

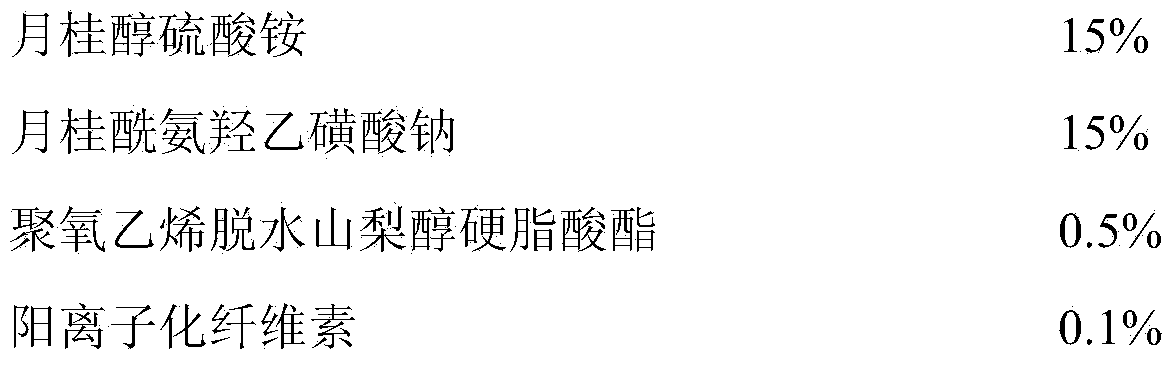

Skin cleaner composition capable of regulating microecological balance of skin and preparation method thereof

ActiveCN103622901APromote Microecological BalanceEasy to cleanCosmetic preparationsToilet preparationsCleansers skinMetabolite

The invention discloses a skin cleaner composition capable of regulating a microecological balance of skin. The raw material formula of the composition especially has the function of regulating the microecological balance of the skin by adding a composition of oligosaccharide and probiotic bacteria metabolites. By adopting the composition, not only can dirt on the skin be washed off, but also the skin can be moisturized and moistened, and the composition has the functions of proliferating beneficial bacteria on the skin surface, inhibiting harmful bacteria on the skin surface and maintaining normal ecological balance of the skin.

Owner:广州晟美个人护理用品有限公司

Fiber filter paper for disposable medical and hygienic products and manufacturing method thereof

ActiveCN102031724AUniform and soft paperHigh wet and dry tensile strengthSynthetic cellulose/non-cellulose material pulp/paperFiltration separationPolyethylene terephthalate glycolPolymer science

The invention relates to fiber filter paper for disposable medical and hygienic products and a manufacturing method thereof, and belongs to the technical field of wet-method non-weaving papermaking. The fiber filter paper is prepared from 15 to 45 weight percent of plant fibers, 30 to 75 percent of artificial fibers and 10 to 55 percent of low-melting point chemical fibers which serve as raw materials through a wet-method non-weaving process, wherein the artificial fibers comprise tencel and viscose; the low-melting point chemical fibers comprise poly ethylene (PE) fibers, ethylene vinyl silane (EVOH) fibers, ethylene-propylene side by side (ES) fibers with a skin-core structure and fibers or composite fibers which contain components such as propene polymer (PP), polyamide (PA), polyethylene terephthalate (PET) and the like and have the melting point of between 80 and 160 DEG C. The fiber filter paper for the medical and hygienic products has uniform and soft quality, and high wet-dry strength, hydrophily, dyeing property and printability, is air-permeable and comfortable, can keep skin clean and dry and comfortable, and is non-toxic, tasteless, safe and sanitary, so the fiber filter paper can be used for producing middle and high-grade disposable medical and hygienic products with different colors or printing patterns.

Owner:浙江鹏辰造纸研究所有限公司

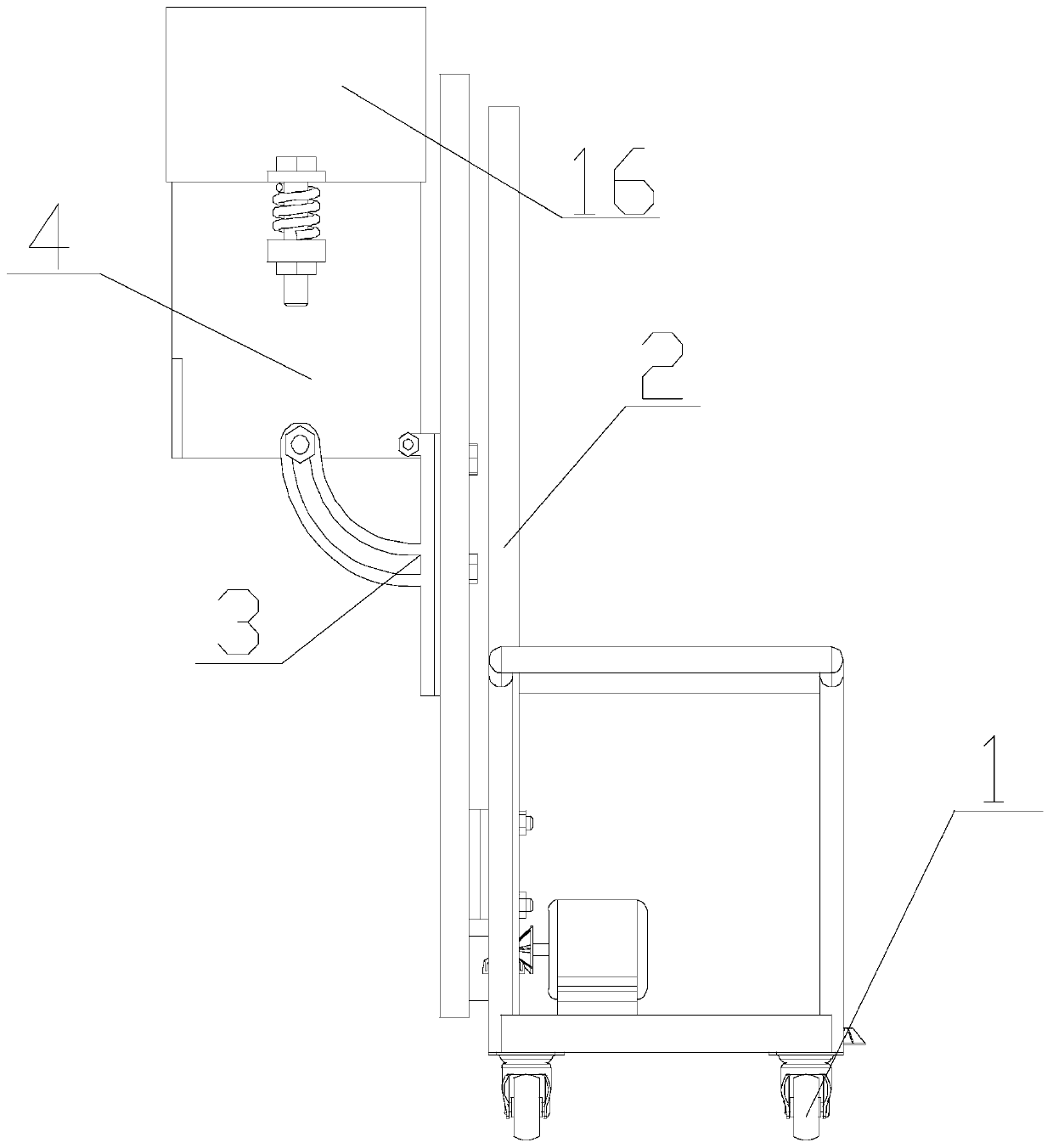

Steel plate oxide skin cleaner

InactiveCN103639876AEasy to cleanImprove labor efficiencyGrinding machinesSheet steelPulp and paper industry

The invention relates to a steel plate oxide skin cleaner and belongs to the technical field of steel plate surface oxide skin cleaning machines. Two guide rails are fixed symmetrically on the two sides of a base, racks are fixed on upper planes of the two guide rails symmetrically, an n-shaped support is arranged between the two guide rails, gears arranged at the bottom of the two sides of the n-shaped support are meshed with the racks, and the n-shaped support moves under the drive of power, a roller is hung on the lower portion of the n-shaped support by corresponding mechanisms and rotates at the high speed under the drive of a working mechanism, and the steel plate surface is cleaned by steel wires on the roller. The cleaner has the advantages of being good in oxide skin cleaning effect, high in labor efficiency, simple and reliable in equipment and convenient to install, maintain and use.

Owner:SUZHOU BLUE KING MACHINE TOOL TECH CO LTD

Deodorizing and skin cleaning

A method for cleaning, benefiting, or deodorizing skin or hair utilizing a body wash, skin cleaner, soap, shampoo or deodorizer formulation containing a controlled release skin benefit or deodorizing salt, a hydrophilic moisturizing polymer and surfactants is described. The method imparts benefits or deodorizing agents to the skin or hair and maintains effective levels for an extended period.

