Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

873 results about "Cobalt alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cobalt alloys are naturally ferromagnetic. The crystallographic nature of cobalt alloys allow them to maintain their strength, even at higher temperatures and feature improved wear resistance and corrosion resistance than other metals.

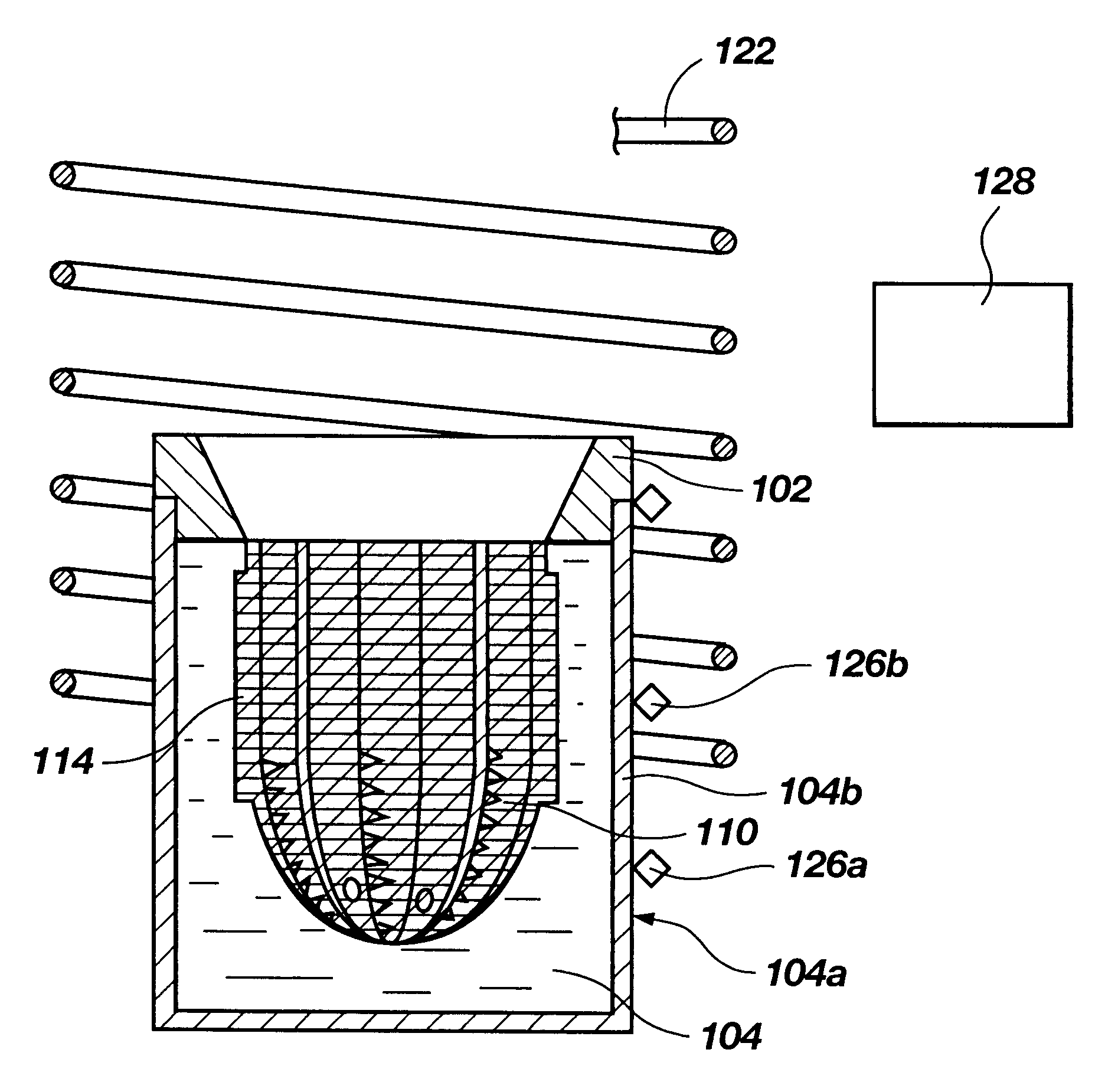

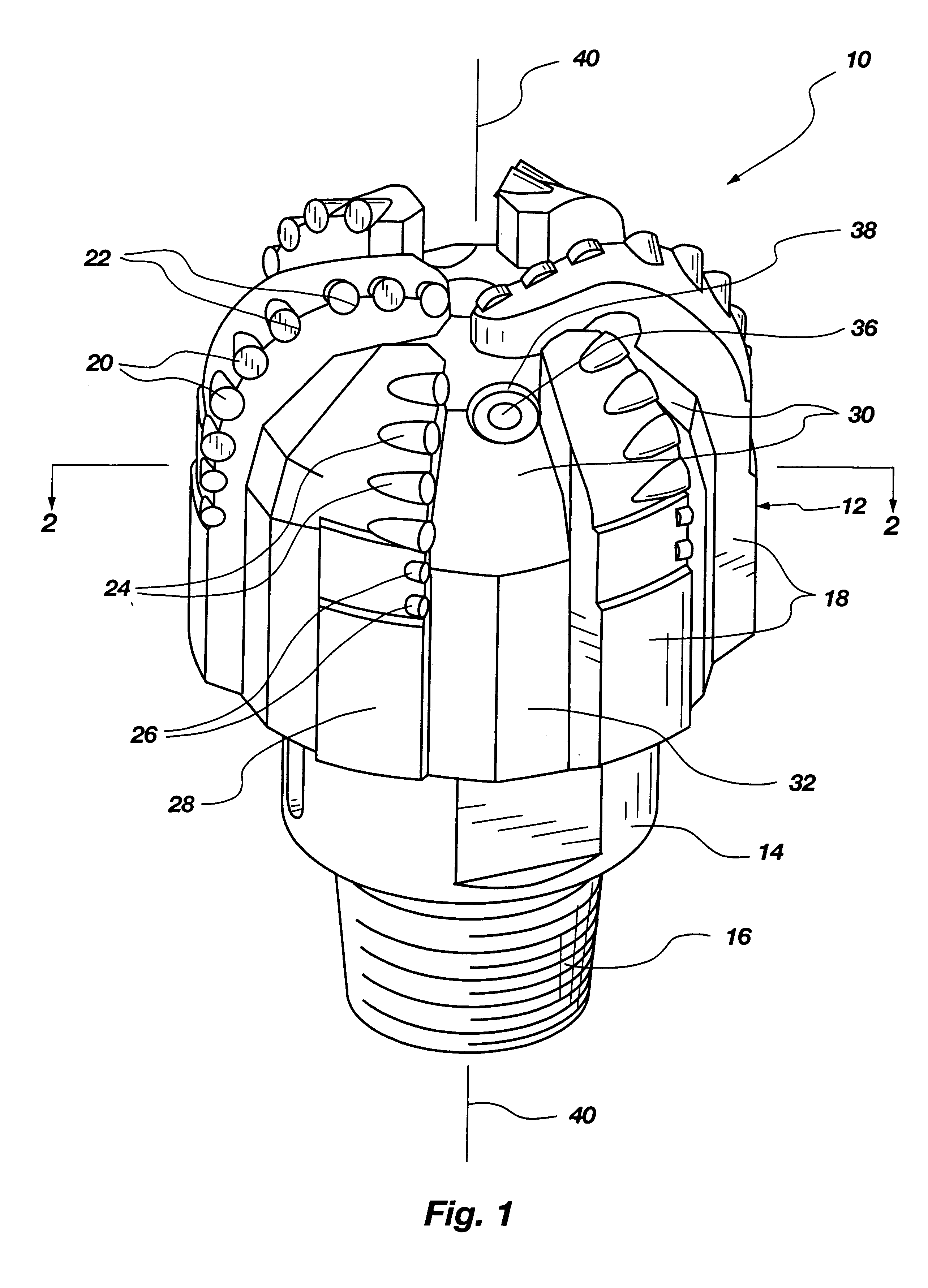

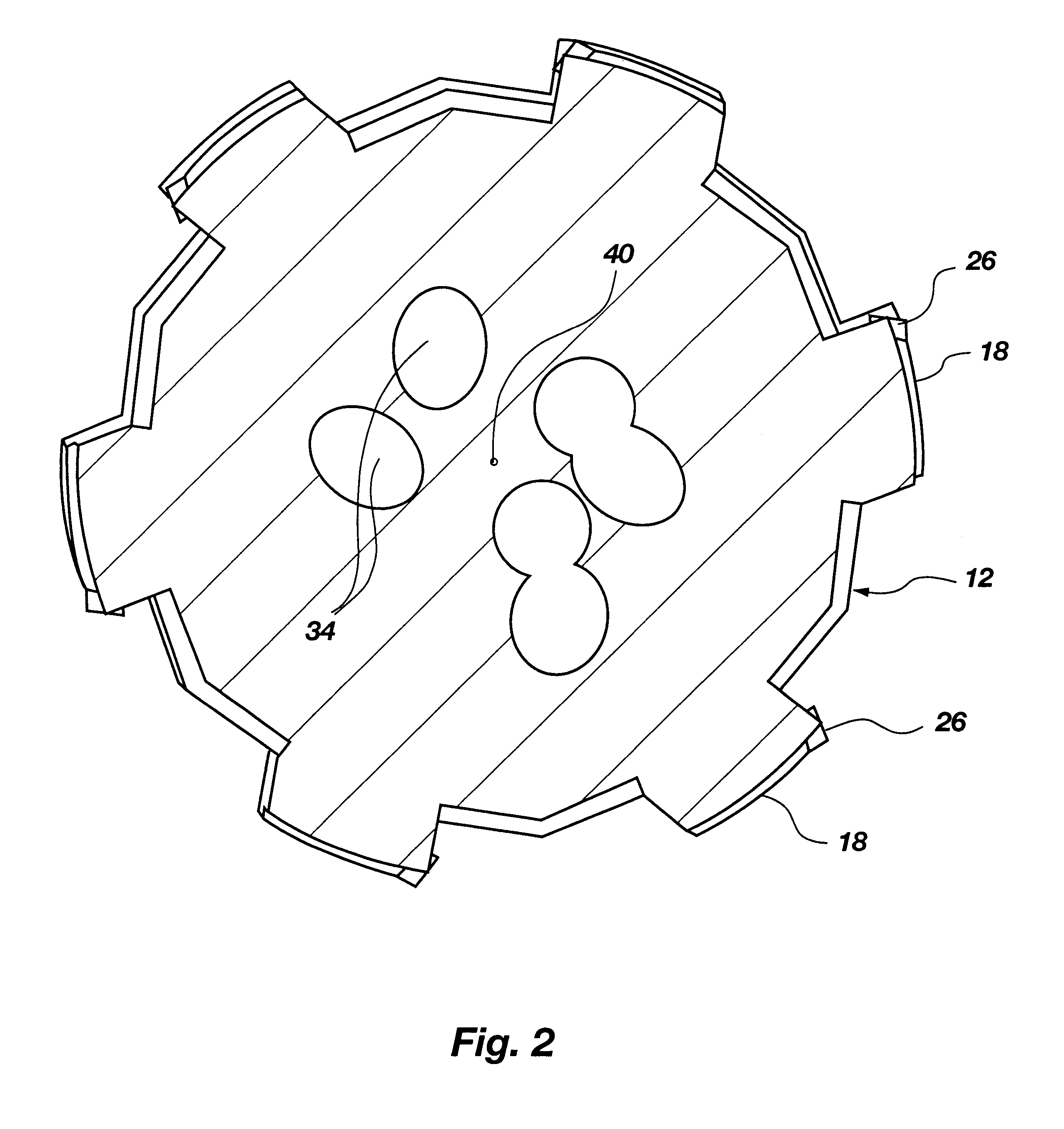

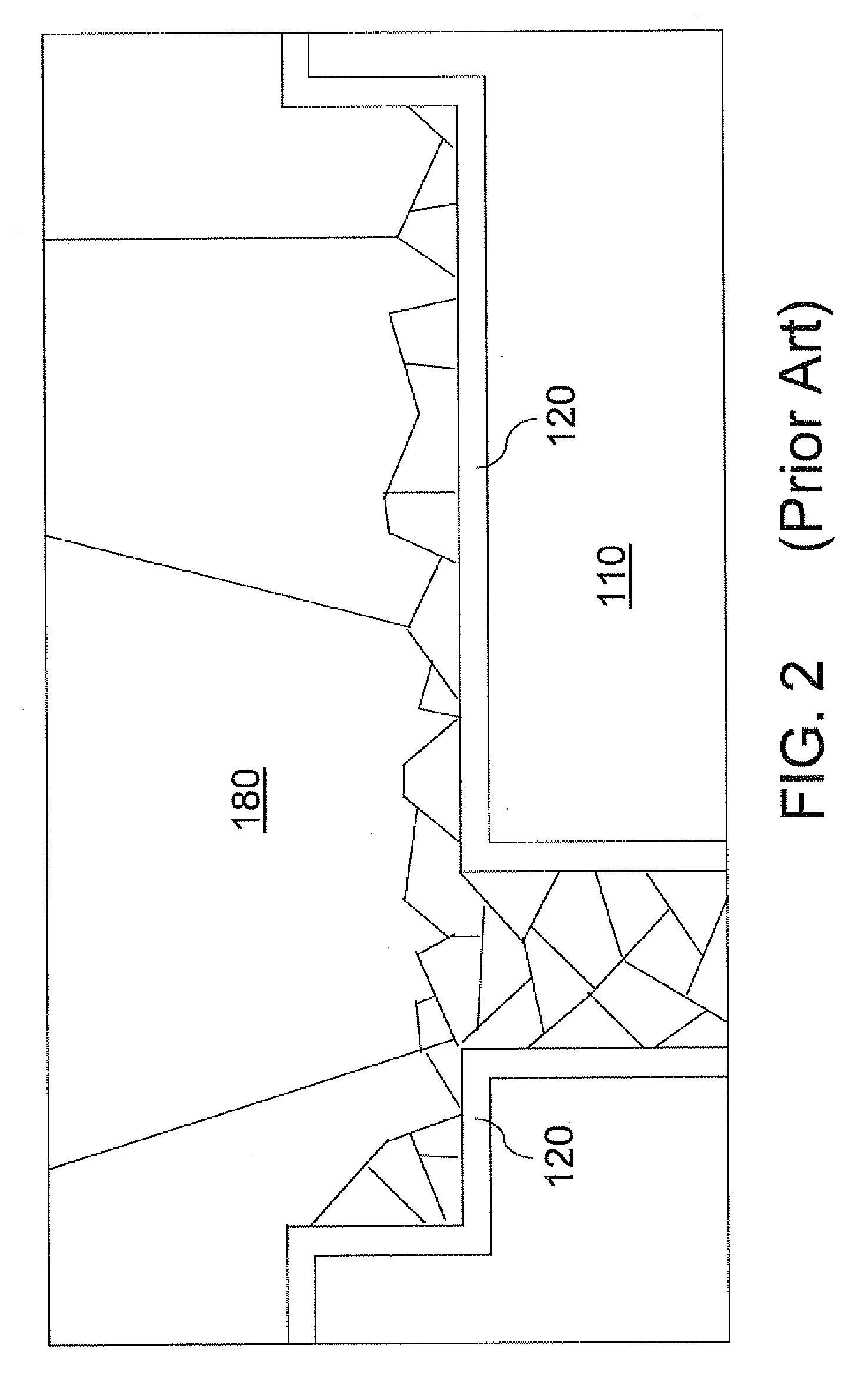

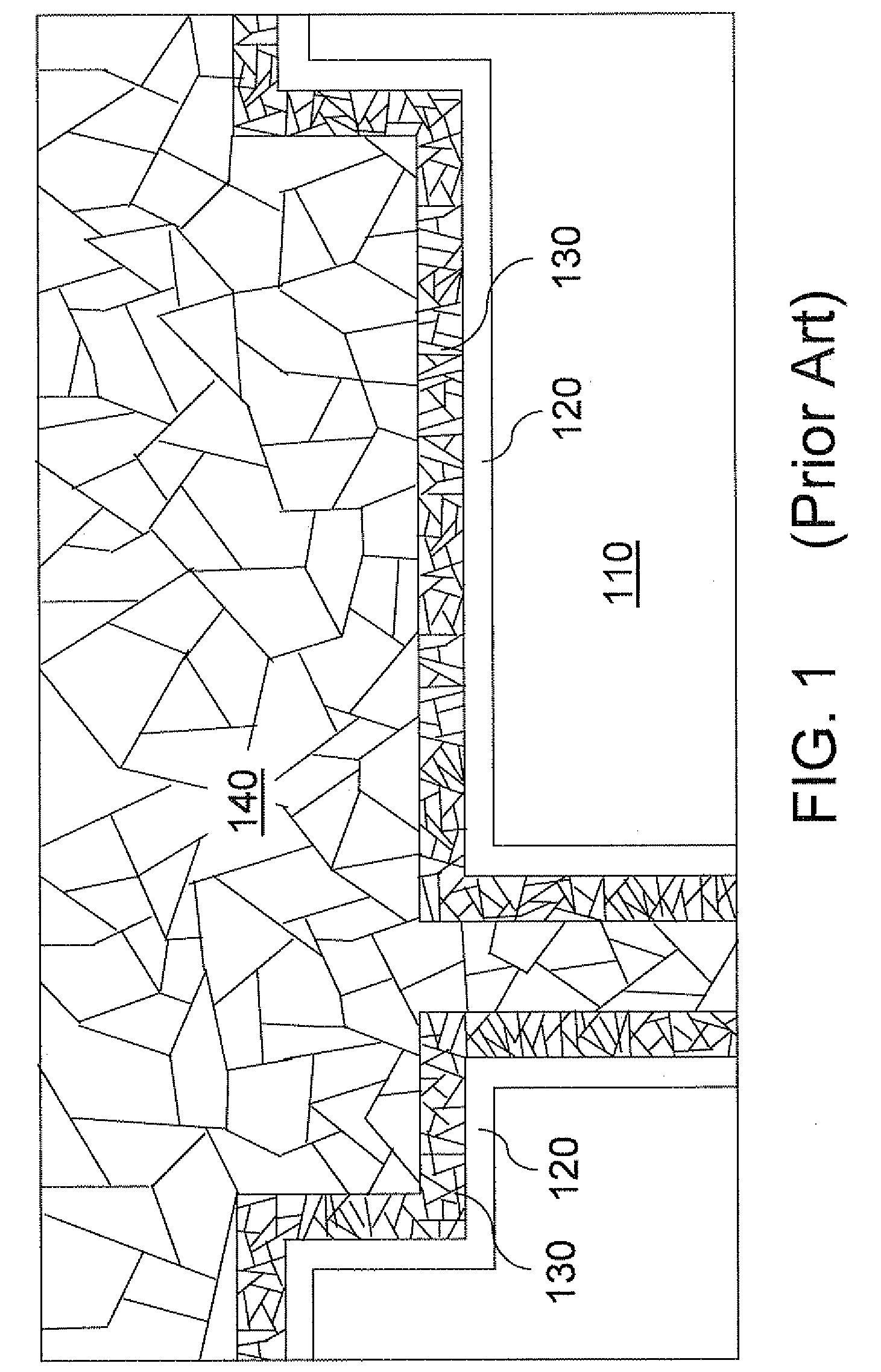

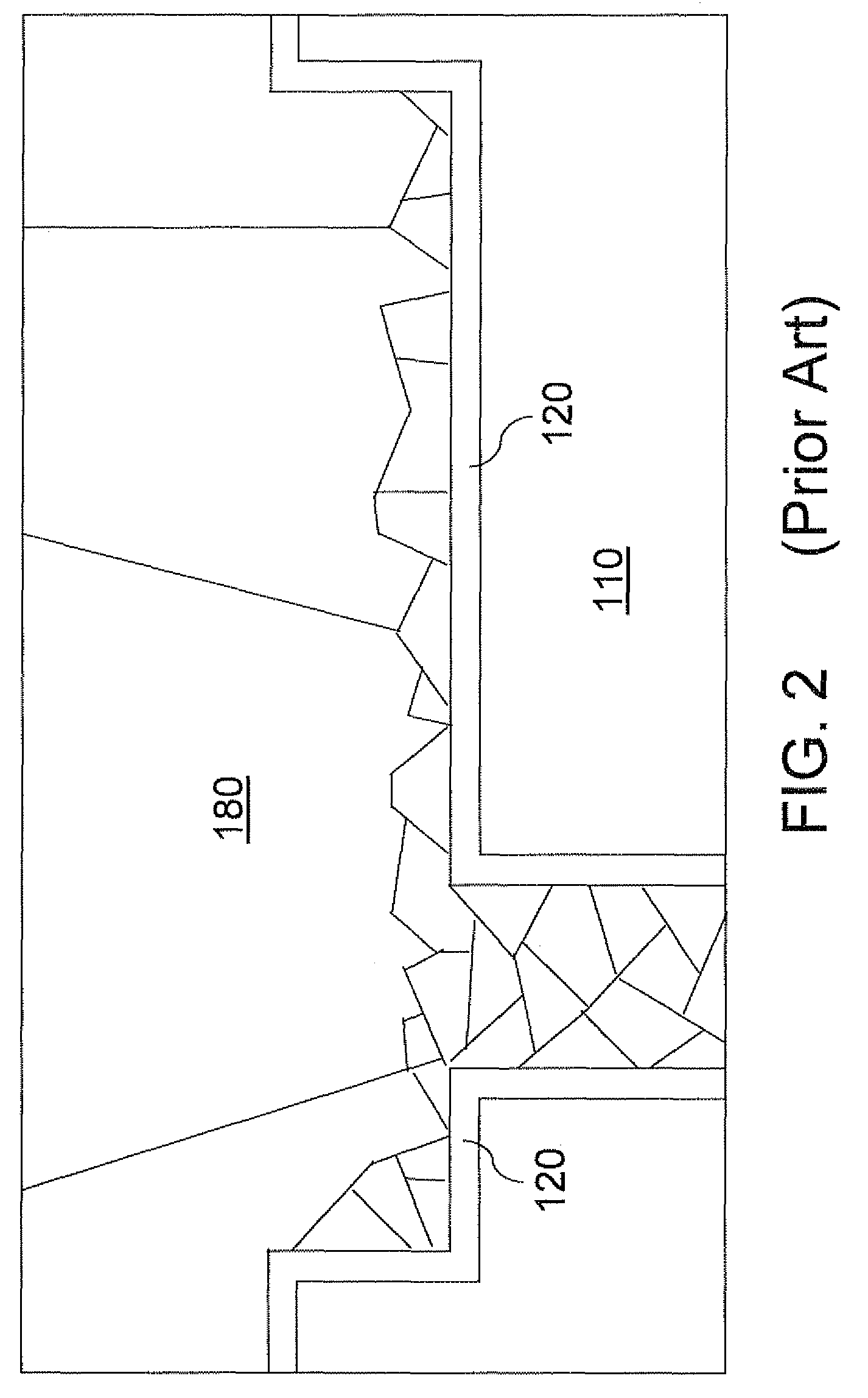

Methods of high temperature infiltration of drill bits and infiltrating binder

A method of manufacturing a bit body, other drilling-related component, or other article of manufacture, including fabricating a particulate-based matrix and infiltrating the particulate-based matrix with a binder that includes cobalt or iron. The binder may be a cobalt alloy or an iron alloy. The particulate-based matrix may be disposed within a non-graphite mold. The particulate-based matrix and binder are placed within an induction coil and an alternating current is applied to the induction coil in order to directly heat the binder, permitting the binder to infiltrate or otherwise bind the particles of the matrix together. The molten binder may then be directionally cooled by forming a cooling zone around an end portion of the bit body and increasing the size of the cooling zone relative to the bit body. The invention also includes a bit body, other drilling-related component, or other article of manufacture which includes a particulate-based matrix that is bound together with a binder that includes iron or cobalt.

Owner:BAKER HUGHES INC

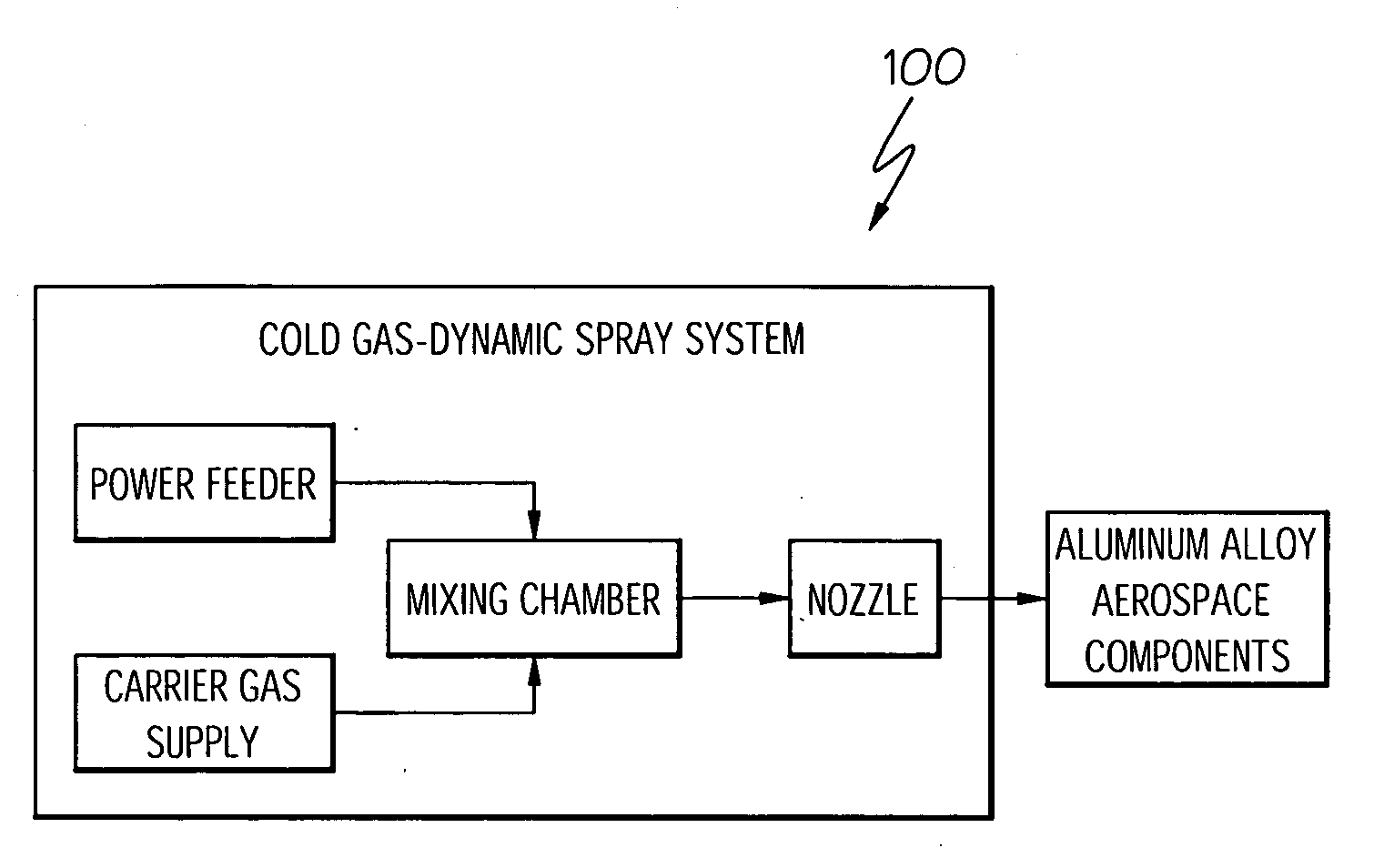

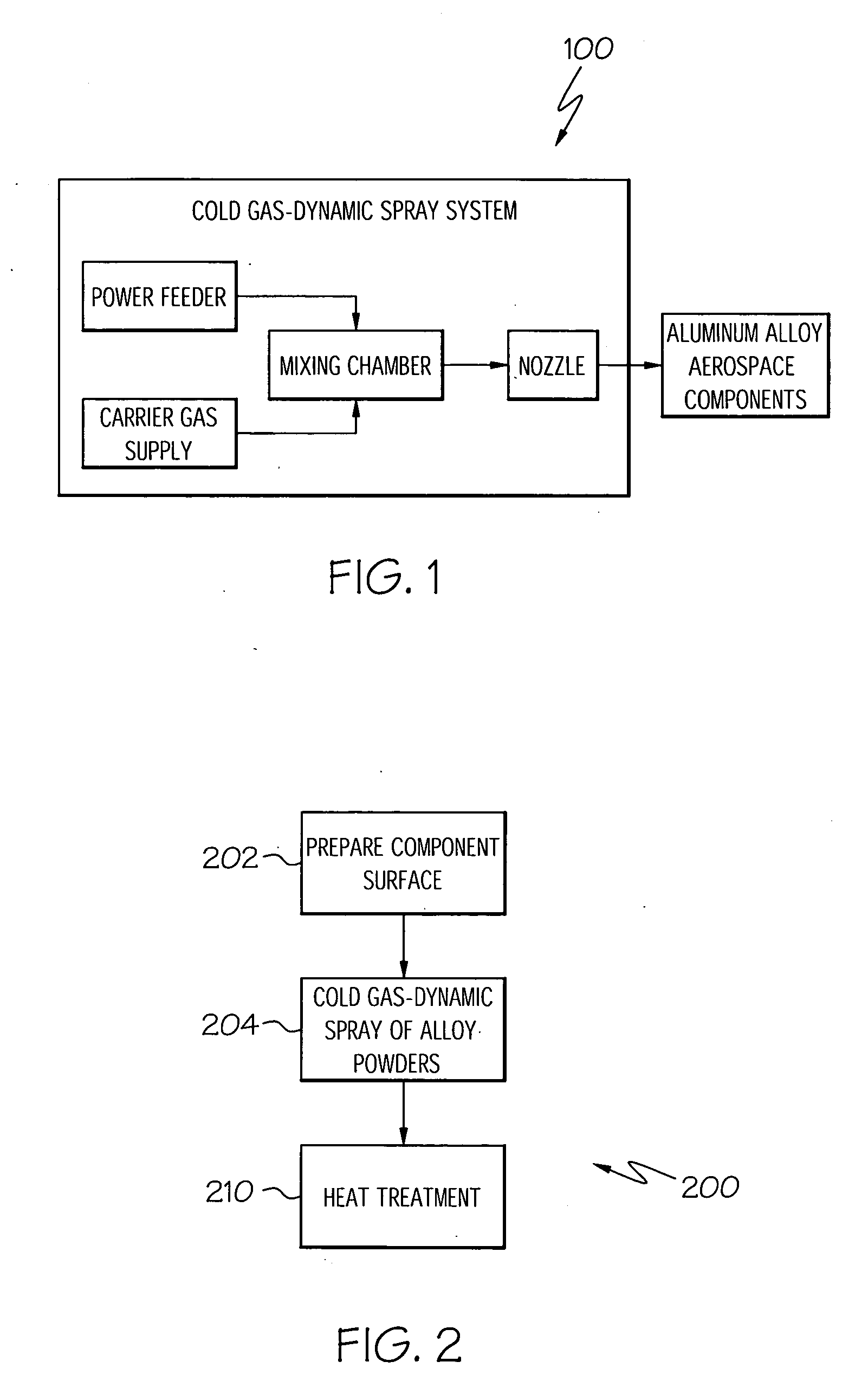

Aluminum articles with wear-resistant coatings and methods for applying the coatings onto the articles

InactiveUS20060093736A1Liquid surface applicatorsSuperimposed coating processWear resistantTitanium alloy

A method for coating a surface of a component formed from aluminum or an alloy thereof includes the step of cold gas-dynamic spraying a powder material on the component surface to form a coating, the powder material comprising at least one alloy from the group consisting of titanium, a titanium alloy, nickel, a nickel alloy, iron, an iron alloy, aluminum, an aluminum alloy, copper, a copper alloy, cobalt, and a cobalt alloy. In one embodiment, the method further includes the step of heat treating the turbine component after the cold gas-dynamic spraying.

