Metal component optimization method based on additive process forming and forming equipment with same

A metal component and additive process technology, applied in the direction of additive processing, etc., can solve the problems of large energy consumption, complicated process route, and long process time, and achieve the effect of improving surface hardness, high surface finish, and friendly working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

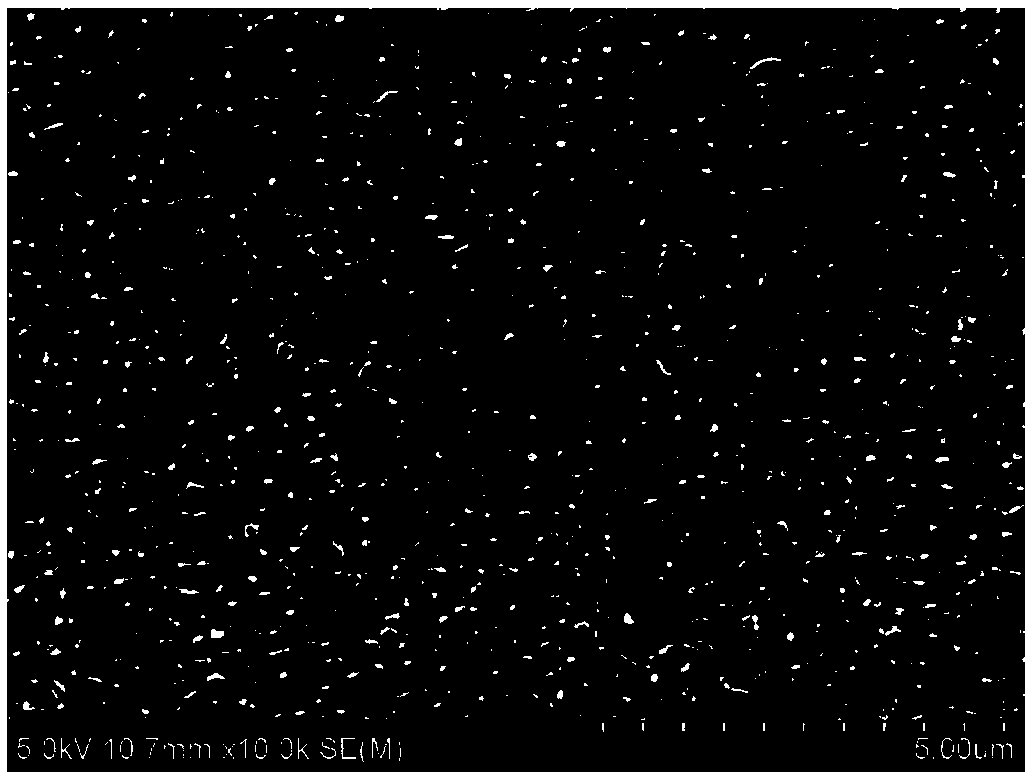

[0044] First, the metal component is formed by the additive process, specifically, the metal powder is fused according to the preset 3D printing filling scanning path. The fusion methods of the metal powder used in this embodiment include but are not limited to laser fusion, flame fusion, and plasma. Body fusion, welding fusion and electric heat source fusion, and the metal components formed by fusion have several cladding layers. The metal components in this embodiment are 316L stainless steel components.

