Preparation method of sodalite zeolite membrane

A technology of zeolite membrane and sodalite, which is applied in the coating process and coating of metal materials, can solve the problems of high requirements for crystallization kettles and unfavorable treatment area of metal surfaces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

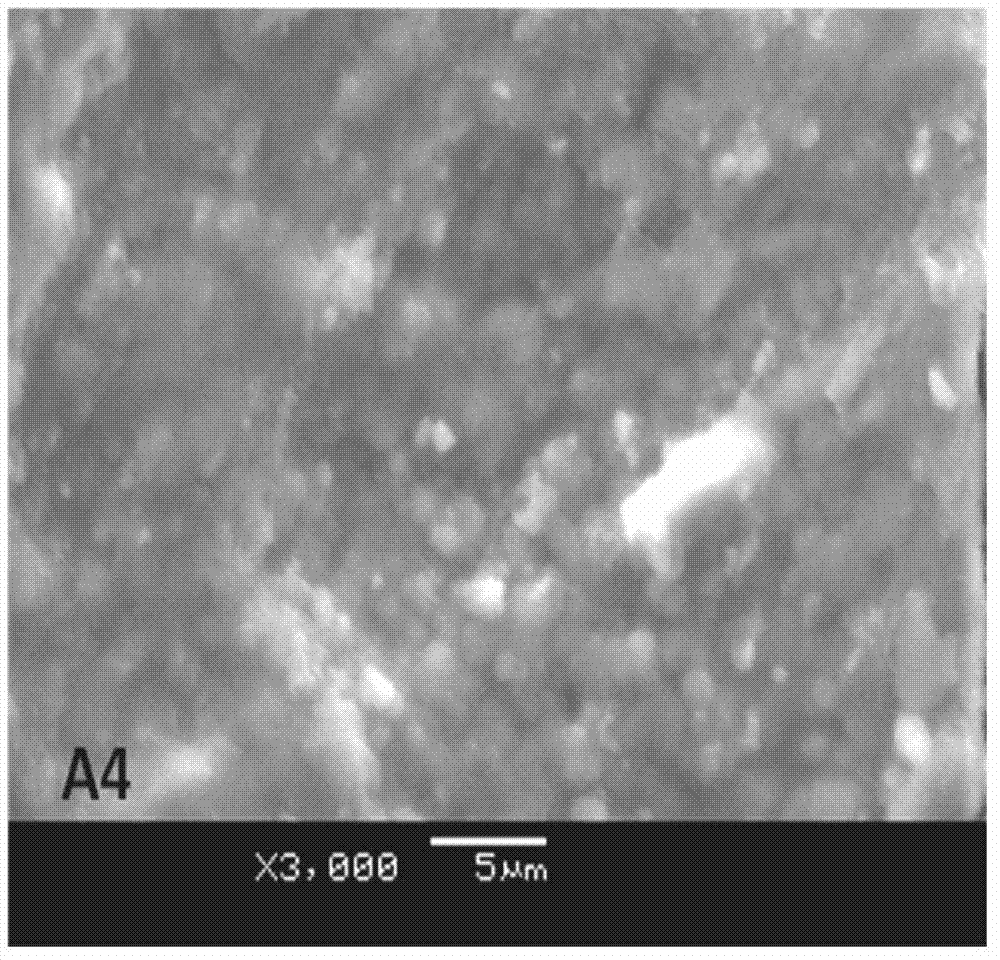

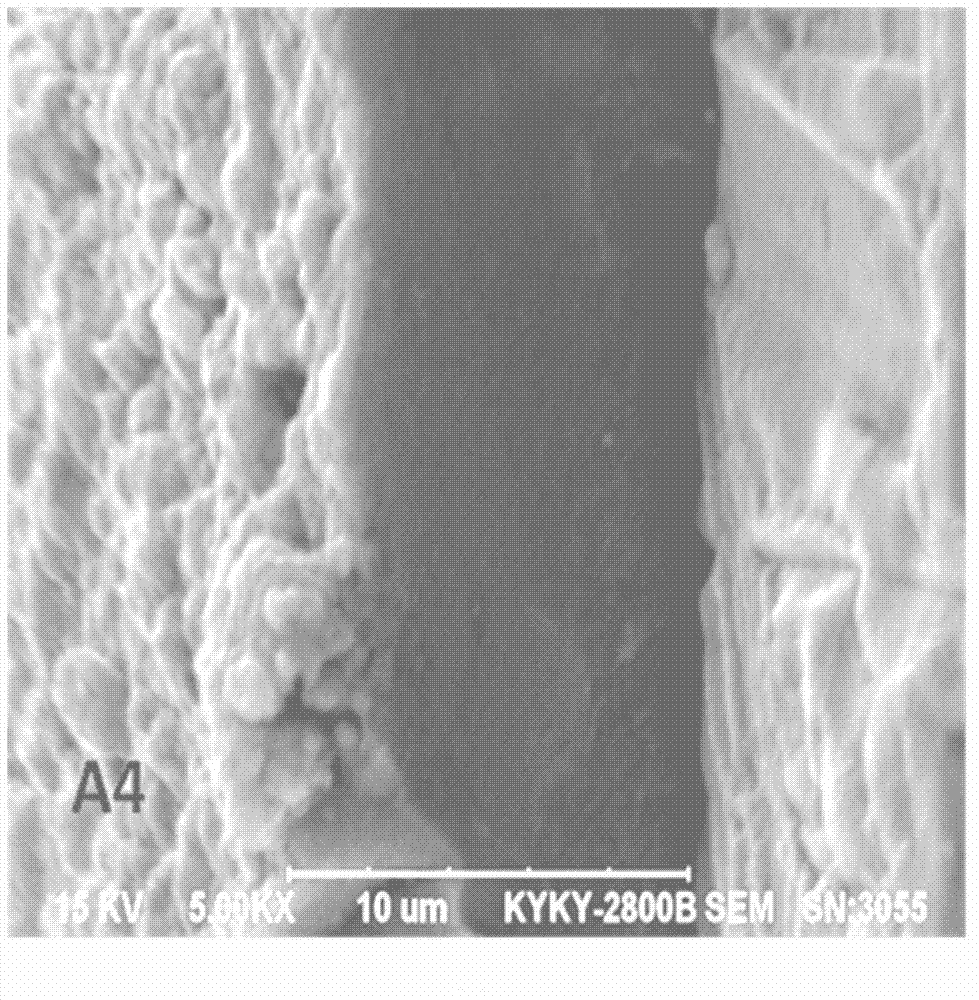

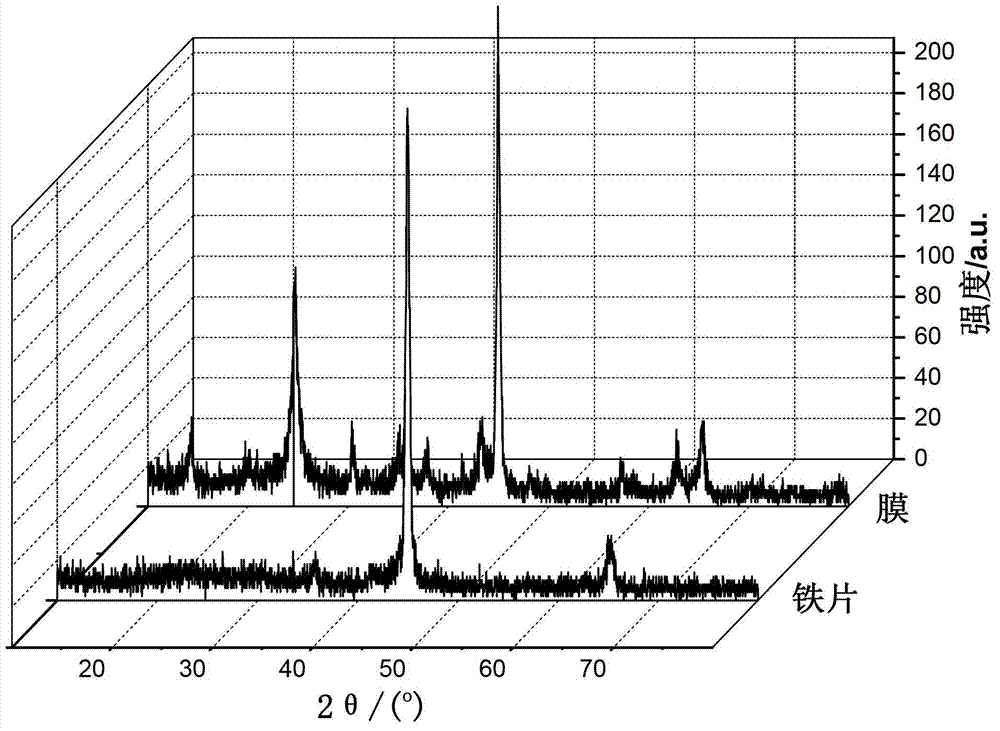

Image

Examples

Embodiment 1

[0031] Preparation of step 1 reaction precursor

[0032] Weigh 1.5g Na in a beaker 2 SiO 3 9H 2 O, 0.085gNaOH and 0.24gKOH, add 3g deionized water, stir well to make A liquid; weigh 0.695g NaAlO in another beaker 2 , add 2.7g deionized water and stir well to make liquid B; then slowly add liquid A to liquid B and stir quickly to make it evenly mixed to make silica-alumina sol; add 8g [emim] to the above silica-alumina gel Br ionic liquid (that is, liquid 1-ethyl-3-methylimidazolium bromide), and magnetically stirred for 1-2 hours to prepare the reaction precursor.

[0033] Step 2 Vector Pretreatment

