Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

492results about How to "Achieve bonding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

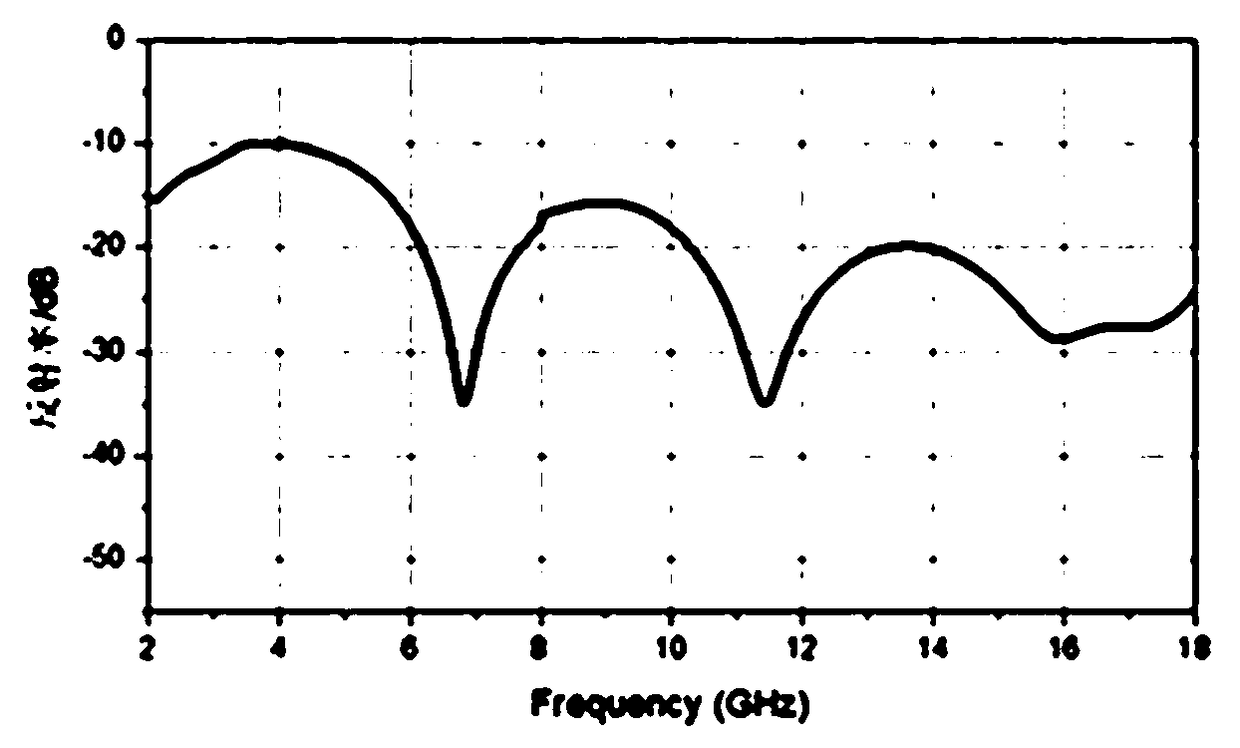

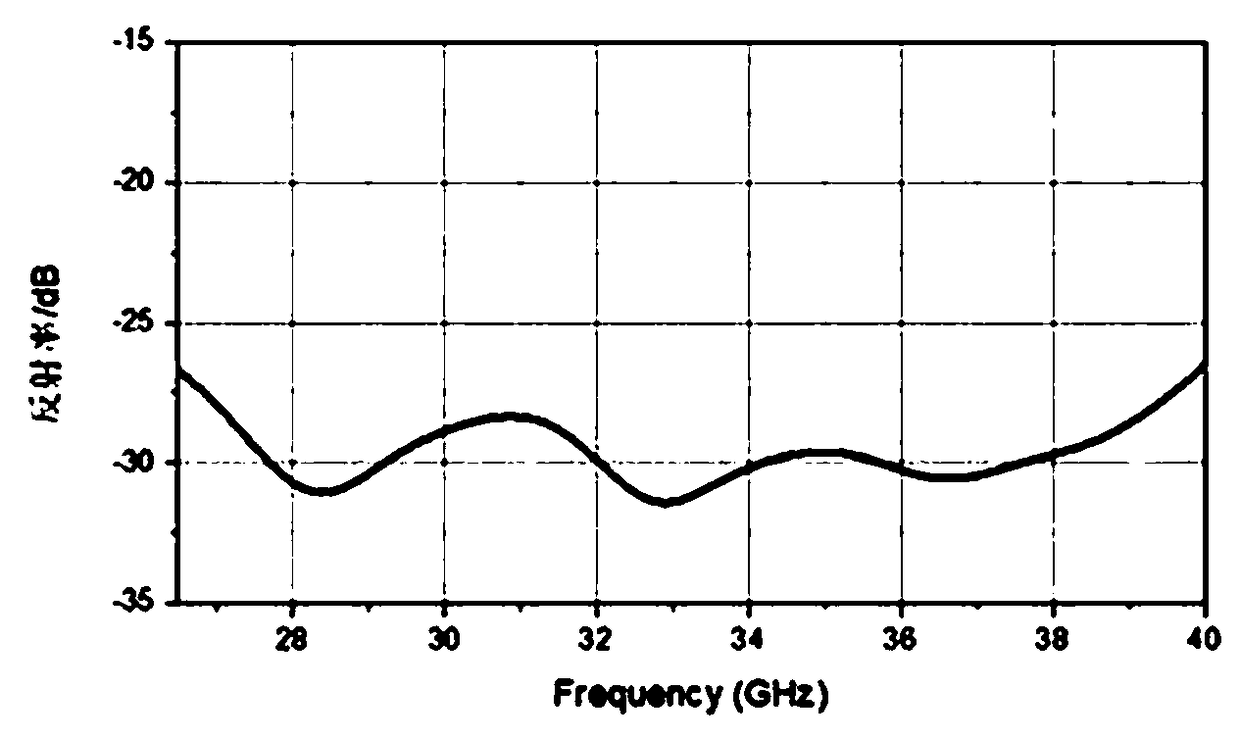

Composite polymethacrylimide foam wave absorption material

ActiveCN103923337AAchieve bondingImprove mechanical propertiesFlight vehicleElectromagnetic wave interference

The invention discloses a composite polymethacrylimide foam wave absorption material which is prepared by the following steps: (1) performing surface treatment on a wave absorber, namely uniformly mixing the wave absorber and a surfactant with a solvent, ultrasonically processing, drying to remove the solvent, and breaking and grinding to obtain a wave absorber subjected to surface treatment; (2) preparing expandable polymethacrylimide resin particles; (3) preparing the composite polymethacrylimide foam wave absorption material. The material is good in wave absorption performance, heat resistance and mechanical property, can be used for avoiding the defects of complex process, material waste and the like caused by a process that the material is machined to obtain a complex shape, can absorb electromagnetic waves to prevent electromagnetic wave interference, can be applied to the aspects of medical appliances, household appliances, electronic products, high-rise buildings, communication equipment, measurement equipment and the like, also can be used for stealth of various aircrafts, and has wide application prospect in the civil or military field.

Owner:湖南兆恒材料科技有限公司

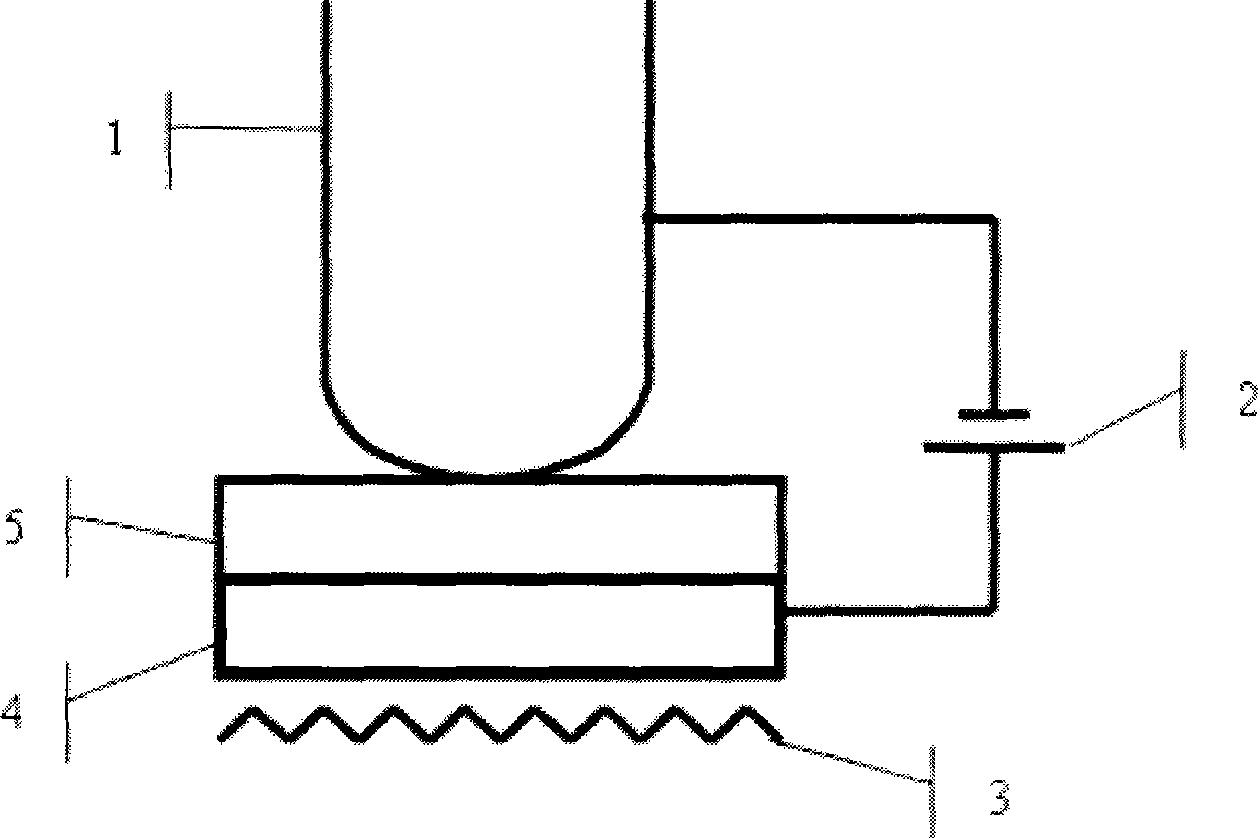

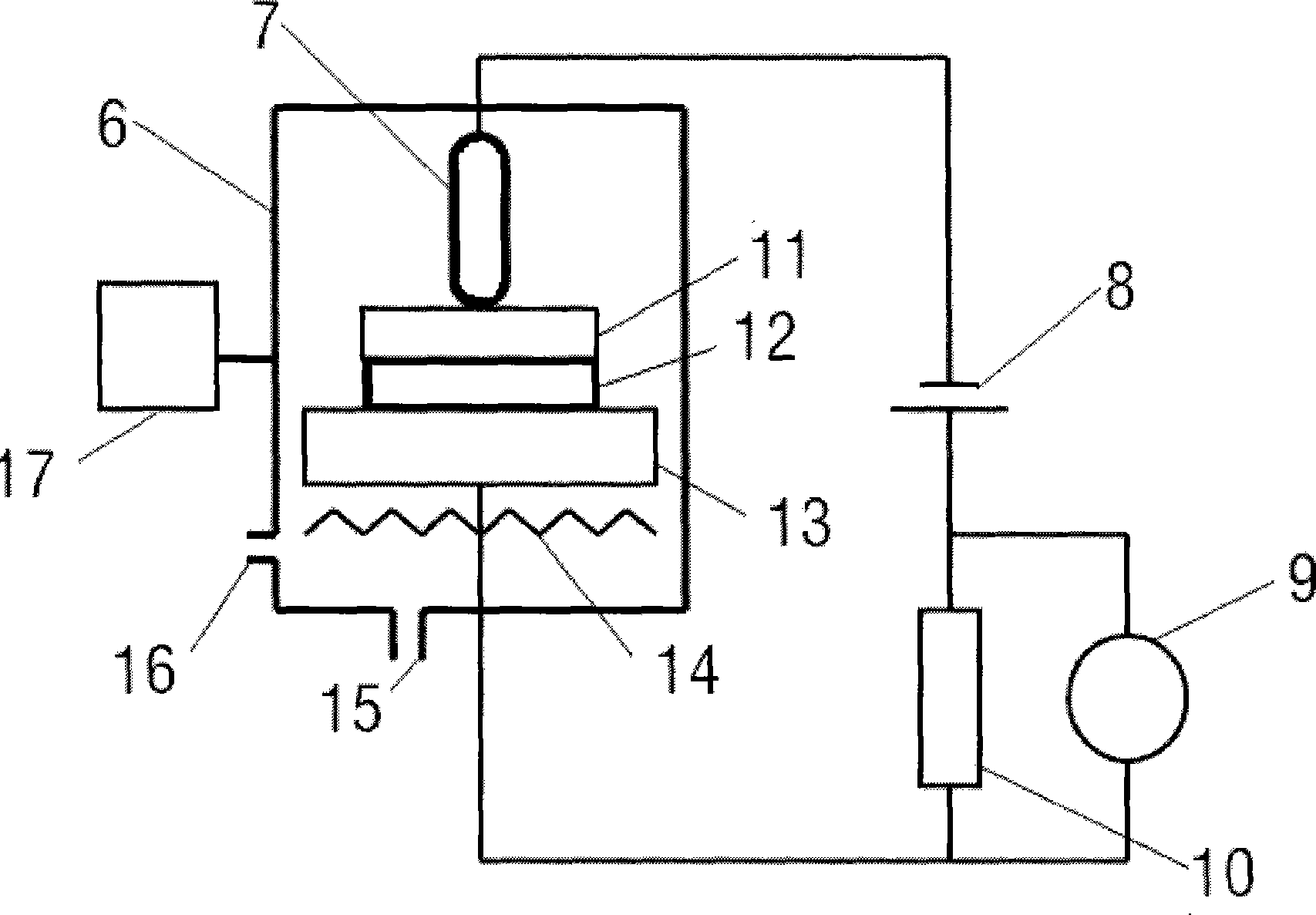

Miniature atomic air chamber encapsulation apparatus and technology method

InactiveCN101439843AImplement encapsulationAchieve bondingPrecision positioning equipmentSoldering apparatusChemical reactionRubidium

The invention discloses packaging equipment for a micro atomic gas chamber and a process technology method thereof. The equipment comprises a sample chamber, a pressure bar, a sample wafer, a sample stage, a heating wire, a temperature measurement probe, a vacuum pump connector, an inflation inlet, a direct-current high-voltage power supply, a voltmeter, a resistor, and other measurement and control devices. The method comprises: step 1, the selection of materials; step 2, the processing of the materials; step 3, the washing of the sample wafer; step 4, the bonding of a first surface; step 5, the bonding of a second surface; and step 6, the detection of a sample, and is a method which closes metal rubidium generated by adopting an in-situ chemical reaction method in a micro gas chamber. The method has the advantages that the special equipment is a common high vacuum system which is based on an anode bonding technology principle and adopts a relatively cheap mechanical pump, namely molecular pump air-bleed set; at the same time, inert gas is used to take measures such as the repeated inflation to the vacuum system to clean, the high temperature baking to the local sample wafer to remove gas and so on, to lighten the influence of residual gas and adsorbed gas as far as possible, particularly lighten the oxidation of rubidium.

Owner:PEKING UNIV

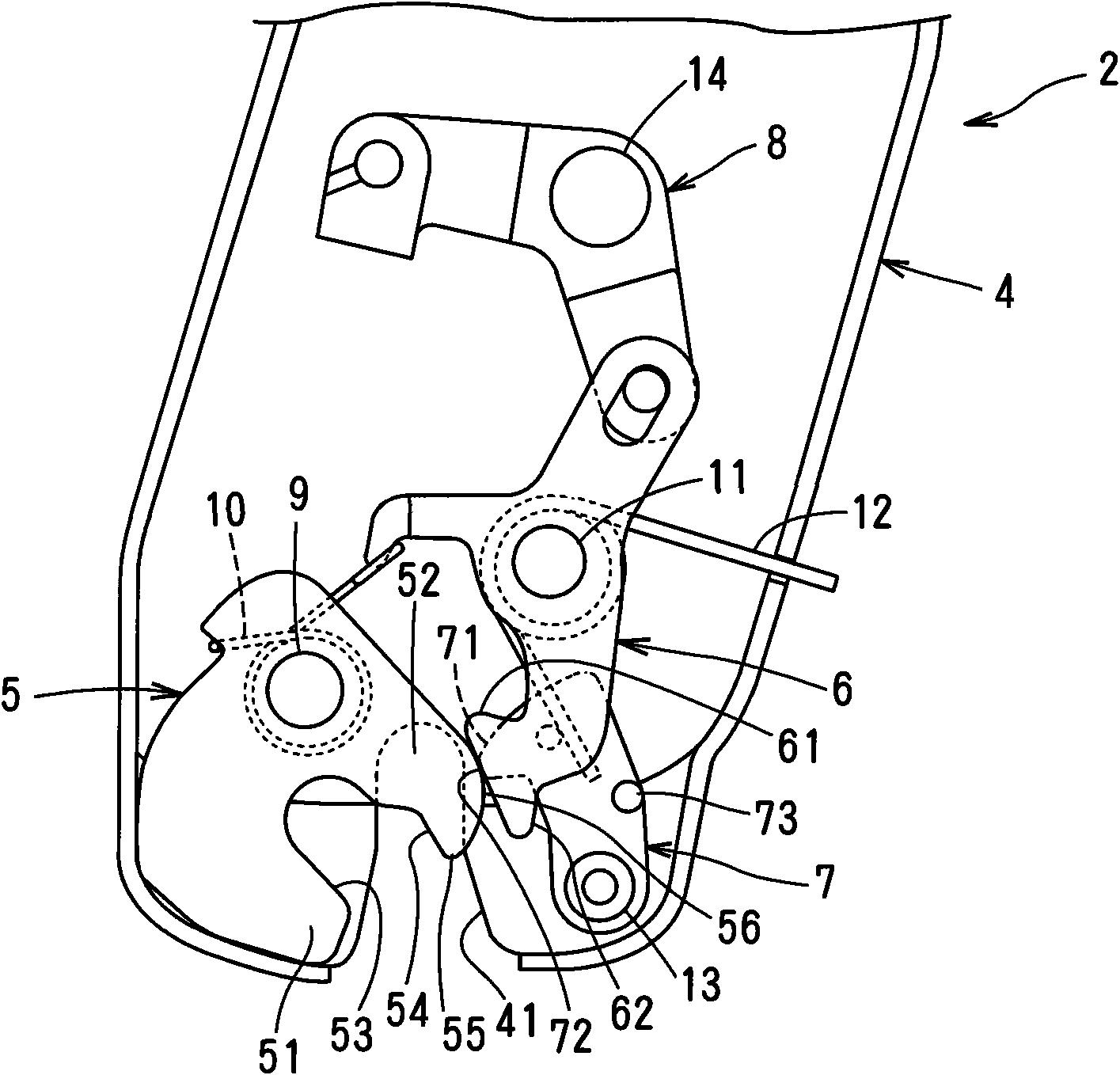

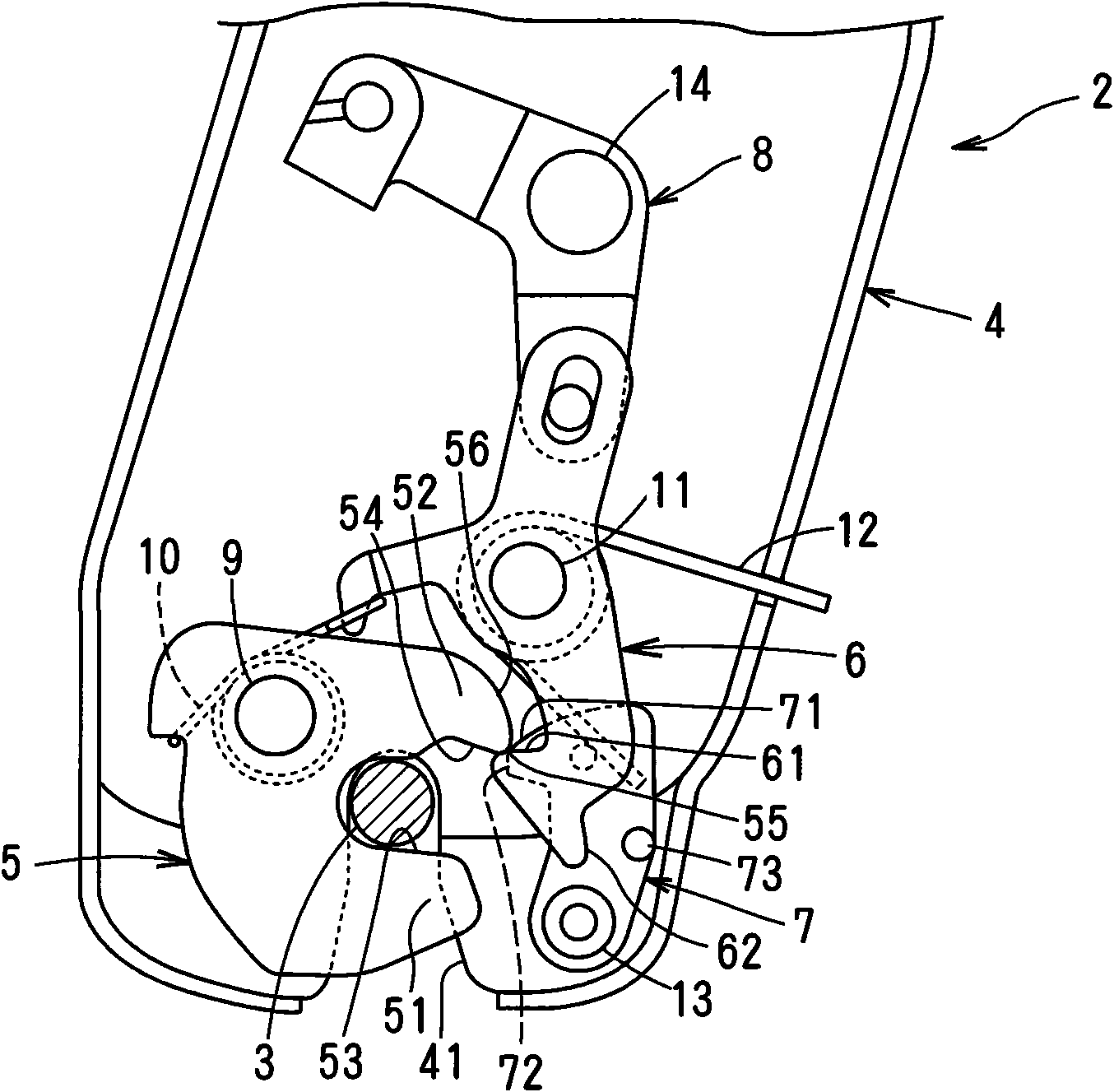

A latch device in a vehicle

ActiveCN101624025AReduce resistanceAchieve bondingVehicle seatsNoise-prevention/anti-rattling lockingCamLocking plate

A latch device comprises a latch lock operated to engage a striker. When the latch lock engages the striker, a cam disk contacts the latch lock slidably to rotate the latch lock, thereby preventing loose between the lock and the striker. The latch lock comprises a limiting part, which contacts with a locking plate, then the latch lock rotates, such that the limiting part separates from the locking plate, thereby engaging the latch lock and the striker with small force.

