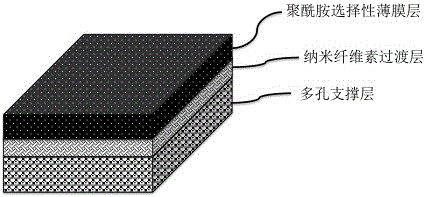

Composite thin membrane with multilayer composite structure and preparation method thereof

A transition layer and membrane surface technology, applied in the field of semi-permeable membrane separation technology, can solve the problems of low porosity, difficult operation, high energy consumption, etc., and achieve the effect of reducing membrane energy consumption, expanding application fields, and simple equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A 200 µm thick porous polysulfone support layer substrate including a backing non-woven fabric was coated with a nanocellulose transition layer according to the following steps:

[0040] (1) Preparation of nanocellulose acetate sodium by TEMPO method: 20g of never-dried softwood chemical pulp fiber was placed in a trough beater and 1500g of water was added. After thawing for 40min, 0.25g of TEMPO, 2.5g of NaBr and 5mL of 12% NaClO solution by mass percentage, stirring for full reaction, adding 0.5 molar concentration of sodium hydroxide solution and 0.5 molar concentration of hydrochloric acid solution from time to time to maintain the pH of the slurry at 10.5 After reacting for 24 hours, the oxidized fiber and waste water were separated to obtain oxidized fiber with a carboxyl content of 0.30 mmol / g; the obtained oxidized fiber was nano-treated using a high-pressure homogenizer to obtain a uniform and transparent sodium acetate nanocellulose solution;

[0041] (2) The ...

Embodiment 2

[0055] The process described in Example 1 is basically the same, but the number of repetitions of steps (4) to (7) in step (8) is 5 times to obtain the nanocellulose transition layer of 6 double-layer nanostructures, and other parameters are different. Change. After testing, the salt rejection rate of the obtained composite membrane was 98.8%, and the flux was 3.1 L / m 2 h.

Embodiment 3

[0057] The process described in Example 1 is basically the same, but the number of repetitions of steps (4) to (7) in step (8) is 20 times to obtain 21 nanocellulose transition layers of double-layer nanostructure, and other parameters are different. Change. After testing, the salt rejection rate of the obtained composite membrane was 99.2%, and the flux was 3.0 L / m 2 h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com