Owner:HONEYWELL INT INC

Composition and process for post-etch removal of photoresist and/or sacrificial anti-reflective material deposited on a substrate

ActiveUS20050197265A1Cationic surface-active compoundsOrganic detergent compounding agentsAnti-reflective coatingPhotoresist

A composition and process for removing photoresist and / or sacrificial anti-reflective coating (SARC) materials from a substrate having such material(s) thereon. The composition includes a base component, such as a quaternary ammonium base in combination with an alkali or alkaline earth base, or alternatively a strong base in combination with an oxidant. The composition may be utilized in aqueous medium, e.g., with chelator, surfactant, and / or co-solvent species, to achieve high-efficiency removal of photoresist and / or SARC materials in the manufacture of integrated circuitry, without adverse effect on metal species on the substrate, such as copper, aluminum and / or cobalt alloys, and without damage to SiOC-based dielectric materials employed in the semiconductor architecture.

Owner:ENTEGRIS INC

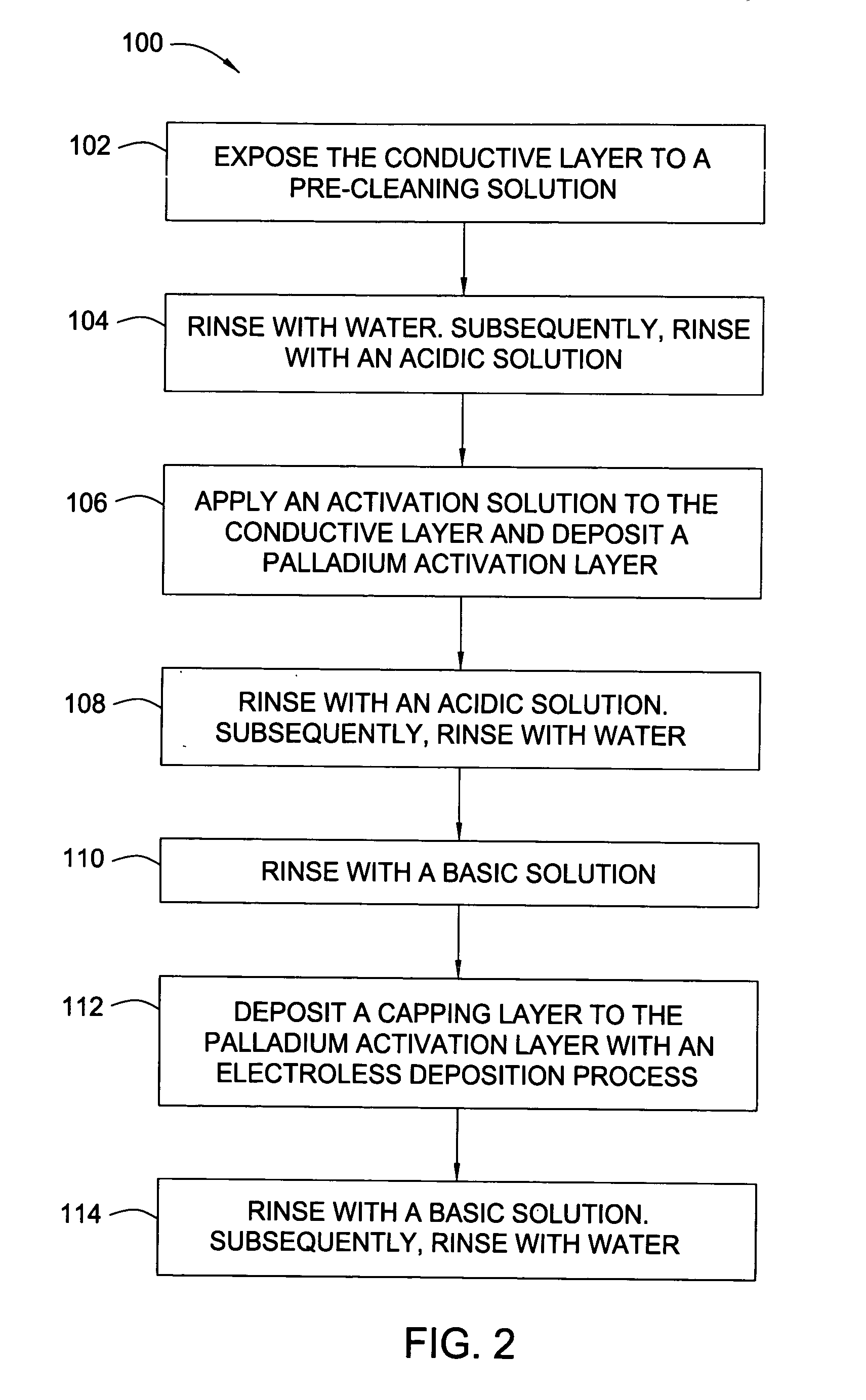

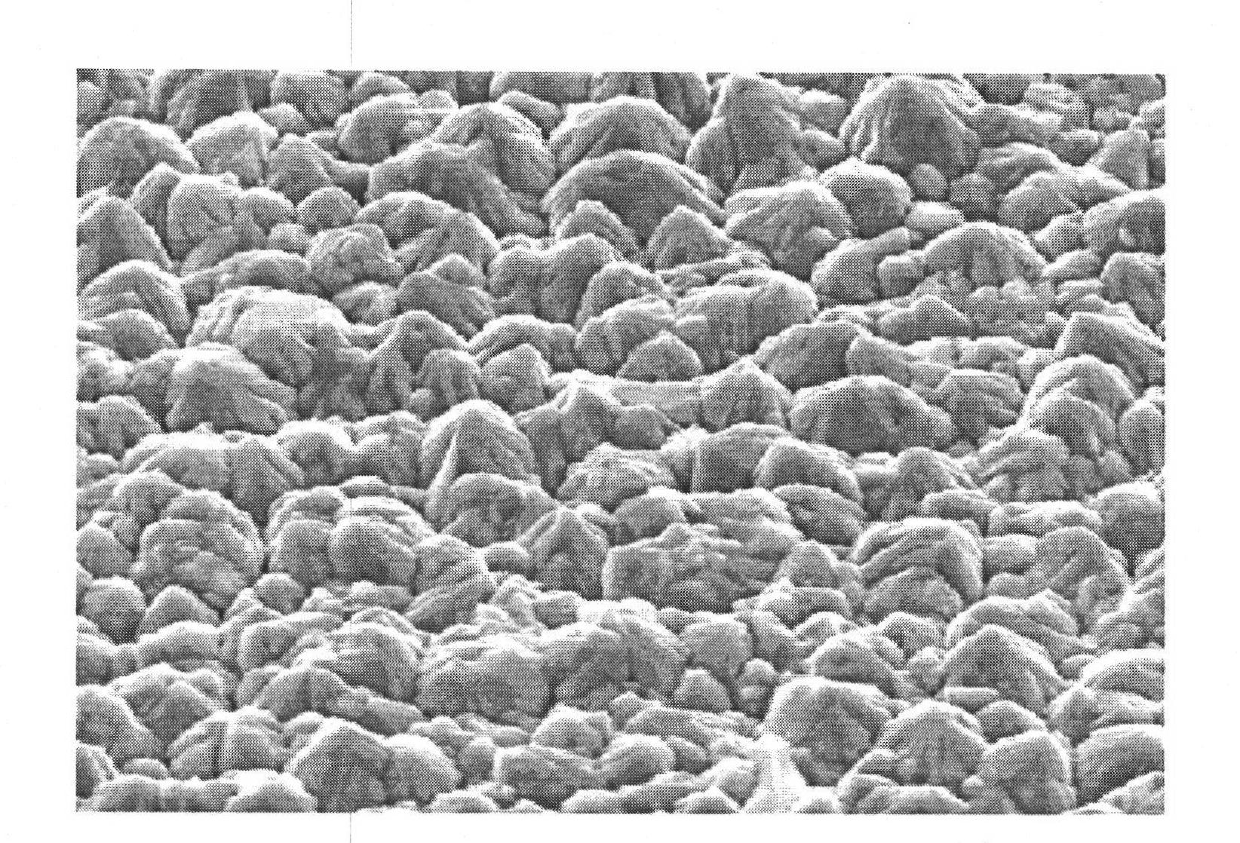

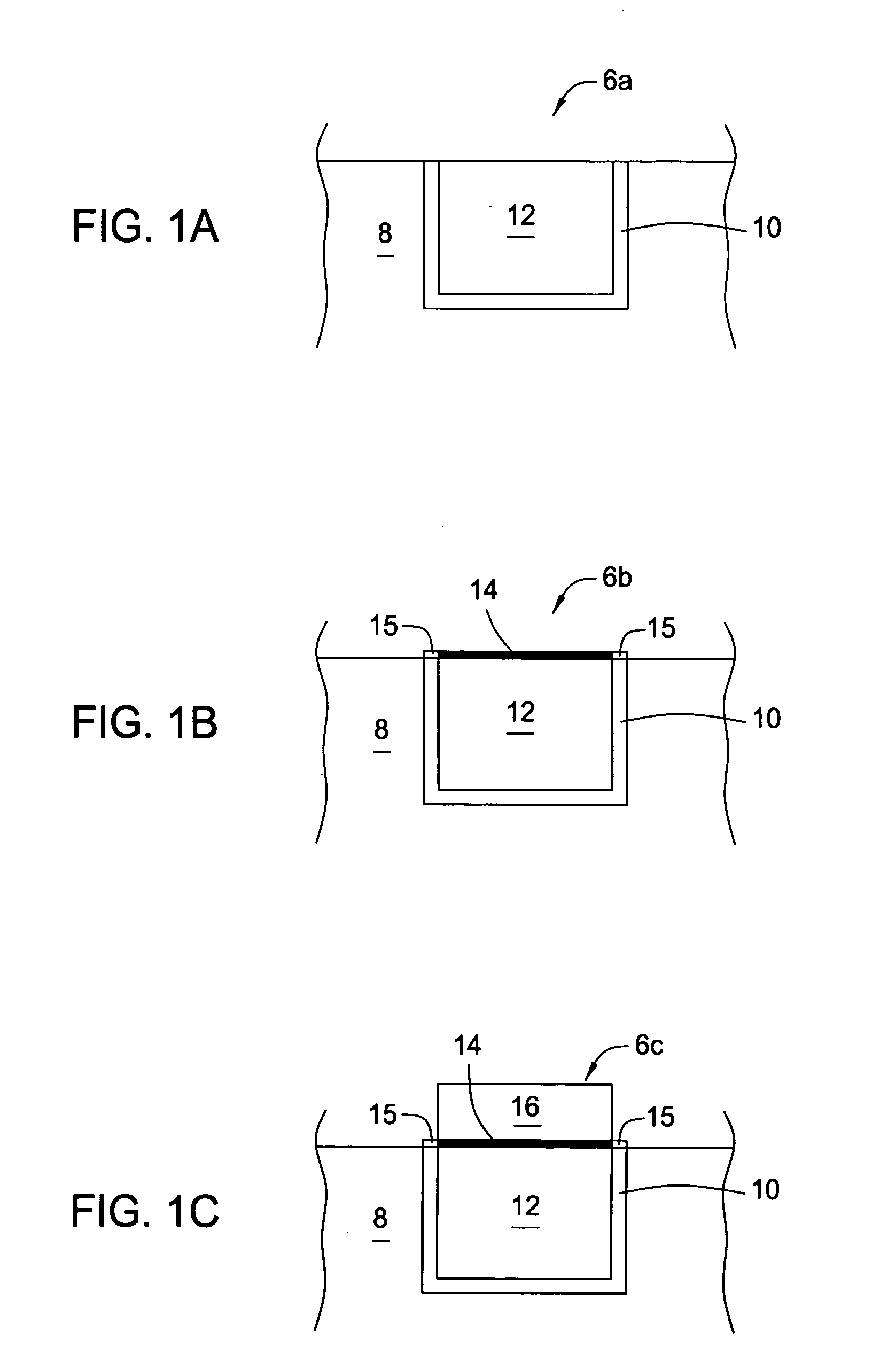

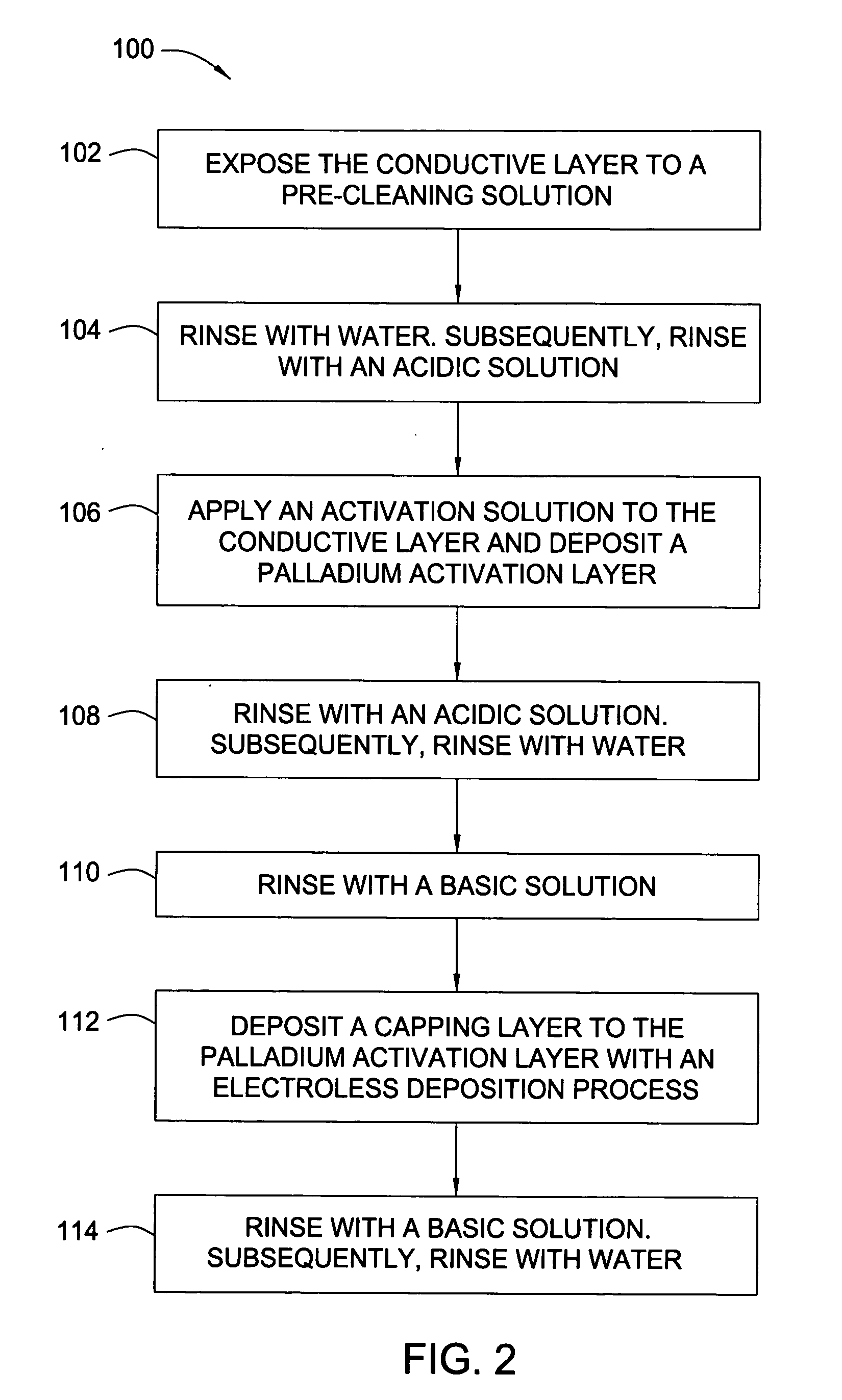

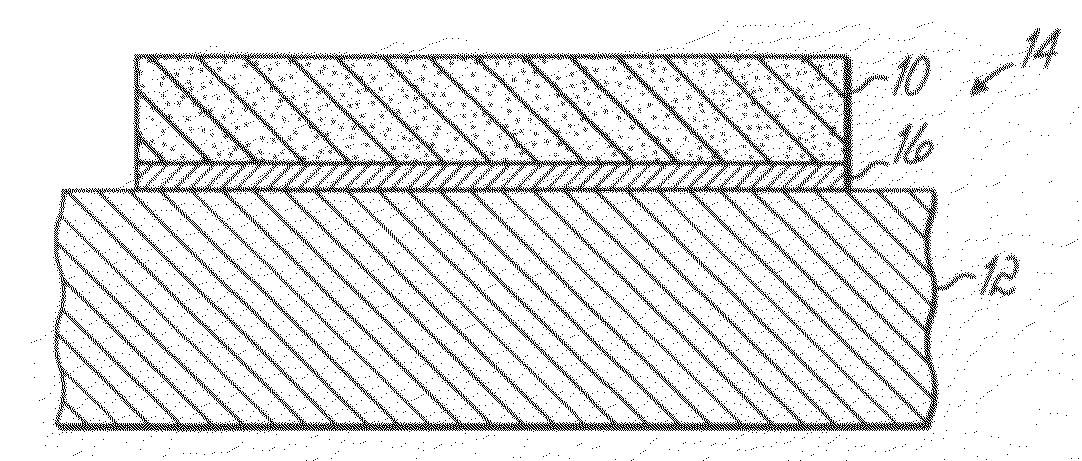

Electroless cobalt alloy deposition process

InactiveUS20050161338A1Semiconductor/solid-state device manufacturingLiquid/solution decomposition chemical coatingDeposition processSURFACTANT BLEND

In one embodiment, a method for depositing a cobalt-containing capping layer on a metal layer is provided which includes rinsing the metal layer with a deionized water wetting step, depositing a palladium layer on the metal layer by exposing the metal layer to an electroless activation solution comprising a palladium precursor and an acid, and depositing the cobalt-containing capping layer on the palladium layer by exposing the palladium layer to an electroless cobalt-containing solution comprising a cobalt source, a tungsten source, an oxygen scavenger and a surfactant. Ascorbic acid may be used as the oxygen scavenger. In another embodiment, a composition of an electroless plating solution is provided which includes a cobalt source at a concentration in a range from about 50 mM to about 250 mM, a tungsten source at a concentration in a range from about 10 mM to about 100 mM, a complexing agent at a concentration in a range from about 10 mM to about 200 mM, at least one reductant at a concentration in a range from about 1 mM to about 100 mM, a surfactant at a concentration in a range from about 1 mg / L to about 100 mg / L, and ascorbic acid at a concentration in a range from about 30 mg / L to about 300 mg / L.

Owner:APPLIED MATERIALS INC

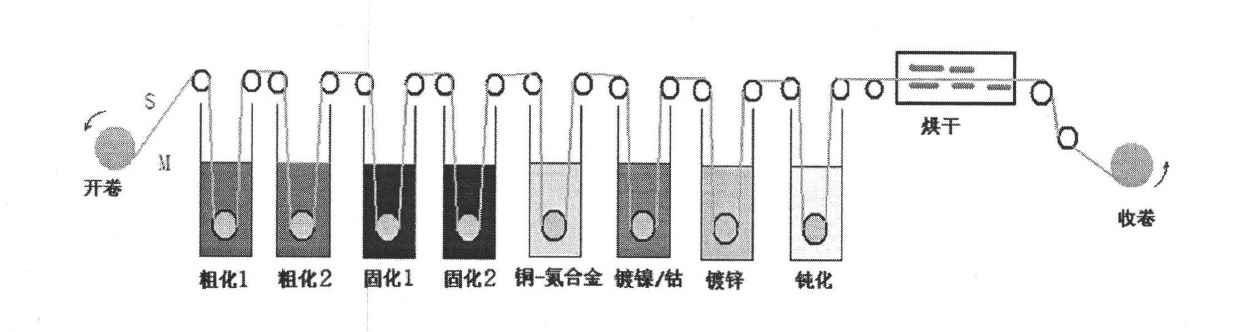

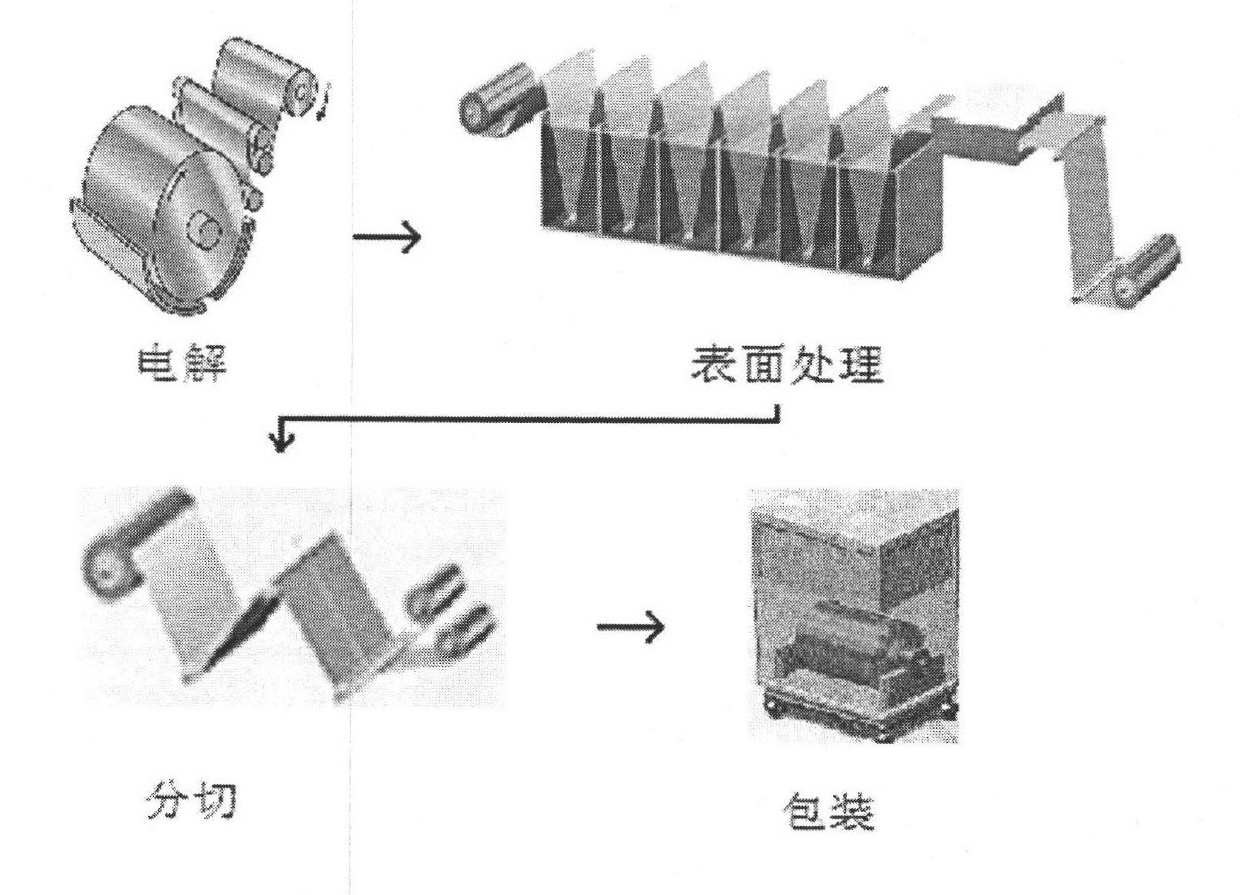

Black surface treatment process of electrolytic copper foil

ActiveCN101906630AImprove antioxidant capacityAccelerated corrosionSuperimposed coating processZinc alloysCopper foil

The invention relates to a black surface treatment process of an electrolytic copper foil, belonging to the technical field of production processes of high and precision electrolytic copper foils. The black surface treatment process of an electrolytic copper foil is characterized in that a VLP (Very Low Profile) electrolytic copper foil of 8-12 mu m is used as an electrode, and then copper or copper alloy is roughened, solidified, weakly roughened and electrically deposited at a running speed of 25.0+ / -0.1m / min; a layer of nano-scale nickel or cobalt alloy and a layer of nano-scale zinc alloy are sequentially and electrically deposited; and then alkaline chromate passivation is carried out and a layer of coupling agent is coated. In the invention, the black copper foil for an FPC (Flexible Printing Circuit) is obtained by carrying out a series of special surface treatments on the ultrathin and VLP electrolytic copper foil of 8-12 mu m, wherein the surface roughness Ra of the obtained copper foil is smaller than or equal to 0.30 mu m, Rz is smaller than or equal to 2.5 mu m; the thickness of the copper foil subjected to the surface treatments is increased by 1.40-1.80 mu m; the copper foil does not contain elements having serious damages to the human body, such as lead, mercury, cadmium, stibium, and the like and has excellent oxidation resistance as well as corrosion and etching resistance; the peel strength of the copper foil on a PI (Polyimide) film reaches higher than 1.0N / mm, and the folding strength on the PI film reach more than 100 thousand numbers of times; the copper foil has good appearance characteristics after the copper foil is microetched, and after the copper foil is made into an FCCL (Flexible Copper Clad Laminate), the copper foil has similar appearance characteristics to a rolled copper foil; and the properties of the copper foil product are equivalent to that of an electrolytic copper foil with the same specification for the FCCL.

Owner:SHANDONG JINBAO ELECTRONICS

Metal and Dielectric Compatible Sacrificial Anti-Reflective Coating Cleaning and Removal Composition

ActiveUS20080242574A1Detergent mixture composition preparationOrganic non-surface-active detergent compositionsAnti-reflective coatingEtching

A liquid removal composition and process for removing sacrificial anti-reflective coating (SARC) material from a substrate having same thereon. The liquid removal composition includes at least one fluoride-containing compound, at least one organic solvent, optionally water, and optionally at least one chelating agent. The composition achieves at least partial removal of SARC material in the manufacture of integrated circuitry with minimal etching of metal species on the substrate, such as aluminum, copper and cobalt alloys, and without damage to low-k dielectric materials employed in the semiconductor architecture.

