Medical composite dressing for wound repair and preparation method thereof

A wound repair and intermediate layer technology, applied in the field of medical materials, can solve problems such as unfavorable wound healing, poor mechanical properties, and single function, and achieve the effects of promoting wound healing, high porosity, and reducing diffusion area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

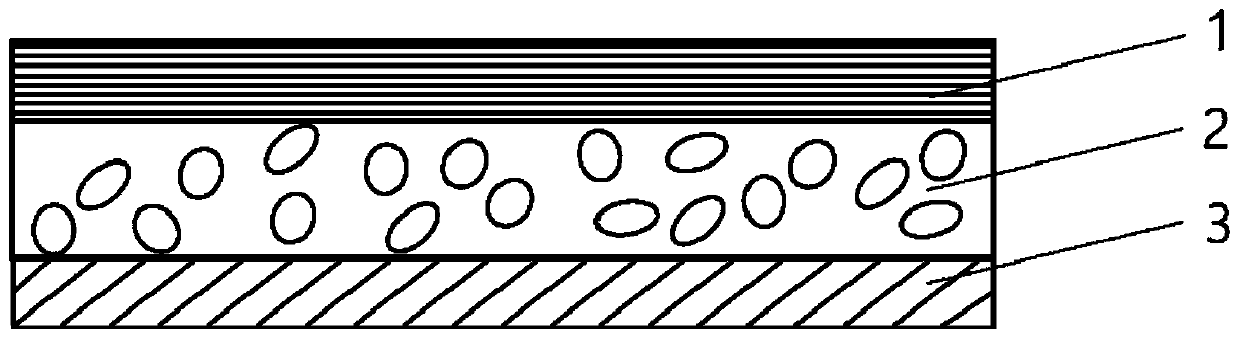

[0032] Such as figure 1 As shown, this embodiment provides a composite dressing for medical wound repair. The dressing has three layers: inner, middle and outer layers: the inner layer 1 in contact with the wound is chitosan / polyvinyl alcohol / sodium oxidized alginate blended in a certain proportion Nanofiber antibacterial layer; the middle layer 2 is a sodium alginate / polyvinyl alcohol / sodium carboxymethyl cellulose nanofiber membrane prepared by cutting and freeze-drying aerogel moisture absorption layer; the outer layer 3 is a non-woven breathable layer , The inner layer 1, the middle layer 2, and the outer layer 3 are compounded by medical glue and cut into the same shape and size to obtain a composite dressing for medical wound repair. The thickness of the inner layer of the composite structure dressing is 0.1mm, the thickness of the middle layer is 1mm, and the thickness of the outer layer is 1mm.

[0033] The preparation method is as follows:

[0034] Step 1. Preparation of...

Embodiment 2

[0045] Such as figure 1 As shown, this embodiment provides a composite dressing for medical wound repair. The dressing has three layers: inner, middle and outer layers: the inner layer 1 in contact with the wound is chitosan / polyvinyl alcohol / sodium oxidized alginate blended in a certain proportion Nanofiber antibacterial layer; the middle layer 2 is a sodium alginate / polyvinyl alcohol / sodium carboxymethyl cellulose nanofiber membrane prepared by cutting and freeze-drying aerogel moisture absorption layer; the outer layer 3 is a non-woven breathable layer , The inner layer 1, the middle layer 2, and the outer layer 3 are compounded by medical glue and cut into the same shape and size to obtain a composite dressing for medical wound repair. The thickness of the inner layer of the composite structure dressing is 0.2mm, the thickness of the middle layer is 2mm, and the thickness of the outer layer is 1mm.

[0046] The preparation method is as follows:

[0047] Step 1. Preparation of...

Embodiment 3

[0058] Such as figure 1 As shown, this embodiment provides a composite dressing for medical wound repair. The dressing has three layers: inner, middle and outer layers: the inner layer 1 in contact with the wound is chitosan / polyvinyl alcohol / sodium oxidized alginate blended in a certain proportion Nanofiber antibacterial layer; the middle layer 2 is a sodium alginate / polyvinyl alcohol / sodium carboxymethyl cellulose nanofiber membrane prepared by cutting and freeze-drying aerogel moisture absorption layer; the outer layer 3 is a non-woven breathable layer , The inner layer 1, the middle layer 2, and the outer layer 3 are compounded by medical glue and cut into the same shape and size to obtain a composite dressing for medical wound repair. The thickness of the inner layer of the composite structure dressing is 0.3mm, the thickness of the middle layer is 3mm, and the thickness of the outer layer is 1mm.

[0059] The preparation method is as follows:

[0060] Step 1. Preparation of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com