Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

466 results about "Electromagnetic wave interference" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

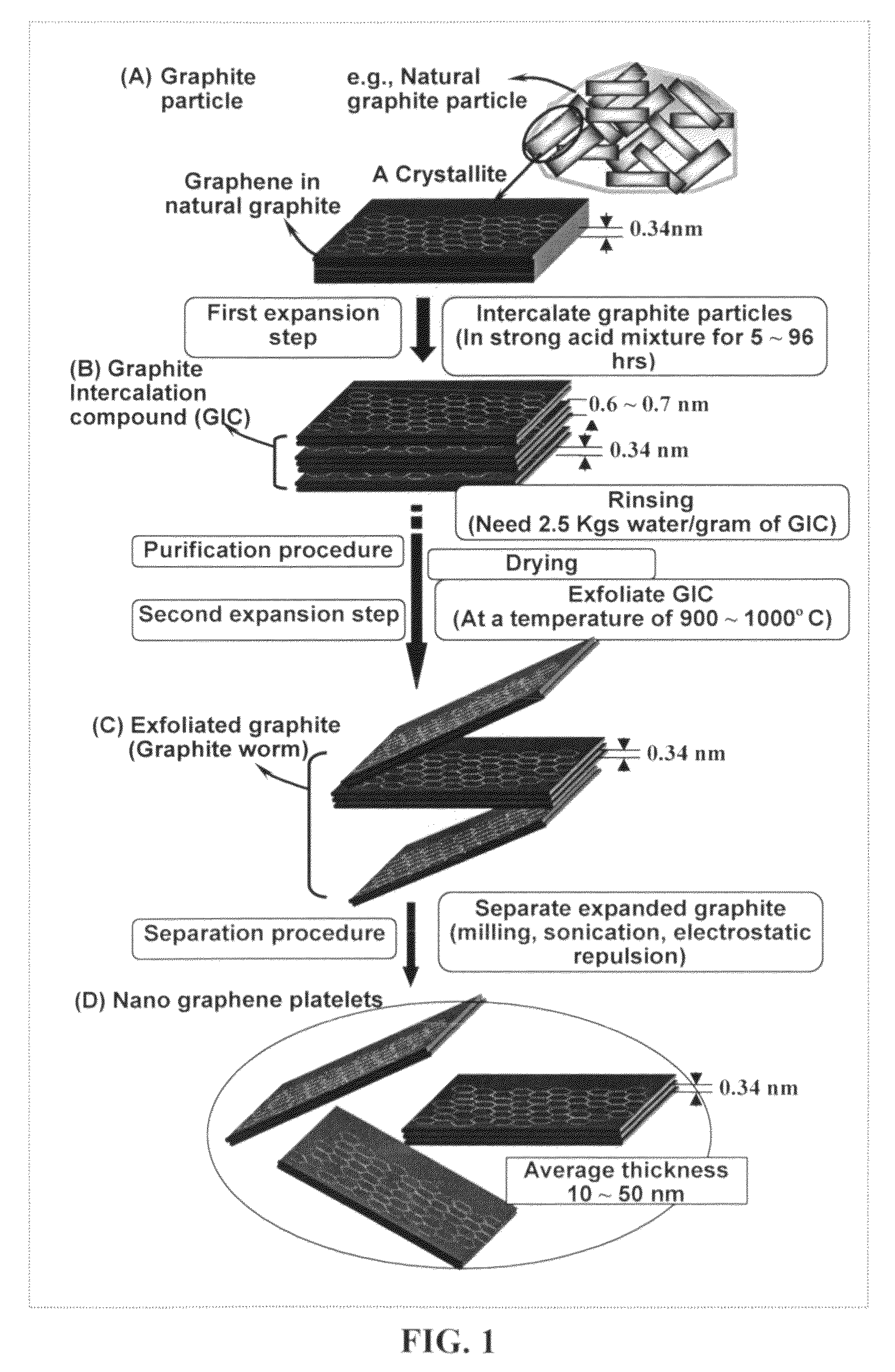

Process for producing dispersible Nano Graphene Platelets from oxidized graphite

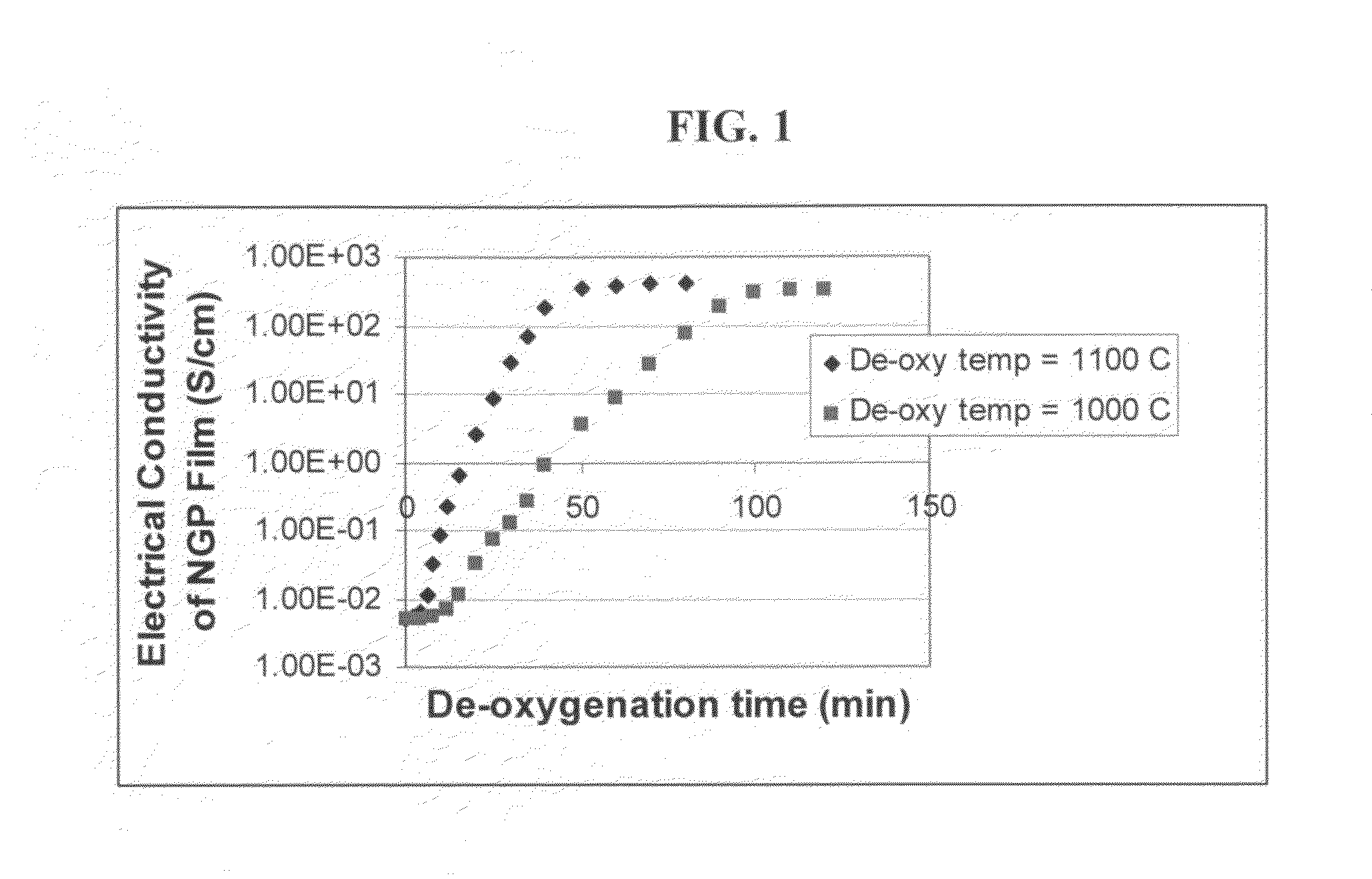

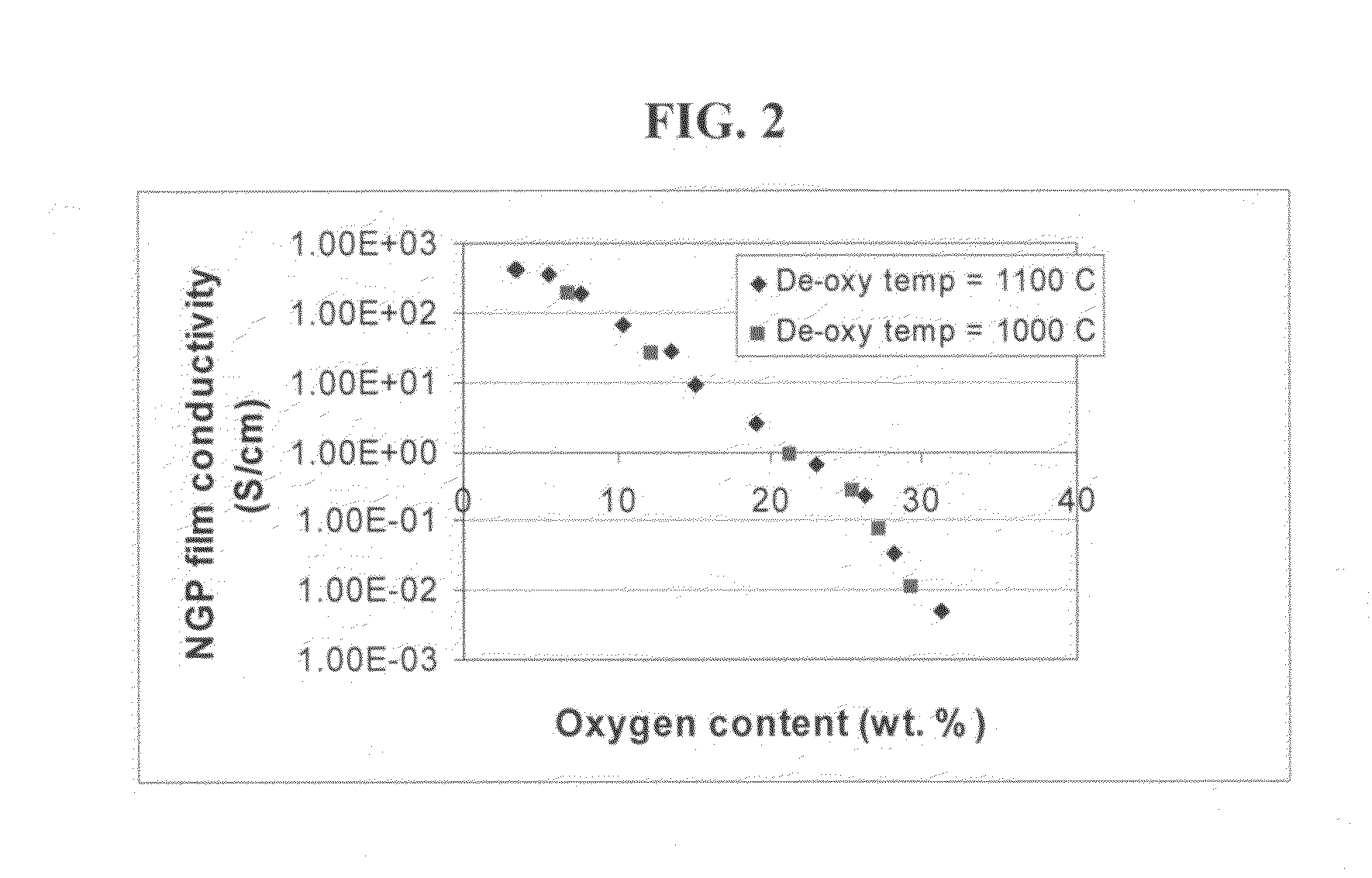

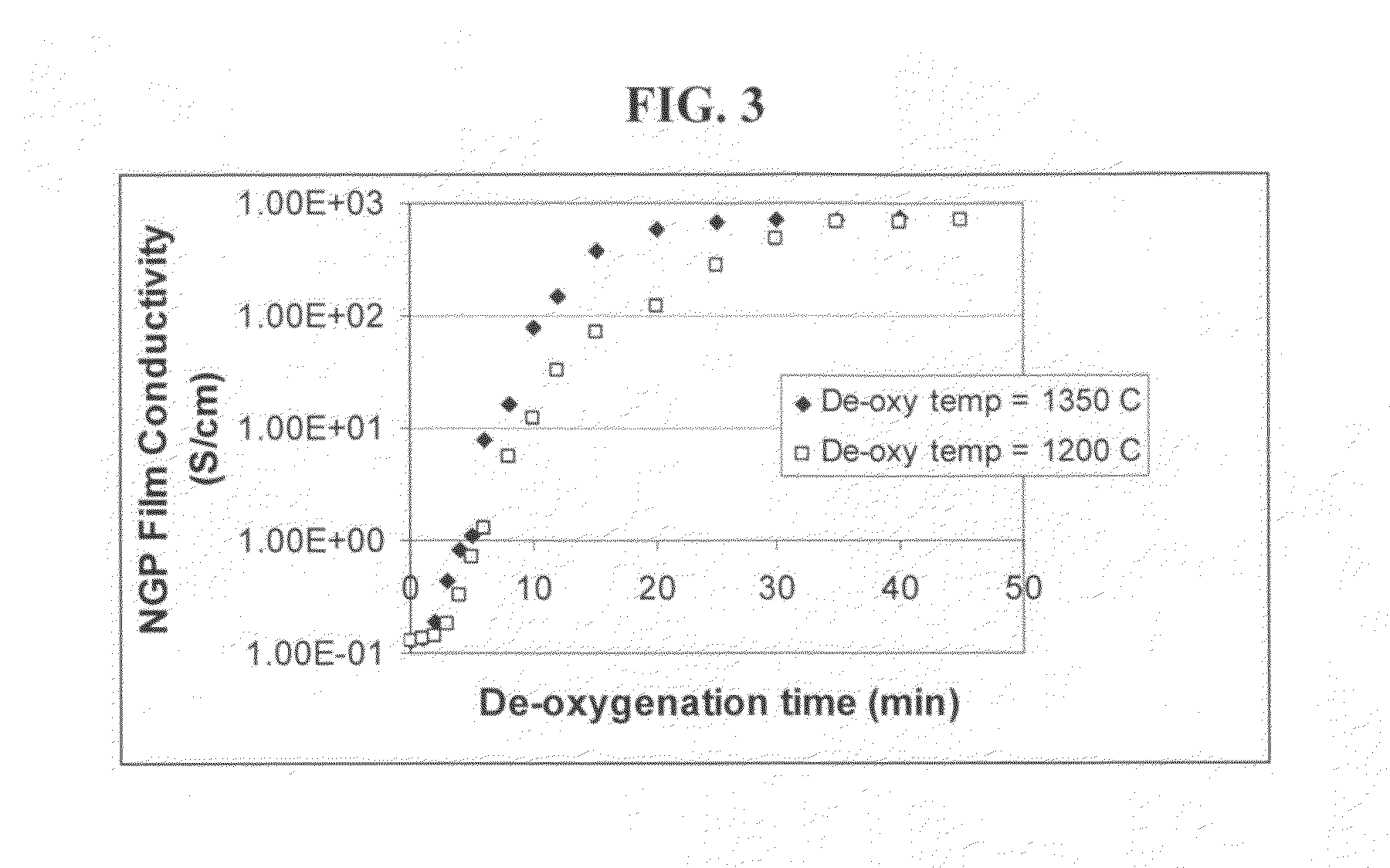

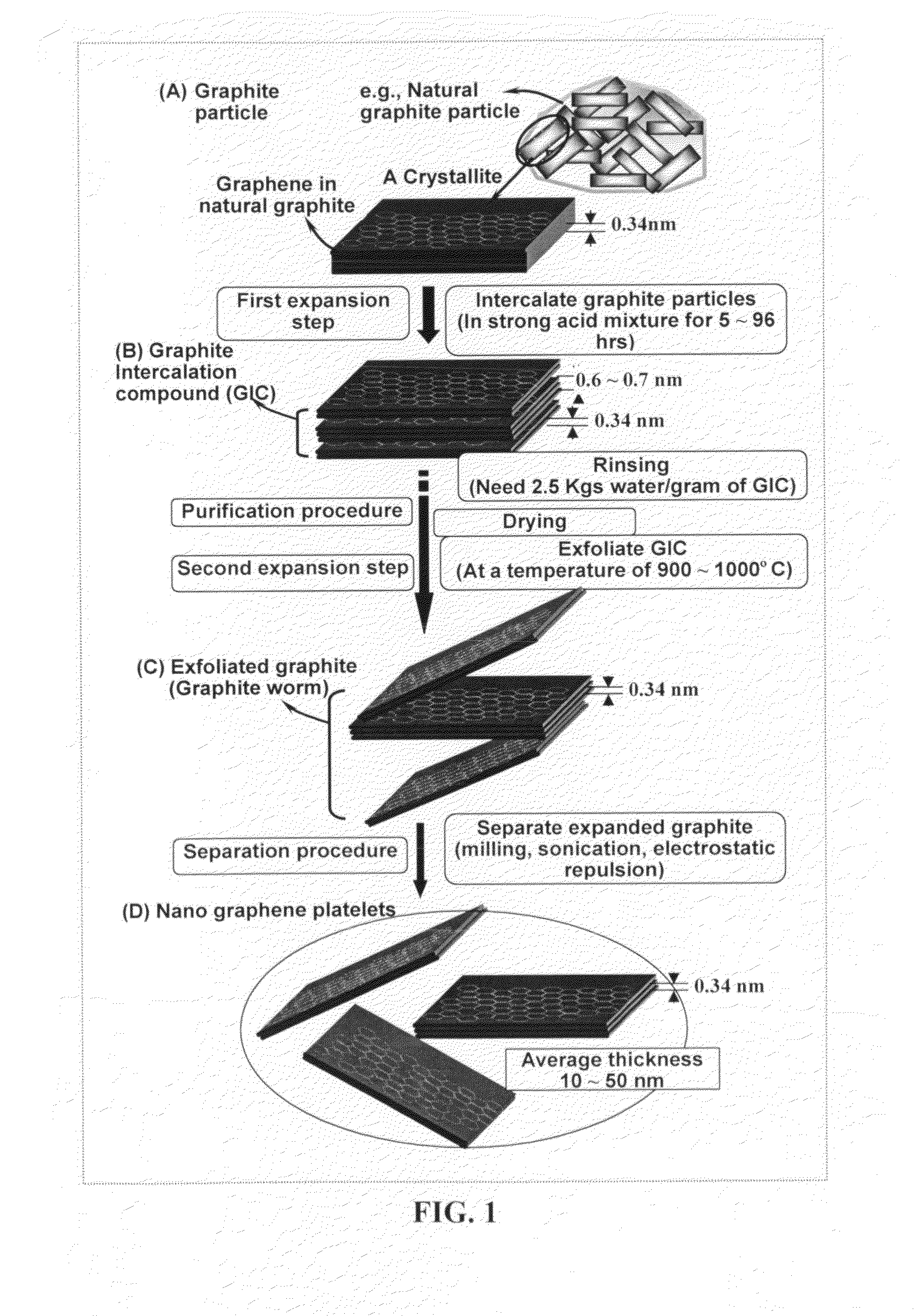

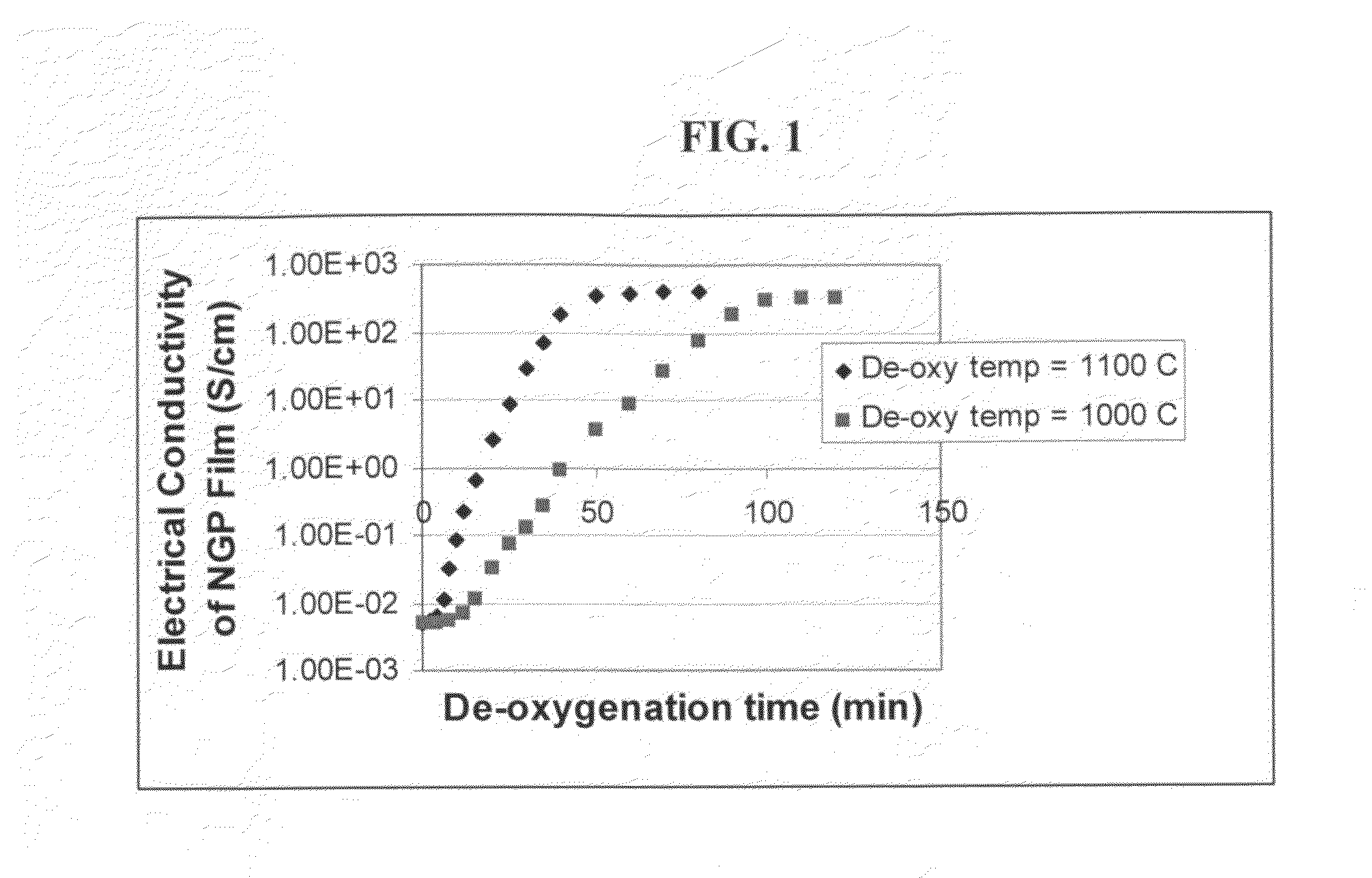

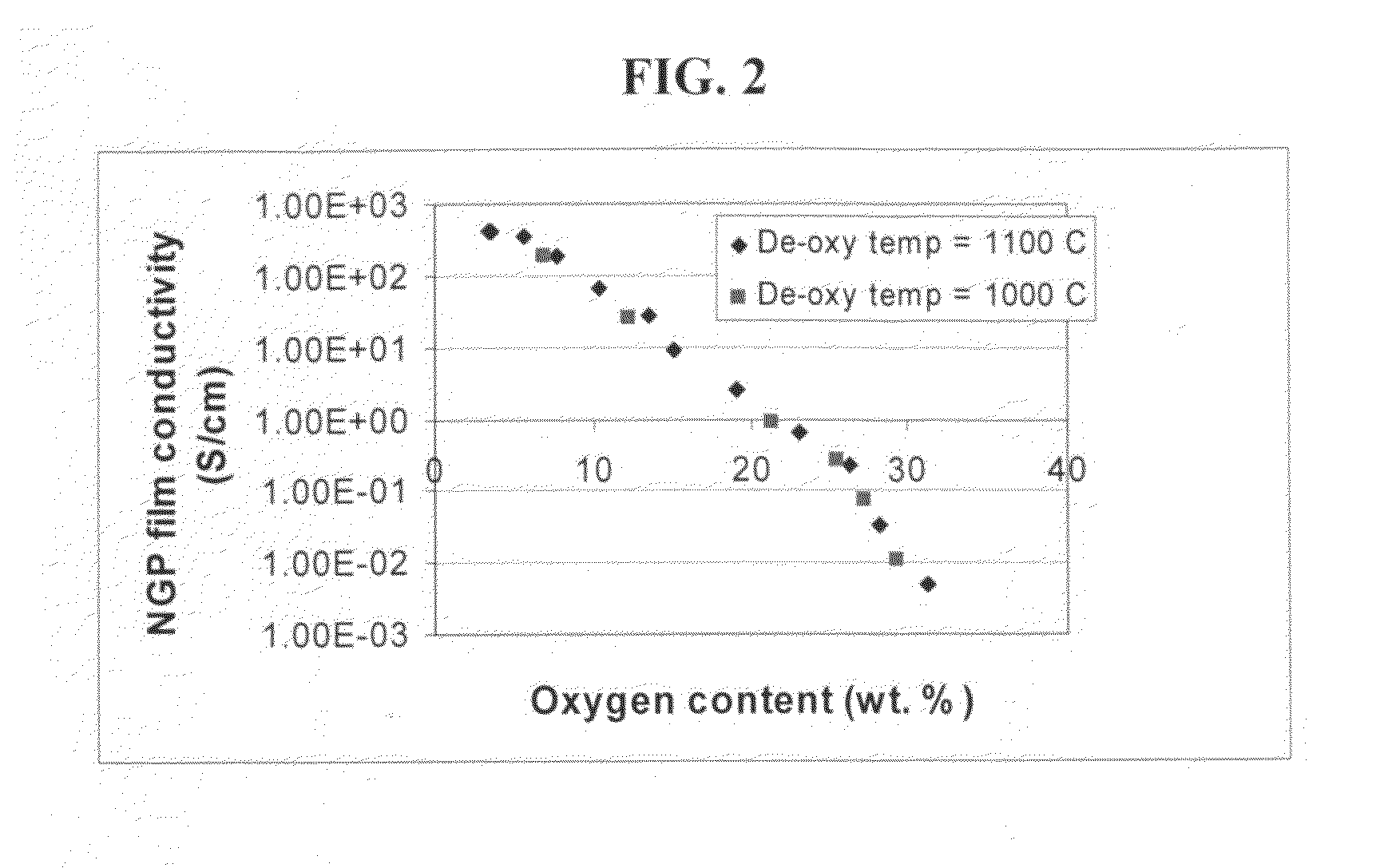

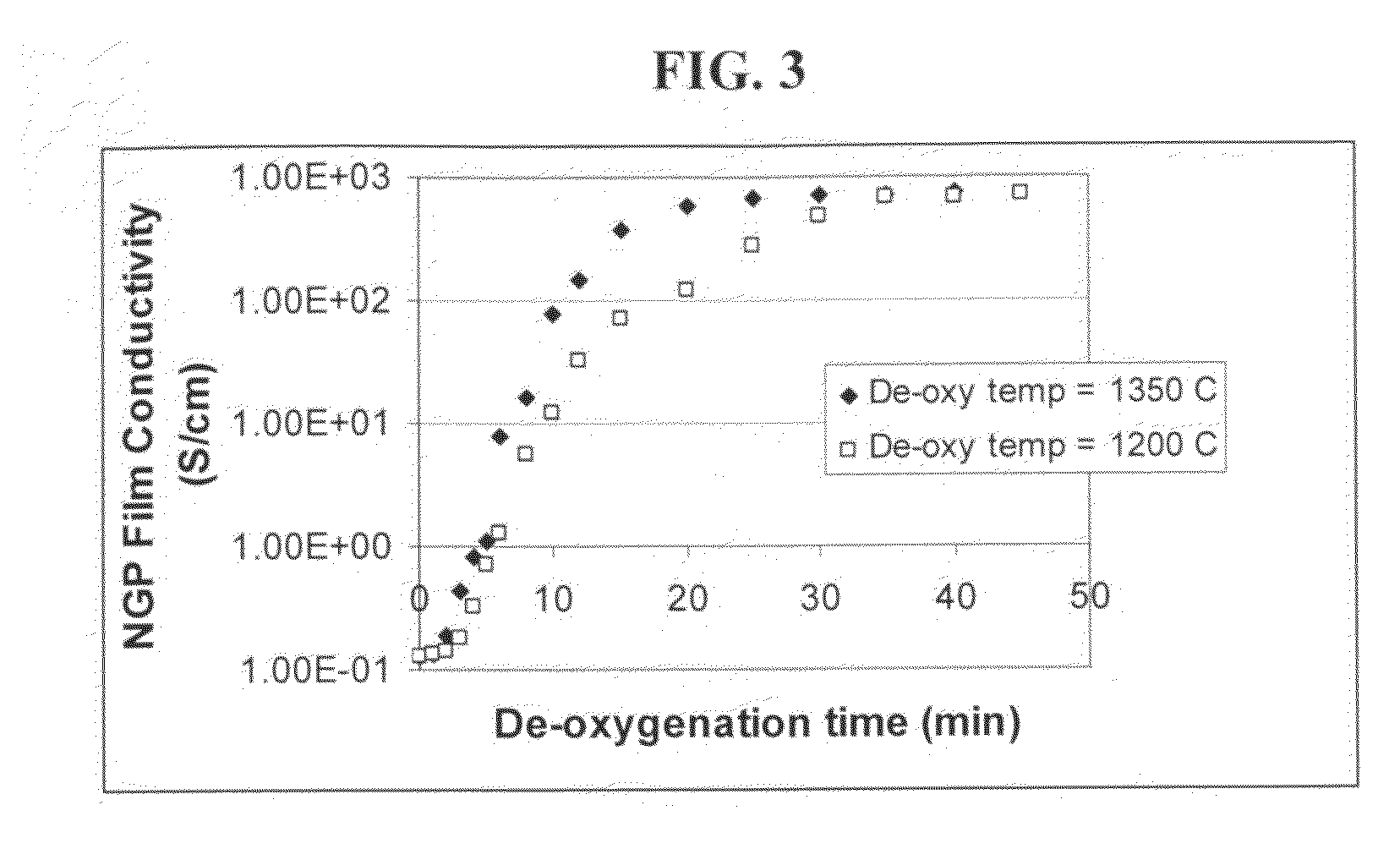

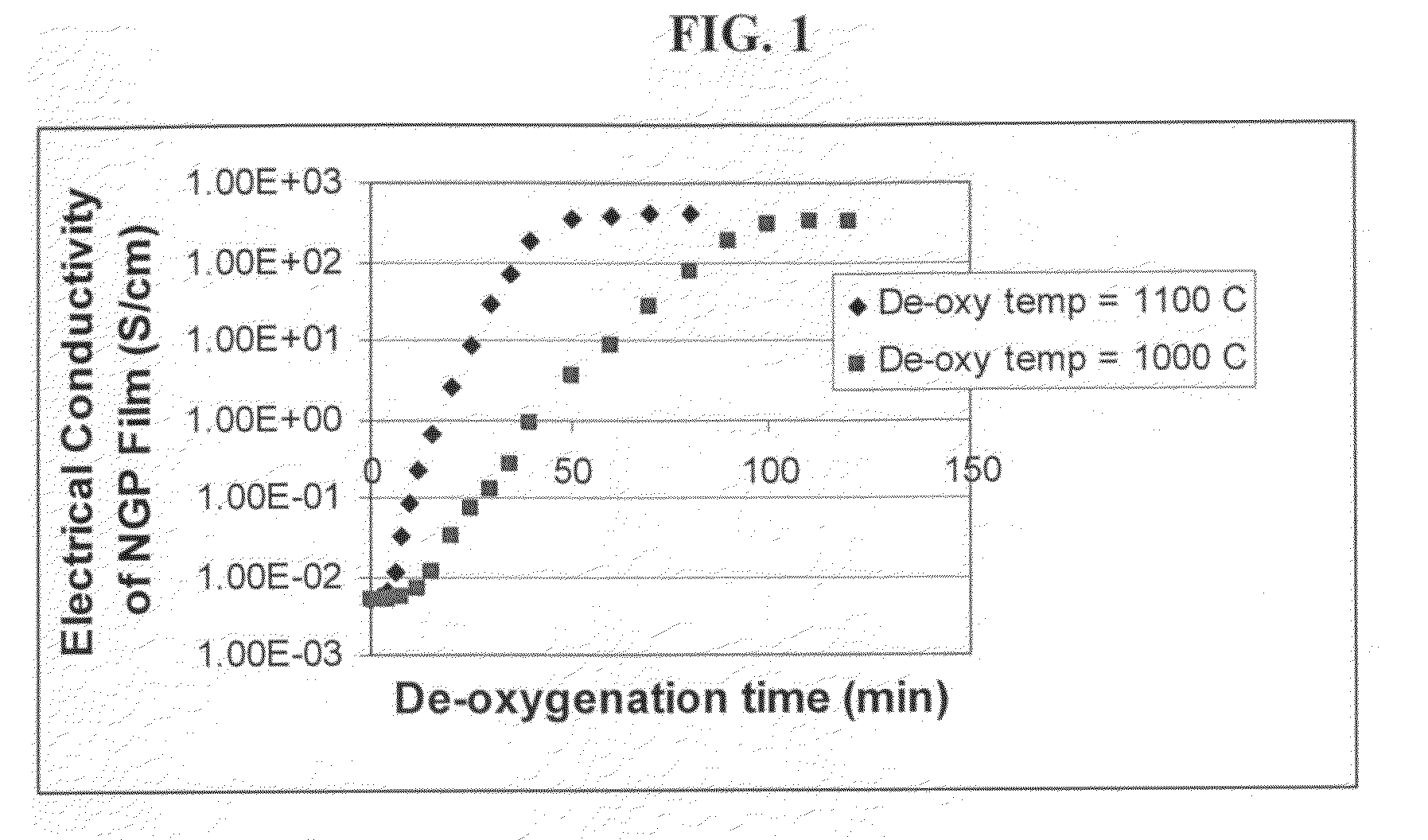

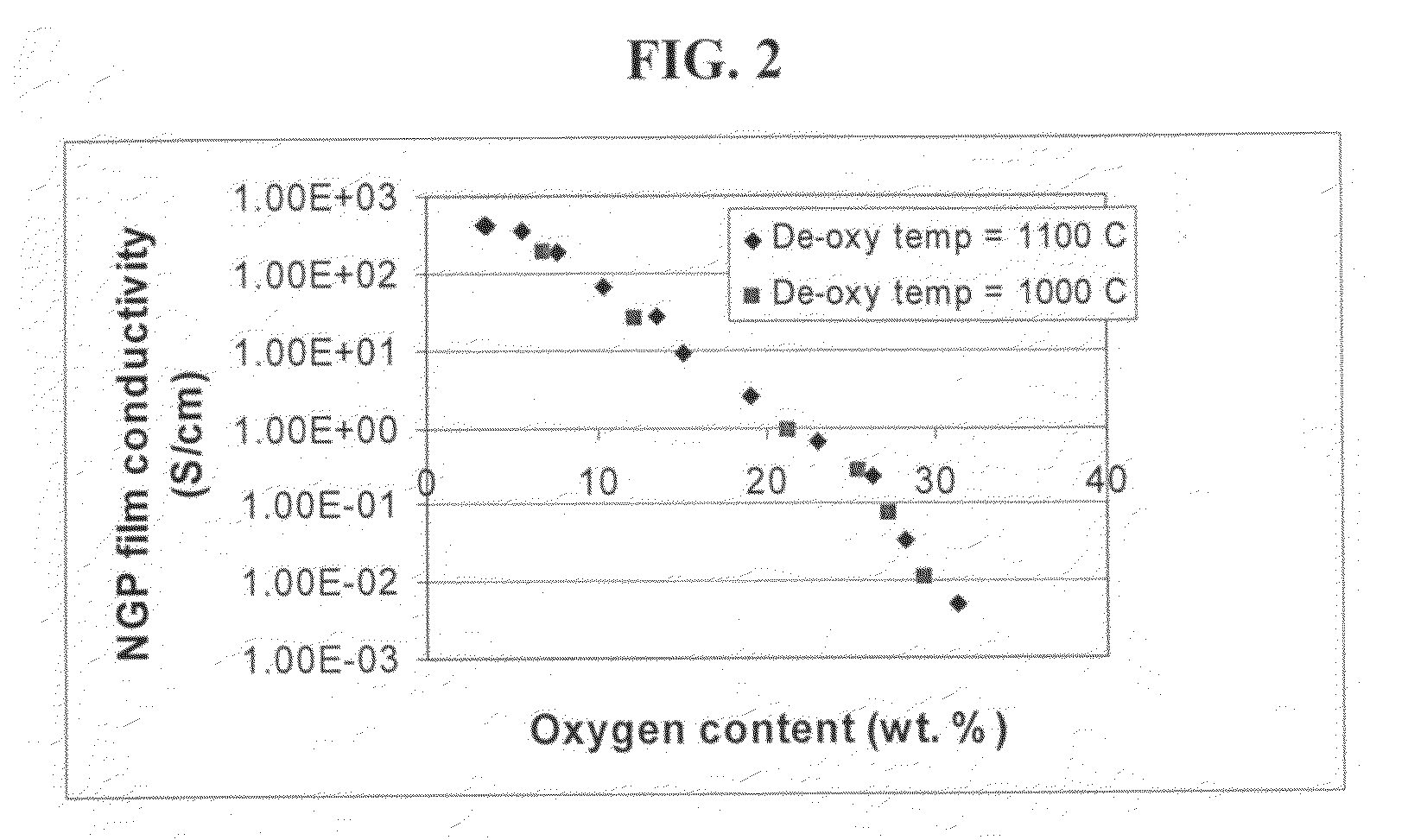

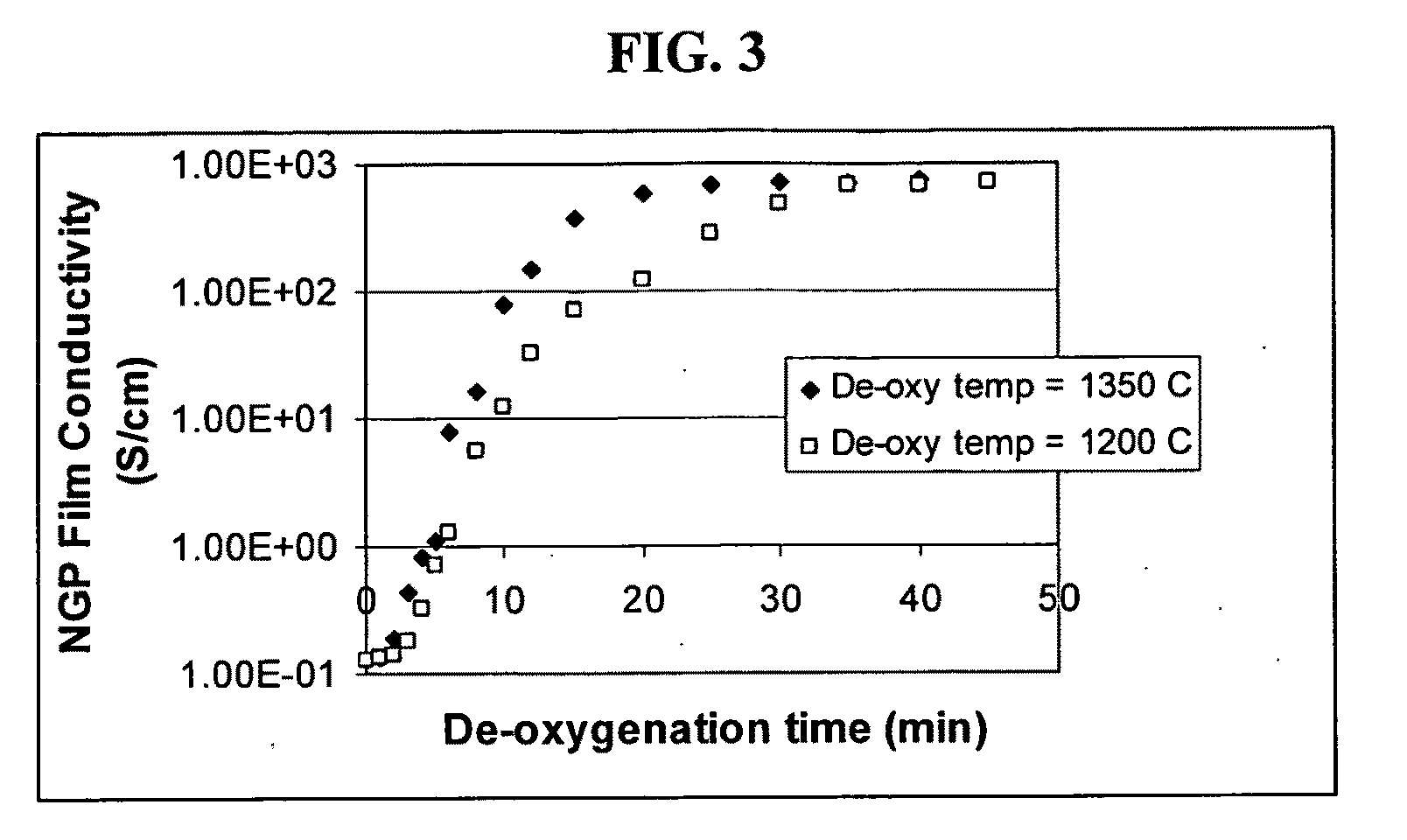

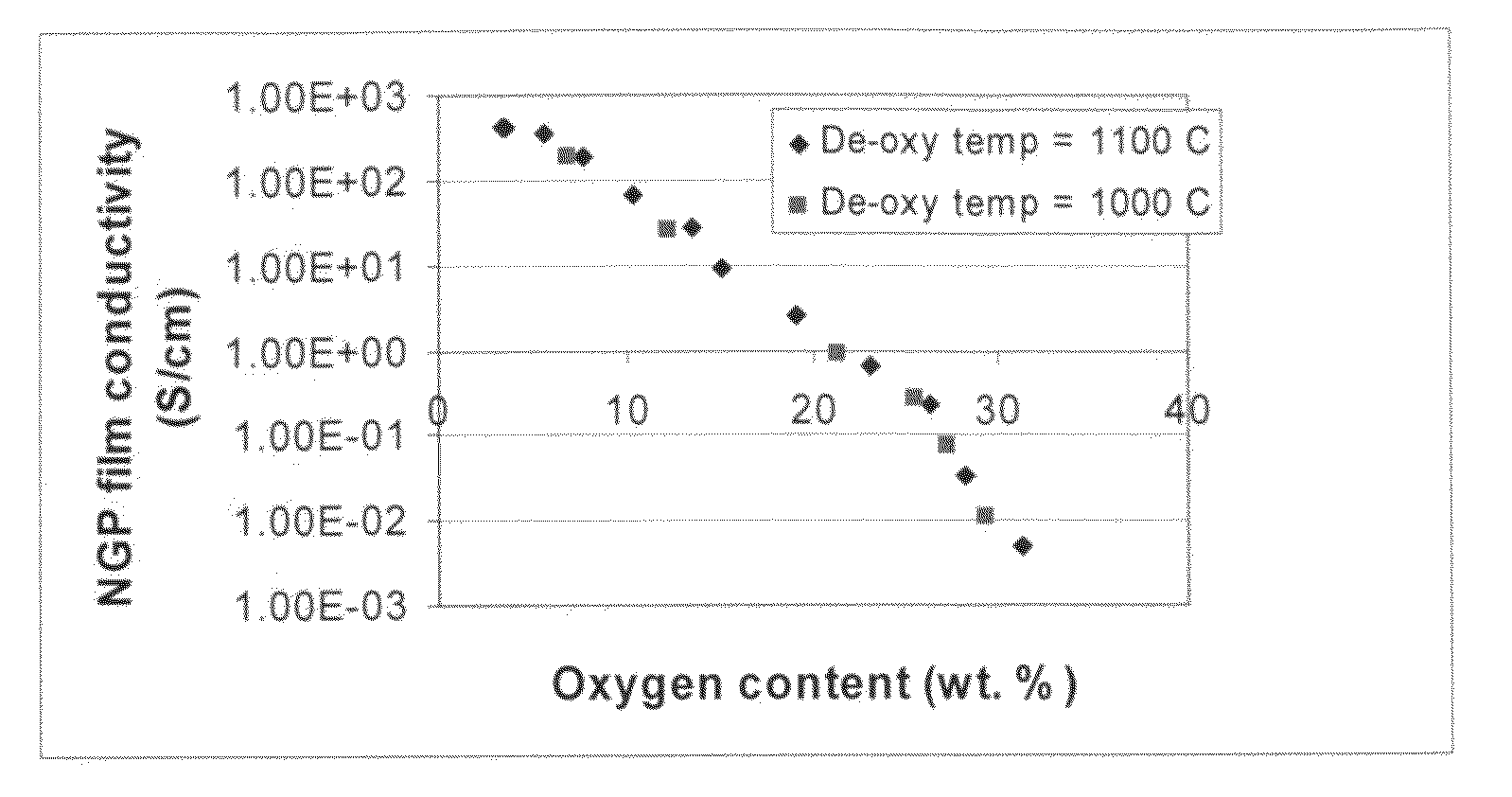

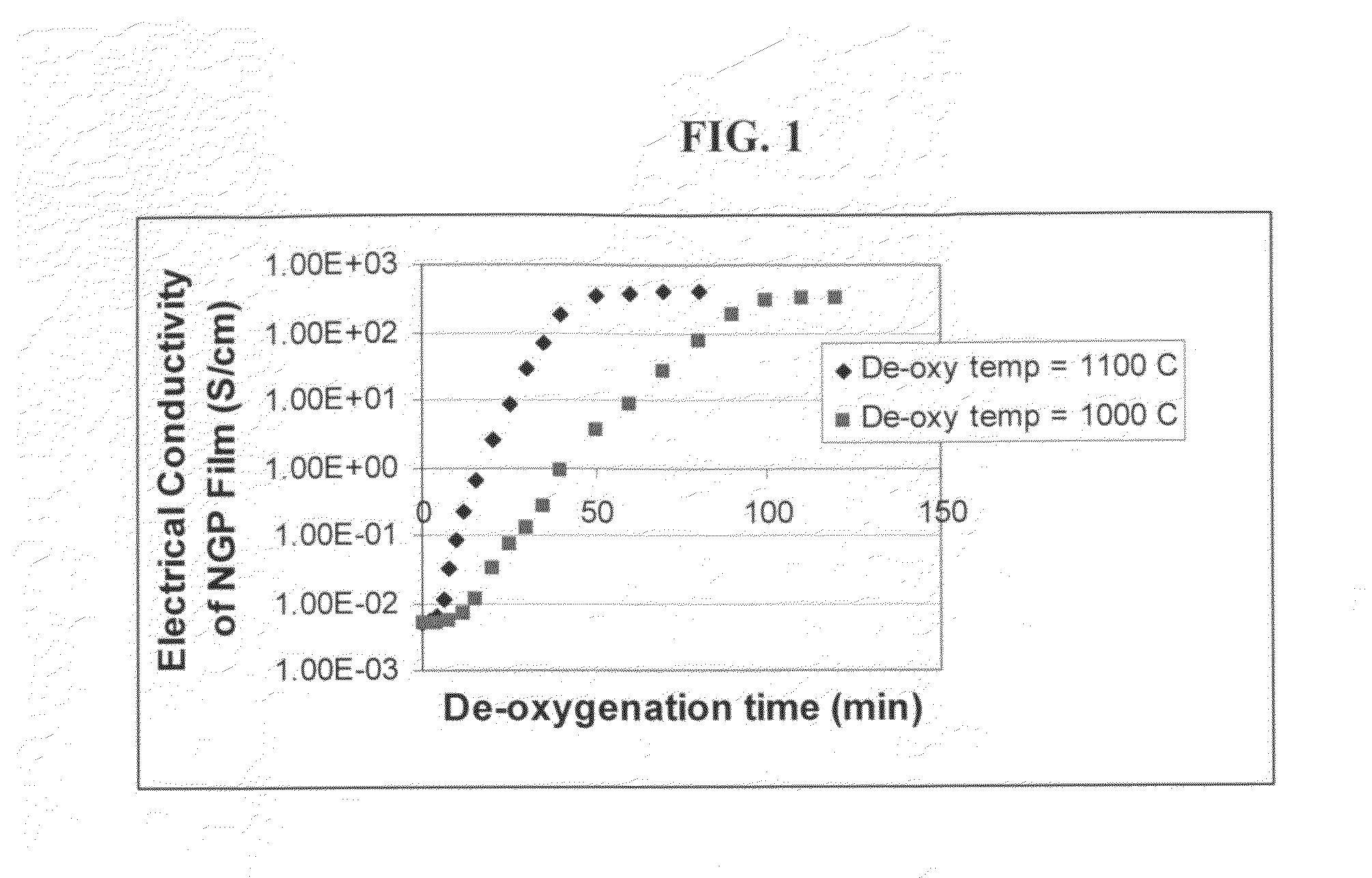

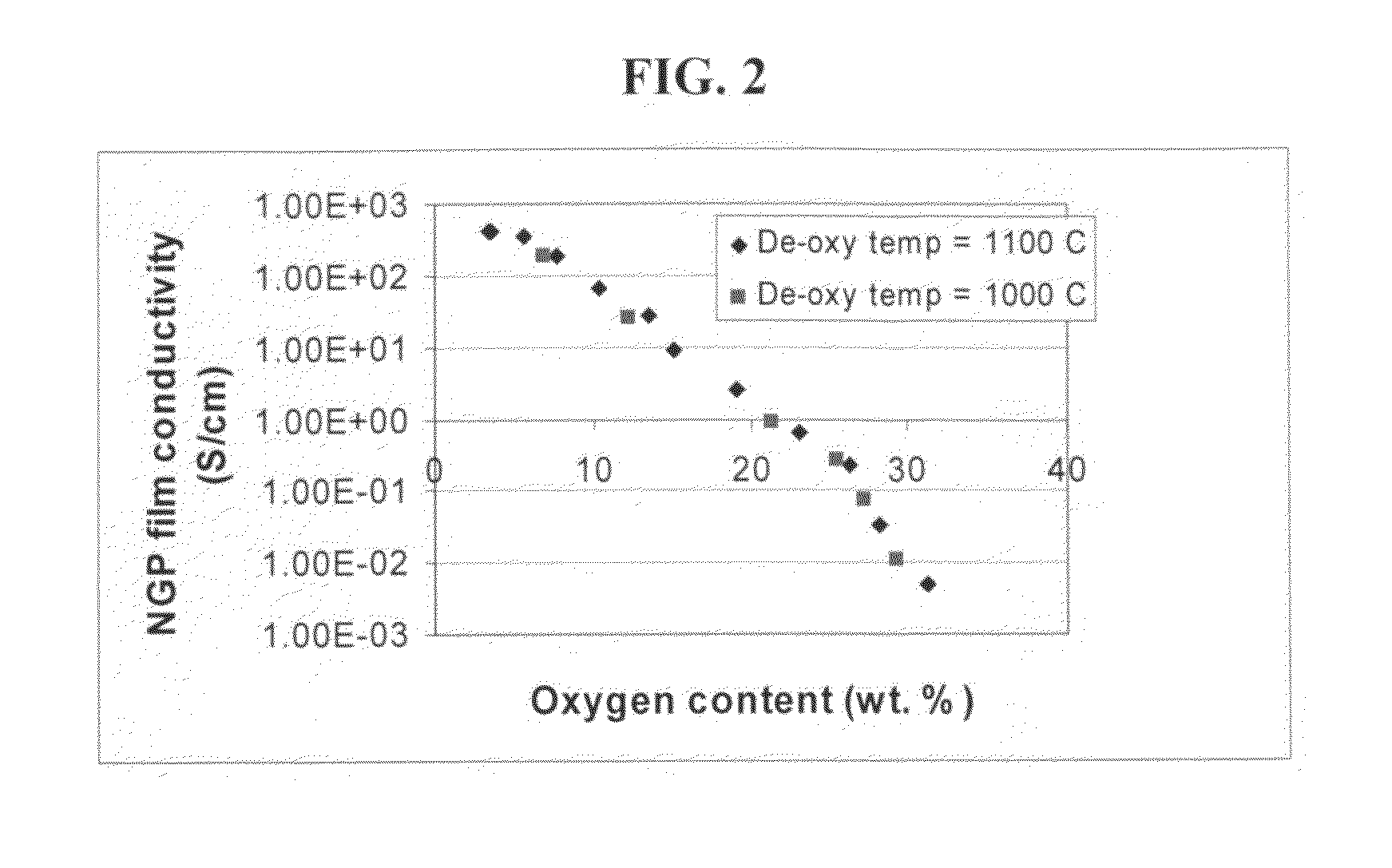

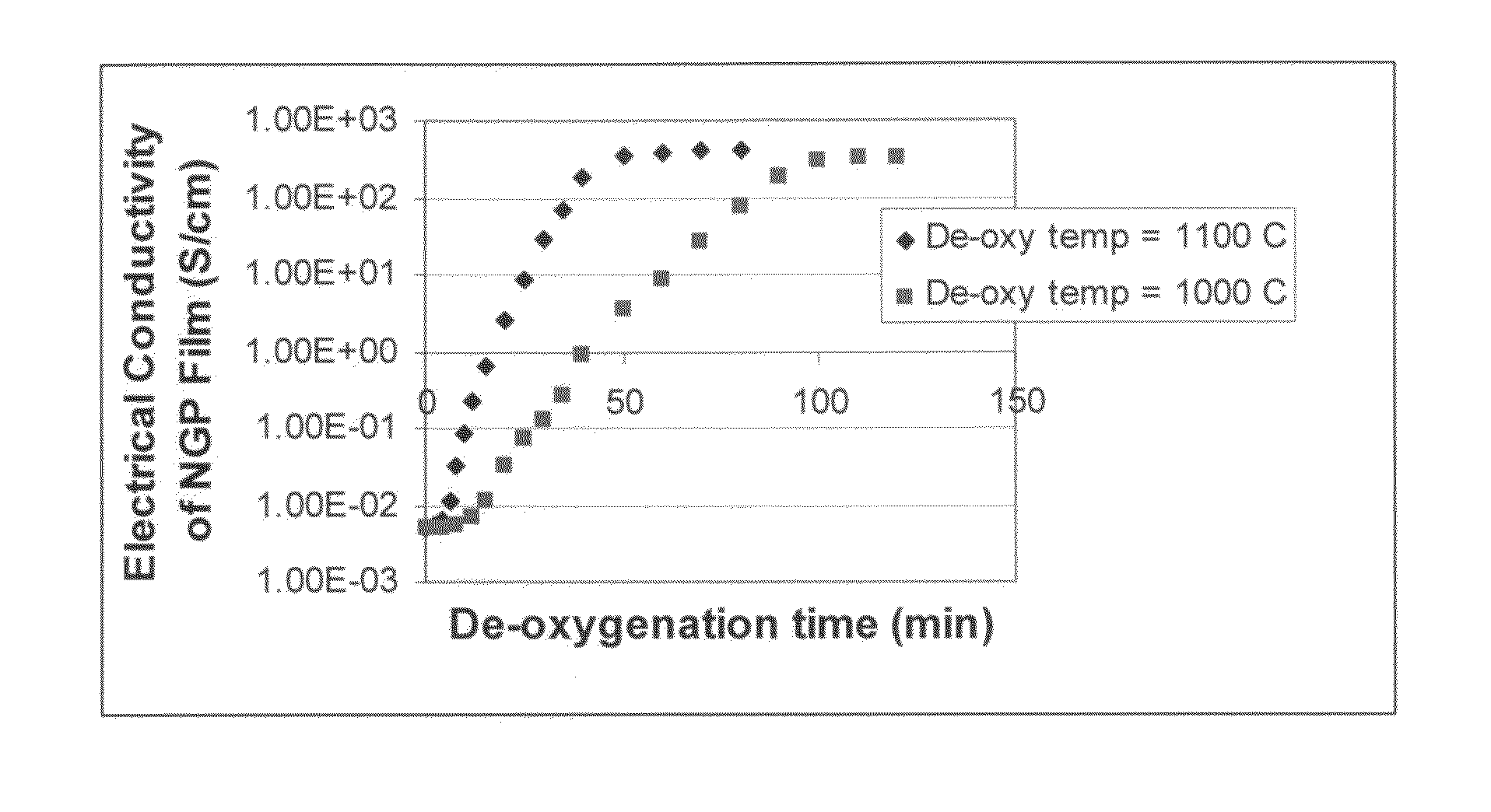

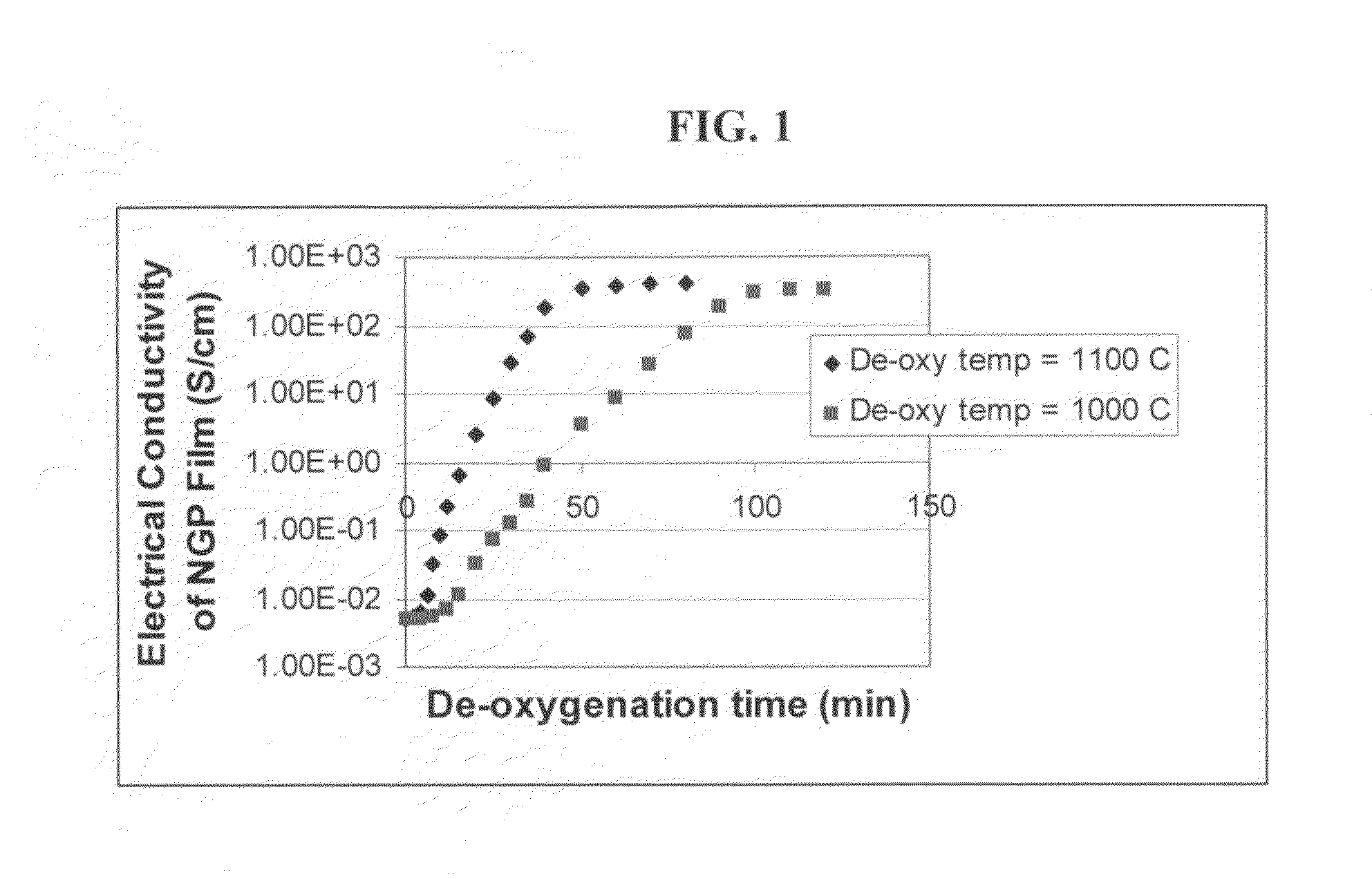

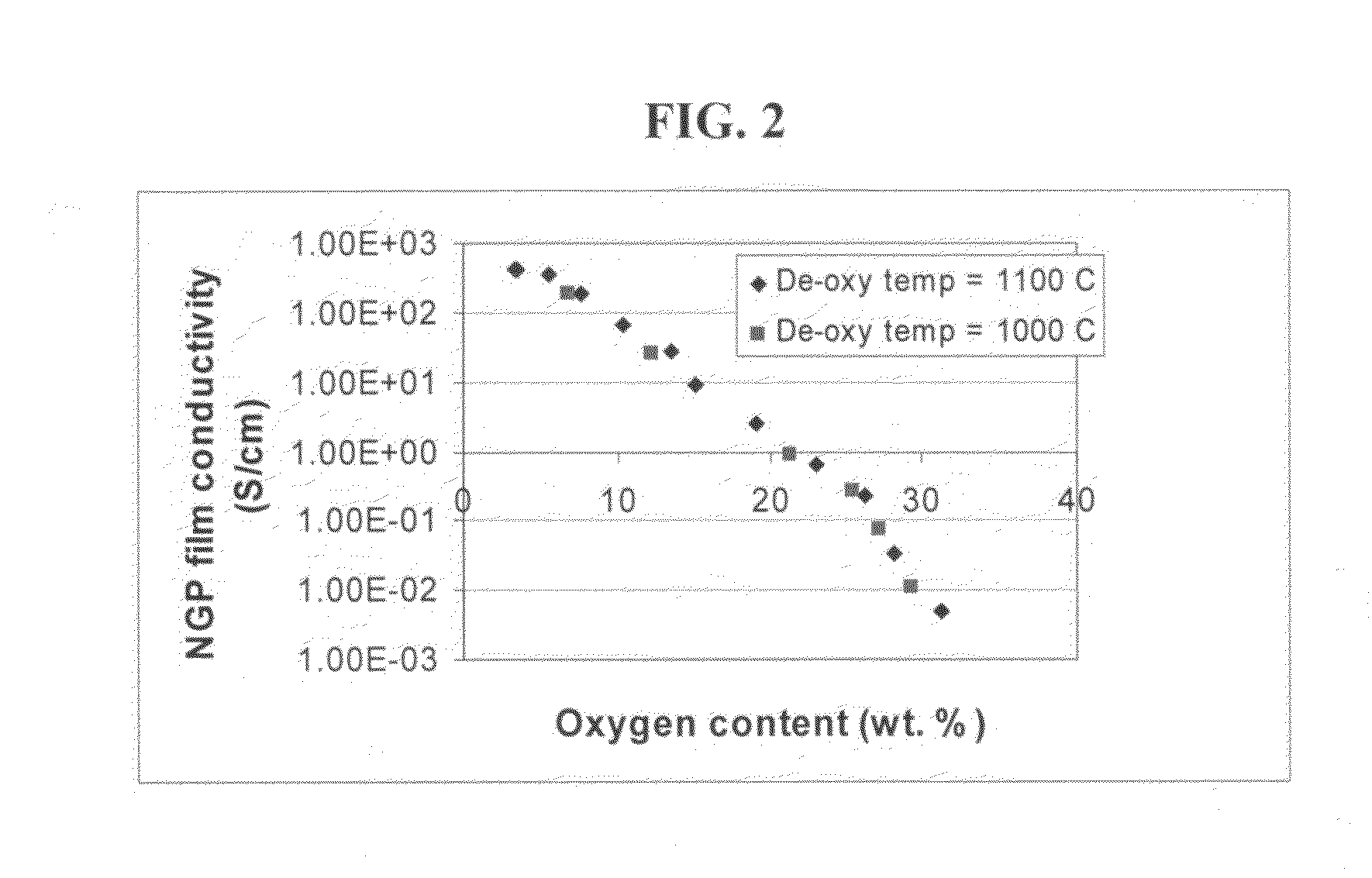

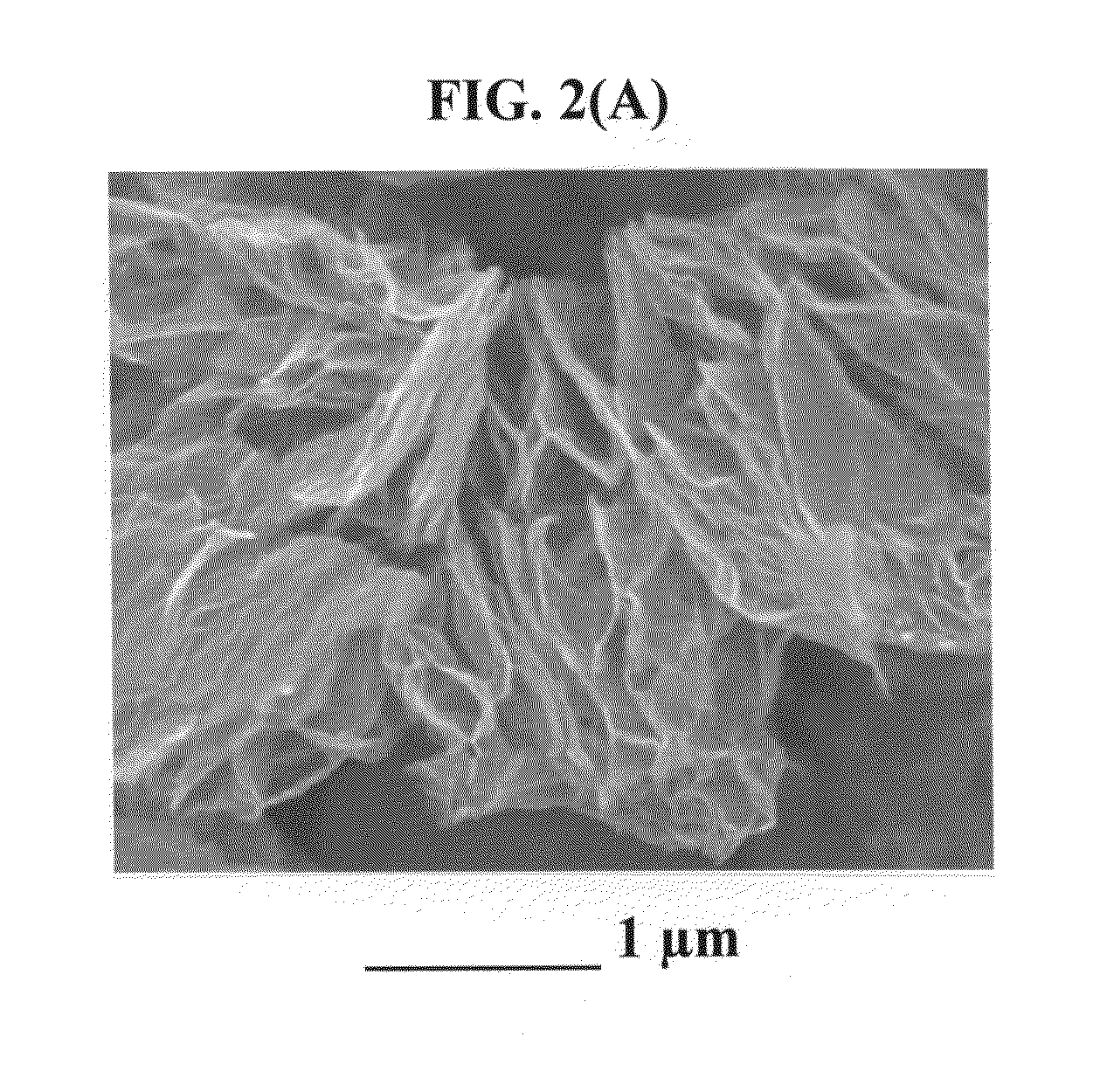

