High-temperature-resistant thermal insulation material and preparation method thereof

A heat-insulating material and high-temperature-resistant technology, applied in zirconia and other directions, can solve the problem that heat-insulating materials cannot meet high-temperature heat-insulation and other problems, achieve excellent mechanical and physical properties, low thermal conductivity, and make up for the lack of mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

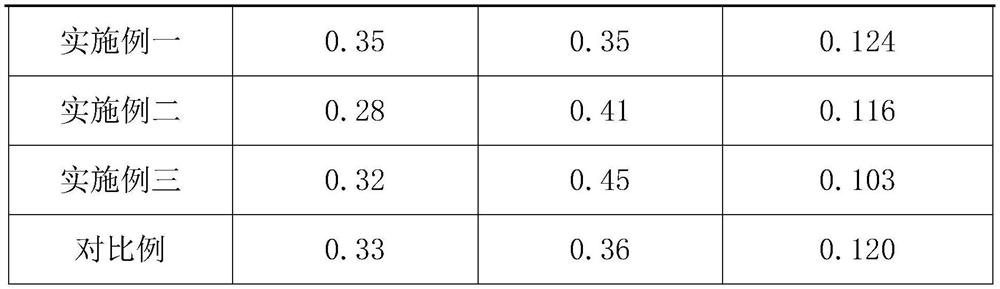

Embodiment 1

[0031]A heat-resistant heat insulation material, comprising the following raw materials in parts by weight: 55 parts of ceramic fiber cotton, 5 parts of potassium hexatitanate whiskers, 4 parts of modified expanded vermiculite, 5 parts of zirconia airgel, silane diacetal 1 part of joint agent KH-550, 2 parts of water glass, 1 part of cationic starch, 1 part of polyaluminum chloride, 2 parts of polyethylene oxide. The preparation method of the modified expanded vermiculite is: mix the expanded vermiculite, sodium carbonate, and aluminum chloride solution in a mass ratio of 1:0.8:4, the concentration of the aluminum chloride solution is 180g / L, and the The hydrothermal reaction was carried out for 15 hours at a reaction temperature of 250°C. After the reaction was completed, it was centrifuged, washed with water three times, and then calcined at a high temperature of 500°C for 3 hours to obtain modified expanded vermiculite. The preparation method of the zirconium dioxide airgel...

Embodiment 2

[0039] A high temperature resistant heat insulation material, comprising the following raw materials in parts by weight: 65 parts of ceramic fiber cotton, 10 parts of potassium hexatitanate whiskers, 6 parts of modified expanded vermiculite, 12 parts of zirconia airgel, silane di Joint agent KH-5603 parts, silica sol 4 parts, phenolic resin 2 parts, aluminum sulfate 3 parts, carboxymethyl cellulose 3 parts. The preparation method of the modified expanded vermiculite is: mix the expanded vermiculite, sodium carbonate, and aluminum chloride solution according to the mass ratio of 1:1:5, the concentration of the aluminum chloride solution is 210g / L, and the The hydrothermal reaction was carried out for 20 hours at a reaction temperature of 220°C. After the reaction was completed, it was centrifuged, washed with water three times, and calcined at a high temperature of 550°C for 2 hours to obtain modified expanded vermiculite. The preparation method of the zirconium dioxide airgel ...

Embodiment 3

[0047] A high temperature resistant heat insulation material, comprising the following raw materials in parts by weight: 75 parts of ceramic fiber cotton, 15 parts of potassium hexatitanate whiskers, 8 parts of modified expanded vermiculite, 18 parts of zirconia airgel, silane di Joint agent KH-5706 parts, aluminum sol 5 parts, acrylic emulsion 3 parts, polyacrylamide 5 parts, carboxyethyl cellulose 4 parts. The preparation method of the modified expanded vermiculite is: mix the expanded vermiculite, sodium carbonate and aluminum chloride solution according to the mass ratio of 1:1.2:6, the concentration of the aluminum chloride solution is 250g / L, and the The hydrothermal reaction was carried out for 25 hours at a reaction temperature of 200°C. After the reaction was completed, it was centrifuged, washed with water three times, and calcined at 600°C for 3 hours at a high temperature to obtain modified expanded vermiculite. The preparation method of the zirconium dioxide airge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com