Lithium ion battery negative electrode material and preparation method thereof

A technology for lithium ion batteries and negative electrode materials, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as difficulty in controlling alloy size dispersion, and achieve good cycle stability, improved rate performance, and high specific capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1) Weigh 1.2g of cobalt nitrate hexahydrate, add it into 100mL of methanol and stir until it becomes clear. Dissolve 1.4g of the ligand 2-methylimidazole in 100mL of methanol and stir until clear. The above two solutions were mixed and reacted at room temperature for 24h. The product was centrifuged to obtain a purple precipitate. Centrifuge and wash 3 times with ethanol. Vacuum drying at 100 °C for 8 h yielded Co-MOF.

[0024] 2) Weigh 1g of tin tetrachloride pentahydrate, dissolve it in 500 microliters of ethanol, and add it to 500mg of the Co-MOF obtained in step 1). The resulting mixed solution was calcined in air at 180°C for 4h.

[0025] 3) The mixture obtained in step 2) was raised to 550° C. at a heating rate of 5° C. per minute under an argon atmosphere, and kept for 4 hours. After cooling, the nanometer tin-cobalt alloy / carbon composite material is obtained.

[0026] The overall morphology of the obtained composite material is as follows figure 1 shown....

Embodiment 2

[0029] 1) Weigh 1.2g of cobalt nitrate hexahydrate, add it into 100mL of methanol and stir until it becomes clear. Dissolve 1.4g of the ligand 2-methylimidazole in 100mL of methanol and stir until clear. The above two solutions were mixed and reacted at room temperature for 24h. The product was centrifuged to obtain a purple precipitate. Centrifuge and wash 3 times with ethanol. Vacuum drying at 100 °C for 8 h yielded Co-MOF.

[0030] 2) Weigh 500 mg of tin dichloride and dissolve it in 500 microliters of ethanol, and add it to 500 mg of Co-MOF obtained in step 1). The resulting mixed solution was calcined in air at 180°C for 4h.

[0031] 3) The mixture obtained in step 2) was raised to 550° C. at a heating rate of 5° C. per minute under an argon atmosphere, and kept for 4 hours. After cooling, the nanometer tin-cobalt alloy / carbon composite material is obtained.

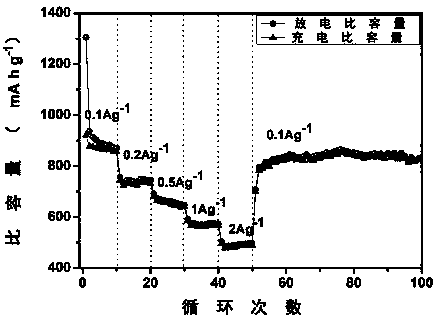

[0032] The resulting nano-SnCo alloy / carbon composites were tested at 100 mA g -1 The first reversible cap...

Embodiment 3

[0034] 1) Weigh 1.2g of cobalt nitrate hexahydrate, add it into 100mL of methanol and stir until it becomes clear. Dissolve 1.4g of the ligand 2-methylimidazole in 100mL of methanol and stir until clear. The above two solutions were mixed and reacted at room temperature for 24h. The product was centrifuged to obtain a purple precipitate. Centrifuge and wash 3 times with ethanol. Vacuum drying at 100 °C for 8 h yielded Co-MOF.

[0035]2) Weigh 500 mg of tin dichloride and dissolve it in 500 microliters of ethanol, and add it to 500 mg of Co-MOF obtained in step 1). The resulting mixed solution was calcined in air at 180°C for 4h.

[0036] 3) The mixture obtained in step 2) was raised to 700° C. at a heating rate of 5° C. per minute under an argon atmosphere, and kept for 2 hours. After cooling, the nanometer tin-cobalt alloy / carbon composite material is obtained.

[0037] The resulting nano-SnCo alloy / carbon composites were tested at 100 mA g -1 The first reversible capa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com