Owner:NEVADA NATURALS

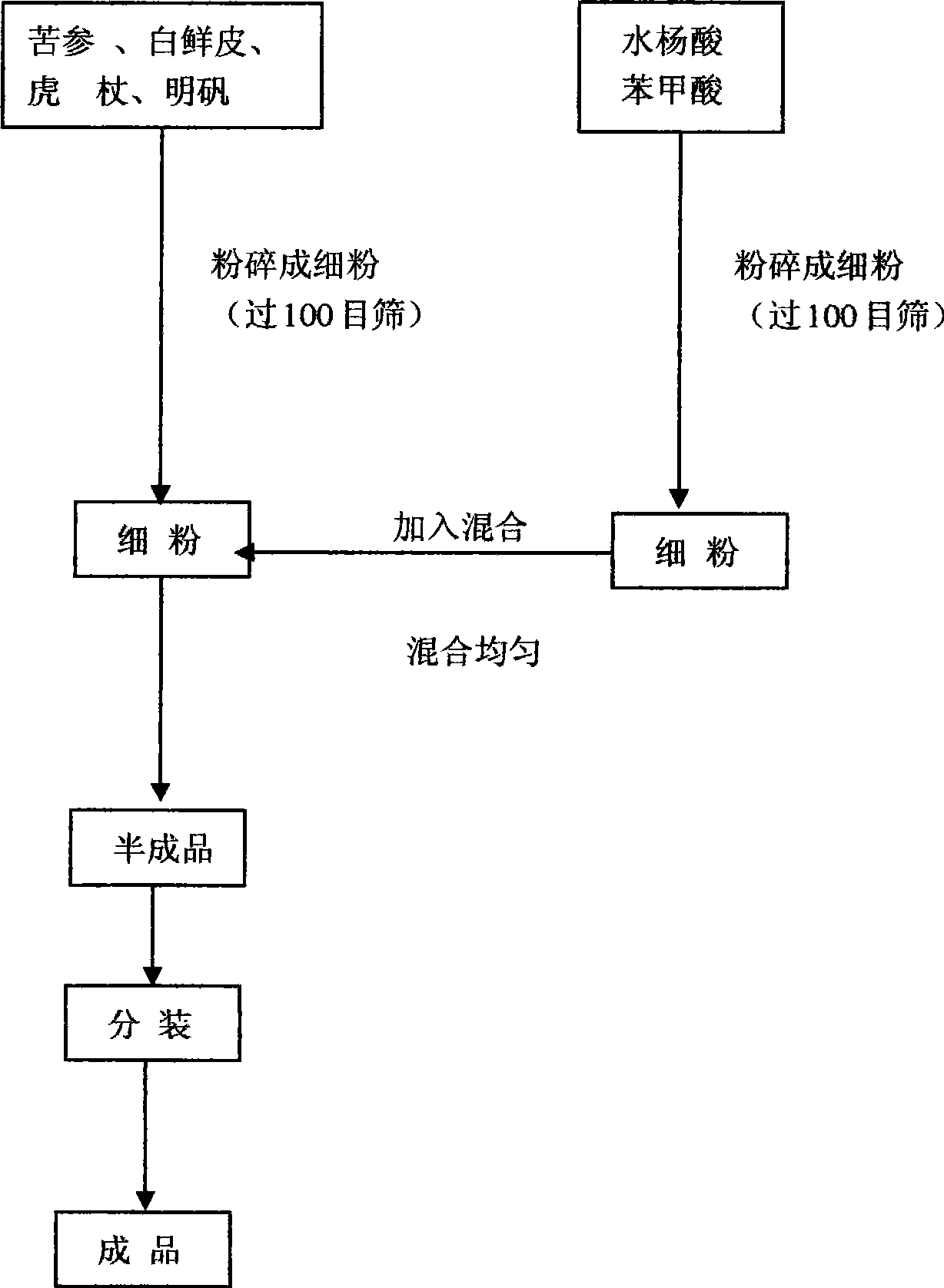

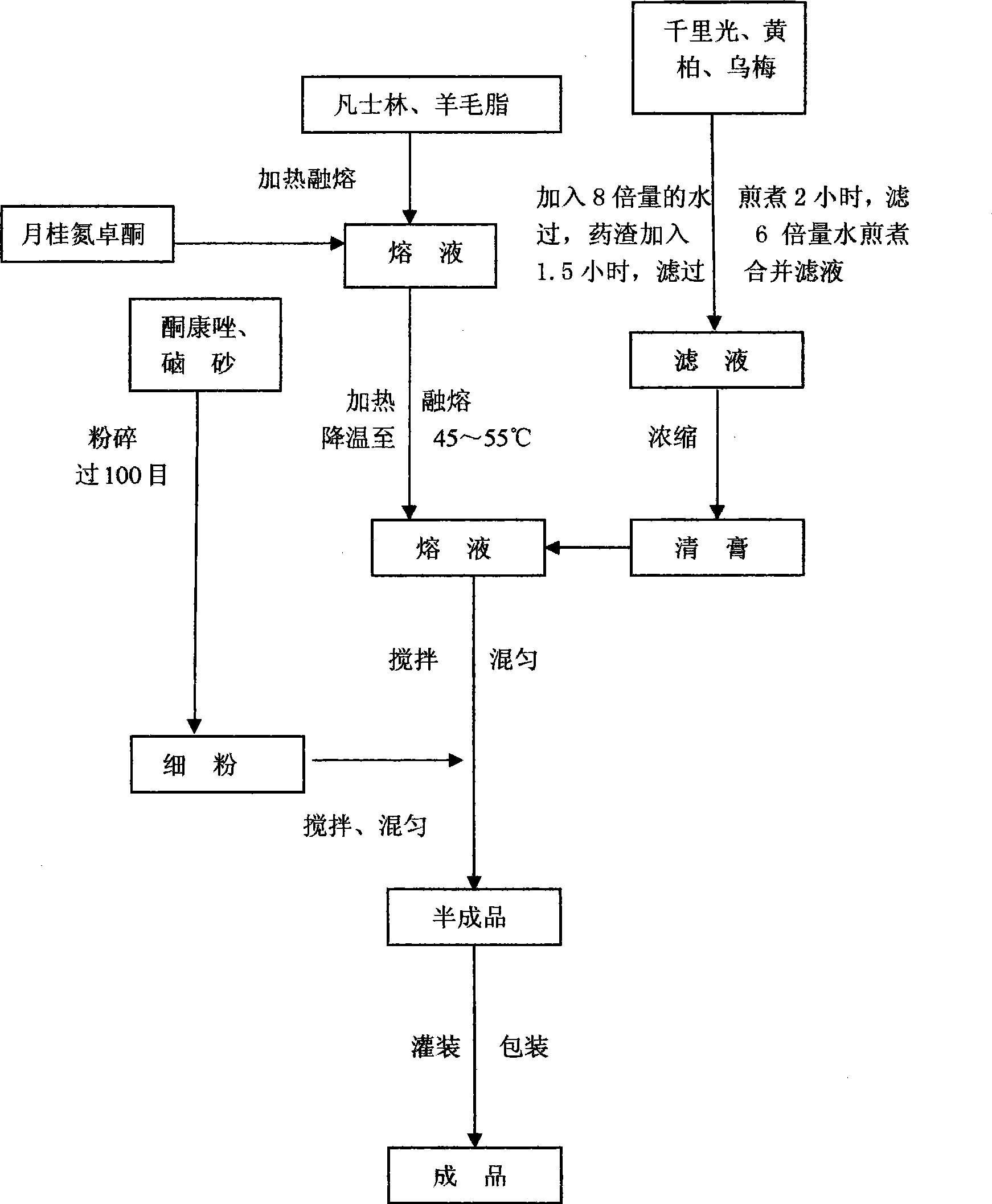

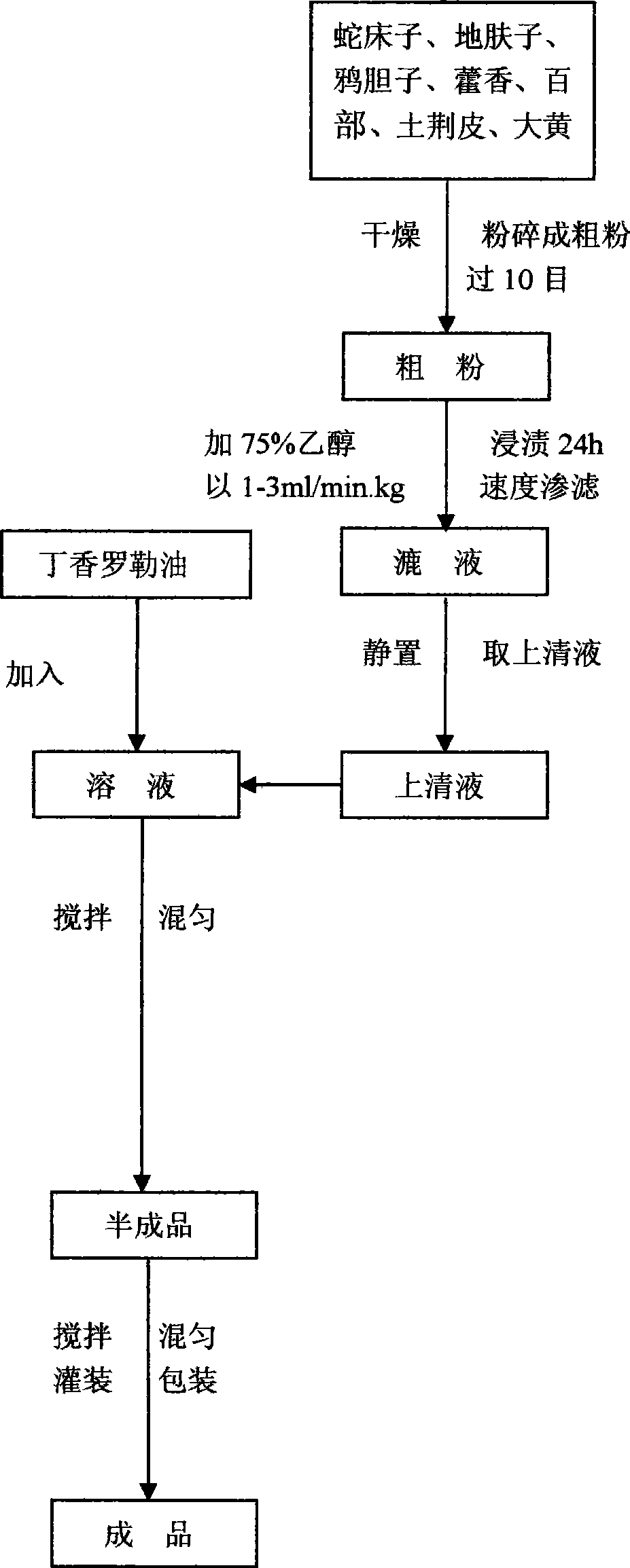

External-use medicament for treating tinea manus and pedis

ActiveCN101502580AQuick killImprove the ability to penetrate the epidermal keratinous tissueBiocidePowder deliveryDiseaseCuticle

The invention provides an externally applied medicament for treating tinea of hands and feet, consisting of three parts of powders A, electuary B and spray C, and the main ingredients comprise lightyellow sophora root, giant knotweed rhizome, dark plum fruit, salicylic acid, ketoconazole and the like, thereby having the effects of clearing heat, removing toxin, sterilization and anti-inflammation. The medicament is different from the previous simple treatment proposals for treating the tinea of hands and feet, the powers A is firstly used for rapidly killing pathogens at the skin surface, changing the infected lesion skin tissue structure of the surface, leading the structure to be loose and forming a smooth channel which is conductive to the penetration of the medicament, then the electuary B is used under the premise of the channel for dredging the penetration of the medicament, thereby rapidly and thoroughly killing the pathogens in skin, the spray C is used for powerful sterilization, keeping a clean environment for the skin and achieving the effect of no recurrence. The medicament carries out multi-level three-dimensional treatment, simultaneously realizes the treatment of external and internal diseases, combines the prevention with the treatment and simultaneously treats both principal and secondary aspect of disease, thereby realizing the special treatment method and reliable efficacy.

Owner:安徽世龙生物医药科技有限公司

Skin cleaning foam and preparation method thereof

ActiveCN102824281AMild performanceResidue reductionCosmetic preparationsToilet preparationsWhole bodyPotassium hydroxide