Owner:ENTEGRIS INC

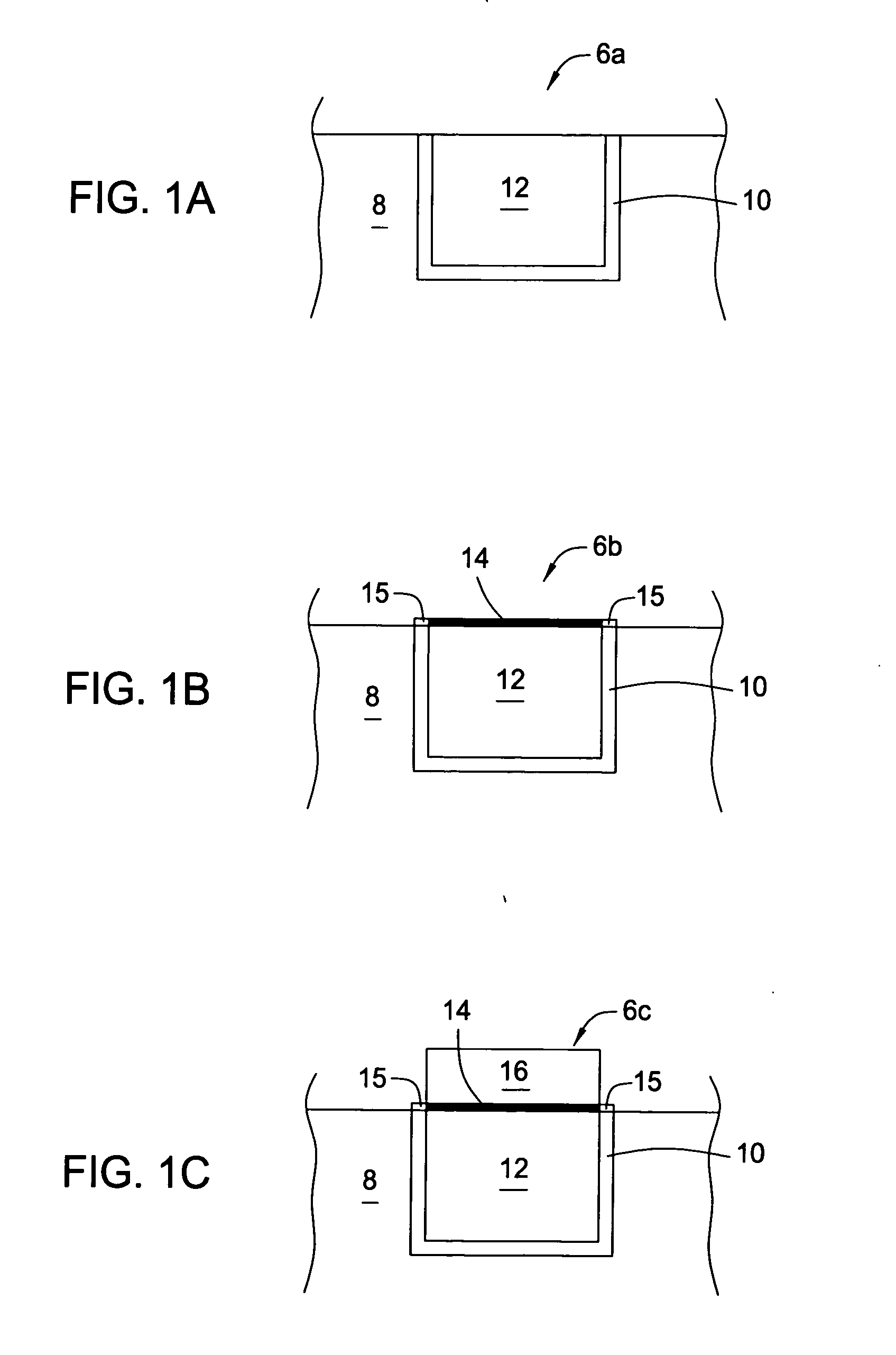

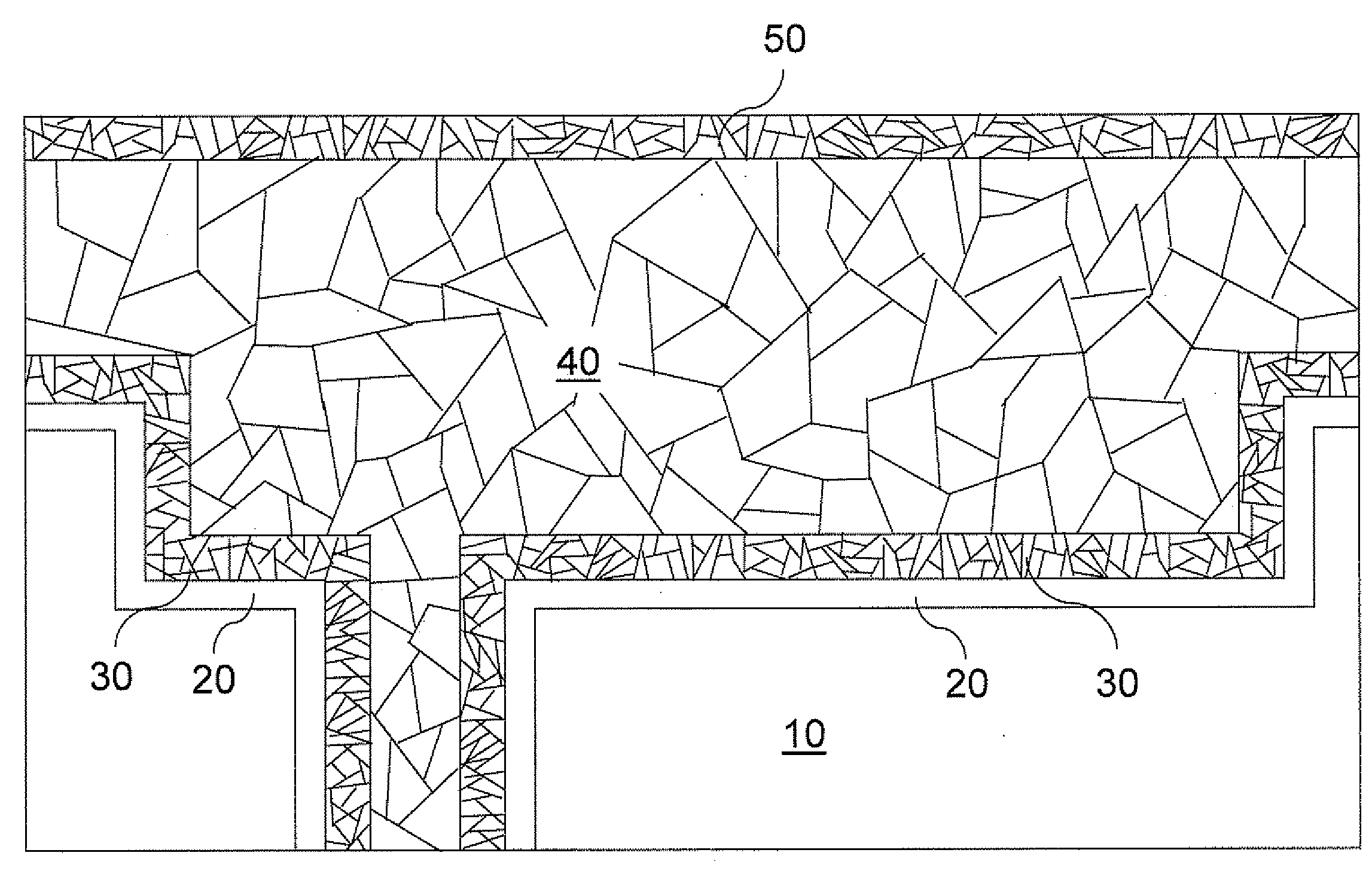

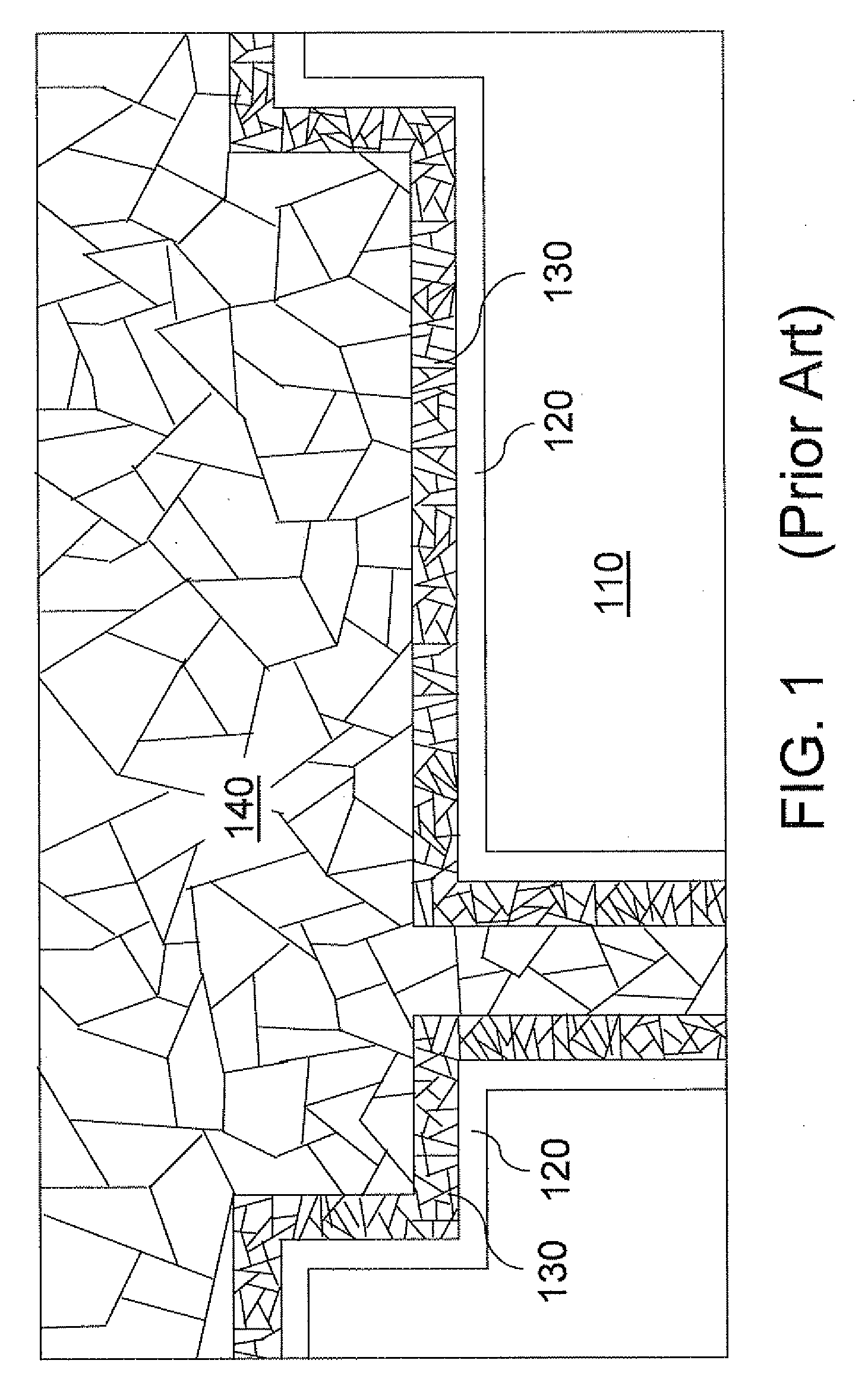

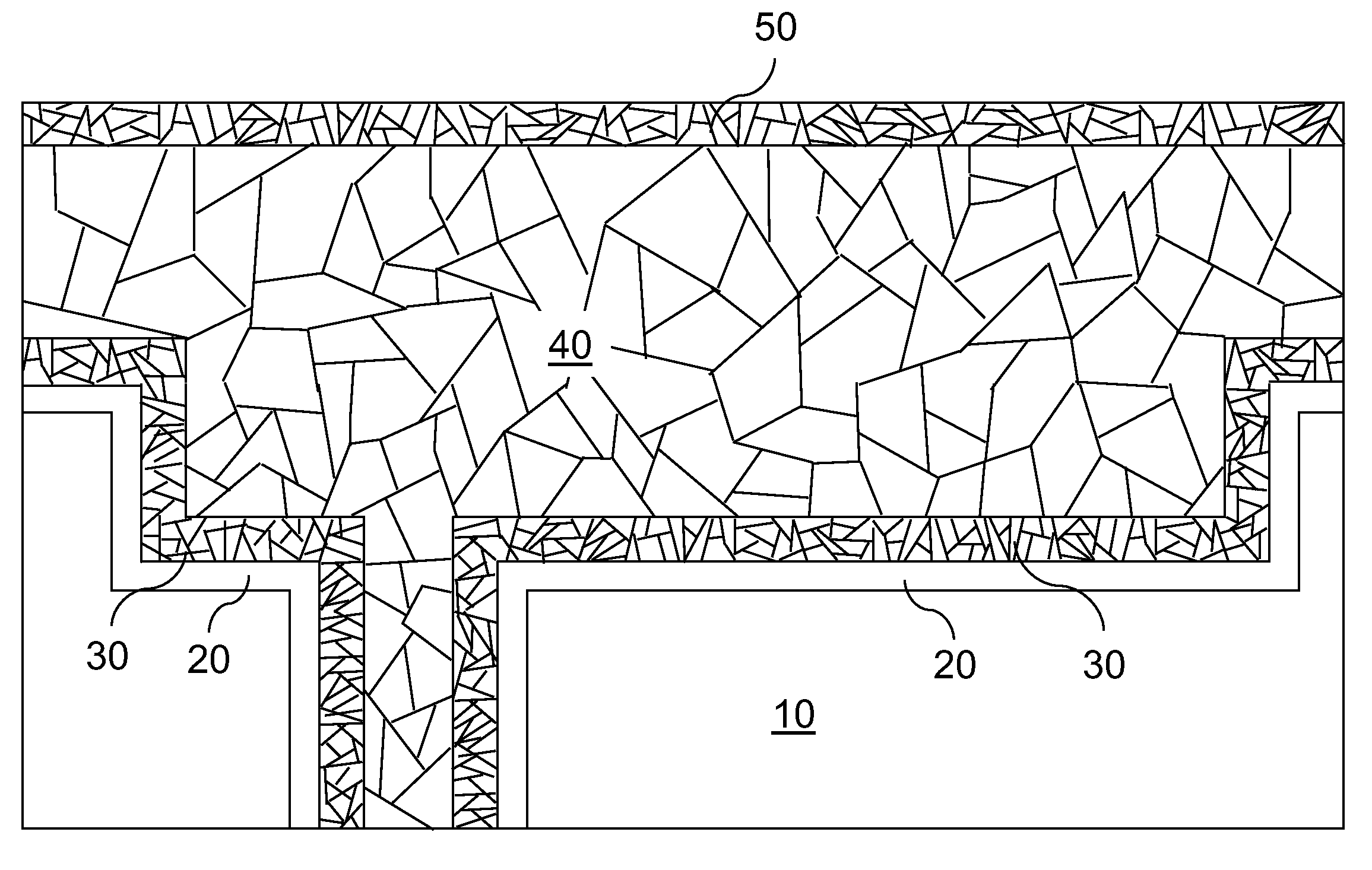

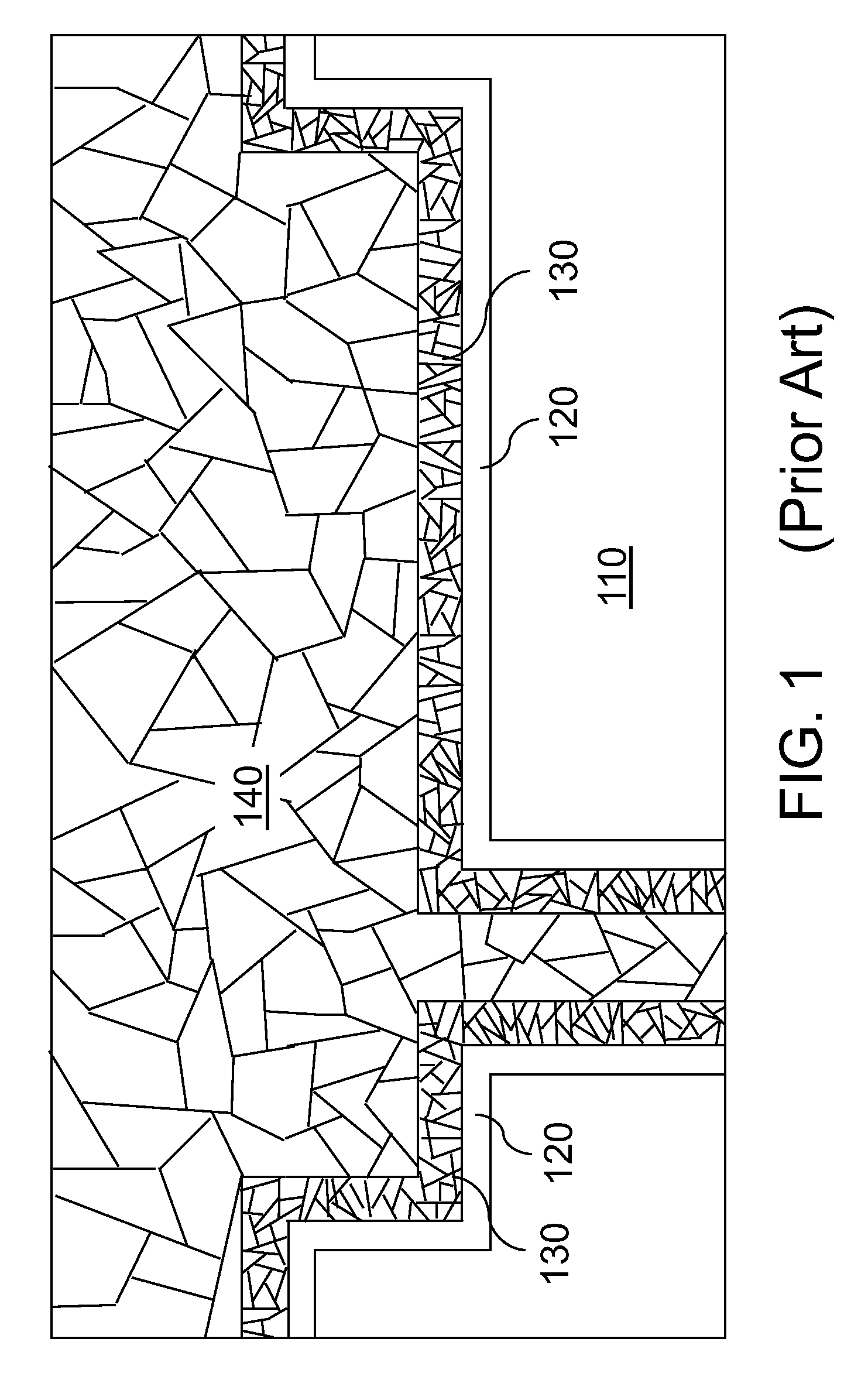

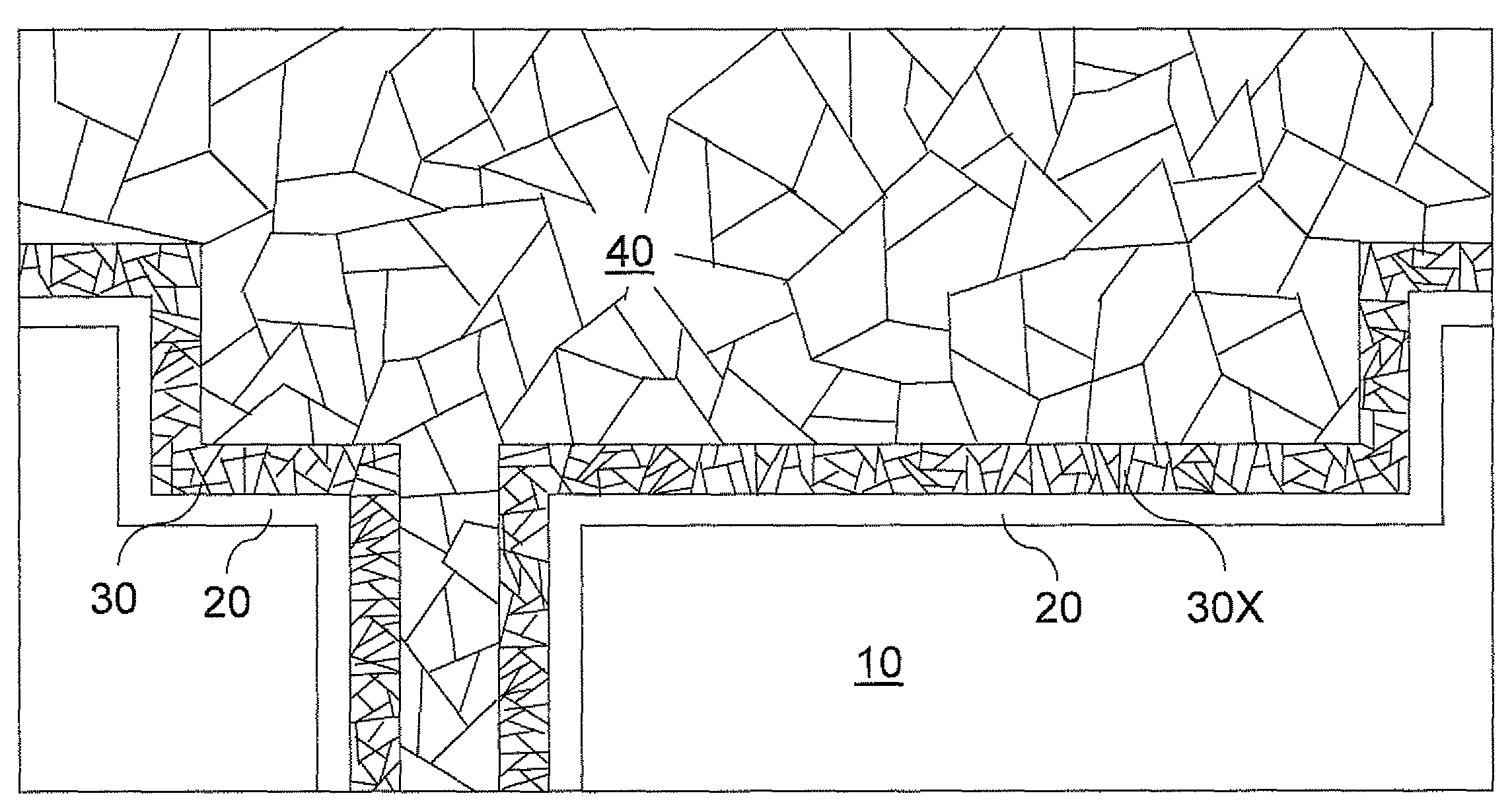

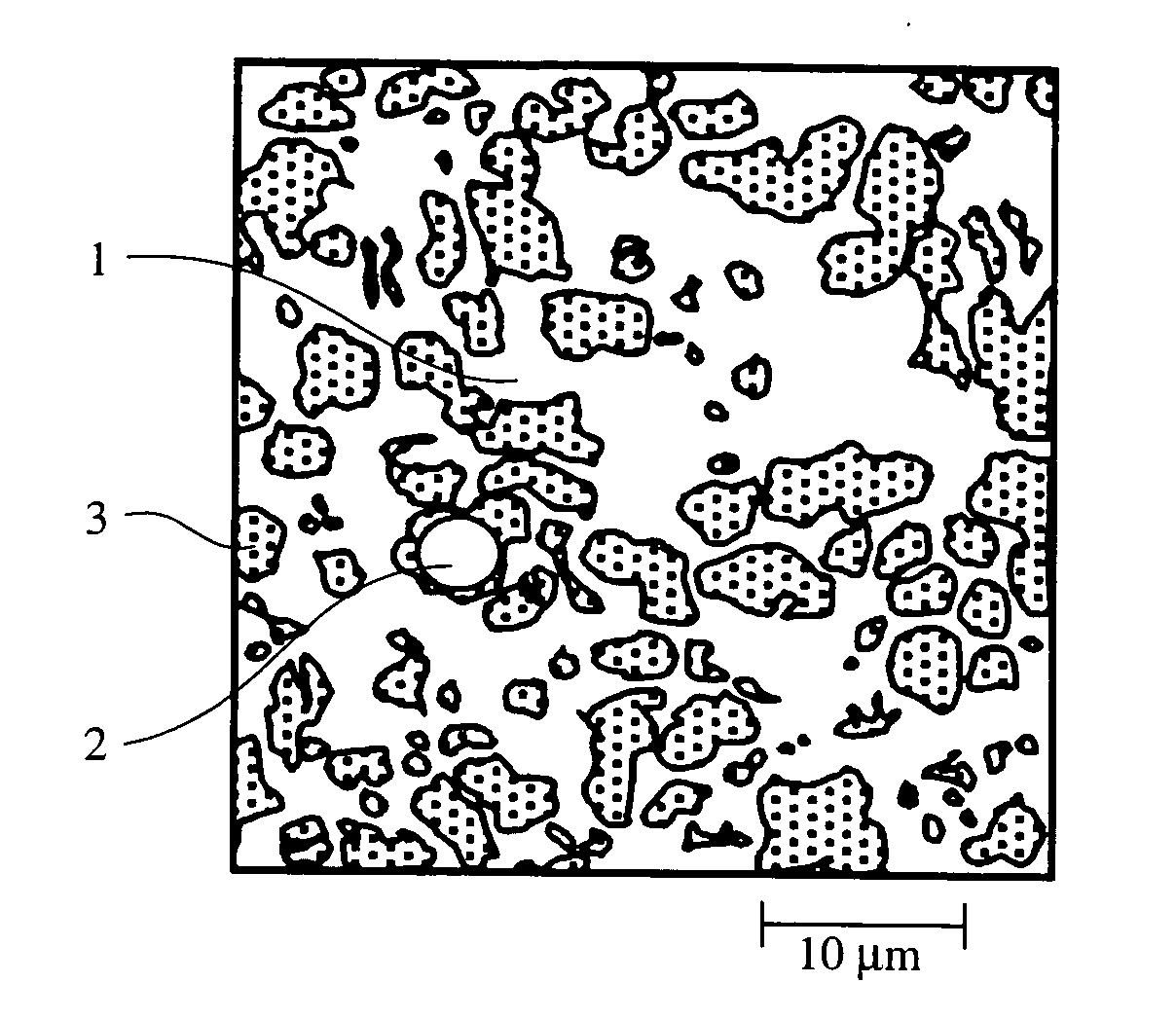

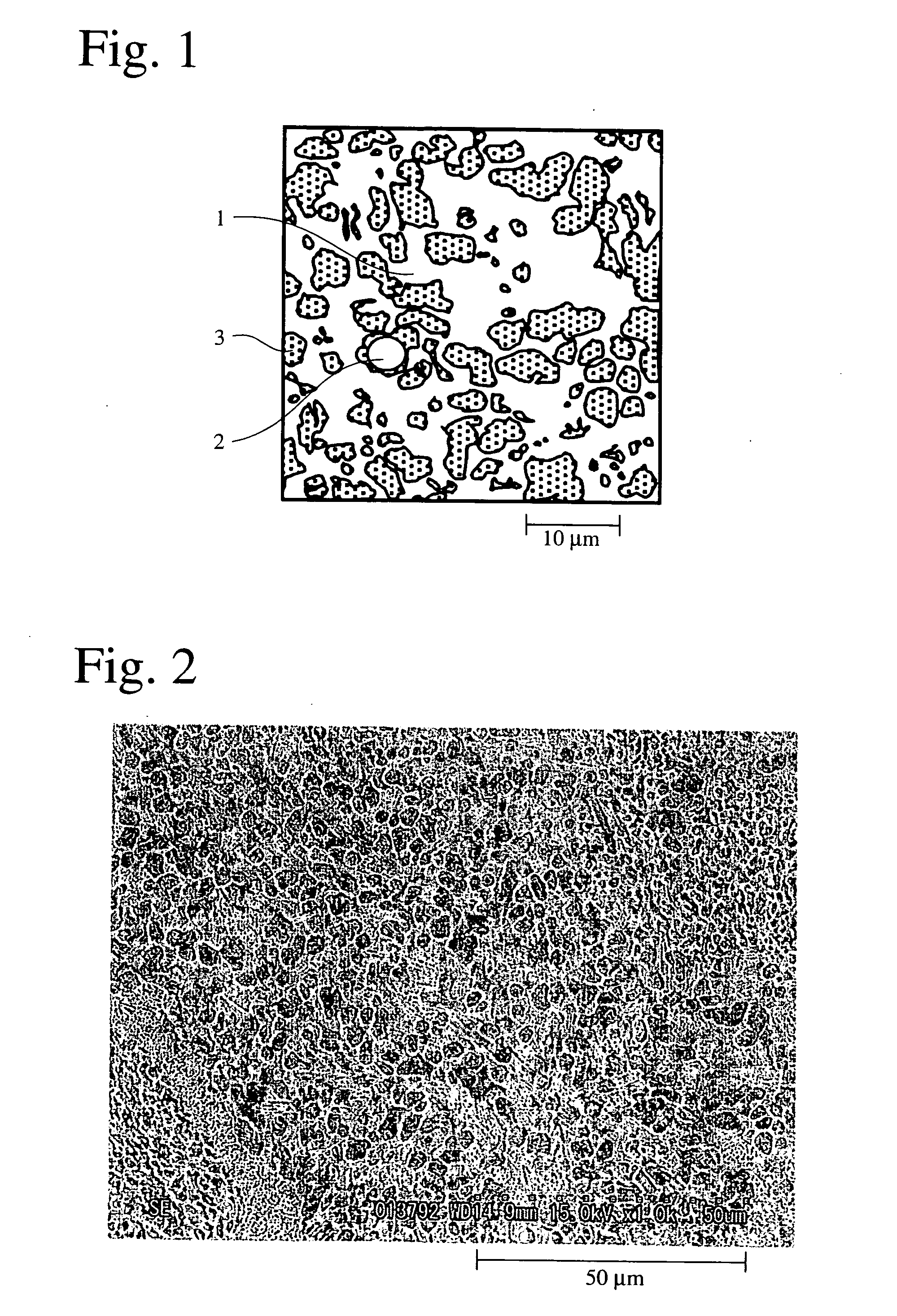

Microstructure modification in copper interconnect structure

ActiveUS20090206484A1Preventing diffusion of copperFaster rateSemiconductor/solid-state device detailsSolid-state devicesCopper platingMetal interconnect

Cobalt is added to a copper seed layer, a copper plating layer, or a copper capping layer in order to modify the microstructure of copper lines and vias. The cobalt can be in the form of a copper-cobalt alloy or as a very thin cobalt layer. The grain boundaries configured in bamboo microstructure in the inventive metal interconnect structure shut down copper grain boundary diffusion. The composition of the metal interconnect structure after grain growth contains from about 1 ppm to about 10% of cobalt in atomic concentration. Grain boundaries extend from a top surface of a copper-cobalt alloy line to a bottom surface of the copper-cobalt alloy line, and are separated from any other grain boundary by a distance greater than a width of the copper-cobalt alloy line.

