Surface chemical plating treatment process for hollow glass microsphere, plated metal hollow glass microsphere and application thereof

A technology of hollow glass microspheres and surface chemistry, which is applied in the field of electroless plating treatment on the surface of hollow glass microspheres and the field of metal-plated hollow glass microspheres, can solve problems such as cumbersome process, poisonous use, and damage of hollow glass microspheres, and achieve The effect of reducing environmental pollution and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

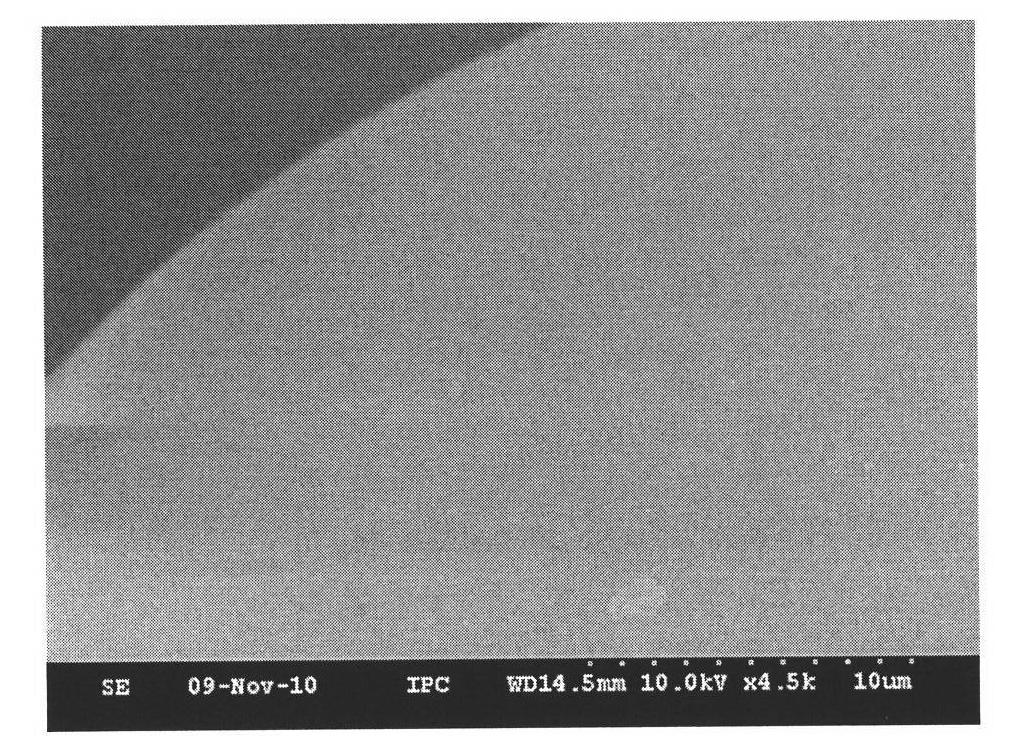

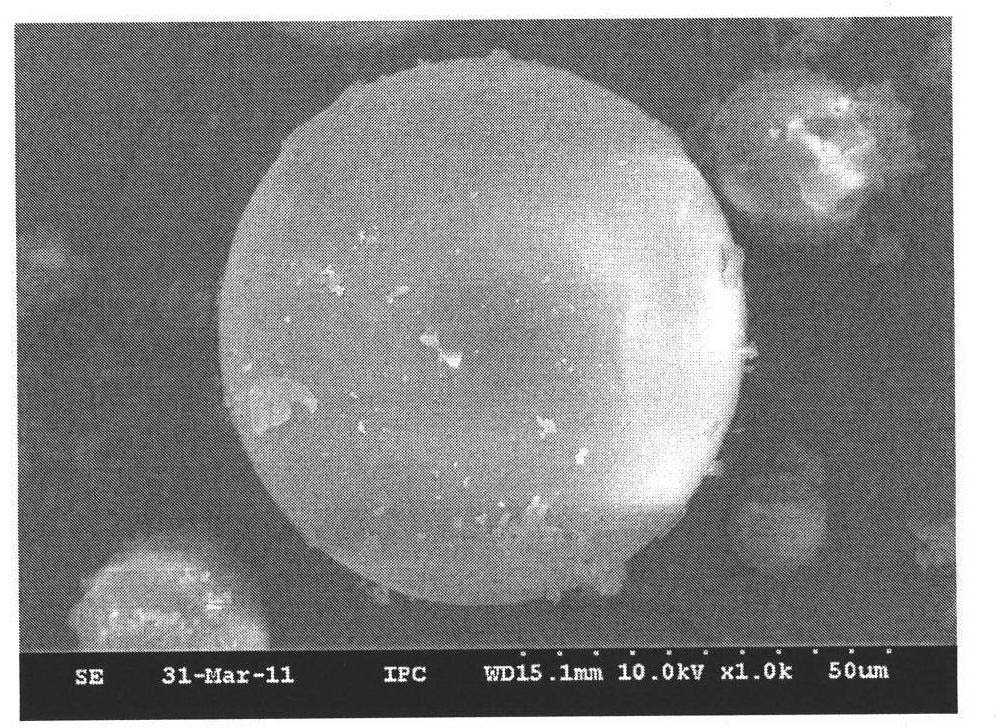

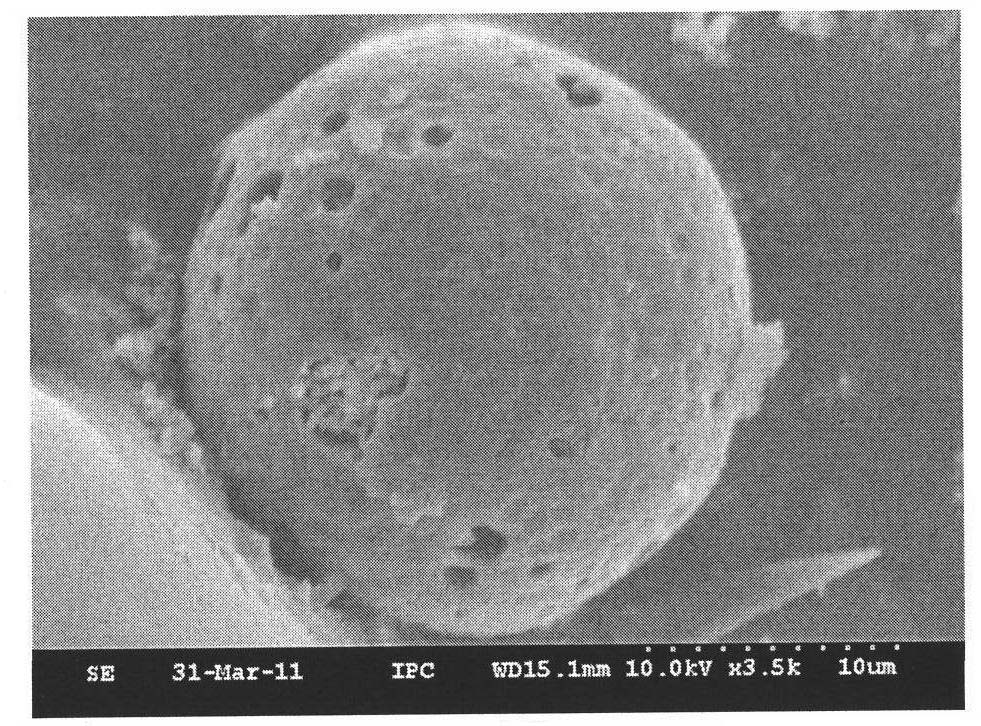

Image

Examples

Embodiment 1

[0051] The first step, cleaning: Weigh 2.0g of hollow glass microspheres and put them into NaOH solution with a concentration of 28g / L, stir and wash them at room temperature for 15 minutes, then filter, and wash the hollow glass microspheres with deionized water to the filtrate is neutral;

[0052] The second step, activation: prepare hydrogen peroxide alkaline solution, measure 10mL hydrogen peroxide solution (containing H 2 o 2 30%) and 10mL ammonia water (mass fraction 25.0% ~ 28.0%, with NH 3 meter), add 200 mL of deionized water to dilute. This hydrogen peroxide alkaline solution contains H 2 o 2 1.5%, with NH 3 1.1%; the hollow glass microspheres treated in the first step are added therein, heated to 82° C., and continuously stirred, and the treatment time is 30 minutes to obtain activated hollow glass microspheres;

[0053] The third step, preparation of plating solution and reducing solution:

[0054] Plating solution: weigh 2.2g AgNO 3 , dissolved in 400 mL ...

Embodiment 2

[0061] The first step, cleaning: Weigh 2.0g of hollow glass microspheres and put them into a NaOH solution with a concentration of 41g / L, stir and wash at room temperature for 15 minutes, then filter, and wash the hollow glass microspheres with deionized water to the filtrate is neutral;