The invention discloses skin cleaning foam which comprises the following components in percentage by mass: 0.5-50 percent of lauryl alcohol ether phosphate ammonium salt, 0-30 percent of lauryl alcohol ether phosphate potassium salt, 0-40 percent of amino acid surfactant, 0-50 percent of amphoteric ion surfactant, 0-30 percent of non-ionic surfactant, 50-95 percent of water and additive. The preparation method of the skin cleaning foam comprises the following steps of: completely dissolving potassium hydroxide into water; adding lauryl alcohol ether phosphate and triethanolamine; improving the temperature and preserving the heat until the system is transparent; adding the amino acid surfactant, the amphoteric ion surfactant and the non-ionic surfactant and uniformly stirring; and reducing the temperature, adding the additive and uniformly stirring to obtain the skin cleaning foam. According to the skin cleaning foam and the preparation method thereof disclosed by the invention, due to the adoption of a mode, the skin cleaning foam is abundant during use and has comfortable skin feeling after washing; the residue of the surfactants on the surface of the skin is little, so that the stimulus to the skin is avoided; and the skin cleaning foam is suitable for cleaning a whole body, is convenient for use and time-saving and water-saving.

Owner:克劳丽化妆品股份有限公司

Washing skin care article of honeysuckle and skullcap root

The washing skin care article consists of extractives of honeysuckle and skullcap root, and medium. The products of the present invention has skin cleaning and protecting effect, and inhibiting and killing effect on various kinds of germs and viruses, and especially it has relatively high inhibiting effect on coronavirus including SARS virus. The products of the present invention include washing article, cosmetics, wet tissue, toothpaste, etc. The present invention makes it possible to prevent the invasion of various bacteria and viruses to human body and to prevent infectious diseases.

Owner:HARBIN PHARM GROUP SANJING PHARMACEUTICAL CO LTD

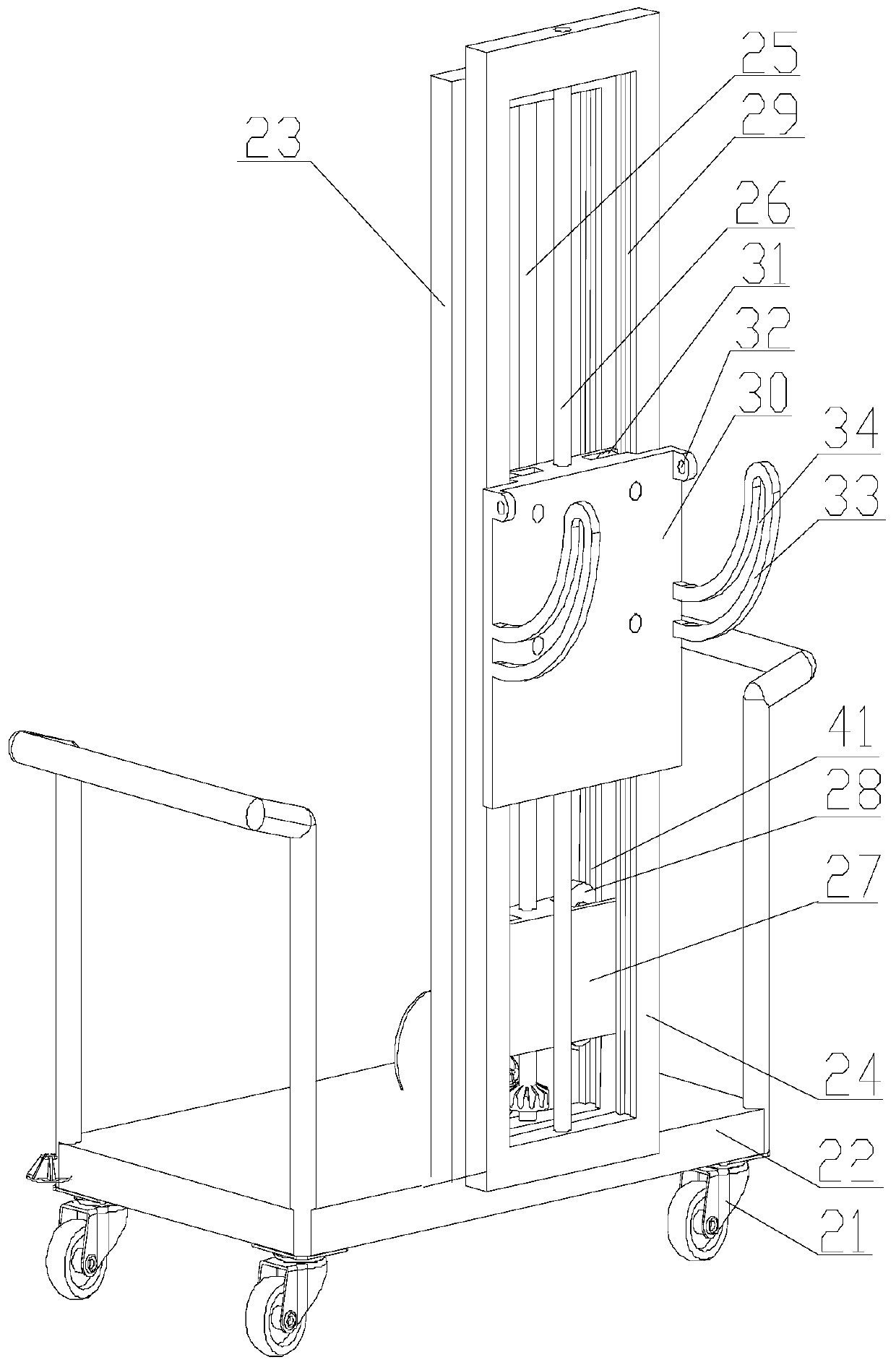

Wall skin cleaning device for building construction and use method thereof

PendingCN111376159AImprove cleaning efficiencyEasy to useBuilding repairsGrinding machinesConstruction engineeringStructural engineering