The present invention provides a process for producing nano graphene platelets (NGPs) that are dispersible and conducting. The process comprises: (a) preparing a graphite intercalation compound (GIC) or graphite oxide (GO) from a laminar graphite material; (b) exposing the GIC or GO to a first temperature for a first period of time to obtain exfoliated graphite; and (c) exposing the exfoliated graphite to a second temperature in a protective atmosphere for a second period of time to obtain the desired dispersible nano graphene platelet with an oxygen content no greater than 25% by weight, preferably below 20% by weight, further preferably between 5% and 20% by weight. Conductive NGPs can find applications in transparent electrodes for solar cells or flat panel displays, additives for battery and supercapacitor electrodes, conductive nanocomposite for electromagnetic wave interference (EMI) shielding and static charge dissipation, etc.

Owner:GLOBAL GRAPHENE GRP INC

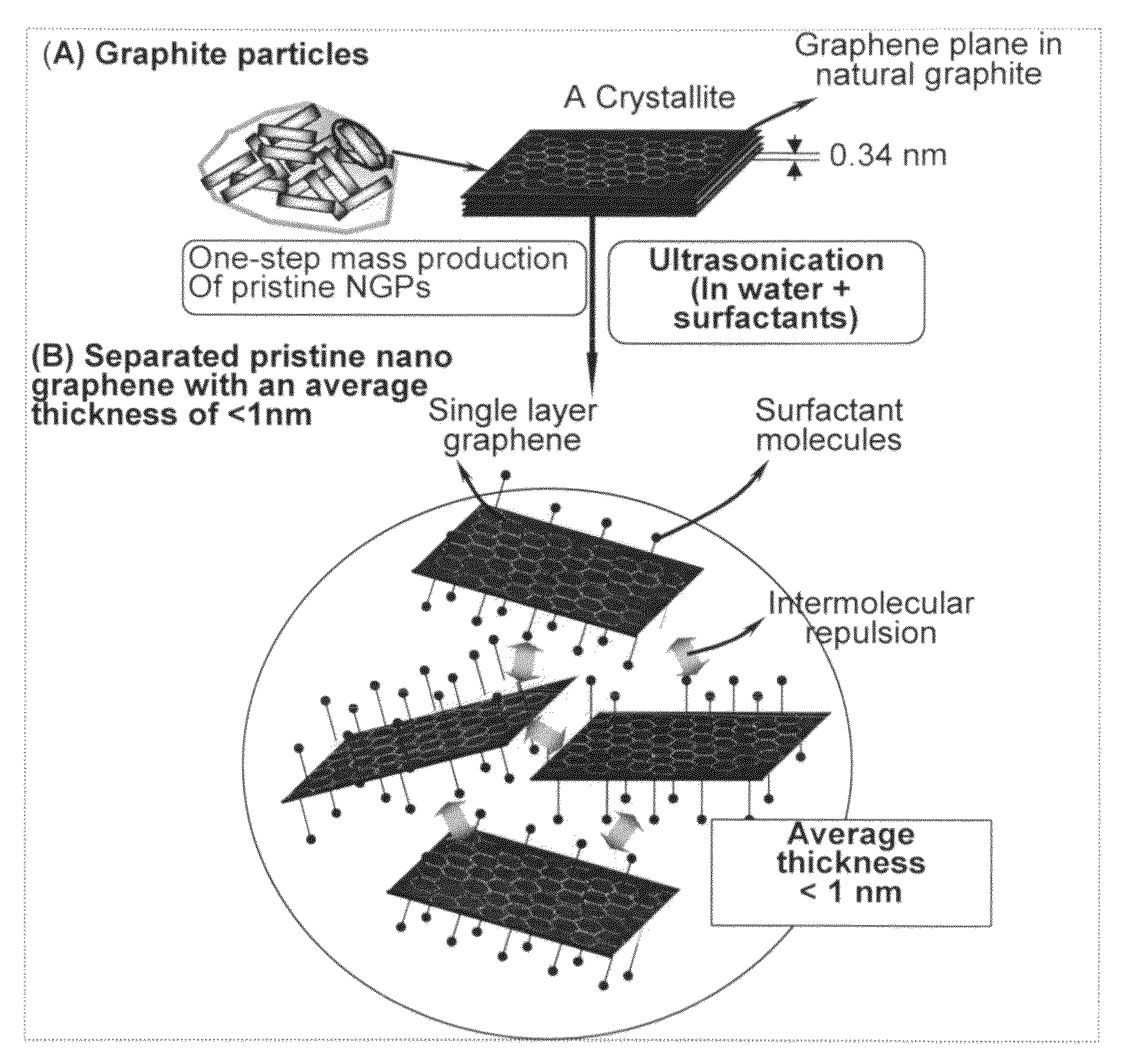

Mass production of pristine nano graphene materials

ActiveUS20110017585A1Reduce surface tensionImprove production yieldMaterial nanotechnologyGrapheneLiquid mediumDisplay device

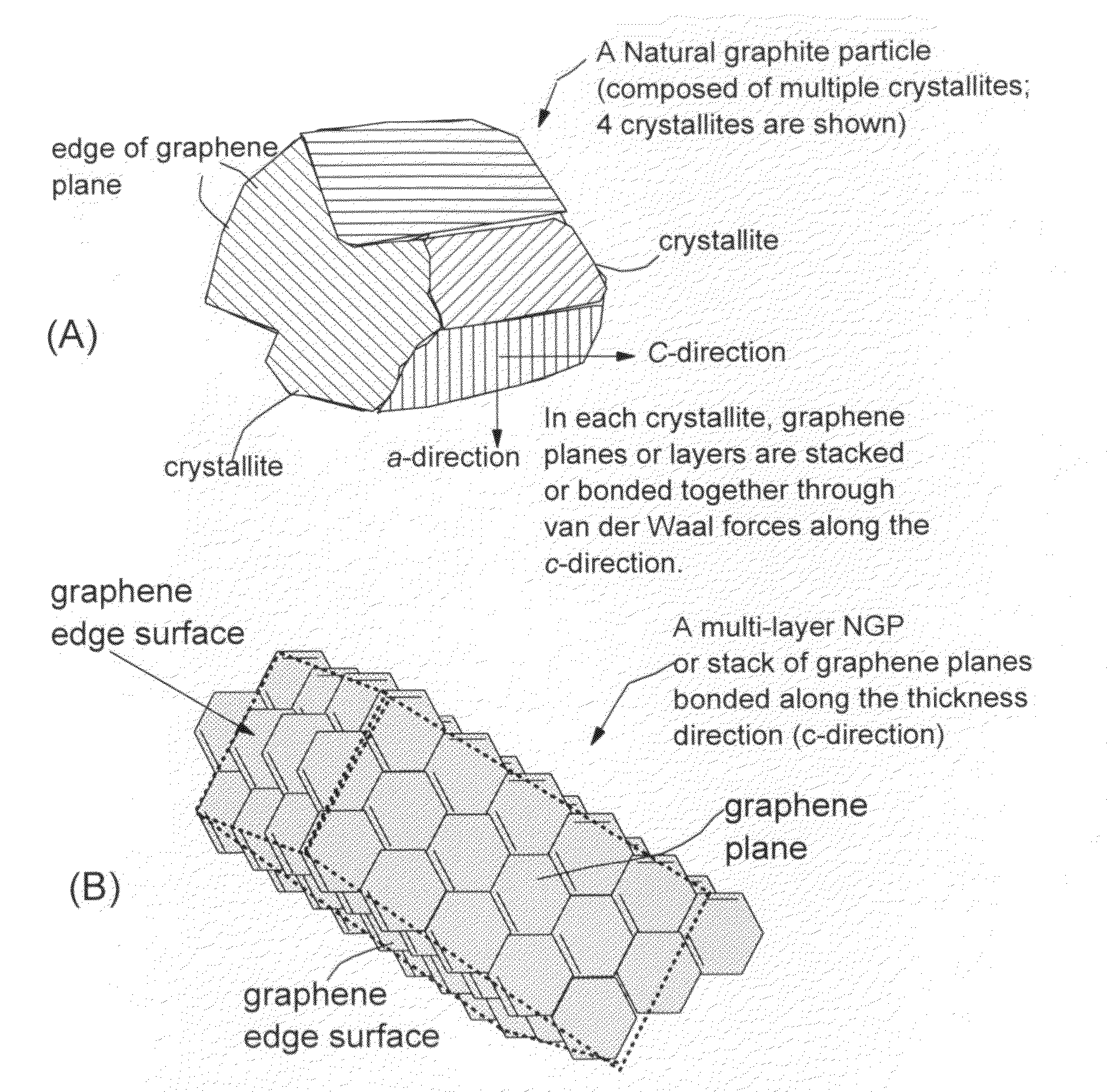

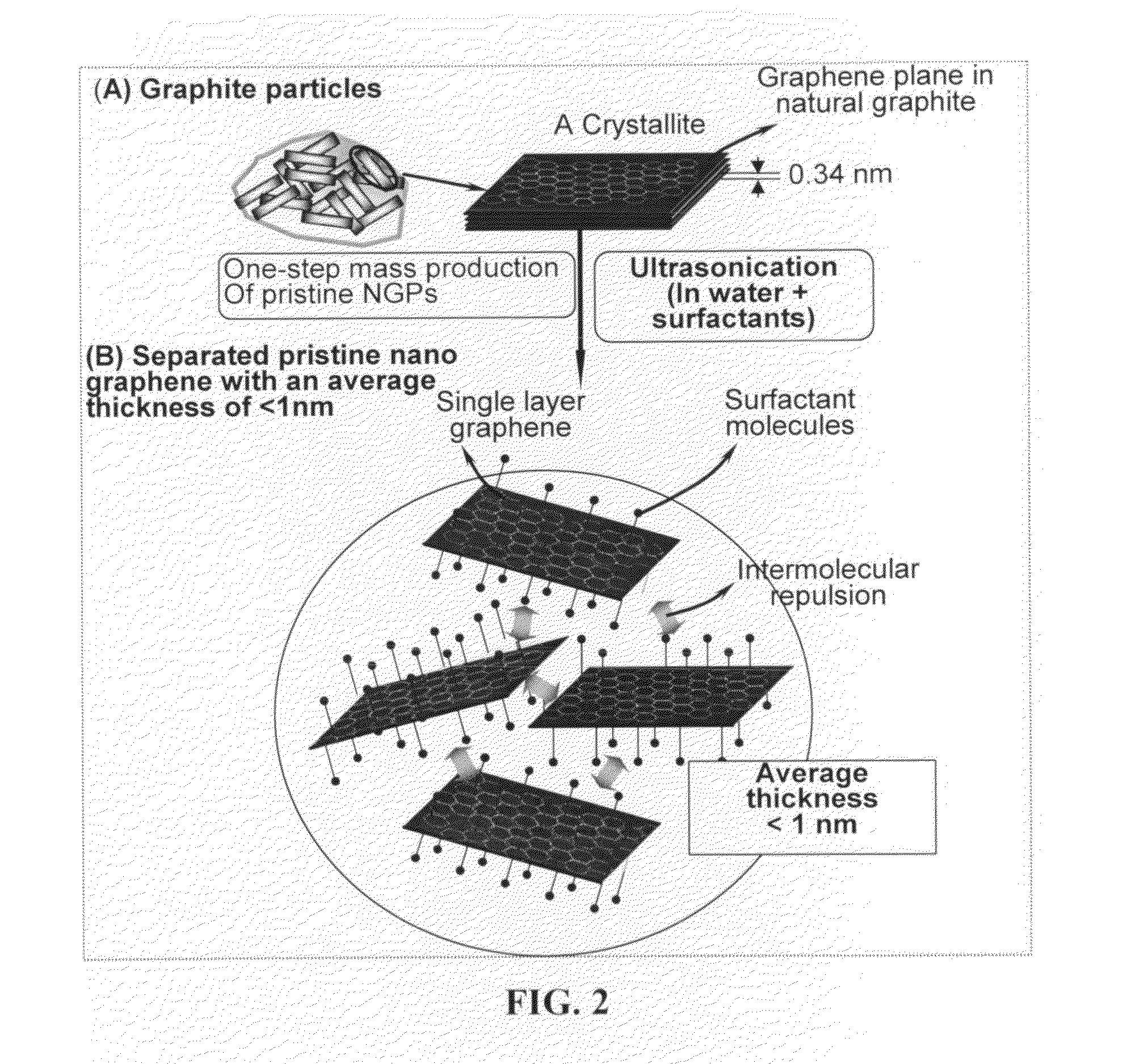

The present invention provides a method of producing pristine or non-oxidized nano graphene platelets (NGPs) that are highly conductive. The method comprises: (a) providing a pristine graphitic material comprising at least a graphite crystallite having at least a graphene plane and an edge surface; (b) dispersing multiple particles of the pristine graphitic material in a liquid medium containing therein no surfactant to produce a suspension, wherein the multiple particles in the liquid have a concentration greater than 0.1 mg / mL and the liquid medium is characterized by having a surface tension that enables wetting of the liquid on a graphene plane exhibiting a contact angle less than 90 degrees; and (c) exposing the suspension to direct ultrasonication at a sufficient energy or intensity level for a sufficient length of time to produce the NGPs. Pristine NGPs can be used as a conductive additive in transparent electrodes for solar cells or flat panel displays (e.g., to replace expensive indium-tin oxide), battery and supercapacitor electrodes, and nanocomposites for electromagnetic wave interference (EMI) shielding, static charge dissipation, and fuel cell bipolar plate applications.

