High-performance volatile fin punching oil and preparation method thereof

A stamping oil and volatile technology, applied in high-performance volatile fin stamping oil and its preparation, in the field of fin stamping oil, it can solve the extreme pressure, anti-corrosion and anti-rust effects of fin stamping oil, etc. problems, to achieve the effects of excellent solubilization, extended service life, and high volatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

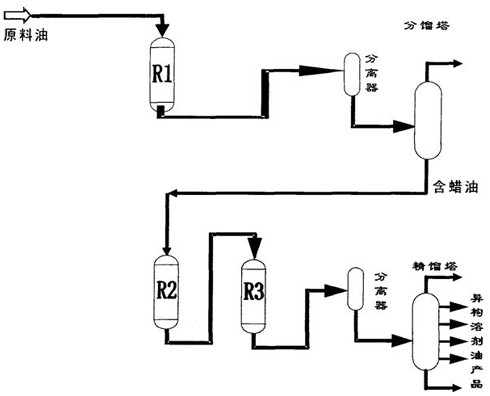

Embodiment 1

[0051] In the present invention, the narrow-fraction isoparaffin base oil is firstly prepared, and the raw material oil for preparing the narrow-fraction isoparaffin base oil includes vacuum distillate oil or solvent-refined deasphalted oil, and the raw material and hydrogen first enter the hydrotreating reaction zone R1 to add The hydrorefining catalyst is used for hydrogenation treatment, and the hydrotreated product is subjected to gas-liquid separation through a separation tower, and the obtained liquid phase is a hydrotreated waxy oil with very low sulfur and nitrogen content, and the hydrotreated waxy oil is used as a raw material, Mix with hydrogen and enter the hydroisomerization reaction zone R2, add a hydroisomerization catalyst for hydroisomerization reaction, the effluent directly enters the hydrogenation supplementary refining reaction zone R3, add a hydrofining catalyst to further remove olefins and aromatics Impurities; the reaction effluent in the hydrogenation ...

Embodiment 2

[0075] In the present invention, the narrow-fraction isoparaffin base oil is first prepared, and the raw material oil for preparing the narrow-fraction isoparaffin base oil includes vacuum distillate oil or solvent-refined deasphalted oil, and the raw material and hydrogen first enter the hydrotreating reaction zone R1 to add The hydrorefining catalyst is used for hydrogenation treatment, and the hydrotreated product is subjected to gas-liquid separation through a separation tower, and the obtained liquid phase is a hydrotreated waxy oil with very low sulfur and nitrogen content, and the hydrotreated waxy oil is used as a raw material, Mix with hydrogen and enter the hydroisomerization reaction zone R2, add a hydroisomerization catalyst for hydroisomerization reaction, the effluent directly enters the hydrogenation supplementary refining reaction zone R3, add a hydrofining catalyst to further remove olefins and aromatics Impurities; hydrogenation and supplementary refining reac...

Embodiment 3

[0103] In the present invention, the narrow-fraction isoparaffin base oil is firstly prepared, and the raw material oil for preparing the narrow-fraction isoparaffin base oil includes vacuum distillate oil or solvent-refined deasphalted oil, and the raw material and hydrogen first enter the hydrotreating reaction zone R1 to add The hydrorefining catalyst is used for hydrogenation treatment, and the hydrotreated product is subjected to gas-liquid separation through a separation tower, and the obtained liquid phase is a hydrotreated waxy oil with very low sulfur and nitrogen content, and the hydrotreated waxy oil is used as a raw material, Mix with hydrogen and enter the hydroisomerization reaction zone R2, add a hydroisomerization catalyst for hydroisomerization reaction, the effluent directly enters the hydrogenation supplementary refining reaction zone R3, add a hydrofining catalyst to further remove olefins and aromatics Impurities; the reaction effluent in the hydrogenation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com