The invention discloses a wall skin cleaning device for building construction. The wall skin cleaning device for building construction includes a walking device, a lifting device, a turning device, amounting frame, a power device, a cleaning disc, and a cleaning blade; the lifting device is installed on the walking device, and the walking device can drive the lifting device to move; the turning device is installed on the lifting device, and the lifting device can drive the turning device to move up and down; the mounting frame is mounted on the turning device, and the turning device can rotate the mounting frame; the power device is fixedly installed on the mounting frame; the cleaning disc is connected to the power device, and the power device can drive the cleaning disc to rotate; and the cleaning blade is mounted on the cleaning disc, and the cleaning blade can move along the axis of the cleaning disc. The cleaning efficiency of the wall skin cleaning device for building construction is high; and through the cleaning blade which is arranged in a floating manner, the wall skin cleaning device for building construction can adapt to the cleaning of uneven wall surfaces.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

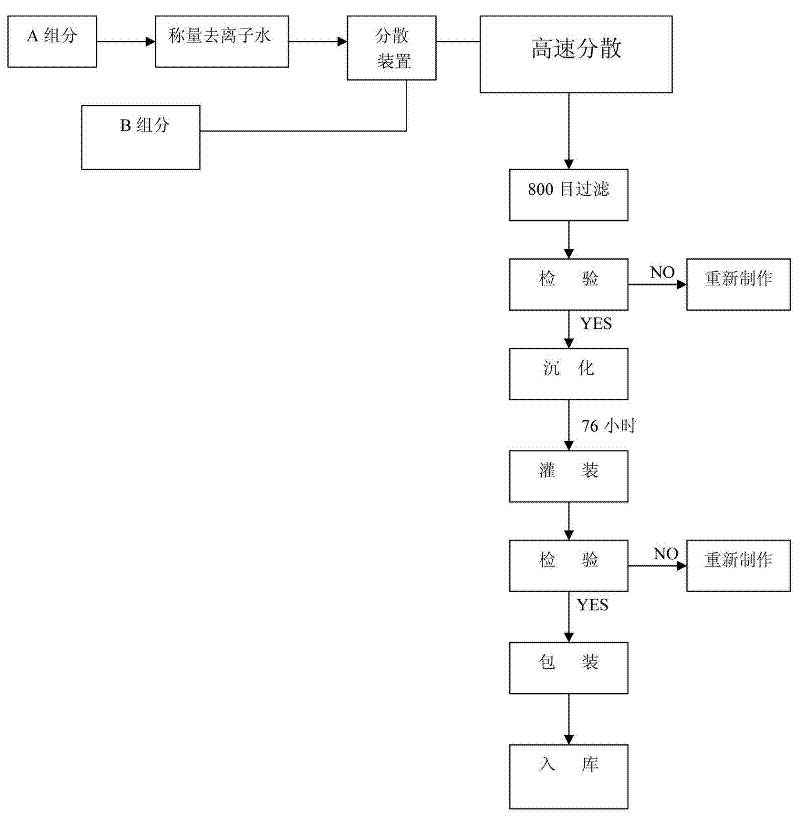

Skin cleaning solution

InactiveCN102366375AFormulation InnovationReasonable formulaCosmetic preparationsToilet preparationsBetaineSodium citrate

The invention discloses a skin cleaning solution, the raw materials of which comprise component A and component B. Specifically, the component A consists of an amino acid surfactant, water, glycerin, sodium dodecyl sulfate, betaine, citric acid, sodium citrate, mushroom glucan, phytosterol, an edelweiss extract, and a pomegranate flower extract; while the component B consists of essential oil and methyl ester. The skin cleaning solution provided in the invention has the advantages of innovative and reasonable formula, no harm to the skin, obvious effect and convenient usage.

Owner:FUZHOU YAMASI BIO TECH

Interlocked fabric of polypropylene fibre functional filament and flock

InactiveCN1982520ALow thermal conductivityImprove insulation effectWoven fabricsCelluloseEngineering

A functional polypropylene continuous yarn and chopped fiber interwoven fabric, which is shuttle-weaving fabric, the weft of the fabric is functional polypropylene continuous yarn, the warp is chopped fiber yarn. The said functional polypropylene continuous yarn is far-infrared polypropylene functional continuous yarn or functional magnetic polypropylene continuous yarn or polypropylene anion functional continuous yarn, polypropylene medical stone functional continuous yarn, polypropylene pearl protein functional continuous yarn, polypropylene skin-cleaning functional continuous yarn. The stated chopped fiber is polyester yarns or polypropylene or nylon or acrylic fiber or wool or cellulose or other chopped fiber yarn. The invention overcomes the ball-appearing, split-up, break of silk, wrinkle easily phenomenon emerged during weaving process of functional polypropylene continuous yarn. Meanwhile, adopting interweaves of functional polypropylene continuous yarn and chopped fiber yarn, surface of fabric is soft and plimpy, effectively solve the difficult to ordinate of pure polypropylene fabric and unstable to form problems. Its benefits are: the fabrics has wicking effect and dry rapidly, light weight, low thermal conductivity, chemical resistance, excellent color fastness, antibacterial and odor resistance, abrasion resistance, protect environment, healthy and so on.