Owner:MITSUI KINZOKU ACT

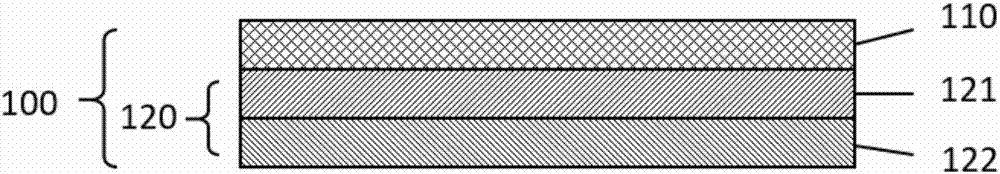

Single-crystal film bonding body and manufacturing method thereof

InactiveCN105420674AReduce direct reflectionReduce or even eliminate reflectionVacuum evaporation coatingSputtering coatingThin membraneSingle crystal

The invention provides a single-crystal film bonding body and a method for manufacturing the single-crystal film bonding body. The single-crystal film bonding body comprises a silicon substrate, a lithium niobate single-crystal film or lithium tantalate single-crystal film and a silicon-based film located between the silicon substrate and the lithium niobate single-crystal film or lithium tantalate single-crystal film. The silicon-based film is formed on the lithium niobate single-crystal film or lithium tantalate single-crystal film through deposition and is bonded with the silicon substrate through a direct bonding method, and the silicon-based film is a silicon film or a silicon dioxide film or a silicon nitride film. By means of the single-crystal film bonding body of the three-layer structure, the reflection effect of interfaces between the lithium niobate or lithium tantalate single-crystal film and the silicon substrate on optical waves and sound waves can be effectively reduced and even eliminated, and the interference caused by the reflection effect between the interfaces to optical or sound wave signals is reduced.

Owner:JINAN JINGZHENG ELECTRONICS

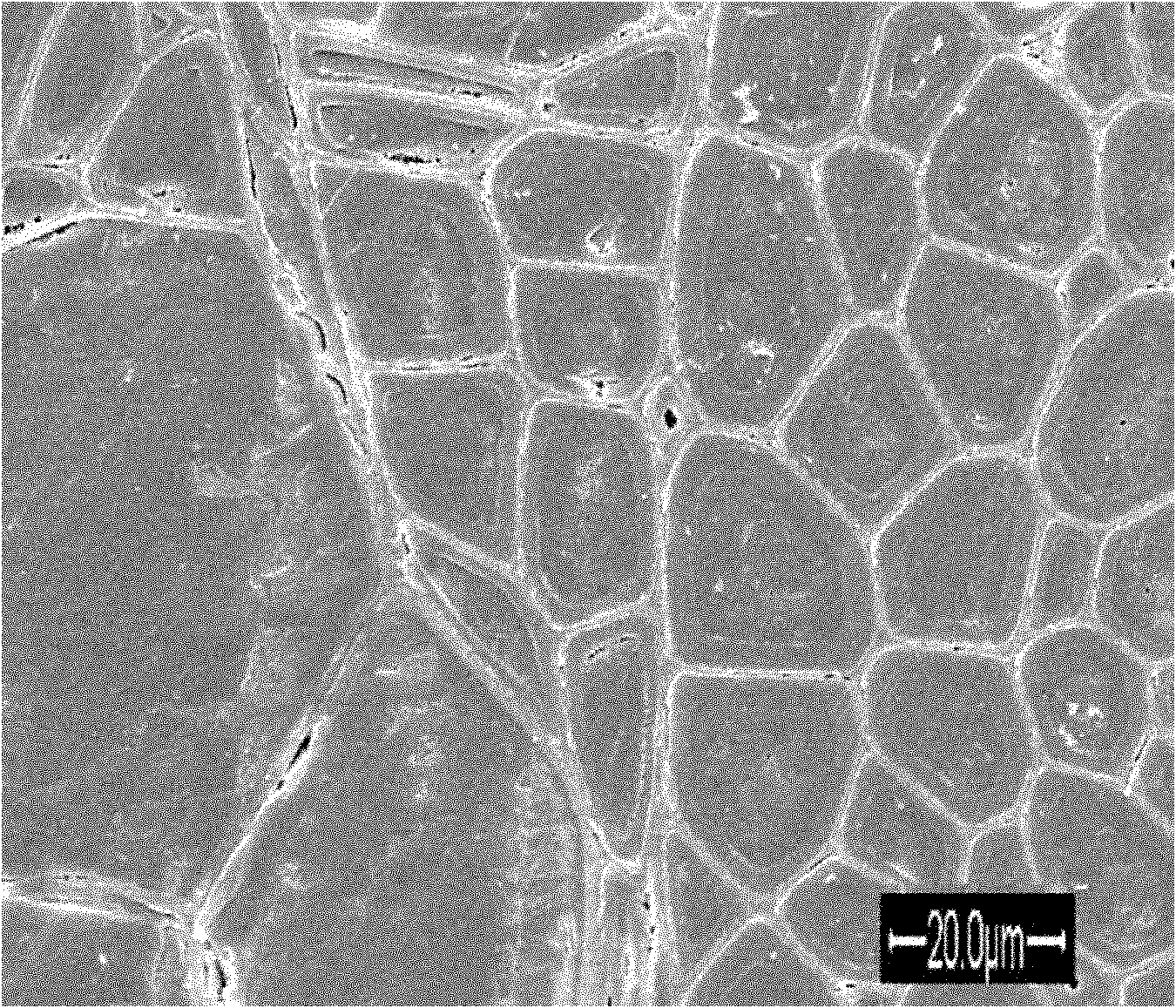

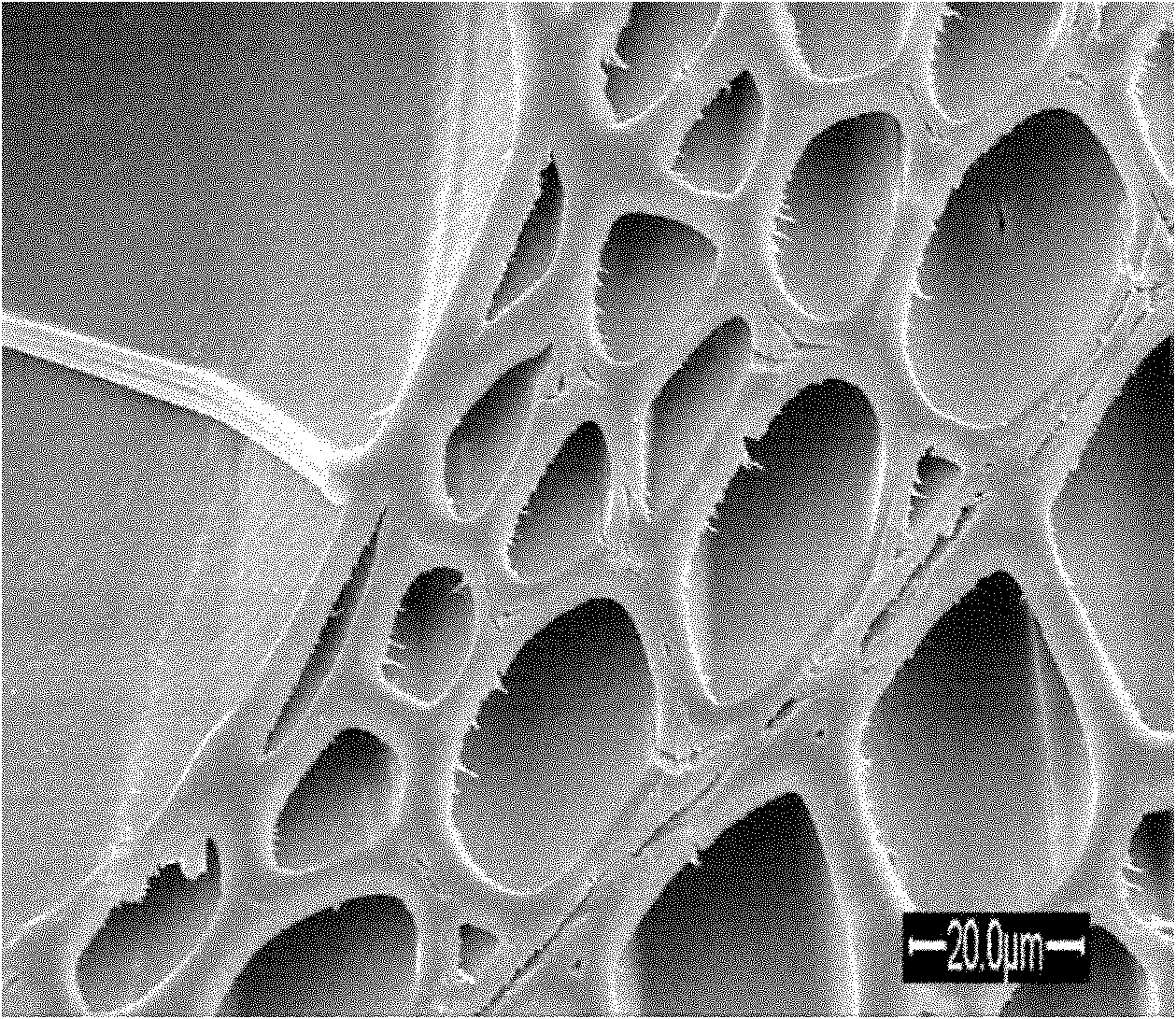

Method for modifying wood by filling grafted cell walls with organic monomers and polymerization-filling cell cavities

InactiveCN101954662AIncreased durabilityImprove mechanical propertiesPressure impregnationWood impregnation detailsCell cavityCell wall

The invention discloses a method for modifying wood by filling grafted cell walls with organic monomers and polymerization-filling cell cavities, which relates to a wood modification method. The invention solves the problem of difficulty in simultaneously enhancing mechanical properties and durability of wood in the existing wood modification method. The method comprises the following steps: 1, preparing organic acid anhydride solution; 2, soaking the wood with the organic acid anhydride solution; 3, filling grafted wood cell walls with organic acid anhydride by heating; 4, preparing the organic polymerizable monomer solution; 5, soaking the wood with the organic polymerizable monomer solution; and 6, carrying out polymerization-filling on the wood cell cavities with the monomers by heating. Since organic function micromolecules firstly enter the wood cell walls, the method realizes filling and bonding and eliminates a great deal of hydroxyl groups in the cell walls, thereby enhancing wood durability; and the wood cell cavities are soaked by the organic polymerizable monomers to initiate the polymerization and realize the filling of the cell cavities, so that the wood has higher mechanical properties and durability.

Owner:NORTHEAST FORESTRY UNIVERSITY

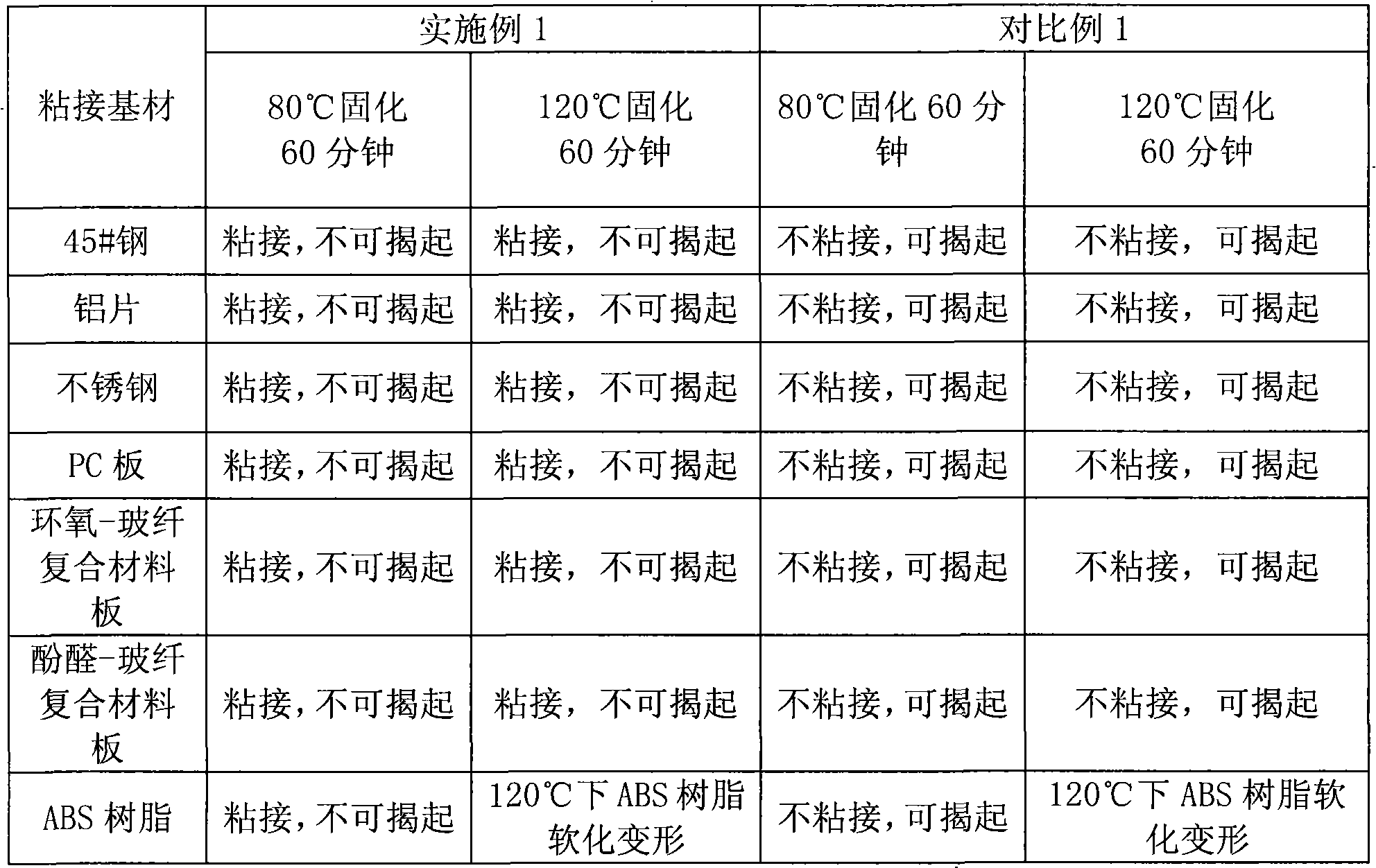

Aqueous adhesive for binding rubber and metal and preparation thereof

The invention discloses a water-based adhesive used for the bonding between rubber and metal; according to the parts by weight, the adhesive comprises 60-90 parts of soft monomer, 30-60 parts of hard monomer, 2-8 parts of functional monomer, 3-10 parts of emulsifier, 0.4-0.8 part of initiator, 0.6-1.0 part of pH buffer, 100 parts of deionized water or distilled water, 0.05-0.1 part of anticorrosive bactericide, and 1.4-1.6 parts of pH regulator. The invention also discloses a preparation method for preparing the water-based adhesive. The adhesive can replace the existing solvent-typed adhesive, effectively realizes the bonding between the rubber and the metal, has no poison, no combustion and no explosion, is safe and protects the environment. The preparation method which applies the seed latex polymerization has simple preparation process and high production efficiency and is beneficial for the industrial production.

Owner:GUANGDONG HENGDA NEW MATERIALS TECH

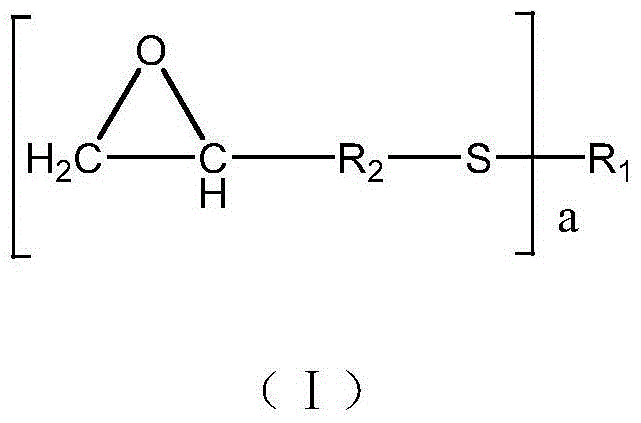

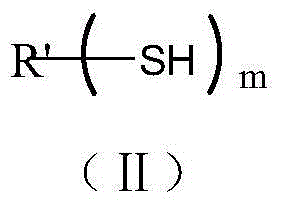

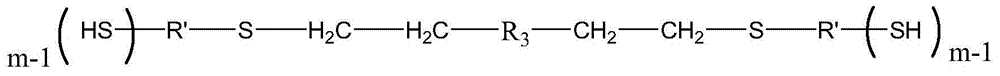

Epoxy group end-capped polysulfide polymer, preparation method and application thereof and room temperature fast-curing epoxy resin adhesive containing epoxy group end-capped polysulfide polymer

The invention provides an epoxy group end-capped polysulfide polymer as shown in a general formula (I), a preparation method thereof and application of the epoxy group end-capped polysulfide polymer as an epoxy resin adhesive toughening agent. The invention also provides an epoxy resin adhesive which contains the epoxy group end-capped polysulfide polymer. The epoxy group end-capped polysulfide polymer provided by the invention contains an epoxy group end group and a polysulfide bond, is capable of increasing the curing speed of an adhesive and enhancing the properties, namely impact resistance, fracture toughness, oil resistance and the like, of a cured material obtained after curing when used for the epoxy resin adhesive, and prevents the pungent smell brought by sulfhydryl. The epoxy resin adhesive provided by the invention has the advantages of no special smell in preparation and usage processes after the adhesive is cured, good product properties, no pollution on the environment and suitability for large-scale industrialized production.

