Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

152 results about "Stress Problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chronic stress is continual exposure to acute stressors, and may lead to serious mental health issues, such as depression, as well as physical ailments, including heart problems. When an individual suffers from the condition, he inadequately adapts to stress, causing high levels of hormones called glucocorticoids to remain in the blood and tissues.

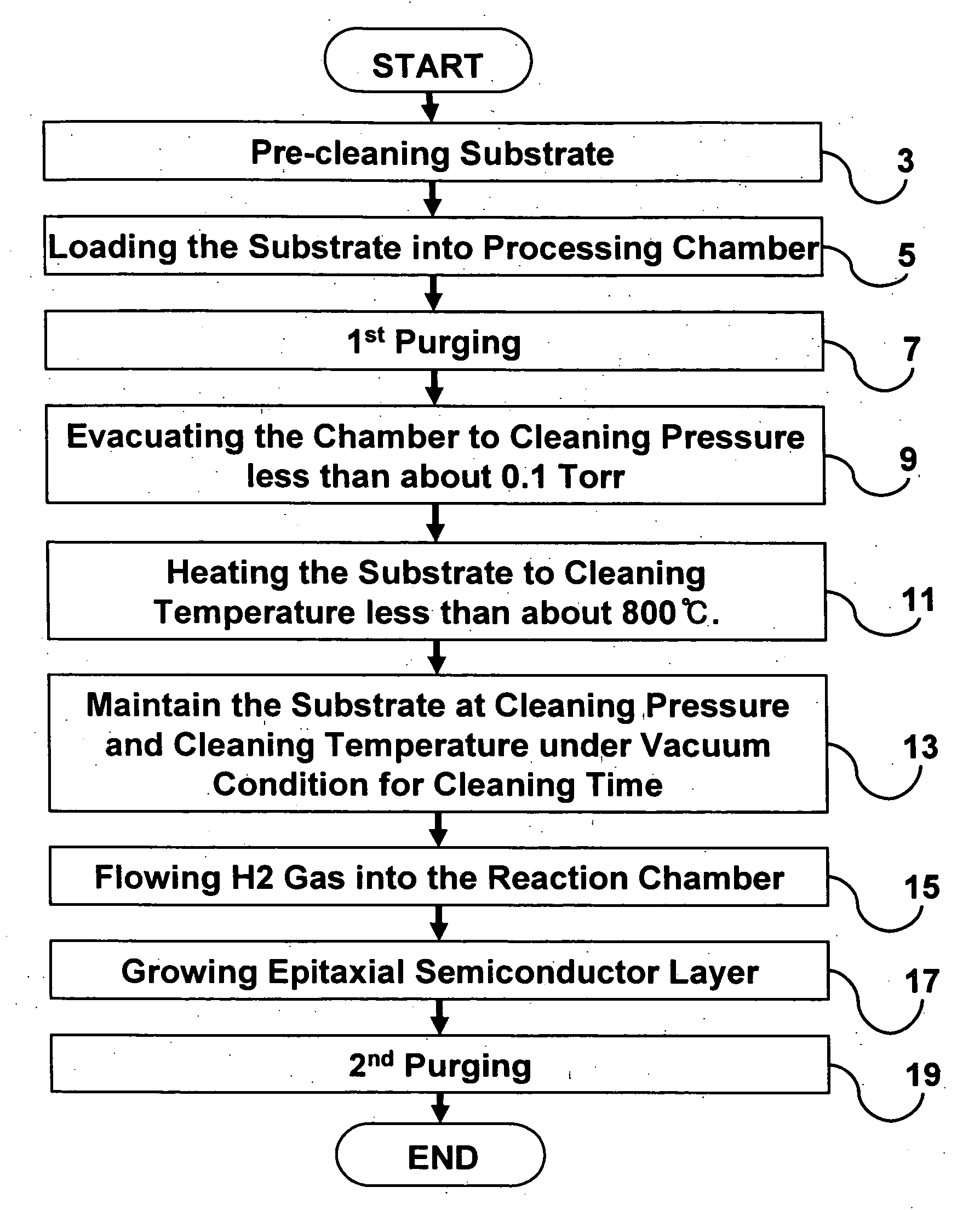

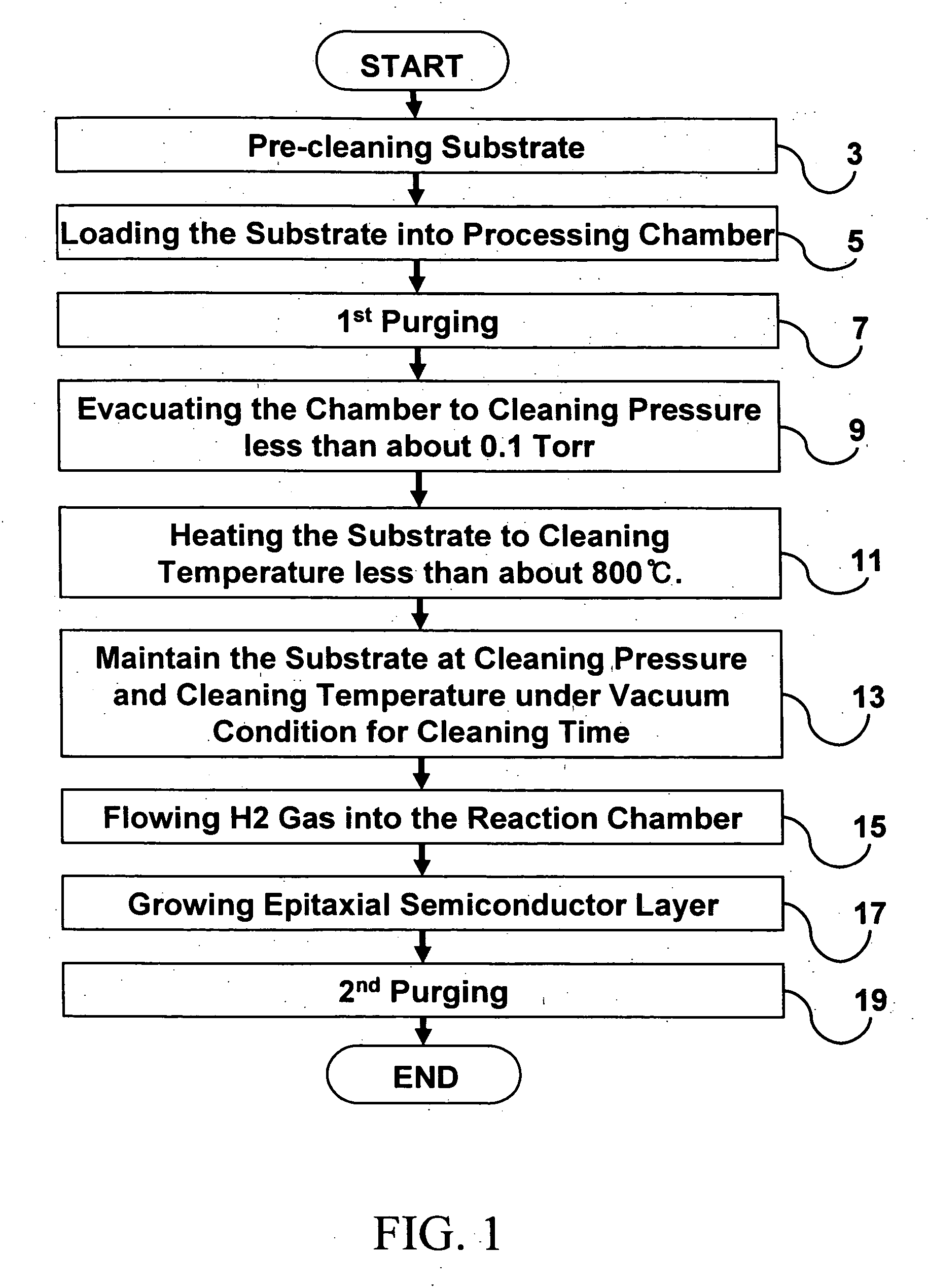

Methods for in-situ cleaning of semiconductor substrates and methods of semiconductor device fabrication employing the same

