Making method for electromagnetic wave interference resisting iron ,silicon, aluminum and nickel alloy

An anti-electromagnetic wave, SensiAlNi technology, applied in the direction of circuits, magnetic materials, electrical components, etc., can solve the problems of brittle texture and difficult cold working, and achieve the effects of improving magnetic permeability, saving production costs, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1) Put the raw materials in a mass ratio: 85.5% of iron, 4% of silicon, 5% of aluminum, and 5.5% of nickel, into an intermediate frequency vacuum induction furnace with alumina as a crucible, and evacuated to 10 -1 Pa, and then send electricity to preheat the charge to eliminate the adsorbed gas, moisture and organic matter of the charge. At this time, the vacuum in the furnace drops, and then evacuates to 10 -2 Above Pa, fill with high-purity argon gas to the furnace pressure of 0.5×10 5 Pa, high-power transmission to completely melt the charge, and then low-power refining for 10 minutes before pouring.

[0025] 2) The smelted FeSiAlNi master alloy is put into the rapid quenching equipment, the alloy ingot is remelted by arc under the protection of high-purity argon gas, and then quickly poured onto the high-speed rotating roller to obtain fast-condensing flakes. The quenching rate is 15m / s;

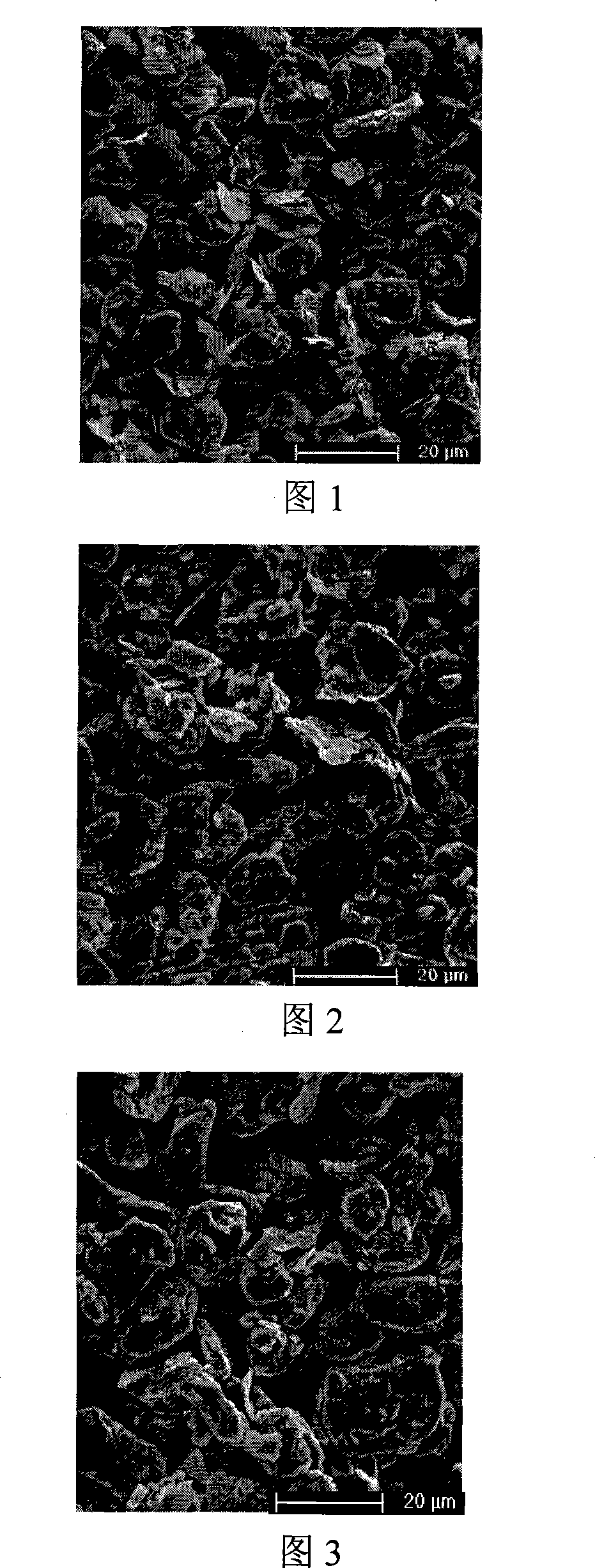

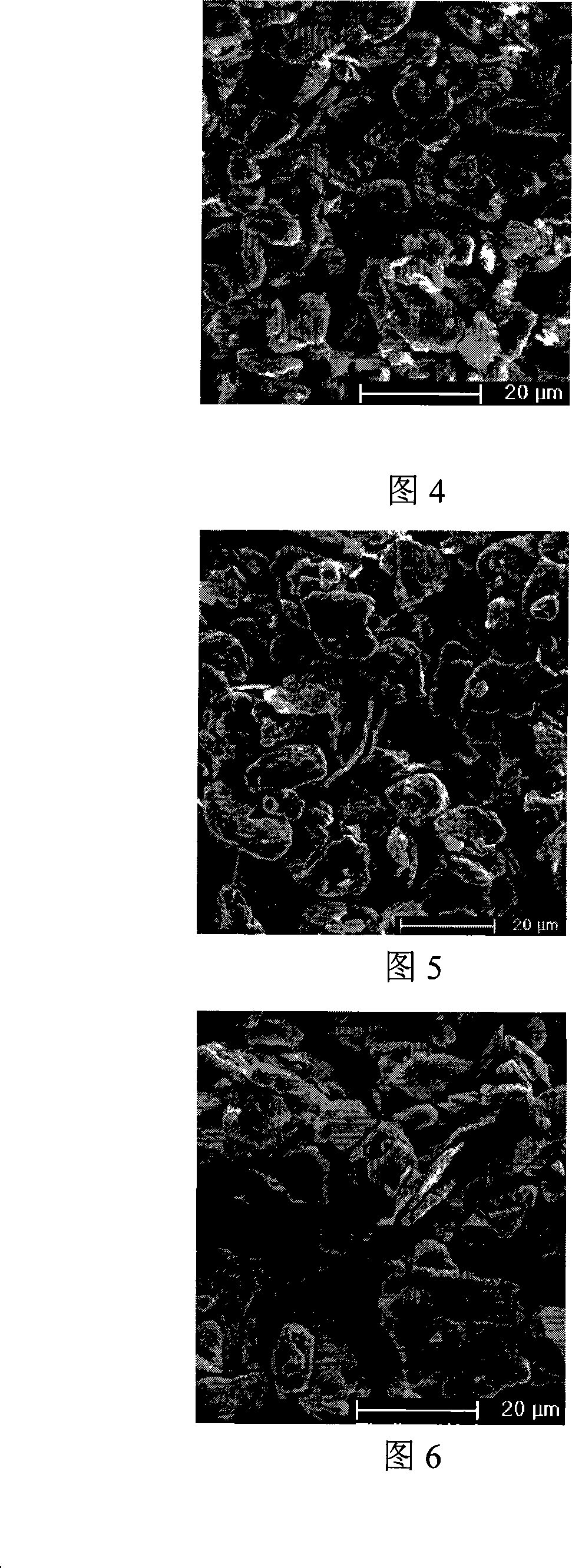

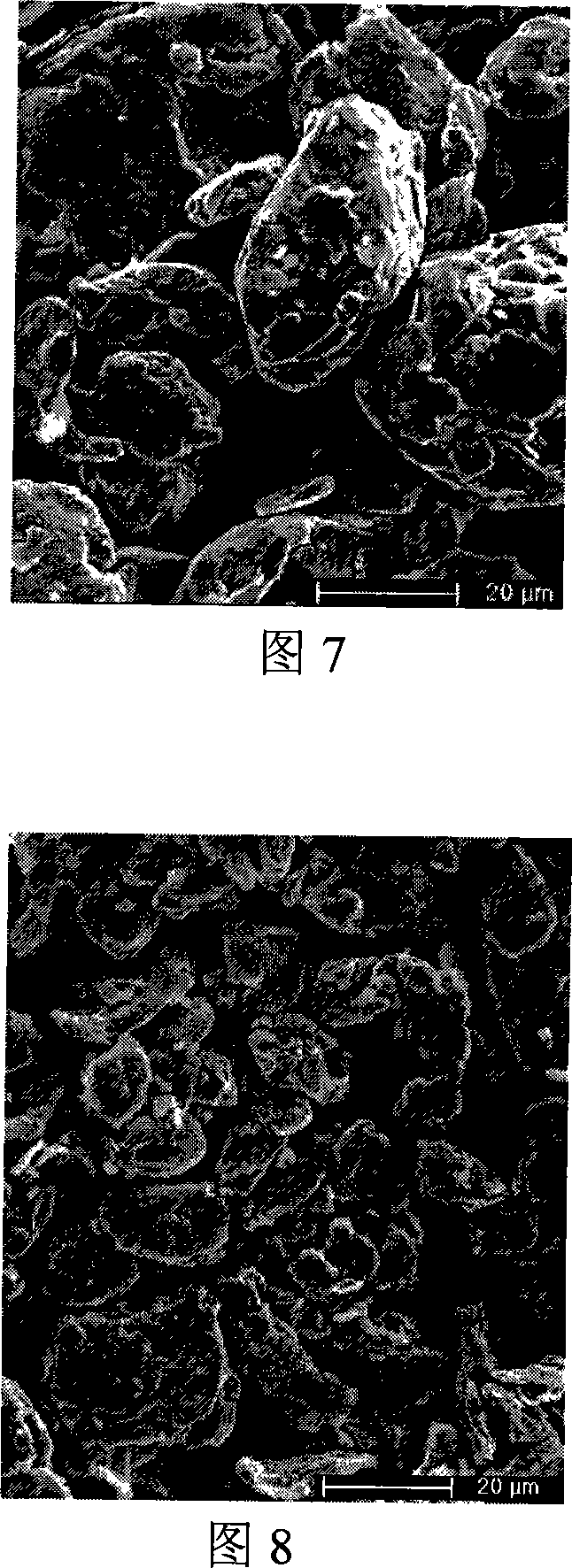

[0026] 3) Put the FeSiAlNi flakes into a ball mill for ball milling and flatteni...

Embodiment 2

[0030] 1) Put the raw materials in a mass ratio of 84% iron, 8% silicon, 4.5% aluminum, and 3.5% nickel into an intermediate frequency vacuum induction furnace with alumina as a crucible, and evacuated to 10 -1 Pa, and then send electricity to preheat the charge to eliminate the adsorbed gas, moisture and organic matter of the charge. At this time, the vacuum in the furnace drops, and then evacuates to 10 -2 Above Pa, fill with high-purity argon gas to the furnace pressure of 0.5×10 5 Pa, high-power transmission to completely melt the charge, and then low-power refining for 10 minutes before pouring.

[0031] 2) The smelted FeSiAlNi master alloy is put into the rapid quenching equipment, and the alloy ingot is remelted under the protection of high-purity argon gas and then quickly poured onto the high-speed rotating roller to obtain a rapidly condensing thin strip. 25m / s;

[0032] 3) Put the FeSiAlNi thin strip into a ball mill for ball milling and flattening to obtain a flat powd...

Embodiment 3

[0036] 1) Put the raw materials in a mass ratio of 90% iron, 6% silicon, 2.5% aluminum, and 1.5% nickel into an intermediate frequency vacuum induction furnace using alumina as a crucible, and evacuated to 10 -1 Pa, and then send electricity to preheat the charge to eliminate the adsorbed gas, moisture and organic matter of the charge. At this time, the vacuum in the furnace drops, and then evacuates to 10 -2Above Pa, fill with high-purity argon gas to the furnace pressure of 0.5×10 5 Pa, high-power transmission to completely melt the charge, and then low-power refining for 10 minutes before pouring.

[0037] 2) The smelted FeSiAlNi master alloy is put into the rapid quenching equipment, and the alloy ingot is remelted under the protection of high-purity argon gas and then quickly poured onto the high-speed rotating roller to obtain a rapidly condensing thin strip. 20m / s;

[0038] 3) Put the FeSiAlNi thin strip into a ball mill for ball milling and flattening to obtain a flat powd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com