Owner:ZHENGZHOU ZHONGYUAN SILANDE HIGH TECH CO LTD

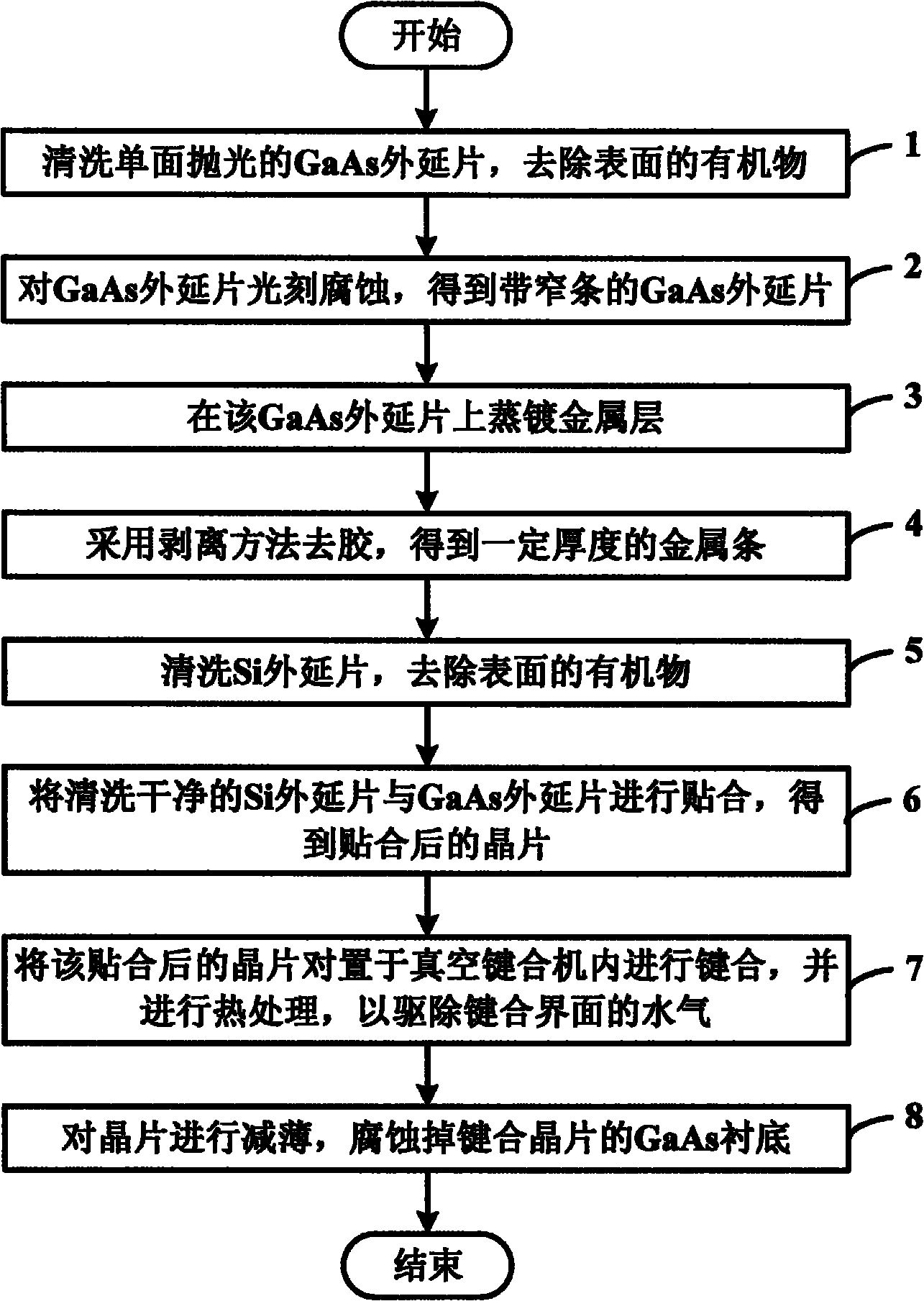

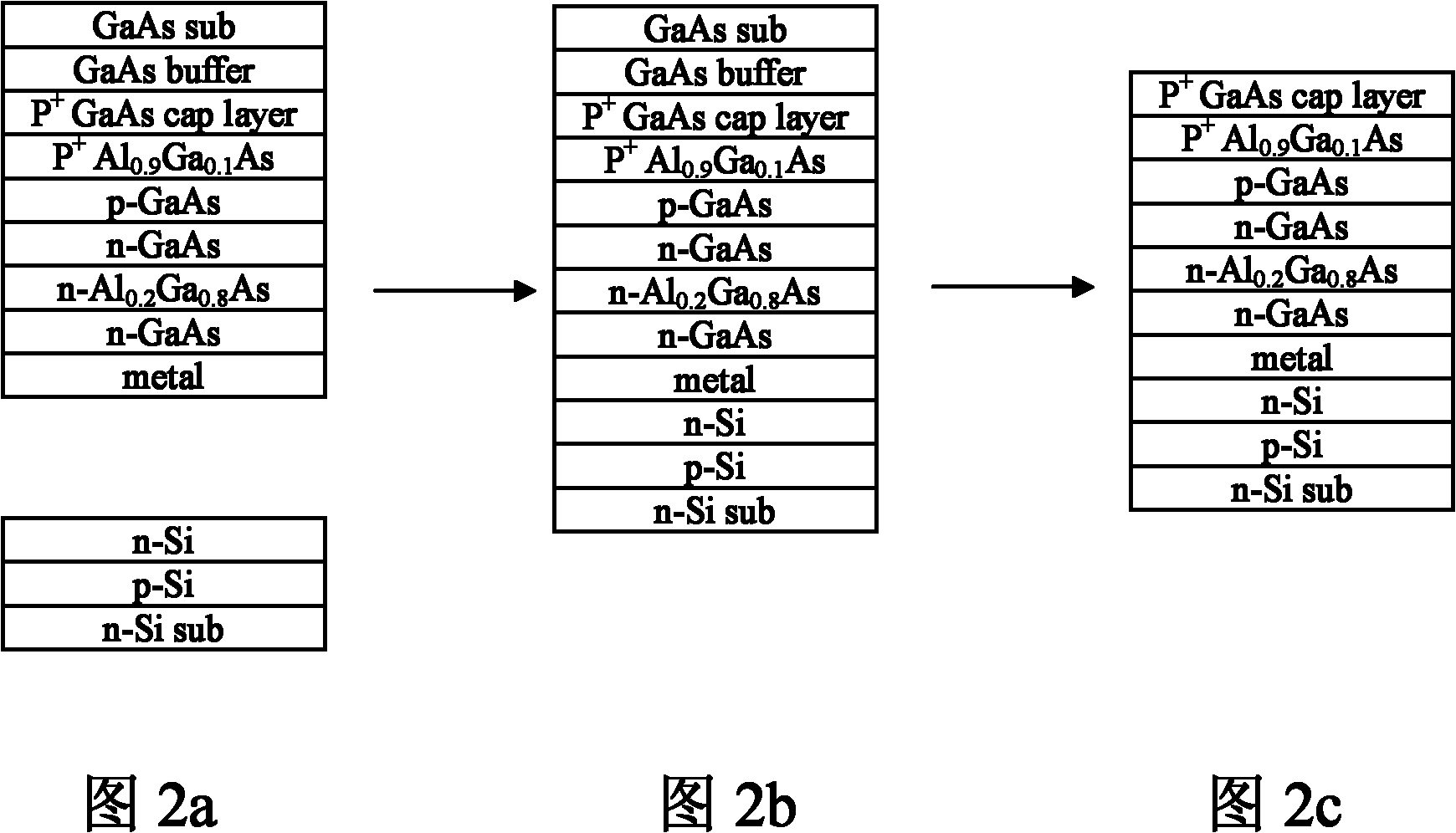

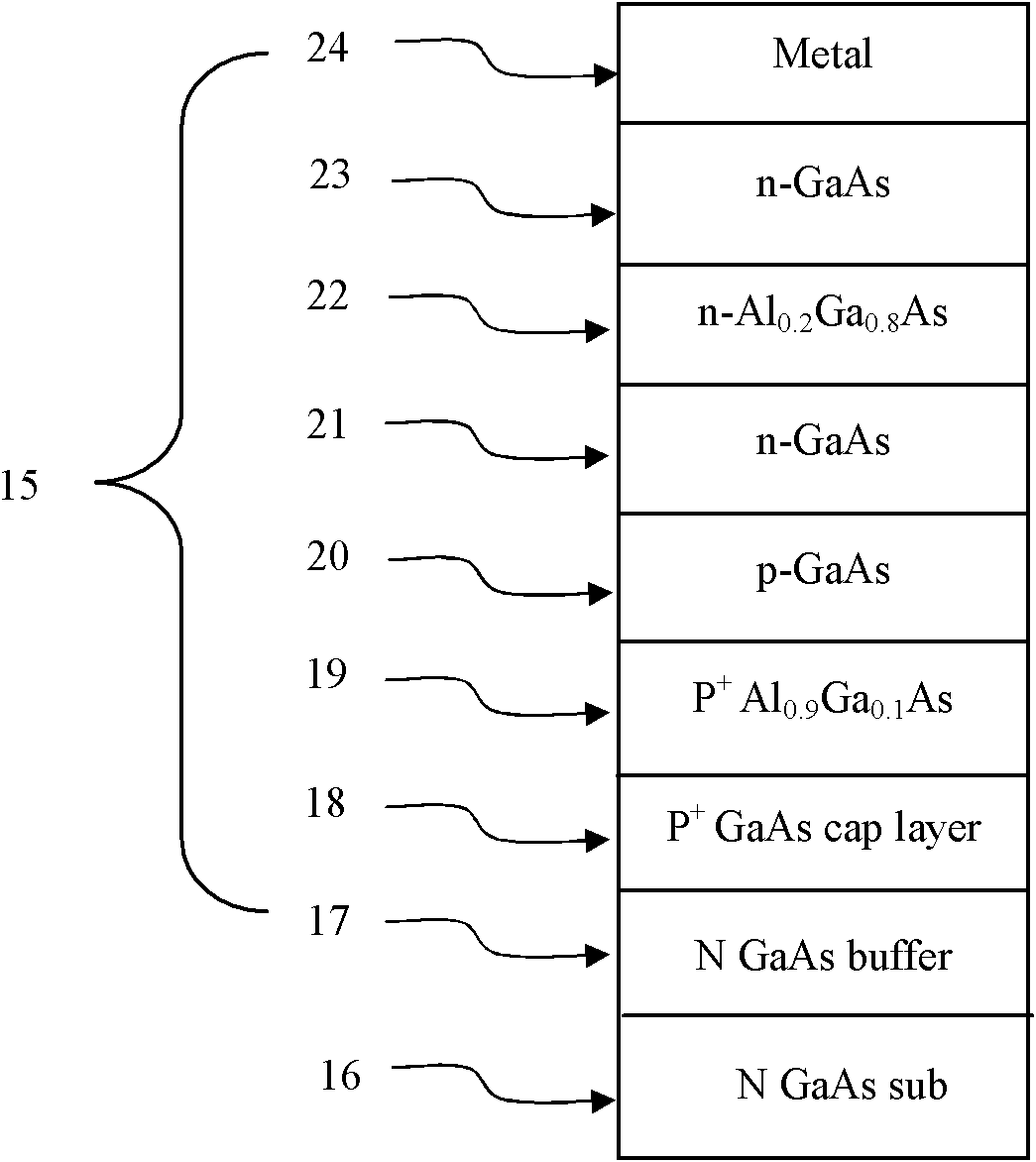

Method for performing low-temperature metal bonding on GaAs and Si

InactiveCN102110594ARealize the structureAchieve bondingFinal product manufactureSemiconductor/solid-state device manufacturingMetal stripsBond interface

The invention discloses a method for performing low-temperature metal bonding on GaAs and Si. The method comprises the following steps of: cleaning a single-side polished GaAs epitaxial wafer to remove organic substances on the surface of the wafer; performing photoresist etching on the GaAs epitaxial wafer to obtain the GaAs epitaxial wafer with a narrow strip; performing evaporation on the GaAs epitaxial wafer to form a metal layer; removing a photoresist by a stripping method to obtain a metal strip with a certain thickness; cleaning a Si epitaxial wafer to remove organic substances on the surface of the wafer; treating the surface of the Si epitaxial wafer by using H2SO4 solution and RCAl solution and attaching the cleaned Si epitaxial wafer to the GaAs epitaxial wafer so as to obtain an attached wafer; oppositely arranging the attached wafer in a vacuum bonding machine for bonding and performing thermal treatment to remove vapor of a bonding interface; and thinning the bound wafer and corroding off the GaAs substrate of the bound wafer. By the method, the low-temperature metal bonding of the GaAs and the Si is realized; and the method can be extended to the bonding between two III-V groups (or materials such as Si, Ge and the like of an IV group).

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

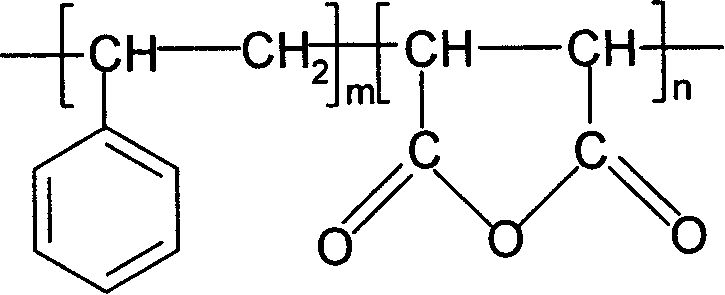

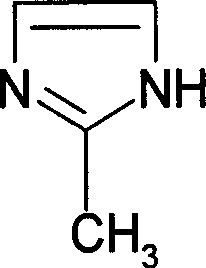

Epoxy composite of semi-solidified sheet and its use

InactiveCN1955219AImprove hydrophobicityImprove insulation performanceLaminationLamination apparatusEpoxyNetwork structure

This invention is an epoxide resin composite, and its feature is that benzene vinyl-Maleic Anhydride interpolymer, 2-methyl glyoxaline and solvent are added into epoxide resin according a certain proportion. Its components weight amount is that epoxide resin 10-79.99%, SMA interpolymer 10-74%, 2-methyl glyoxaline 0.01-6%. The solvent is dimethylformamide(DMF), and its weight amount is 10%. The feature of this invention is that when epoxide resin composite solidifies, SMA is not only the curing agent of the composite, but also contributes to the formation of network structure of the solidified product. This solidified product overcomes the fragibility of present epoxide resin solidification, and improve its wet fastness,tenacity and heat stability. This epoxide resin composite can be used in the production of binding agent and laminated wood of composite multilayer electric circuit panel.

Owner:JIANGSU UNIV OF SCI & TECH

Preparation method for polymethacrylimide composite foam conductive wave-absorbing material

The invention specifically relates to a preparation method for a polymethacrylimide composite foam conductive wave-absorbing material, belonging to the field of preparation of novel materials. The preparation method comprises the following steps: weighing (meth)acrylic acid, (meth)acrylonitrile, a third monomer, a functionalized wave-absorbing agent, a dispersing agent, an anti-settling agent, aninitiator, a nucleating agent, a polymerization inhibitor, a cerium-containing foaming material and a cross-linking agent, adding the weighed substances into a reaction vessel, and performing a polymerization reaction to prepare an expandable polymethacrylimide resin particle; and then mixing the expandable polymethacrylimide resin particle with a binder, an auxiliary agent, the functionalized wave-absorbing agent and a fibrous substance, and carrying out preheating and foaming to obtain the polymethacrylimide composite foam conductive wave-absorbing material. The material of the invention hasgood wave-absorbing properties, heat resistance and mechanical properties, can be used for preparing special-shaped parts, and can avoid defects such as complicated process and wasting of materials during mechanical processing of materials for acquisition of complicated shapes.