[0062] The second step, activation: prepare hydrogen peroxide alkaline solution, measure 10mL hydrogen peroxide solution (containing H 2 o 2 30%) and 10mL ammonia water (mass fraction 25.0% ~ 28.0%, with NH 3 meter), add 200 mL of deionized water to dilute. This hydrogen peroxide alkaline solution contains H 2 o 2 1.5%, with NH 3 1.1%; the hollow glass microspheres treated in the first step are added therein, heated to 87° C., and continuously stirred for 20 minutes to obtain activated hollow glass microspheres;

[0063] The third step, preparation of plating solution and reducing solution:

[0064] Plating solution: weigh 1.3g AgNO 3 , dissolved in 400 mL of deionized water to prep...

Embodiment 3

[0071] The first step, cleaning: Weigh 2.0g of hollow glass microspheres and put them into a NaOH solution with a concentration of 15.5g / L, stir and wash them at room temperature for 20 minutes, then filter, and wash the hollow glass microspheres with deionized water until they are filtered out liquid is neutral;

[0072] The second step, activation: prepare hydrogen peroxide acidic solution, measure 10mL hydrogen peroxide solution (containing H 2 o 2 30%) and 10 mL of concentrated hydrochloric acid (mass fraction 36% to 38%), add 200 mL of deionized water to dilute. This hydrogen peroxide acidic solution contains H 2 o 2 1.5%, containing 2.0% HCl; add the hollow glass microspheres treated in the first step, heat to 77°C, and keep stirring for 20 minutes to obtain activated hollow glass microspheres;

[0073] The third step, preparation of plating solution and reducing solution:

[0074] Plating solution: weigh 0.7g AgNO 3 , dissolved in 400 mL of deionized water to prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com