[0034]Soak the cut rectangular metal substrate with a length of about 1cm-3cm and a width of about 0.5-1.5cm in 0.1mol / L hydrochloric acid for 1 hour, then rinse it with deionized water until neutral; take it out and soak it in a degreasing agent solution 0.5h, then rinse with deionized water; then use 400#, 600#, 800#, 1200# to smooth the surface of the substrate, and then ...

Embodiment 2

[0039] Preparation of step 1 reaction precursor

[0040] Weigh 1.32g Na in a beaker 2 SiO 3 9H 2 O, 0.065gNaOH and 0.184gKOH, add 2.5g deionized water, stir well to make A liquid; weigh 1g NaAlO in another beaker 2 , add 2.3g deionized water and stir well to make liquid B; then slowly add liquid A to liquid B and stir quickly to make it evenly mixed to make silica-alumina sol; add 6.365g [emim ] Br ionic liquid (that is, liquid 1-ethyl-3-methylimidazolium bromide), and magnetically stirred for 1 to 2 hours to make a reaction precursor.

[0041] Step 2 Vector Pretreatment

[0042] Soak the cut rectangular metal substrate with a length of about 1cm-3cm and a width of about 0.5-1.5cm in 0.1mol / L hydrochloric acid for 1 hour, then rinse it with deionized water until neutral; take it out and soak it in a degreasing agent solution 1h, then rinse with deionized water; then use 400#, 600#, 800#, 1200# to smooth the surface of the substrate, and then put the substrate into the ult...

Embodiment 3

[0046] Preparation of step 1 reaction precursor

[0047] Weigh 2.14g Na in a beaker 2 SiO 3 9H 2 O, 0.21gNaOH and 0.378gKOH, add 5.2g deionized water, stir well to make A liquid; weigh 1.236g NaAlO in another beaker 2 , add 4.3g deionized water and stir well to make liquid B; then slowly add liquid A to liquid B and stir quickly to make it evenly mixed to make silica-alumina sol; add 14.4g [emim ] Br ionic liquid (that is, liquid 1-ethyl-3-methylimidazolium bromide), and stirred for 1 to 2 hours to make the reaction precursor.

[0048] Step 2 Vector Pretreatment

[0049] Soak the cut rectangular metal substrate with a length of about 1cm-3cm and a width of about 0.5-1.5cm in 0.1mol / L hydrochloric acid for 1 hour, then rinse it with deionized water until neutral; take it out and soak it in a degreasing agent solution 0.5h, then rinse with deionized water; then use 400#, 600#, 800#, 1200# to smooth the surface of the substrate, and then put the substrate into the ultrasonic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com