Owner:TESSERA INC

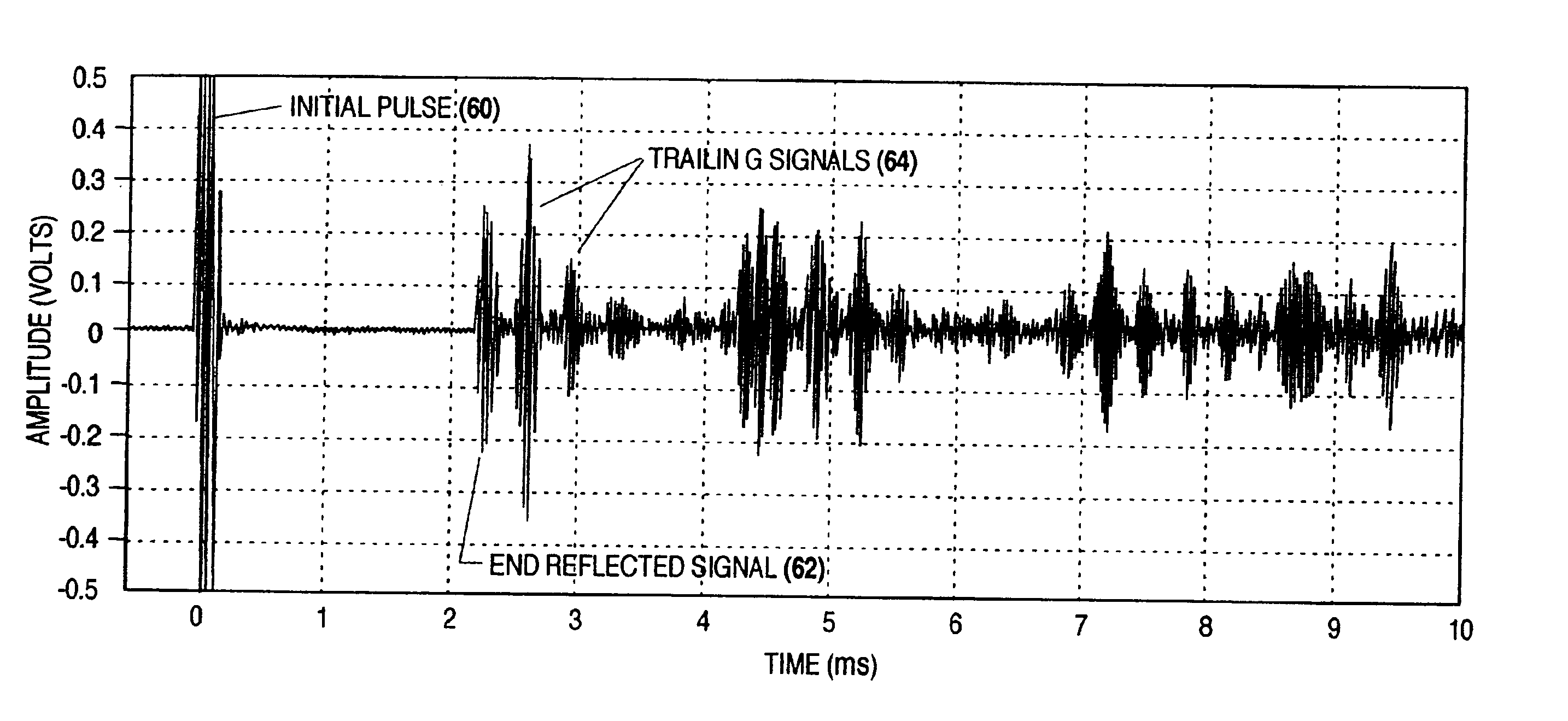

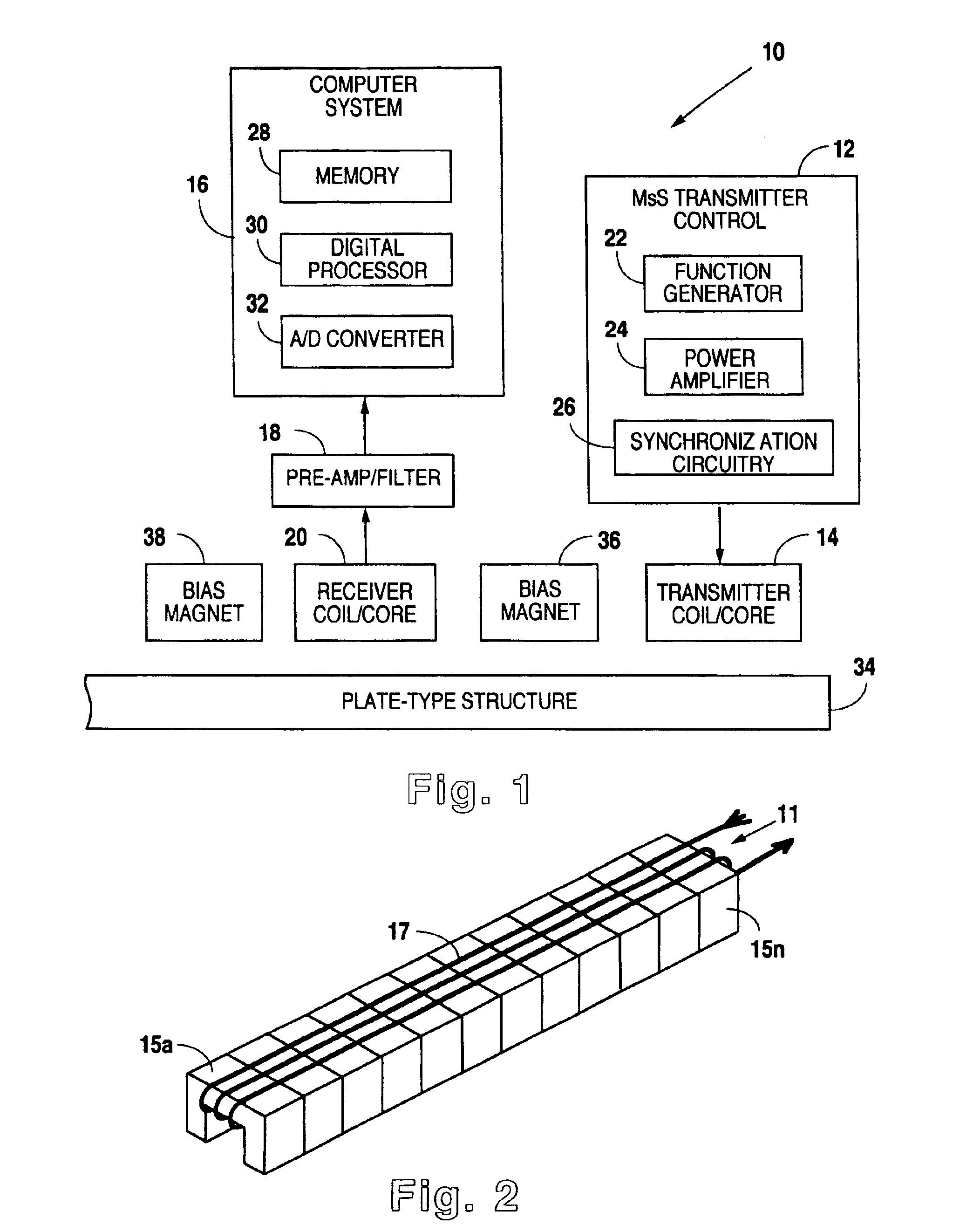

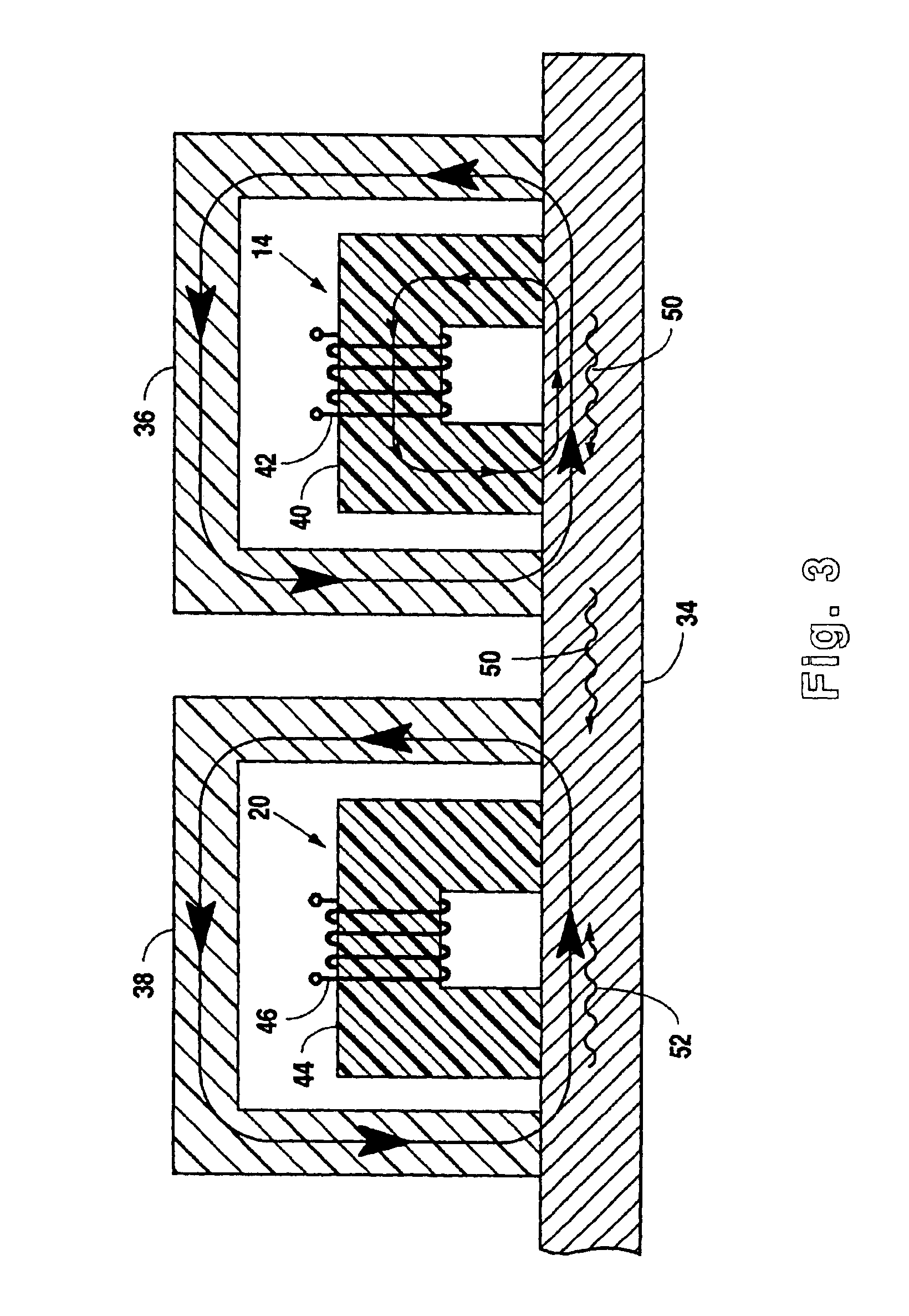

Method and apparatus generating and detecting torsional wave inspection of pipes or tubes

InactiveUS6917196B2High sensitivityLong rangeAnalysing solids using sonic/ultrasonic/infrasonic wavesUsing electrical meansEngineeringMagnetostriction

A method and apparatus for implementing magnetostrictive sensor techniques for the nondestructive evaluation of pipes or tubes. A magnetostrictive sensor generates guided waves in a pipe or tube, which waves travel therethrough in a direction parallel to the longitudinal axis of the pipe or tube. This is achieved by using a magnetized ferromagnetic strip being pressed circumferentially against the pipe or tube. For improved efficiency, the strip may be made from an iron-cobalt alloy. The guided waves are generated in the strip and coupled to the pipe or tube and propagate along the length of said pipe or tube. For detection, the guided waves in the pipe or tube are coupled to the thin ferromagnetic strip and are detected by receiving MsS coils. Reflected guided waves may represent defects in the pipe or tube.

Owner:SOUTHWEST RES INST

Copper foil excellent in laser beam drilling performance and production method therefor

InactiveUS6638642B2Improve drilling effectFine surfaceRadiation applicationsExtrusion containersIndiumCopper foil

Owner:JX NIPPON MINING & METALS CORP

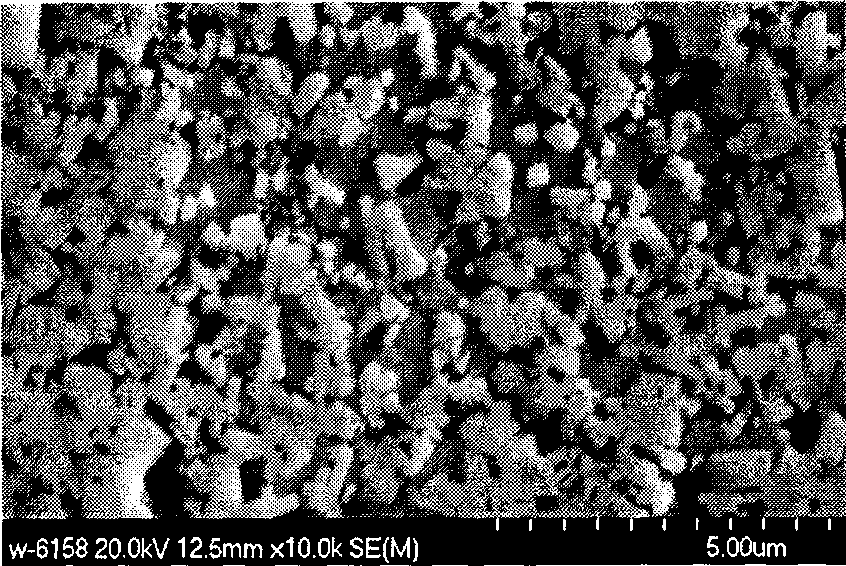

Nitrogen-doped carbon nanotube-loaded nitrogen-doped carbon-coated iron-cobalt alloy bifunctional catalyst and preparation method and application thereof

InactiveCN110783582ALarge specific surface areaMany active sitesMaterial nanotechnologyFuel and secondary cellsCarbon layerPtru catalyst

The invention discloses a nitrogen-doped carbon nanotube-loaded nitrogen-doped carbon-coated iron-cobalt alloy bifunctional catalyst and a preparation method and an application thereof. The catalyst is characterized in that for a structural unit, nitrogen-doped carbon nanotubes (NCNTs) are utilized as a conductive network, and iron-cobalt alloy nanoparticles wrapped by a nitrogen-doped ultrathin carbon layer are loaded on the nitrogen-doped ultrathin carbon layer. The preparation method comprises steps of pretreatment of carbon nanotubes, removing impurities on surfaces of the carbon nanotubesthrough cleaning, and generating a large number of defects and oxygen-containing surface functional groups on the surfaces of the carbon nanotubes through acid treatment; carrying out grafting reaction of an iron-cobalt organic ligand and melamine on the surfaces of the functionalized carbon nanotubes; calcining the iron-cobalt organic ligand and the melamine-grafted functionalized carbon nanotubes under a high-temperature condition to obtain the nitrogen-doped carbon nanotube-loaded nitrogen-doped carbon-coated iron-cobalt alloy bifunctional catalyst.

Owner:ZHEJIANG SCI-TECH UNIV

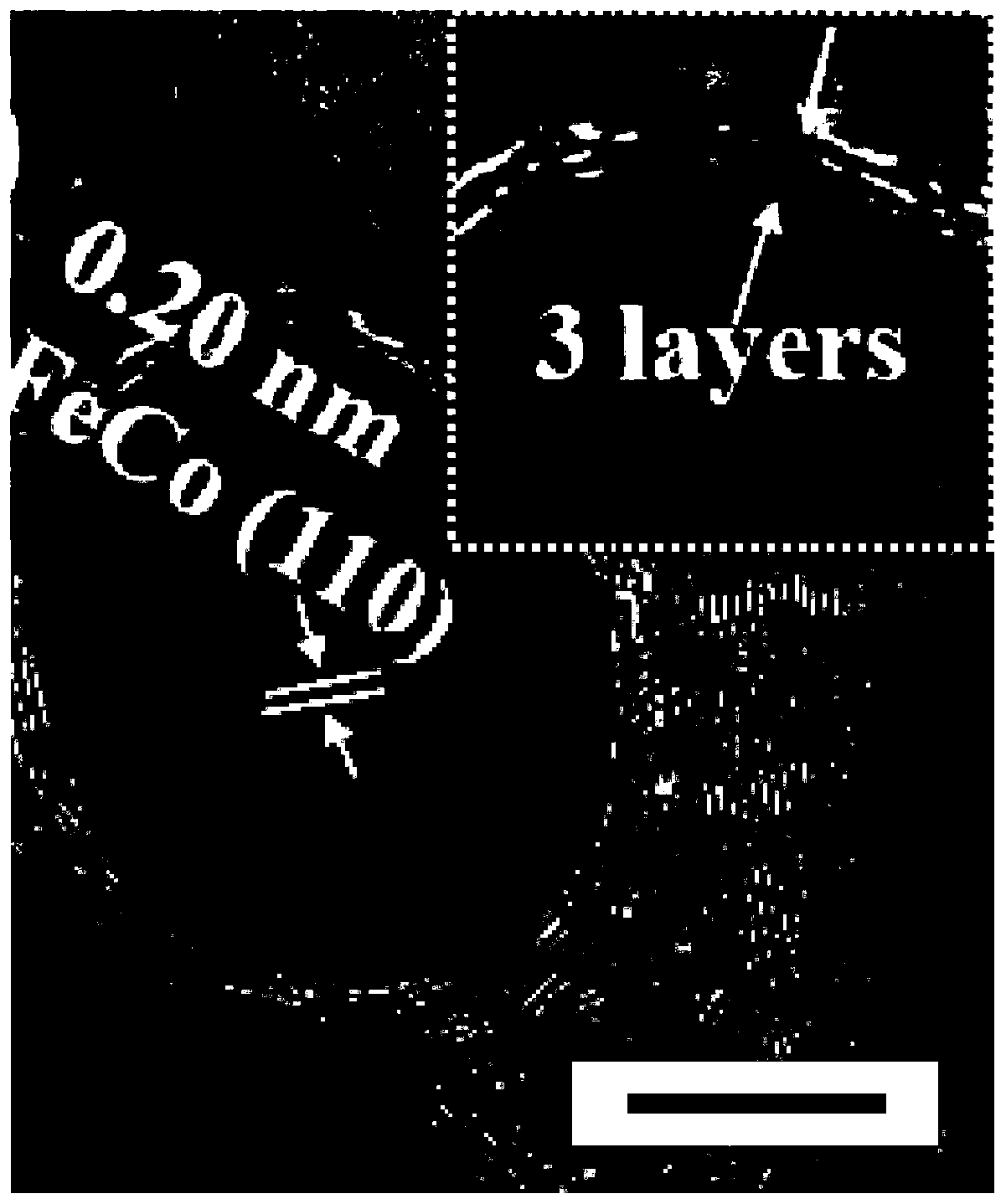

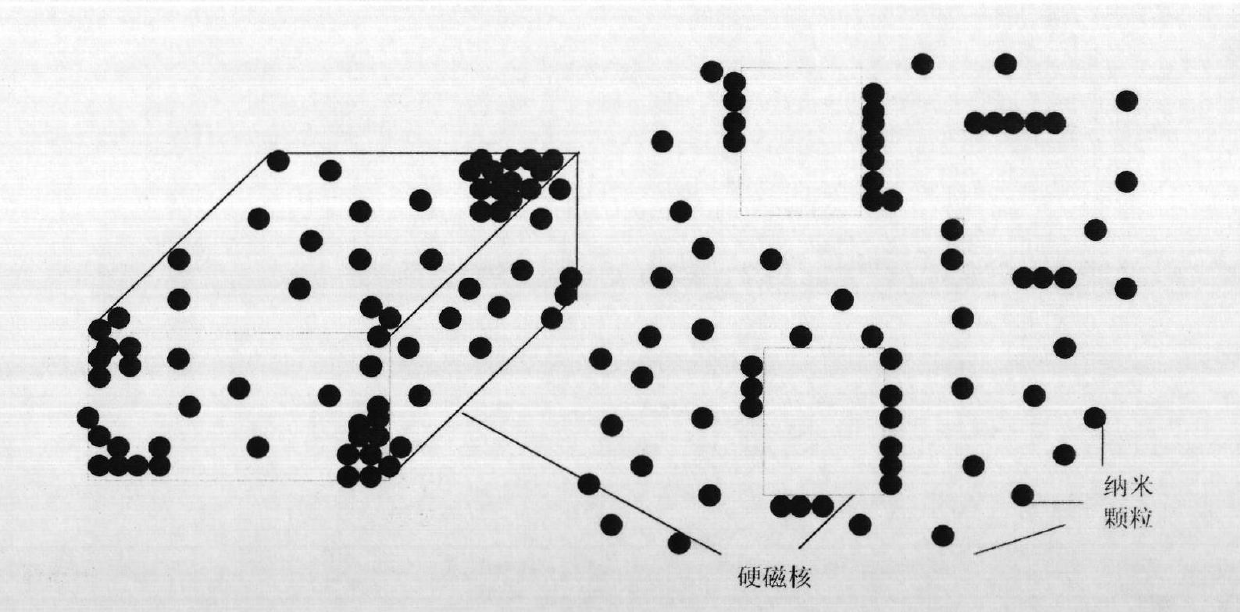

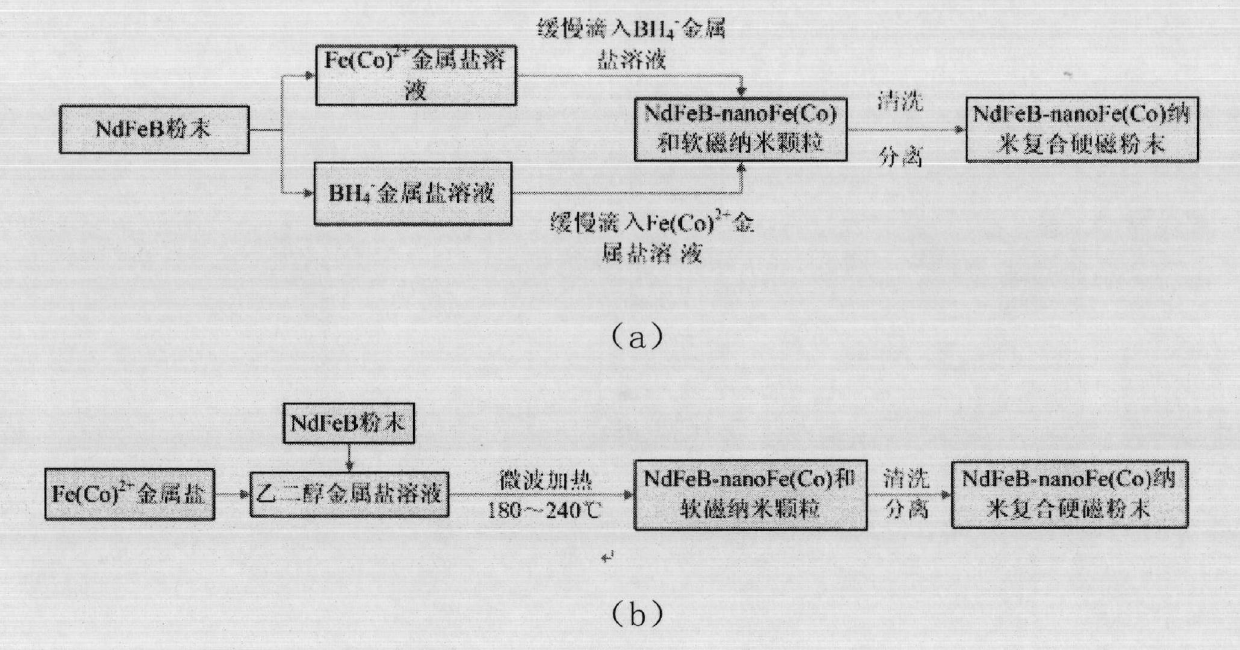

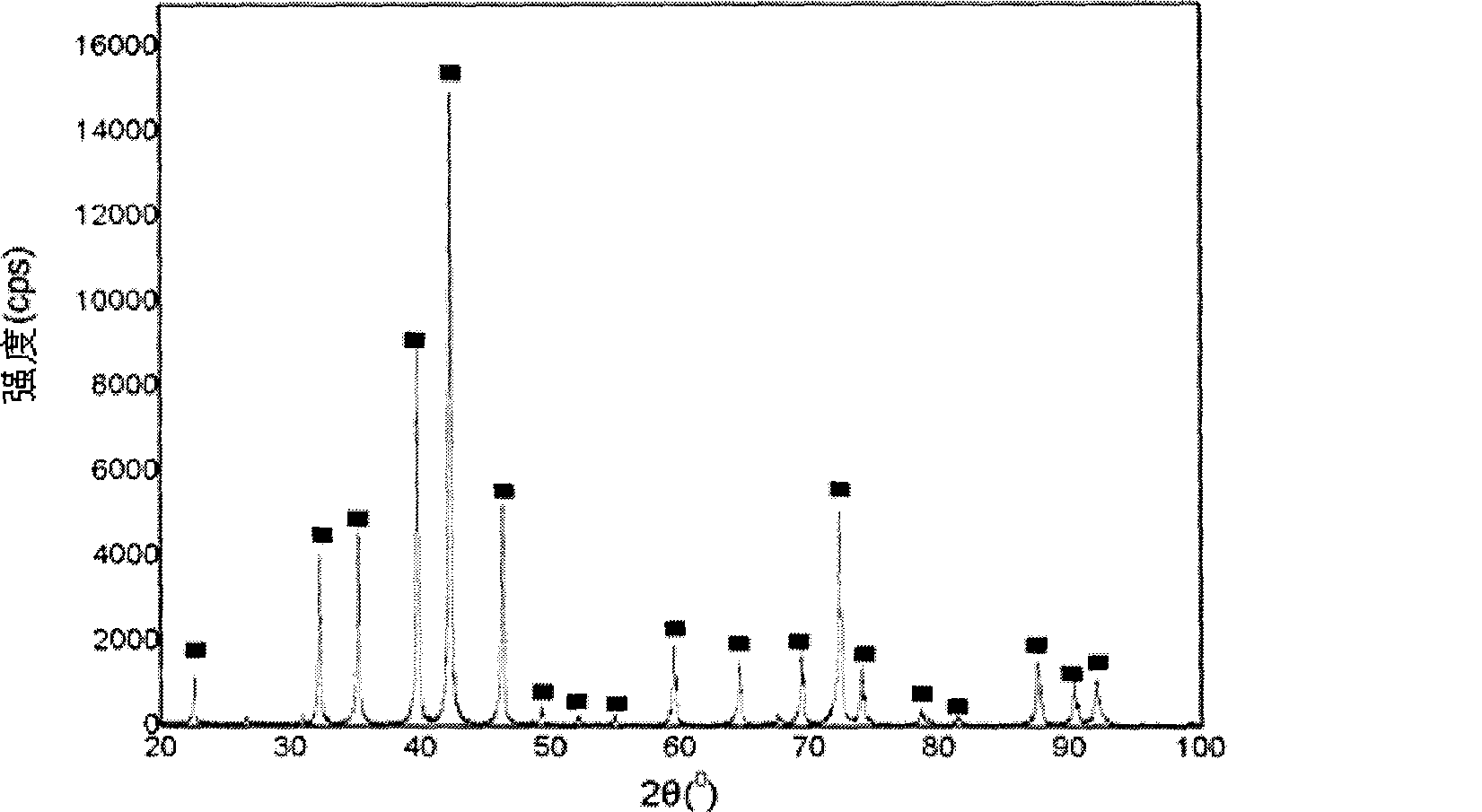

Exchange coupling dual-phase nano composite permanent magnet particles and preparation method thereof

InactiveCN102000816AGood size controlEvenly distributedInorganic material magnetismNanoparticleMicrowave assisted

The invention discloses exchange coupling dual-phase nano composite NdFeB permanent magnet particles and a preparation method thereof. The nano composite rare-earth permanent magnet particles are formed by uniformly distributing soft magnetic nano particles on the surface of hard magnetic particles, wherein the soft magnetic nano particles are iron, cobalt or iron cobalt alloy nano particles and account for 3-20 percent by weight of the nano composite rare-earth permanent magnet particles, and the hard magnetic particles are NdFeB magnetic powder. In the invention, the nano composite permanent magnet powder is prepared by wrapping the iron, cobalt or iron cobalt alloy nano particles on the surfaces of the single-phase hard magnet particles NdFeB by using a coprecipitation method or microwave-assisted polyalcohol reduction method. The preparation method of the invention has simple process and relatively lower cost and is suitable for mass production, the permanent magnet powder obtained by the method disclosed in the invention can be prepared into high-performance nano composite permanent magnets after being sintered, bonded or densified subsequently; in addition, the invention canremarkably reduce the rare-earth content in a permanent magnet material, decrease the production cost and improve the magnetic performance of the prepared product.

