Preparation method of single-component polyurethane waterproofing paint

A polyurethane waterproof, one-component technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve environmental and human health hazards, carcinogenic and other problems, and achieve excellent waterproof performance, excellent mechanical properties and chemical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

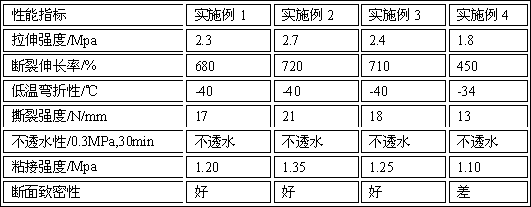

Examples

Embodiment 1

[0023] Take 88g of polyether diol, 30g of polyether triol, and 90g of plasticizer, add them to a three-necked flask, raise the temperature to 70°C, add 15g of porous microbead carrier getter (ceramic porous microbeads—adsorption auxiliary agent— Calcium oxide), 83g talcum powder and 20g kaolin, heat up to 105°C-125°C for vacuum dehydration for 3h, cool down to 40-50°C, add 8.6 toluene diisocyanate, slowly heat up, control the temperature at 75-83°C, react for 2h, cool down When the temperature is below 70°C, add a catalyst, a leveling agent, an anti-aging agent, and a defoamer, stir for 30 minutes, and discharge to obtain the waterproof coating of the present invention.

Embodiment 2

[0025] Take 88g of polyether diol, 30g of polyether triol, and 90g of plasticizer, add them to a three-necked flask, raise the temperature to 70°C, add 15g of porous microbead carrier getter (ceramic porous microbeads—adsorption auxiliary agent— Calcium Oxide - Magnesium Oxide). 83g talcum powder and 20g kaolin, heat up to 105°C-125°C for vacuum dehydration for 3 hours, cool down to 40-50°C, add 8.6 toluene diisocyanate, slowly heat up, control the temperature at 75-83°C, react for 2h, cool down to below 70°C , add catalyst, leveling agent, anti-aging agent, defoamer, stir for 30 minutes, and discharge to obtain the waterproof coating of the present invention.

Embodiment 3

[0027] Take 88g of polyether diol, 30g of polyether triol, and 90g of plasticizer, add them to a three-necked flask, raise the temperature to 70°C, add 15g of porous microbead carrier getter (ceramic porous microbeads—adsorption auxiliary agent— Magnesium oxide), 83g talcum powder and 20g kaolin, heat up to 105°C-125°C for vacuum dehydration for 3h, cool down to 40-50°C, add 8.6 toluene diisocyanate, slowly heat up, control the temperature at 75-83°C, and react for 2h, Cool down to below 70°C, add catalyst, leveling agent, anti-aging agent, defoamer, stir for 30 minutes, and discharge to obtain the waterproof coating of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com