Asphalt mixture for improving microwave absorption efficiency and preparation method thereof

An asphalt mixture and microwave absorption technology, which is applied in the field of road engineering materials, can solve the problems of difficult to guarantee the safety and reliability of high-power microwave maintenance devices, unreasonable microwave heating, and low efficiency of road maintenance, so as to improve electromagnetic parameters And electrothermal performance, improve regenerative heating effect, good effect of microwave heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

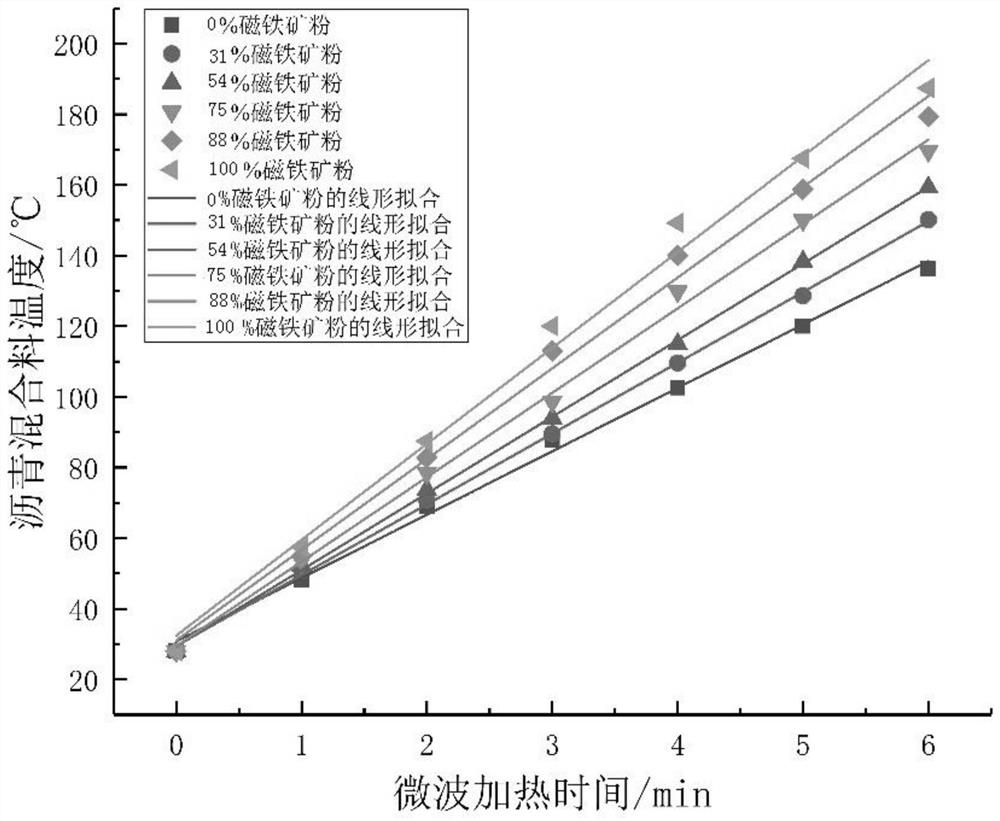

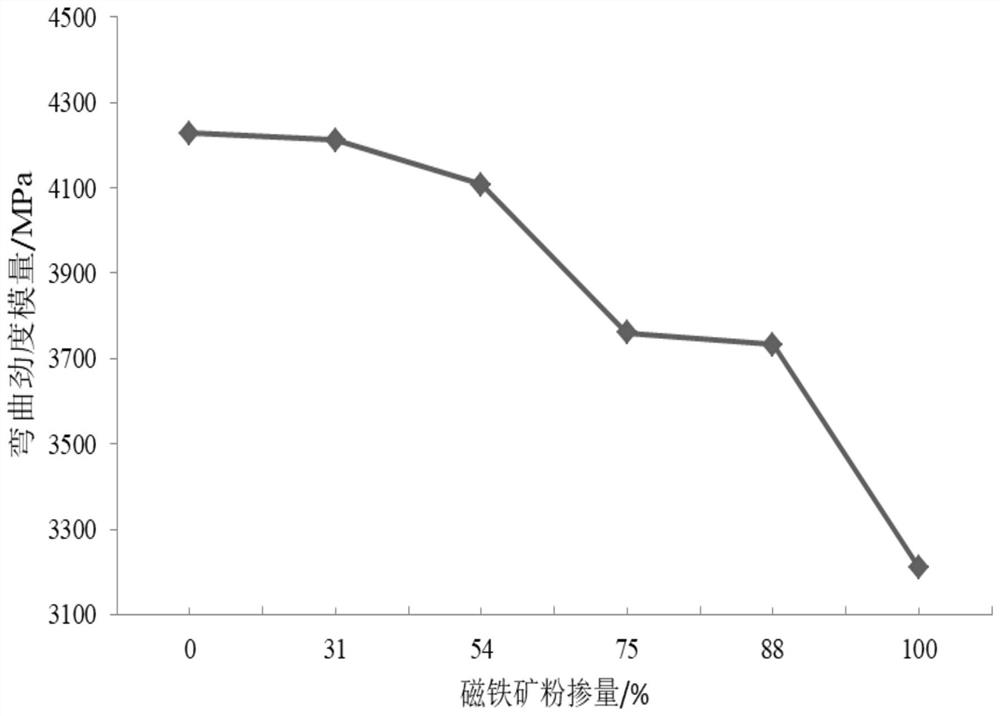

[0030] The asphalt mixture for improving microwave absorption efficiency in this embodiment is composed of the following raw materials in percentage by weight: 15% of asphalt filler mixed with magnetite powder, 5% of asphalt cement, 60% of basalt coarse aggregate, and 20% of basalt fine aggregate; Wherein, the asphalt filler mixed with magnetite powder is formed by mixing magnetite powder and common limestone powder, and the weight of the magnetite powder accounts for 31% of the total weight of the asphalt filler mixed with magnetite powder.

[0031] In this embodiment, the basalt coarse aggregate and basalt fine aggregate are collectively referred to as basalt aggregate, and the particle diameters of the basalt coarse aggregate are 2.36mm, 4.75mm, 9.5mm and 13.2mm, and the particle diameter is 2.36 mm. The weight of basalt coarse aggregate of mm accounts for 17% of the total weight of basalt aggregate, the weight of basalt coarse aggregate with a particle size of 4.75mm accoun...

Embodiment 2