Owner:TIANJIN SAIYUAN HEALTH PROD

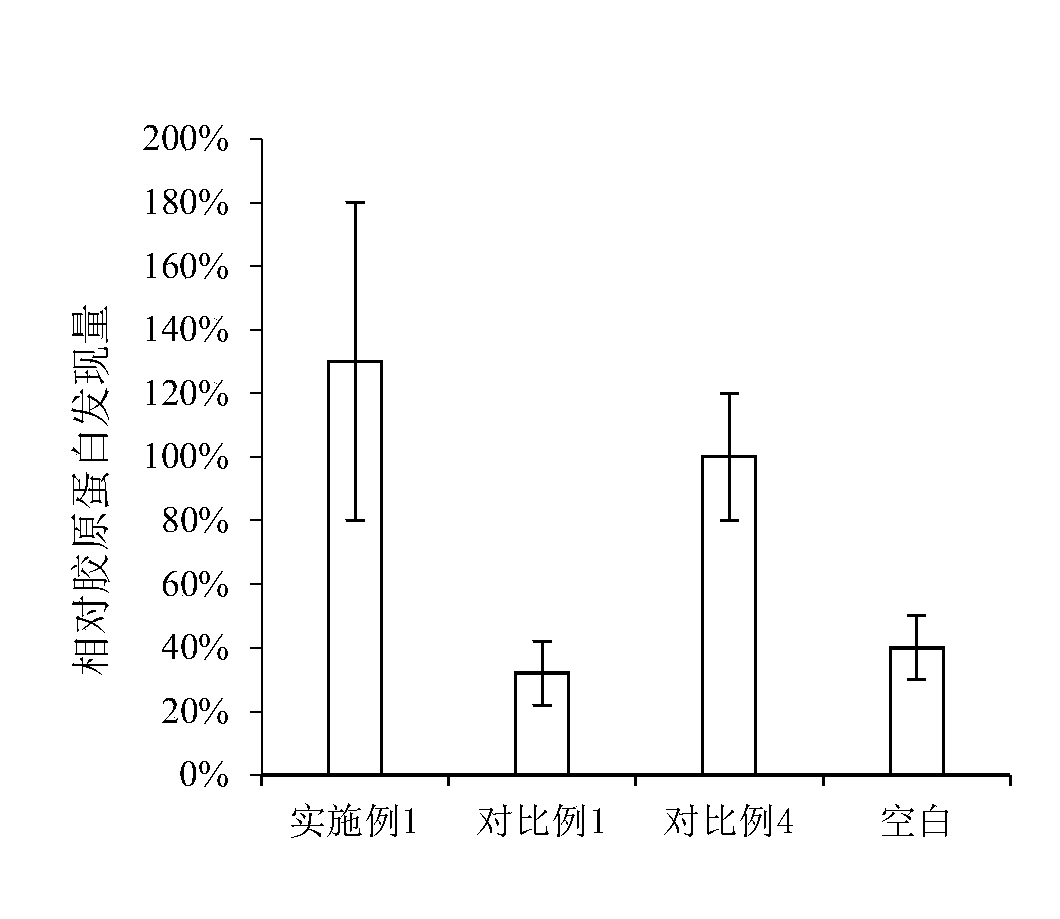

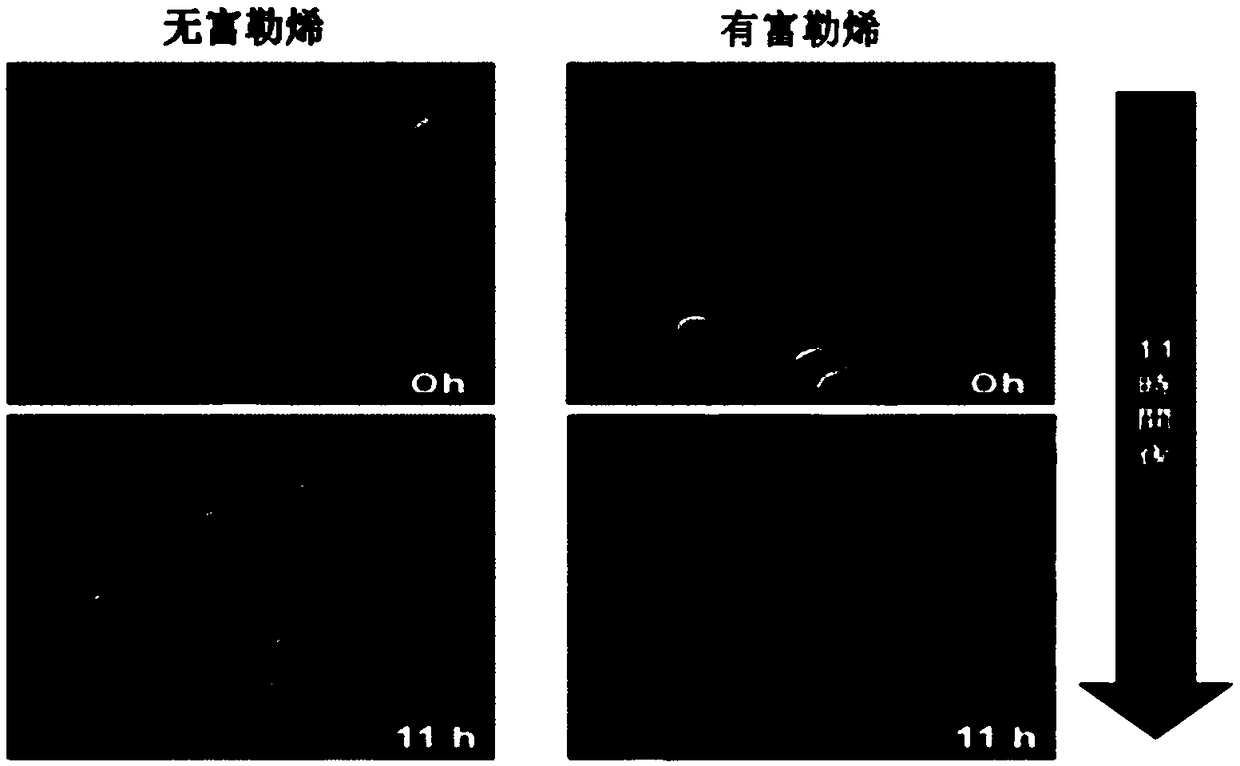

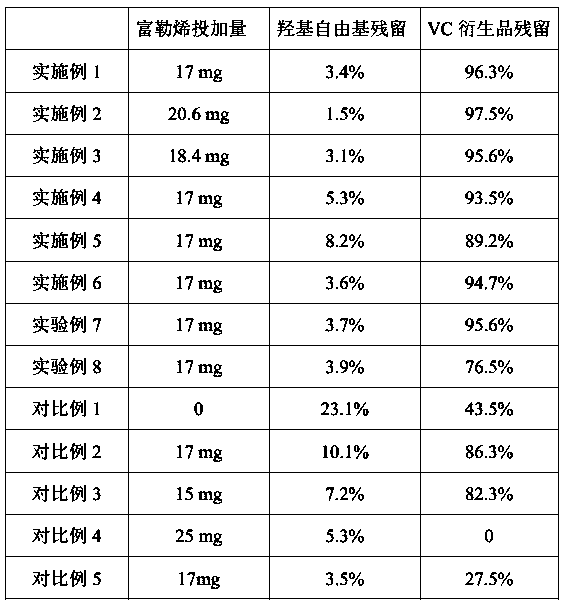

Fullerene skin cleaning skin care product and use method thereof

ActiveCN108743415ARetain activityLong storage timeCosmetic preparationsToilet preparationsFreeze-dryingSolvent

The invention relates to the field of skin care products, provides a fullerene skin cleaning skin care product and a use method thereof and aims at solving the problem of easiness in oxidation of VC derivatives. The invention provides the fullerene skin cleaning skin care product and the use method thereof. The fullerene skin cleaning skin care product is prepared from a freeze-dried powder and asolvent; the freeze-dried powder is prepared from the following components in parts by mass: 2-5 parts of water-soluble fullerene, 3-8 parts of the VC derivative, 0.5-1 part of trehalose and 75-90 parts of water; and the solvent is prepared from the following components in parts by mass: 0.1-0.5 part of carnosine, 6-12 parts of promoter, 1-3 parts of revertose skin brightening agent and 80-99 parts of water. The VC derivative can inhibit melanin pigmentation, but is very easily oxidized and is difficultly absorbed by skin, so that the VC derivative needs to be modified to be improved in oxidation resistance; the fullerene has efficient oxidation resistance, the VC derivative and the fullerene are compounded, the trehalose or the revertose skin brightening agent are added to improve the moisturizing effect, and the promoter is added to improve the effect of production of melanin; and the carnosine can strengthen the antioxidant effect of the fullerene and is reacted with a part of freeradicals.

Owner:广州宝莱生物科技有限公司

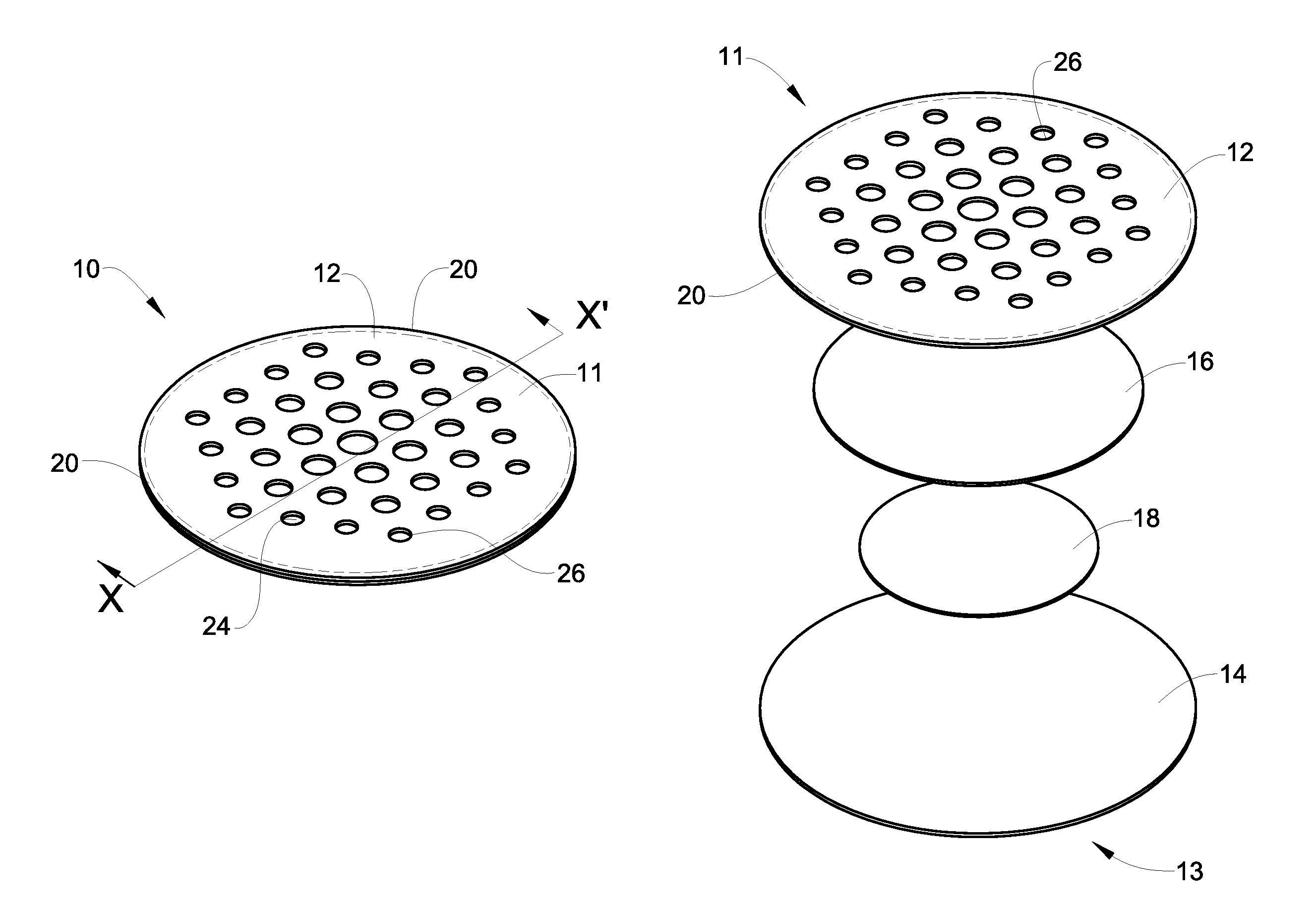

Personal care cleaning article

Owner:KIMBERLY-CLARK WORLDWIDE INC

Crocodile skin clean leather-making processing method

ActiveCN104630394AReduce dosageAvoid creasesTanning treatmentPre-tanning chemical treatmentEnvironmental engineeringChloride