Owner:GLOBAL GRAPHENE GRP INC

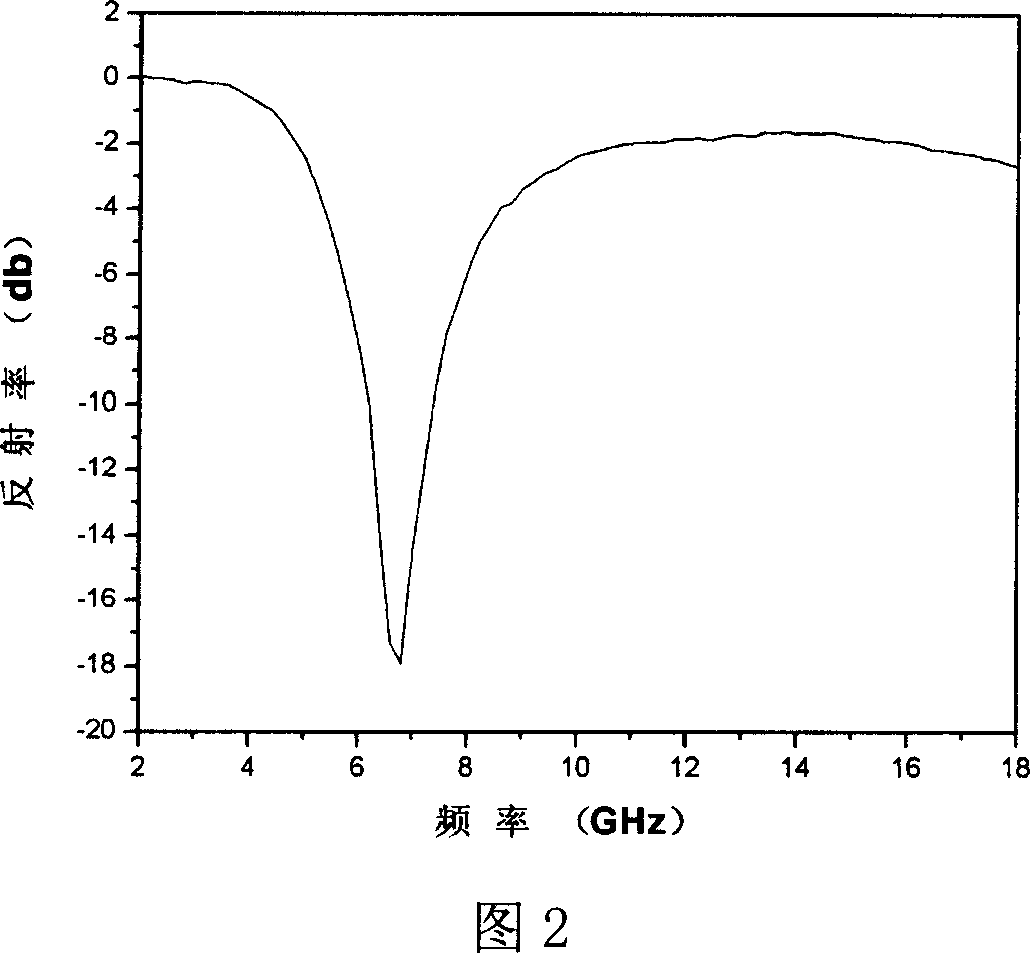

Composite polymethacrylimide foam wave absorption material

ActiveCN103923337AAchieve bondingImprove mechanical propertiesFlight vehicleElectromagnetic wave interference

The invention discloses a composite polymethacrylimide foam wave absorption material which is prepared by the following steps: (1) performing surface treatment on a wave absorber, namely uniformly mixing the wave absorber and a surfactant with a solvent, ultrasonically processing, drying to remove the solvent, and breaking and grinding to obtain a wave absorber subjected to surface treatment; (2) preparing expandable polymethacrylimide resin particles; (3) preparing the composite polymethacrylimide foam wave absorption material. The material is good in wave absorption performance, heat resistance and mechanical property, can be used for avoiding the defects of complex process, material waste and the like caused by a process that the material is machined to obtain a complex shape, can absorb electromagnetic waves to prevent electromagnetic wave interference, can be applied to the aspects of medical appliances, household appliances, electronic products, high-rise buildings, communication equipment, measurement equipment and the like, also can be used for stealth of various aircrafts, and has wide application prospect in the civil or military field.

Owner:湖南兆恒材料科技有限公司

Process for producing dispersible and conductive Nano Graphene Platelets from non-oxidized graphitic materials

ActiveUS20100056819A1Impart dispersibilityImpart solubilityMaterial nanotechnologyPigmenting treatmentDisplay deviceSolar cell

The present invention provides a process for producing nano graphene platelets (NGPs) that are both dispersible and electrically conducting. The process comprises: (a) preparing a pristine NGP material from a graphitic material; and (b) subjecting the pristine NGP material to an oxidation treatment to obtain the dispersible NGP material, wherein the NGP material has an oxygen content no greater than 25% by weight. Conductive NGPs can find applications in transparent electrodes for solar cells or flat panel displays, additives for battery and supercapacitor electrodes, conductive nanocomposite for electromagnetic wave interference (EMI) shielding and static charge dissipation, etc.

Owner:GLOBAL GRAPHENE GRP INC

Dispersible and conductive Nano Graphene Platelets

ActiveUS20100055458A1Impart dispersibilityImpart solubilityMaterial nanotechnologySynthetic resin layered productsDisplay deviceSolar cell

The present invention provides a dispersible and electrically conductive nano graphene platelet (NGP) material comprising at least a single-layer or multiple-layer graphene sheet, wherein the NGP material has an oxygen content no greater than 25% by weight and no less than 5% by weight. This NGP material can be produced by: (a) preparing a pristine NGP material from a graphitic material; and (b) subjecting the pristine NGP material to an oxidation treatment. Alternatively, the production process may comprise: (A) preparing a graphite oxide (GO) from a laminar graphite material; (b) exposing the GO to a first temperature for a first period of time to obtain exfoliated graphite; and (c) exposing the exfoliated graphite to a second temperature in a protective atmosphere for a second period of time. Conductive NGPs can find applications in transparent electrodes for solar cells or flat panel displays, additives for battery and supercapacitor electrodes, conductive nanocomposite for electromagnetic wave interference (EMI) shielding and static charge dissipation, etc.

Owner:GLOBAL GRAPHENE GRP INC

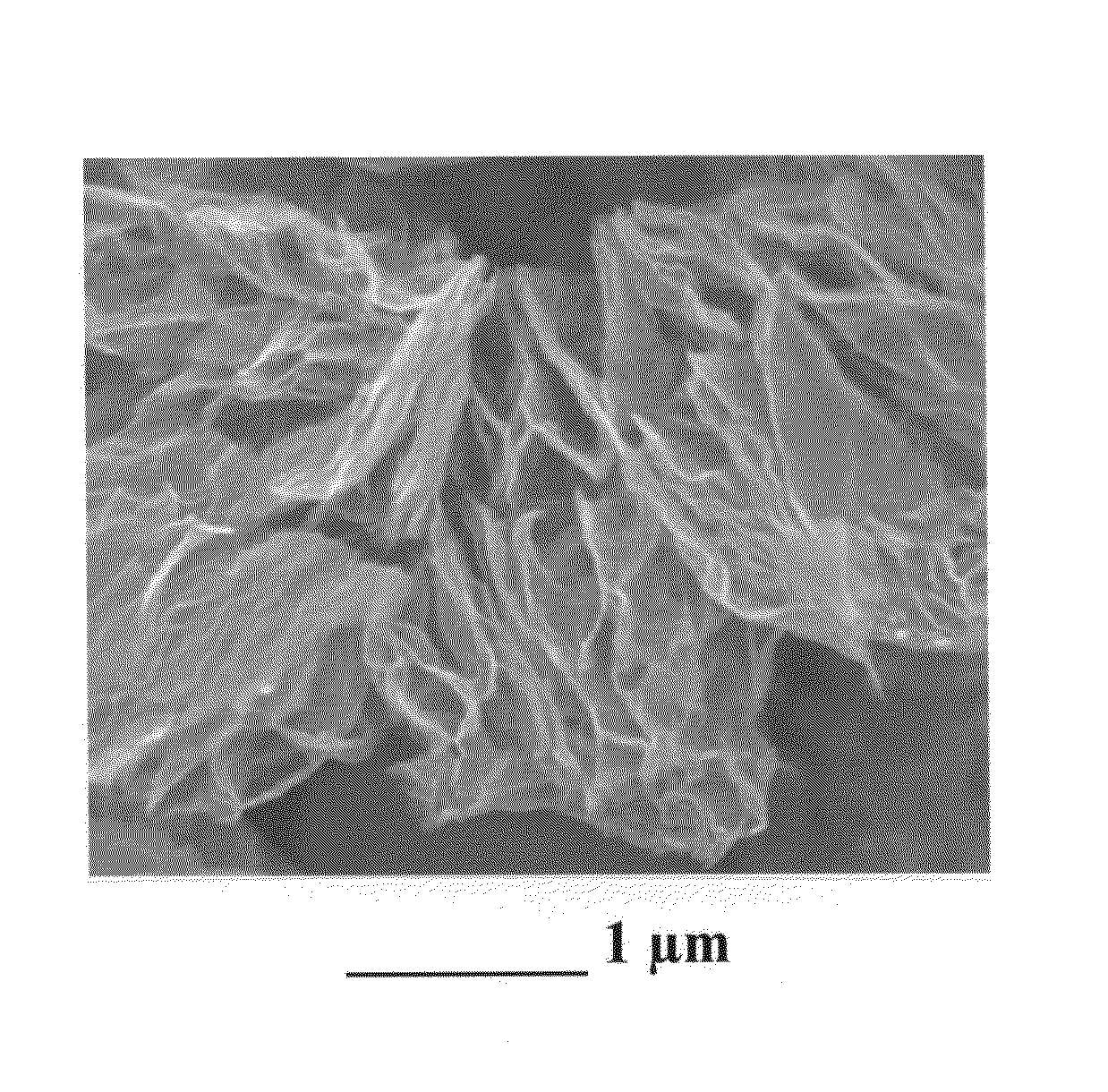

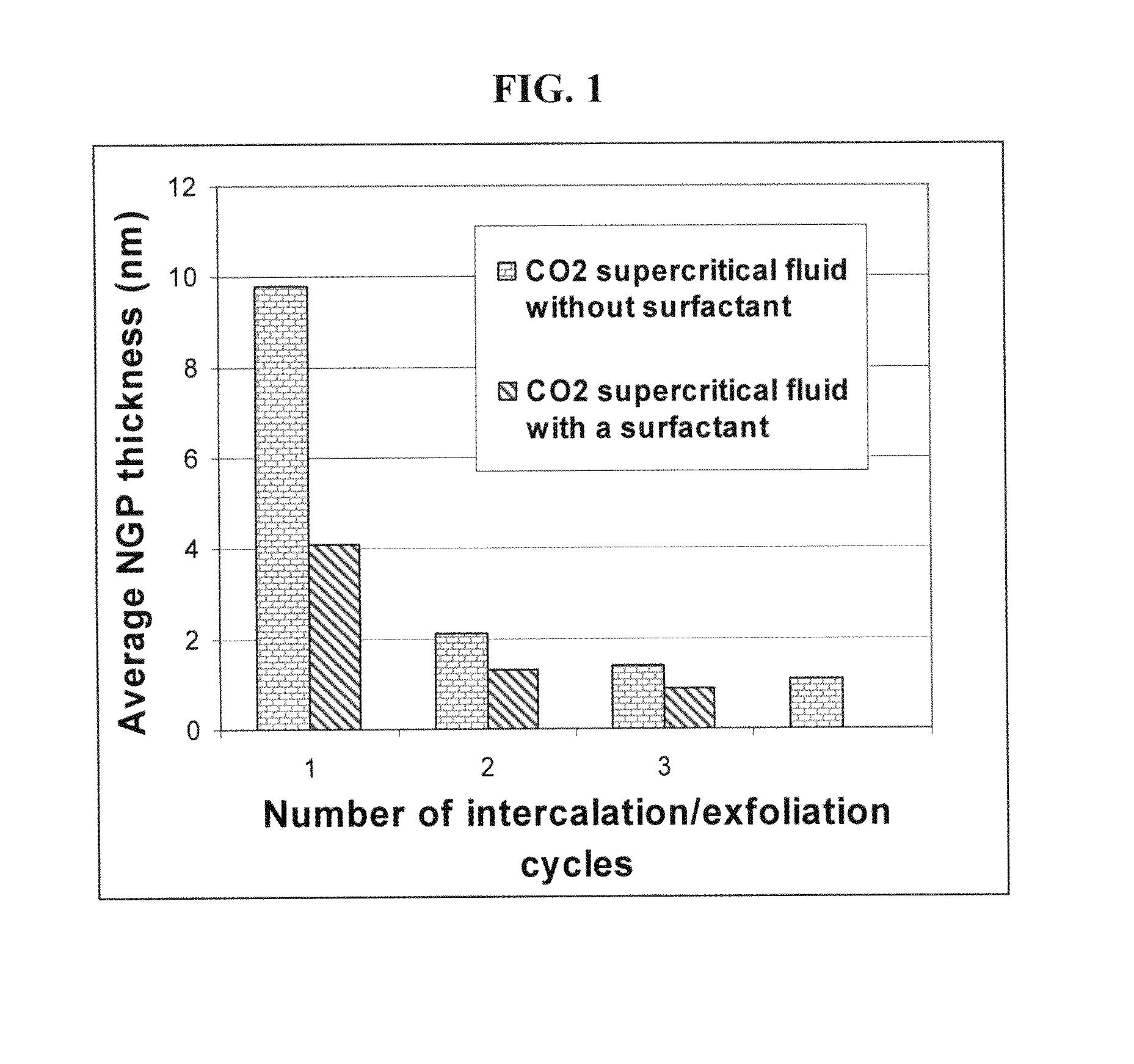

Supercritical fluid process for producing nano graphene platelets

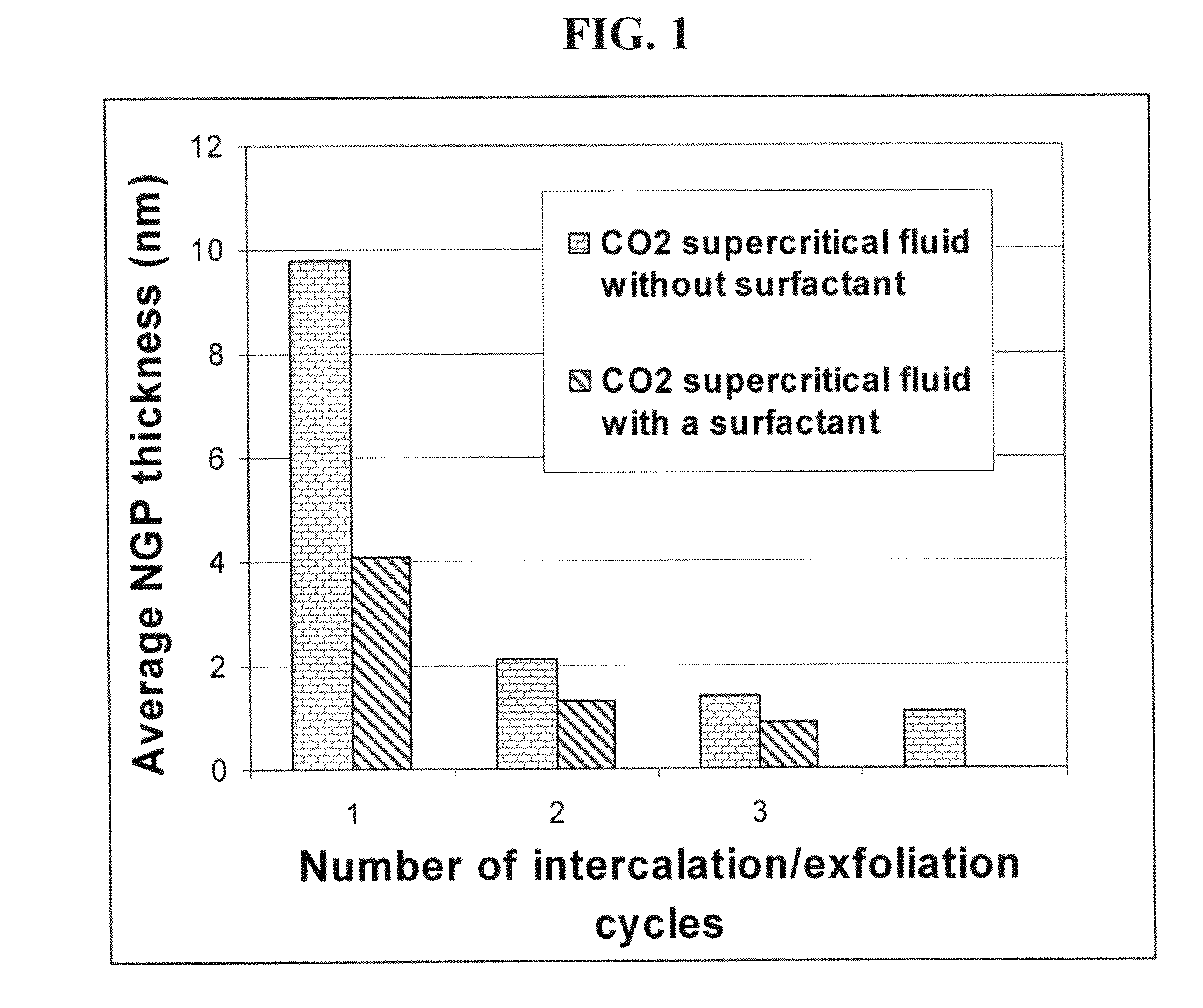

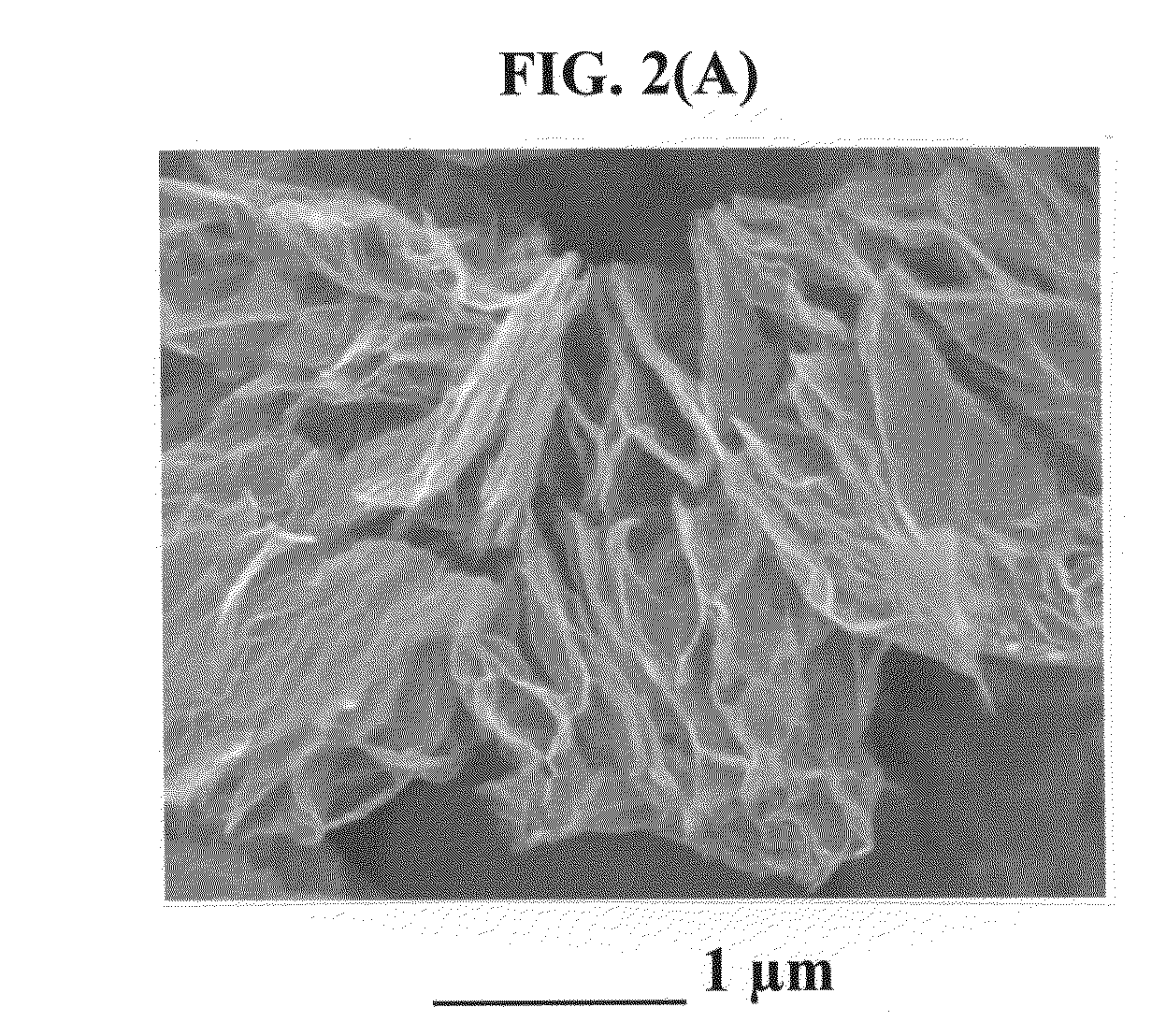

ActiveUS20100044646A1Improve conductivityPigmenting treatmentNon-metal conductorsDisplay deviceSolar cell

The present invention provides a process for producing pristine or non-oxidized nano graphene platelets (NGPs) that are highly conductive. The process comprises: (i) subjecting a graphitic material to a supercritical fluid at a first temperature and a first pressure for a first period of time in a pressure vessel and then (ii) rapidly depressurizing the fluid at a fluid release rate sufficient for effecting exfoliation of the graphitic material to obtain the NGP material. Conductive NGPs can be used as a conductive additive in transparent electrodes for solar cells or flat panel displays (e.g., to replace expensive indium-tin oxide), battery and supercapacitor electrodes, and nanocomposite for electromagnetic wave interference (EMI) shielding and static charge dissipation, etc.

Owner:GLOBAL GRAPHENE GRP INC

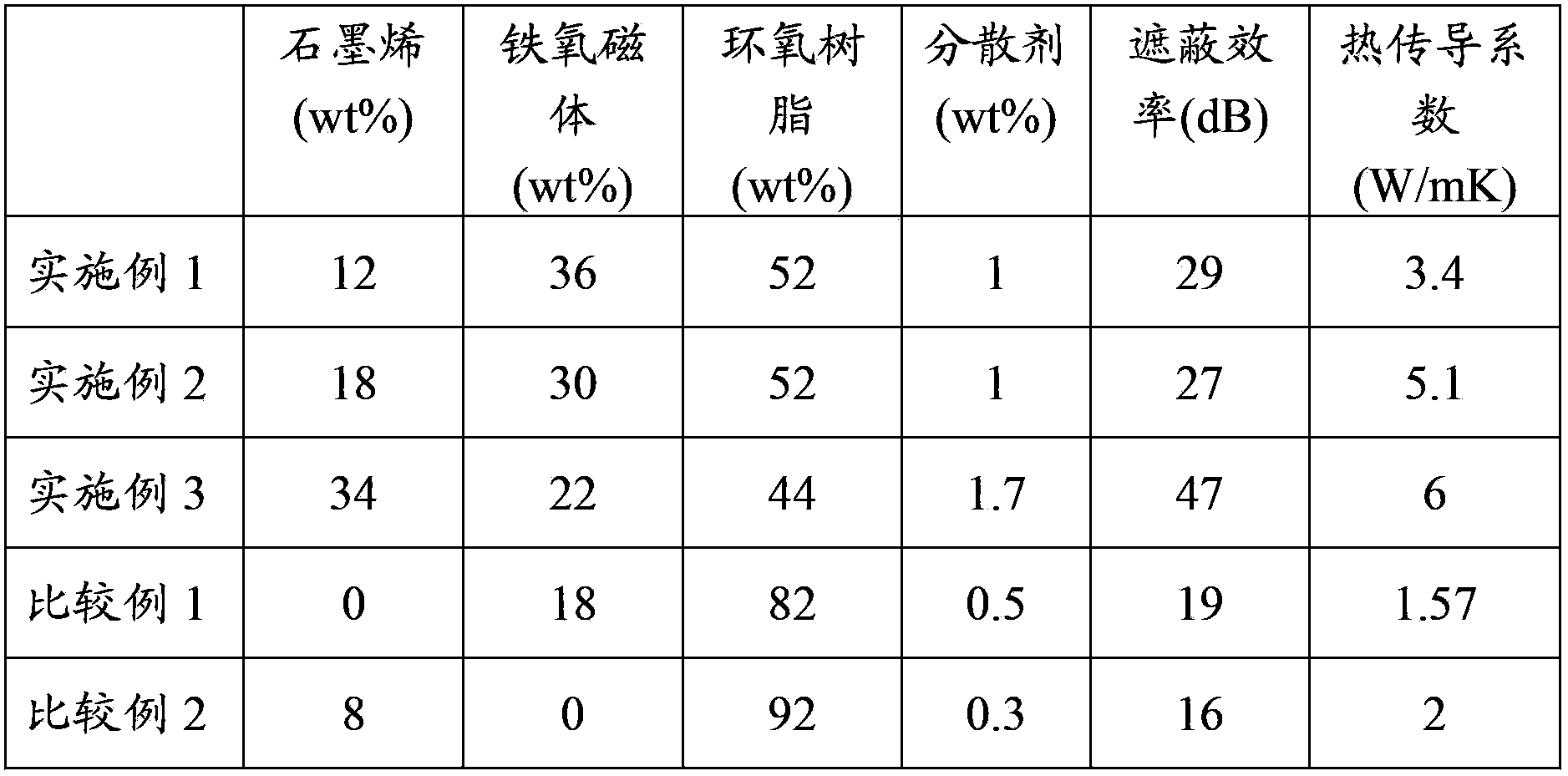

High thermal conductivity and EMI sheltering high polymer composite material

The invention provides a high polymer composite material, which is formed by fully blending a thermal conduction material (such as graphene), with an electromagnetic wave shielding material with EMI shielding efficacy and a high polymer binder. Thus, the thermal conductivity coefficient and the shielding efficiency of the overall composite material are enhanced, so that the provided composite material can be ensured to have thermal energy dissipated by a heat producing source and can effectively shelter electromagnetic wave interference.

Owner:TENNRICH INT

Process for producing dispersible and conductive nano graphene platelets from non-oxidized graphitic materials

Owner:GLOBAL GRAPHENE GRP INC

Nano foamed concrete, reinforced insulation wallboard and preparation method of reinforced insulation wallboard

ActiveCN103359997AAvoid interferenceAvoid pollutionBuilding componentsFoam concreteAdditive ingredient

The invention belongs to the field of building materials and construction technologies and relates to nano foamed concrete, a reinforced insulation wallboard and a preparation method of the reinforced insulation wallboard. The nano foamed concrete disclosed by the invention is prepared from the following ingredients in parts by weight: 100 parts of cement, 0.1-5 parts of desulfurized oil coke ash residue, 0.012 part of waterproofing agent, 10-30 parts of fly ash, 0.1-6 parts of superplasticizer, 50-200 parts of water, 1-20 parts of foamer and 0.01-5 parts of nano wave absorbing agent. Thus, when a wallboard product, prepared by embedding steel wire meshes in the nano foamed concrete disclosed by the invention, is applied nearby airports, docks, navigation marks, television stations and receiving stations or applied to concrete-based retaining walls of electromagnetic wave interference preventing scientific research departments, precise instrument plants and information leakage prevention high-grade buildings of national confidential units and the like, the most basic physical, mechanical, heat preservation and heat insulation properties are guaranteed on one hand, and the wallboard product has the capabilities of lowering noise and insulating sound on the other hand.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Process for producing dispersible nano graphene platelets from oxidized graphite

The present invention provides a process for producing nano graphene platelets (NGPs) that are dispersible and conducting. The process comprises: (a) preparing a graphite intercalation compound (GIC) or graphite oxide (GO) from a laminar graphite material; (b) exposing the GIC or GO to a first temperature for a first period of time to obtain exfoliated graphite; and (c) exposing the exfoliated graphite to a second temperature in a protective atmosphere for a second period of time to obtain the desired dispersible nano graphene platelet with an oxygen content no greater than 25% by weight, preferably below 20% by weight, further preferably between 5% and 20% by weight. Conductive NGPs can find applications in transparent electrodes for solar cells or flat panel displays, additives for battery and supercapacitor electrodes, conductive nanocomposite for electromagnetic wave interference (EMI) shielding and static charge dissipation, etc.

