High temperature resistance film for blister package of medical equipment and preparation method thereof

A technology for medical equipment and blister packaging, which is applied in the field of high-temperature sterilization-resistant blister packaging films for medical equipment and its preparation, can solve the problem of poor heat-sealing properties of the blister packaging films, affecting the health of patients, and ethylene oxide. Difficulty in penetration and other problems, to achieve the effect of excellent transparency and softness, good peeling fastness, and reduction of production links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

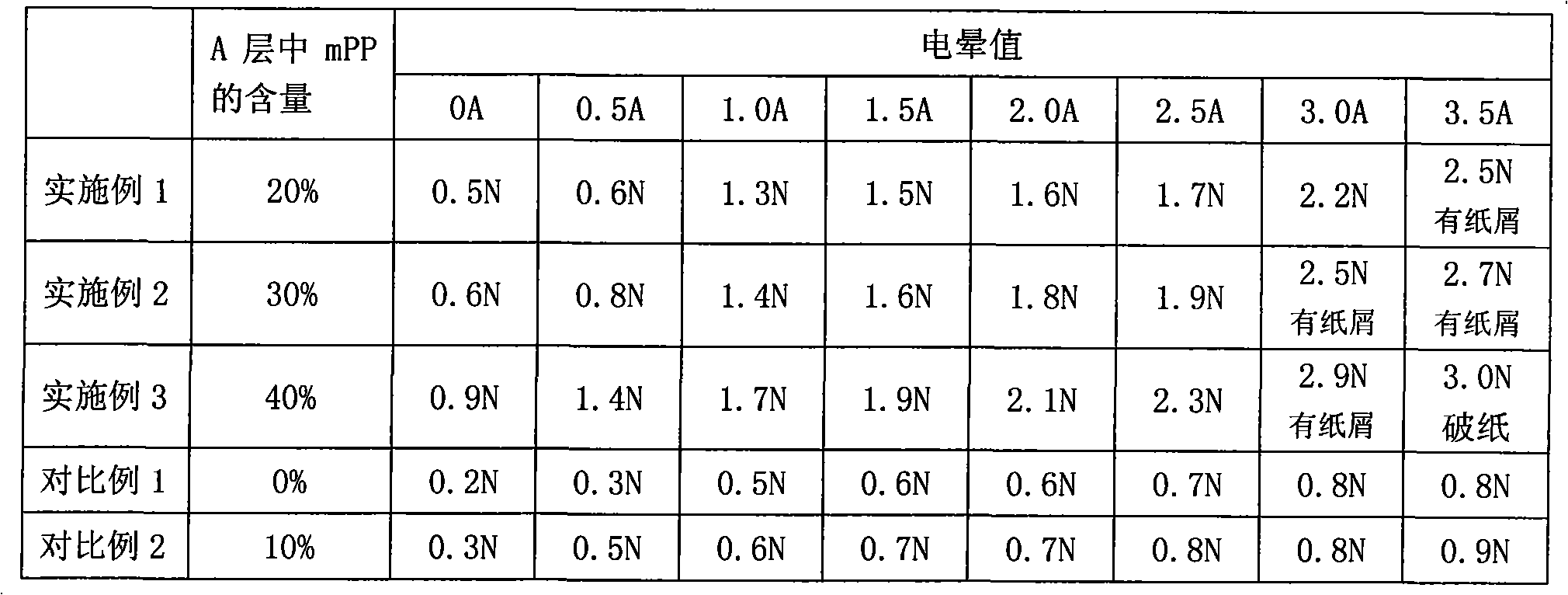

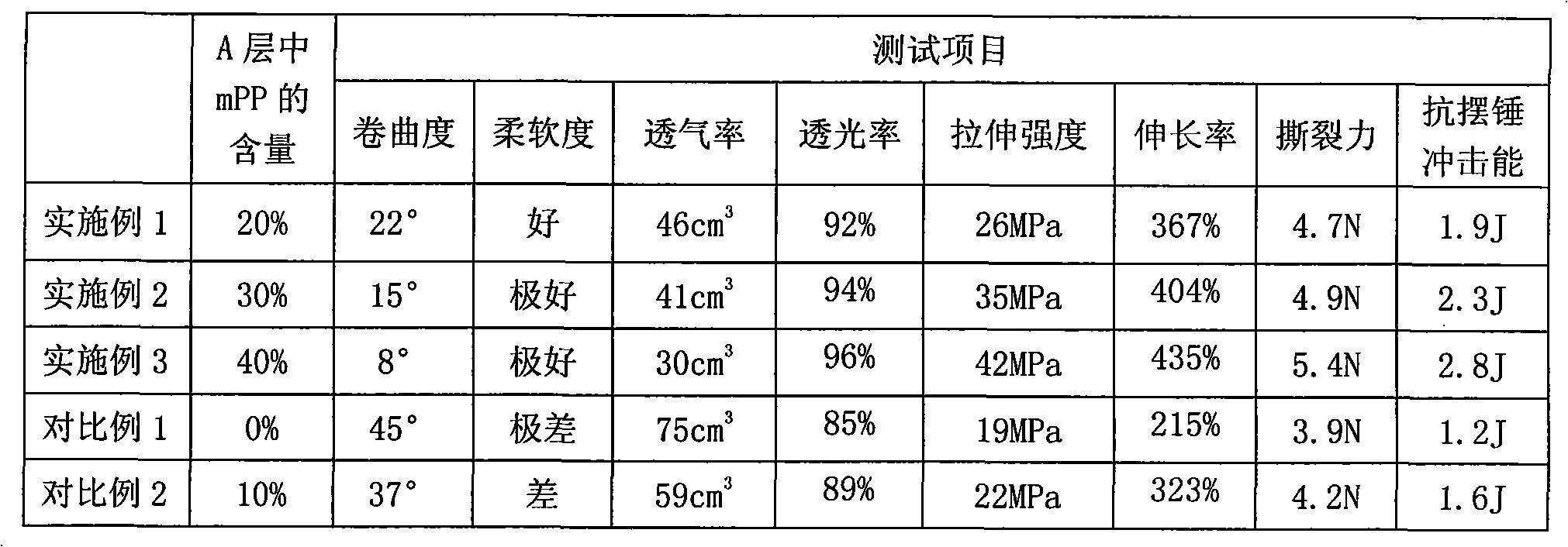

Embodiment 1~ Embodiment 3、 comparative example 1 and comparative example 2

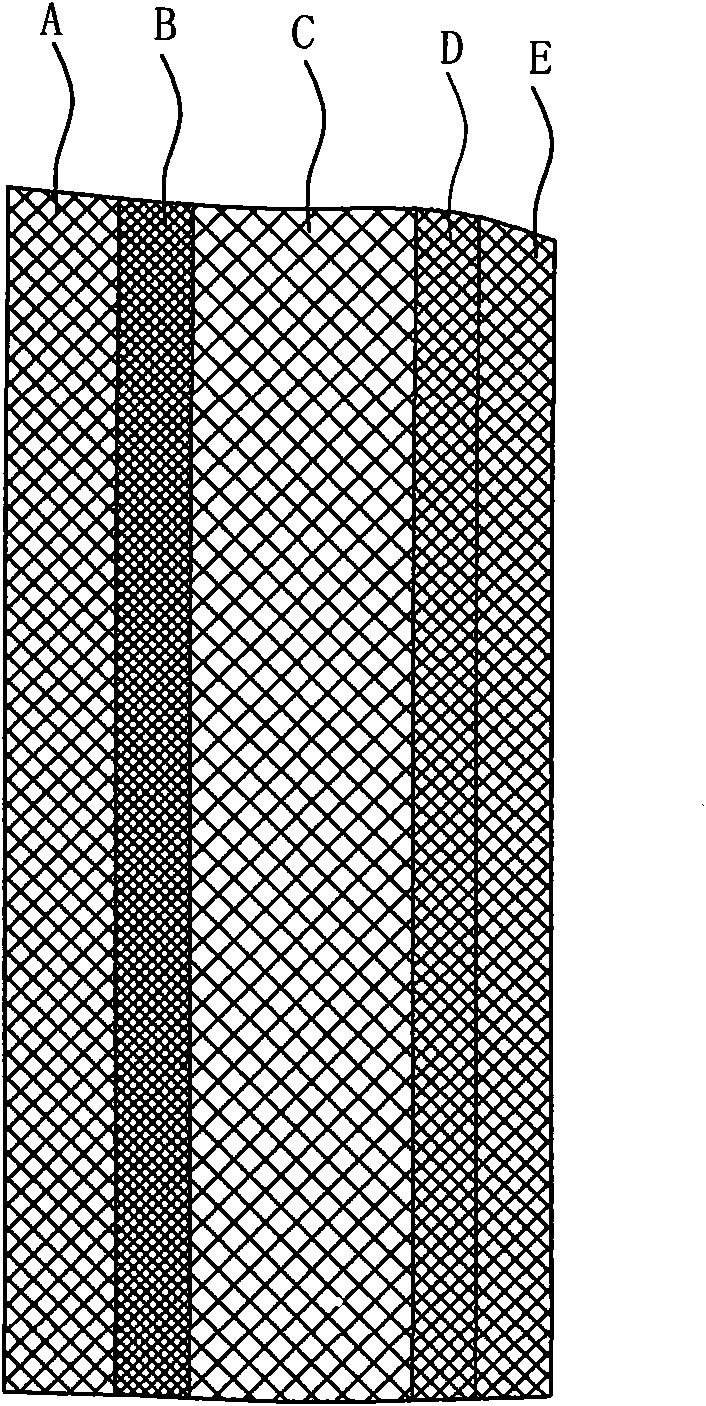

[0032] Such as figure 1 As shown, it reflects the arrangement of each layer of the high temperature sterilization-resistant medical device blister packaging film of the present invention. It can be seen from the figure that it has a five-layer structure in terms of material composition. The first to fifth layers are heat-sealing layer A, sub-inner layer B, core layer C, adhesive layer D, and weather-resistant layer E.

[0033] Choose a melt index of 1.7-6.8g / min and a density of 0.89-0.91g / cm 3 A blended resin composed of block copolymerized polypropylene and mPP, with a melt index of 1.8-5g / min and a density of 0.90-0.91g / cm 3 Homopolymerized polypropylene with a melt index of 1.6-5.5g / min and a density of 0.90-0.92g / cm 3 Homopolymerized polypropylene with a melt index of 1.3-2.5g / min and a density of 0.89-0.91g / cm 3 Maleic anhydride graft copolymerized polypropylene with a melt index of 1.7-2.8g / min and a density of 0.91-0.93g / cm 3 Nylon 6 or nylon 66, as the raw materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com