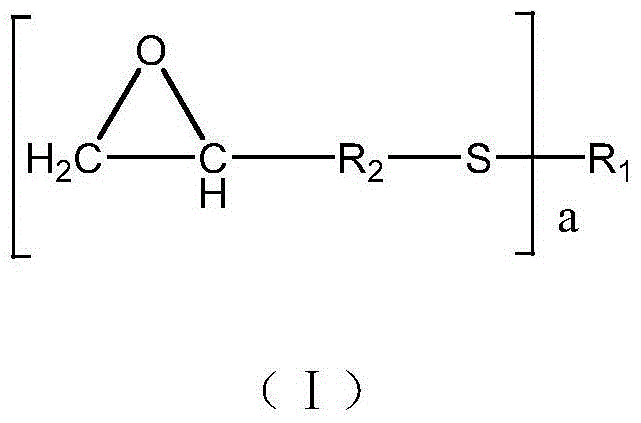

Epoxy group end-capped polysulfide polymer, preparation method and application thereof and room temperature fast-curing epoxy resin adhesive containing epoxy group end-capped polysulfide polymer

An epoxy resin and epoxy-based technology, applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., can solve the problems of reducing the cohesive strength of the resin, unfavorable industrialization, and slow curing reaction, so as to improve the impact resistance and fracture toughness, avoid irritating odor, and improve oil stain resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] The preparation process of epoxy adhesive is:

[0065] Component A: First, add epoxy resin and epoxy-terminated polysulfide polymer into a double planetary stirring tank, vacuumize and stir, add filler after the temperature rises to about 50°C, and stir at a high speed of 800-1000rpm for 10 ~20min to make component A.

[0066] Component B: First, add the curing agent, accelerator and filler into the dual planetary stirring tank in sequence, the vacuum degree is 0.1Mpa, the rotation speed is 500-1000rpm, the stirring time is 30-60min, and the temperature does not exceed 70°C throughout the process. Finally, add the coupling agent, vacuumize and stir for 5-10 minutes to make component B.

Embodiment 1

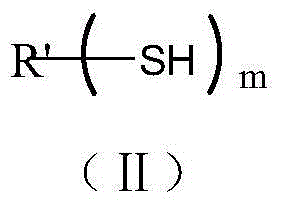

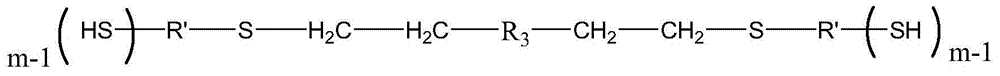

[0068] In a nitrogen atmosphere, add 1200g of dithiol-terminated liquid polysulfide rubber (polysulfide rubber LP-3 from Japan Toray Polysulfide Co., Ltd. The molecular weight is 1000, the number of moles is 1.2mol, and the content of mercapto groups is 6.6%), heating and stirring until the temperature is 50°C, adding a total amount of 106.7g (the number of moles is 0.75mol) 1,4-butanediol divinyl within 1 hour ether, and 0.05 g of catalyst 2,2'-azobisisobutyronitrile was added, and the reaction was maintained for 3 h under airtight conditions. Track and measure the vinyl content. When the vinyl content drops to 0, add 110g (1.12mol) of 1,2-epoxy-5-hexene within 1 hour at 70°C and keep the reaction for 3h , measure the content of thiol group, when the content of thiol group is 0, remove the unreacted 1,2-epoxy-5-hexene in the reaction mixture for 2 hours under the vacuum condition of 70 ℃ and 1kPa, and cool After reaching room temperature, a light yellow transparent epoxy-ter...

Embodiment 2

[0070] In a nitrogen atmosphere, add 1375g (0.55mol in moles, 3.9% in mercapto group) trimercapto-terminated liquid polysulfide rubber (Japan Toray Polysulfide Co., Ltd. polysulfide rubber LP-980, molecular weight 2500), heating and stirring until the temperature is 50 ° C, adding a total amount of 75.84g (molar number is 0.48mol) diethylene glycol divinyl ether within 50 minutes, And add 0.05 g of catalyst 2,2'-azobisisobutyronitrile, and maintain the reaction for 3 hours under airtight conditions. Follow up and measure the vinyl content. When the vinyl content drops to 0, add 86.64g (0.76mol moles) of allyl glycidyl ether within 50 minutes at 70°C, keep the reaction for 3h, and measure the thiol group content, when the thiol group content is 0, remove the unreacted allyl glycidyl ether in the reaction mixture for 2 hours at 70°C and 1kPa vacuum conditions, and cool to room temperature to obtain a light yellow transparent liquid ring Oxygen-terminated polysulfide polymers of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com