Owner:GLOBAL GRAPHENE GRP INC

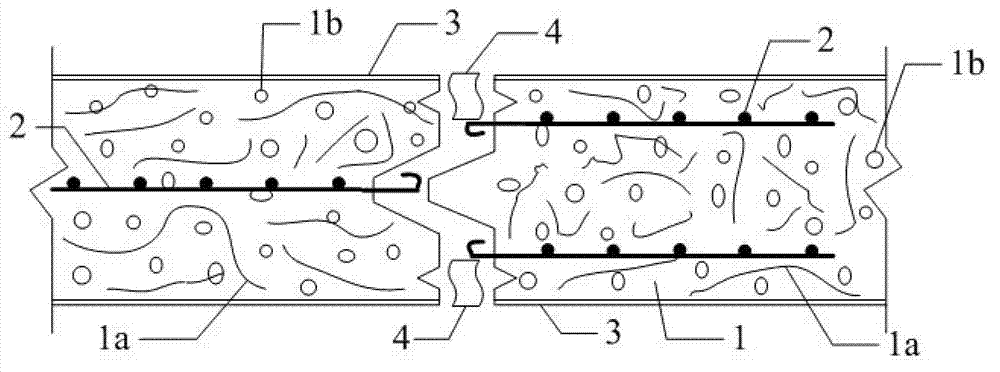

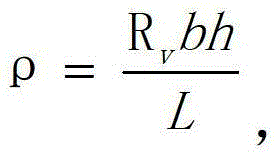

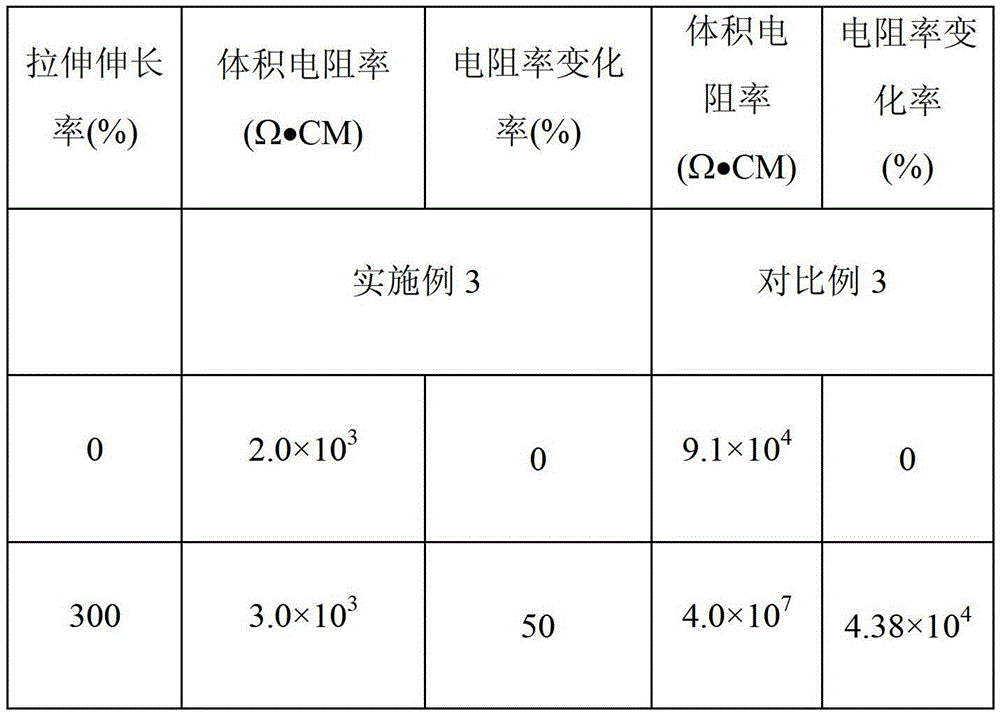

Conductive polymer composite material and preparation method thereof

The invention provides a conductive polymer composite material and a preparation method thereof. The composite material includes following blended components: a. thermoplastic resin; b. rubber particles having crosslinking structures; c. a conductive filling material; and d. low-melting-point metal. Gel content in the component b is, by weight, 60% or more than 60%. An average particle size of the rubber particles is 0.02-1 [mu]m. The component c is not melted at a processing temperature of the thermoplastic resin. The component d is at least one of a single-component metal and a metal alloy. A melting point of the component d ranges from 20-480 DEG C and is lower than the processing temperature of the thermoplastic resin. The conductive polymer composite material is low in filling amount of the conductive filling material and the low-melting-point metal, is more excellent in conductive performance, can be prepared through a conventional melt blending method, can be used for manufacturing electronic production devices and tools which have an anti-static function and an electromagnetic wave interference resistant function and is of a dust-free requirement, can be used for manufacturing shells of electronic instruments and meters, can be used as a decoration material in a dust-free production workshop and can be used as shells and circuit boards of various flexible electronic products.

Owner:CHINA PETROLEUM & CHEM CORP +1

Conductive thermoplastic elastomer and preparation method thereof

ActiveCN104098795AConductiveEvenly dispersedNon-conductive material with dispersed conductive materialThermoplasticConductive polymer composite

The invention provides a conductive thermoplastic elastomer and a preparation method thereof. The thermoplastic elastomer includes following blended components: a. thermoplastic resin; b. rubber particles having crosslinking structures; c. a conductive filling material; and d. low-melting-point metal. Gel content in the component b is, by weight, 60% or more than 60%. An average particle size of the rubber particles is 0.02-1 [mu]m. The component c is not melted at a processing temperature of the thermoplastic resin. The component d is at least one of a single-component metal and a metal alloy. A melting point of the component d ranges from 20-480 DEG C and is lower than the processing temperature of the thermoplastic resin. A weight ratio of the component b to the component a is more than 30:70 and is lower than 75:25. The conductive polymer composite material is low in filling amount of the conductive filling material and the low-melting-point metal, is excellent in conductive performance, can be prepared through a melt blending method, can be used for manufacturing electronic production devices and tools which have an anti-static function and an electromagnetic wave interference resistant function and is of a dust-free requirement, can be used for manufacturing shells of electronic instruments and meters, can be used as a decoration material in a dust-free production workshop and can be used as shells and circuit boards of various flexible electronic products.

Owner:CHINA PETROLEUM & CHEM CORP +1

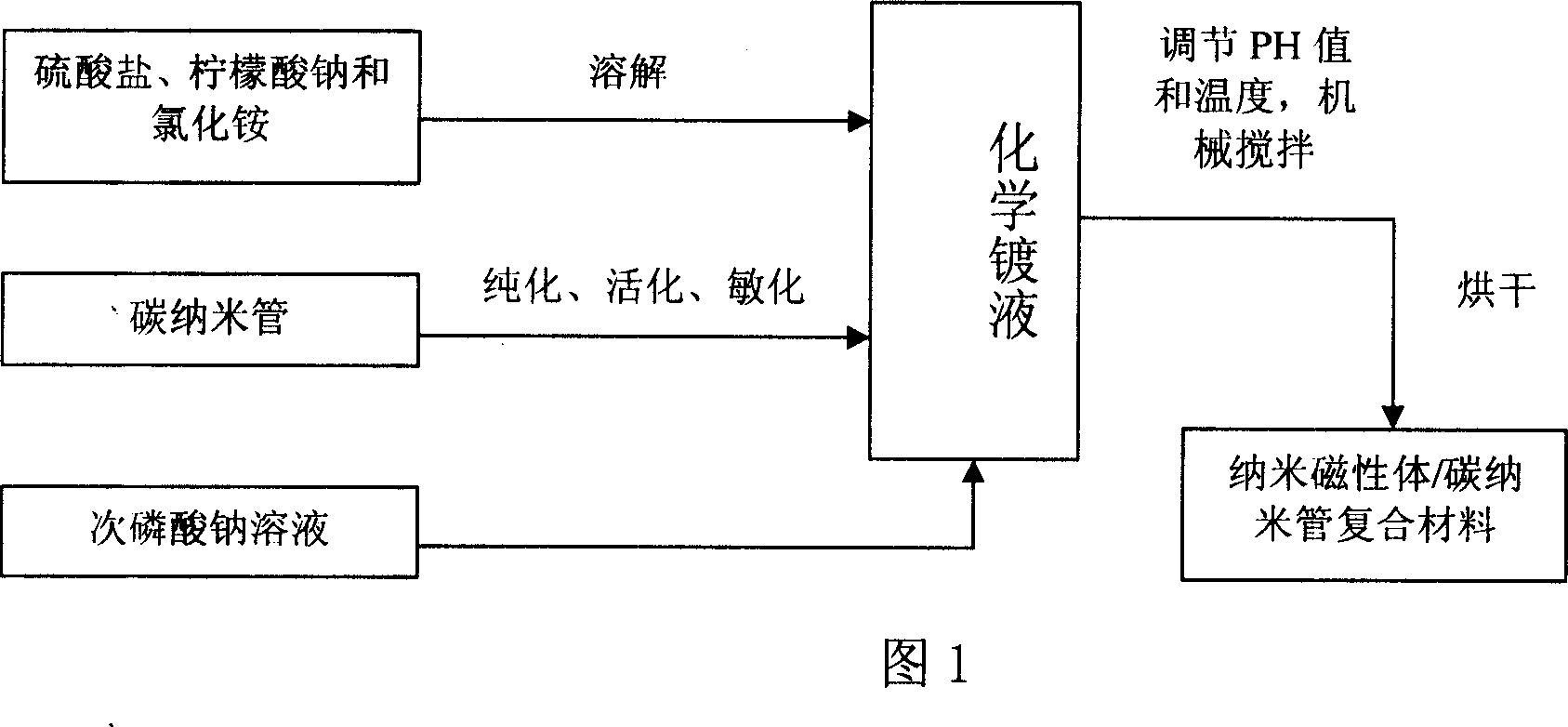

Carbon nano tube wave absorbtion mateirla of surface carried with magnetic alloy particle and preparation method thereof

InactiveCN101045533AGood electrical and magnetic propertiesSimple preparation processNanostructure manufactureScreening apparatusMicrowaveCarbon nanotube

A carbon nanotube carrying magnetic alloy particles on its surface and used as wave absorbing material is prepared through uniformly dispersing carbon nanotubes in the solution of the sulfate of Fe, Co and Ni, and oxidizing-reducing reaction for deposition the magnetic alloy particles on carbon nanotubes.

Owner:TSINGHUA UNIV

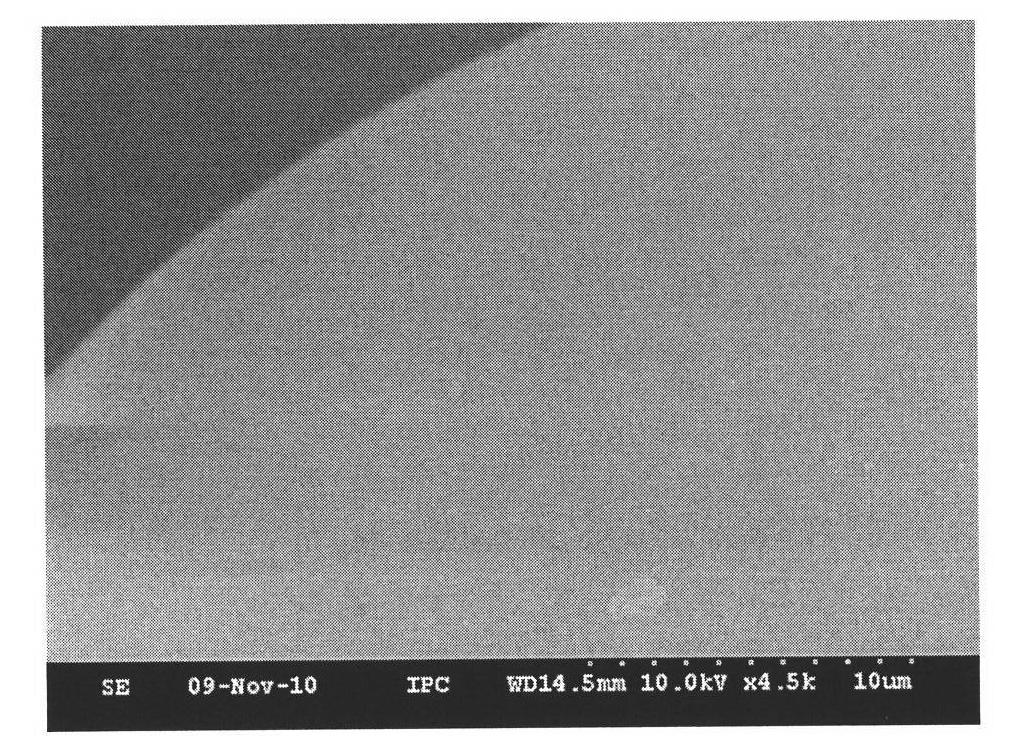

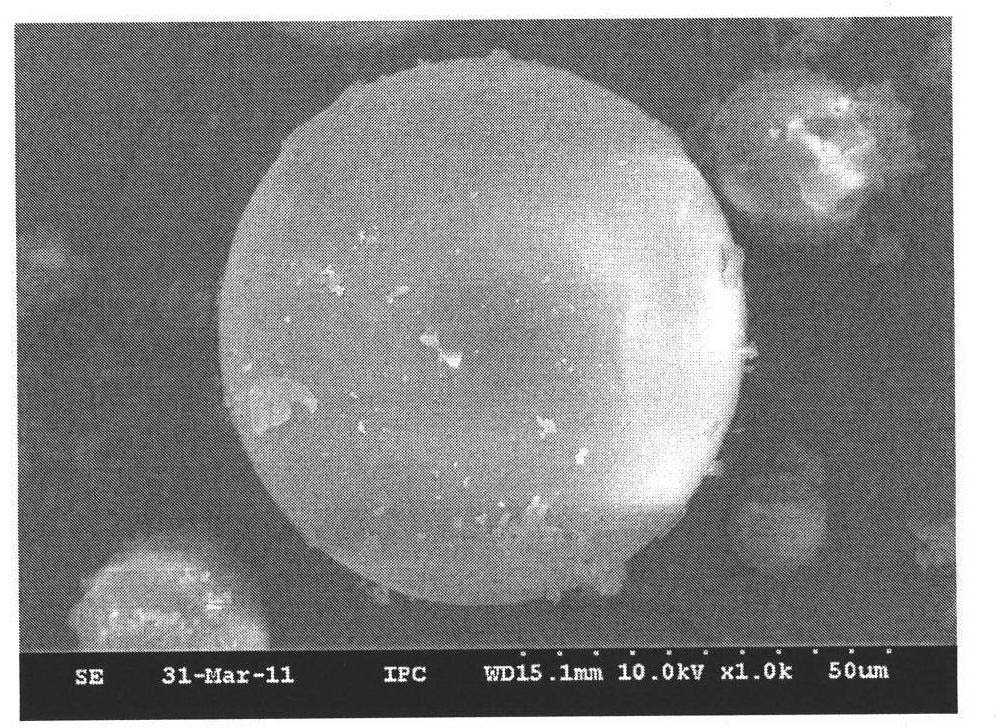

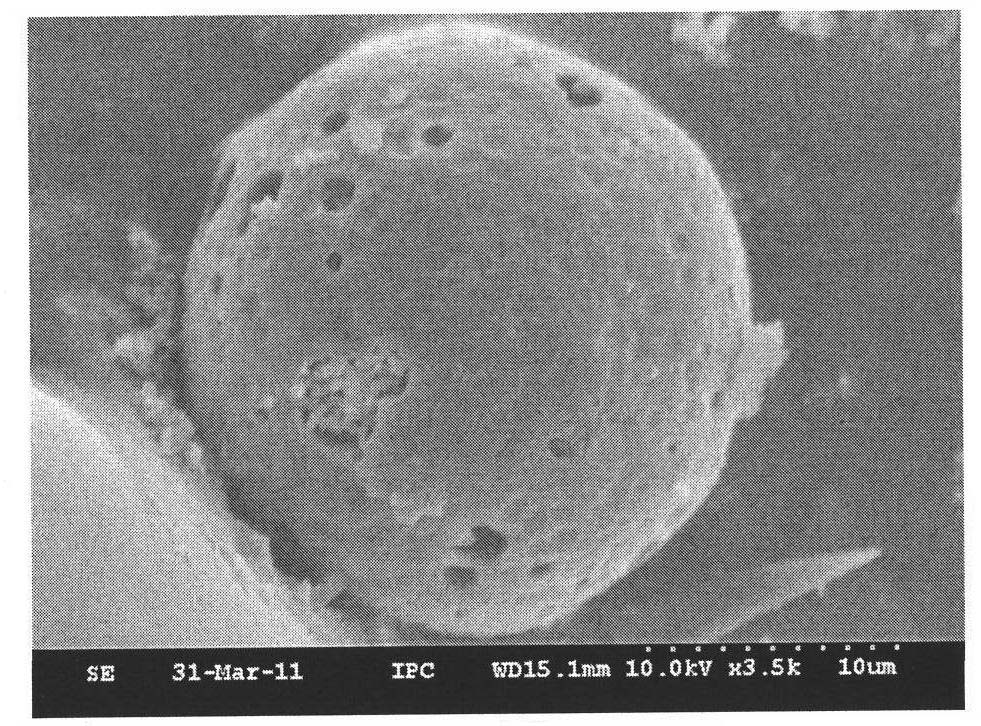

Surface chemical plating treatment process for hollow glass microsphere, plated metal hollow glass microsphere and application thereof

The invention relates to the technical field of a composite material with a core shell structure and provides a surface chemical plating treatment process for hollow glass microspheres. The surface chemical plating treatment process comprises the following steps: carrying out alkaline wash and hydrogen peroxide wash before plating to coarsen and hydroxylate the surface of the hollow glass microsphere; and carrying out chemical plating on the processed hollow glass microsphere to obtain a metal-plated hollow glass microsphere. In the method, complex preprocessing technology, such as sensitization, activation and the like in the existing method, can be simplified, and the use of expensive stannous chloride and palladium chloride which are not environmentally-friendly is avoided. Compared with the existing hot alkaline liquor processing method, the process provided by the invention has the advantages that possible microsphere fracture caused by the long-time soaking in the alkaline liquor can be avoided, and the surface hydroxylation efficiency of the hollow glass microsphere can be greatly increased by using hydrogen peroxide. The hollow glass microsphere processed with the method is easy to plate. The obtained metal-plated hollow glass microsphere has the advantages of a complete metal layer, light weight, good electrical conductivity and the like. When the obtained metal-plated hollow glass is used as a filler, material density can be lowered, cost is lowered, mechanical property is enhanced, and the plated metal hollow glass microsphere is applied to the aspects of staticelectricity coating, electromagnetic wave interference coating, wave adsorption coating and the like.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Conductive plastic and preparation method thereof

The invention provides a conductive plastic and a preparation method thereof. The conductive plastic comprises the following blended compositions: a, thermoplastic resin; b, rubber particle with a crosslinking structure; c, a conductive filter; and d, a low-melting-point metal. The gel content of the composition b is 60% by weight or more, and the average particle size of the composition b is 0.02-1 mu m; the composition c is not fused at a thermoplastic-resin processing temperature; the composition d is at least one of a single-composition metal or metal alloy, the melting point of the composition d is 20-480 DEG C and is lower than the thermoplastic-resin processing temperature; and the weight ratio of the composition b to the composition a is 0.1:99.9-30:70. The conductive plastic is low in filling content of the conductive filler and the metal, is relatively low in conductive performance, can be prepared by using a common melt blending method, and can be used to prepare antistatic electromagnetic-wave-interference-resisting electron production equipment and tools with dust-free requirements, and electronic apparatuses, instrument housings and decoration materials of dust-free production workshops.