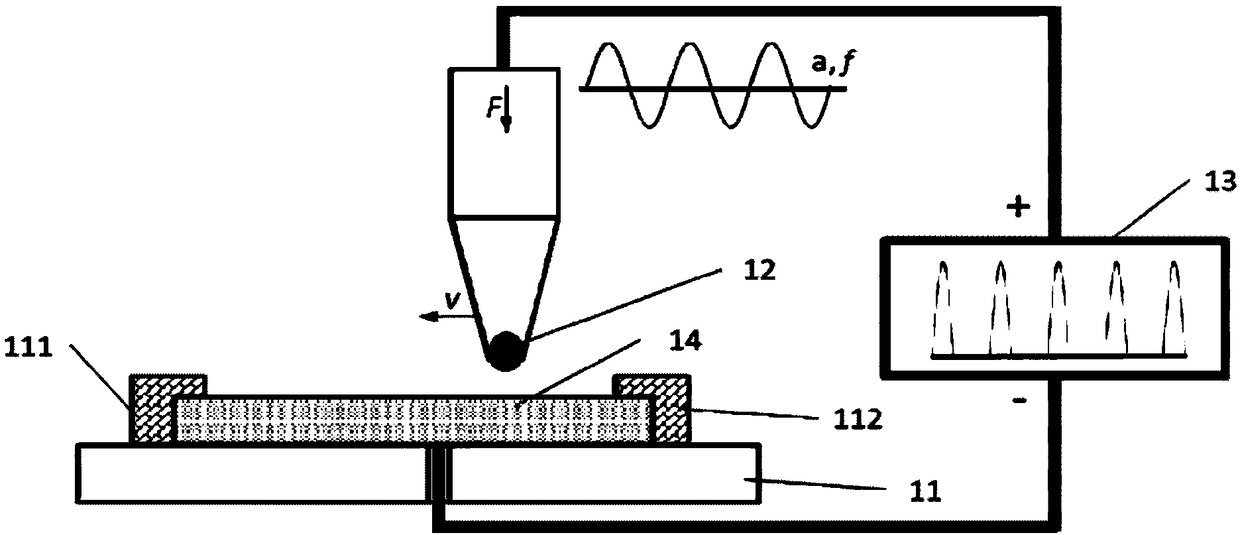

[0045] Then perform the step of ultrasonic rolling treatment and the step of applying pulse current. In this embodiment, the scheme of applying pulse current while performing ultrasonic rolling treatment is adopted. refer to figure 1 , shows a schematic structural diagram of the optimization equipment implementing the optimization method in the present invention. As shown in the figure, the optimization equipment includes a support platform 11, which is used to support a...

Embodiment 2

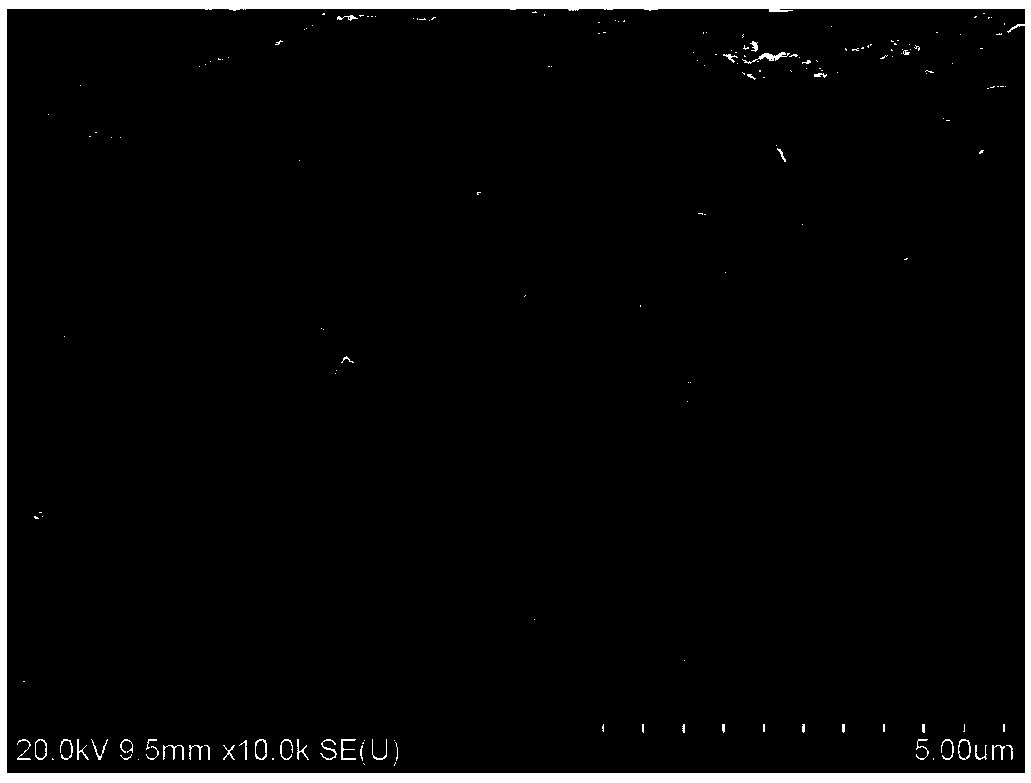

[0054] First, the metal component is formed by the additive process, specifically, the metal powder is fused according to the preset 3D printing filling scanning path. The fusion methods of the metal powder used in this embodiment include but are not limited to laser fusion, flame fusion, and plasma. Body fusion, welding fusion and electric heat source fusion, and the metal components formed by fusion have several cladding layers. The metal components in this embodiment are 316L stainless steel components.

[0055] Then perform the step of ultrasonic rolling treatment and the step of applying pulse current. In this embodiment, the scheme of performing ultrasonic rolling treatment first and then applying pulse current is adopted. refer to Figure 4 , shows a schematic structural diagram of the optimization equipment implementing the optimization method in the present invention. As shown in the figure, the optimization equipment includes a support platform 21, and an ultrasoni...

Embodiment 3

[0062] The difference between this embodiment and Embodiment 1 and Embodiment 2 is that in the above embodiment, the optimization step of the component is carried out independently of the molding step, and the optimization equipment and the molding equipment are relatively independent equipment; in this embodiment, the optimization Equipment and molding equipment are centralized. refer to Figure 5 , shows a schematic structural view of the molding equipment implementing the optimization method in the present invention. As shown in the figure, the molding equipment includes a support platform 31, an ultrasonic rolling head 32 and a pulse power supply 33. The connection relationship between the support platform 31, the ultrasonic rolling head 32 and the pulse power supply 33 is the same as that of the first embodiment, and will not be repeated here. The molding device also includes a printing head 34 for realizing additive molding, and the printing head 34 can adopt the existi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com