InactiveUS20060156970A1Reduce the possibilityReduce processing timePolycrystalline material growthMixing/kneading with horizontally-mounted toolsDecompositionGas composition

Provided is an in-situ precleaning method for use in conjunction with epitaxial processes that utilizes temperatures at or below those typically utilized during the subsequent epitaxial deposition under pressure and ambient conditions suitable for inducing decomposition of semiconductor oxides, such as native oxides, from exposed semiconductor surfaces. The reduced temperature and the resulting quality of the cleaned semiconductor surfaces will tend to reduce the likelihood of temperature related issues such as unwanted diffusion, autodoping, slip, and other crystalline stress problems while simultaneously reducing the overall process time. The combination of pressure, ambient gas composition and temperature maintained within the reaction chamber are sufficient to decompose semiconductor oxides present on the substrate surface. For example, the reaction chamber may be operated so that the concentration of evolved oxygen within the reaction chamber is less than about 50%, or even less than 10%, of the equilibrium vapor pressure under the cleaning conditions.

Owner:SAMSUNG ELECTRONICS CO LTD

Method for improving bonding strength of hard alloy and diamond coating

ActiveCN104746030AAvoid the problem of interfacial stressHigh bonding strengthVacuum evaporation coatingSputtering coatingShielding gasGlow plasma

The invention relates to a method for improving the bonding strength of a hard alloy and a diamond coating. The method is realized by the technical scheme that by adopting a double glow plasma surface alloying technology, taking a metal carbide forming element material or a composite material of metal carbide forming elements as a target, inert gases as protecting gases, as well as carbon-containing gases as precursors, a diffusion barrier layer is prepared on the surface layer of the hard alloy, and then the diamond coating is deposited on the hard alloy surface on which the diffusion barrier layer is prepared by using a chemical vapor deposition method. By the use of the diffusion barrier layer prepared by the method disclosed by the invention, the diffusion of Co element to the surface layer of the hard alloy can be effectively stopped, the damage to a hard alloy matrix due to a surface Co removing treatment method is avoided, and the interface stress problem introduced by a transition layer applying method due to new interface addition can be avoided, so that the bonding strength between the diamond coating and the hard alloy matrix can be greatly improved.

Owner:TAIYUAN UNIV OF TECH

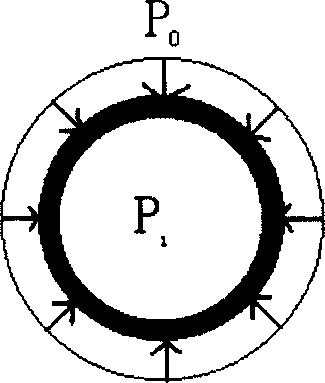

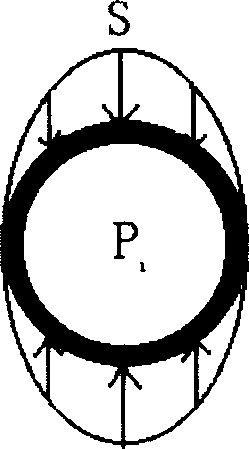

Stress sheath demage predicting method

ActiveCN1598529AMitigate or avoid casing damageReduce repair costsForce measurementMaterial strength using tensile/compressive forcesEngineeringBusiness forecasting

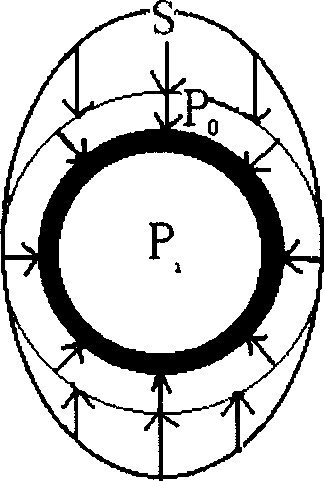

The invention discloses a forecasting method for stress damage. Its character lies in: at first, the radius strain of and ground stress are supervised; secondly, takes no account of affection of sleeve pipe axis stress, the sleeve pipe is considered as ring stress problem in condition of plane, deduces out the radius strain formula generated by the ring plastic deformation and the sleeve pipe plastics intensity formula, works out the stress carrier and correspondent limit intensity according to the two formulas. Finally, through the comparison of sleeve stress carrier and sleeve limit intensity, it judges the probability of damage.