Owner:CHINA PETROLEUM & CHEM CORP +1

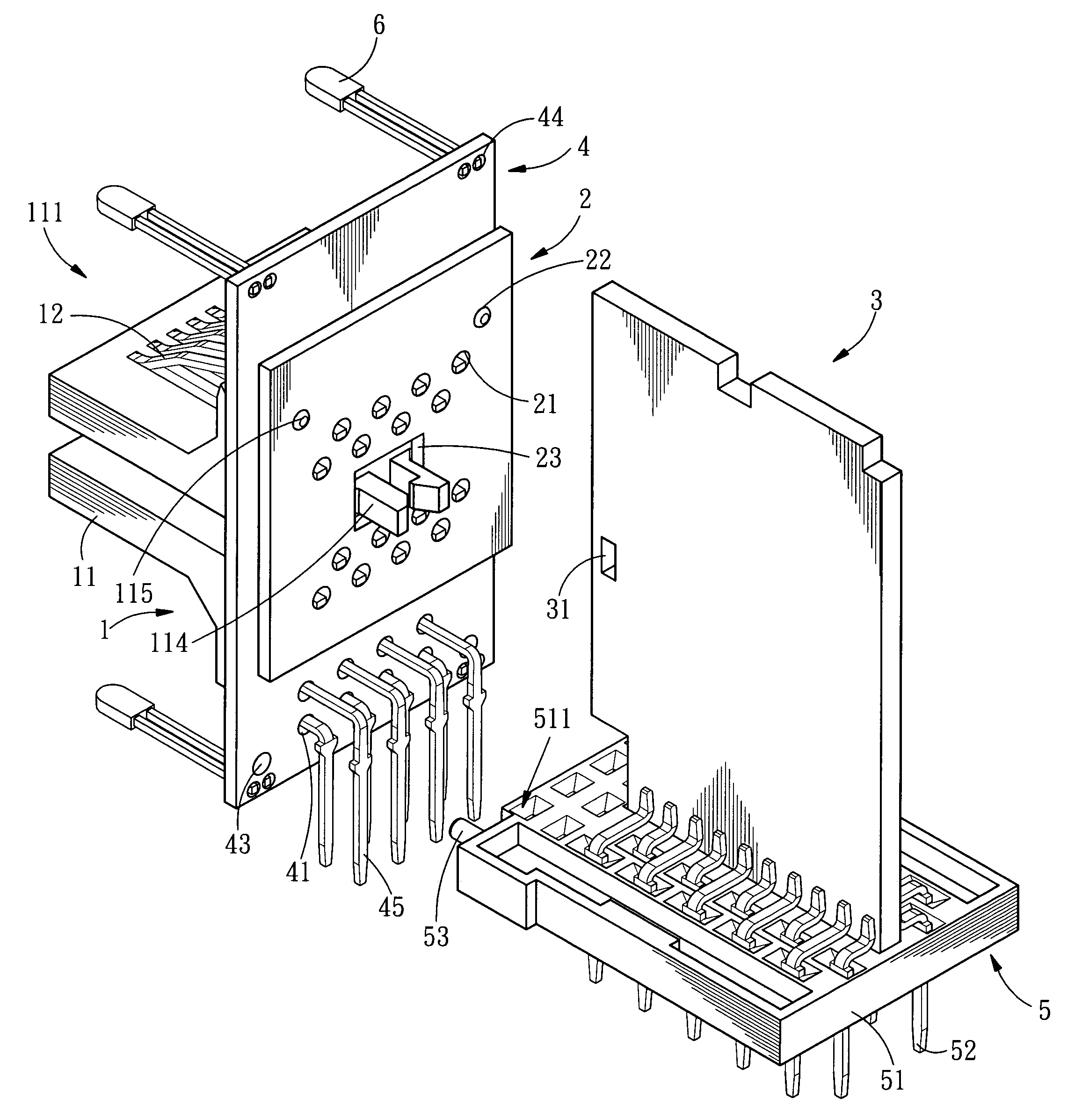

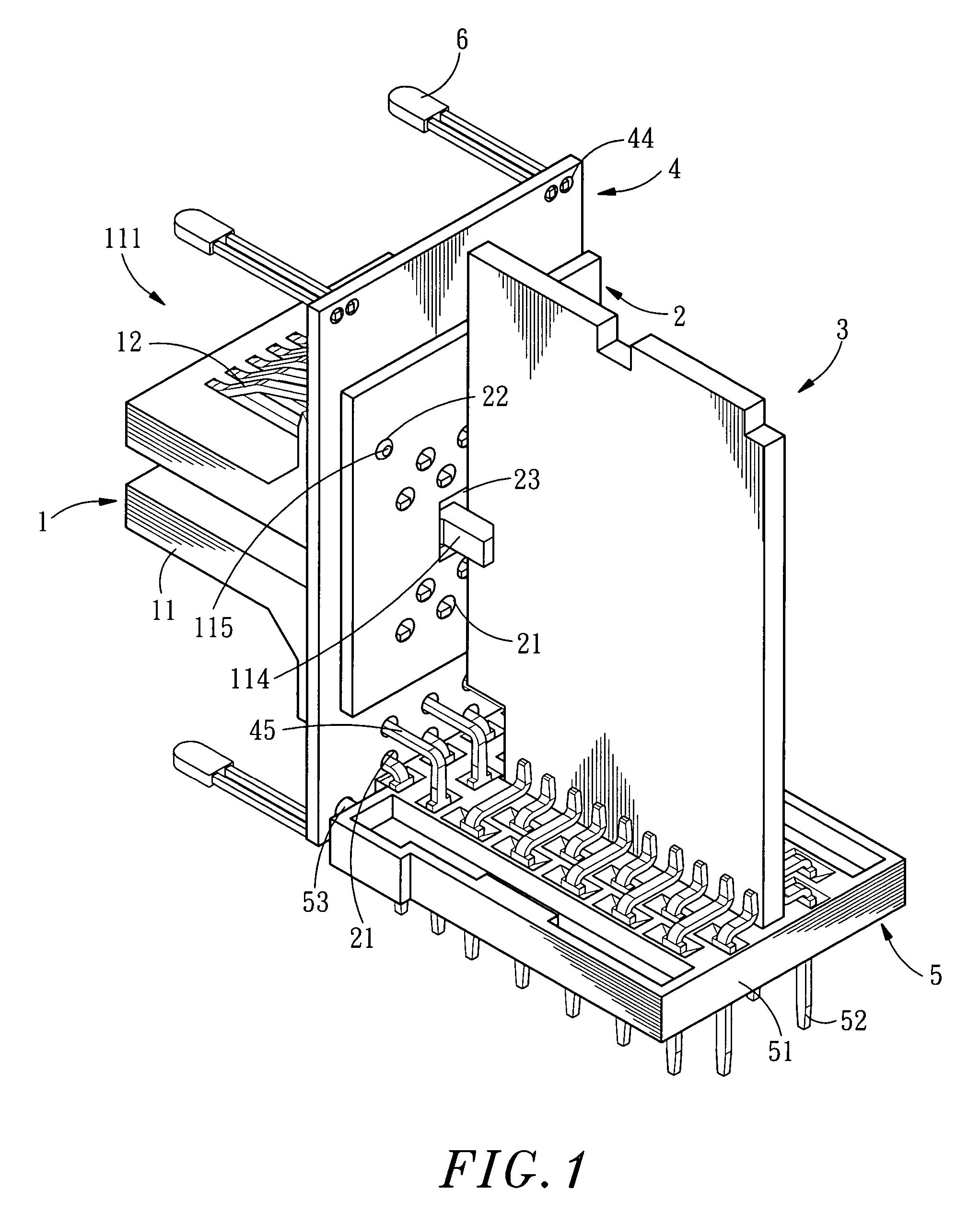

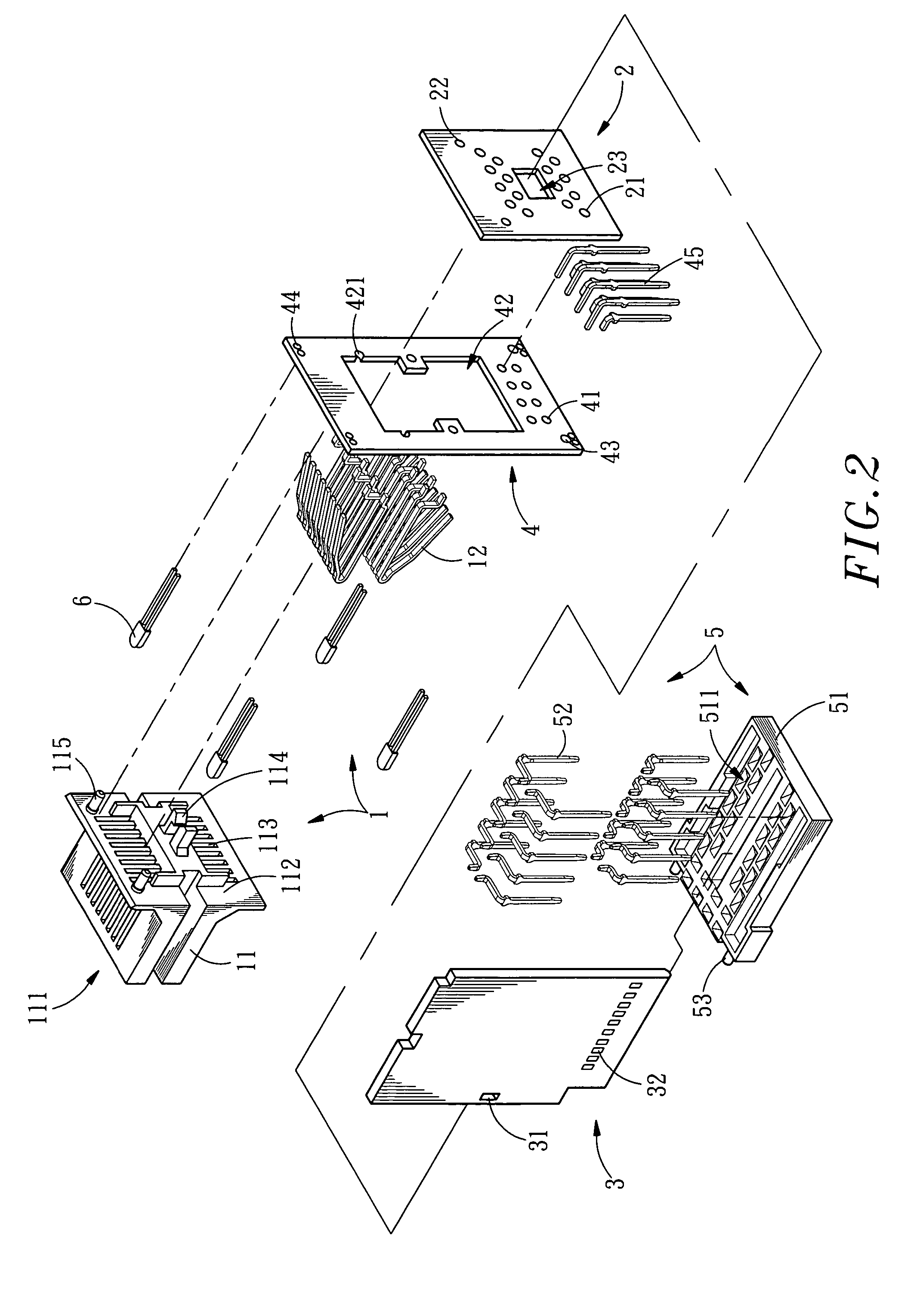

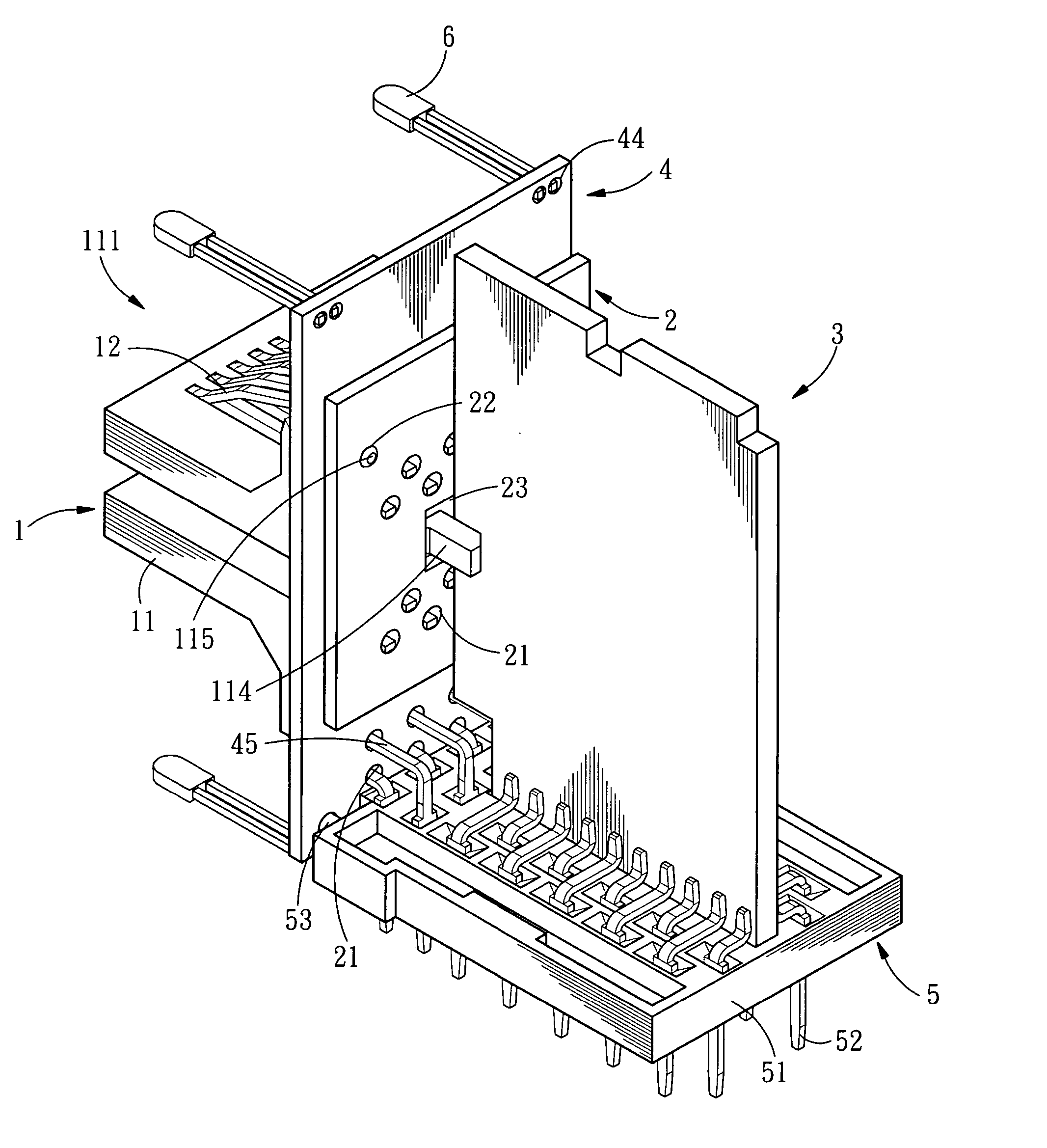

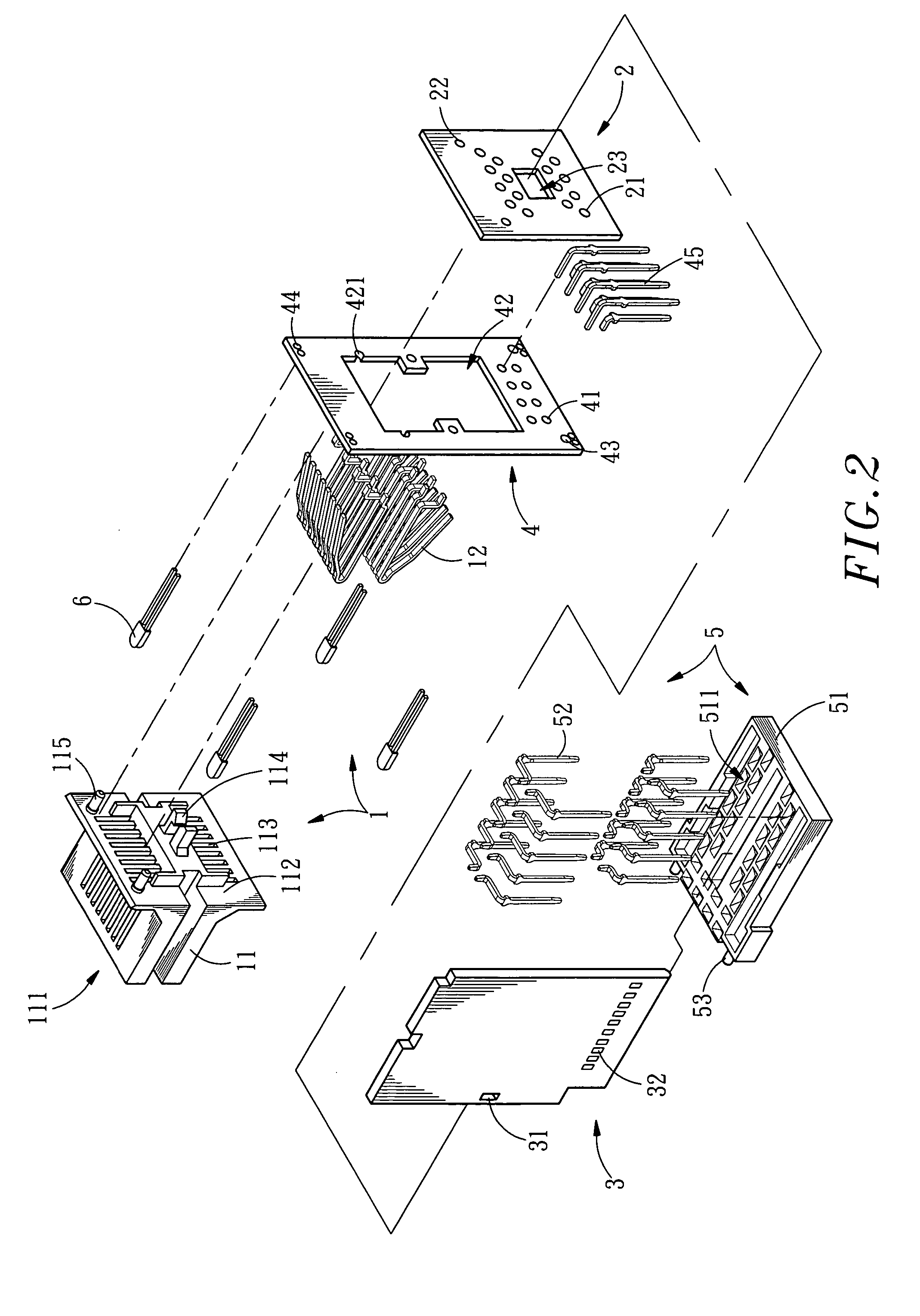

Structure of connector for reducing electro-magnetic wave interference

InactiveUS7025635B2Reduce electromagnetic interferenceCost-effective structureCoupling for high frequencyTwo-part coupling devicesElectromagnetic wave interferenceElectrical and Electronics engineering

A connector for reducing electro-manetic wave interference has a receiving module, a first circuit board, a second circuit board, a third circuit board and adaptor module. The circuits of various characteristics are set onto the first circuit board and the second circuit board respectively for reducing electro-magnetic wave interferences during signal transmission.

Owner:SPEED TECH

Supercritical fluid process for producing nano graphene platelets

ActiveUS8696938B2Improve conductivityNon-metal conductorsMaterial nanotechnologyDisplay deviceSolar cell

The present invention provides a process for producing pristine or non-oxidized nano graphene platelets (NGPs) that are highly conductive. The process comprises: (i) subjecting a graphitic material to a supercritical fluid at a first temperature and a first pressure for a first period of time in a pressure vessel and then (ii) rapidly depressurizing the fluid at a fluid release rate sufficient for effecting exfoliation of the graphitic material to obtain the NGP material. Conductive NGPs can be used as a conductive additive in transparent electrodes for solar cells or flat panel displays (e.g., to replace expensive indium-tin oxide), battery and supercapacitor electrodes, and nanocomposite for electromagnetic wave interference (EMI) shielding and static charge dissipation, etc.

Owner:GLOBAL GRAPHENE GRP INC

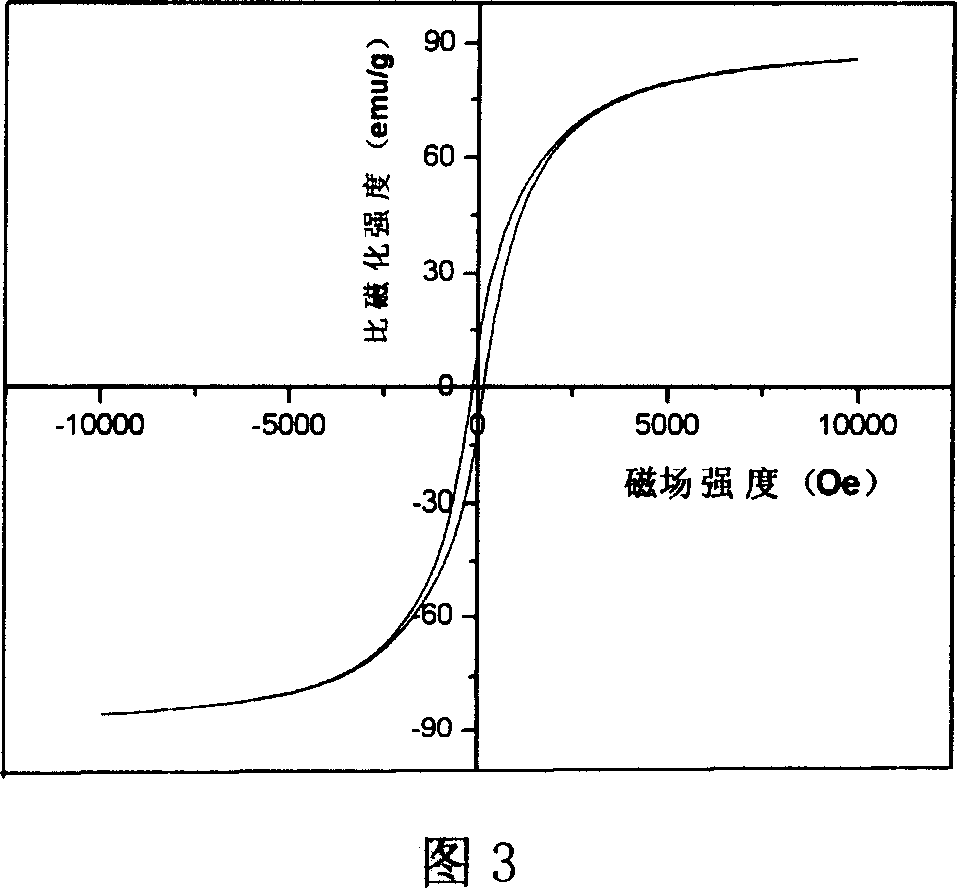

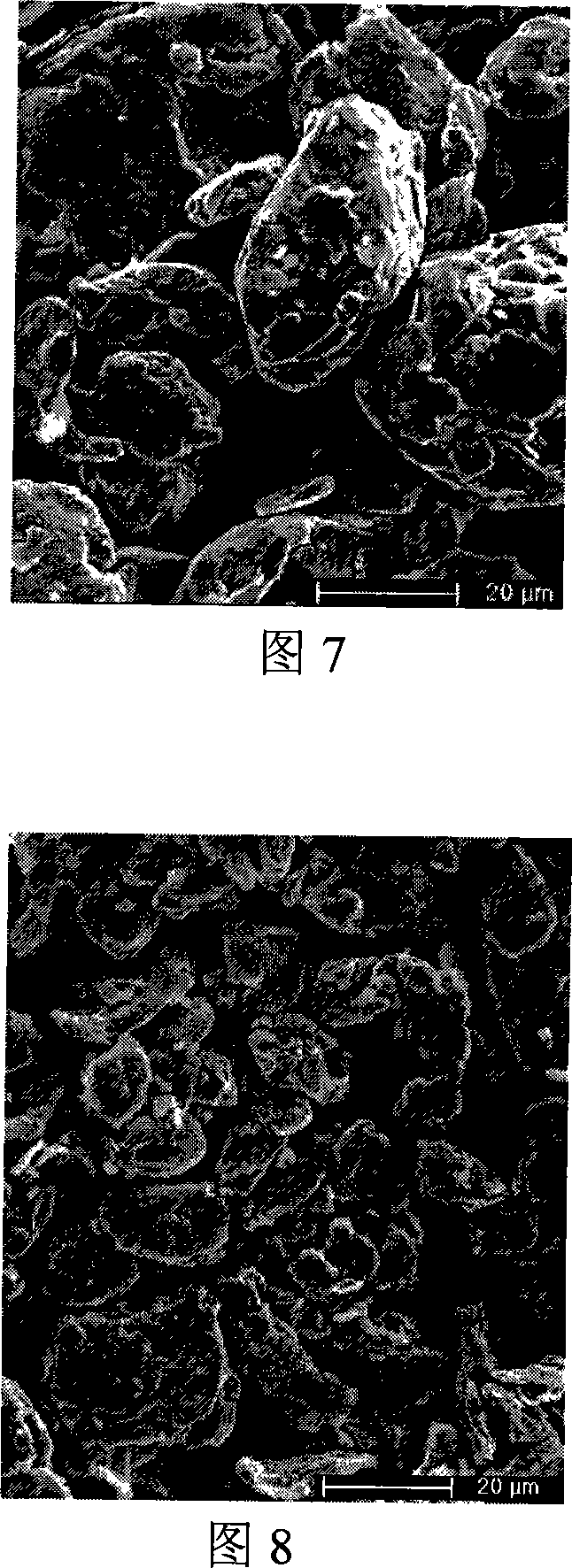

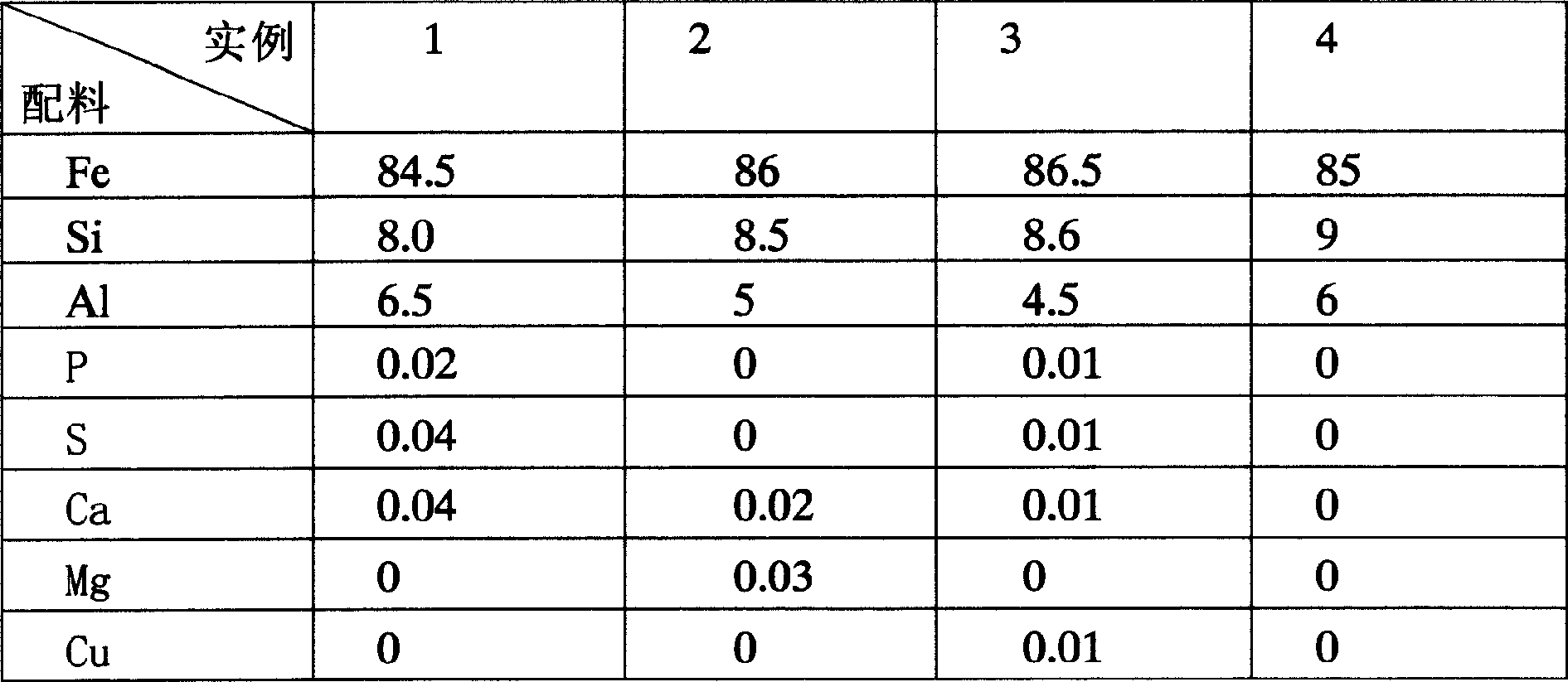

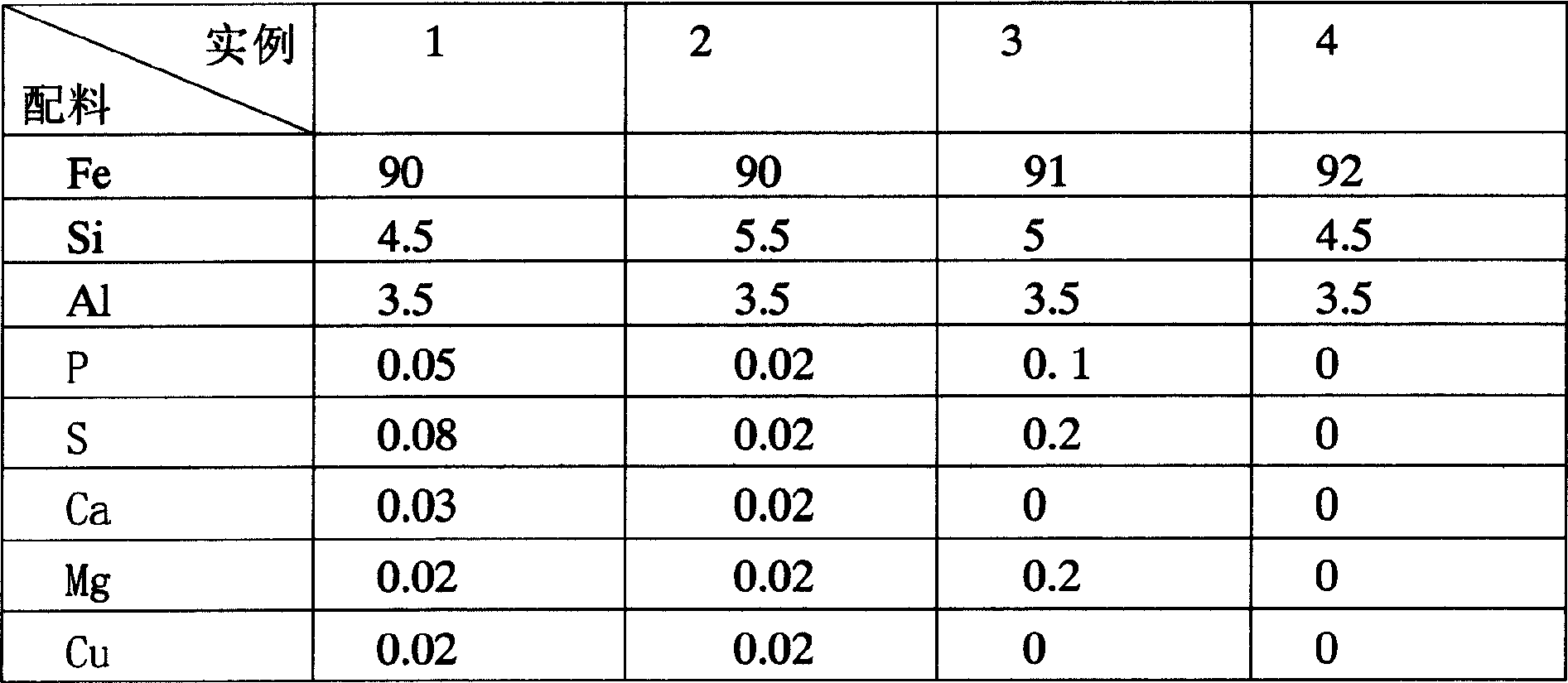

Making method for electromagnetic wave interference resisting iron ,silicon, aluminum and nickel alloy

The invention discloses a preparation method for electromagnetic wave interference resistant iron silicon aluminum nickel alloys. The invention comprises the following steps: firstly, ferrum, aluminum, silicon and nickel with a purity more than 99.9 weight percent are taken as raw materials and laid into a medium frequency vacuum induction furnace for smelting, and a master alloy is obtained; secondly, the master alloy after smelting is laid into a quick quenching device; an alloy ingot casting is quickly poured on a water-cooling roll wheel which rotates at high speed after arc remelting under the protection of high purity inert gases, and a quickly condensed sheet band or a quickly condensed sheet is obtained; thirdly, the sheet band or the sheet is laid into a ball mill for ball milling flat processing, and flat powder is obtained; fourthly, the flat powder is laid into a stainless steel tube which is then vacuumized and filled with high purity inert gases for protection, and then the stainless steel tube is laid into a tube furnace for heating, heat preservation and cooling along with the furnace; fifthly, the flat powder and binding agents are mixed and milled for processing the sheet. The preparation method for the electromagnetic wave interference resistant iron silicon aluminum nickel alloys adds adequate nickel into Sendust alloys, thereby the processability of the alloys is improved; the ball milling time is reduced; the cost of industrial production is saved; simultaneously the magnetic conductivity can be improved and the magnetic shielding effect can be improved.