The invention relates to a crocodile skin clean leather-making processing method. In the existing leather-making process, the problems of chloride ion contamination, excessive sulfide in a waste liquid, high chromaticity of dyeing wastewater, difficulty in the thickness adjustment of the crocodile skin and the like are more serious. The crocodile skin clean leather-making processing method comprises the following steps of soaking the fresh crocodile skin in saline water, rolling salt, preserving, transporting, classifying, grouping and batching, bundling, weighing, pre-soaking, soaking, removing meat, degreasing, pre-liming, liming, brushing scale, deliming, carrying out primary combined bleaching, softening, carrying out secondary combined bleaching, softening oracle bone, pickling, softening, tanning, fluffing leather, degreasing, rinsing, neutralizing, re-tanning, dyeing, greasing, drying on a nail plate, scrubbing the leather and finishing. By the crocodile skin clean leather-making processing method, the usage amount of salt can be greatly decreased in the aspect of corrosion resistance of raw crocodile skin, the crocodile skin is convenient to transport, the content of S<2-> in the waste liquid and the chromaticity of the waste liquid are effectively decreased, the thickness of the leather can be precisely adjusted and the high-brightness leather can be obtained by virtue of finishing. The crocodile skin produced by the clean production process has clear pattern and the shrinkage temperature and physical and mechanical properties can reach the national standards.

Owner:蚌埠启邦科技信息咨询有限公司

Liquid for cleaning and disinfecting skin

InactiveCN101129807AGood curative effectSignificant effectAnthropod material medical ingredientsAntiviralsGastrodiaMedicine

The invention provides a skin-cleaning antiseptic solution, comprising glabrous greenbrier rhizome 18-22g, oak-apple 16-20g, worm seed 16-20g, Blumea balsamifera DC. 16-12g, honeysuckle 18-22g, finger citron 16-20g, broom cypress fruit 16-20g, cnidium fruit 16-20g, ginseng 16-20g, ledebouriella root 18-22g, rhizoma Gastrodiae 16-20g, cicada shell 16-20g, speranskia herb 16-20g, licorice root 16-20g, Chinese dittany bark 16-20g, Great Dragon Robe tea 16-20g.

Owner:孔建鑫

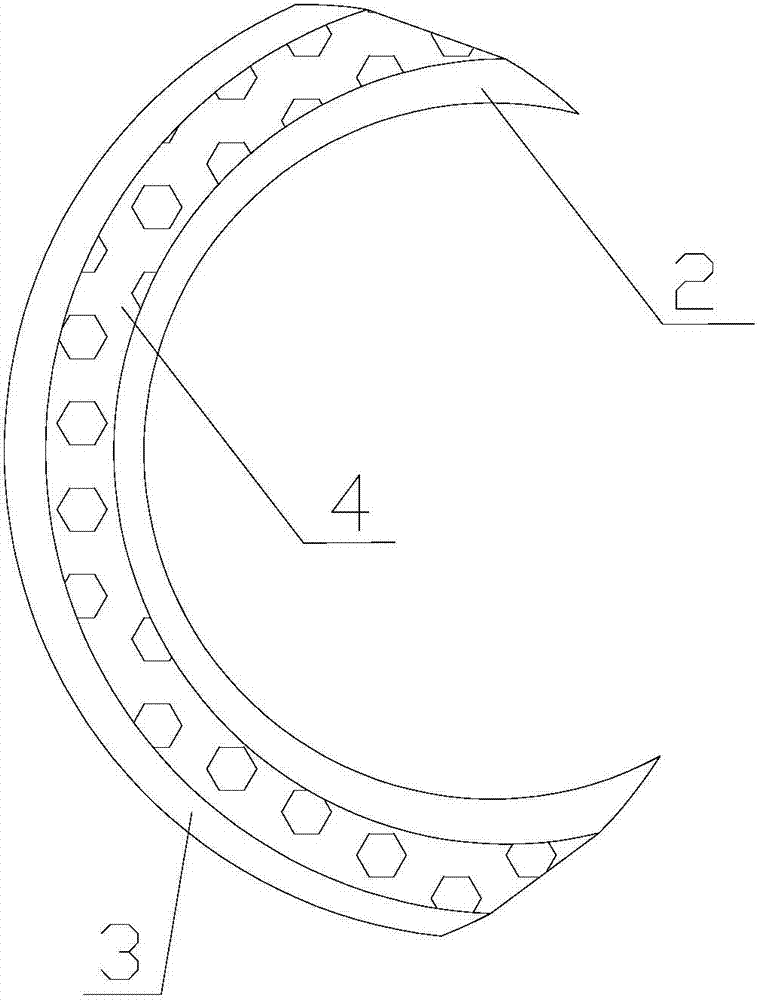

Steering wheel sleeve

InactiveCN104512453AProtect clean and comfortableWith shockproof functionHand wheelsRubber layered productsSteering wheelSkin clean

The invention provides a steering wheel sleeve. The steering wheel sleeve comprises a sleeve body which is equipped with a C-shaped cross section; the bottom layer of the sleeve body is a rubber layer, and while an outer layer is a fabric layer; a sponge layer is arranged between the rubber layer and the fabric layer; an axial opening is formed in the sleeve, and a zipper is arranged at the opening; massaging blocks are arranged at intervals on the fabric layer. The steering wheel sleeve has the beneficial effects that the sponge layer is arranged in the sleeve body and can absorb sweat so as to keep the skin clean and comfortable; in addition, the steering wheel sleeve has the shockproof function; the outer layer is the fabric layer and touches great and is smooth; the opening equipped with the zipper is formed in the sleeve body, so that the convenience of dismounting is ensured; tapered bulges can be used for massaging and irritate hands to prevent the fatigue caused by driving.

Owner:JINHENGTONG TIANJIN AUTO PARTS MFG

Key nursing method aiming at skin cell growth

InactiveCN103340801AReduce surface tensionGood miscibilityCosmetic preparationsToilet preparationsSkin cellCell growth

The invention discloses a key nursing method aiming at skin cell growth. The key nursing method aiming at skin cell growth is good in skin-friendliness, high in effective component absorption rate, good in security and capable of greatly prompting self-renewal healthy growth of skin cells. The nursing method comprises the following steps of: carrying out skin cleaning treatment on skin cells by using a skin caring agent with a skin cleaning effect, carrying out moisturizing treatment on the skin cells by using a skin caring agent with a moisturizing effect, carrying out elasticity enhancing treatment on the skin cells by using a skin caring agent with an elasticity enhancing effect, carrying out micro wrinkle elimination treatment on the skin cells by using a skin caring agent with a micro wrinkle elimination effect, carrying out skin whitening and softening treatment on the skin cells by using a skin caring agent with a skin whitening and softening effect, carrying out immunity enhancing treatment on the skin cells by using a skin caring agent with an immunity enhancing effect, and carrying out pore minimizing treatment on the skin cells by using a skin caring agent with the pore minimizing effect, wherein the method is optimally repeated for twice each month according to the steps at interval time of two days each time.