[0043] The present embodiment improves the asphalt mixture of microwave absorption efficiency, is made up of the raw material of following percentage by weight: 8% of asphalt filler doped with magnetite powder, 4% of asphalt cement, 48% of basalt coarse aggregate, 40% of basalt fine aggregate; Wherein, the asphalt filler mixed with magnetite powder is formed by mixing magnetite powder and common limestone powder, and the weight of the magnetite powder accounts for 54% of the total weight of the asphalt filler mixed with magnetite powder.

[0044] In this embodiment, the basalt coarse aggregate and basalt fine aggregate are collectively referred to as basalt aggregate, and the particle diameters of the basalt coarse aggregate are 2.36mm, 4.75mm, 9.5mm and 13.2mm, and the particle diameter is 2.36 mm. The weight of basalt coarse aggregate of mm accounts for 14% of the total weight of basalt aggregate, the weight of basalt coarse aggregate with a particle size of 4.75mm accounts f...

Embodiment 3

[0056] The asphalt mixture for improving microwave absorption efficiency in this embodiment is composed of the following raw materials in weight percentage: 12% of asphalt filler mixed with magnetite powder, 5% of asphalt cement, 50% of basalt coarse aggregate, and 33% of basalt fine aggregate; Wherein, the asphalt filler mixed with magnetite powder is formed by mixing magnetite powder and ordinary limestone powder, and the weight of the magnetite powder accounts for 75% of the total weight of the asphalt filler mixed with magnetite powder.

[0057] In this embodiment, the basalt coarse aggregate and basalt fine aggregate are collectively referred to as basalt aggregate, and the particle diameters of the basalt coarse aggregate are 2.36mm, 4.75mm, 9.5mm and 13.2mm, and the particle diameter is 2.36 mm. The weight of basalt coarse aggregate of mm accounts for 15% of the total weight of basalt aggregate, the weight of basalt coarse aggregate with a particle size of 4.75mm account...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com