Owner:ZHEJIANG UNIV +1

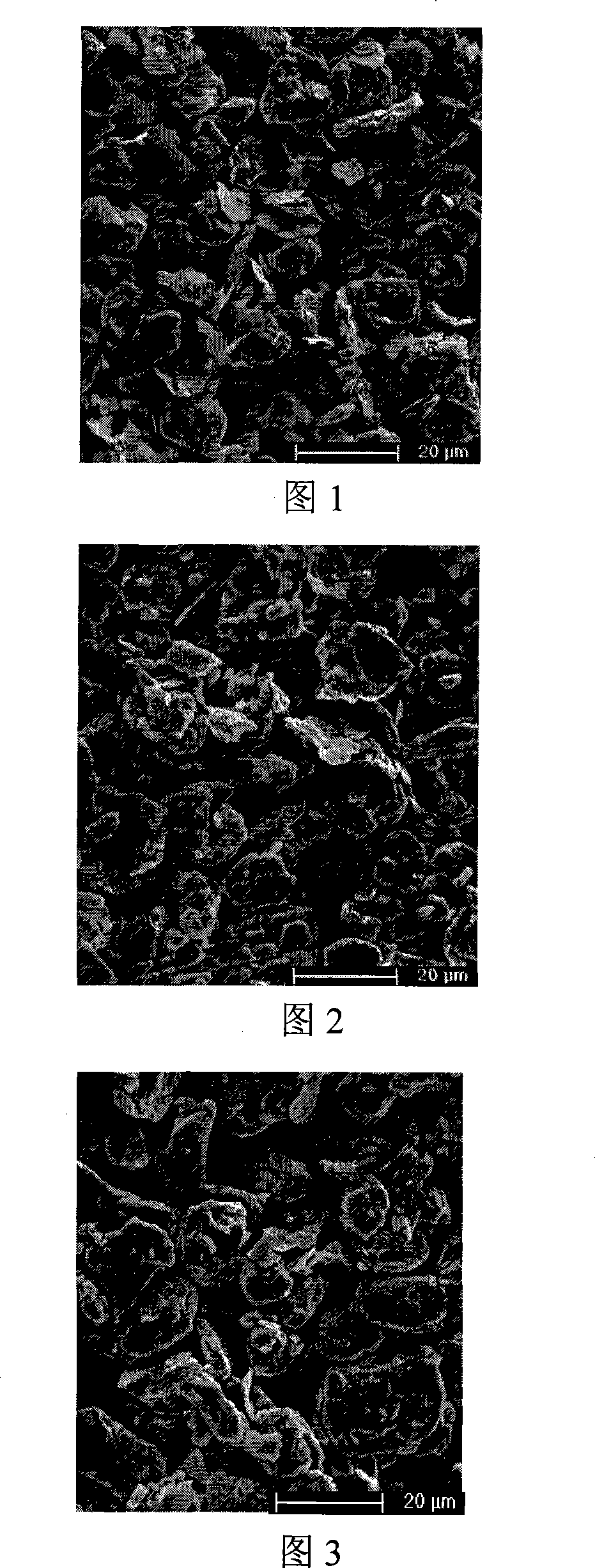

Electromagnetic wave interference preventive material and production thereof

InactiveCN1646000AHigh specific surface areaIncrease reflectionMagnetic/electric field screeningIron powderSendust

The anti electromagnetic interference material is composed of several layers: the impedance matching layer is made of absorbing type sendust powder, manganese-zinc ferrite and resin; the absorbing layer is made of absorbing type sendust powder, nickel zinc ferrite and resin; the reflecting layer is made of reflection type sendust powder, iron powder and resin.

Owner:横店集团东磁有限公司

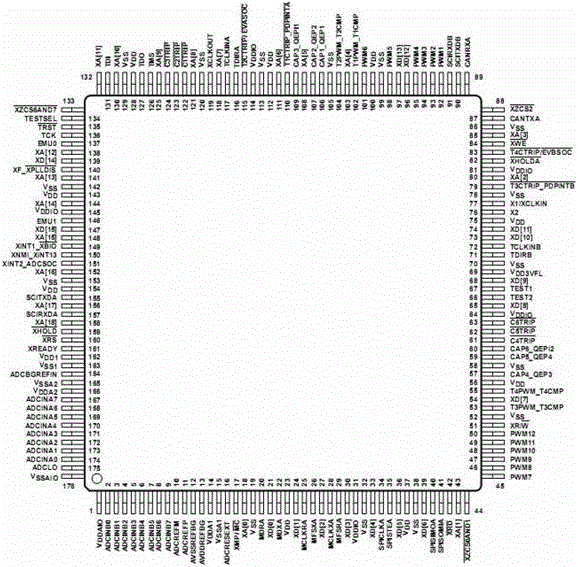

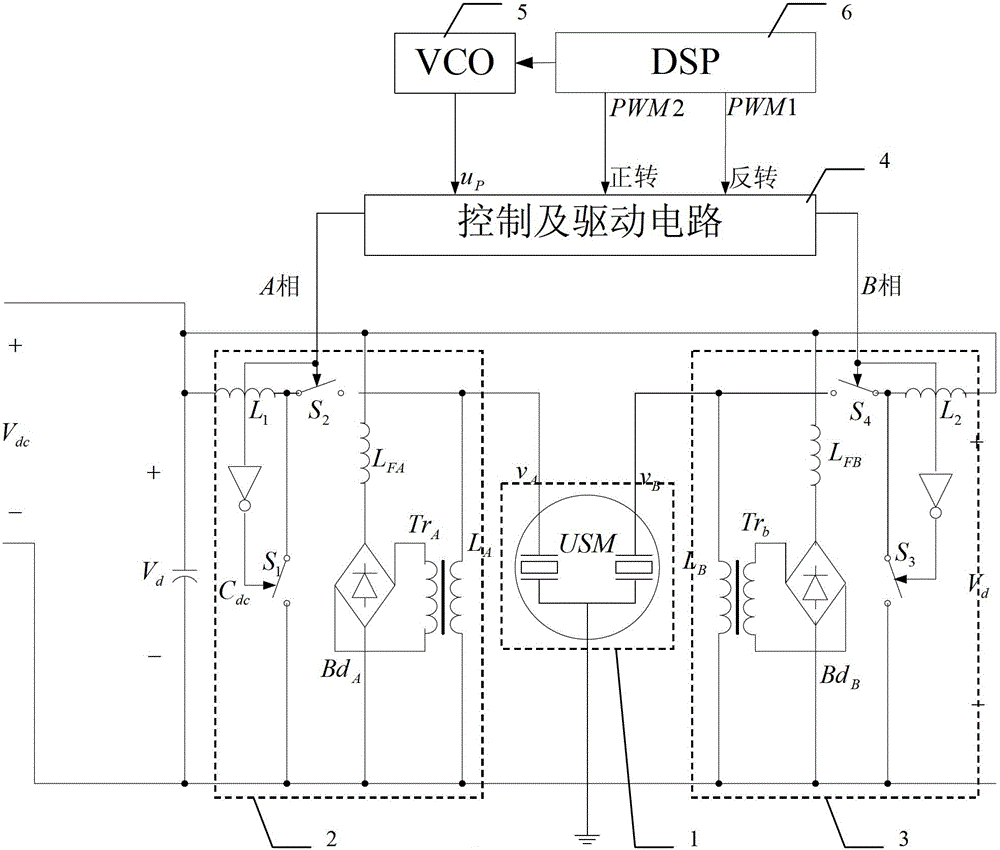

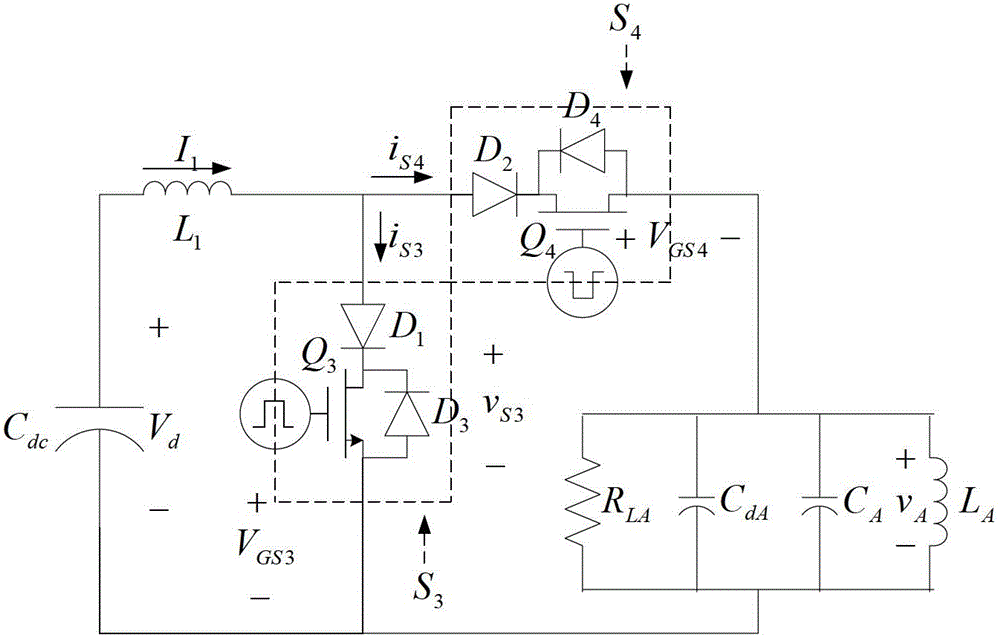

Device and method for controlling XY working platform of ultrasonic motor based on neural network

InactiveCN102722136ASmall torqueIncrease torquePiezoelectric/electrostriction/magnetostriction machinesNumerical controlMathematical modelEngineering

The invention discloses a device and a method for controlling an XY working platform of an ultrasonic motor based on a neural network. The device comprises an ultrasonic motor circuit, a resonance trough main circuit, a voltage-controlled oscillator (VCO), a control and driving circuit and a digital signal processor, wherein the resonance trough main circuit comprises a current source parallelly-connected resonance driving circuit; and the current source parallelly-connected resonance driving circuit comprises two current source parallelly-connected resonance inverters with energy feedback functions. An ultrasonic motor is adopted; compared with other motors, the ultrasonic motor has the advantages of being influenced by electromagnetic wave interference difficultly along with high torque at low rotating speed and the like; furthermore, the current source parallelly-connected resonance inverters with the energy feedback functions control the ultrasonic motor, so that advantages of relatively large operation frequency range, relatively small direct current harmonic, no need of buffers and the like are achieved; and according to the characteristic of the ultrasonic motor that a math model is determined difficultly, the ultrasonic motor is controlled by adopting a fuzzy neural network algorithm, so that the tracking precision of a system is improved.

Owner:SHENYANG POLYTECHNIC UNIV

Structure of connector for reducing electro-magnetic wave interference

InactiveUS20050026509A1Reduce electromagnetic interferenceCost-effective structureCoupling for high frequencyTwo-part coupling devicesEngineeringElectromagnetic wave interference

A structure of a connector is provided. The connector comprises a receiving module, a first circuit board, a second circuit board, a third circuit board and adaptor module. The circuits of various characteristics are set onto the first circuit board and the second circuit board respectively for reducing electro-magnetic wave inferences during signal transmission.

Owner:SPEED TECH

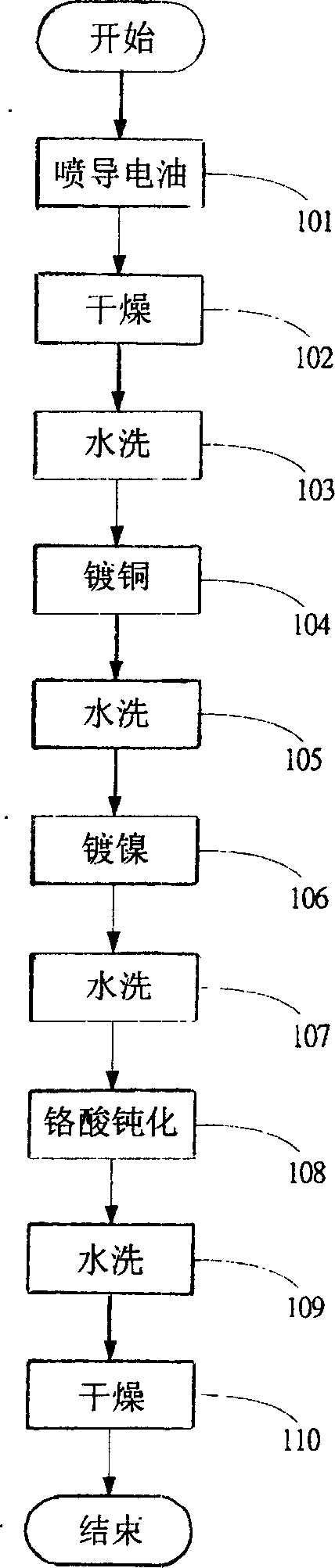

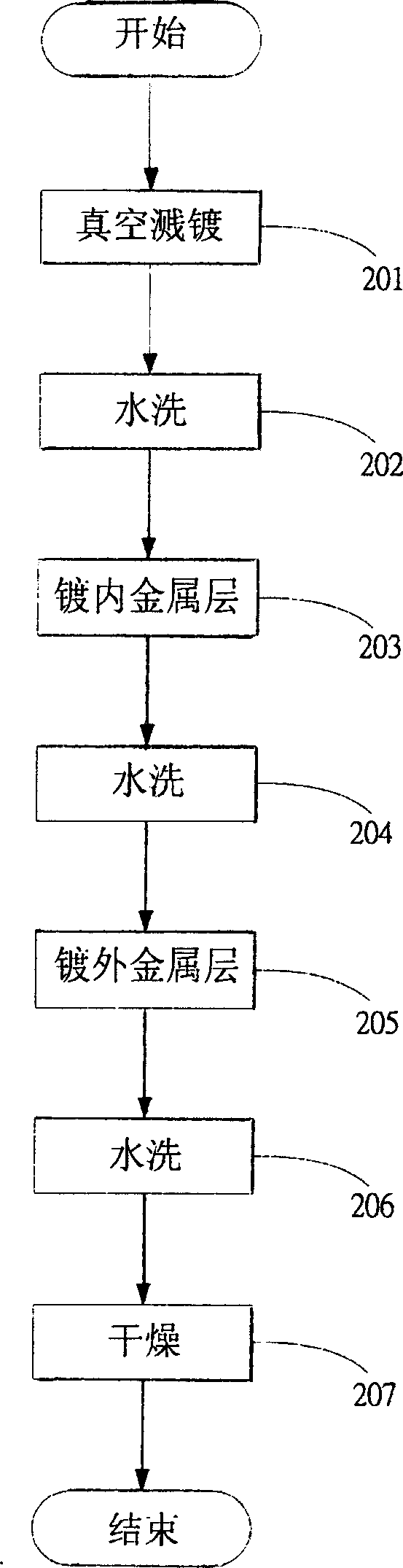

Method for metallizing surface of nonmetallic material, and composing structure of surface

InactiveCN1696345AIncreasing the thicknessImprove conductivitySuperimposed coating processSputteringMetallic materials

A process for alloying the surfaces of non-metal material for preventing electromagnetic interference includes vacuum sputtering to form a basic thin metal film on the surface of non-metal material and chemical or electric plating to form an internal emtal layer (Cu) and an external metal layer (Ni, Cr, etc).

Owner:吴东兴

Mass production of pristine nano graphene materials

ActiveUS8226801B2Reduce surface tensionHigh product yieldMaterial nanotechnologyGrapheneEdge surfaceLiquid medium

The present invention provides a method of producing pristine or non-oxidized nano graphene platelets (NGPs) that are highly conductive. The method comprises: (a) providing a pristine graphitic material comprising at least a graphite crystallite having at least a graphene plane and an edge surface; (b) dispersing multiple particles of the pristine graphitic material in a liquid medium containing therein no surfactant to produce a suspension, wherein the multiple particles in the liquid have a concentration greater than 0.1 mg / mL and the liquid medium is characterized by having a surface tension that enables wetting of the liquid on a graphene plane exhibiting a contact angle less than 90 degrees; and (c) exposing the suspension to direct ultrasonication at a sufficient energy or intensity level for a sufficient length of time to produce the NGPs. Pristine NGPs can be used as a conductive additive in transparent electrodes for solar cells or flat panel displays (e.g., to replace expensive indium-tin oxide), battery and supercapacitor electrodes, and nanocomposites for electromagnetic wave interference (EMI) shielding, static charge dissipation, and fuel cell bipolar plate applications.

Owner:GLOBAL GRAPHENE GRP INC

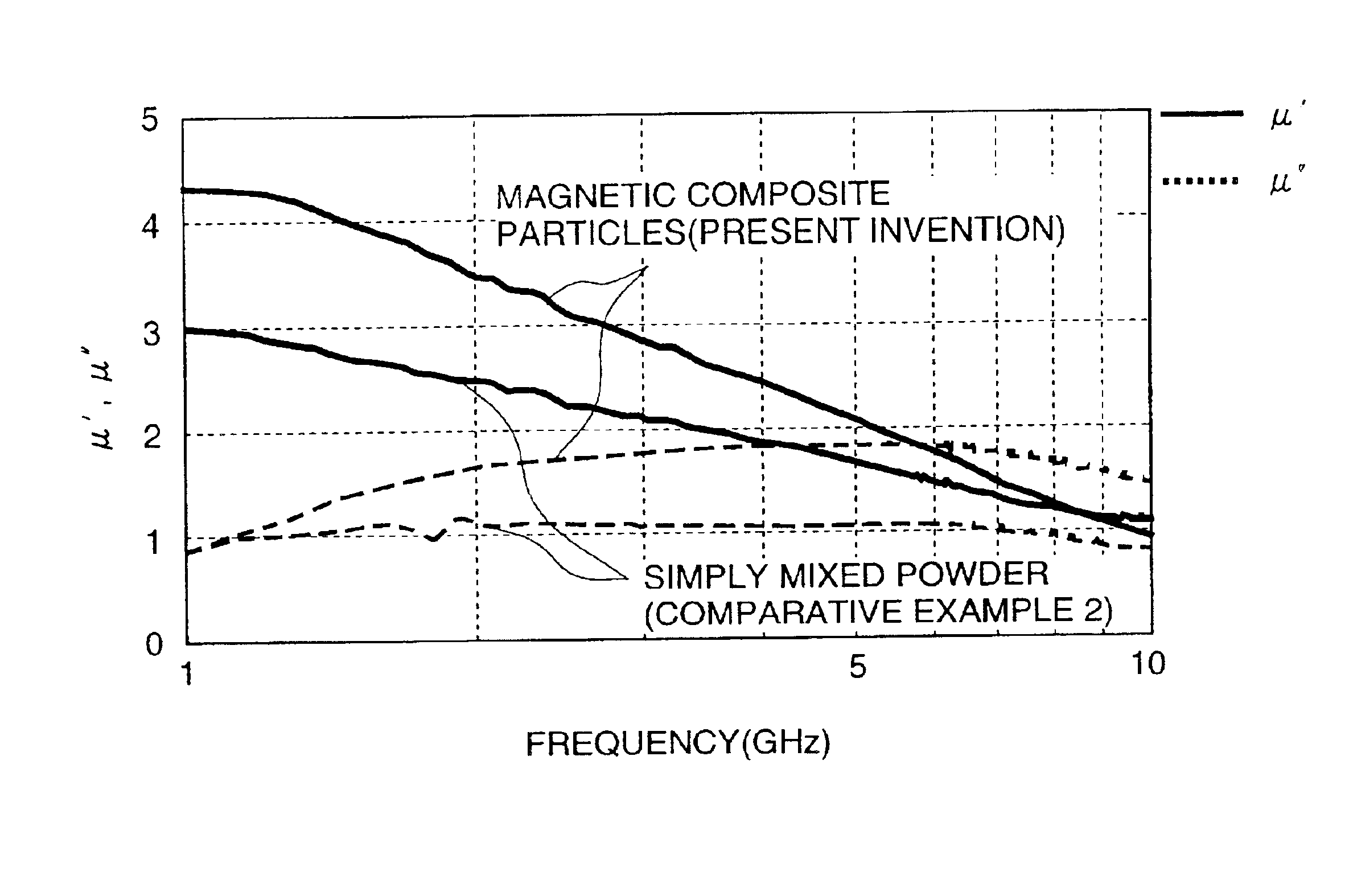

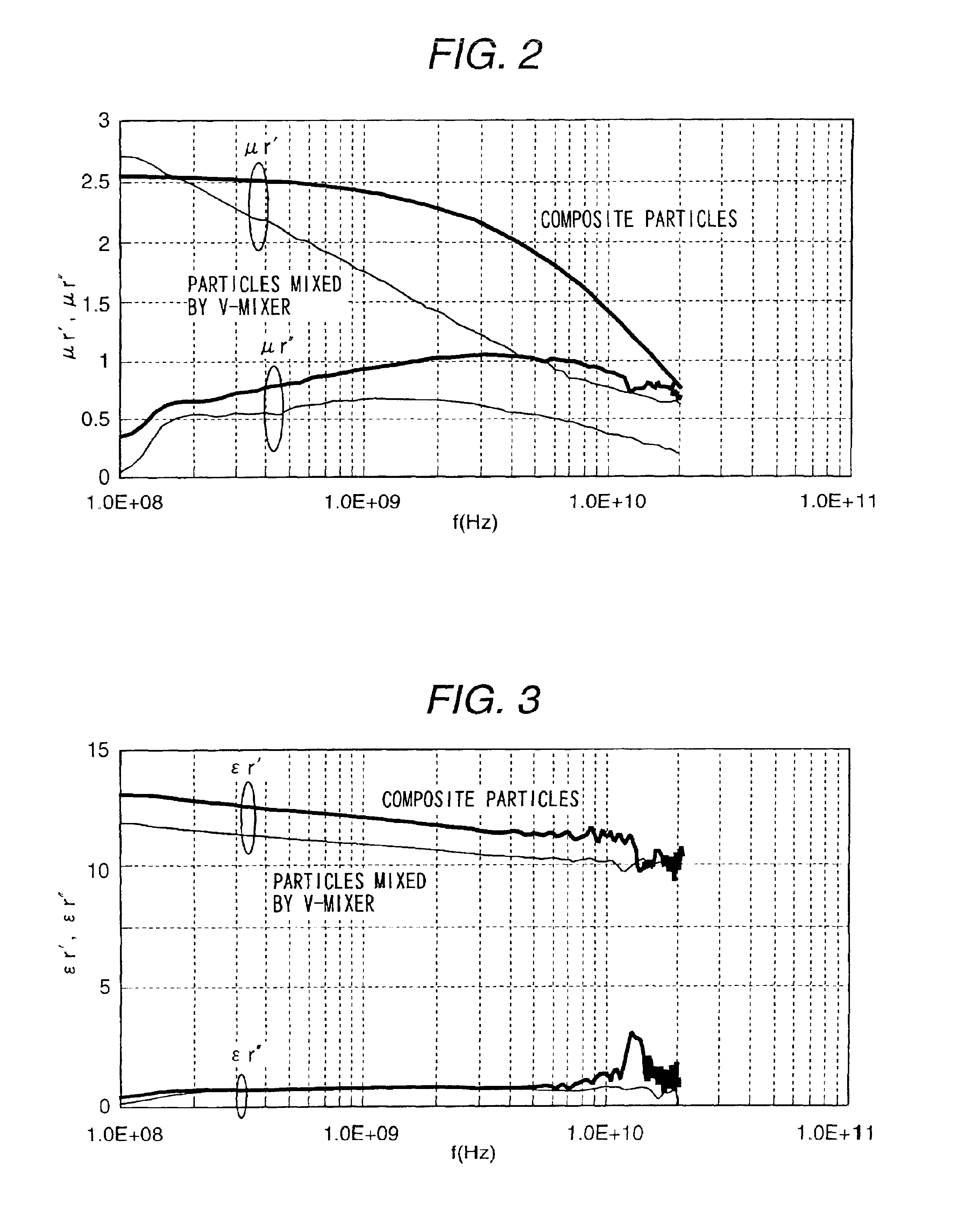

Electromagnetic wave absorber, method of manufacturing the same and appliance using the same

InactiveUS6919387B2Excellent electromagnetic wave absorbing characteristicIncrease heightMagnetic/electric field screeningRoad vehicles traffic controlElectromagnetic wave absorberElectromagnetic absorbers

Owner:HITACHI LTD

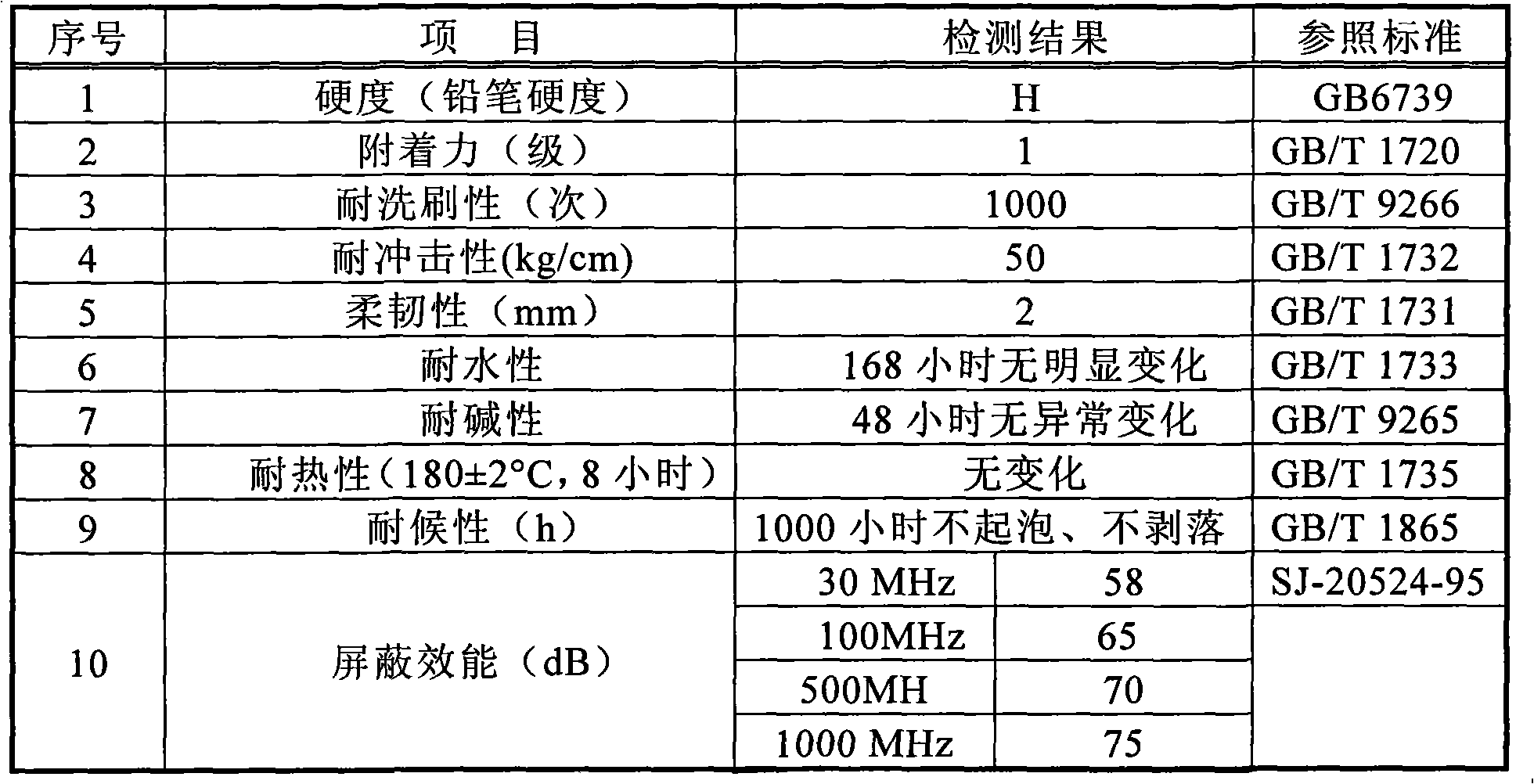

Civil air defence electromagnetic shielding coating and preparation method thereof

InactiveCN101629029AWide shielding frequency bandImprove shielding effectPolyurea/polyurethane coatingsWater basedSolvent

The invention discloses a civil air defence electromagnetic shielding coating which can be divided to oil-based coating and water-based coating. The coating comprises base coat and finishing coat, wherein, the base coat comprises the following components by weight percent: 25-35% of film forming matter, 40-50% of conductive filler, 5-6% of additive and 20-35% of solvent, and the finishing coat comprises the following components by weight percent: 45-55% of film forming matter, 5-6% of nanometer oxide, 2-4% of additive and 35-45% of solvent. The coating of the invention has good physical and chemical properties and wide frequency band masking, can prevent electromagnetic interference, has positive effect for preventing threat of electromagnetic radiation to electronic equipments and human health and can be applicable to being used in constructions, electronic equipments and the like; the preparation method is simple, the device and technological requirements are not high so that the method is applicable to industrialized production.

