Formula of compoiste adhering magnet

A technology of bonded magnets and formulations, applied in the direction of magnetic objects, magnetic materials, and inorganic materials, can solve the problems of poor fluidity of ingredients, low magnetic properties, and accelerated thermal decomposition of binders, etc., and meets the low requirements of equipment , Wide range of magnetic properties, good machinability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

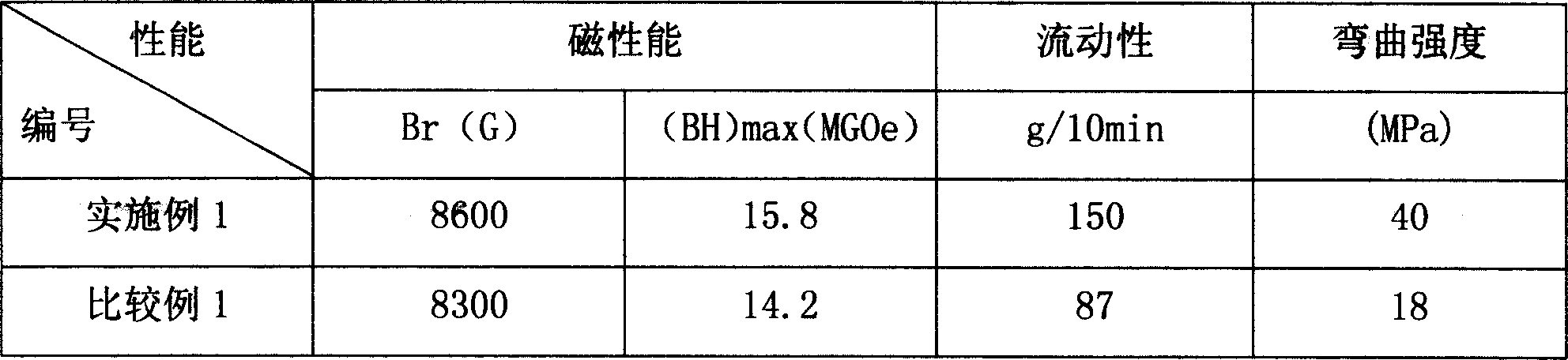

Embodiment 1

[0028] First, mix 95 grams of anisotropic Nd-Fe-B magnetic powder with 5 grams of anisotropic strontium ferrite magnetic powder, add 1.0 gram of silane coupling agent to surface treat the magnetic powder, add 0.9 gram of oleic acid after drying and knead for 10 Minutes, and then add 1.0 g of epoxy resin thereto, and mix for another 20 minutes to obtain a composite resin bonded magnet mixture, and measure the fluidity of the mixture according to the ASTM-D1238 standard. Then inject the mixture into a molding mold, compress and mold in a magnetic field of 15KOe, and harden the molded body at 100°C for 1 hour to obtain a composite bonded magnet. The tensile strength of each formula is under the condition of non-orientation magnetic field, according to the above-mentioned molding process conditions, according to the ASTM-D790 standard molding test sample, and then test the bending strength of the test sample under the test conditions specified in the ASTM-D790 standard.