Owner:GUANGZHOU YIKALA KANGMEI BIOTECH

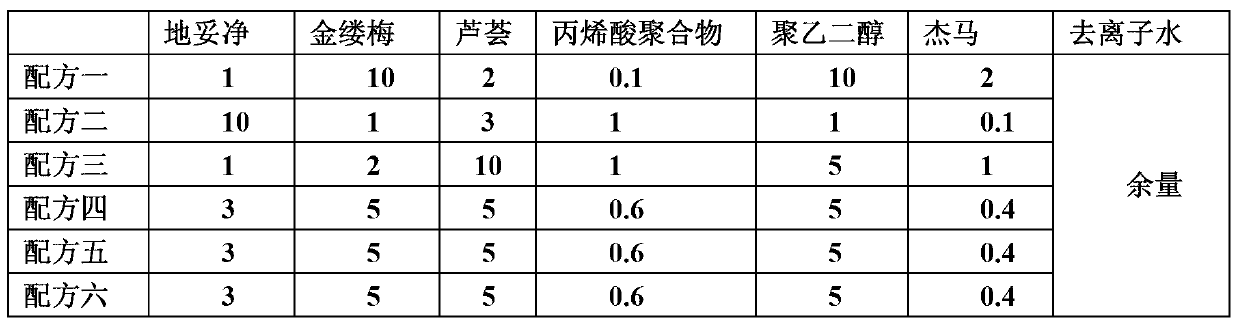

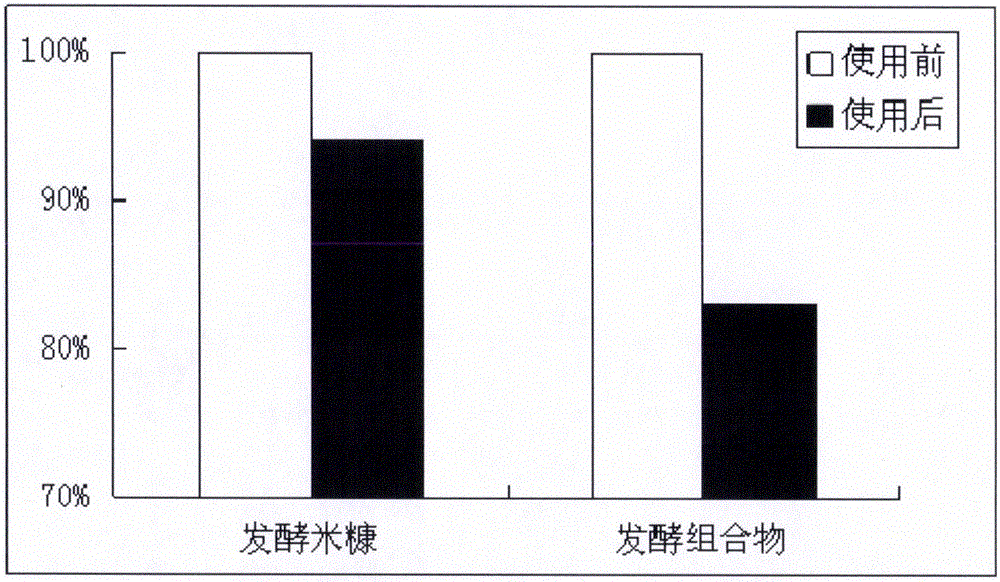

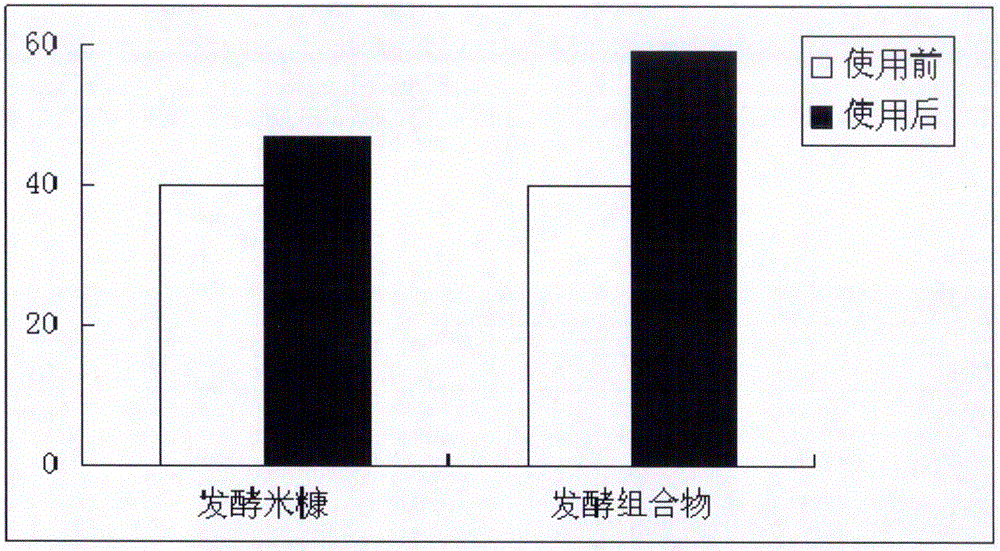

Skin cleaning product containing grain and ginseng stem and leave fermenting products and preparation method skin cleaning product

The invention relates to grain and ginseng stem and leave fermenting products and applications of the grain and ginseng stem and leave fermenting products in skin cleaning products. A method comprises the following steps: carrying out heat sterilizing on a culture medium containing grain or ginseng stem and leaves, inoculating microbes into the culture medium, and carrying out fermentation and sterilization, thus obtaining the fermentation product containing the thallus, a fermentation filtrate and solid particles. The fermentation product is used for the cleaning products. The fermentation product has the good effects of removing the grease on surface of the skin, smoothing the skin, resisting inflammation and acne, etc, and has the characteristics of being capable of nourishing the skin and mildly removing the skin cuticala, being low in irritation, and being safe and mild.

Owner:益盛汉参化妆品有限公司

Microbubble washing composition, microbubble washing method, and microbubble washing apparatus

ActiveUS7635671B2Reliable removalEasy to cleanCosmetic preparationsOrganic detergent compounding agentsMicrobubblesAnimal use

The present invention provides a microbubble washing composition for washing a human body or an animal, a microbubble washing method using the microbubble washing composition, and a microbubble washing apparatus suitable for carrying out the method are provided which are capable of safely removing sebum and old keratin adhering to the surfaces of the pores in a short period of time, keeping the skin clean for a long period of time, preventing an odor. Specifically, the present invention provides a microbubble washing composition for washing a human body or an animal including a protease and a lipase, a microbubble washing method for washing a human body or an animal including washing a human body or an animal using a washing liquid containing the washing composition and microbubbles, and a microbubble washing apparatus.

Owner:TOWA ENZYME +1

Climbing wall type building construction wall skin cleaning equipment

InactiveCN111706100AAchieve cleanupImplement spot cleanupBuilding repairsArchitectural engineeringElectric machinery

The invention discloses climbing wall type building construction wall skin cleaning equipment and relates to the technical field of wall skin cleaning. The climbing wall type building construction wall skin cleaning equipment comprises a climbing wall mechanism capable of climbing along a wall and a wall skin cleaning mechanism arranged on the climbing wall mechanism, wherein the wall skin cleaning mechanism comprises a cleaning box body of a rectangular structure, and the cleaning box body is internally provided with a wall face drilling breaking unit, a wall skin breaking unit and a wall skin shovelling removing unit from top to bottom in sequence; and the climbing wall mechanism comprises a main shell, and the main shell is provided with a first climbing wall unit, a second climbing wall unit, a third climbing wall unit and a fourth climbing wall unit. According to the climbing wall type building construction wall skin cleaning equipment, by means of the manners that the cleaning box body is used and a rubber seal layer is arranged at the end portion, the fact that wall skin cleaning and recycling of ash residue, rubbish and the like generated by cleaning are performed inside the cleaning box body when the climbing wall type building construction wall skin cleaning equipment is used is realized, dust is avoided from splashing into the environment to cause environmental pollution in the cleaning process, and meanwhile, the labor intensity is reduced by motor driving.

Owner:创际建工集团有限公司

Walnut leaf cleaning products

Disclosed are walnut cleaning products, wherein each 1000g of the product comprises extract of walnut leaf 0.001-1, 000g, folium isatidis 0.001-550g, tea 0.001-450g and balancing base material. The product provided by the invention not only has skin cleaning and moistening action, but also has certain suppressing and eradicating action for various bacteria and viruses, specifically, it has good eradication effect for viruses and bacteria of epidemic infestation diseases. The product can be appended into washing articles, cosmetics, moisture tissues, dry and wet paper towel, toothpaste and other daily use articles. The product has the effects of sterilization, disinfection and skin lotion but no stimulation to skin, no adverse effects, it can effectively prevent human body injury by various bacteria and viruses. The beneficial effects of the invention include easiness in use, low cost of production, easy production, good market prospect, and easy application.

Owner:王浩贵

Moutan bark cleaning products

The invention is characterized in that, each 1000g of the product comprises extract of bark of peony root 0.001-1000g, ledebouriella root 0.001-550g, gingko leaf 0.001-450g and balancing base material. The product provided by the invention not only has skin cleaning and moistening action, but also has certain suppressing and eradicating action for various bacteria and viruses, specifically, it has good eradication effect for viruses and bacteria of epidemic infestation diseases. The product can be appended into washing articles, cosmetics, moisture tissues, dry and wet paper towel, toothpaste and other daily use articles. The product has the effects of sterilization, disinfection and skin lotion but no stimulation to skin, no adverse effects, it can effectively prevent human body injury by various bacteria and viruses. The beneficial effects of the invention include easiness in use, low cost of production, easy production, good market prospect, and easy application.