Owner:SOUTH CHINA UNIV OF TECH

Microstructure modification in copper interconnect structure

InactiveUS20100323517A1Inhibited DiffusionFaster rateSemiconductor/solid-state device detailsSolid-state devicesCopper platingMetal interconnect

Cobalt is added to a copper seed layer, a copper plating layer, or a copper capping layer in order to modify the microstructure of copper lines and vias. The cobalt can be in the form of a copper-cobalt alloy or as a very thin cobalt layer. The grain boundaries configured in bamboo microstructure in the inventive metal interconnect structure shut down copper grain boundary diffusion. The composition of the metal interconnect structure after grain growth contains from about 1 ppm to about 10% of cobalt in atomic concentration. Grain boundaries extend from a top surface of a copper-cobalt alloy line to a bottom surface of the copper-cobalt alloy line, and are separated from any other grain boundary by a distance greater than a width of the copper-cobalt alloy line.

Owner:TESSERA INC

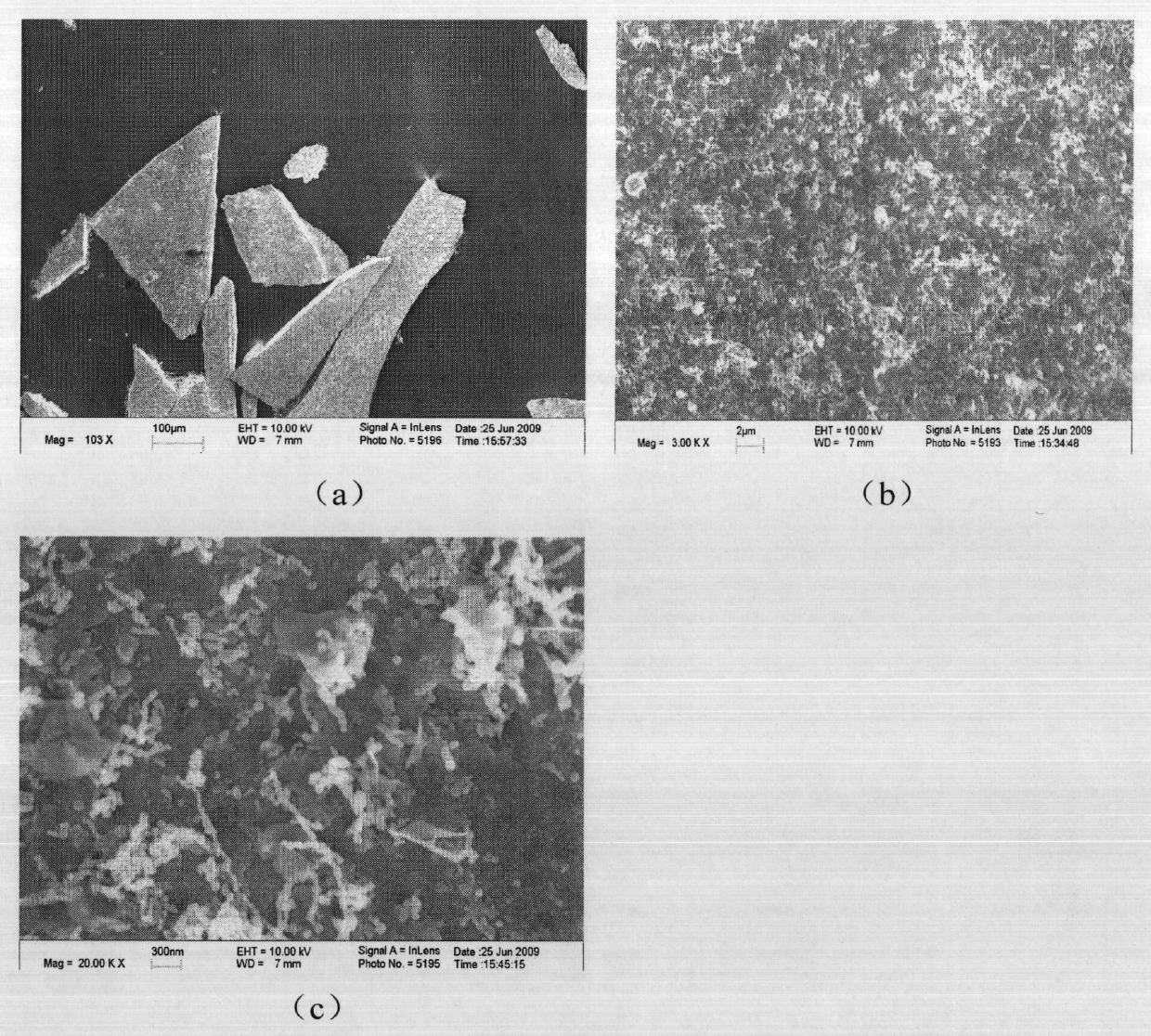

Nano modified WC/Co cemented carbide material and manufacturing method thereof

The invention discloses a nano-modified WC / Co hard alloy material and a method for manufacturing the same, which relate to a modified WC / Co hard alloy material and a method for manufacturing the same and avoids the problems of complicated preparation technology, high requirements for process parameters, updating of equipment, high cost and grain growing easily in the prior method for improving the comprehensive property. The nano-modified WC / cobalt hard alloy is made by nano-modified material and WC / cobalt alloy. The preparation method comprises the following: a step of mixing powder; a step of drying and screening; a step of mixing wax; a step of drying and screening; a step of press molding; and a step of vacuum sintering. Compared with the nano before modification, the hardness of the nano-modified WC / Co hard alloy material is increased to more than 1 HRA, the bending strength is increased by about 20 percent, the impact ductility is increased by about 40 to 50 percent, the elongation is increased by 20 to 40 percent, and the impact wear property is increased to more than 100 percent. The preparation method has a simple process and low requirements on process parameters, which compared with the powder metallurgy has the advantage of high ratio of property to price.

Owner:无锡海韵新材料科技有限公司

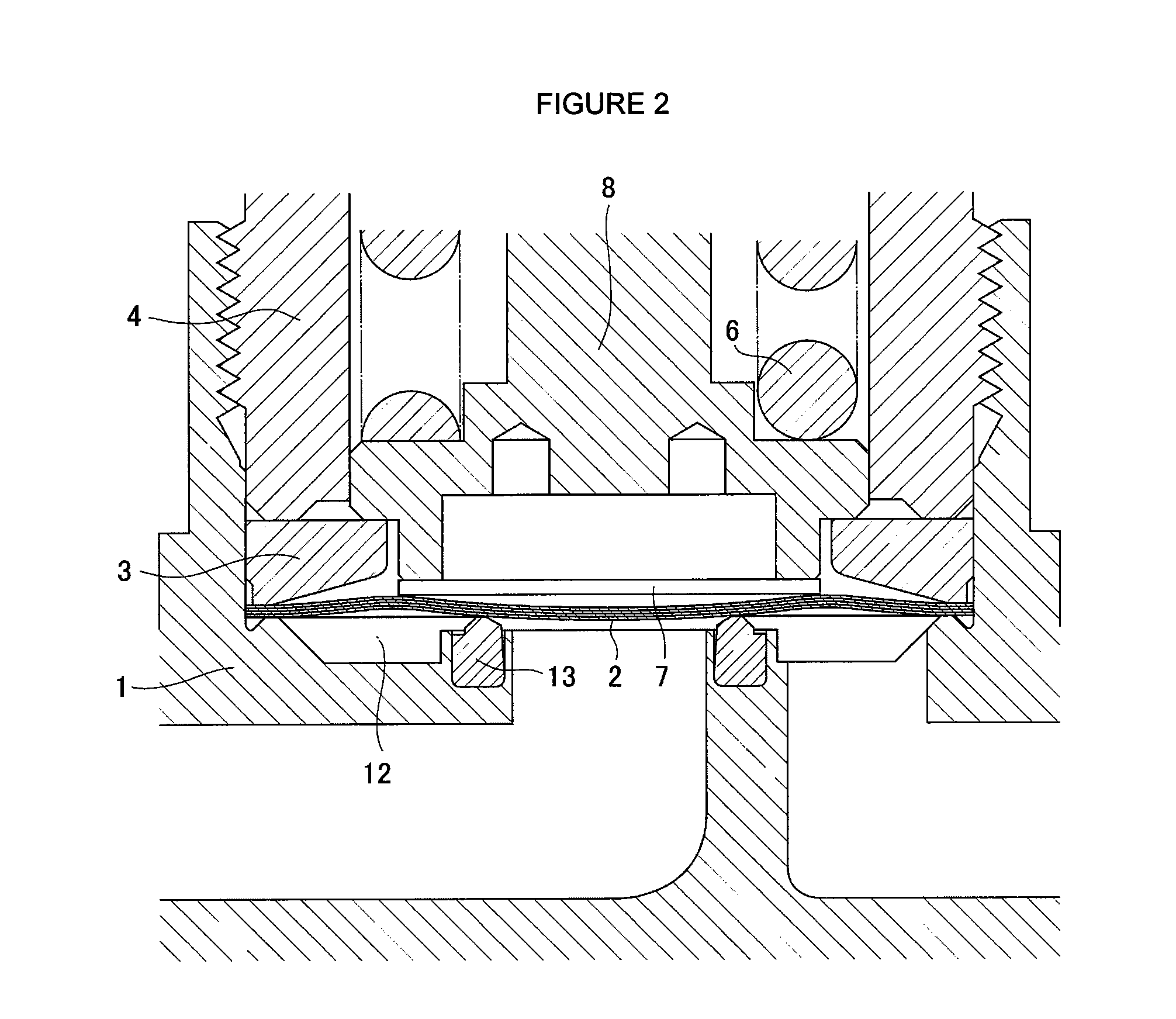

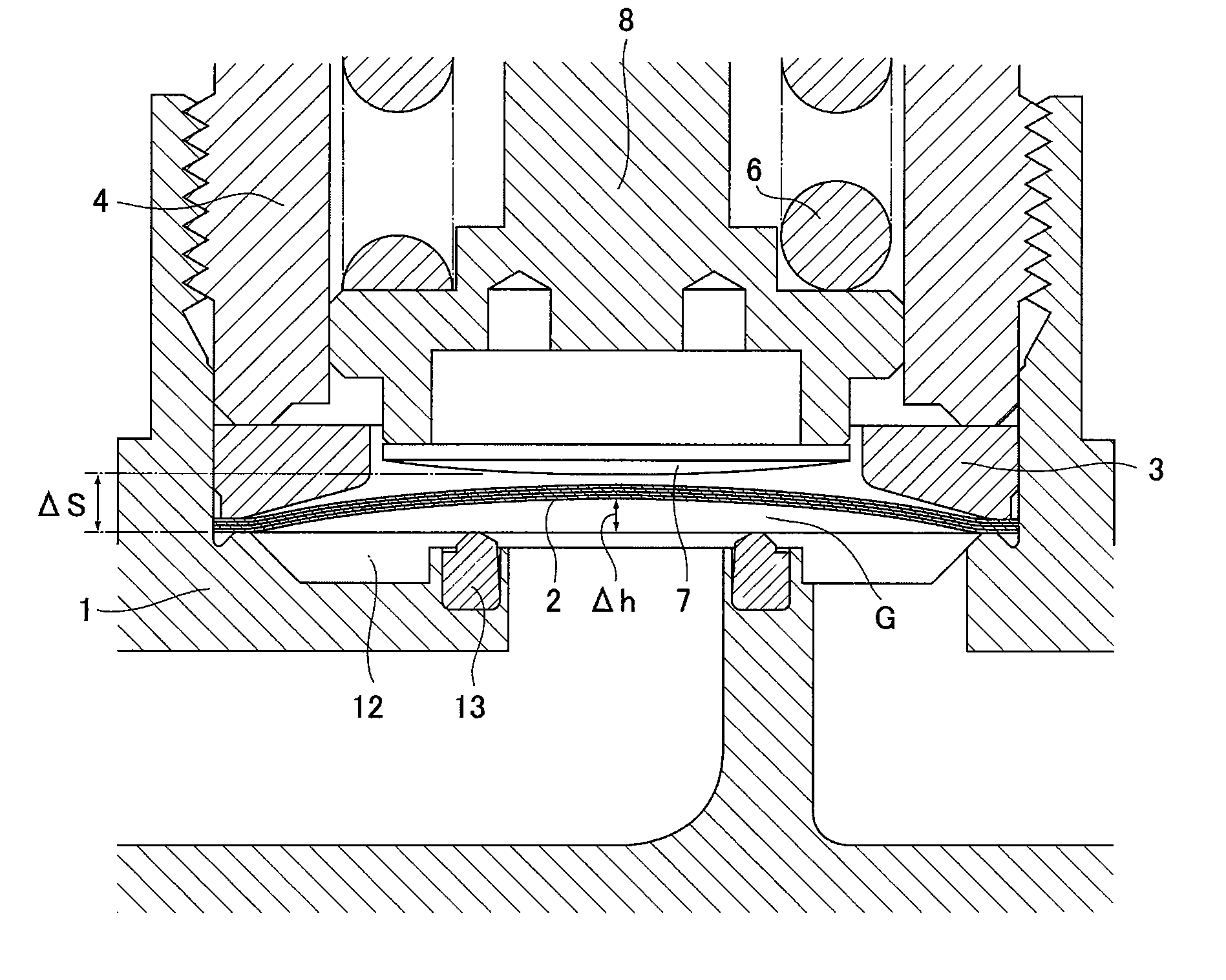

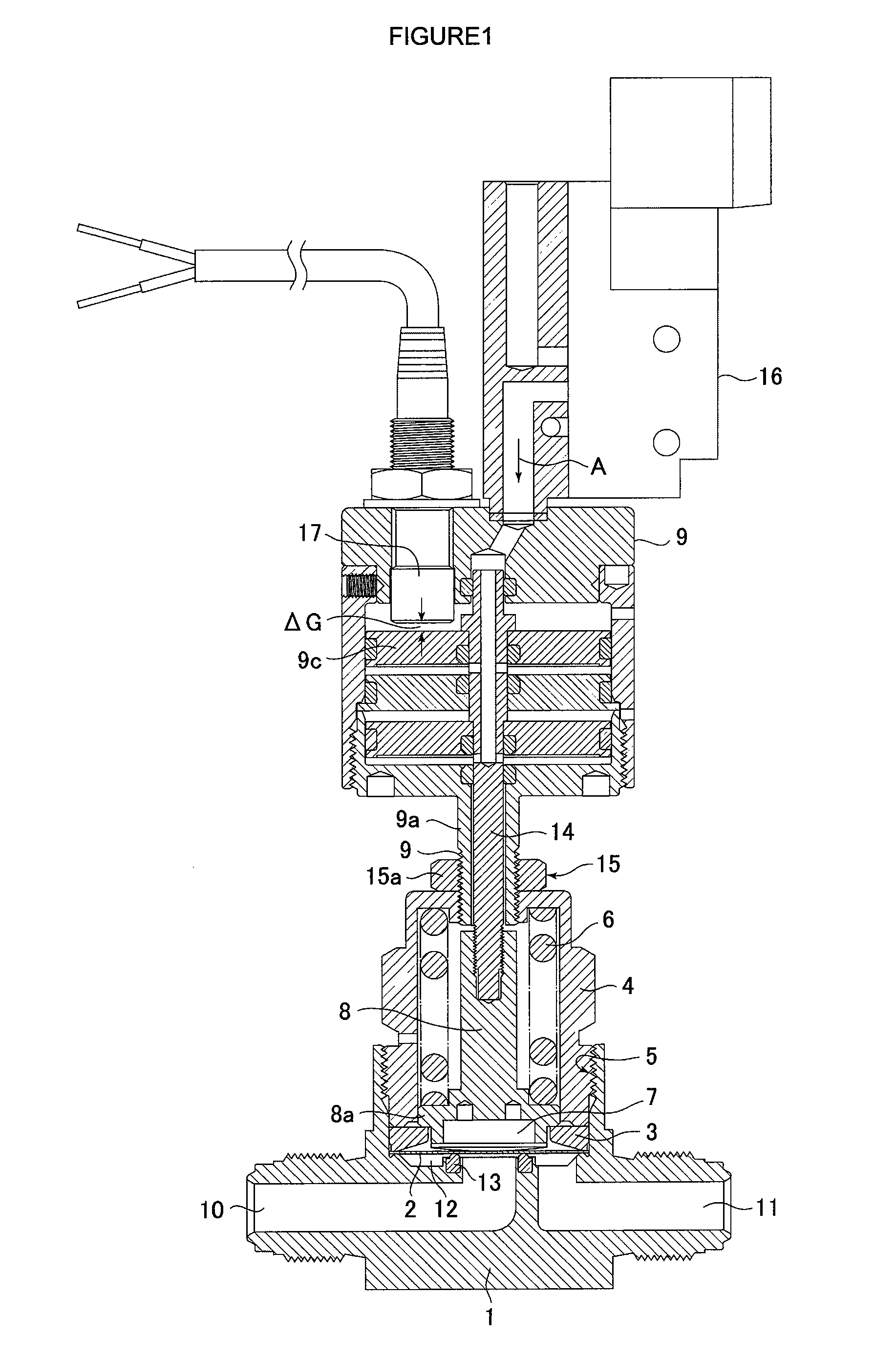

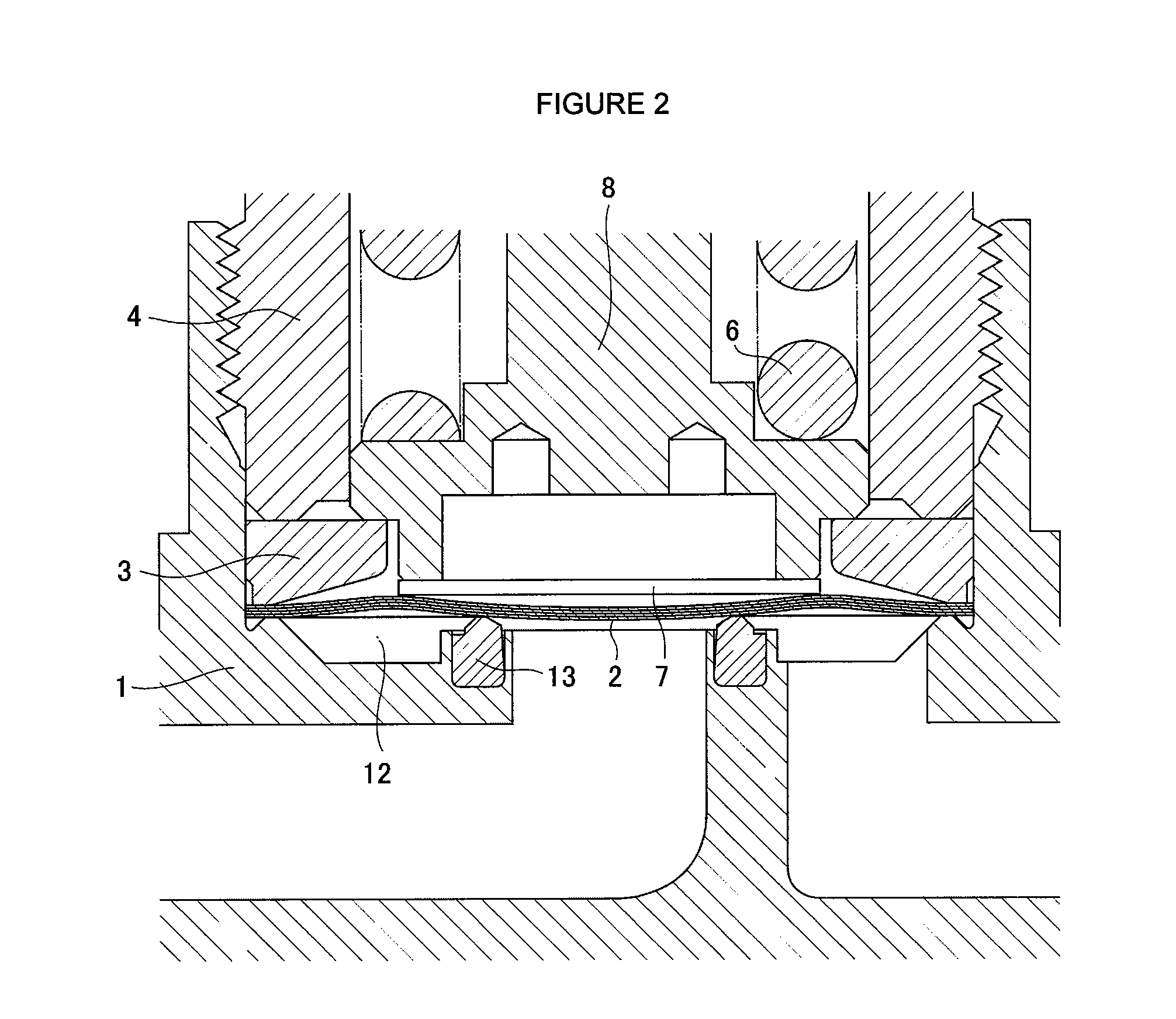

Direct touch type metal diaphragm valve

ActiveUS20100090151A1Reduce replacement timeAchieve stabilityDiaphragm valvesOperating means/releasing devices for valvesDirect touchEngineering

A direct touch type metal diaphragm valve, wherein durability of the valve, that is to say, the ensured number of continuous open / close operations of the valve, is substantially increased under conditions that an appropriate flow rate coefficient Cv is maintained, and changes of the afore-mentioned Cv value over time are mitigated by means of restricting the deformation of the valve seat over time. The afore-mentioned metal diaphragm is formed in a round, reverse-dish shape by laminating a plural number of thin stainless steel plates and a thin Nickel.Cobalt alloy plate, and its center part is bulged upward, and the maximum valve stroke of the valve is regulated to be 55% to 70% of the distance of the maximum bulge height Δh of the afore-mentioned metal diaphragm.

Owner:FUJIKIN INC

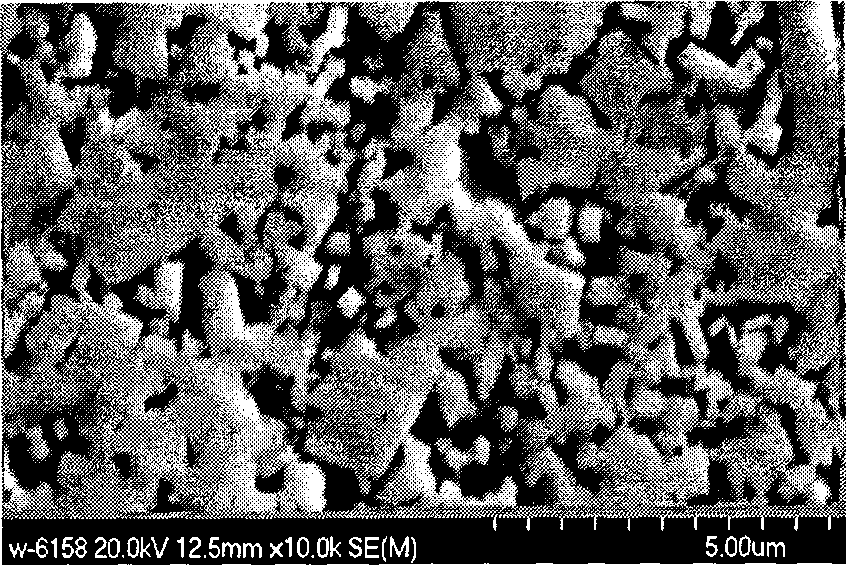

Preparation method of nitrogen-doped carbon nanotube wrapped metal iron-cobalt alloy composite material

InactiveCN108160077ARaw materials are easy to getLow costMetal/metal-oxides/metal-hydroxide catalystsElectrodesFiltrationAcid washing

Belonging to the technical field of material preparation, the invention relates to a preparation method of a nitrogen-doped carbon nanotube wrapped metal iron-cobalt alloy composite material (FeCo-NCNTs). The technical scheme includes: firstly, dissolving a metal salt and a carbon-nitrogen source in water, ethanol or ethylene glycol, mixing the substances evenly, and then performing drying and grinding to obtain a precursor; then putting the precursor in a tubular furnace, in a nitrogen atmosphere, conducting programmed heating to a roasting temperature, and conducting high temperature roasting and grinding to obtain a black powder sample; and then subjecting the black sample to pickling treatment until the pH value of the solution is neutral, and conducting pumping filtration and naturaldrying, thus obtaining the nitrogen-doped carbon nanotube wrapped metal iron-cobalt alloy composite material (FeCo-NCNTs). The obtained composite material can be used as a good electrocatalytic hydrogen evolution catalyst. The composite material prepared by the method provided by the invention has the characteristics of easily available raw materials and low cost, and has important significance inelectrochemical application.