Owner:徐瑞龙 +1

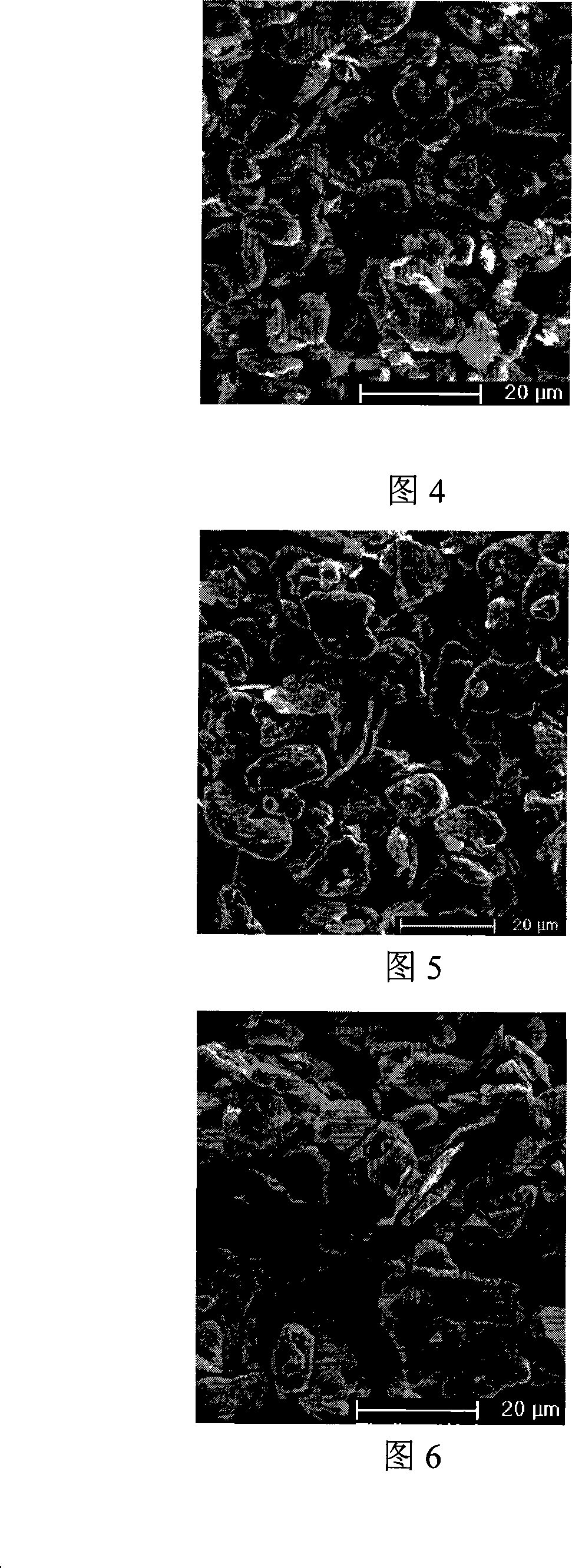

Method for manufacturing iron base alloy electromagnetic-interference-resistance

InactiveCN101226801AUniform compositionHigh crystallinityInorganic material magnetismVacuum pumpingTube furnace

The invention discloses a process for preparing anti-electromagnetic wave interference material of ferrous alloy, which comprises steps of 1) placing melted ferrous master alloy in a rapidly quench device, quickly pouring cast ingots of the ferrous master alloy under the protection of inert gas to a roller rotating at high speed after remelting to obtain bands rapidly condensed, 2) flattening the bands via ball-milling process to obtain flat powder, 3) placing the flat powder into a stainless steel tube, after vacuum-pumping and charging protective inert gas, placing the stainless steel tube into a tube furnace for heating and heat-insulating, then cooling along with the furnace, 4) mixing and processing the flat powder and binding agent into flaky flexible anti-electromagnetic interference material. The invention improves the technique of preparing the anti-electromagnetic interference material, processing parameter is easy to control, large-scale mass production is suitable, magnetic bodies have high magnetic permeability, and magnetic shielding effect is largely increased.

Owner:ZHEJIANG UNIV

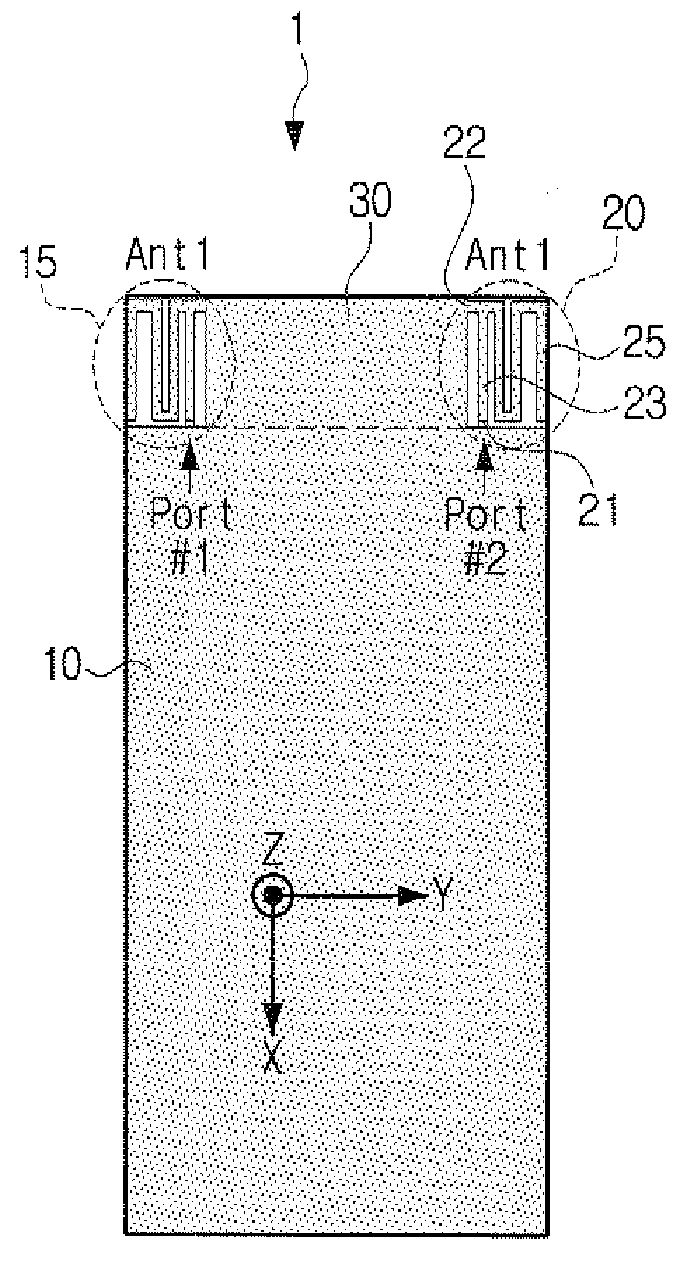

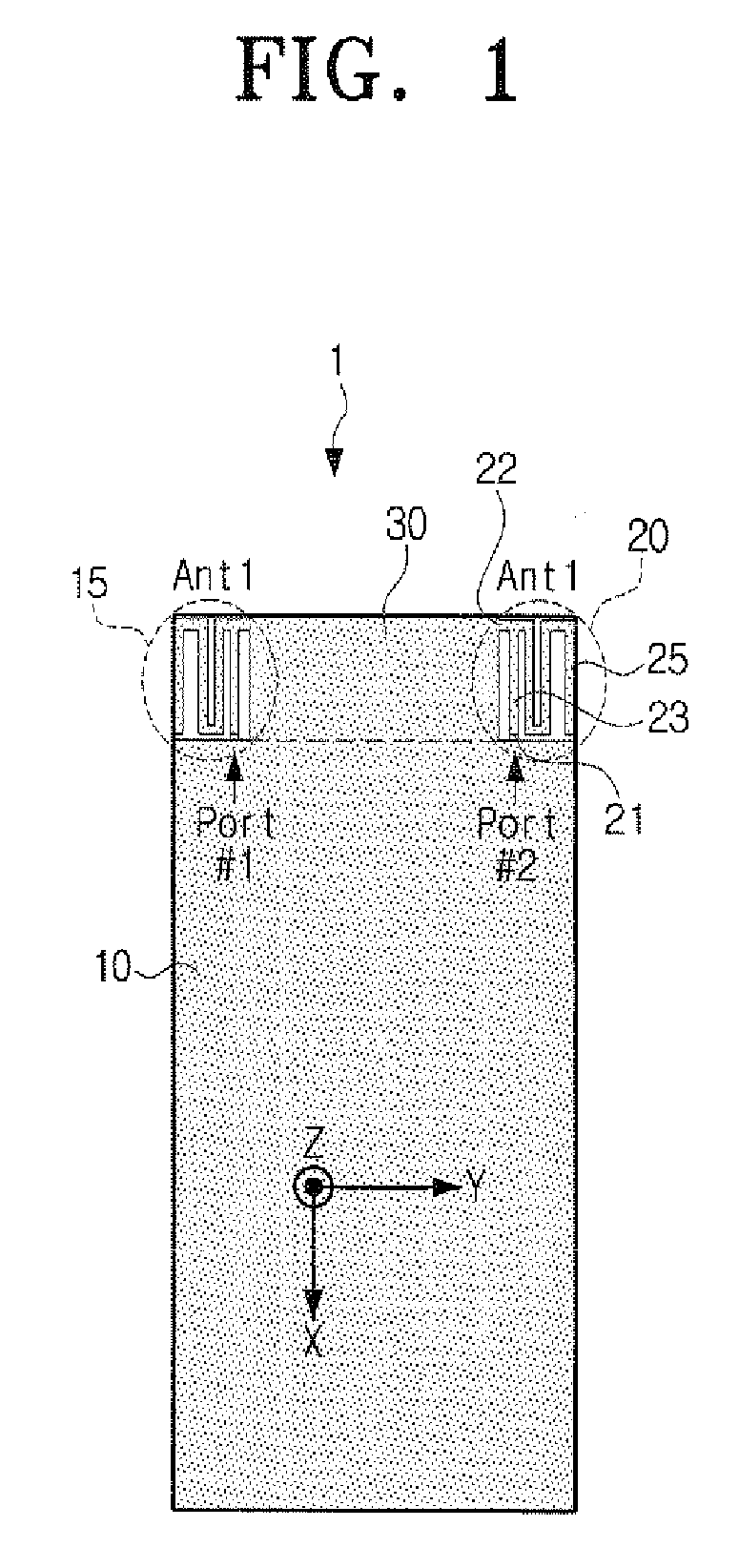

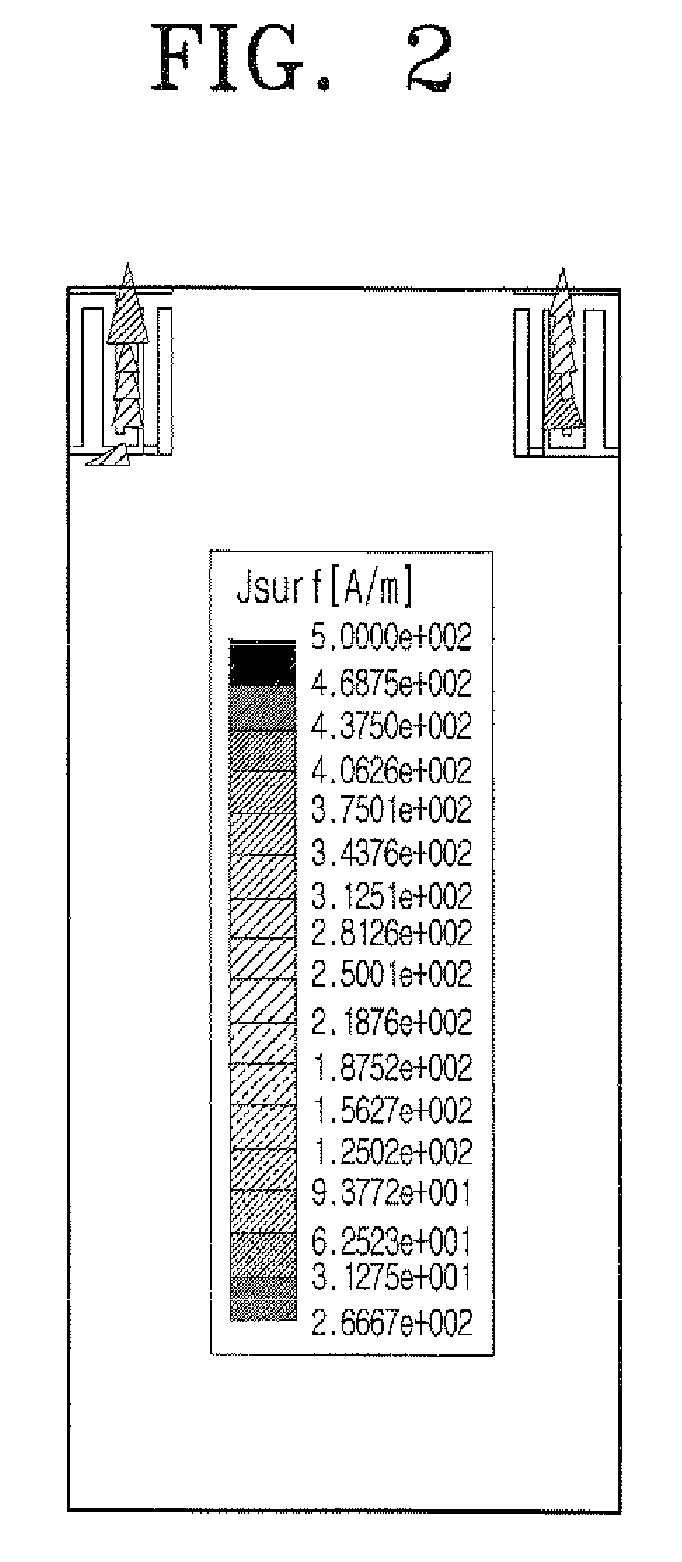

Antenna having additional ground

InactiveUS20080129632A1Avoid electromagnetic interferenceFree installationAntenna earthingsIndependent non-interacting antenna combinationsMiniaturizationAntenna element

An antenna having an additional ground, includes a first ground which is formed in one side of a substrate; a plurality of antenna elements which are formed symmetrically with respect to each other and spaced apart from one end of the first ground; and a second ground which is interposed between the plurality of the antenna elements and integrally formed with the first ground. Accordingly, the deterioration of the antenna characteristics can be minimized even after the arrangement of the antenna elements with the ground, and the antenna can be miniaturized and easily fabricated in a two-dimensional structure. Furthermore, the electromagnetic wave interference can be minimized between the antenna elements.

Owner:SAMSUNG ELECTRONICS CO LTD

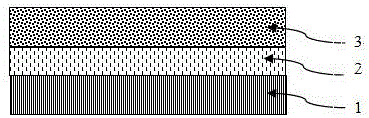

Photoelectric thin film capable of strengthening adhesive force and application of photoelectric thin film

InactiveCN106098806ANo obvious sheddingGood adhesionSemiconductor devicesChemical platingSilicon oxide

The invention discloses a photoelectric thin film capable of strengthening the adhesive force. A thin film structure comprises a substrate, one, two or multiple interface modification layers and a metal thin film layer, wherein the interface modification layers are the same or different in material; the substrate is a glass, quartz, lead-containing glass, ceramic, zirconium oxide, aluminum oxide, silicon wafer, mica or plastic substrate; the interface modification layers are made of silicon oxide, aluminum oxide, zirconium oxide, titanium oxide or a compound of two or more of the silicon oxide, the aluminum oxide, the zirconium oxide and the titanium oxide; and the metal thin film layer is made of aluminum, silver, copper, gold and various metal alloys. Each interface modification layer is prepared by CVD, PVD or a chemical method such as a sol-gel method; and the metal thin film layer is prepared by the methods of PVD, CVD or chemical plating and the like. After the interface modification layers are adopted, the adhesion properties of the substrate and the metal thin film layer are obviously improved; the disadvantage that the metal thin film layer easily falls off on the substrate is well overcome; and the photoelectric thin film can be applied to the fields of a photoelectric device electrode, a light reflector or an anti-electromagnetic interference protective layer and the like.

Owner:EAST CHINA NORMAL UNIV

Preparation of conductive dynamically vulcanized thermoplastic elastomer material

The invention relates to a conductive dynamically vulcanized thermoplastic elastomer material, which is characterized in that the invention is prepared by adopting the following raw materials in weight percentage: 10 per cent to 50 per cent of propylene copolymers, 20 per cent to 75 per cent of ethylene propylene diene monomers, 4 per cent to 8 per cent of antistatic agents, 1 per cent to 20 per cent of polyethylene waxes, 0.1 per cent to 0.5 per cent of curing agents, 0.1 per cent to 0.5 per cent of antioxidants and 0.1 per cent to 0.5 per cent of lubricants.The preparation method comprises the following steps: the raw materials are scaled and taken according to a weight proportion; all the materials are put into a high mixing machine to be mixed for 2-5 minutes; the materials are taken out; the mixed materials are put into a screw compressor for extruding granulations. The rotating speed of the screw compressor is 180-600r / m and temperature is 160-200 DEG C. The invention has the advantages that the prepared thermoplastic elastomer material has excellent conductivity, has a surface resistance ranging from 200 Omegas to 800 Omegas and can be used for fabricating the electronic production equipments, tools, electronic instruments, meter shells and decorative materials for dustfree production workshops, on which the demands for static electricity prevention, electromagnetic wave interference prevention and inexistence of dust are met.

Owner:SHANGHAI SUNNY

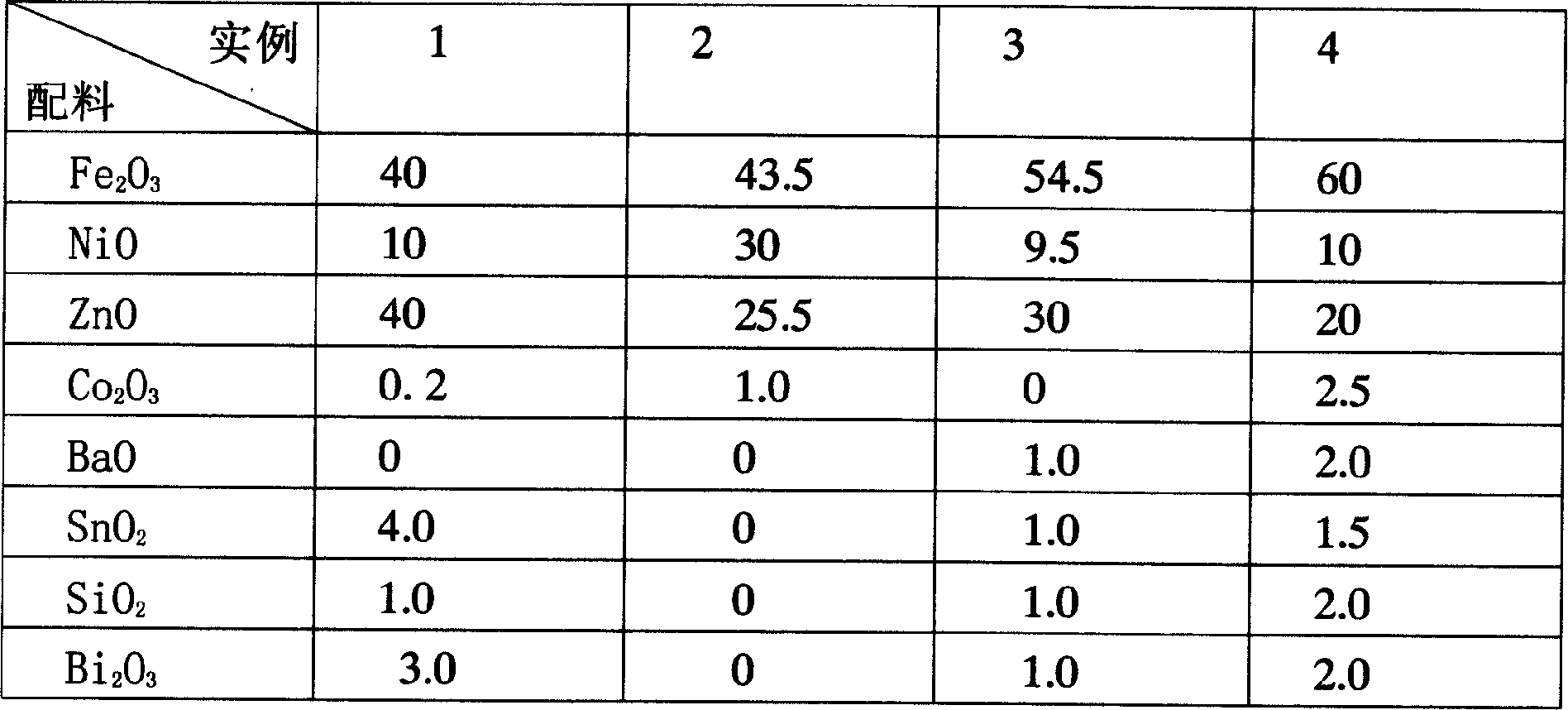

Anti-EMI (electromagnetic interference) ferrite material and preparation method thereof

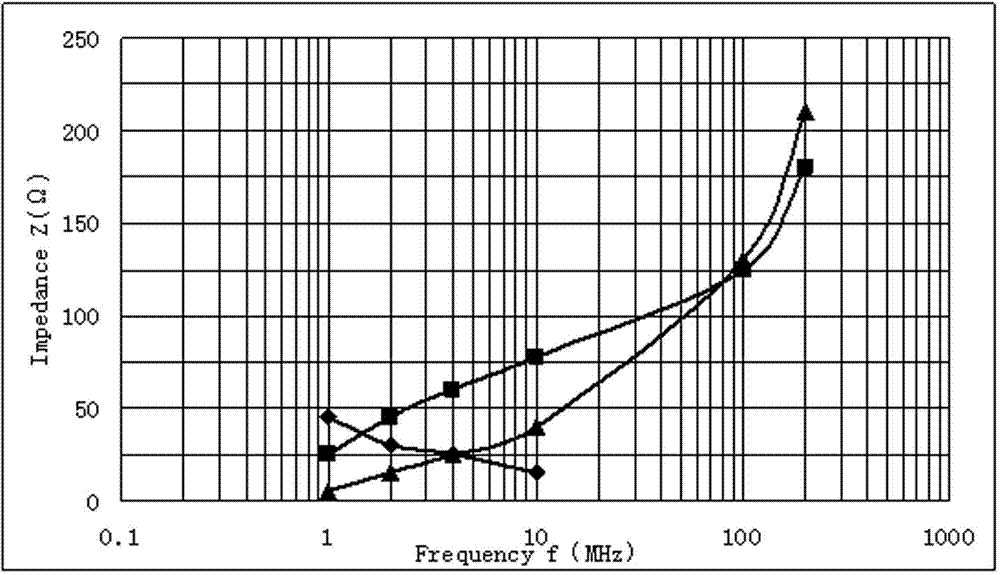

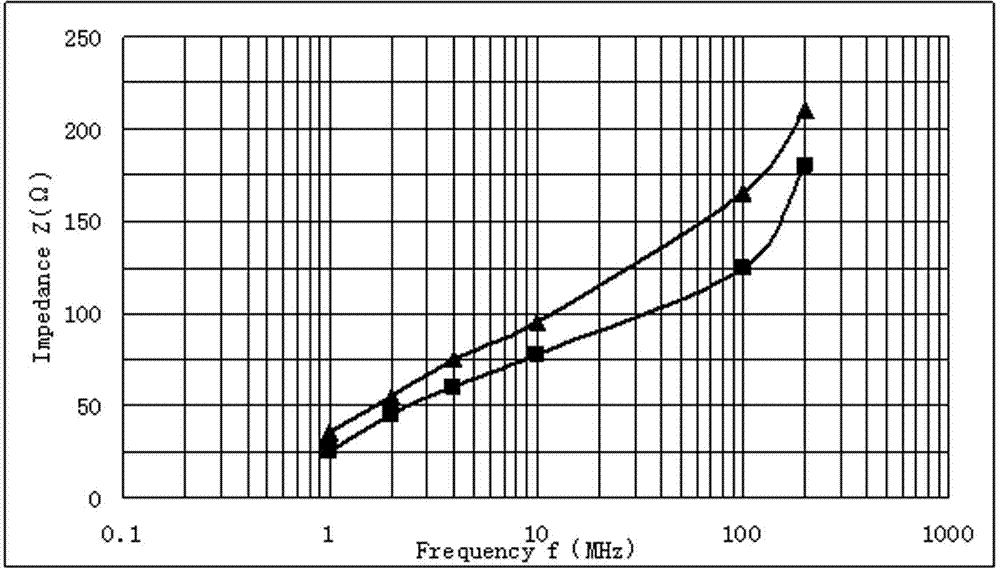

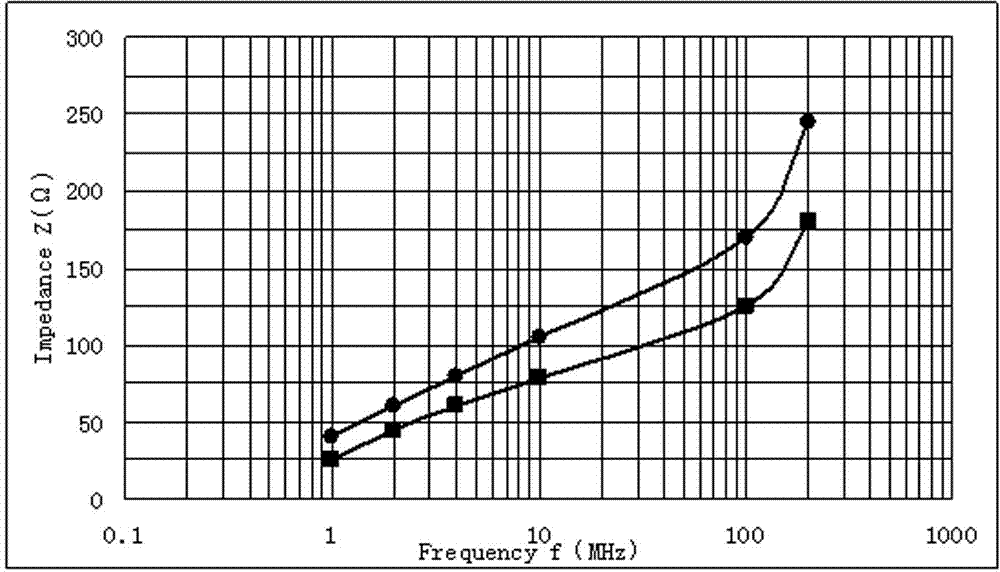

InactiveCN104261812AImprove permeabilityImprove impedance characteristicsInitial permeabilityElectromagnetic interference

The invention discloses an anti-EMI (electromagnetic interference) ferrite material and a preparation method thereof. The initial permeability of the ferrite material provided by the invention at the normal temperature is over 2000, the volume resistivity is over 100 ohm, and the ferrite material has an excellent impedance characteristic in a frequency band of 1-100M and can be used for effectively reducing electromagnetic wave interference of electronic equipment. The anti-EMI ferrite material disclosed by the invention can be produced and prepared by adopting conventional equipment and is simple in process, low in energy consumption and strong in adaptability of raw materials.

Owner:麦格磁电科技(珠海)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com