Owner:DAQING OILFIELD CO LTD +1

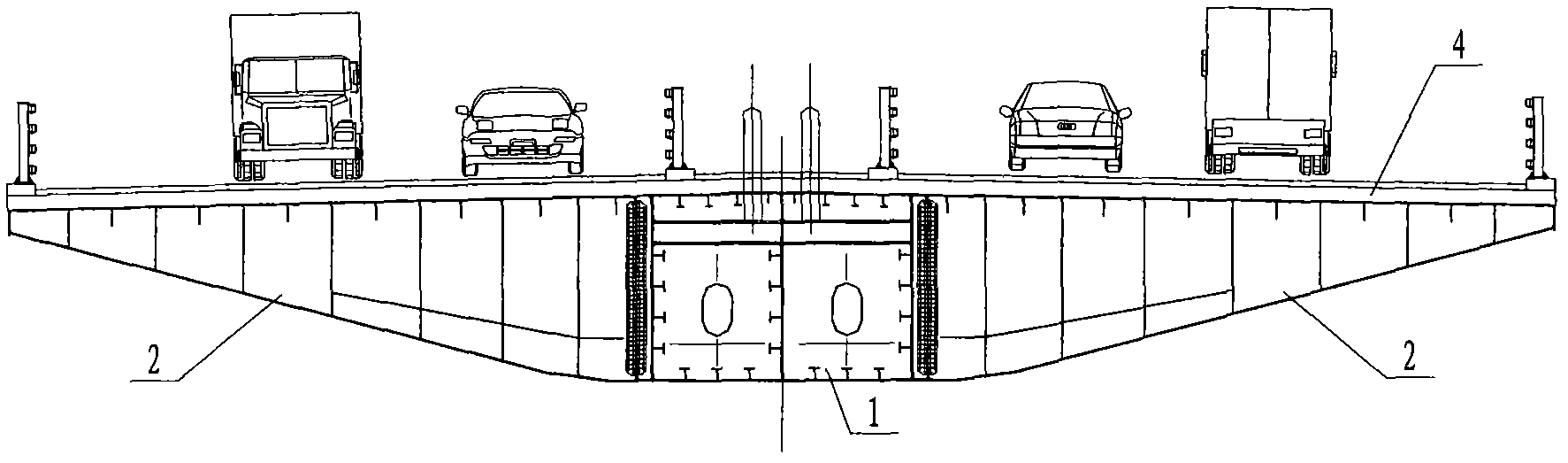

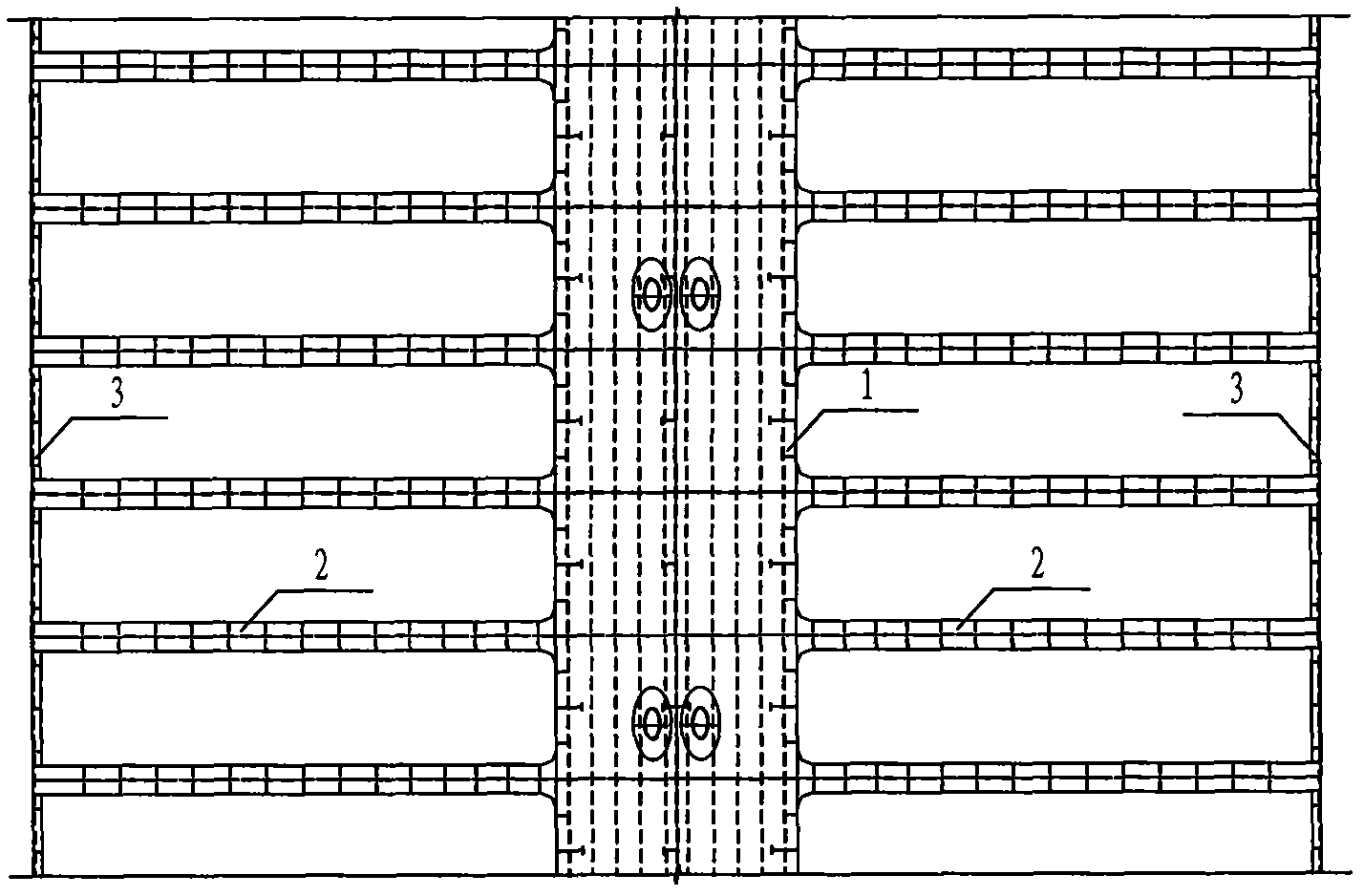

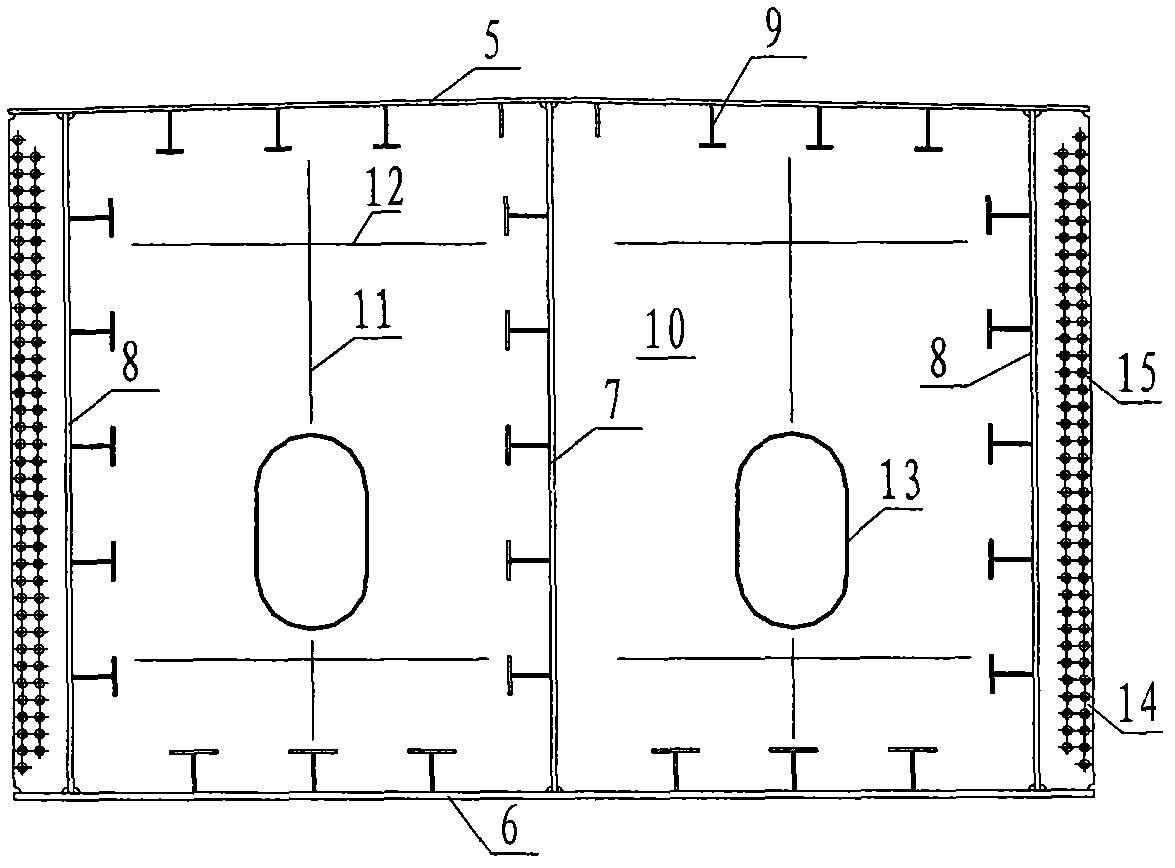

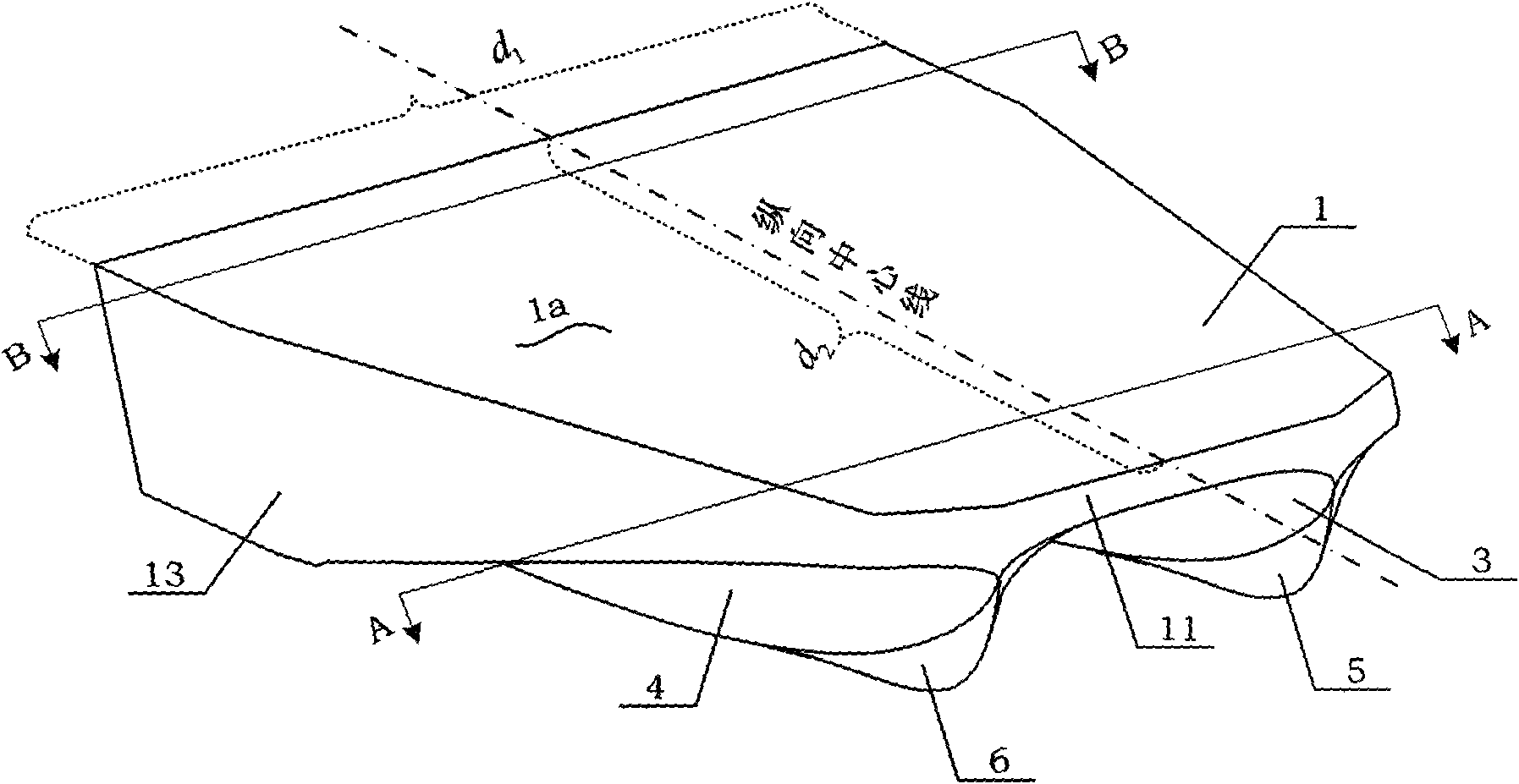

Main girder of steel box composite girder with long cantilever arms for single-plane cable stayed bridge

InactiveCN102094385AReduce horizontal sizeSolve the torsion problemCable-stayed bridgeBridge structural detailsCable stayedBridge deck

The invention relates to a main girder of a steel box composite girder with long cantilever arms for a single-plane cable stayed bridge. The two sides of a steel box girder in the middle of the main girder are respectively provided with a steel cantilever arm, and the steel box girder and the steel cantilever arms are connected by high strength bolts in bolting and welding modes; and the end part of each steel cantilever arm is provided with a longitudinal side beam, the tops of the steel box girder and the steel cantilever arms are paved with concrete bridge decks or cast-in-situ bridge decks, traffic lanes are arranged on the steel cantilever arms, the steel box girder is in a single-box single-chamber structure or multi-chamber structure, and a steel anchor box is arranged at the anchor point of a stayed cable. By adopting the steel box composite girder with long cantilever arms, the stress problems of the main girder, such as the torsion resistance and the like of the single-plane cable stayed bridge, are solved, and the horizontal dimension of the main girder is reduced; the main girder can be transported to the bridge location to carry out erection and installation, thereby solving the problem that the sectional dimension of the appearance is limited; and because most of the components of the main girder are prefabricated ones, the in-situ workload is reduced, and the construction quality and construction period can be effectively guaranteed. The main girder provided by the invention is specially adapted to the construction conditions in severe cold districts, for example, the main girder is applied to the construction of the Wusu Bridge in HeiXiazi Island of Heilongjiang Province, and achieves a good application effect.