Owner:CASHEM ADVANCED MATERIALS HI TECH CO LTD ZHEJIANG

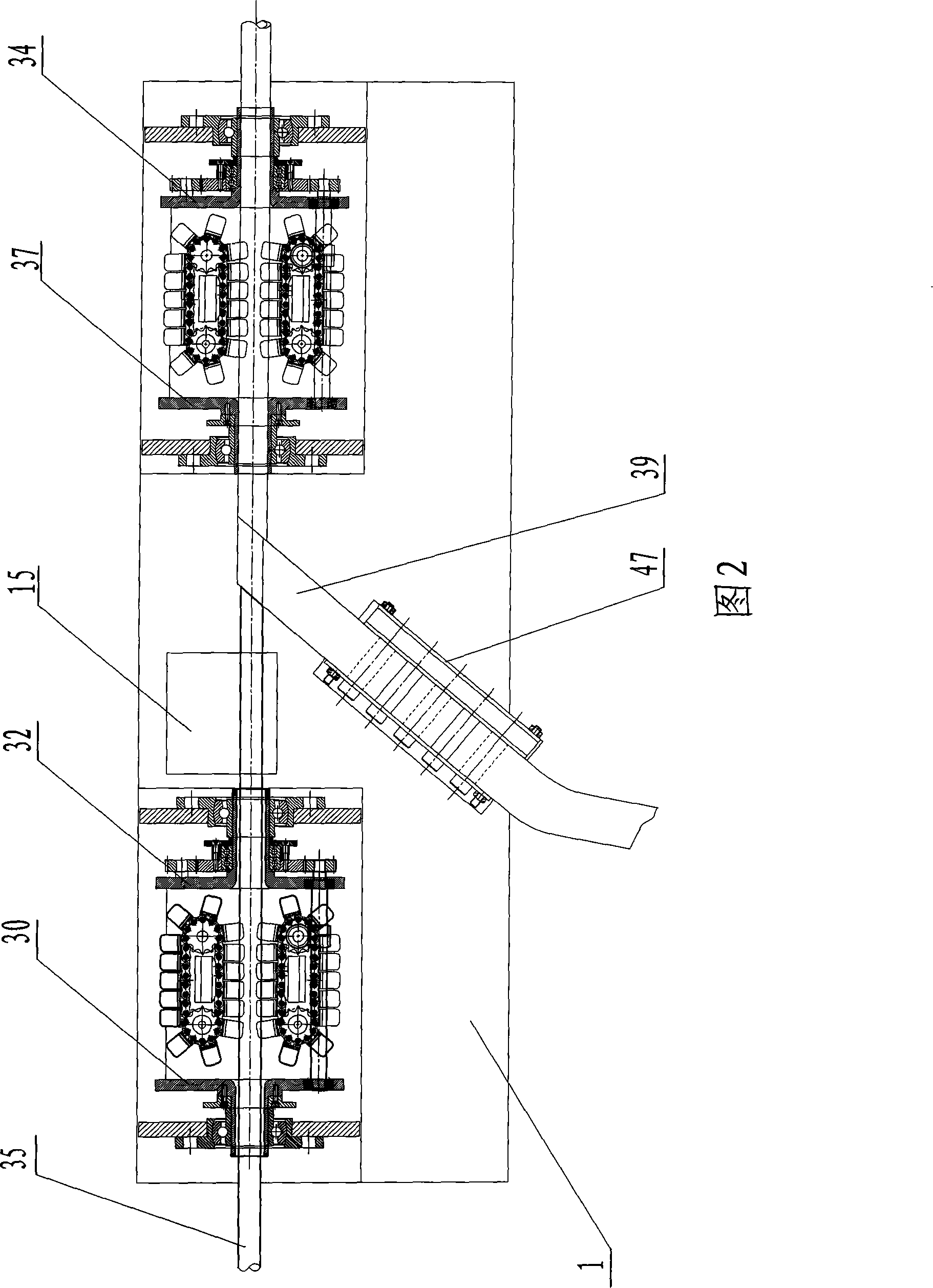

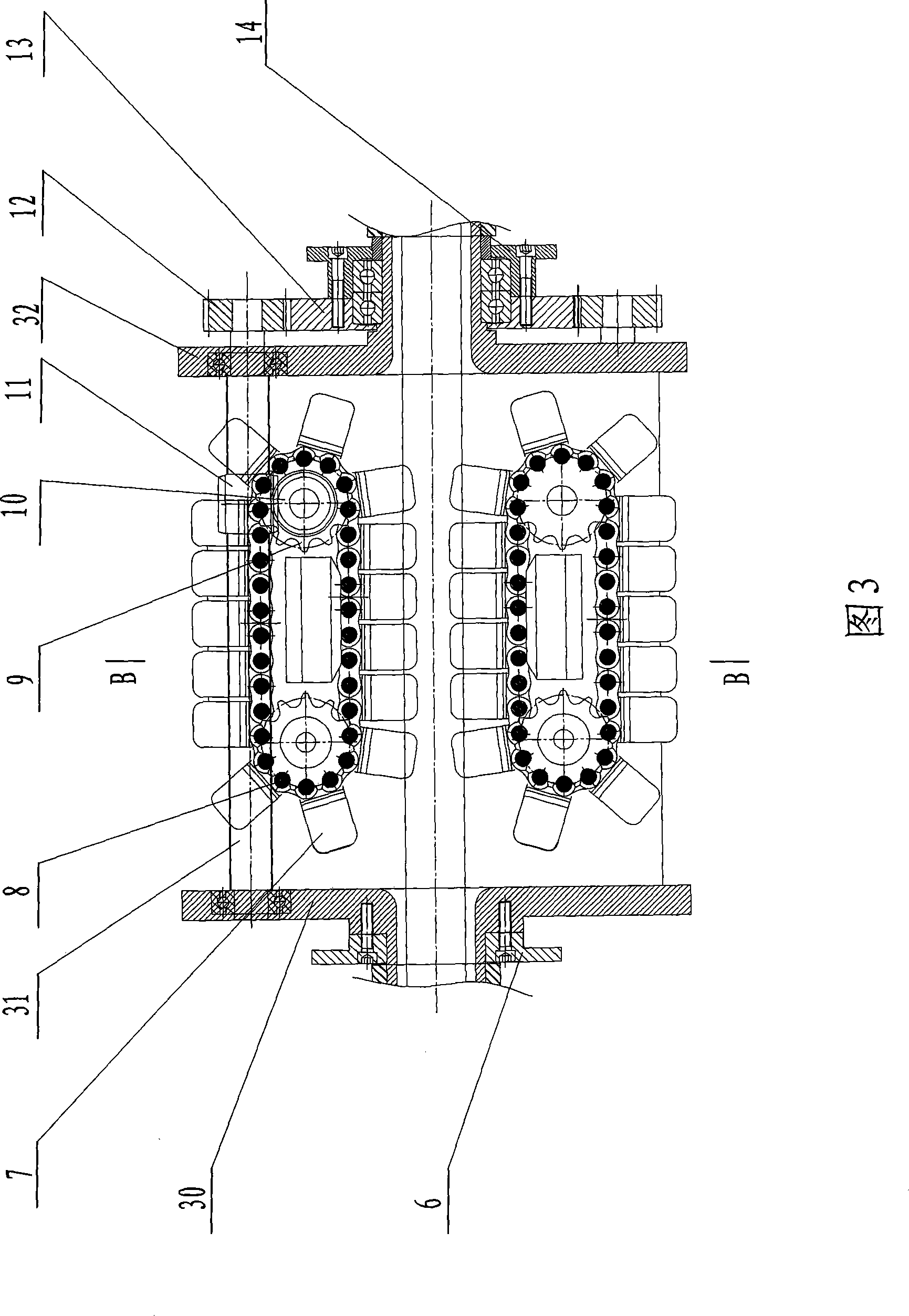

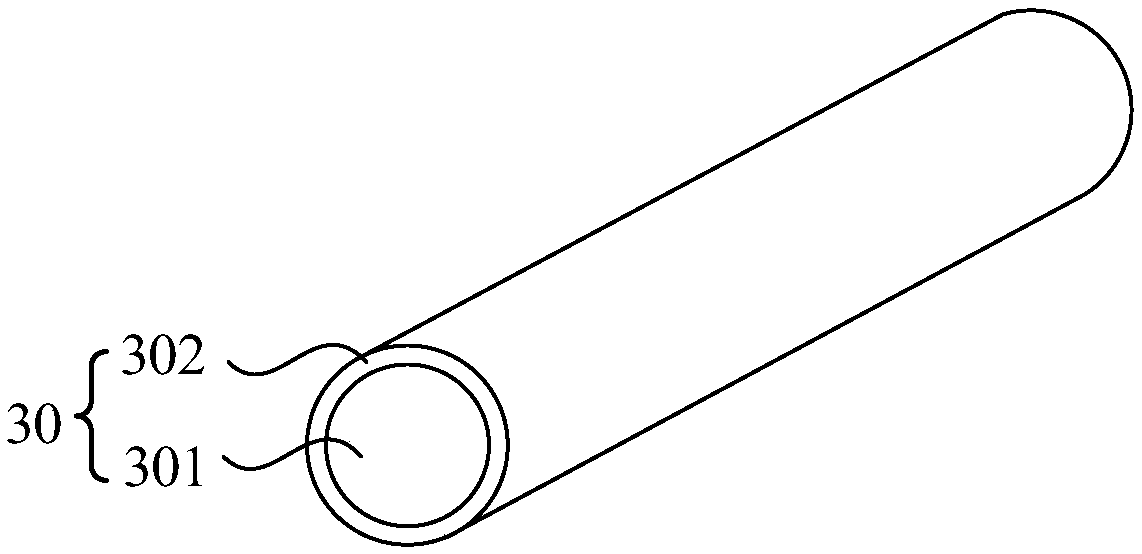

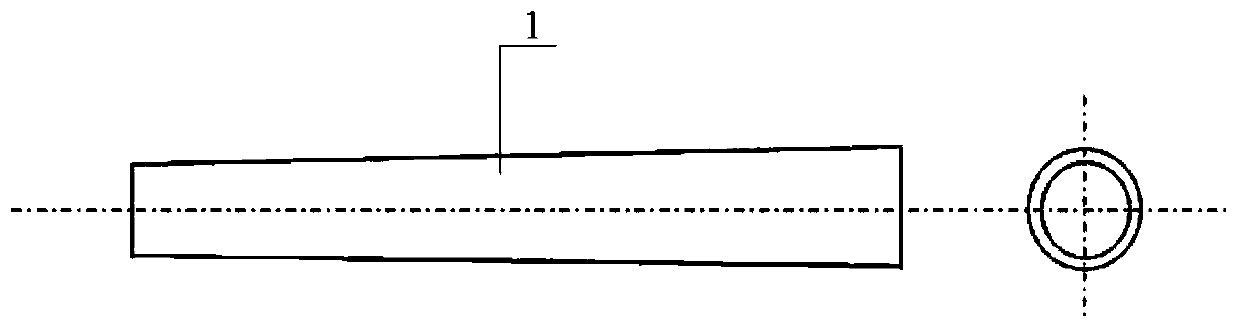

Process equipment for roller brush

InactiveCN101250940AReduce the number of starts and endsThe production process is simpleLiquid surface applicatorsAdhesive processes with adhesive heatingSizingEngineering

Roller brush processing equipment is used to fix brush hair made of plush cotton flannel on the surface of a core tube. The equipment comprises a frame supporting the core tube and a sizing drum and a heater corresponding to the core tube, and is characterized in that: the left end and the right end of the frame are respectively provided with a left transmission device and a right transmission device which can realize friction movement and holding of the core tube; moreover, the frame is provided with an axial movement device which can synchronously drive the core tube to move in axial direction through the left transmission device and the right transmission device as well as a rotating device which can drive the core tube to rotate. After adopting the structure, the core tube can move in axial direction when rotating; therefore, the length of the core tube which is arranged on the frame is no longer limited by the equipment, and the core can be output forwards ceaselessly, thereby realizing the goal that plush cotton flannel can be stuck to the external surface of the core tube without stop; thus, the roller brush processing equipment reduces the start and end times of the plush cotton flannel on the surface of the core tube without frequently replacing the core tube, thereby having the characteristics of simple manufacture process, high operation efficiency and low operation difficulty; moreover, the equipment ensures that a processed roller brush has low production cost and has stronger market competitive power.

Owner:何朝良

Liquid optically clear photo-curable adhesive for display application

InactiveCN104812858AAchieve bondingEasy to solveLamination ancillary operationsPolyureas/polyurethane adhesivesChemistryPhotoinitiator

Liquid optically clear photo-curable adhesive for display application A process for reworking an optical assembly and a liquid optically clear photo-curable adhesive, which comprises: (a) 10 to 50 wt % of an urethane acrylate, (b) 30 to 70 wt % of plasticizer, (c) 0.002 to 5 wt % of photo initiator, (d) 1 to 30 wt % of acrylate monomer are described.

Owner:HENKEL KGAA +1

Addition type silicone adhesive composition and preparation method thereof

InactiveCN101787256ADoes not affect mechanicsDoes not affect electrical performanceNon-macromolecular adhesive additives(Hydroxyethyl)methacrylateAlkyne

The invention discloses an addition type silicone adhesive composition and a preparation method thereof. The addition type silicone adhesive composition comprises (A) 60 to 100 mass parts of organopolysiloxane, (B)1 to 10 mass parts of substance obtained by reacting Si-H groups in the organopolysiloxane with hydroxyls in hydroxy ethyl acrylate or hydroxy propyl methacrylate; (C) 1 to 50 mass parts of gaseous-phase silica, (D) 0.001 to 0.01 weight parts of alkyne inhibitor, and (E) 0.1 to 2 mass parts of platinum catalyst, wherein the content of platinum atoms is 5-2,000ppm; and the preparation method of the addition type silicone adhesive composition comprises the following steps: uniformly mixing the (A), (C) and (D) in vacuum, then sequentially adding (B) and (E) to carry out vacuum defoamation, and solidifying the obtained mixture for 5 to 60 minutes at the temperature of between 80 and 210 DEG C.

Owner:TONSAN ADHESIVES INC

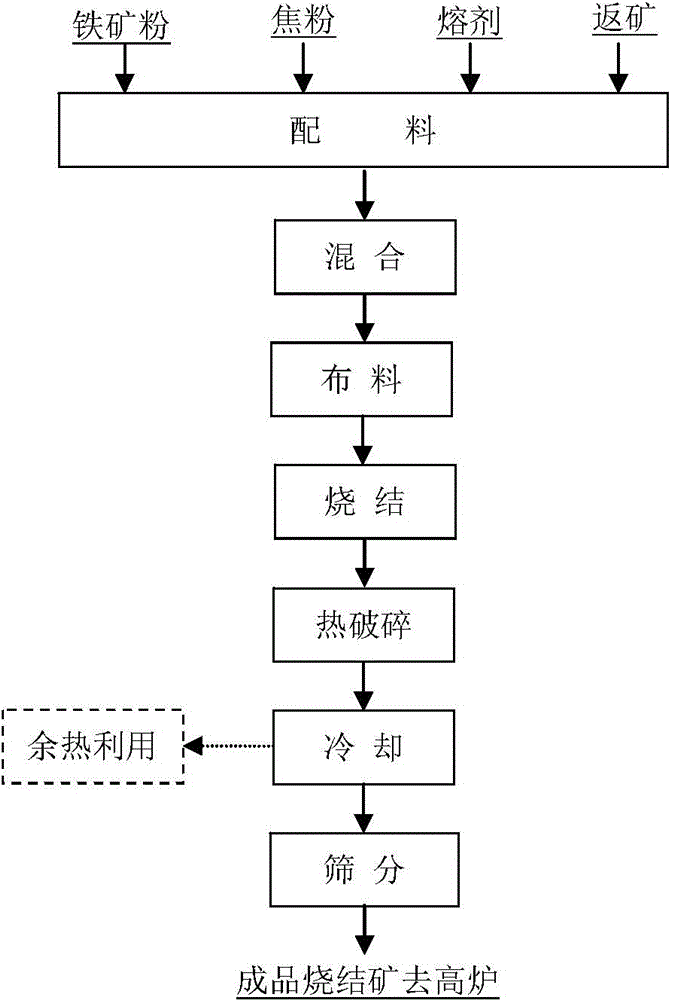

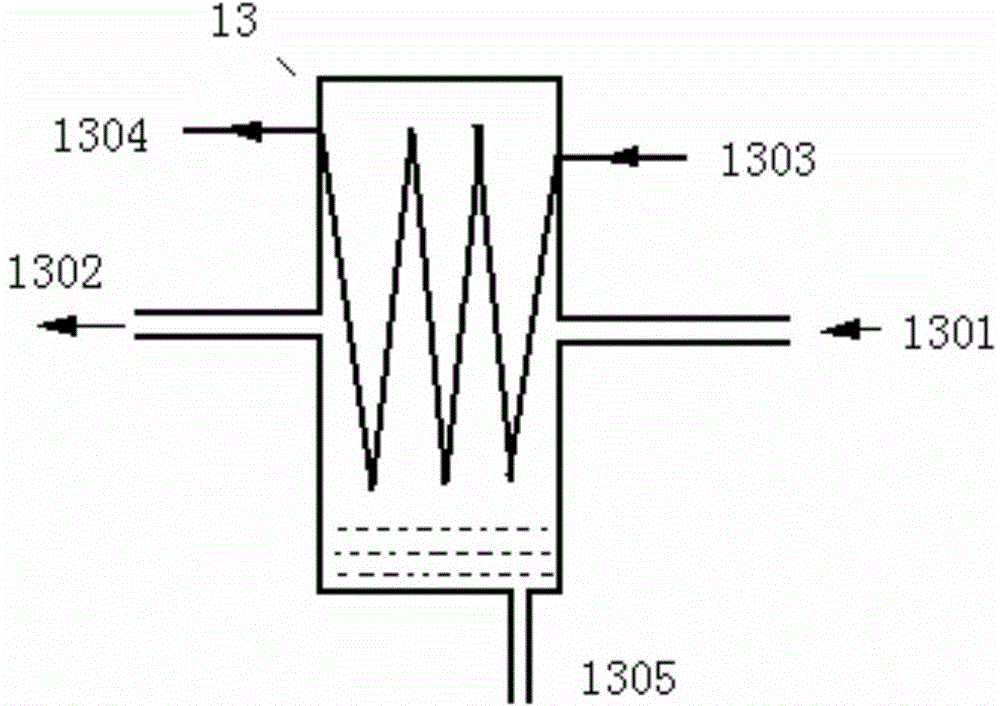

Smoke circulation type pre-reduction sintering technique and device

ActiveCN106282546AAchieve recyclingAchieve the goal of energy saving and emission reductionIncreasing energy efficiencyWaste heat treatmentSolventCoal

The invention provides a smoke circulation type pre-reduction sintering device and method. The pre-reduction sintering method comprises the steps that (1) pelletizing is conducted after iron fine powder and coal fuel are evenly mixed, so that carbon-burdened pellets are obtained; (2) iron ore powder, a solvent and coal fuel powder are proportioned, and then water is added into a primary mixing machine for mixing, so that a sintering mixture is obtained; (3) the carbon-burdened pellets, the sintering mixture and additional coal fuel fine powder are mixed in a secondary mixing machine, so that a pre-reduction sintering mixture is obtained, wherein the use amount ratio, by weight, of the sintering mixture to the carbon-burdened pellets to the additional coal fuel fine powder is (50-70):(28-48):(1-5); (4) the pre-reduction sintering mixture is arranged on a sintering trolley for conducting smoke circulation type pre-reduction sintering; and (5) pre-reduction sintered ore obtained after sintering is cooled under an anaerobic condition.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

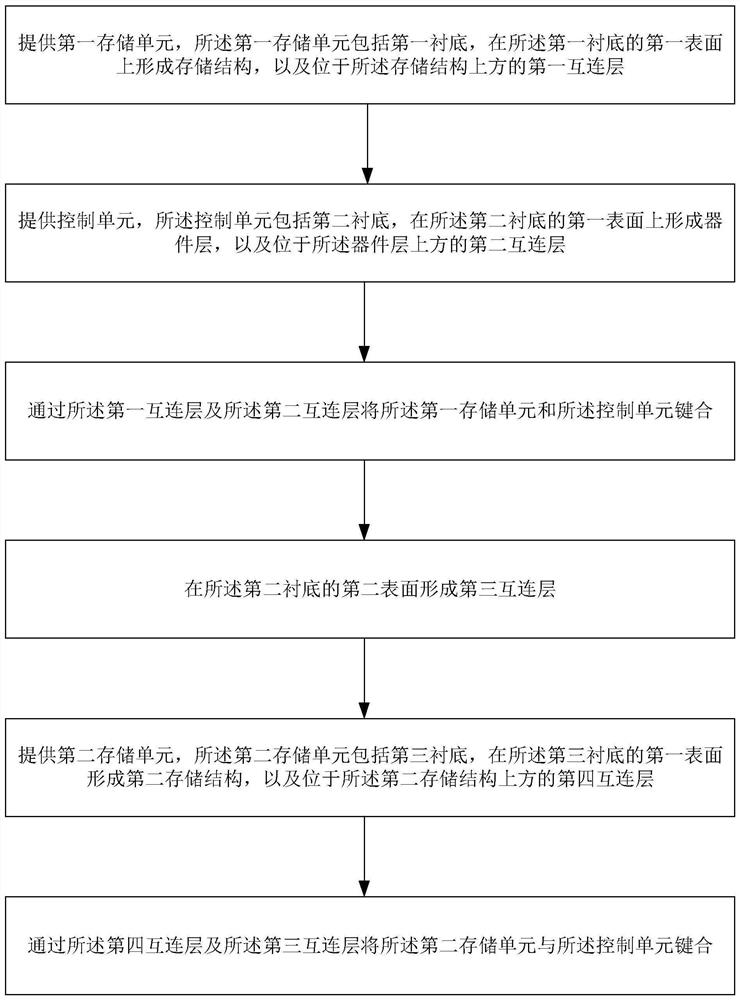

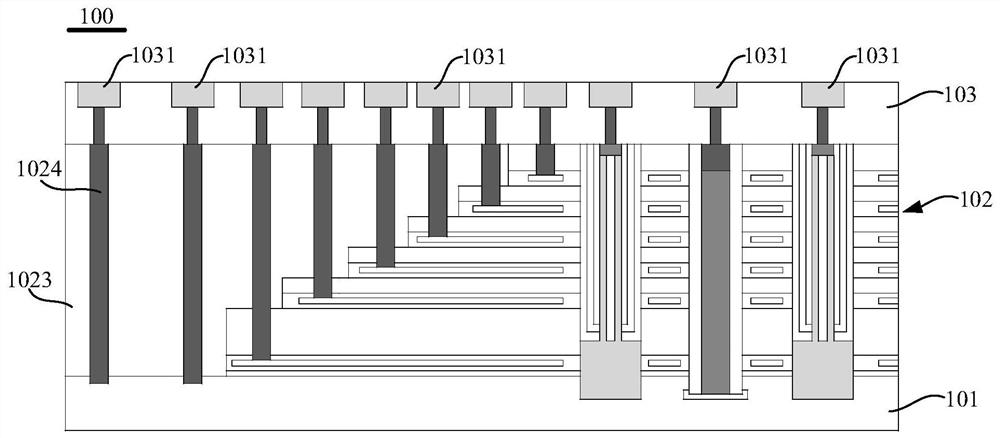

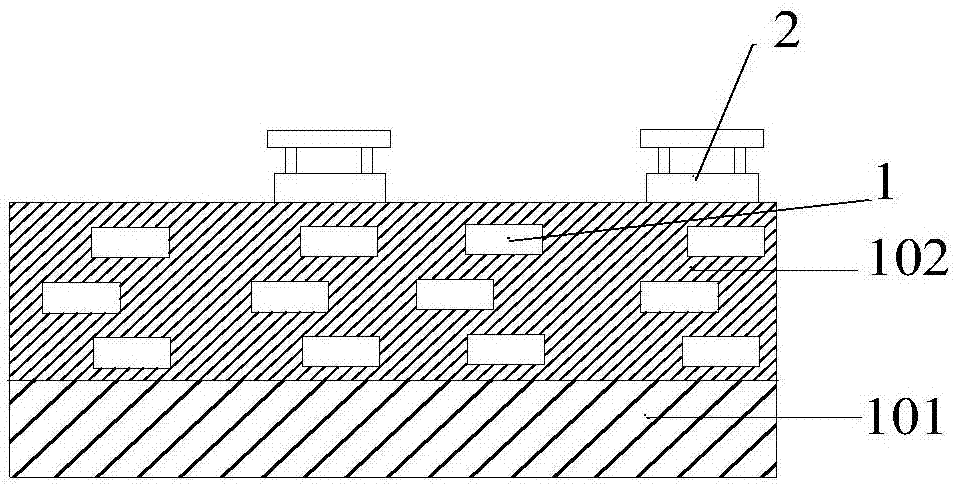

Three-dimensional memory device and forming method thereof

ActiveCN112614853AAchieve bondingSimple processSolid-state devicesSemiconductor devicesControl cellStructural engineering

The invention provides a three-dimensional memory device and a forming method thereof. A memory unit is bonded with a control unit, and then another memory unit is bonded on the back surface of a substrate of the control unit, so that bonding of at least three units is realized. Therefore, wafer-level bonding is realized, the process is simpler, the stress problem can be effectively solved while the number of storage layers is increased, the structure is more stable, and the risk of structural collapse is reduced. After the memory unit and the control unit are bonded, the bonding pads on the two sides are led out, the bonding pads can be led out from the sides of the two memory units, the bonding pads can also be led out from the two sides of one memory unit and the two sides of the control unit, and a control circuit of the control unit is used for controlling the memory unit accessed during memory. The pad leading-out mode is added, and the number of bonding pads per unit area is increased. The number of bonding pads per unit area is increased, the access hit rate of the memory unit can be improved, and therefore the memory period of the memory unit can be greatly shortened.

