Preparation for anode material of tin-cobalt alloy/carbon nanofiber film lithium ion battery

A technology of carbon nanofibers and lithium-ion batteries, applied in battery electrodes, nanotechnology, nanotechnology, etc., to achieve the effects of increasing conductivity, high specific capacity, and buffering volume changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

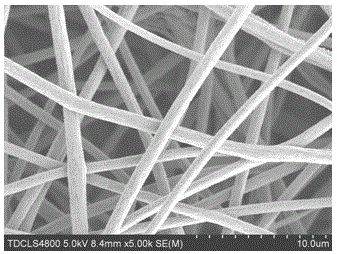

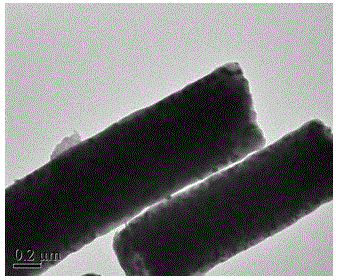

[0019] Weigh 0.314g cobalt acetate tetrahydrate and 0.504g stannous octoate (molar ratio 1:1) and dissolve in N,N-dimethylformamide solution with polyacrylonitrile mass volume concentration of 0.07g / mL, and stir in a water bath until A homogeneous solution is used for electrospinning. Electrospinning uses a 0.6mm inner diameter needle, voltage 8kV, injection speed 0.4mL / min, electrospinning for 6 hours, pre-oxidation heating rate 1°C / min, pre-oxidation at 280°C for 1.5 hours, carbonization heating rate 1°C / min, in Carbonization at 850°C for 1 hour in a high-purity nitrogen atmosphere. The tin-cobalt alloy / carbon nanofiber composite film material can be obtained. The film has good flexibility and can be cut into an appropriate shape and directly used as the negative electrode material of the lithium-ion battery for battery testing.

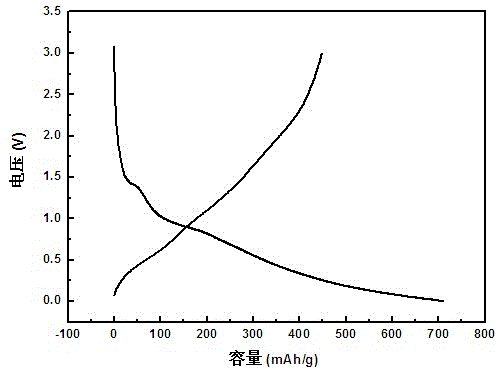

[0020] In this thin film, the tin-cobalt alloy forms a CoSn-type alloy with a tin content of 25wt%, and the specific capacity remains at 440 mAh...

Embodiment 2

[0022] Weigh 0.367g of cobalt nitrate and 0.219g of tin chloride (molar ratio 3:2) and dissolve in N,N-dimethylformamide solution with a mass volume concentration of polyacrylonitrile of 0.10g / mL, stir in a water bath until uniform The solution is used for electrospinning. Electrospinning uses a 0.8mm inner diameter needle, voltage 10kV, injection speed 0.6mL / min, electrospinning for 6 hours, pre-oxidation heating rate 3°C / min, pre-oxidation at 280°C for 1 hour, carbonization heating rate 3°C / min, in Carbonization in high-purity nitrogen atmosphere at 700°C for 1.5 hours. The tin-cobalt alloy / carbon nanofiber composite film material can be obtained. The film has good flexibility and can be cut into an appropriate shape and directly used as the negative electrode material of the lithium-ion battery for battery testing.

[0023] In this thin film, the tin-cobalt alloy forms a Co3Sn2 type alloy, and the capacity remains at 320 mAh / g after 40 cycles.

Embodiment 3

[0025] Weigh 0.300g of cobalt chloride and 0.560g of stannous chloride (molar ratio 1:2) and dissolve in N,N-dimethylformamide solution with a mass volume concentration of polyacrylonitrile of 0.12g / mL, and stir in a water bath until A homogeneous solution is used for electrospinning. Electrospinning uses a 1.0 mm inner diameter needle, voltage 12kV, injection speed 0.8mL / min, electrospinning for 6 hours, pre-oxidation heating rate 5°C / min, pre-oxidation at 280°C for 1.5 hours, carbonization heating rate 10°C / min, in Carbonization in high-purity nitrogen atmosphere at 1000°C for 2 hours. The film has good flexibility and can be cut into an appropriate shape and directly used as the negative electrode material of the lithium-ion battery for battery testing.

[0026] In this thin film, the tin-cobalt alloy forms a CoSn2 type alloy, and the capacity remains at 450 mAh / g after 40 cycles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com