Owner:ZHONGTIE MAJOR BRIDGE RECONNAISSANCE & DESIGN INST

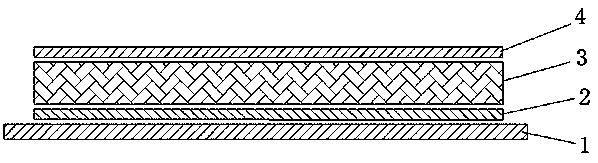

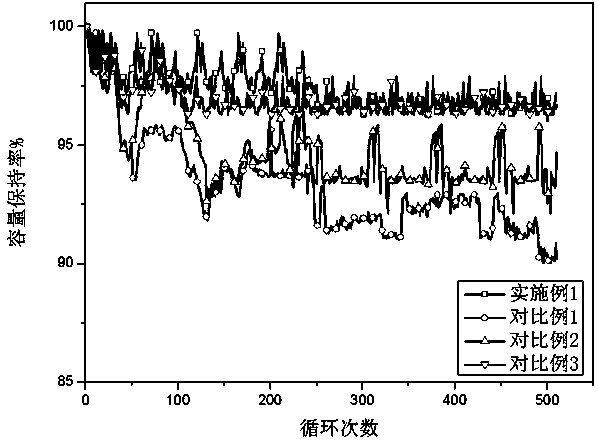

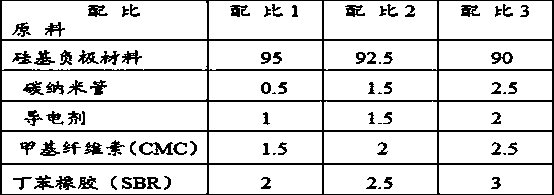

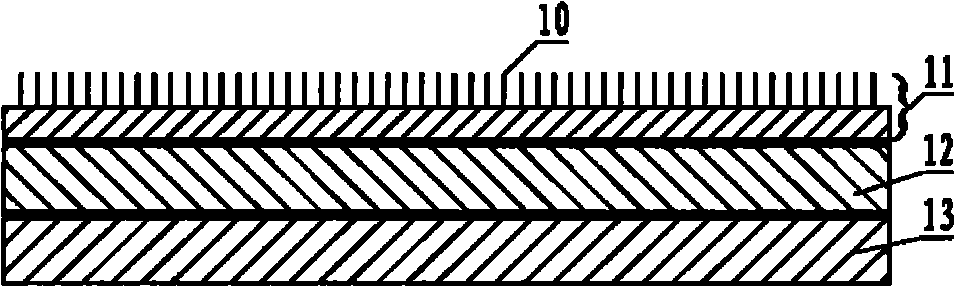

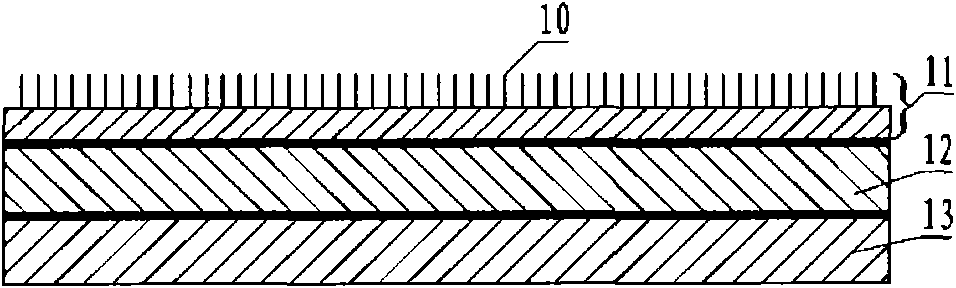

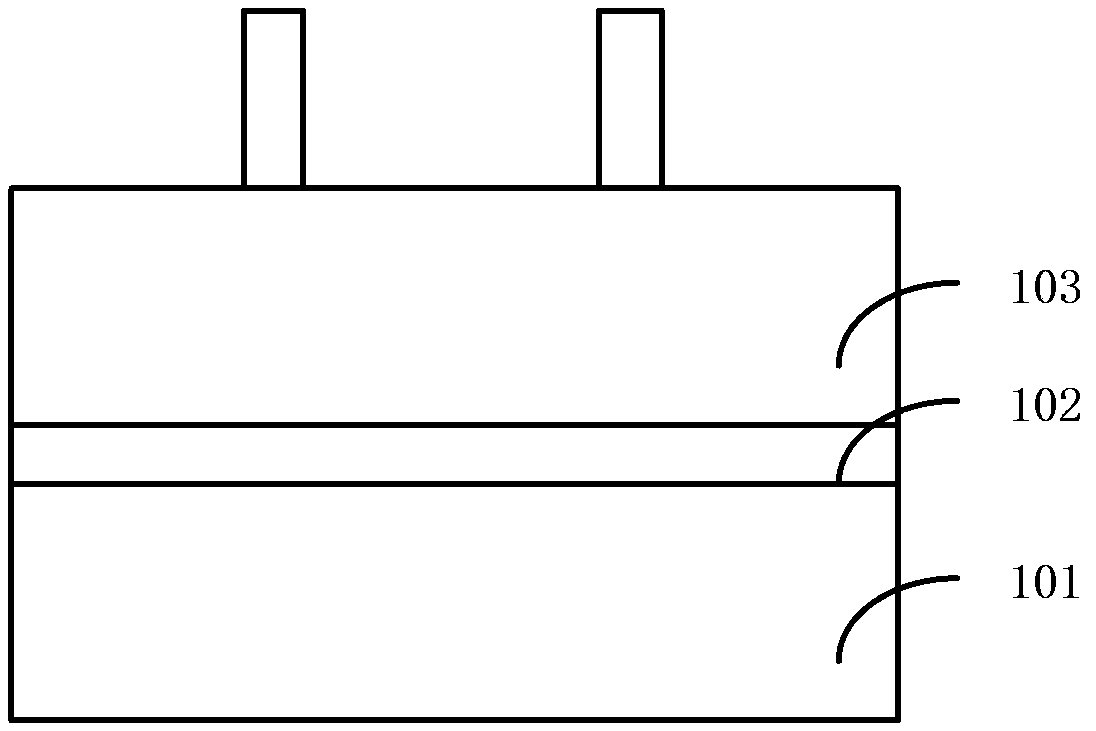

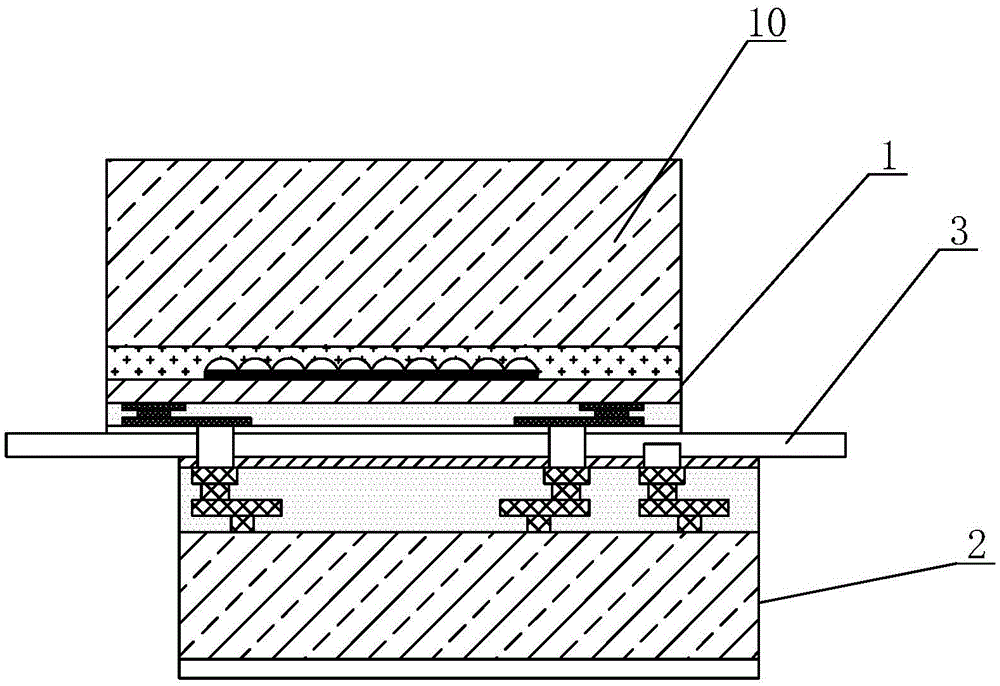

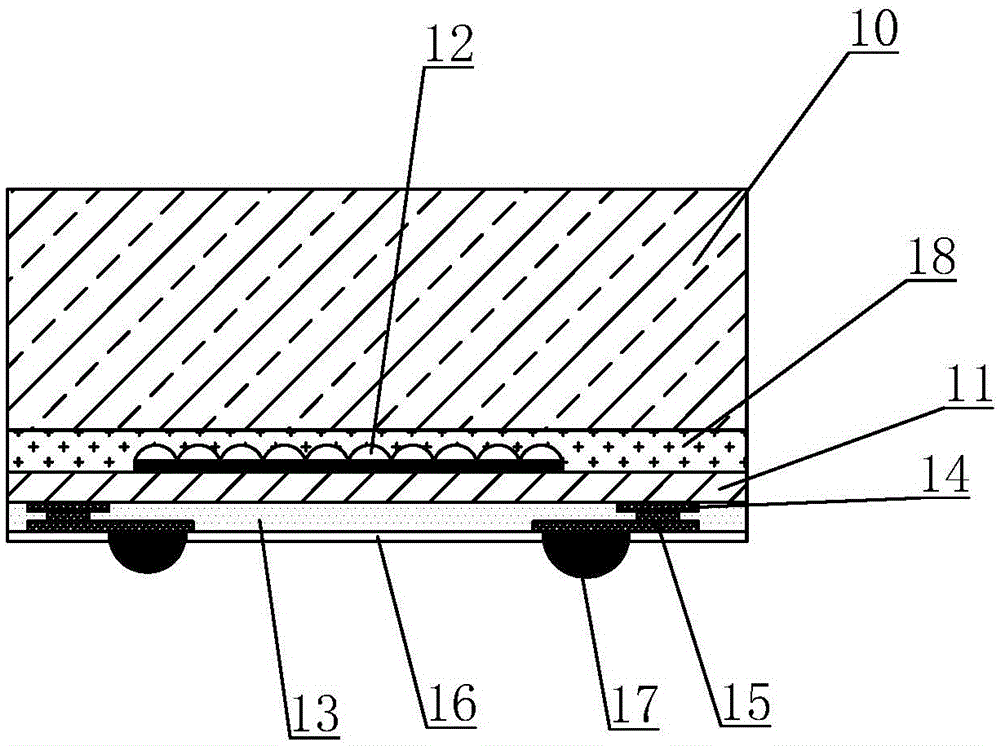

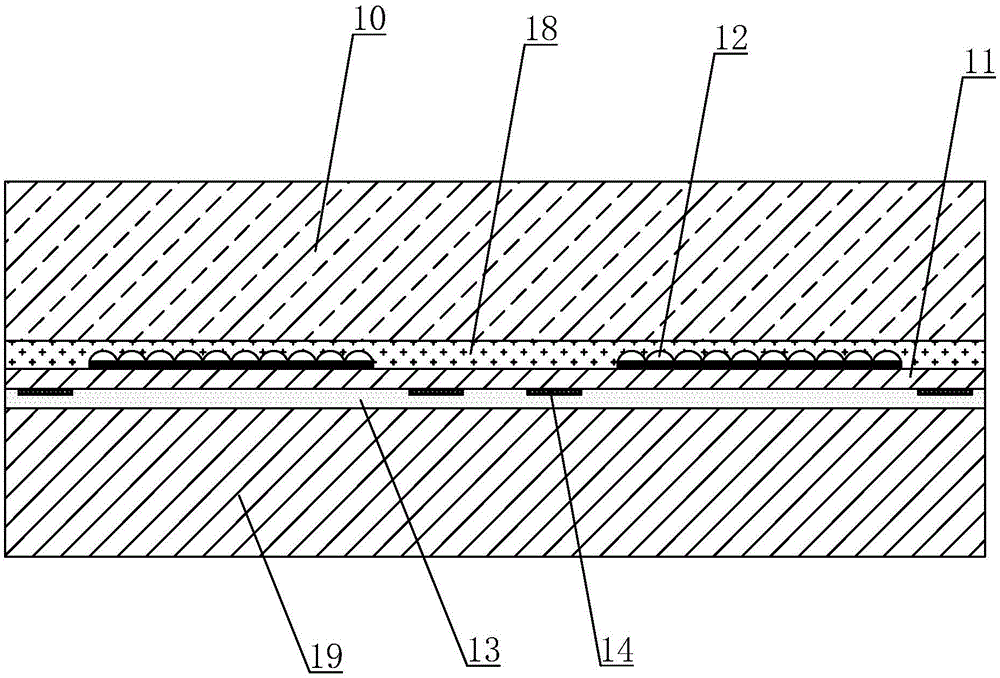

Lithium battery negative pole piece with excellent cycle performance and manufacturing method thereof, and lithium ion battery

ActiveCN110556511AImprove adhesionImproved magnification performanceNegative electrodesSecondary cellsConductive polymerPole piece

The invention discloses a lithium battery negative pole piece with excellent cycle performance and a manufacturing method thereof, and a lithium ion battery. The negative pole piece comprises a current collector, a conductive adhesive layer, a negative pole material layer and a composite conductive layer which are successively arranged on the current collector. A surface of the current collector is coated with the adhesive layer so that an adhesive force between the negative pole material and the current collector can be effectively improved. The adhesive layer is a conductive polymer binder,overall electronic conductivity of the pole piece can be improved, and meanwhile, a rate capability of the pole piece is increased. The negative pole material layer coated on the adhesive layer can effectively buffer a stress problem caused by volume expansion of a silicon material, the adhesive force between a diaphragm and the current collector is increased, and the negative pole material is prevented from falling off. The composite conductive layer which is finally coated can effectively improve a problem of conductive contact between the materials caused by a volume effect of a silicon negative pole material. Simultaneously, a lithium salt additive is added into the composite conductive layer so that a problem of irreversible capacity losses of the battery can be improved.