Owner:YANGTZE MEMORY TECH CO LTD

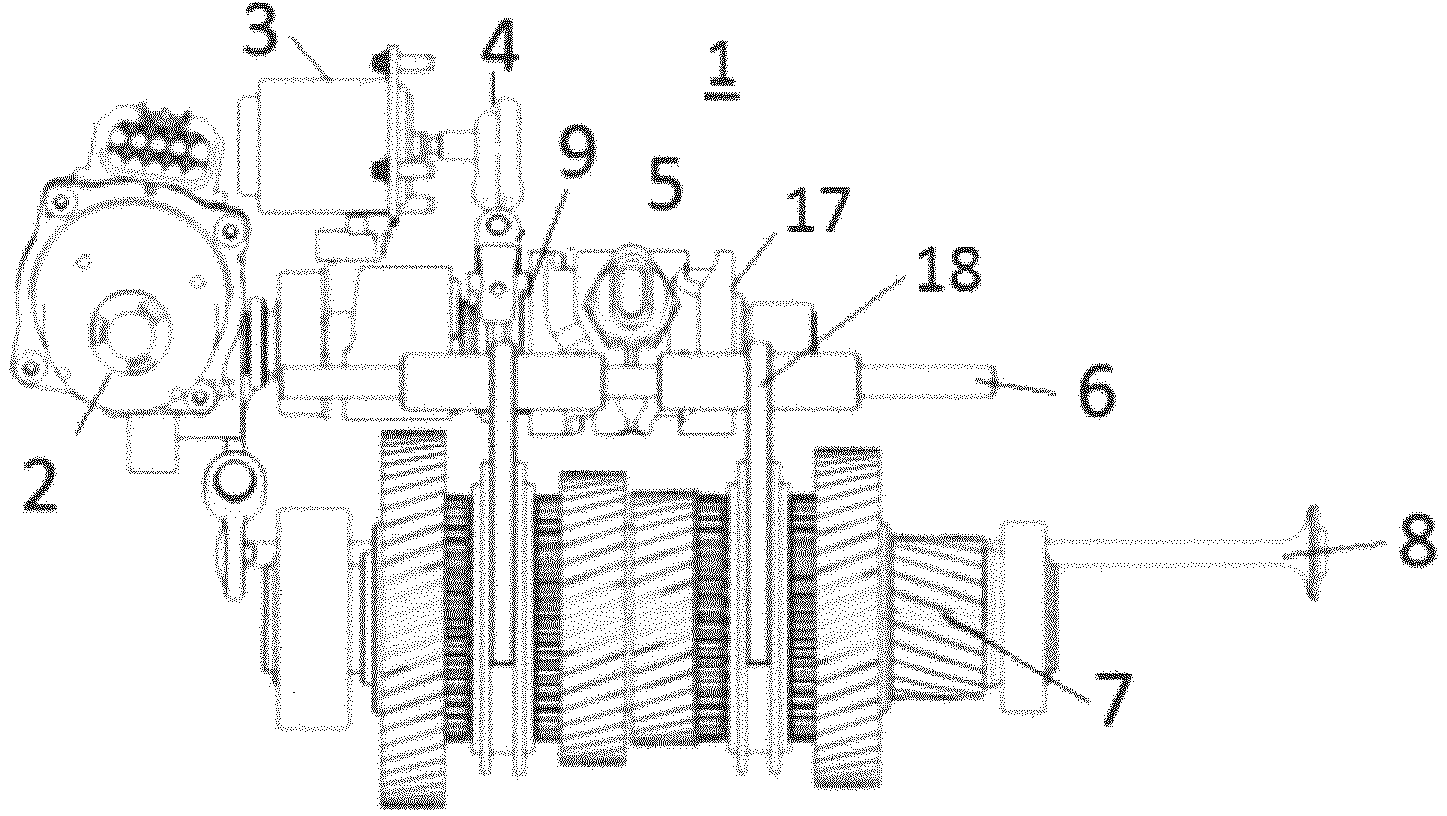

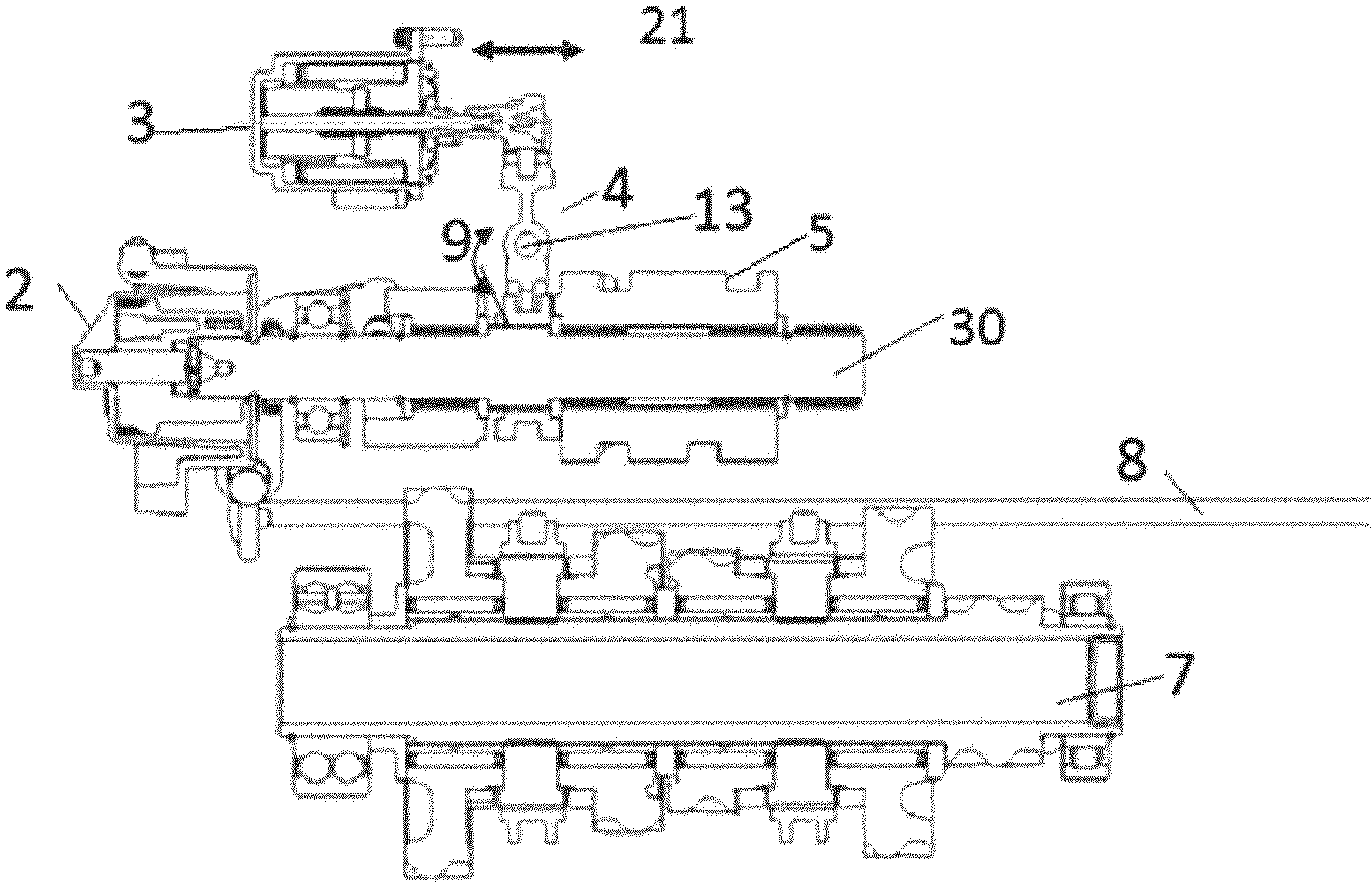

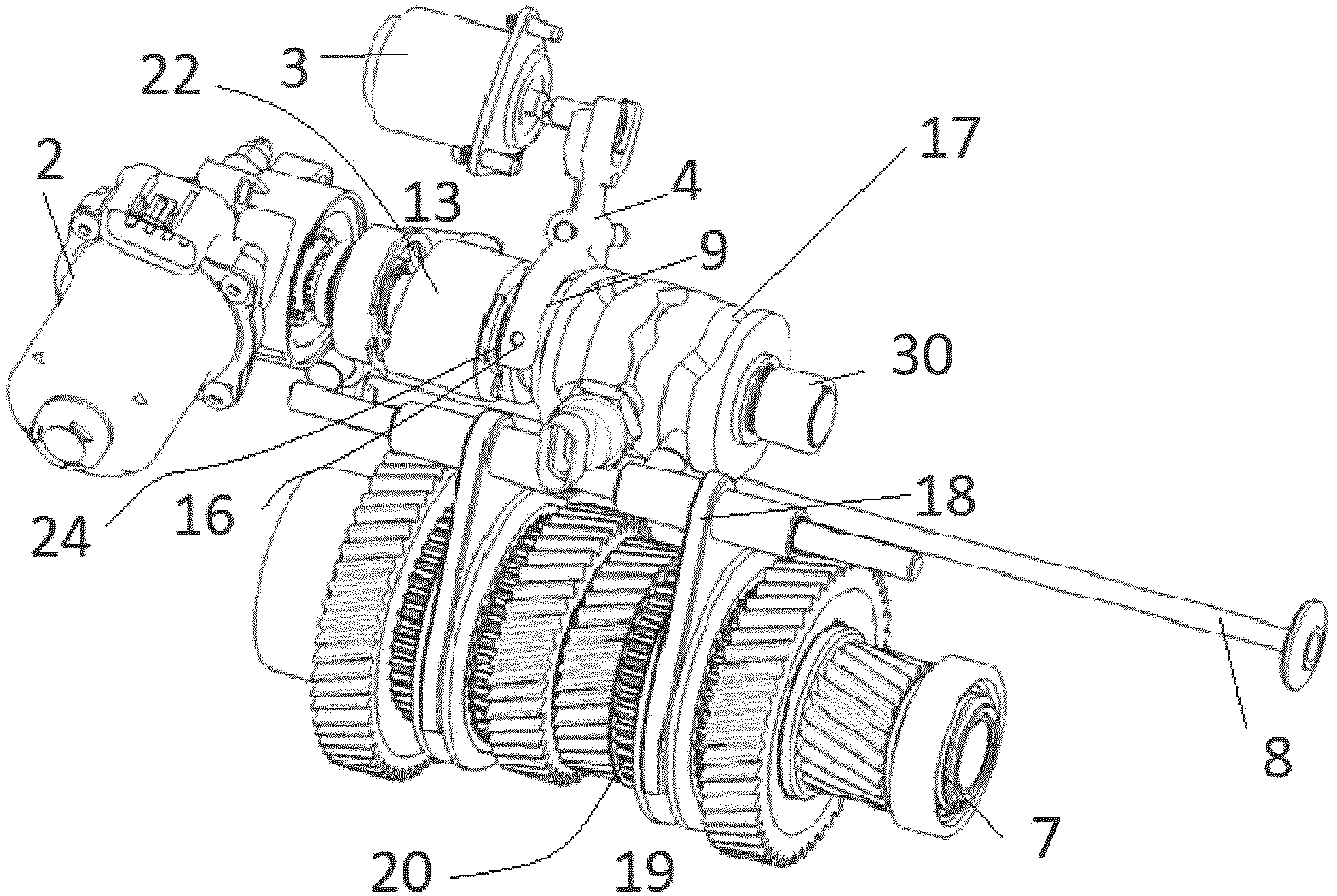

Hybrid transmission

InactiveCN104246319APrevent automatic shift transmissionPrevent the situationMechanical actuated clutchesMagnetically actuated clutchesEngineeringActuator

The invention proposes a hybrid transmission having a main transmission shaft with gearwheels and having, arranged parallel thereto, a main shaft which has at least one shift drum, wherein the main shaft is driven by an actuator and has at least one shift slotted guide. The main shaft has an arrangement which can be activated both so as to connect the shift drum to a clutch and also so as to drive shift sleeves for at least one transmission stage.

Owner:MAGNA POWERTRAIN AG & CO KG

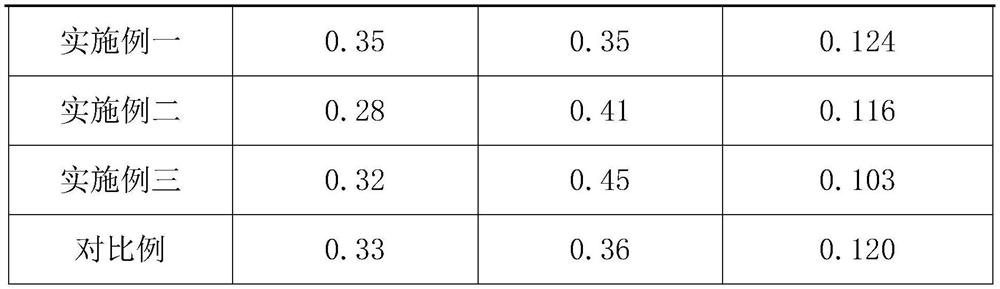

High-temperature-resistant thermal insulation material and preparation method thereof

ActiveCN111848106ALarge specific surface areaGood chemical stabilityZirconium oxidesThermal insulationPotassium titanate

The invention relates to the technical field of thermal insulation materials. The invention provides a high-temperature-resistant thermal insulation material and a preparation method thereof. The high-temperature-resistant thermal insulation material comprises the following raw materials in parts by weight: 55-75 parts of ceramic fiber cotton, 5-15 parts of potassium hexatitanate whiskers, 4-8 parts of modified expanded vermiculite, 5-18 parts of zirconium dioxide aerogel, 1-6 parts of a silane coupling agent, 2-5 parts of an inorganic binding agent, 1-3 parts of an organic binding agent, 1-5parts of a flocculating agent and 2-4 parts of a dispersing agent. The problems that in the prior art, a heat preservation and insulation material made of single ceramic fiber difficultly meets the requirement for high-temperature heat insulation, and the comprehensive performance of the ceramic fiber heat insulation material needs to be further improved are solved.

Owner:福建省中能泰丰节能环保科技有限公司

Photovoltaic transparent composite film, and preparation method and application thereof

InactiveCN106960891AImprove adhesionAchieve bondingPhotovoltaic energy generationSemiconductor devicesComposite filmMetallic materials

The invention discloses a photovoltaic transparent composite film, and a preparation method and application thereof. The transparent composite film comprises a release paper layer and a function layer, the function layer comprises a supporting layer and a bonding layer, and at least one of the supporting layer and the bonding layer is mixed with a light conversion agent which can converting part of ultraviolet light into visible light. The lower surface of the supporting layer is connected with the bonding layer, and the upper surface and the lower surface of the supporting layer are both flat surfaces or at least one surface is provided with certain light tripping microstructures. The bonding layer is formed by an acrylic ester pressure-sensitive adhesive and can bond metal materials well. The transparent composite film can be applied to multi-main grid and non-main grid photovoltaic modules, and plays a role in applying brass wires to a battery piece, and has high transmissivity and an excellent anti-ultraviolet ageing performance, and can satisfy the usage demand of photovoltaic modules.

Owner:HANGZHOU FIRST APPLIED MATERIAL CO LTD

Polyurethane adhesive used for composite fluoroplastic film and preparation method thereof

ActiveCN103709975AHigh peel strengthAchieve bondingNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyurethane adhesivePolycarbonate

The invention provides a polyurethane adhesive used for a composite fluoroplastic film. The polyurethane adhesive is formed by compounding of 100 parts by weight of acrylic acid modified polyurethane prepolymer, 2-5 parts by weight of a curing agent and 0.1-0.5 part by weight of a catalyst. The preparation method of the polyurethane adhesive includes: mixing polycarbonate diol with isophorone diisocyanate to undergo reaction, then conducting curing to obtain a polyurethane prepolymer; subjecting the polyurethane prepolymer and an acrylic monomer to reaction in an organic solvent under the action of an initiator, thus obtaining the acrylic acid modified polyurethane prepolymer; and adding the curing agent and the catalyst into the acrylic acid modified polyurethane prepolymer, and mixing them uniformly to obtain the polyurethane adhesive. Experimental results show that, when the polyurethane adhesive is used for bonding of a fluoroplastic film with other resin (like polyurethane resin, ethylene-vinyl alcohol copolymer, polyester resin, nylon and the like) films, textiles and other flexible materials, the peel strength is higher than 6N / cm.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Display panel and bending method thereof

InactiveCN109559646APrevent changes in the bending arcAvoid breakingSolid-state devicesSemiconductor/solid-state device manufacturingConvex sideEngineering

The invention discloses a display panel and a bending method thereof. The display panel comprises a display screen body, wherein the display screen body comprises a bending region and a binding regionconnected with the bending region, and also comprises a pressing post arranged in the bending region of the display screen body; the bending region forms an accommodating groove after bending along the pressing post; and one side, facing the bending region, of the pressing post is an arc-shaped convex surface. The display panel and the bending method provided by the invention have the advantagesthat the display panel is bent according to a fixed radian, so that the problem of a conventional bending method of easy occurrence of a crease phenomenon or even easy wire distribution fracture on the bending region of the display screen body is solved. Meanwhile, the bent bending region of the bent display screen body can be supported so as to prevent the bending radian change of the bending region in the use process of the display panel.

Owner:YUNGU GUAN TECH CO LTD

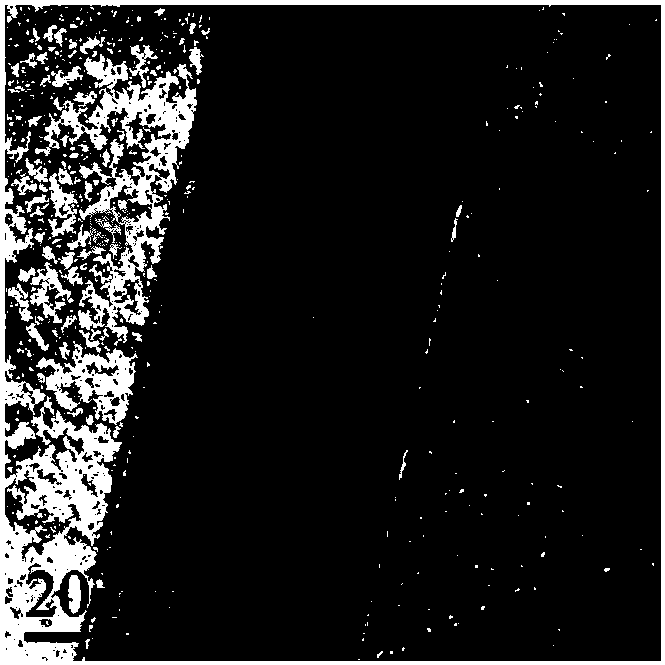

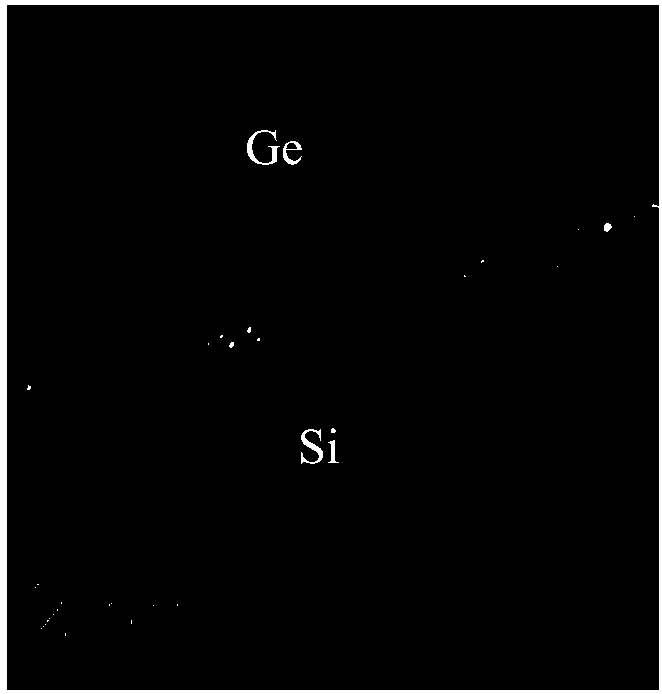

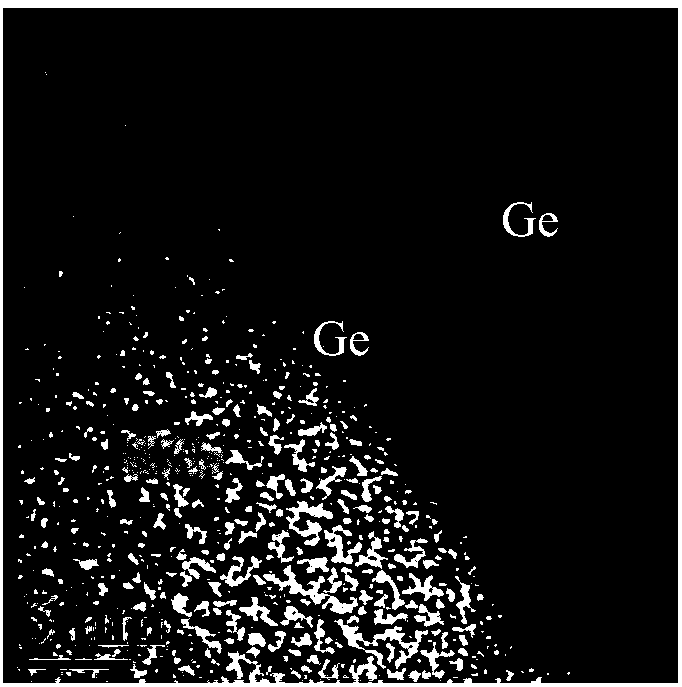

Low-temperature bonding method for semiconductor without oxide layer

InactiveCN108573878AAchieve bondingSolve the problem of introducing a hydrophilic oxide layerSemiconductor/solid-state device manufacturingInterfacial oxideBond interface

The invention relates to a low-temperature bonding method for a semiconductor without an oxide layer, which relates to a semiconductor bonding process. A transition layer technology is adopted, a thinGe layer is introduced at a Si, Ge and SiO2 semiconductor bonding interface, and the low-temperature crystallization characteristics and the crystallization atomic migration characteristics of the Gematerial are used to realize non-oxide layer Si wafer bonding, Ge / Si bonding and GOI bonding. The low-temperature crystallization characteristics of a magnetron sputtering Ge layer are used to realize a non-interfacial oxide layer semiconductor bonding interface, a semiconductor Ge transition layer grows on the surface of a wafer after being cleaned, the low-temperature crystallization characteristics of the Ge are used, crystallization of the Ge transition layer is realized through low-temperature annealing, migration of atoms at the bonding interface is thus driven, and the oxide layer is finally dissociated. According to the method in the invention, the problem of introducing a hydrophilic oxide layer at the interface during a direct hydrophilic bonding process can be solved, crystallization of the semiconductor bonding interface transition layer can also be realized under the low temperature of 300 to 400 DEG C, and atomic bond bonding is thus realized.