Owner:王浩贵

Phellodendron bark cleaning products

Disclosed are phellodendron bark cleaning products, wherein each 1000g of the product comprises extract of phellodendron bark 0.001-1, 000g, honeysuckle flower 0.001-550g, dragon's blood 0.001-450g and balancing base material. The product provided by the invention not only has skin cleaning and moistening action, but also has certain suppressing and eradicating action for various bacteria and viruses, specifically, it has good eradication effect for viruses and bacteria of epidemic infestation diseases. The product can be appended into washing articles, cosmetics, moisture tissues, dry and wet paper towel, toothpaste and other daily use articles. The product has the effects of sterilization, disinfection and skin lotion but no stimulation to skin, no adverse effects, it can effectively prevent human body injury by various bacteria and viruses. The beneficial effects of the invention include easiness in use, low cost of production, easy production, good market prospect, and easy application.

Owner:王浩贵

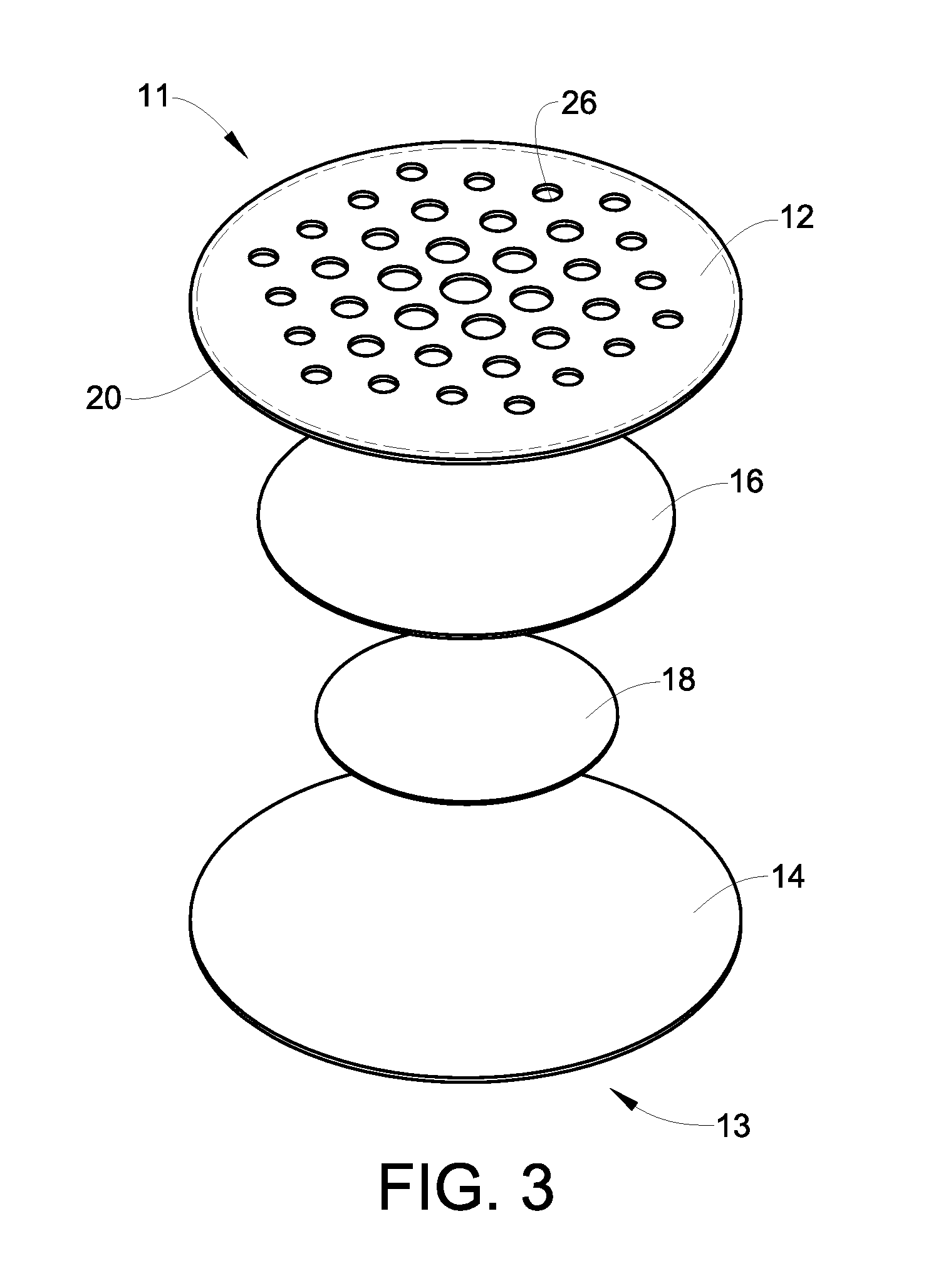

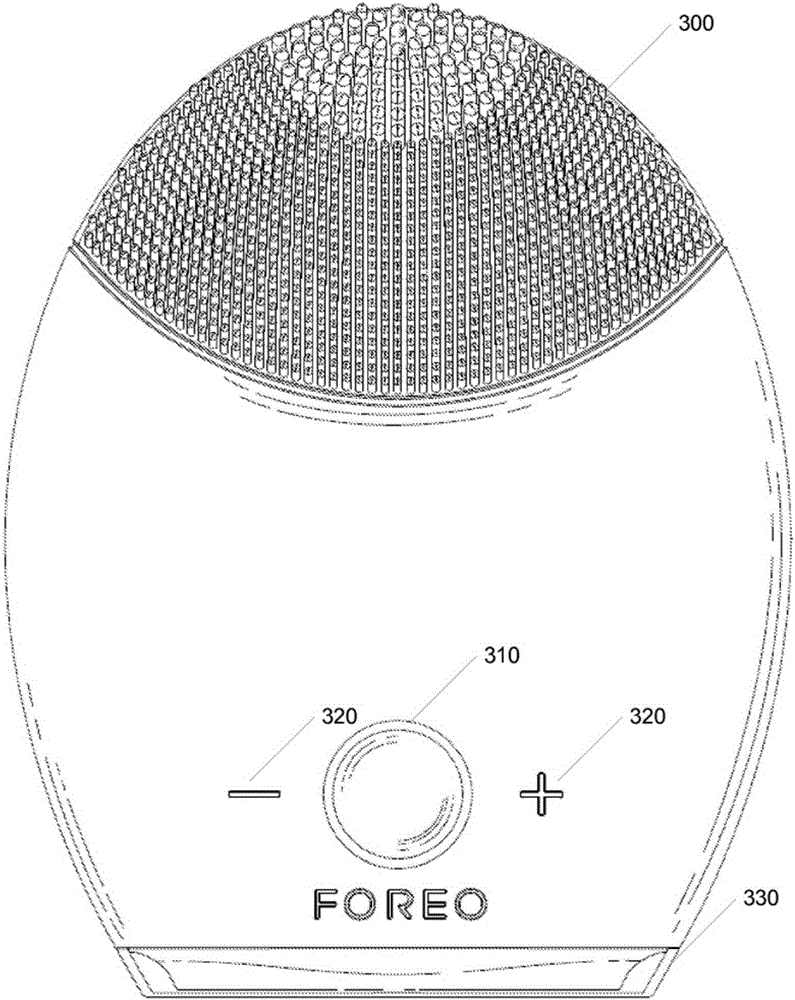

Skin cleanser

A skin cleanser includes a surface, such as a silicone surface, with at least one textured portion for transmitting vibrational tapping to the skin. The skin cleanser includes at least one oscillating motor for generating the tapping motion to the skin. The textured portion includes touch-points or a wave that transmit the tapping motion to skin in contact with the textured portions. The touch-points may include thicker and thinner formations of the touch-points to provide firmer or softer vibrations to the skin. The touch-points are within about 0.5 to 2.5 mm in diameter. One configuration includes multiple oscillating motors configured to provide different vibration frequencies at around 50-300 Hertz and operable simultaneously.

Owner:INTERSELECT TRADING LTD

Microbubble washing composition, microbubble washing method, and microbubble washing apparatus

ActiveUS20080083440A1Reliable removalEasy to cleanCosmetic preparationsHair cosmeticsMicrobubblesAnimal use

The present invention provides a microbubble washing composition for washing a human body or an animal, a microbubble washing method using the microbubble washing composition, and a microbubble washing apparatus suitable for carrying out the method are provided which are capable of safely removing sebum and old keratin adhering to the surfaces of the pores in a short period of time, keeping the skin clean for a long period of time, preventing an odor. Specifically, the present invention provides a microbubble washing composition for washing a human body or an animal including a protease and a lipase, a microbubble washing method for washing a human body or an animal including washing a human body or an animal using a washing liquid containing the washing composition and microbubbles, and a microbubble washing apparatus.

Owner:TOWA ENZYME +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com