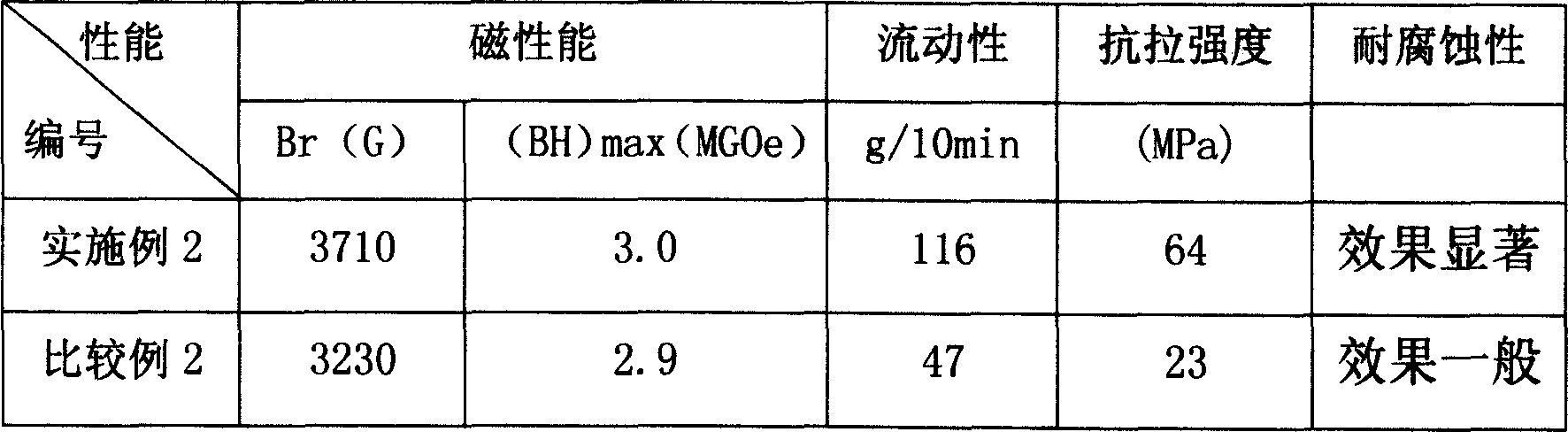

Embodiment 2

[0034] Anisotropic strontium ferrite powder (52wt%), isotropic NdFeB powder (particle size 90μm) (40wt%), silane coupling agent (0.7wt%), thermoplastic resin nylon-12 (6wt%) , phenolic antioxidant (0.7wt%), and organic lubricant EBS (0.6wt%) were mixed uniformly with a high-speed mixer. The fluidity of the mixture was measured according to ASTM-D1238 standard.

[0035] Then, each formulation mixture having the composition shown in Table 2 was sufficiently kneaded at 250° C. using a twin-screw kneader to obtain a composite bonded magnet mixture. Next, pelletizing is performed to obtain pellets with an average particle diameter of 2-6 mm. The samples were then molded in an injection molding machine. The molding temperature was 265°C. An orientation magnetic field of 10000Oe is applied during molding. The size of the molded sample is Φ10mm×10mm.

[0036] The corrosion resistance of the sample is to put the sample in the constant temperature and humidity standard test box, st...

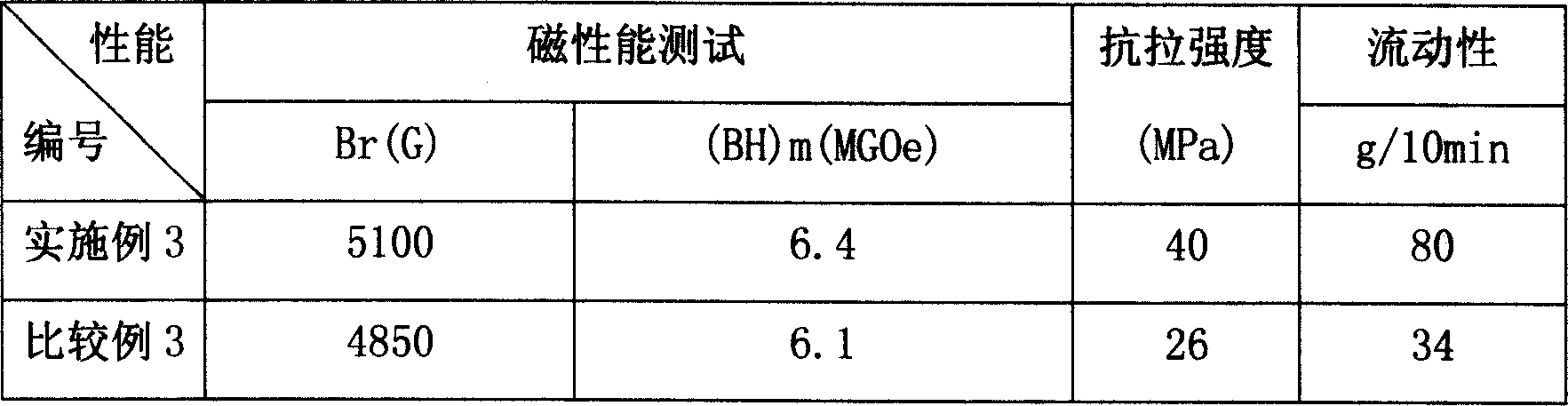

Embodiment 3

[0047] The anisotropic Nd-Fe-B permanent magnetic powder (50wt%) and strontium ferrite magnetic powder (50wt%) were respectively treated with an appropriate amount of silane coupling agent, the two magnetic powders were mixed, and then 1.5wt% of thermosetting resin was added Epoxy resin (containing curing agent and accelerator) and 0.5wt% polyamide elastomer, added 0.1wt% stearic acid lubricant, mixed, pressed in a 16KOe magnetic field, and cured to obtain a bonded composite magnet.

[0048] The flowability of the ingredients is measured according to ASTM-D1238 standard. The tensile strength of the sample is to form the test piece according to the ASTM-D638 standard under the condition of non-orientation magnetic field, and then test the tensile strength of the test piece under the test conditions specified in the ASTM-D638 standard.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com