Owner:XIAMEN UNIV

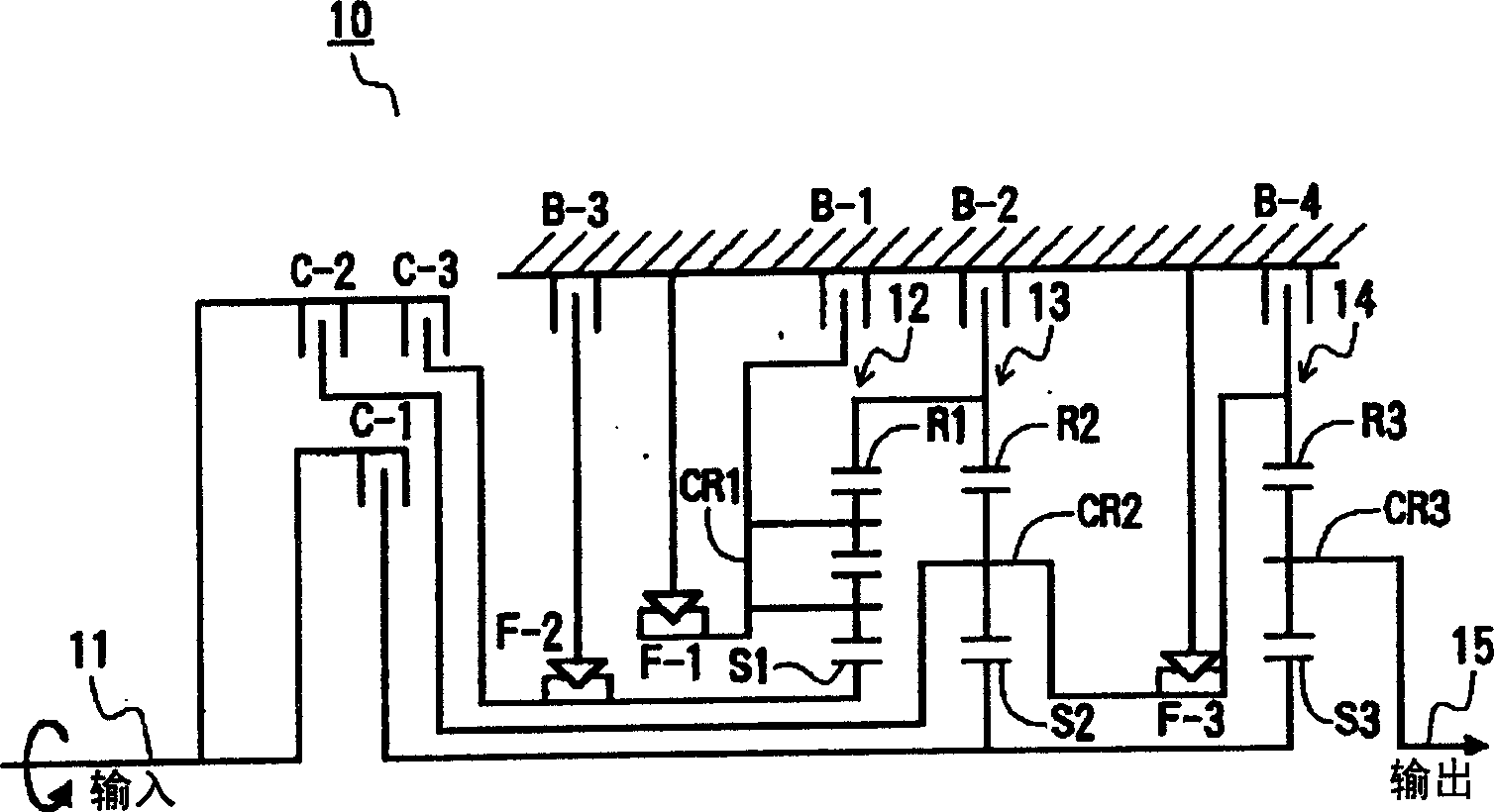

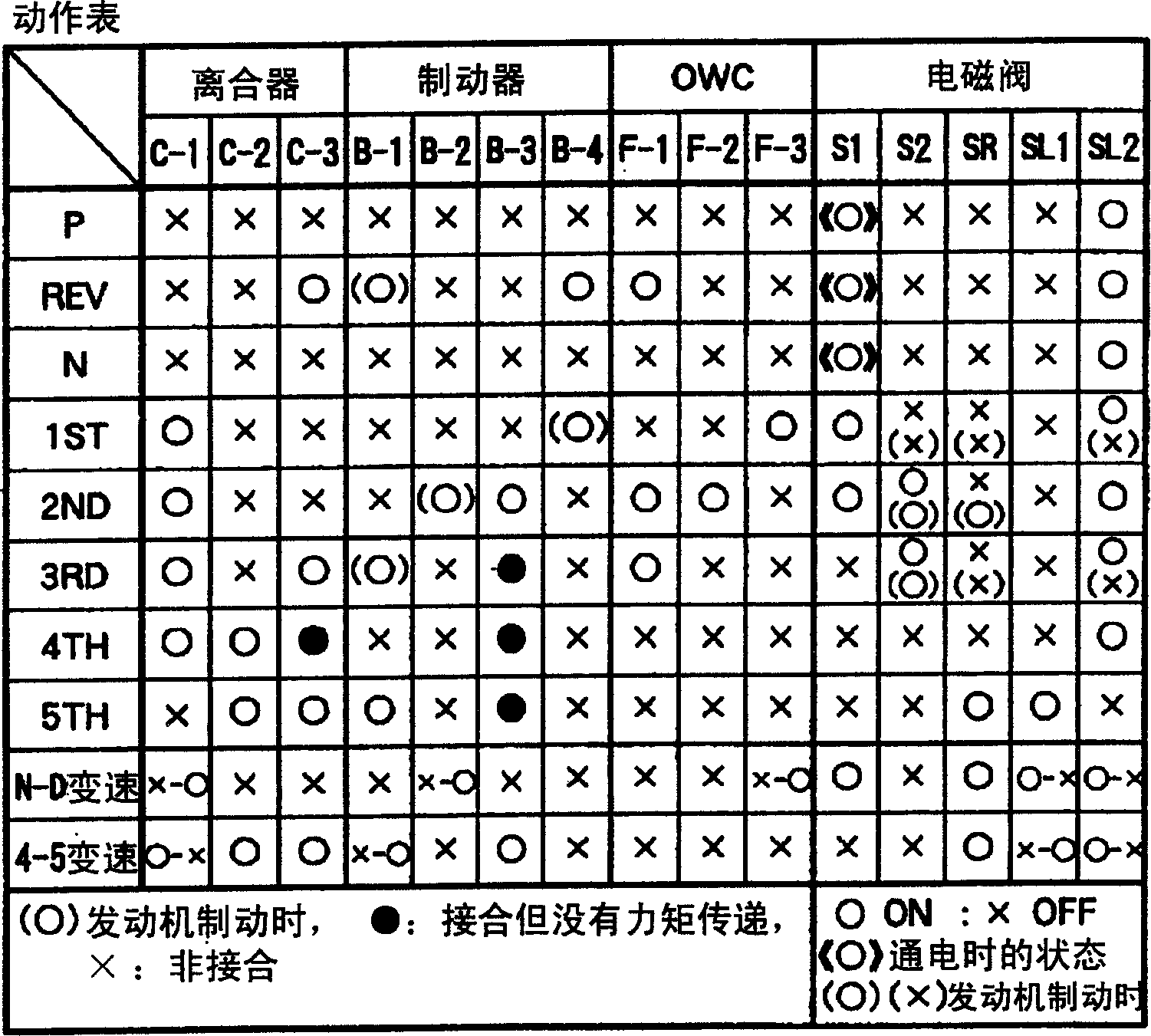

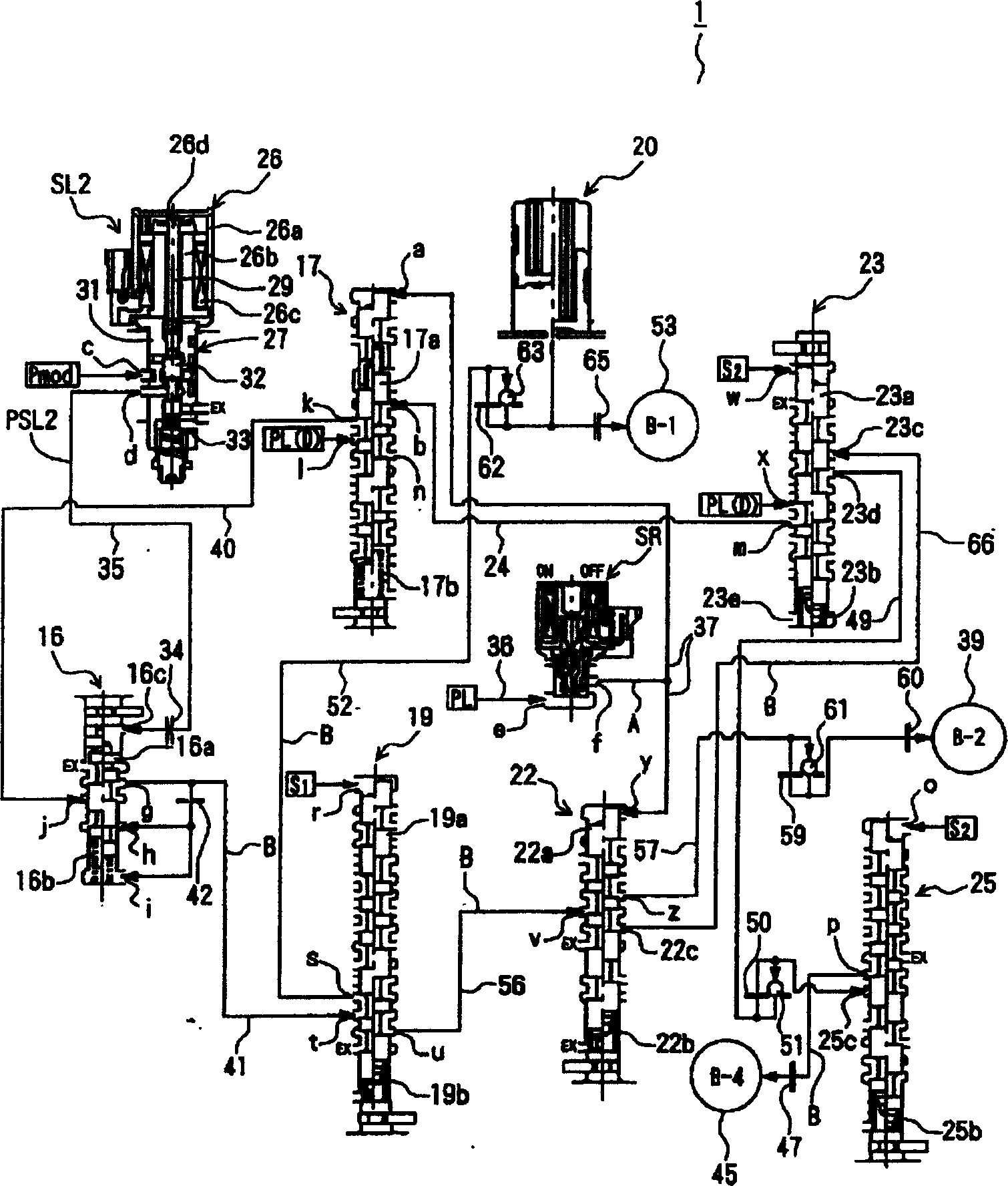

Hydraulic control system for automatic transmission

InactiveCN1501013ASimple compositionCushion the shockGearing controlAutomatic transmissionEngineering

The hydraulic control device 1 of the automatic transmission has a 3-4 shift valve 23 for outputting initial pressure of a first route at a third speed stage lower than a fourth speed stage directly connecting an input shaft 11 and an output shaft 15 of the automatic transmission and a clutch apply control valve 17 for outputting initial pressure of a second route at a fifth speed stage higher than the direct connection stage.Both valves 23 and 17 perform a control to block both initial pressures of the first and second routes at the direct connection stage.