Owner:GREE ELECTRIC APPLIANCES INC

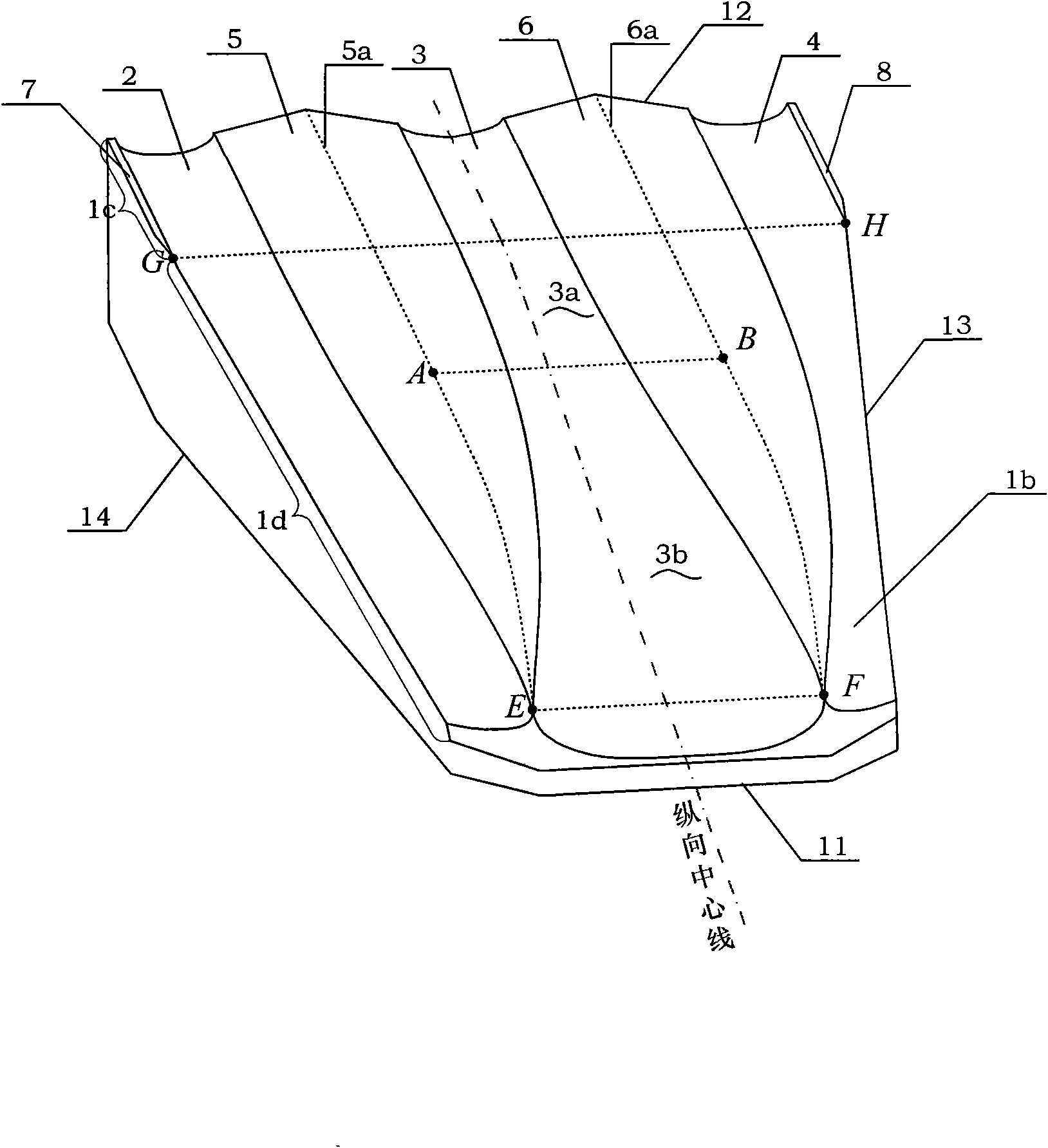

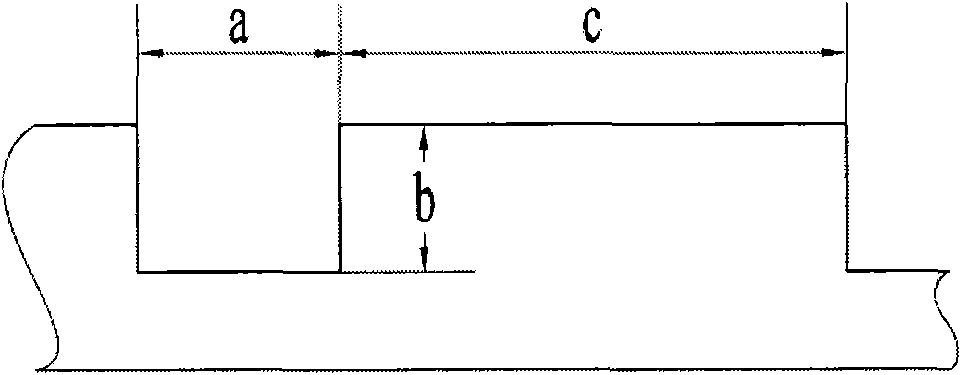

Planing boat with catamaran three-channel hull

InactiveCN101554918AReduced sailing draftSuppressing wavesHull stemsHydrodynamic/hydrostatic featuresStress concentrationStress Problem

The invention discloses a planing boat with a catamaran three-channel hull. The planing boat is provided with a hull and a board at least. The bottom of the hull is provided with an A trunk bulkhead end surface, a B trunk bulkhead end surface, an A slideway, a B slideway, a C slideway, an A planing surface and a B planing surface; the B slideway is arranged along a central line and is a sector structure; the A planing surface and the B planing surface are arranged at two sides of the B slideway; the A slideway is arranged between the A planing surface and a right trunk bulkhead which is provided with the A trunk bulkhead end surface at the stern; and the C slideway is arranged between the B planing surface and a left trunk bulkhead which is provided with the B trunk bulkhead end surface at the stern. The catamaran three-channel hull adopts oval channel section conformation to solve the concentrative stress problem of the hull effectively.simultaneously, on the basis of common channel planing boats, the invention adds two outer side channels at two sides of the stern and changes single channel type into three-channel type, thus greatly increasing the width of the stern, not only improving the effective use area of the board, but also enhancing the transversal stability of the planing boat and being capable of reducing the wave making of the boat.

Owner:BEIHANG UNIV

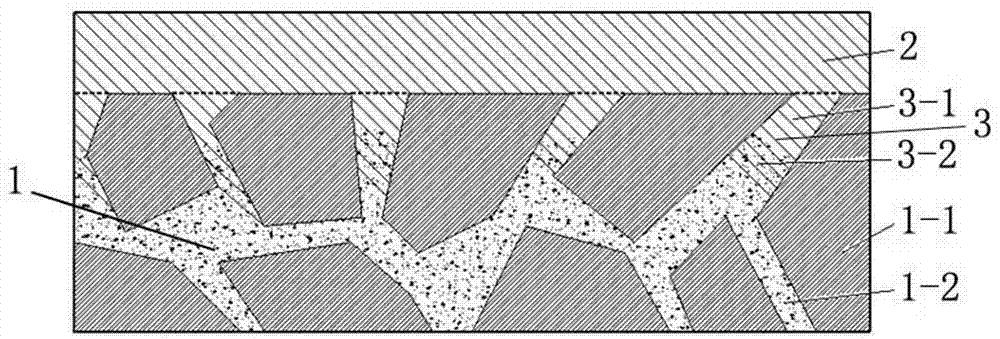

Polishing pad for chemical mechanical planarization and manufacturing method thereof

InactiveCN101905448AWith flexible fiber structureEasy to prepareFlexible-parts wheelsGrinding devicesState of artMaterial removal

The invention discloses a polishing pad for chemical mechanical planarization (CMP) and a manufacturing method thereof, and belongs to the technical field of a chemical mechanical planarization process. The polishing pad comprises a base layer on which a flexible nanometer brush layer is arranged. The nanometer brush polishing pad is prepared by the following steps of: preparing a template, coating polymer solution on the base layer and transferring a nanometer structure on the template to the base layer. Compared with the prior art, the polishing pad has the most outstanding advantage of having a flexible fiber structure; the polishing pad realizes material removal when in flexible contact with a polished surface, can solve the stress problem in the conventional chemical mechanism planarization technique to the largest degree, and is applicable to CMP under ultra-low pressure. Moreover, the polishing pad can overcome the defects of a relatively hard polishing pad such as scratch, over-polishing, butterfly, corrosion and the like, and a higher-quality polished surface can be obtained. The polishing pad has the advantages of simple manufacturing method, high controllability of the technical process and stable polishing performance.

Owner:TSINGHUA UNIV

Antiwear nickel phosphor functionalized gradient plate preparation method

The invention discloses a preparation method for wearable nickel phosphate function gradient plating coat, which comprises: with design idea for gradient material, using single-bath electroplating method, preparing the coat with phosphate content gradient varying by boosting current density gradually and controlling deposition time. This product has proper phosphate content gradient and thermal expansion coefficient to release the thermal stress problem and high bond strength and abrasion resistance. This method can replace current used technique.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

