Method for preparing carbon-wrapped iron-cobalt nano wave-absorbing material

A technology of nano-absorbing materials and carbon-coated iron-cobalt, which is applied to parts, shielding, and instruments of instruments, and can solve problems such as methods without nano-capsule absorbing materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

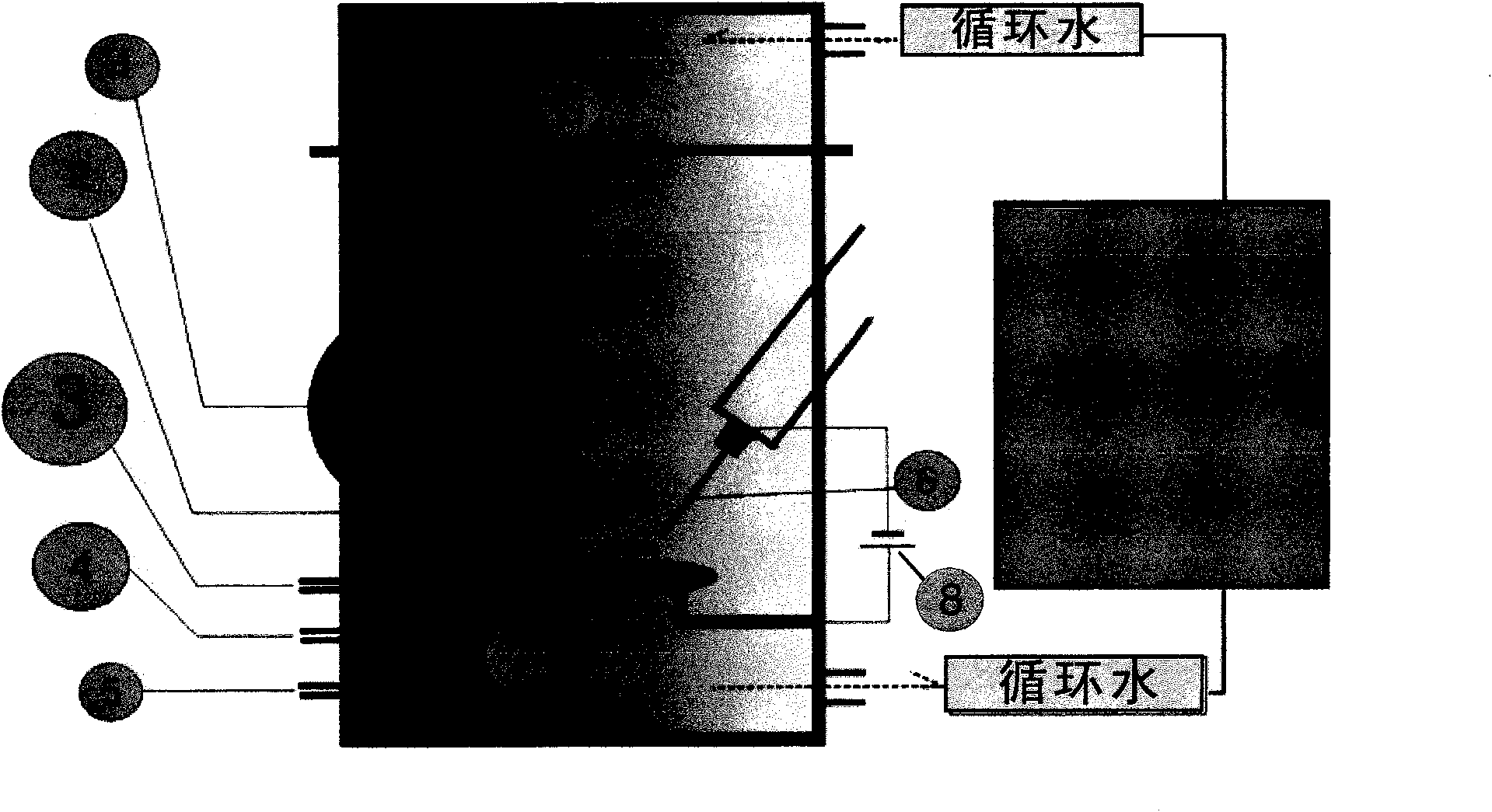

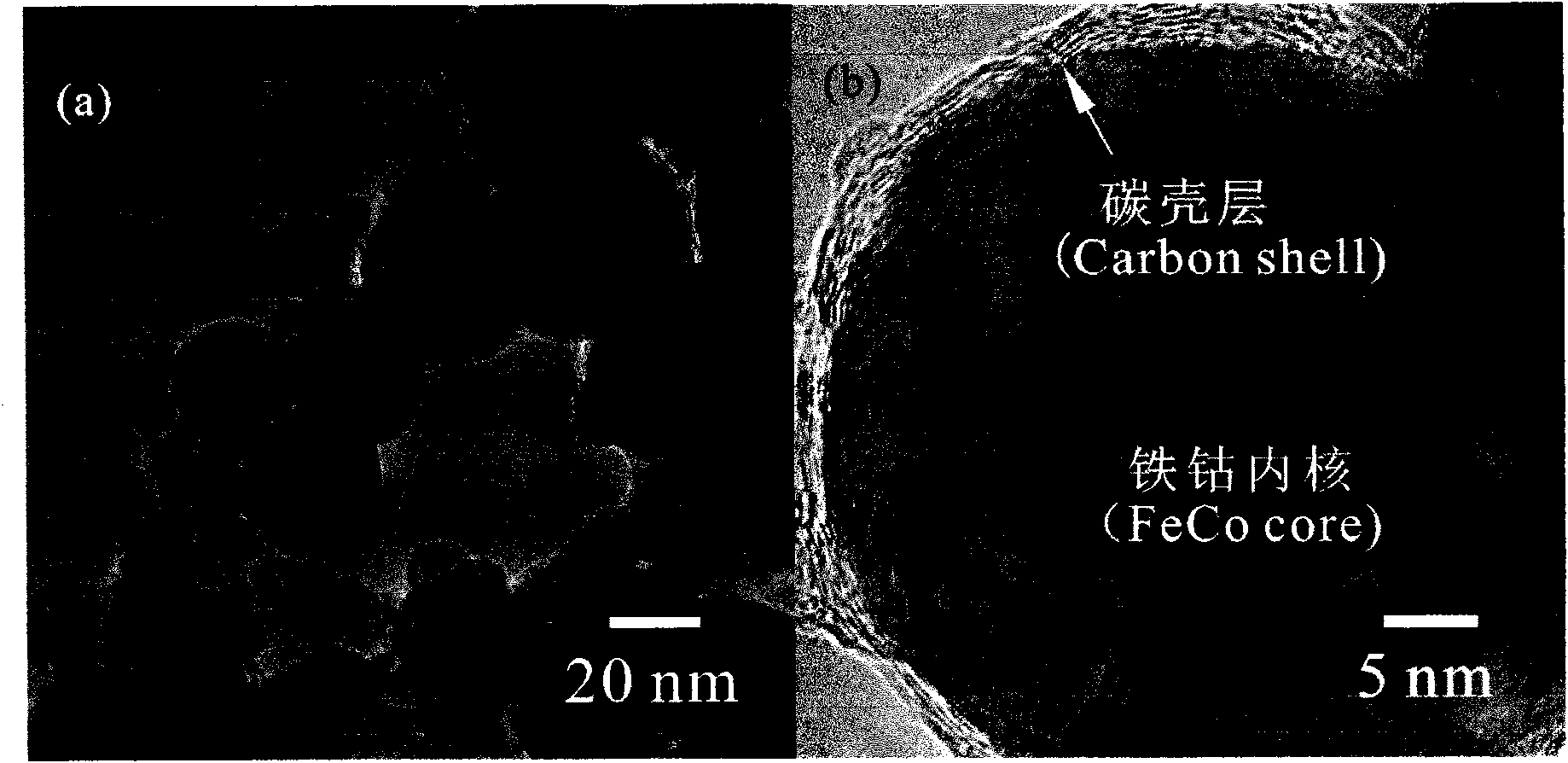

[0026] The anode target Fe 55 co 45 alloy placed in figure 1 In the shown crucible 2 (in order to avoid impurities, the crucible is made of graphite), tungsten is the cathode. Vacuum the entire system to 5 x 10 -3 After Pa, fill in argon with a pressure of 16kPa and about 30ml of absolute ethanol. After the ethanol volatilizes for one hour, pass a current of 80A, a voltage of 20V, and arc discharge for 2 hours. After melting for 8 hours, extract the argon gas, put in the air, and then open the cover to collect the powder on the wall to obtain a carbon-coated iron-cobalt nano-absorbing material with a particle size of 10-40nm, and the transmission of carbon-coated iron-cobalt nanocapsules The electron microscope looks like figure 2 Shown in (a); The enlarged picture of the nanocapsule of carbon-coated iron-cobalt figure 2 Shown in (b), wherein core is FeCo, and shell is C; The X-ray diffraction spectrum of the nanocapsule of carbon-coated iron-cobalt is as image 3 Show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com