Owner:AISIN AW CO LTD +1

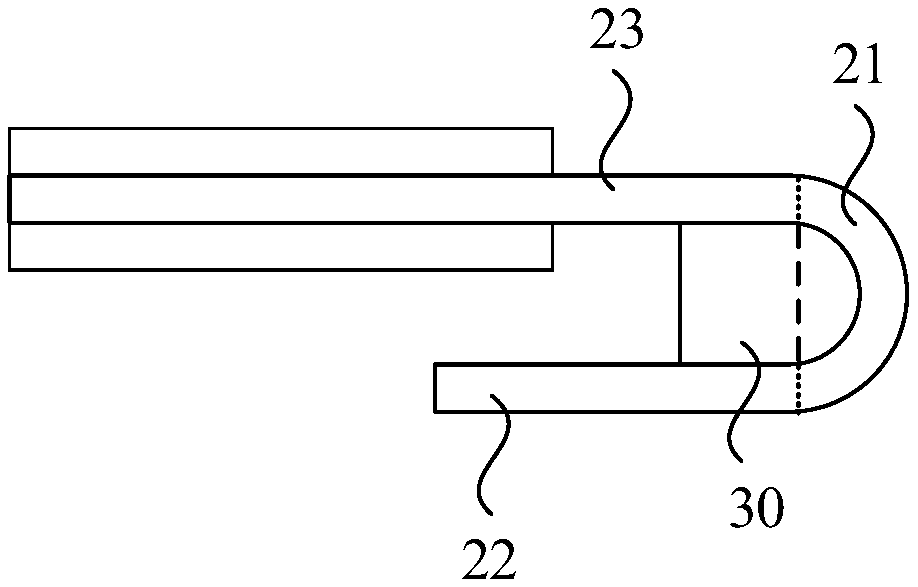

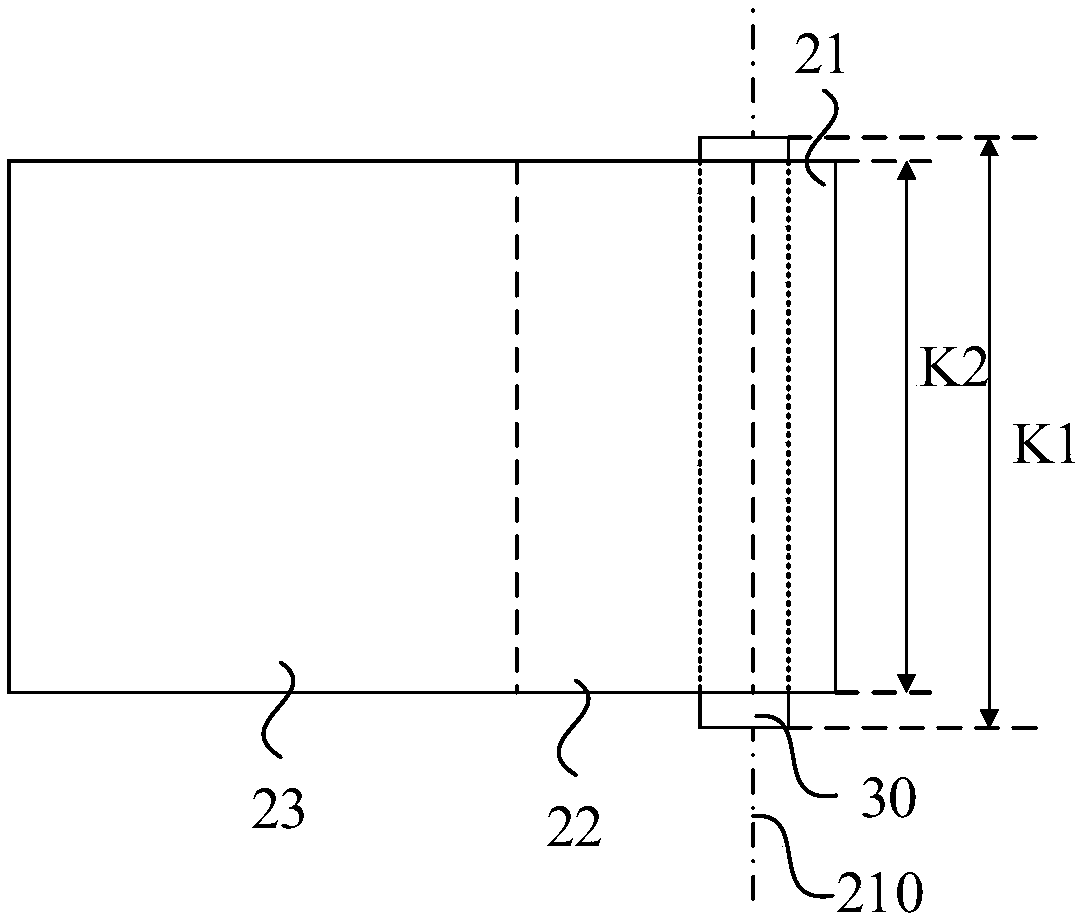

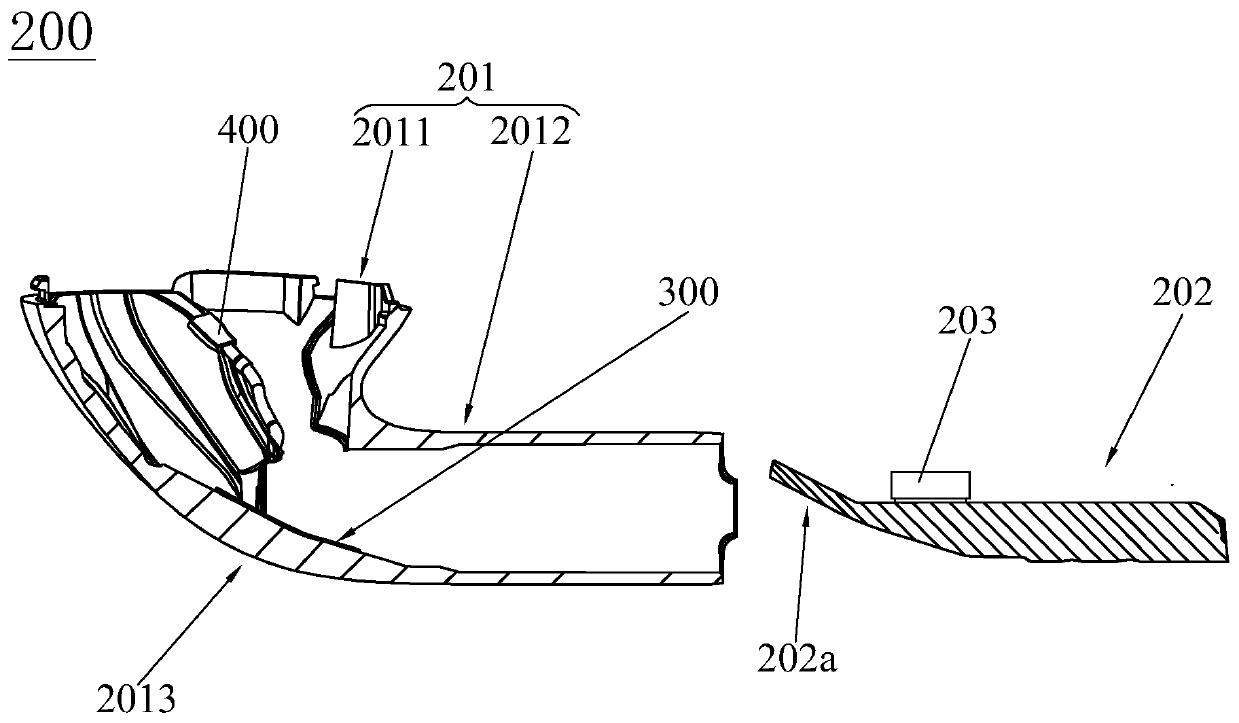

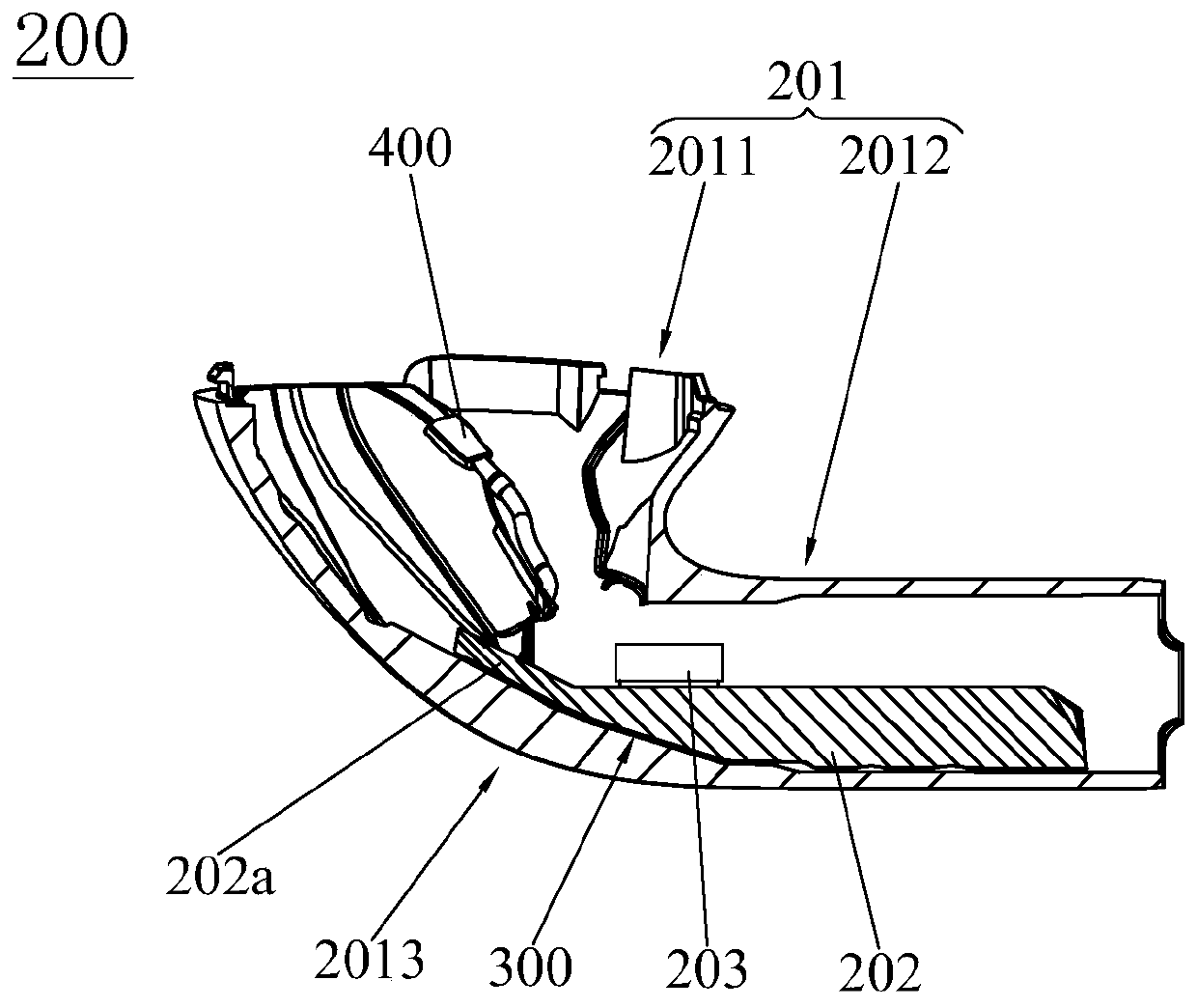

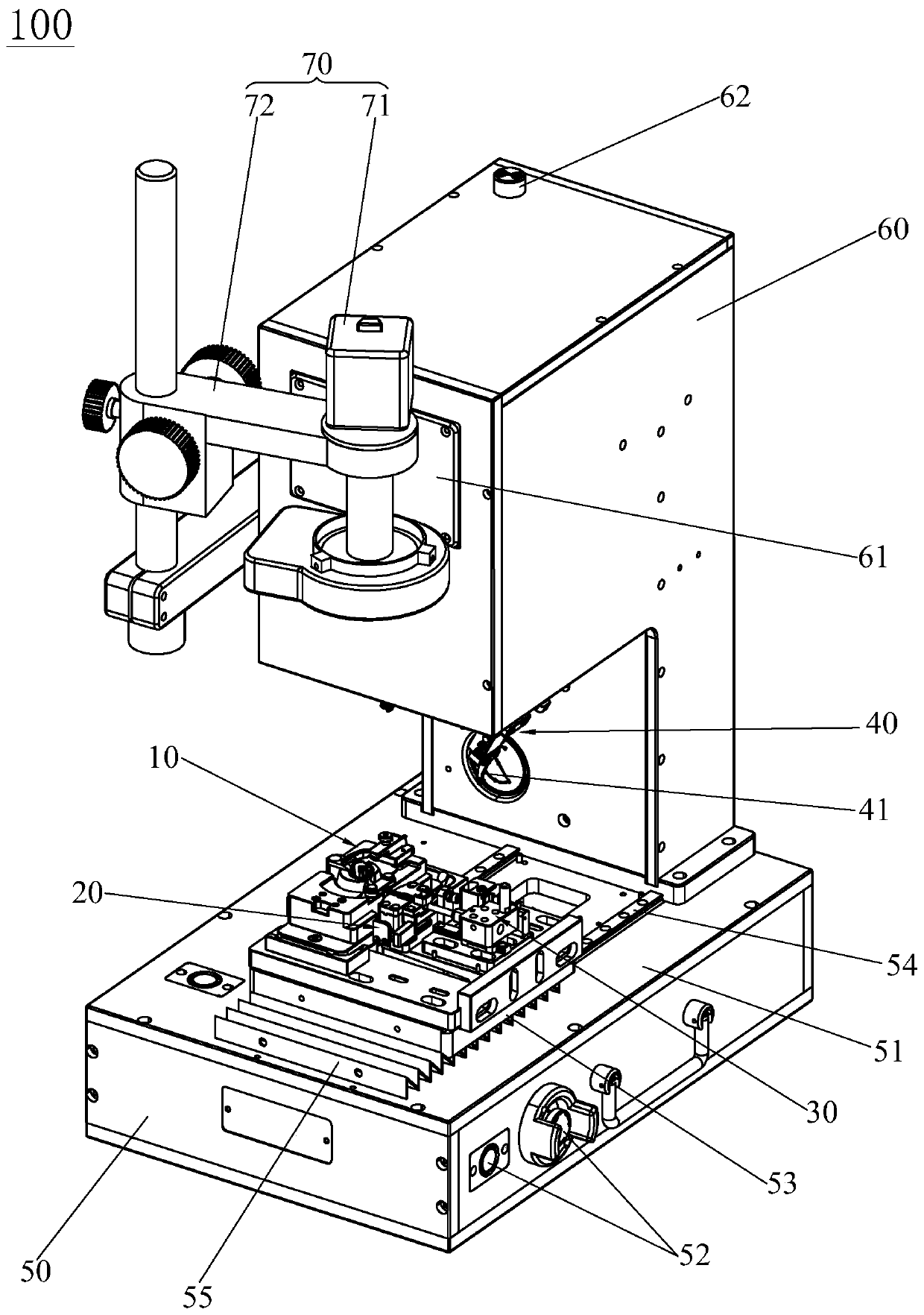

Automatic assembling machine for Bluetooth earphones

The invention discloses an automatic assembling machine for Bluetooth earphones. The automatic assembling machine is used for assembling an earphone device in an earphone body. The arc-shaped inner wall of the earphone body is provided with an attaching area. The automatic assembling machine for the Bluetooth earphones comprises a first carrier, a second carrier, a pushing device and a pressing device. The first carrier is used for fixing the earphone body; the second carrier is used for fixing the earphone device; under the matching of the second carrier, the pushing device pushes the earphone device into the earphone body, the opposite front ends of the earphone device abut against the attaching area, the first pressing head of the pressing device can extend into the earphone body and abut against the earphone device located in the attaching area in the direction perpendicular to the pressed face of the earphone device, the pressure-sensitive adhesive arranged between the earphone body and the earphone device is activated, and then bonding of the earphone body and the earphone device is achieved. The Bluetooth headset automatic assembling machine is simple in structure, high in automation degree, high in efficiency, high in assembling precision and good in effect.

Owner:DONGGUAN WORLD PRECISION MACHINERY

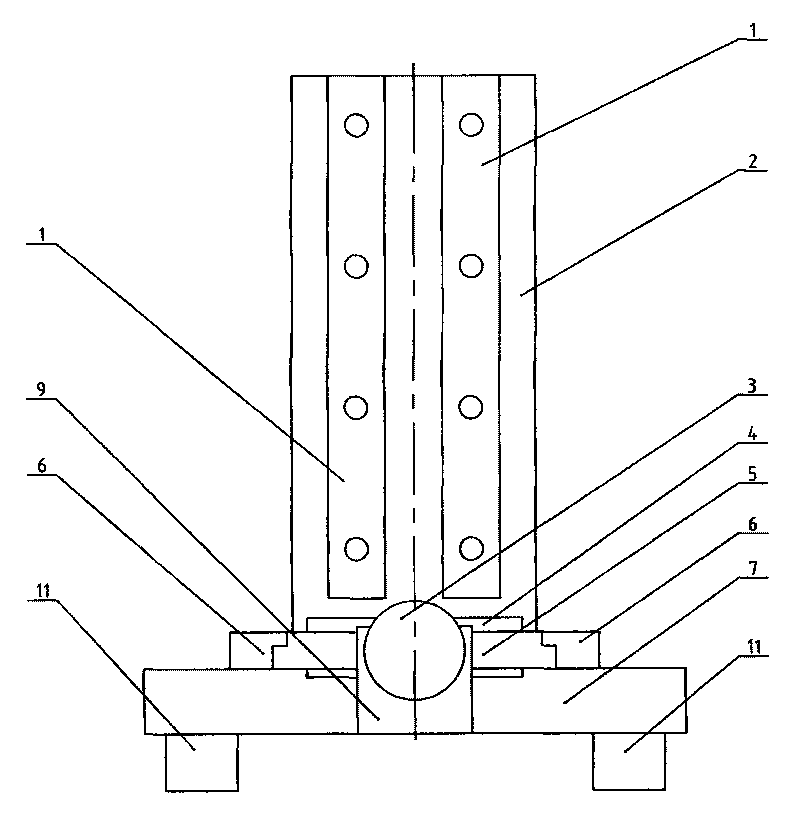

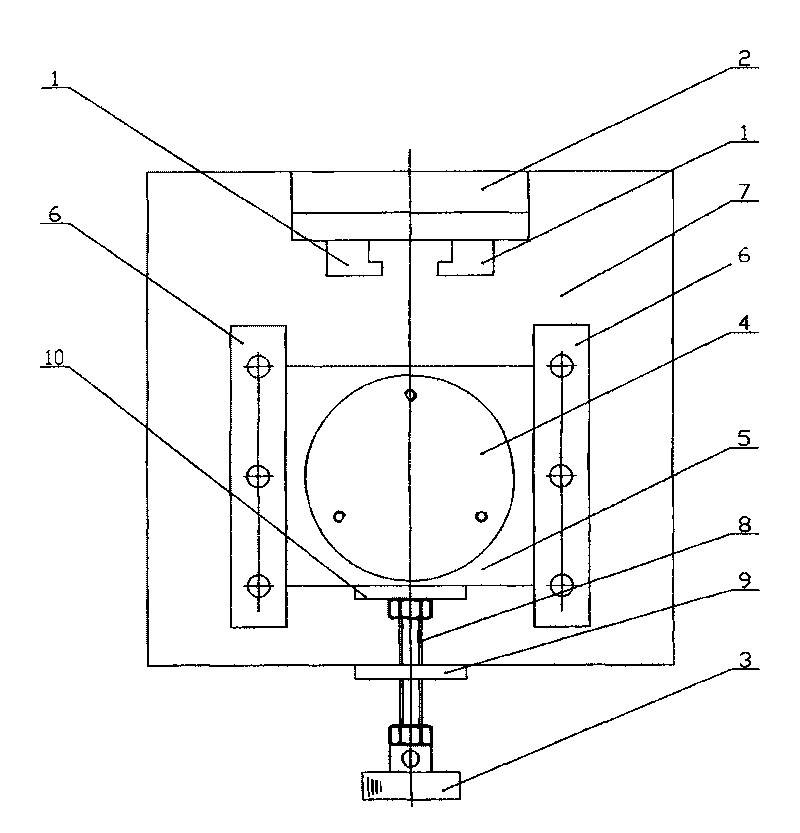

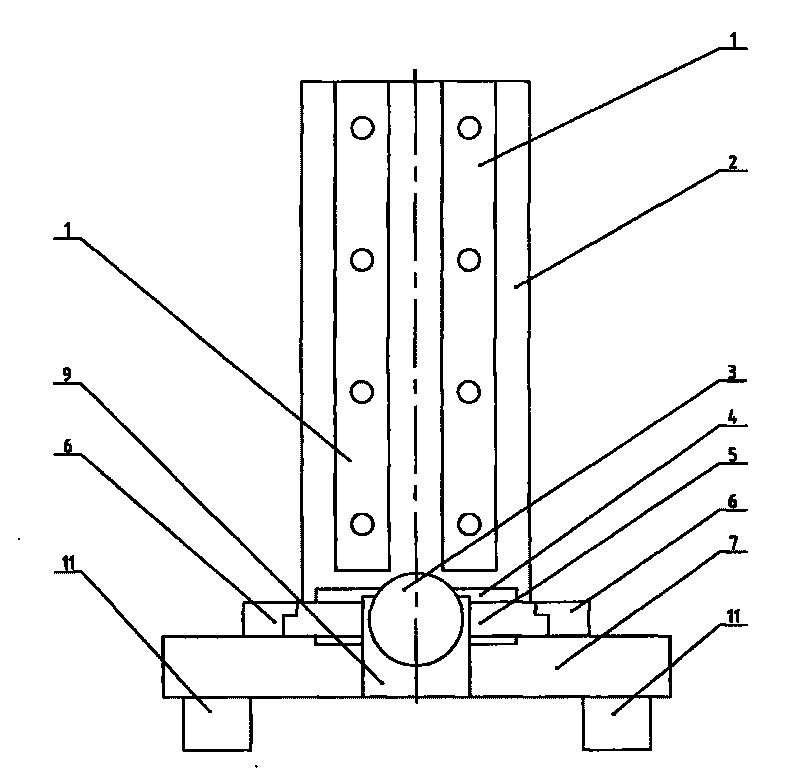

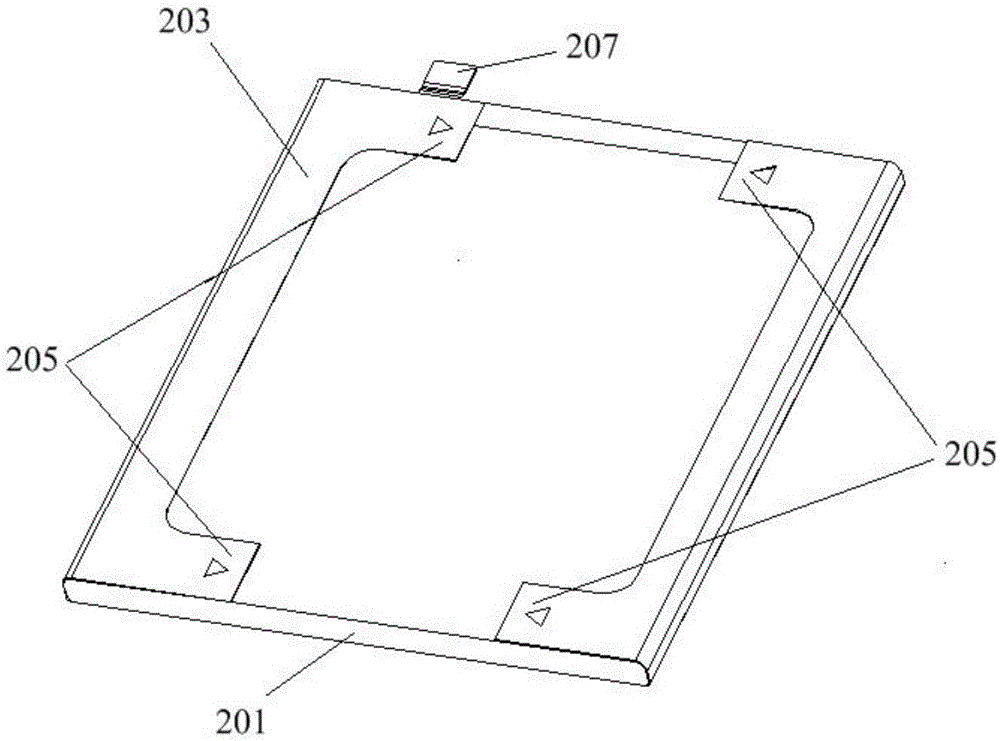

Bonding device of direction-finder

InactiveCN101758565AGuaranteed to be verticalAchieve bondingSemiconductor/solid-state device manufacturingWorking accessoriesCrystal orientationX-ray

The invention relates to a bonding device used for an X-ray direction-finder which is used to measure the crystal orientation deviation of crystal or the crystal orientation position of processed crystal face of crystal bar. The structure of the bonding device is as follows: four supporting feet are arranged under a base, a graphite block slideway is arranged on the base, a T-shaped block is inserted in the graphite block slideway, a graphite block is arranged on the T-shaped block, a binding slideway is arranged on a vertical plate which is fixed on the upper part of the back of the base, a flange is arranged in the mid-position of the front of the T-shaped block, one end of a screw arranged in the mid-position of the front of the T-shaped block is connected with a hand knob, and the other end is screwed in a nut board arranged in the mid-position of the front of the base to be connected with the flange. The device can be used to ensure that the crystal face and the end surface of the graphite block are perpendicular to the axis of crystal rod, the deviation angle in a retainer plate plane can be adjusted, the deviation angle in a plane which is perpendicular to the retainer plate can be adjusted, the bonding device can satisfy the binding demand of crystal rod with different diameters and the high precision slicing demand, the investment is less, the operation is easy, convenient and reliable, and the aim of binding various crystal rods can be effectively achieved.

Owner:DONGDAN AOLONG RADIATIVE INSTR GRP

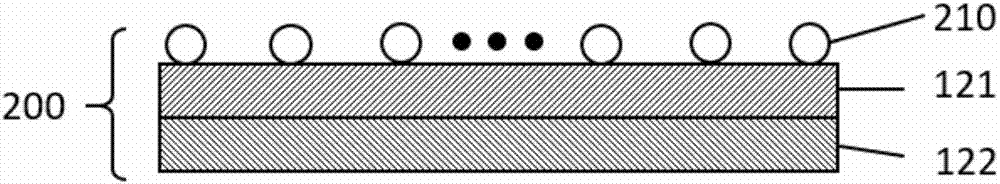

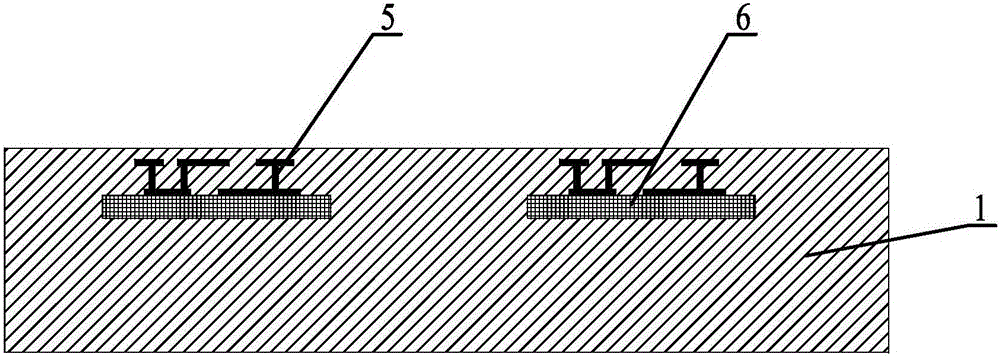

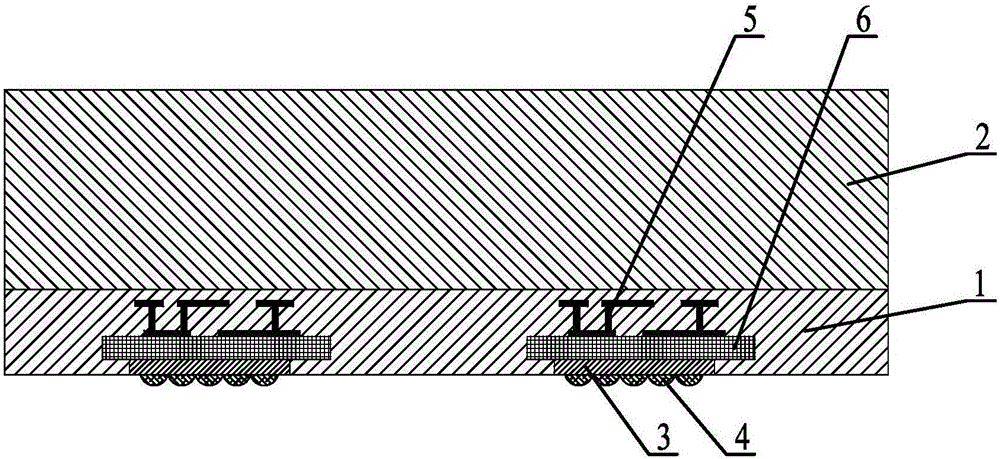

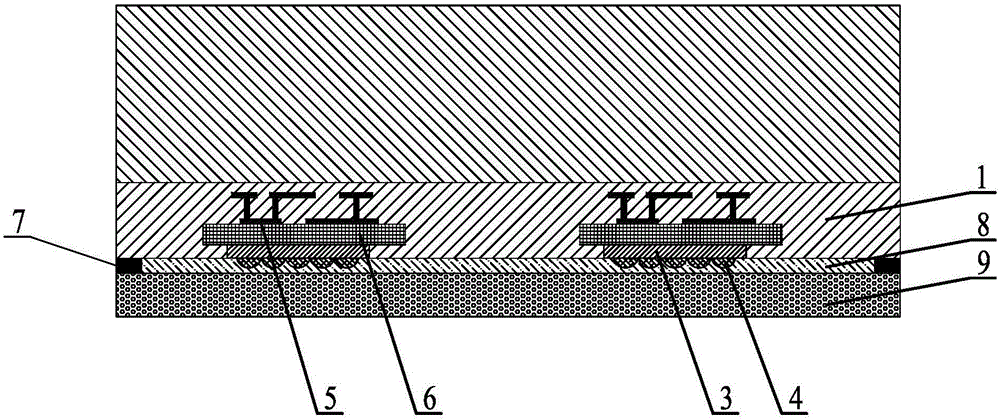

Backside-illuminated image sensor wafer level packaging process and packaging structure

ActiveCN104992955AReduce thicknessAchieve bondingRadiation controlled devicesLight filterElectrical and Electronics engineering

The invention relates to a backside-illuminated image sensor wafer-level packaging process and packaging structure. The packaging process comprises the following steps: bonding a load wafer on the front surface of a CIS wafer, thinning the back surface of the CIS wafer with the load wafer being as a support, and preparing a light filter and a micro lens on the back surface of the thinned CIS wafer; carrying out covering on the edge position of the back surface of the CIS wafer with first bonding glue, carrying out coating with second bonding glue in an enclosed annular shape, and bonding a seal cover onto the back surfaces of the first bonding glue and the second bonding glue; thinning the load wafer with the seal cover being as a support, preparing conductive columns in the thinned load wafer, and depositing a conductive layer on the top end of each conductive column; and removing stickiness of the first bonding glue to enable the CIS wafer and the seal cover to be separated, cleaning the CIS wafer and the seal cover to remove the second bonding glue, and finally, carrying out cutting to obtain the backside-illuminated image sensor wafer-level packaging structure. The process reduces the thickness of the package wafer and can enable the seal cover to be used repeatedly.