Owner:JIANGSU UNIV

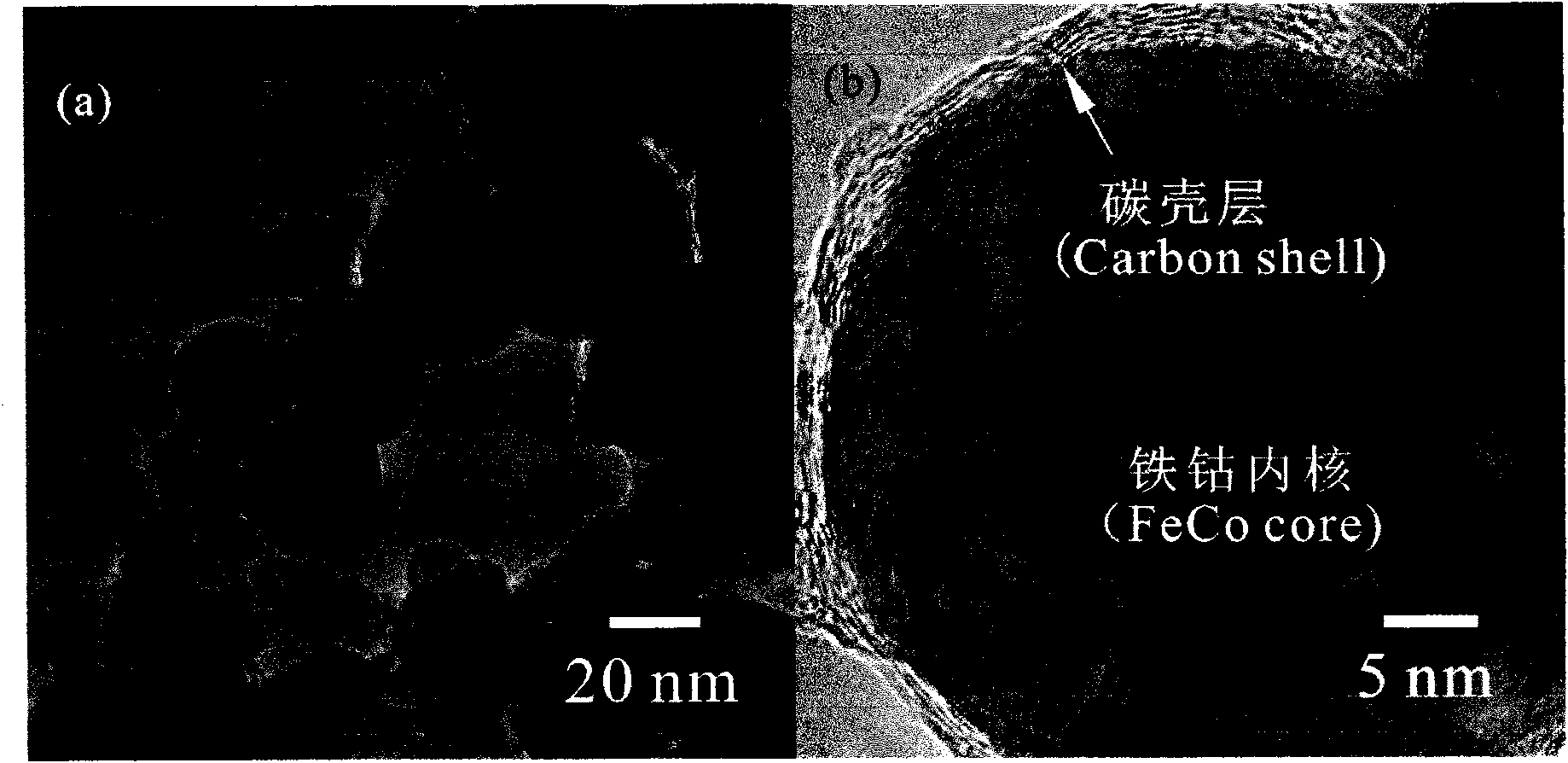

Method for preparing carbon-wrapped iron-cobalt nano wave-absorbing material

InactiveCN101567224AGood microwave absorptionImprove oxidation resistanceScreening apparatusPlasma techniqueOxidation resistantNanometre

The invention provides a method for preparing a carbon-wrapped iron-cobalt nano composite material with broad band and strong absorption. The composite material is prepared by adopting the technology that plasmas is generated by arc discharge of a negative electrode and a positive electrode under working gas, wherein the working gas is argon gas, simultaneously organic substances which can provide carbon elements and do not introduce impurities except C, H and O are added, the negative electrode is made of metals with high melting point and volatile difficulty such as tungsten and the like, and a target material for the positive electrode is iron-cobalt alloy, wherein the iron element accounts for 10 to 90 percent of alloy atomic. The carbon-wrapped iron-cobalt nano wave-absorbing material prepared by the method is a nano capsule formed by wrapping carbon outside the nano-scale iron-cobalt alloy; on one hand, a carbon shell layer is used as an oxidation resistant layer to increase the stability of a nano compound; and on the other hand, the carbon shell layer is used as a dielectric material and compounded with a magnetic iron-cobalt inner core so that the wave-absorbing property of the wave-absorbing material is superior to most classical ferrite and other most nano compound wave-absorbing materials.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

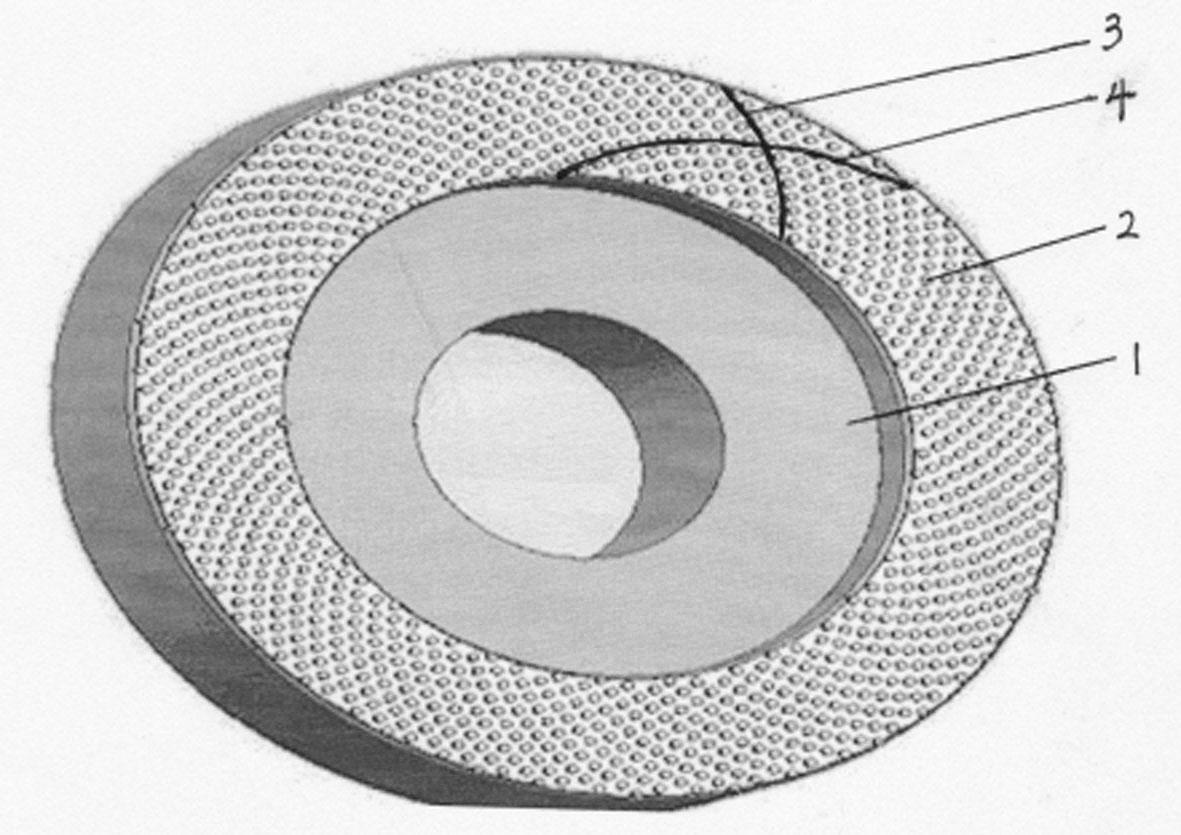

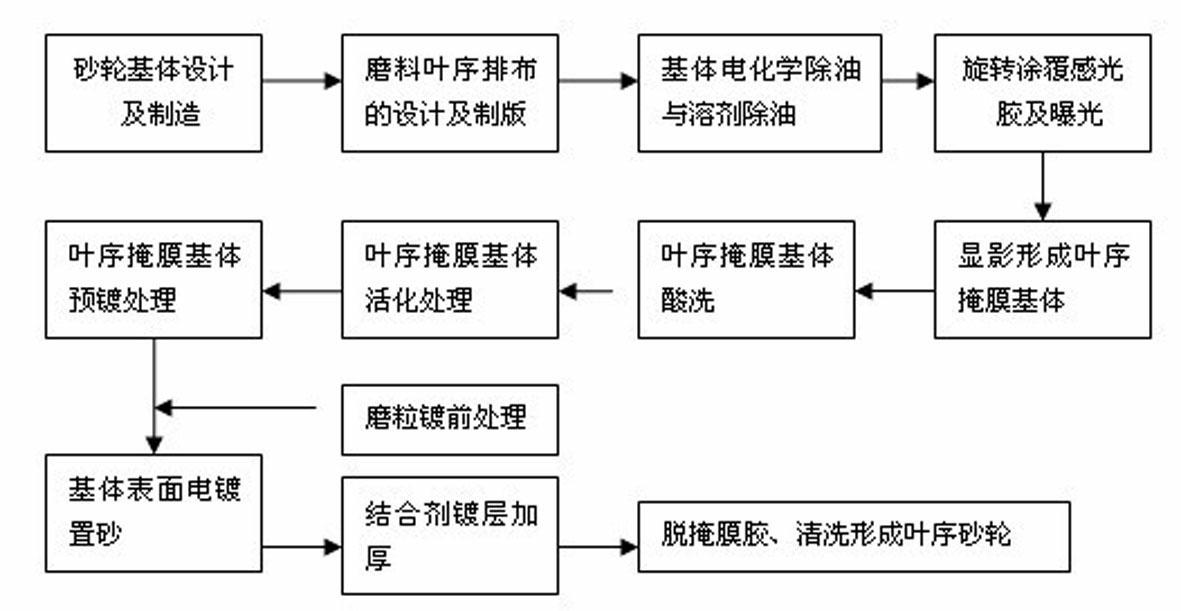

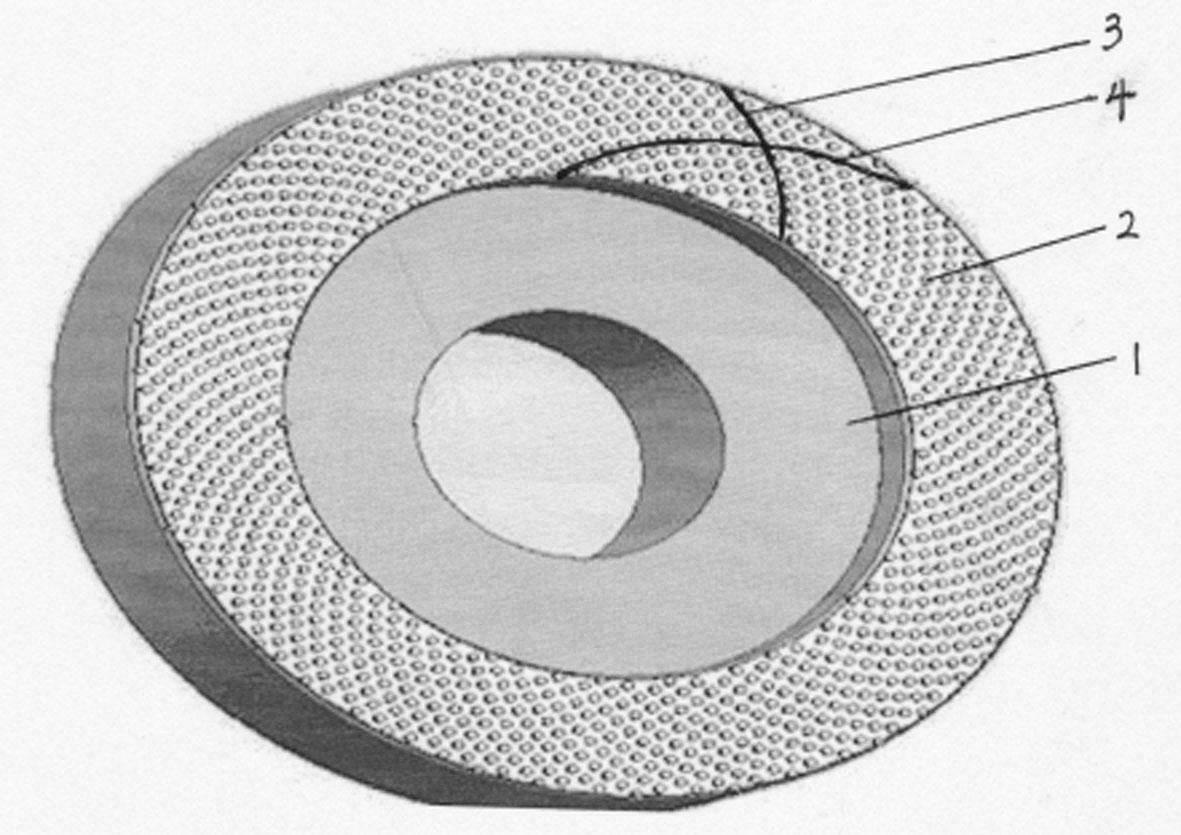

Super-hard abrasive grinding wheel with head face having abrasives in phyllotaxis arrangement and production method thereof

InactiveCN102198641AReduce wearAchieving landform controllabilityBonded abrasive wheelsGrinding devicesWheel wearControllability

The invention discloses a super-hard abrasive grinding wheel with a head face having abrasives in a phyllotaxis arrangement, comprising a grinding wheel basal body. The working surface of the grinding wheel basal body is provided with a plurality of abrasive particles or abrasive particle groups fitting with the biological phyllotaxis theory. The plurality of abrasive particles or abrasive particle groups are fixed on the grinding wheel basal body through a metal bonding agent. According to the biological phyllotaxis theory, the plurality of abrasive particles or abrasive particle groups forma plurality of anticlockwise leaf column line grooves and a plurality of clockwise leaf column line grooves. By means of the invention, the arrangement of the abrasive particles or the abrasive particle groups on the working surface of the grinding wheel fits with the H.Vogel model of the phyllotaxis theory so as to realize the physiographic controllability of the working surface of the grinding wheel. Nickel or nickel-cobalt alloy is adopted to serve as the bonding agent so as to fixedly bond the abrasives. The grinding wheel is capable of controlling the cutting state of the abrasive particles in a grinding region, the cooling liquid distribution and the grinding temperature distribution, and achieving lowest grinding force and specific energy consumption, lowest grinding temperature and burn, lowest abrasion of the grinding wheel, optimal work-surface surface integrity, and the like. The comprehensive grinding performance of the head face grinding of the super-hard abrasive grinding wheel is improved.

Owner:SHENYANG LIGONG UNIV

Microstructure modification in copper interconnect structure

ActiveUS7843063B2Inhibited DiffusionFaster rateSemiconductor/solid-state device detailsSolid-state devicesMetal interconnectCopper plating

Cobalt is added to a copper seed layer, a copper plating layer, or a copper capping layer in order to modify the microstructure of copper lines and vias. The cobalt can be in the form of a copper-cobalt alloy or as a very thin cobalt layer. The grain boundaries configured in bamboo microstructure in the inventive metal interconnect structure shut down copper grain boundary diffusion. The composition of the metal interconnect structure after grain growth contains from about 1 ppm to about 10% of cobalt in atomic concentration. Grain boundaries extend from a top surface of a copper-cobalt alloy line to a bottom surface of the copper-cobalt alloy line, and are separated from any other grain boundary by a distance greater than a width of the copper-cobalt alloy line.

Owner:TESSERA INC

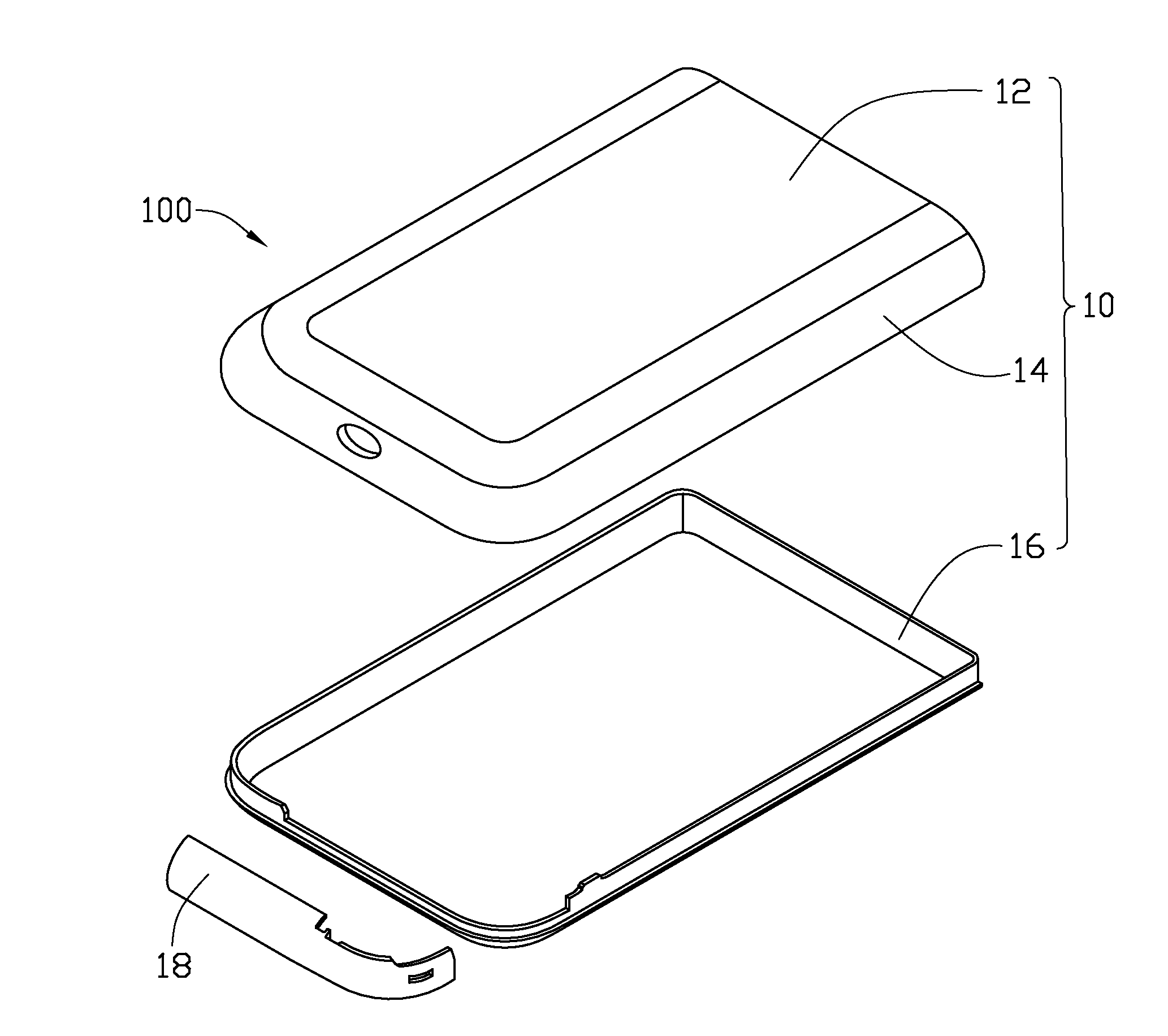

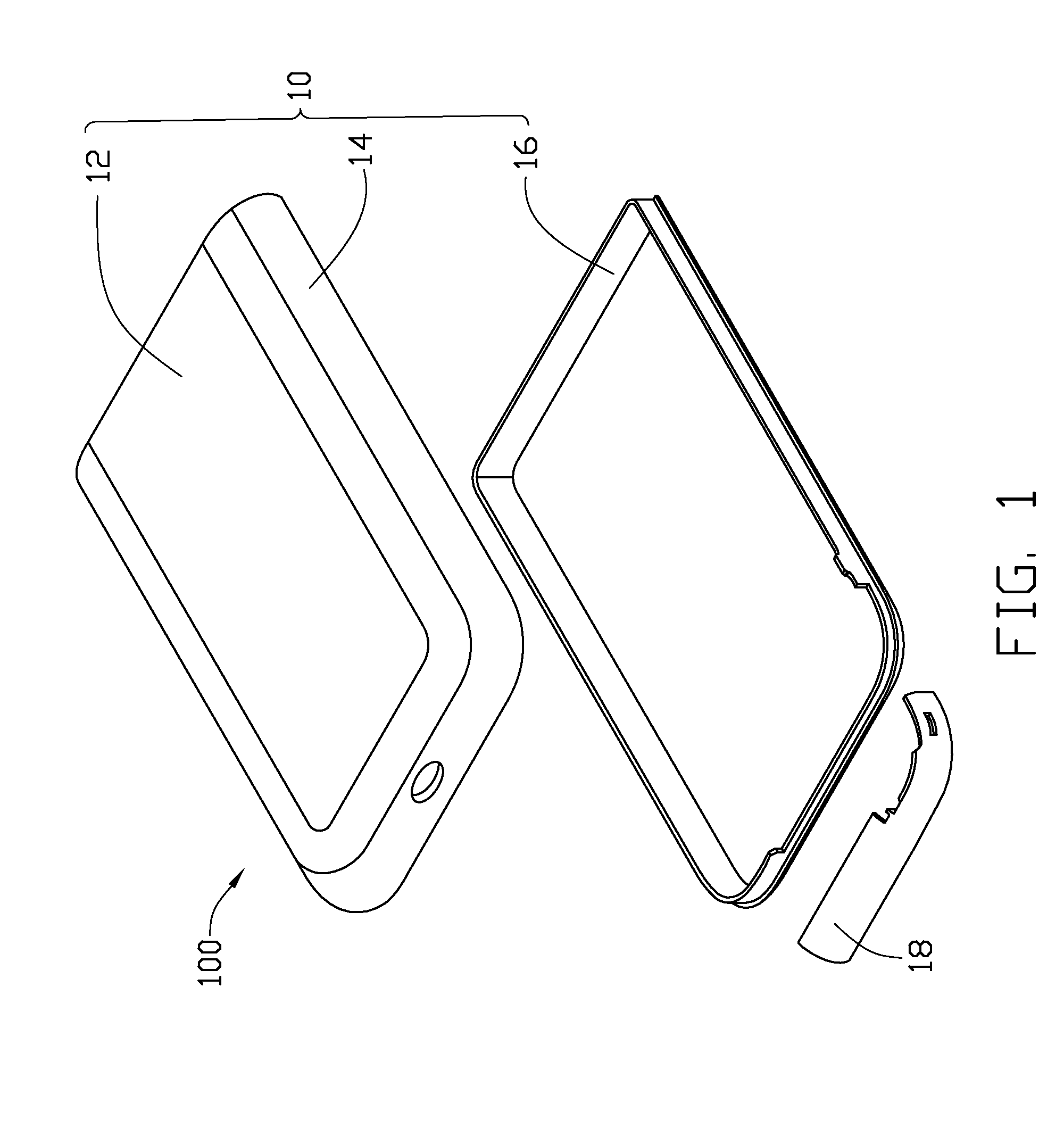

Housing for portable electronic device

InactiveUS20080225468A1Electrically conductive connectionsElectrostatic discharge protectionEngineeringTop cap

An exemplary housing (100) for portable electronic device includes a main structure (10) and a static electricity eliminating structure (18). The main structure includes a top cover (12), a bottom cover (16) and a frame (14). The top cover faces the bottom cover. The frame is located between the top cover and bottom cover. The static electricity eliminating structure is in contact with the frame, which includes a main body (182) and a tin-cobalt alloy layer (184) formed on a surface of the main body.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

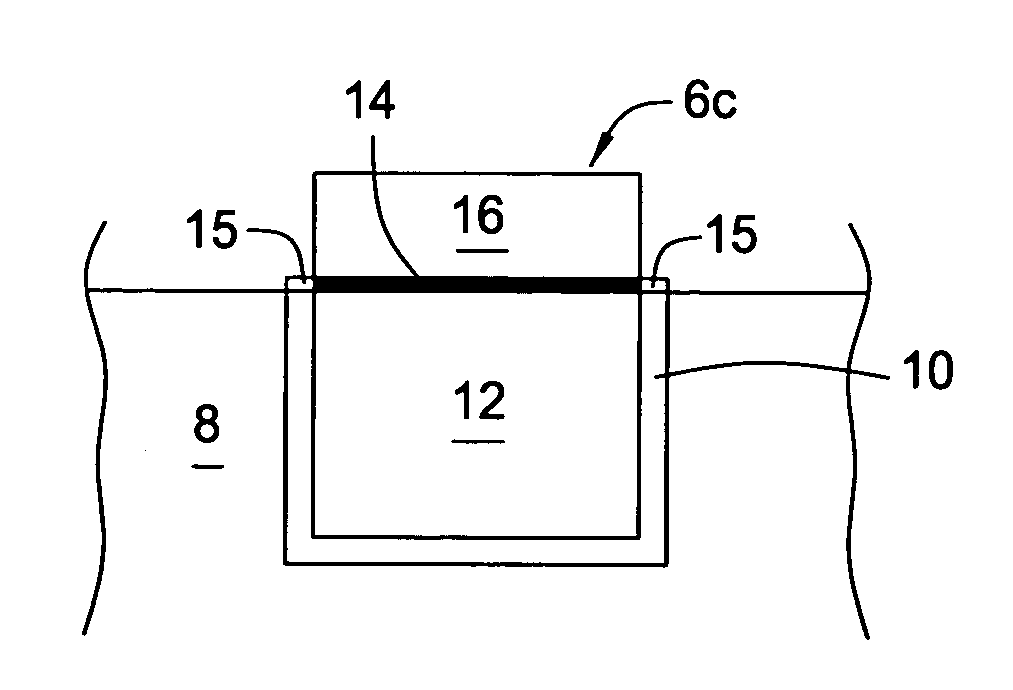

Electroless palladium nitrate activation prior to cobalt-alloy deposition

InactiveUS20050170650A1Semiconductor/solid-state device manufacturingLiquid/solution decomposition chemical coatingBiological activationMethanesulfinic acid

In one embodiment, a method for activating a metal layer prior to depositing a cobalt-containing capping layer is provided which includes exposing the metal layer to an electroless activation solution to deposit a palladium layer on the metal layer and depositing the cobalt-containing capping layer on the palladium layer. The electroless activation solution contains palladium nitrate at a concentration in a range from about 0.01 mM to about 1.0 mM, nitric acid at a concentration in a range from about 0.01 mM to about 3.0 mM and water. In another embodiment, the electroless activation solution contains palladium nitrate at a concentration in a range from about 0.01 mM to about 1.0 mM, methanesulfonic acid at a concentration in a range from about 0.01 mM to about 3.0 mM and water.

