Magnesium fireproof thermal insulation inner wall board

A technology for fire protection and heat preservation and interior wall panels, applied in building components, sustainable waste treatment, solid waste management, etc., can solve problems such as energy consumption, impact on comprehensive environmental management, waste of land resources, etc., and achieve low energy consumption and fast connection , enhance the overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

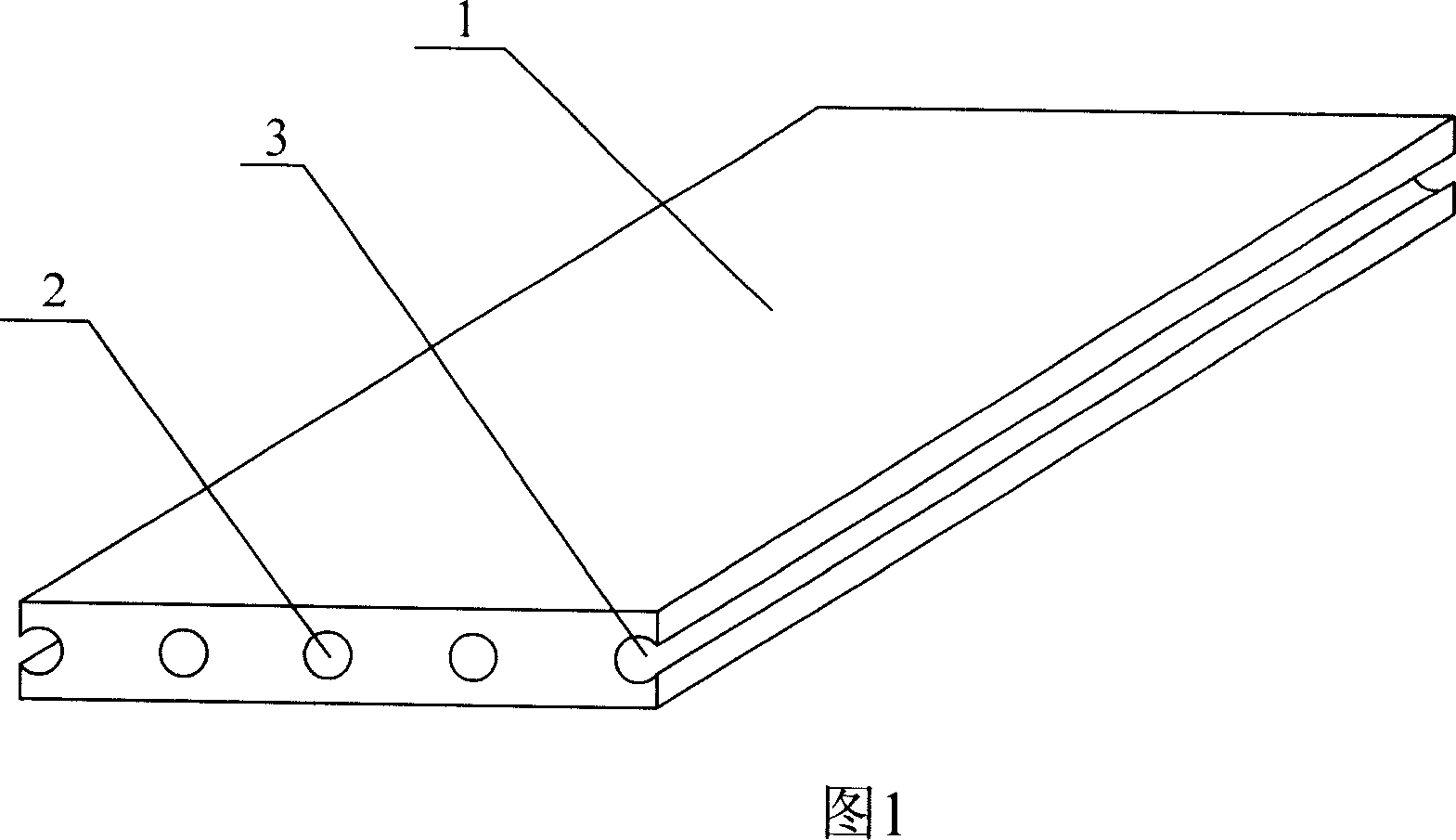

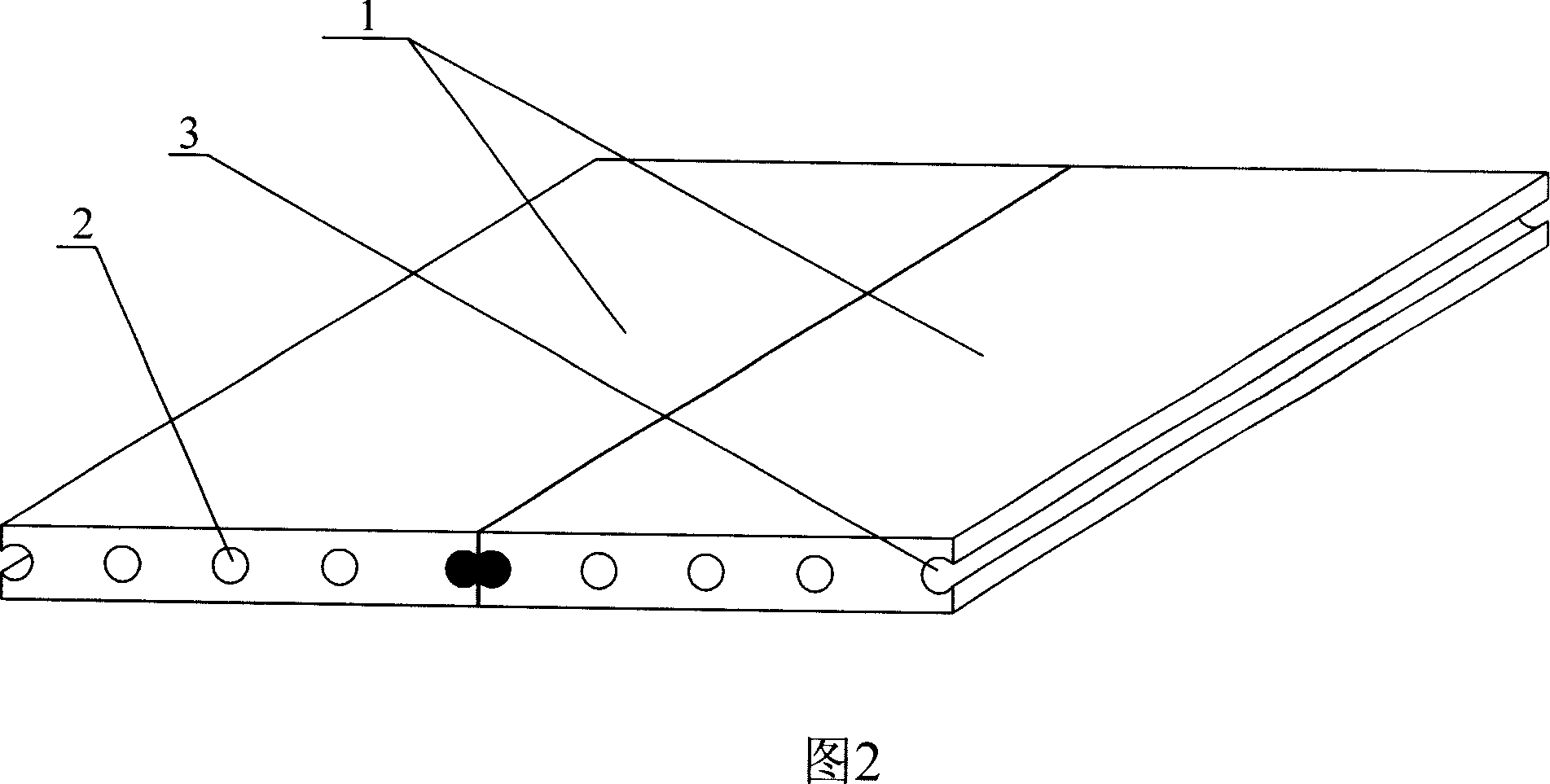

[0021] The main technical points of the magnesium fireproof and thermal insulation inner wallboard are: the wallboard 1 has a plurality of through holes 2 along the longitudinal direction, and semicircular grooves 3 are respectively formed on the end surfaces of the two side walls. The wallboard is made of magnesia, fly ash, magnesium chloride solution and water, add N 1 The foaming agent or ADC foaming agent is prepared by molding after foaming.

[0022] Magnesia, fly ash, magnesium chloride solution, blowing agent N 1 The ingredient ratio with water is: magnesia 100kg, fly ash 10kg, magnesium chloride solution 50kg, blowing agent N 1 1.4kg, water 38kg.

Embodiment 2

[0024] Embodiment 2 is basically the same as Embodiment 1, except that the magnesia is 110 kg, the fly ash is 8.9 kg, the magnesium chloride solution is 52 kg, the ADC foaming agent is 1.2 kg, and the water is 39 kg.

Embodiment 3

[0026] Embodiment three is substantially the same as embodiment one, and its difference is that magnesia is 115kg, fly ash is 11.8kg, magnesium chloride solution is 53kg, blowing agent N 1 1.8kg, water 41kg.

[0027] Among the above raw materials, magnesia contains 80-85% of magnesium oxide, and the particle size is ≥150 mesh; the particle size of fly ash is ≥150 mesh; and the magnesium chloride solution contains magnesium chloride ≥45%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com