Owner:NAT CENT FOR ADVANCED PACKAGING

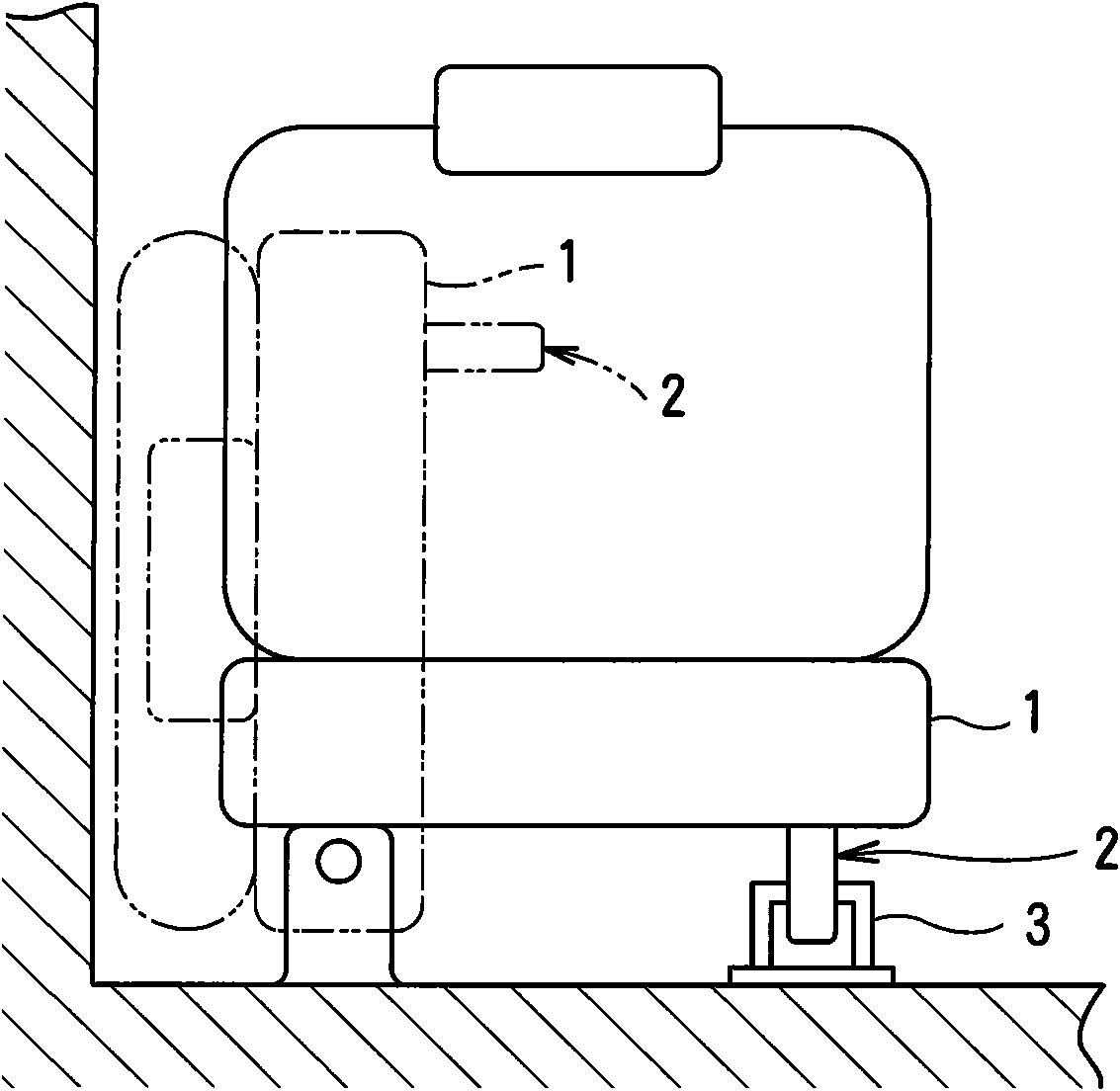

Fixing structure of built-in battery and mobile terminal

InactiveCN106299165AAchieve fixationAchieve bondingSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsAdhesiveEngineering

The embodiment of the invention discloses a fixing structure of a built-in battery and a mobile terminal. The fixing structure of the built-in battery comprises a battery installing cavity, the built-in battery and a Mylar film, wherein the battery installing cavity is arranged inside the machine body of the mobile terminal, the Mylar film forms a wrapping structure for the built-in battery, the wrapping structure is arranged in the battery installing cavity and comprises a first bonding portion and a second bonding portion, the first bonding portion is bonded in the battery installing cavity through a first adhesive to fix the wrapping structure in the battery installing cavity, and the second bonding portion is used for forming the wrapping structure through a second adhesive to fix the built-in battery in the wrapping structure. The built-in battery is wrapped through the Mylar film, and then the wrapping structure is bonded in the battery installing cavity, so that the deformation scrap of the built-in battery in the repair process can be avoided.

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

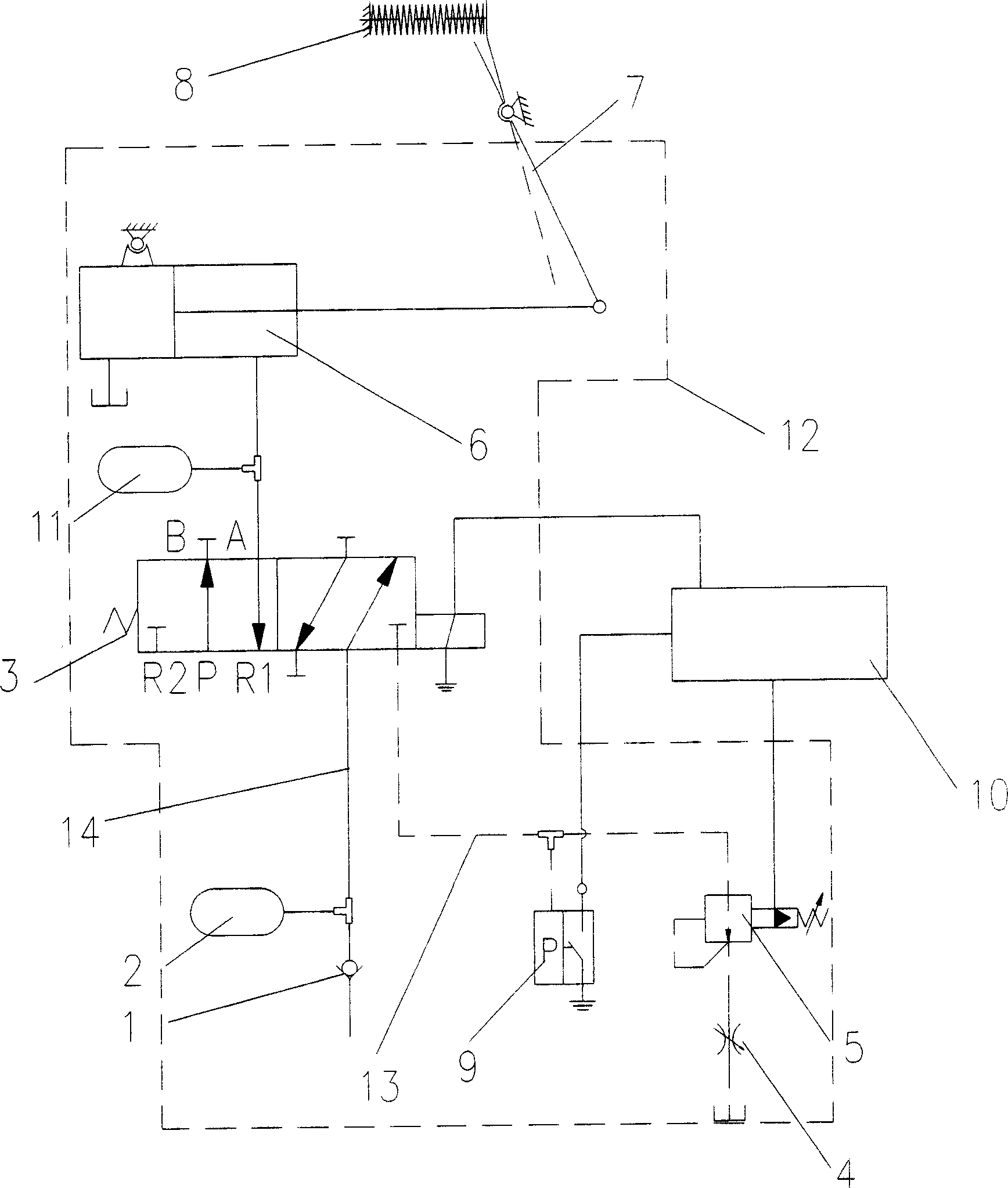

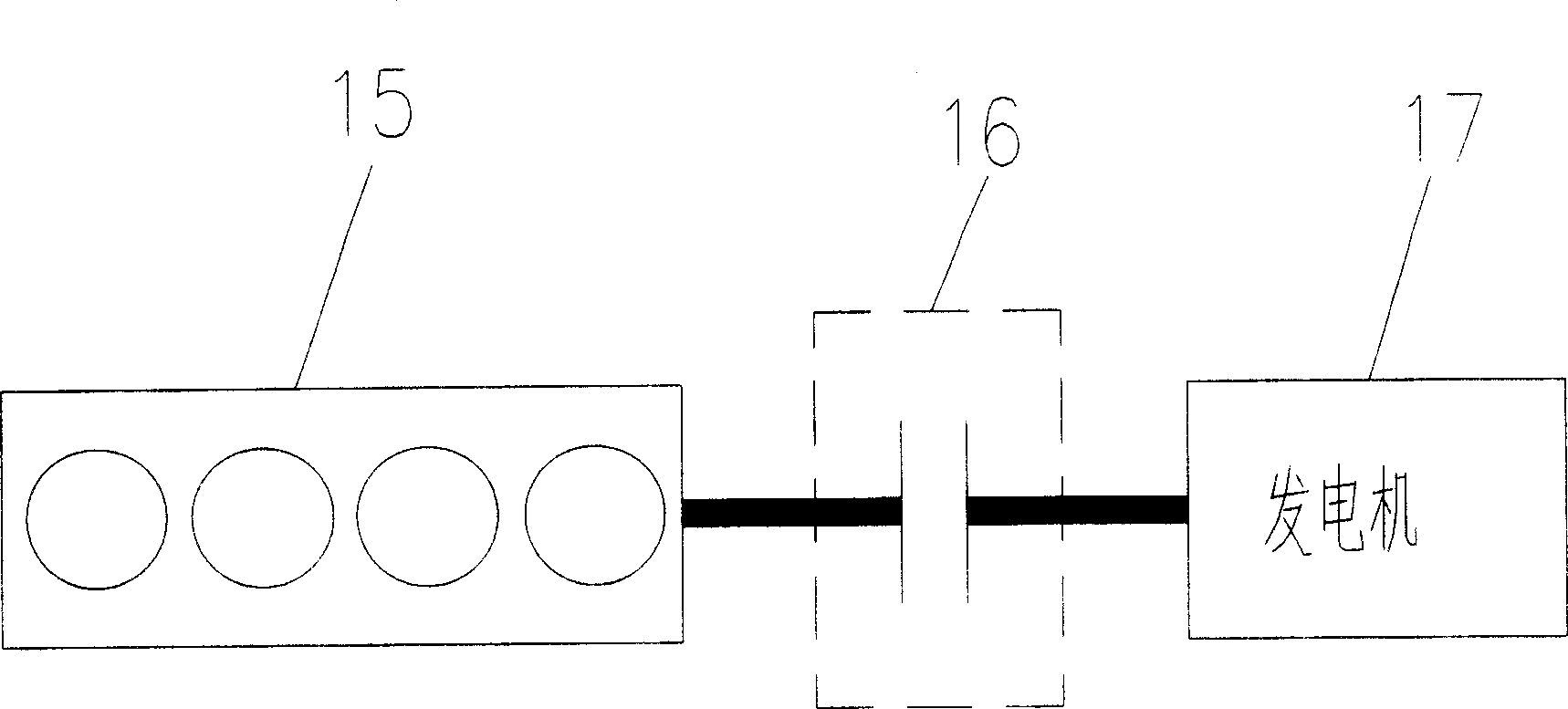

Clutching method and device for vehicle motor and electric generator

ActiveCN1903603AAchieve bondingReduce noiseBatteries circuit arrangementsGas pressure propulsion mountingControl systemEngineering

Owner:CSR ZHUZHOU ELECTRIC LOCOMOTIVE RES INST

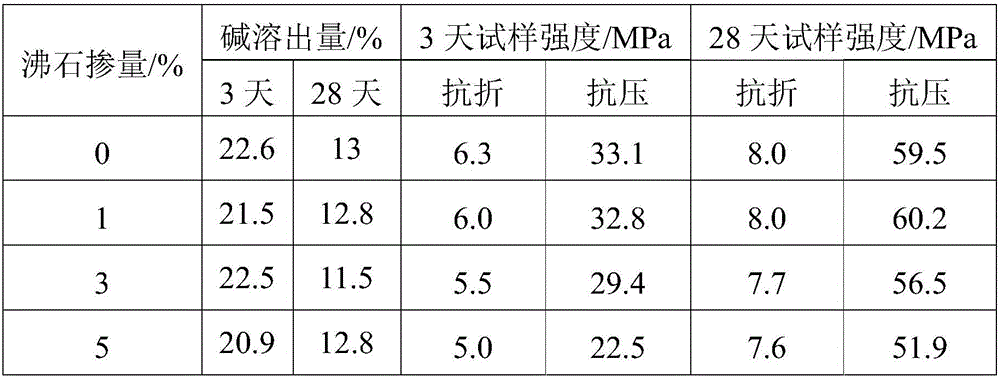

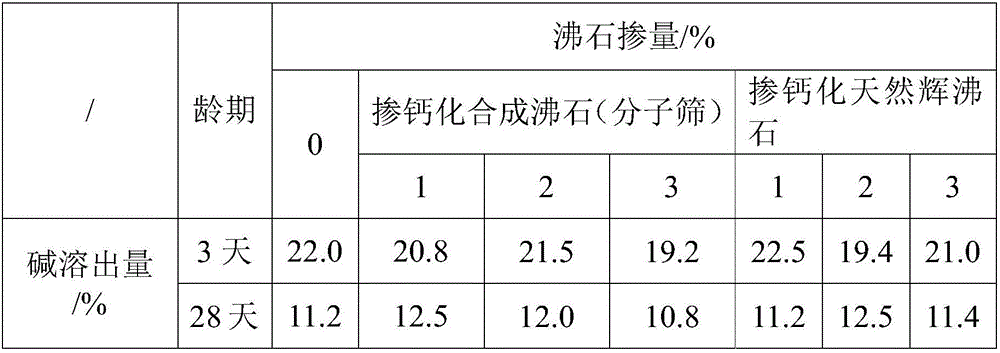

Alkali-activated cementing material and preparation method thereof

ActiveCN106746781AGuaranteed StrengthGuaranteed work performanceCement productionAlkali activatedDissolution

The invention discloses an alkali-activated cementing material and a preparation method thereof, belonging to the building field. The preparation method comprises the following steps: (1) weighing raw materials, wherein the raw materials include powder, an aqueous solution of a liquid activator and calcium-containing zeolite, the powder is prepared by mixing calcined bauxite tailings and slag powder in a mass ratio of (7-8):(3-2), the mass of the aqueous solution of the liquid activator is 4-5% of the mass of the powder based on the mass of Na2O, and the mass of the calcium-containing zeolite is 1-5% of the mass of the powder; and (2) mixing the raw materials to obtain the alkali-activated cementing material, wherein the mass ratio of the water to solid raw materials in the raw materials is 0.4-0.5. In the invention, the cementing material prepared by the method has the advantage of low alkali dissolution.

Owner:CHINA BUILDING MATERIALS ACAD

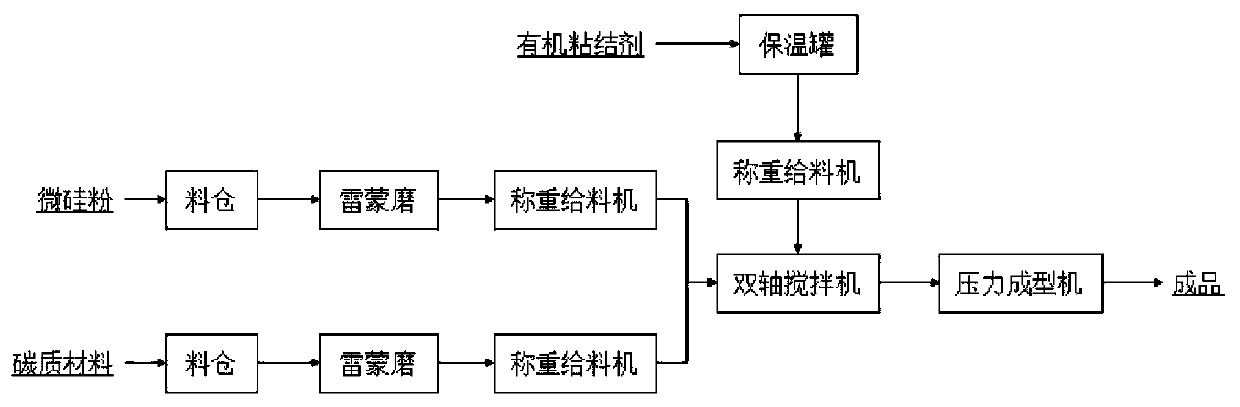

Window blocking material used for high silicon alloy smelting electric furnace

ActiveCN110243185AAvoid pollutionReduce maintenance timesCharge manipulationBrickElectric arc furnace

The invention discloses a window blocking material used for a high silicon alloy smelting electric furnace, and relates to the field of chemical materials. The window blocking material comprises, by weight percent, 10 to 30% of a solid-state inorganic binder, 40 to 60% of a carbon material and 10 to 30% of a liquid-state organic binding agent. The window blocking material can effectively avoid the pollution to the high silicon alloy, it is ensured that the redox reaction of anhydrous steam and the carbon material causes the furnace window carbon brick erosion, and in the use process, the furnace window is repaired, so that the furnace window carbon brick damage speed is effectively reduced; the maintaining period of the furnace window is prolonged to 28 to 42 days, and the furnace window repair cost is reduced; the furnace window replacing frequency is reduced, the coil base yield and the product quality are improved, and the economic benefit is improved; and the window blocking material can be used in cooperation with a high silicon alloy smelting electric furnace window opening and blocking machine, the automation level is improved, operation is easy, and labor force and time are reduced.

Owner:内蒙古鄂尔多斯电力冶金集团股份有限公司 +1

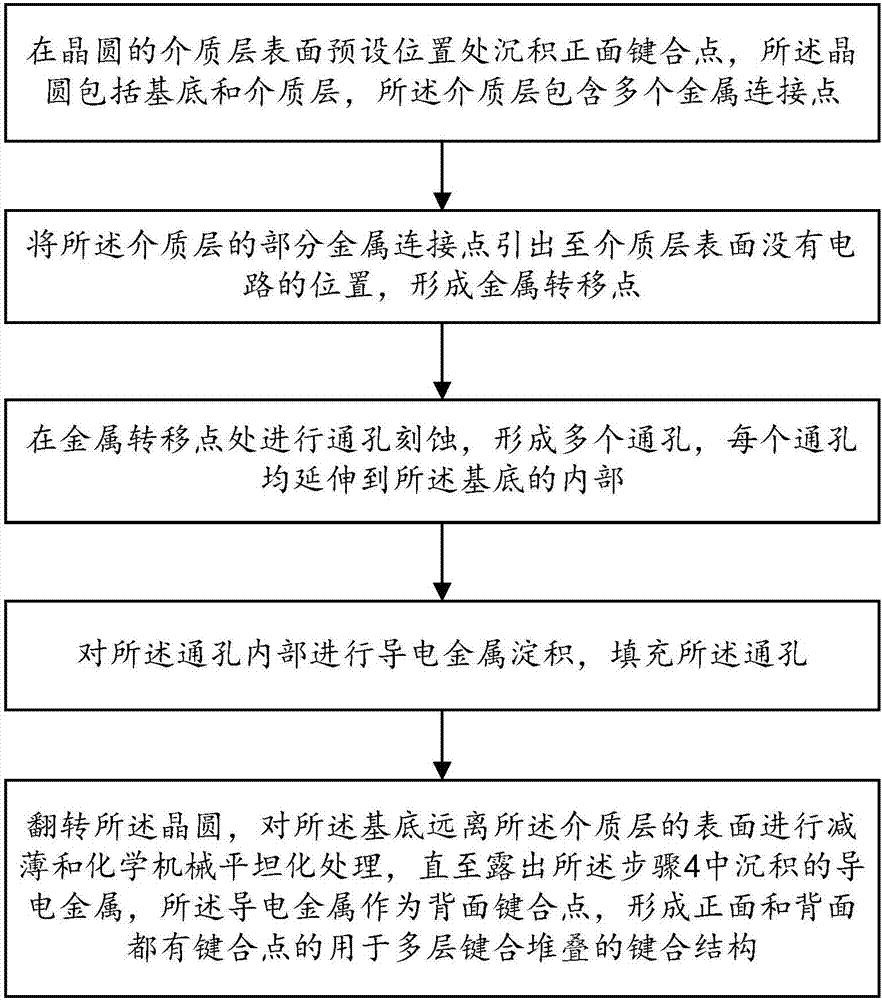

Method of manufacturing bonding structure for multi-layer bonding stack and bonding structure

ActiveCN107359129AImprove the effective use of areaIncrease freedomSemiconductor/solid-state device detailsSolid-state devicesHigh resistanceElectrical resistance and conductance

The invention relates, in particular, to a method of manufacturing a bonding structure for a multi-layer bonding stack and a bonding structure. The method includes the steps of depositing front bonding points at preset positions on a surface of a dielectric layer of a wafer, the wafer including a first substrate and the dielectric layer, and the dielectric layer including a plurality of metal connection points; leading out a part of the metal connection points to form metal transfer points; performing through-hole etching at the metal transfer points to form a plurality of through-holes; performing conductive metal deposition on the inside of the through-holes to fill the through-holes; and subjecting a far surface of the substrate away from the dielectric layer to thinning and chemical mechanical planarization processing until the conductive metal is exposed, and forming, by taking the conductive metal as backside bonding points, the bonding structure for the multi-layer bonding stack and with bonding points on both the front and back sides. The bonding stack of a plurality of wafers or chips can be realized by the method of the invention, the freedom of the circuit design of an integrated circuit chip and the effective utilization area of the chip can be effectively improved, and the problems such as high resistance caused by too long connection wires and bandwidth decrease are reduced.

Owner:WUHAN XINXIN SEMICON MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com