Window blocking material used for high silicon alloy smelting electric furnace

A technology of plugging holes and gold mines, which is applied in the direction of furnaces, furnace components, lighting and heating equipment, etc., can solve the problems of no repair effect of furnace hole damage, labor and time occupation, cumbersome process operations, etc., to avoid scattered labor and Labor time, maintenance cycle extension, and the effect of improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

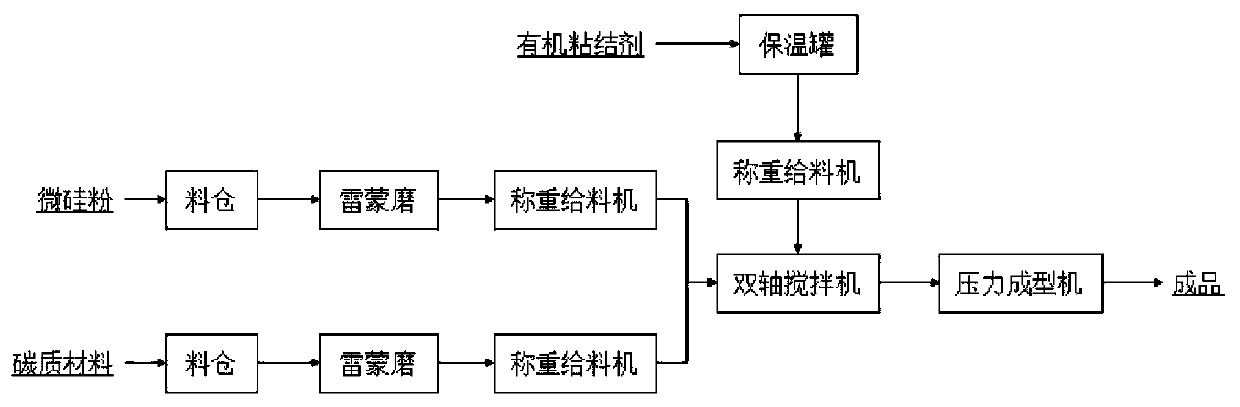

Method used

Image

Examples

Embodiment 1

[0041] Example 1 A kind of plugging material for high silicon alloy submerged arc furnace

[0042] The plugging material comprises, by weight ratio: 30% of solid inorganic binder, 60% of carbonaceous material and 10% of liquid organic binder.

[0043] The solid inorganic binder is microsilica, SiO 2 The content is 75%, and the particle size is 200 mesh; the weight ratio of graphite powder and coke powder in the carbonaceous material is 10:5, that is, 2:1, and the fixed carbon content in the carbonaceous material is 65%, and the particle size is 200 mesh ; The liquid organic binder is a phenolic resin.

[0044] The described solid inorganic binder, carbonaceous material and liquid organic binder do not contain moisture.

Embodiment 2

[0045] Embodiment 2 A kind of plugging material for high silicon alloy submerged arc furnace

[0046] The plugging material comprises, by weight ratio: 30% of solid inorganic binder, 40% of carbonaceous material and 30% of liquid organic binder.

[0047] The solid inorganic binder is microsilica, SiO 2 The content is 90%, the particle size is 325 mesh; the weight ratio of graphite powder and coke powder in the carbonaceous material is 10:3, the fixed carbon content in the carbonaceous material is 85%, and the particle size is 325 mesh; the liquid The organic binder is polyvinyl alcohol.

[0048] The described solid inorganic binder, carbonaceous material and liquid organic binder do not contain moisture.

Embodiment 3

[0049] Embodiment 3 A kind of plugging material for high silicon alloy submerged arc furnace

[0050] The plugging material comprises, by weight ratio: 10% of solid inorganic binder, 60% of carbonaceous material and 30% of liquid organic binder.

[0051] The solid inorganic binder is microsilica, SiO 2 The content is 85%, the particle size is 265 mesh; the weight ratio of graphite powder and coke powder in the carbonaceous material is 10:1, the fixed carbon content in the carbonaceous material is 75%, and the particle size is 265 mesh; the liquid The organic binder is coal tar.

[0052] The described solid inorganic binder, carbonaceous material and liquid organic binder do not contain moisture.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com