High thermal conductivity and EMI sheltering high polymer composite material

A polymer and composite material technology, applied in the field of polymer composite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

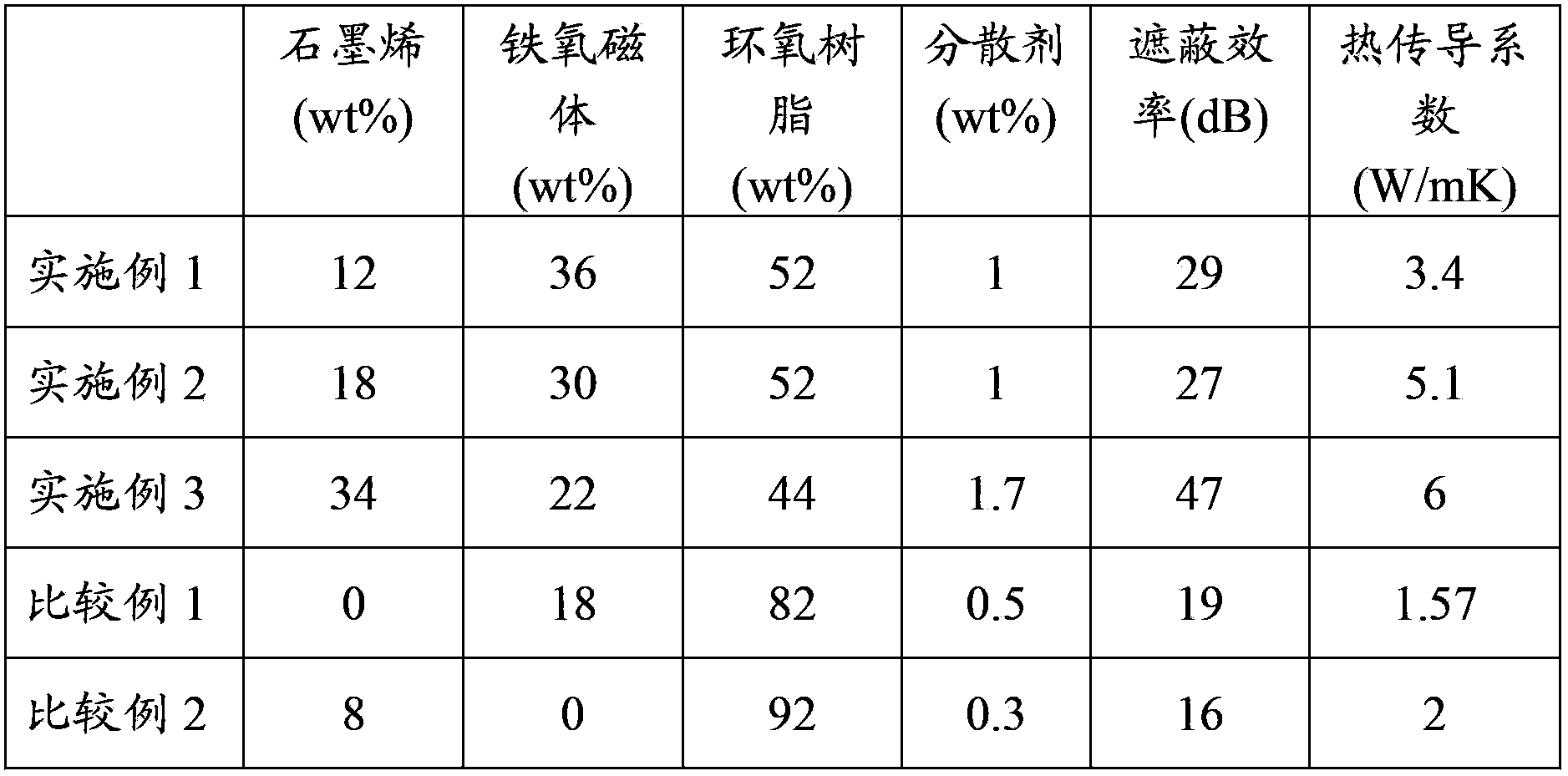

Embodiment 1

[0037] Add 12wt% graphene (Graphene Laboratories Inc.) and 36wt% ferrite magnet (Fe 3 o 4 , Aldrich-637106) in 52wt% epoxy resin, and add another 1wt% dispersant, fully mixed to make it evenly dispersed, so as to manufacture a polymer composite material with both thermal conductivity and EMI shielding.

Embodiment 2

[0039] Add 18wt% graphene (Graphene Laboratories Inc.) and 30wt% ferrite magnet (Fe3O4, Aldrich-637106) in 52wt% epoxy resin, and add 1wt% dispersant in addition, fully mix, make it disperse evenly, In this way, a polymer composite material with thermal conductivity and EMI shielding is manufactured.

Embodiment 3

[0041] Add 34wt% graphene (Graphene Laboratories Inc.) and 22wt% ferrite magnet (Fe3O4, Aldrich-637106) to 44wt% epoxy resin, and add 1.7wt% dispersant, mix well to make it evenly dispersed , so as to manufacture a polymer composite material with both thermal conductivity and EMI shielding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com