Owner:APPLIED MATERIALS INC

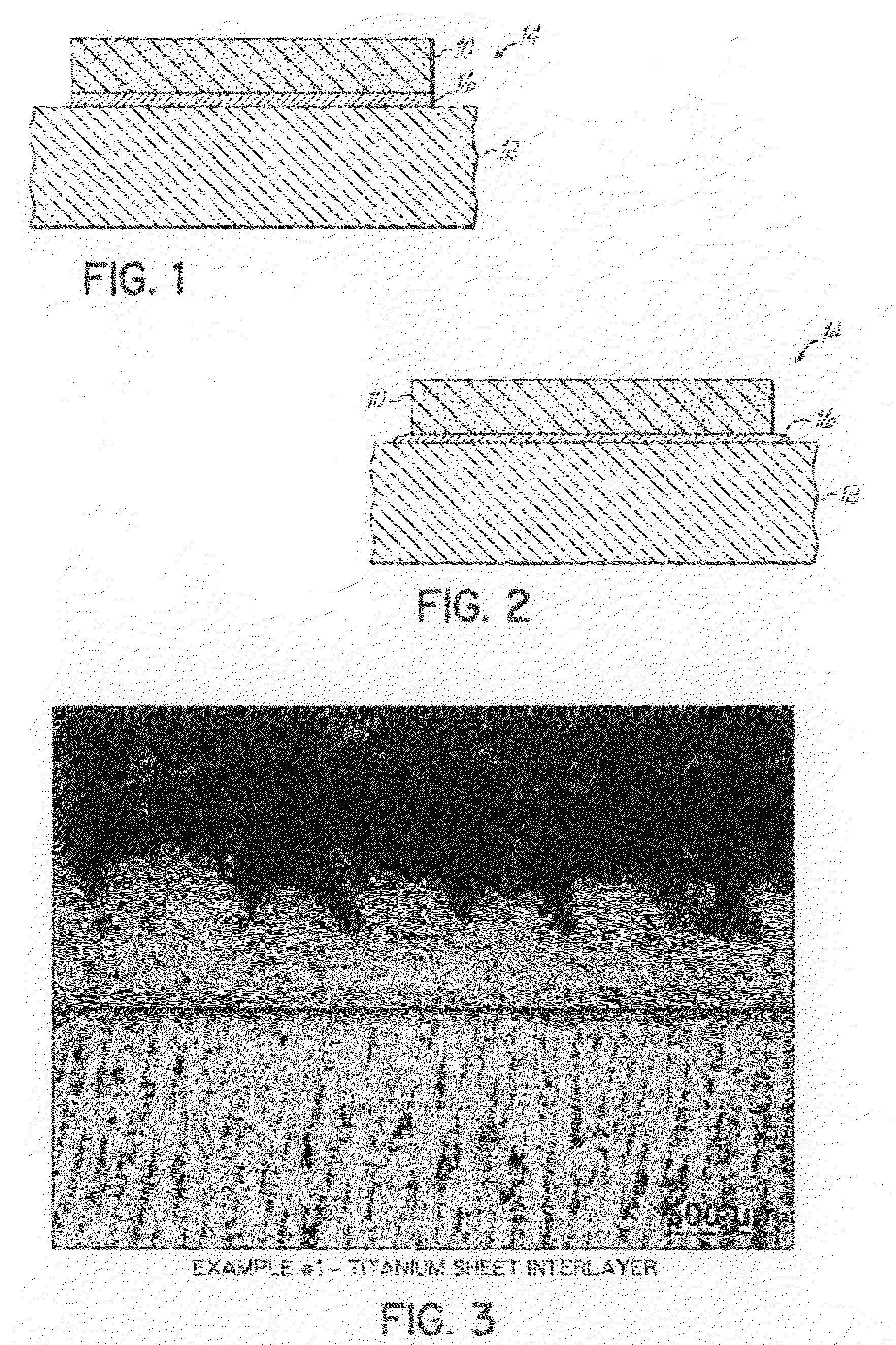

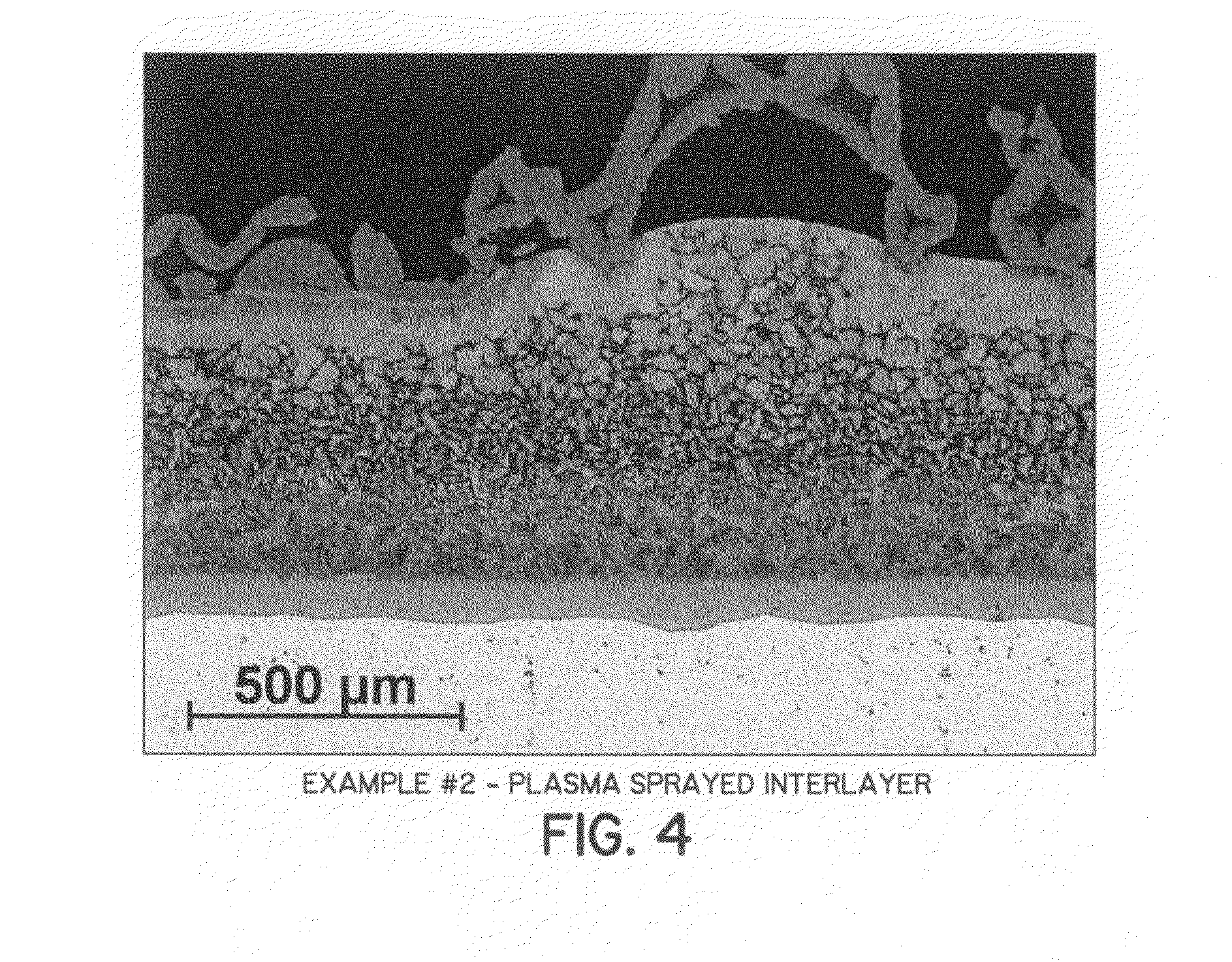

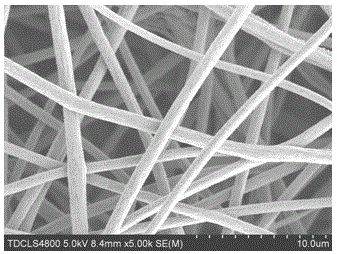

Method for bonding a tantalum structure to a cobalt-alloy substrate

A method for bonding a porous tantalum structure to a substrate is provided. The method comprises providing a substrate comprising cobalt or a cobalt-chromium alloy; an interlayer consisting essentially of at least one of hafnium, manganese, niobium, palladium, zirconium, titanium, or alloys or combinations thereof; and a porous tantalum structure. Heat and pressure are applied to the substrate, the interlayer, and the porous tantalum structure to achieve solid-state diffusion between the substrate and the interlayer and between the interlayer and the porous tantalum structure.

Owner:ZIMMER INC

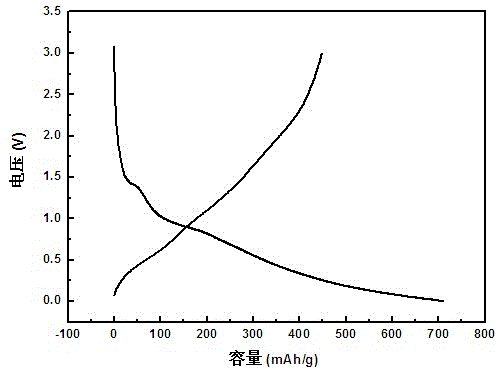

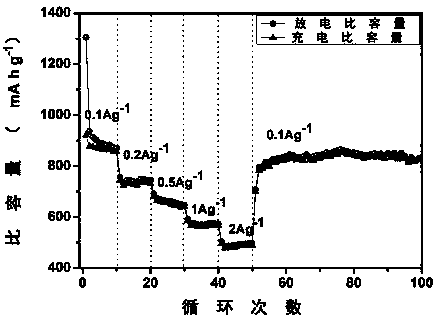

Preparation for anode material of tin-cobalt alloy/carbon nanofiber film lithium ion battery

InactiveCN102751475AImprove conductivitySmall volume changeMaterial nanotechnologyCell electrodesFiberComposite film

The invention discloses a preparation method for anode material of tin-cobalt alloy / carbon nanofiber film lithium ion battery. The method process comprises a first step of preparing a polymer nanofiber film via electrostatic spinning with proper electrostatic spinning parameters by a uniform electrostatic spinning solution which is formed by employing stannous octoate as a tin precursor, cobalt acetate as a cobalt precursor, polyacrylonitrile as a carbon nanofiber precursor and an organic solvent; and a second step of preparing the tin-cobalt alloy / carbon nanofiber film by using a pre-oxidation treatment and a carbonization treatment. The tin-cobalt alloy / carbon nanofiber composite film prepared by the method effectively improves specific capacity and cycle performance of the anode material of the lithium ion battery, because tin-cobalt alloy particles are uniformly dispersed in the carbon nanofibers with uniform diameters; cobalt metal component increases conductivity of the material and can buffer volume change to a certain degree when the tin metal is charged and discharged; and simultaneously the carbon fibers can further play a role for buffering the volume change of the materials.

Owner:TIANJIN UNIV

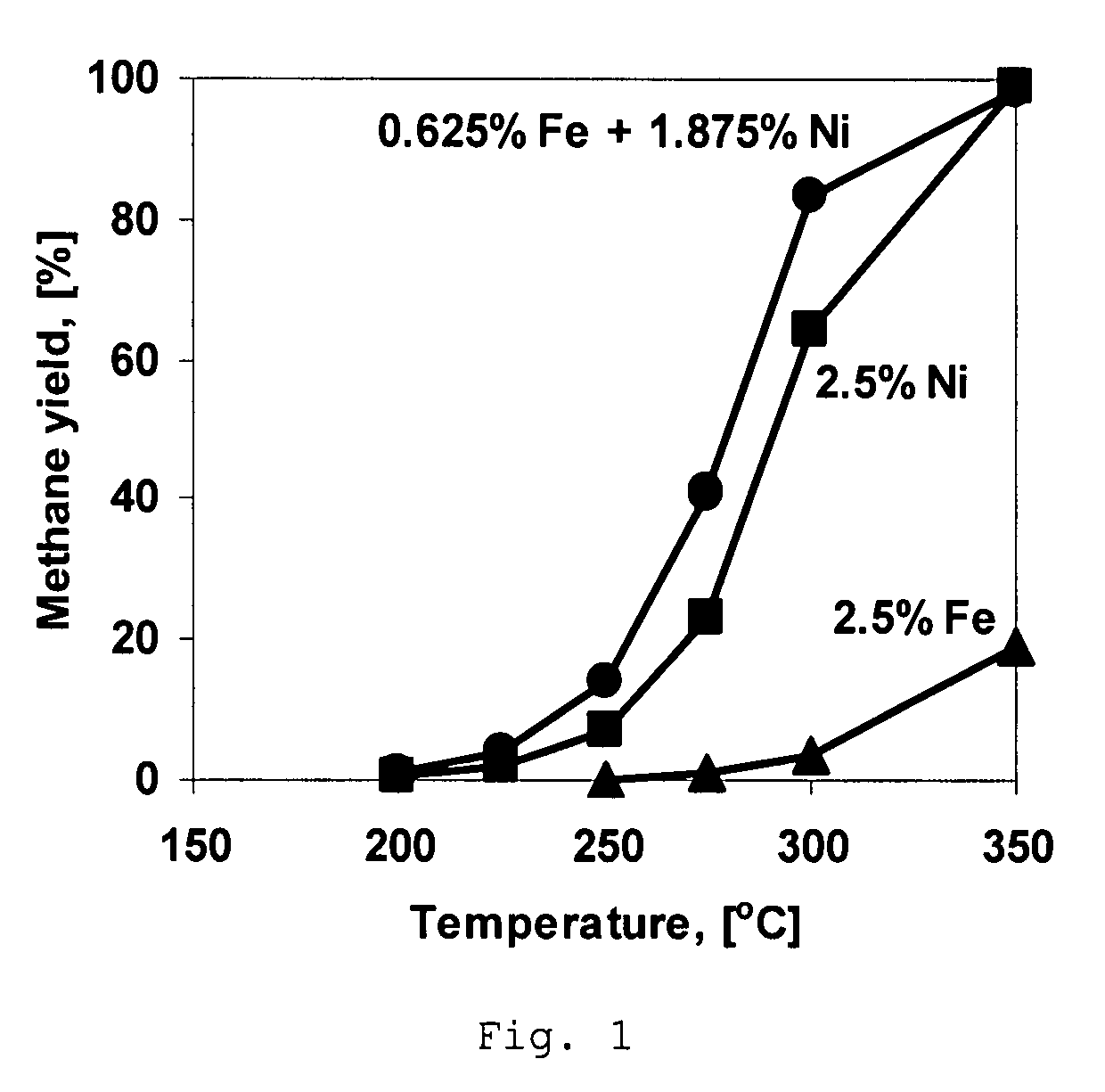

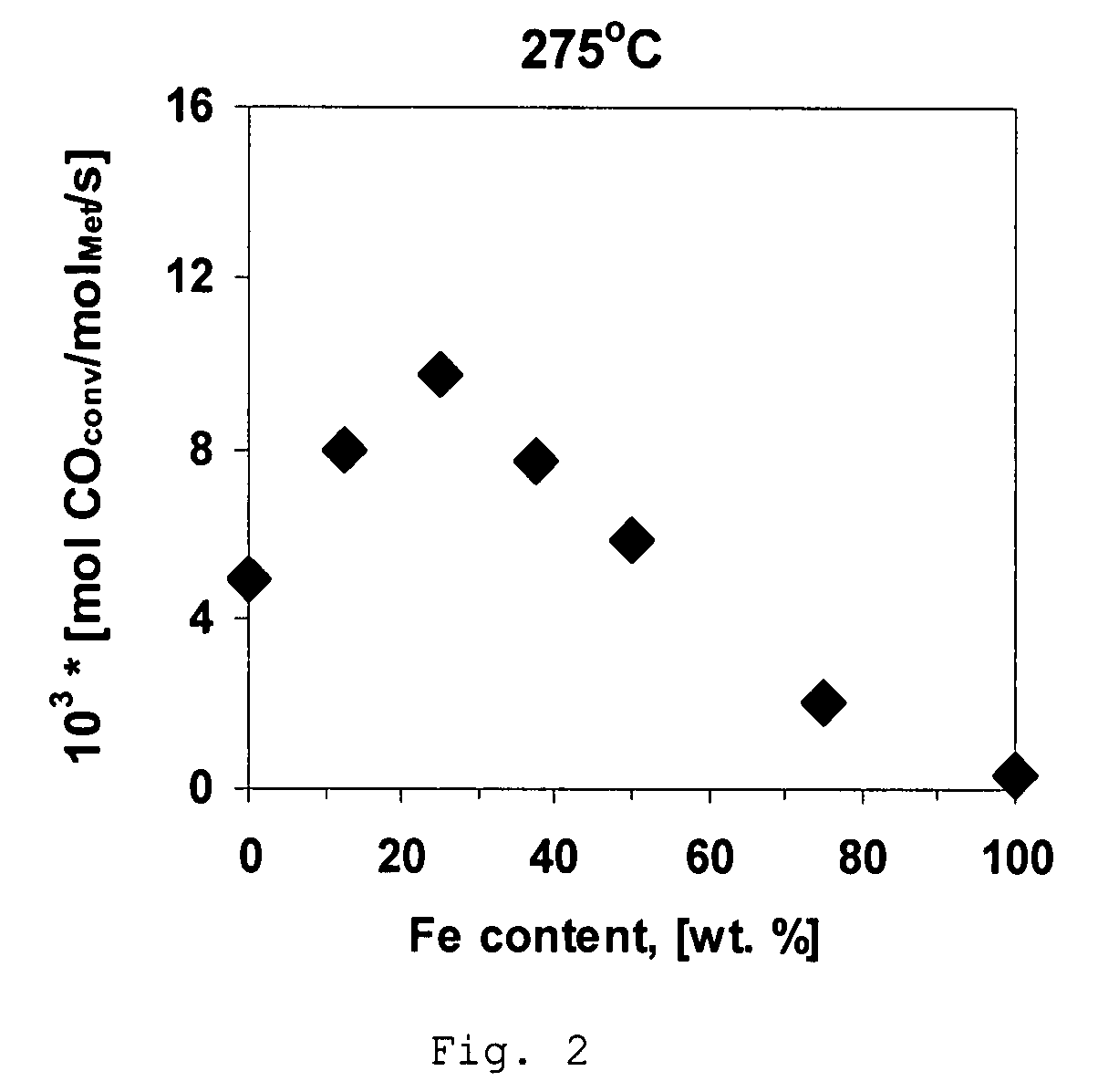

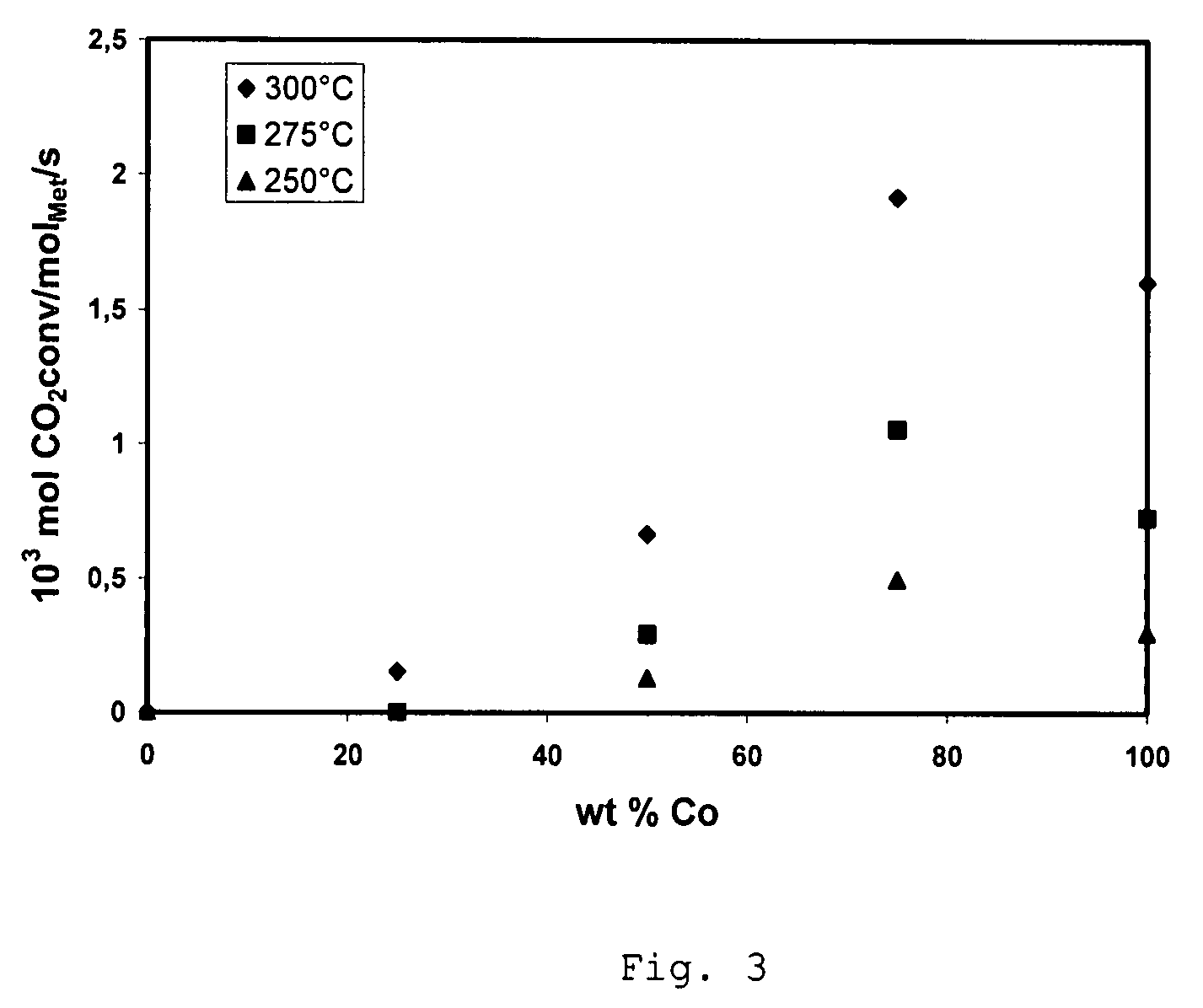

Process and catalyst for hydrogenation of carbon oxides

InactiveUS7790776B2High activityOrganic compound preparationOxygen compounds preparation by reductionHydrogenCarbon oxide

A process for hydrogenation of carbon oxides comprising contacting a gas mixture containing carbon oxides and of hydrogen with a catalyst comprising bimetallic iron-nickel or iron-cobalt alloys as the active catalytic material supported on a carrier of an oxide. The carrier is preferably formed to have a surface area greater than 20 m2 / g.

Owner:HALDOR TOPSOE AS

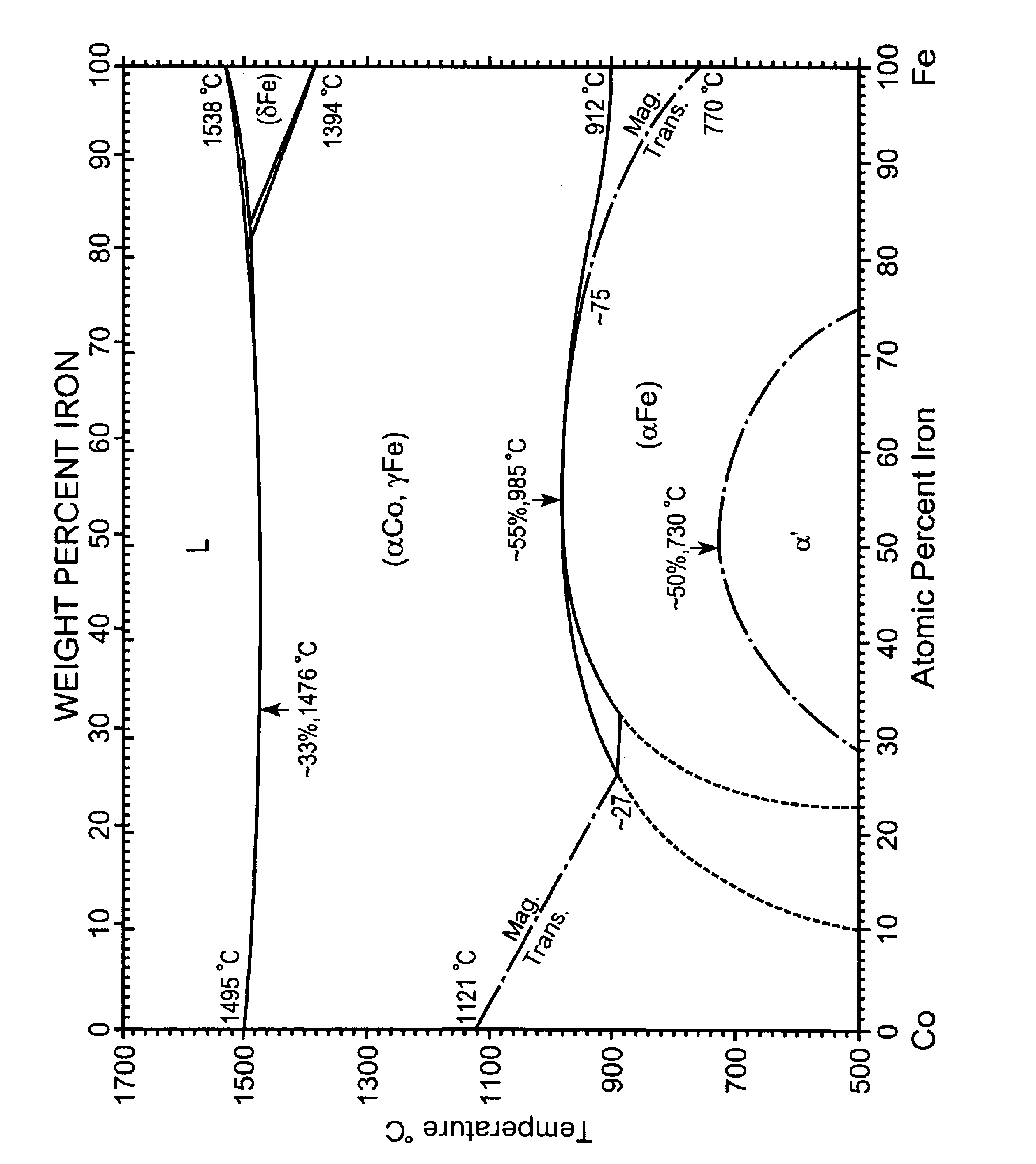

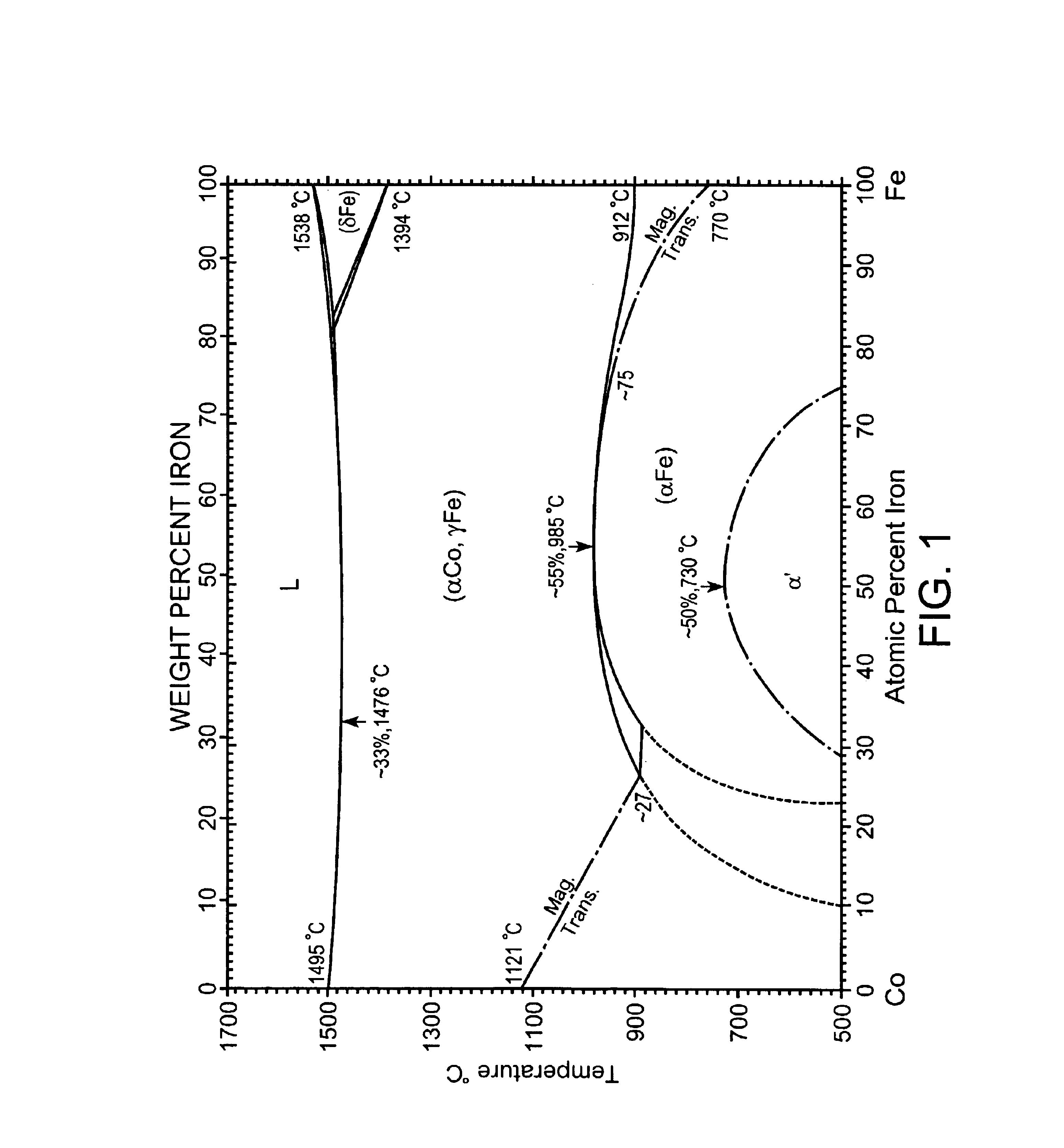

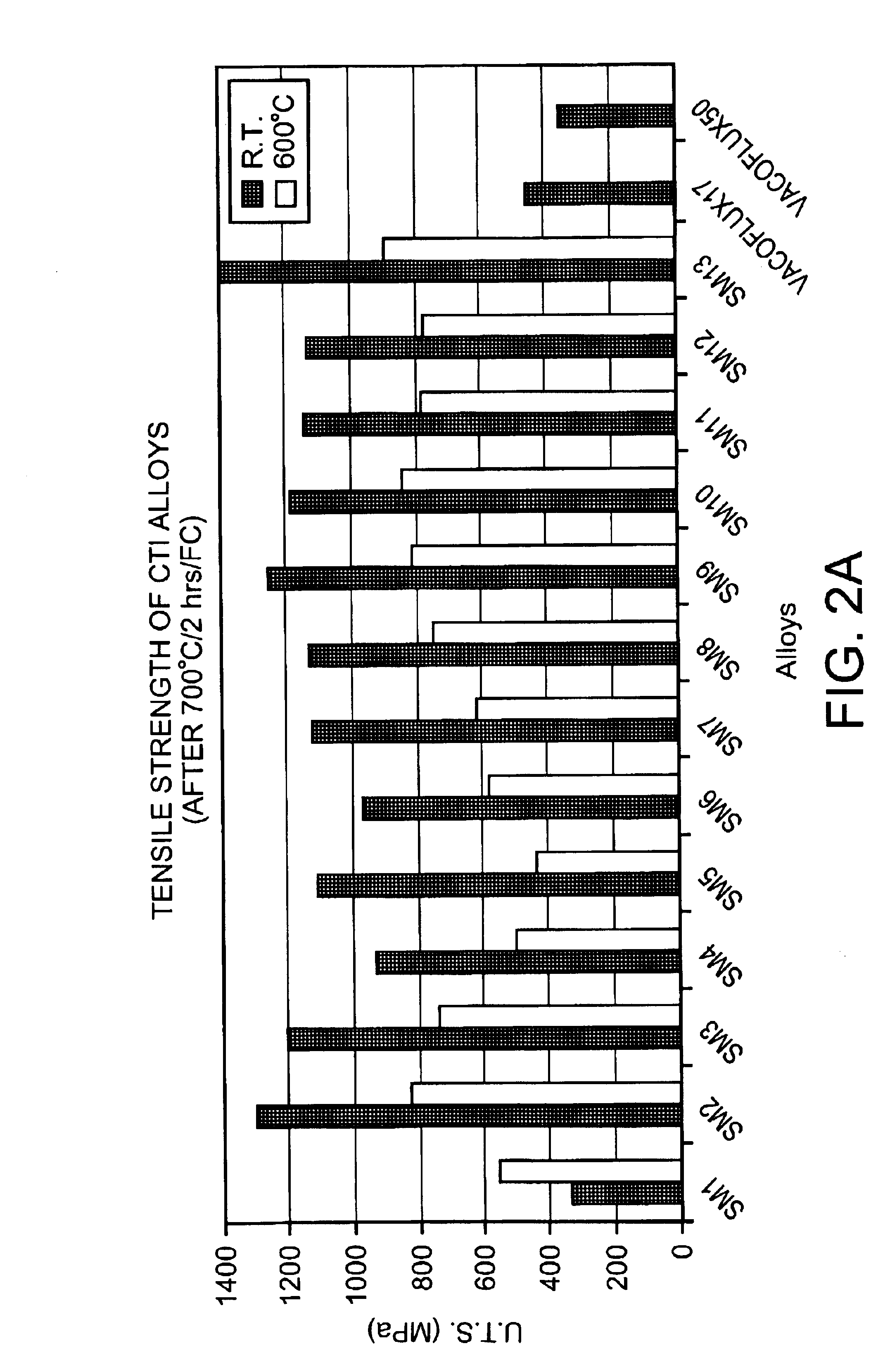

High-strength high-temperature creep-resistant iron-cobalt alloys for soft magnetic applications

A high strength and creep resistant soft magnetic Fe—Co alloy includes, in weight %, Fe and Co such that the difference between the Fe and Co is at least 2%, at least 35% Co, and 2.5%≦(V+Mo+Nb), wherein 0.4%≦Mo and / or 0.4%≦Nb. This alloy can further include B, C, W, Ni, Ti, Cr, Mn and / or Al. A vanadium-free high strength soft magnetic Fe—Co alloy includes, in weight %, Fe and Co such that the difference between the Fe and Co is at least 2%, and at least 15% Co, the alloy further satisfying (0.1%≦Nb and 0.1%≦W) or 0.25%≦Mn. This alloy can further include B, C, Ni, Ti, Cr and / or Al.

Owner:PHILIP MORRIS USA INC

Direct touch type metal diaphragm valve

ActiveUS8256744B2Reduce replacement timeFlow rate coefficient Cv (Cv value) is more stableDiaphragm valvesOperating means/releasing devices for valvesDirect touchDiaphragm valve

A direct touch type metal diaphragm valve, wherein durability of the valve, that is to say, the ensured number of continuous open / close operations of the valve, is substantially increased under conditions that an appropriate flow rate coefficient Cv is maintained, and changes of the afore-mentioned Cv value over time are mitigated by means of restricting the deformation of the valve seat over time. The afore-mentioned metal diaphragm is formed in a round, reverse-dish shape by laminating a plural number of thin stainless steel plates and a thin Nickel.Cobalt alloy plate, and its center part is bulged upward, and the maximum valve stroke of the valve is regulated to be 55% to 70% of the distance of the maximum bulge height Δh of the afore-mentioned metal diaphragm.

Owner:FUJIKIN INC

Co alloy target and its production method, soft magnetic film for perpendicular magnetic recording and perpendicular magnetic recording medium

InactiveUS20050223848A1Reduce unevennessReduce particlesBase layers for recording layersTransportation and packagingAlloyImpurity

Owner:HITACHI METALS LTD

Composite electromagnetic screen film material and mfg. method thereof

InactiveCN1787114AMeet the needs of normal workLow costMagnetic/electric field screeningScreening apparatusComposite filmElectromagnetic shielding

The invention belongs to the field of magnetic material, relating to an electromagnetic shielding material and the making method thereof. The invention is a composite metallic film formed on a conductive substrate by multiple deposition in the water solution, and the obtained composite metallic film is 1-100 mum thick, and each layer of the composite metallic film is 1.1-99.9 mum thick, and the combination between the layers of the composite film is by chemical bond, and each layer is layered. The substrate can be stainless steel, copper plate, Ti plate, Al plate or one of the corrosion-resistant alloy plates, and also made of conductive glass, conductive plastics, polymer high molecular material, or other material; the composite metallic film comprises two or above different metallic film layers; each metallic film layer can be of copper, iron, iron-nickel alloy, nickel-cobalt alloy, iron-cobalt alloy or iron-cobalt-nickel alloy. The invention can shield the frequencies between 50Hz and 100 Hz and the shielding efficacy reaches above 70dB.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

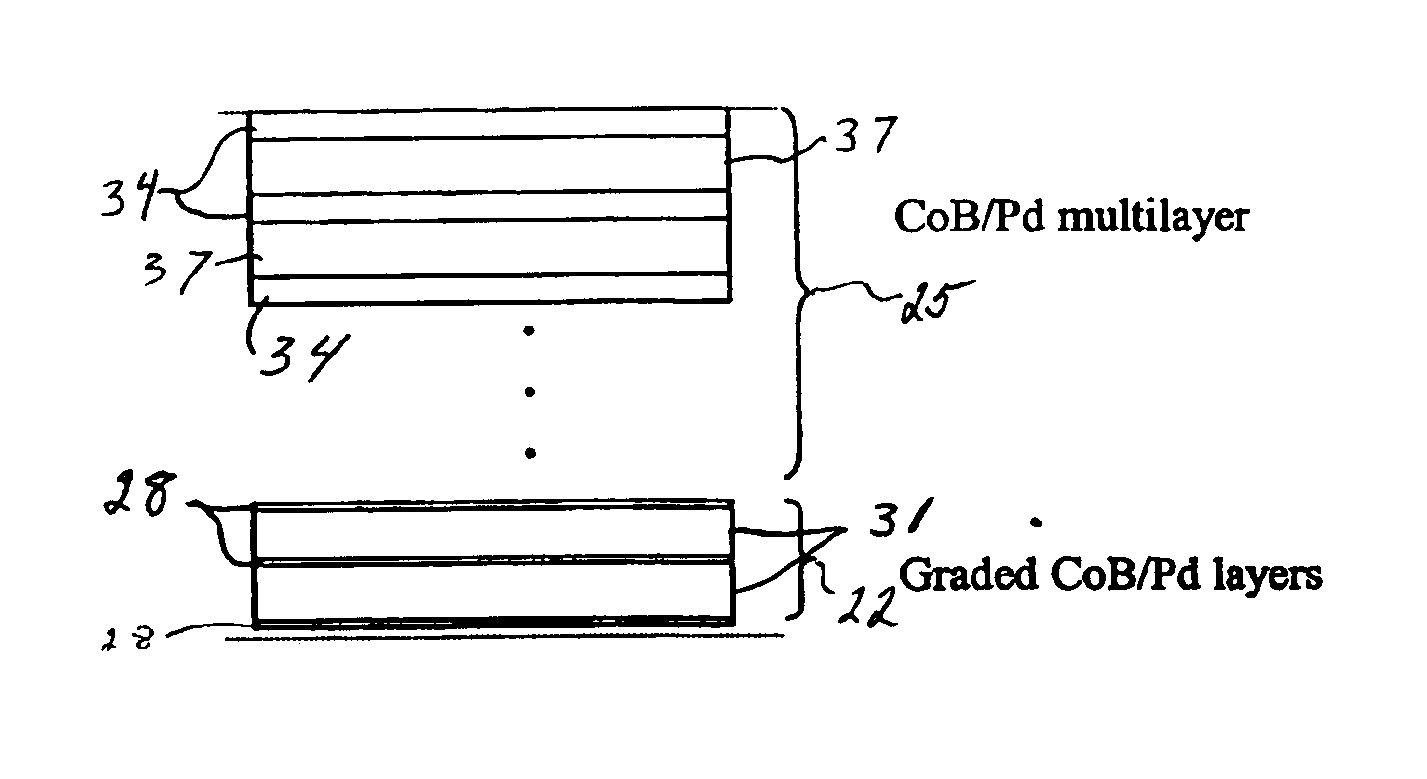

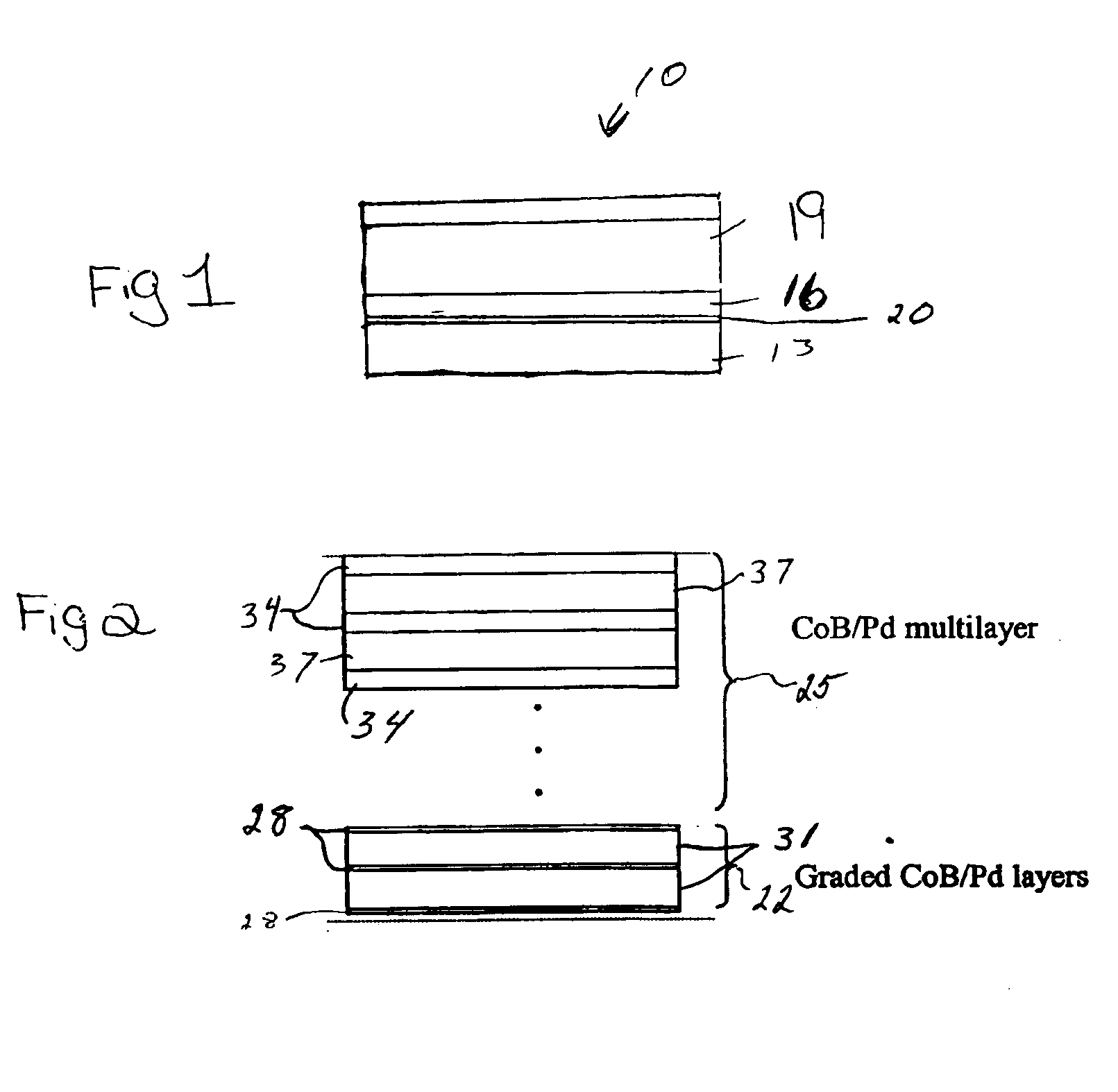

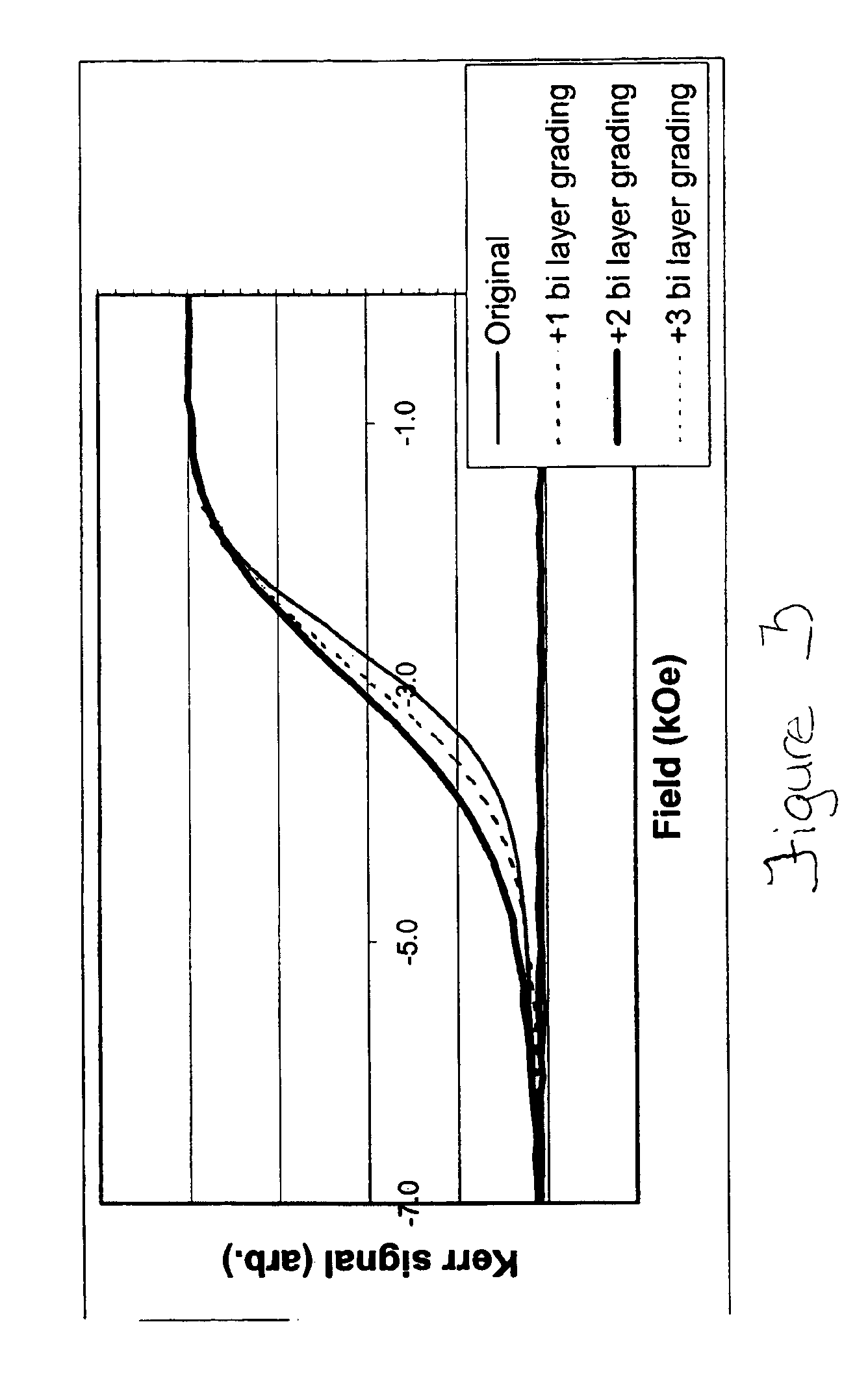

Exchange decoupled cobalt/noble metal perpendicular recording media

InactiveUS6955857B2Reduce thicknessRecord information storageMagnetic recordingSignal-to-noise ratioMaterials science

A magnetic recording medium of the perpendicular type, for a disc drive. The magnetic recording material includes a Cobalt alloy layer interspersed with a noble metal layer. The initial graded material is paramagnetic to increase to the magnetic properties of perpendicular recording media into increase the signal to noise ratio. The final recording layer has 8-20 alternating multilayer of the Cobalt alloy and a noble metal.

Owner:SEAGATE TECH LLC

Lithium ion battery negative electrode material and preparation method thereof

InactiveCN108321358AImproved magnification performanceImprove electrochemical performanceCell electrodesCarbon compositesHigh rate

The invention provides a tin-based alloy / carbon composite material for a lithium ion battery negative electrode material and a preparation method thereof. Metal salt and organic ligands are stirred and dissolved in a solvent according to a certain proportion; normal temperature or solvent heat reaction is performed for preparing a porous MOF (metal-organic framework); tin salt is added into the MOF, so that the tin salt is fully adsorbed; MOF precursor powder containing the tin salt is calcined in air; carbonization is performed in inert gas to obtain a nanometer tin cobalt alloy / carbon composite material. The appearance of the prepared nanometer tin cobalt alloy / carbon composite material is a regular polyhedral spherical shape; the nanometer tin alloy size is smaller than 10nm; the material is uniformly dispersed in a porous polyhedral carbon base body. When the material is used for a lithium ion battery negative electrode, high reversible capacity, good cycling stability and high-rate performance are realized.

Owner:BEIJING UNIV OF CHEM TECH

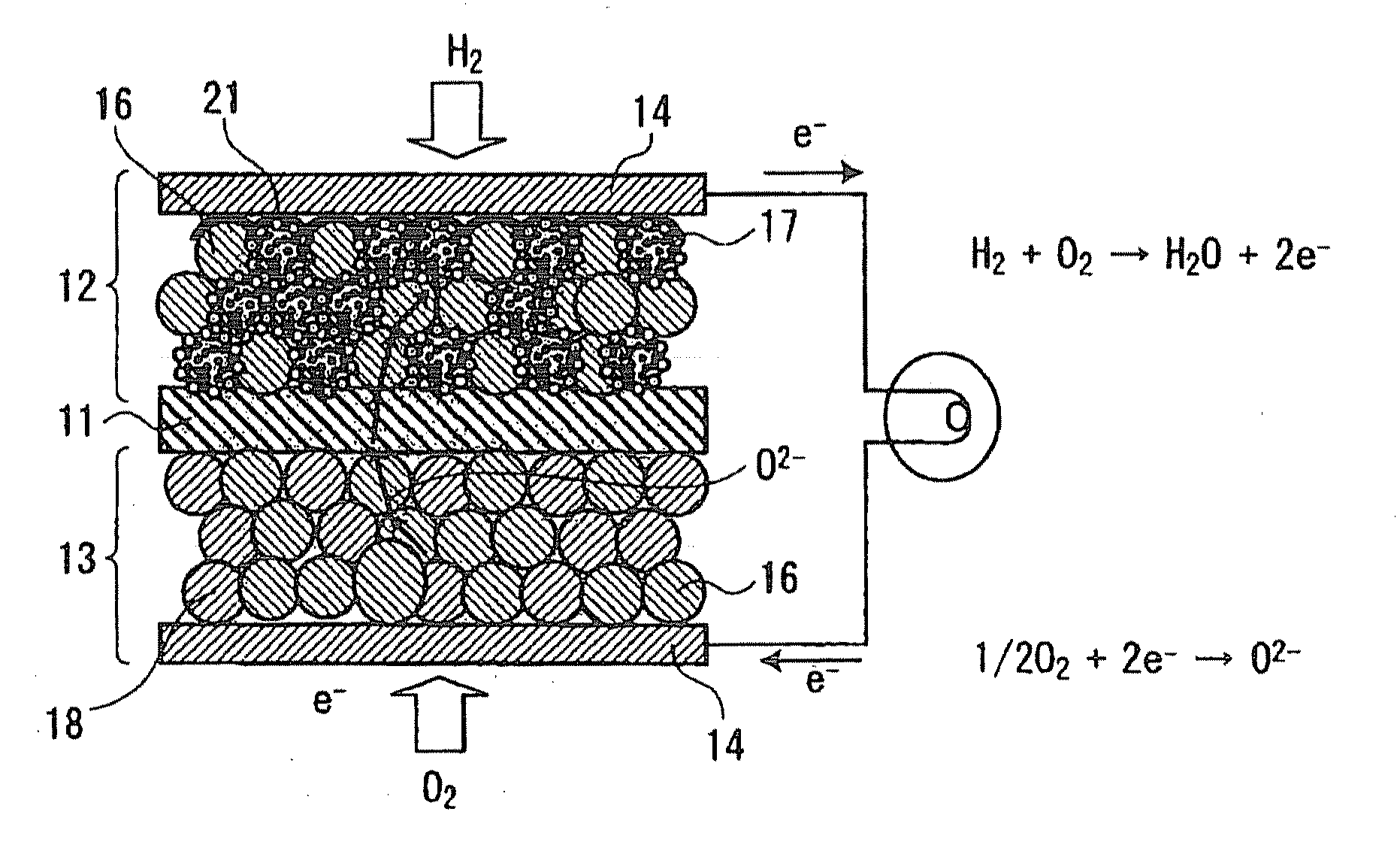

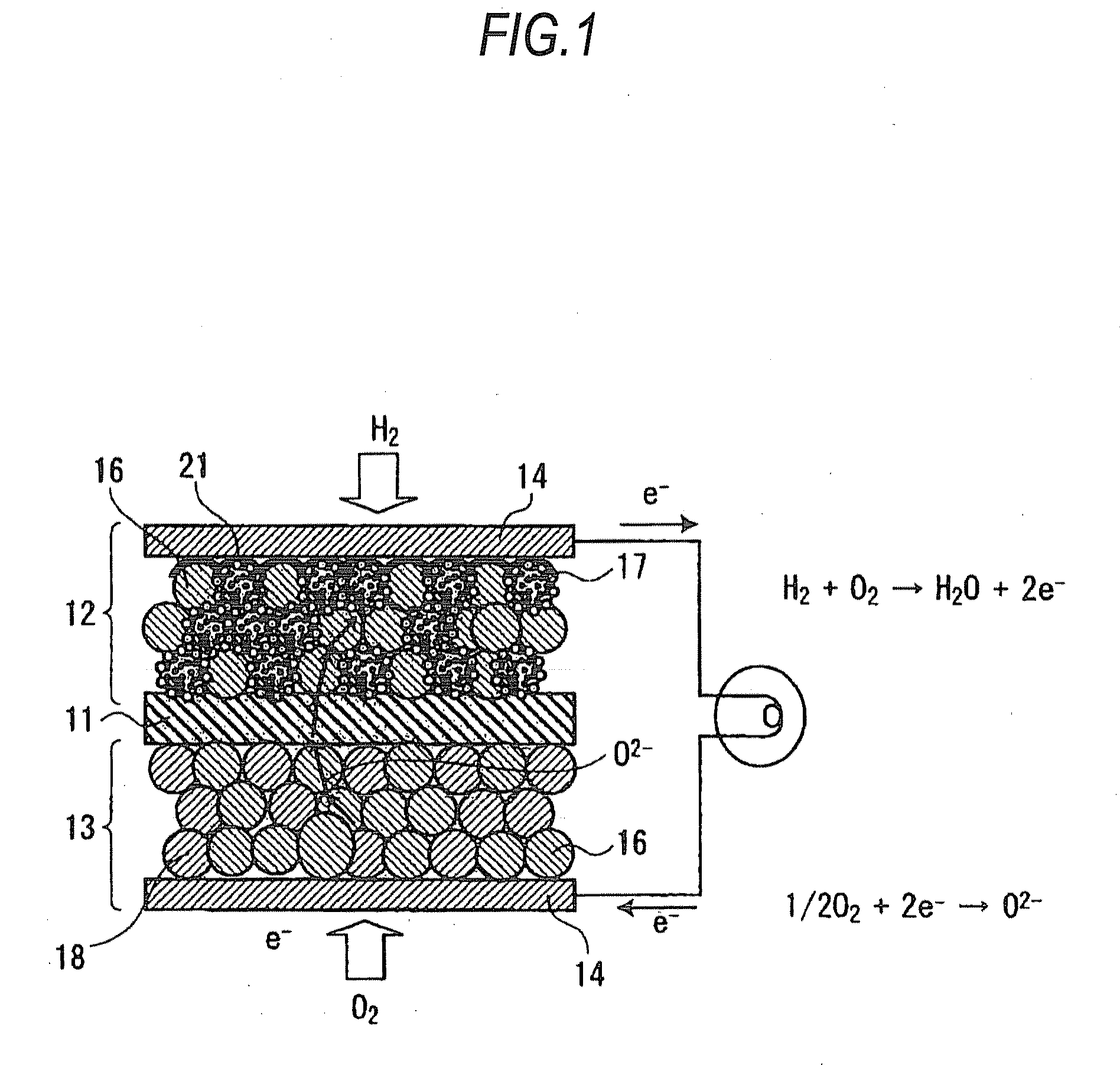

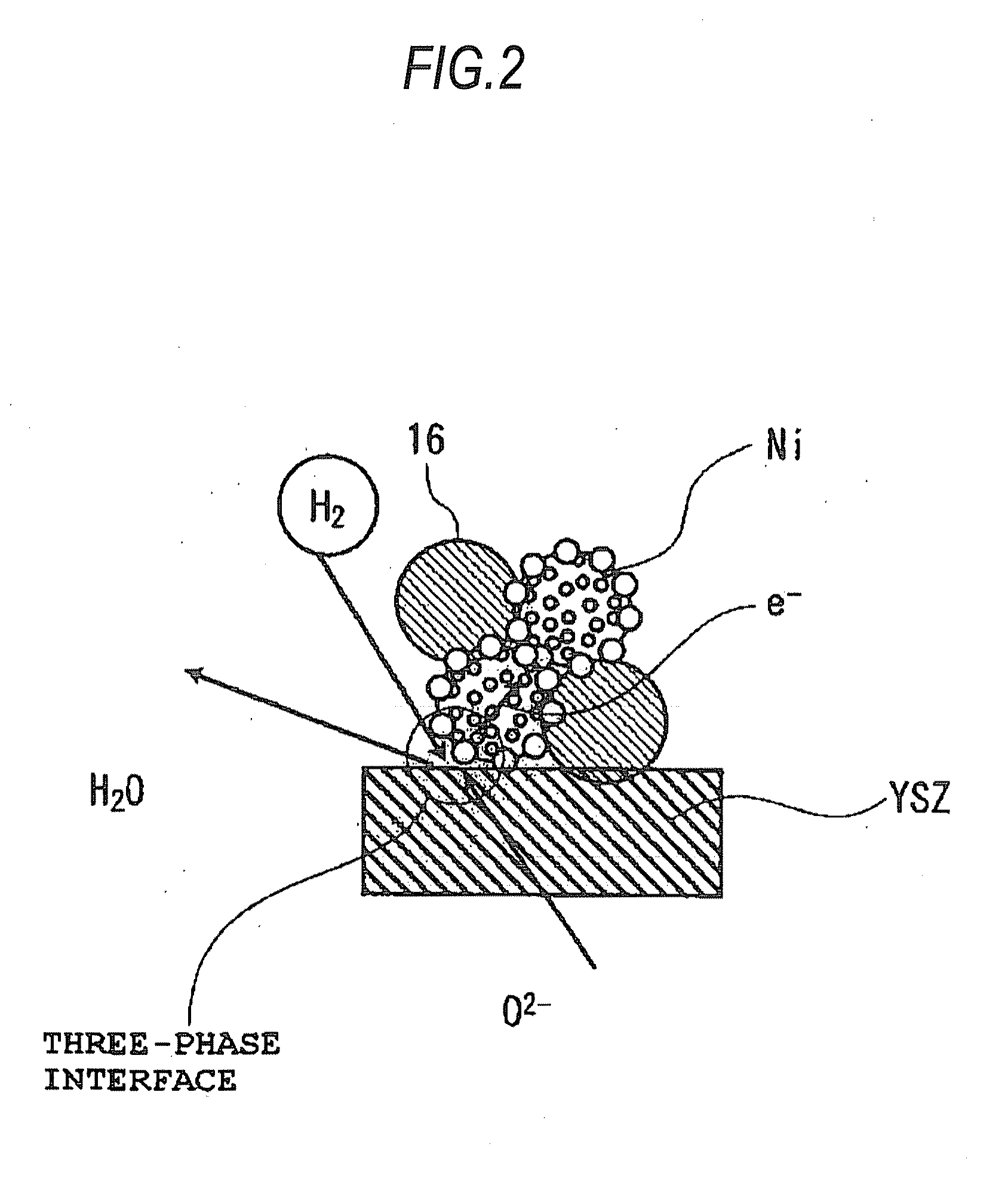

Fuel electrodes for solid oxide electrochemical cell, processes for producing the same, and solid oxide electrochemical cells

InactiveUS20090068533A1High catalytic activityImprove output performanceFuel cells groupingFinal product manufactureYTTERBIUM OXIDEYttrium

A fuel electrode for a solid oxide electrochemical cell includes: an electrode layer including a mixed phase constituted of zirconia stabilized with yttrium oxide, ytterbium oxide, or scandium oxide and of an oxide selected from the group including an aluminum-based oxide and a magnesium-based composite oxide, said oxide having, supported on a surface part thereof, particles of at least one member selected from nickel, cobalt, and nickel-cobalt alloys; a meshy wiring formed on a surface layer part of the electrode layer and made of a material having higher electronic conductivity than the electrode layer; and a current collector which overlies the electrode layer and is in contact with at least the wiring.

Owner:KK TOSHIBA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com