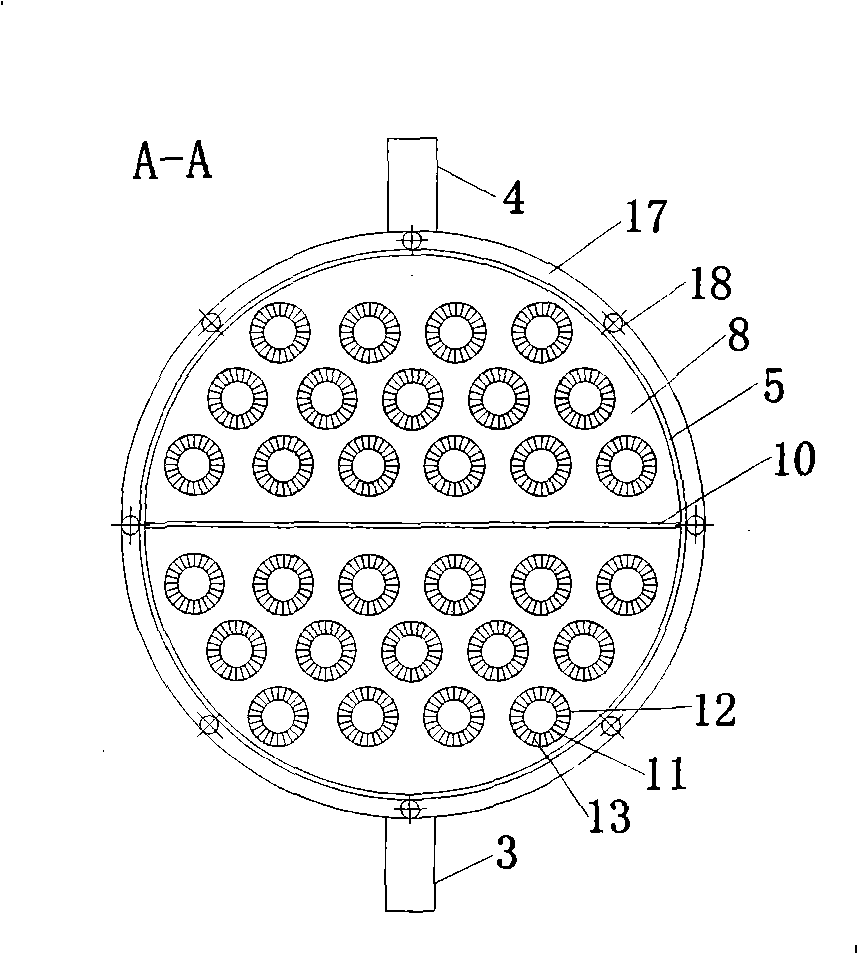

Internal and external fins intubatton type high temperature heat exchanger

InactiveCN101349514ASolve thermal stressImprove stabilityStationary tubular conduit assembliesManufacturing cost reductionHoneycomb

The invention relates to an internal and external fin bayonet-tube type high temperature exchanger, which comprises a casing, a tube box which is connected on the casing, a closed head, a longitudinal baffle, a baffle plate, tube plates of an internal tube and an external tube, a tube side inlet and outlet pipe, a casing side inlet and outlet pipe, wherein one ends of the internal tube and the external tube are respectively fixed on the tube plates of the internal tube and the external tube, and the other ends are both free ends, the internal tube is a honeycomb duct whose two ends are open, and the external tube is a heat exchange tube whose one end is open, and the other end is closed, the internal and external walls of the external tube are respectively provided with an internal fin and an external fin to form an internal and external fin bayonet-tube heat exchanging unit, and the internal fin can relatively move to the internal tube. The exchanger is divided into a high temperature shell pass and a low temperature shell pass, the components of the two shell passes are respectively produced by high temperature-resistant material and common material, also can be produced by the same material. The internal walls of the casing, the longitudinal baffle and the tube plates of the internal tube and the external tube are provided with ceramic insulating layers, and fluid on two sides of a shell is crossly flow in reverse directions. The invention can increase the heat exchange efficiency and compactness of the exchanger, reduces production cost, and can overcome the thermal stress problem, and can be applied in high temperature condition.

Owner:XI AN JIAOTONG UNIV

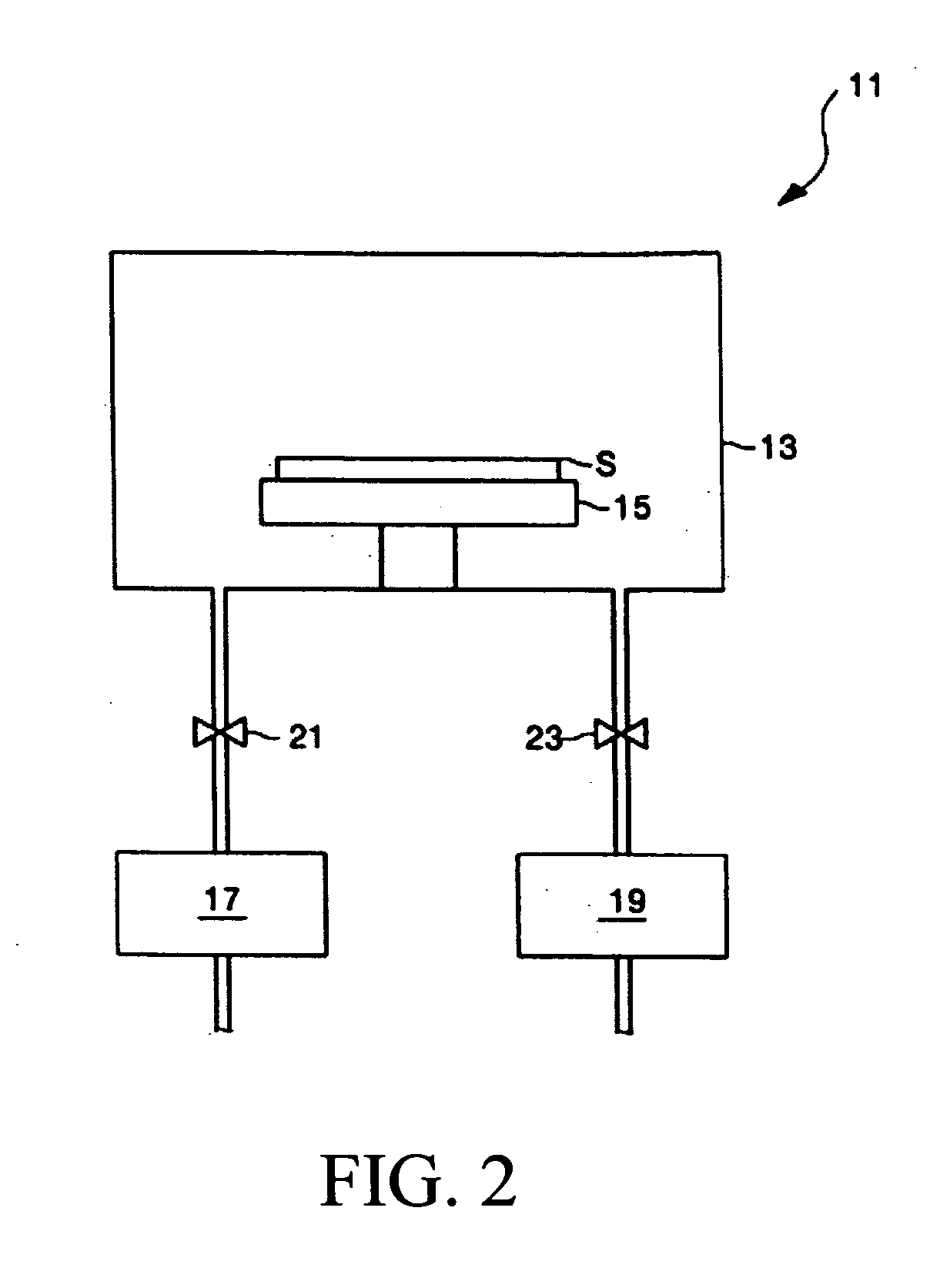

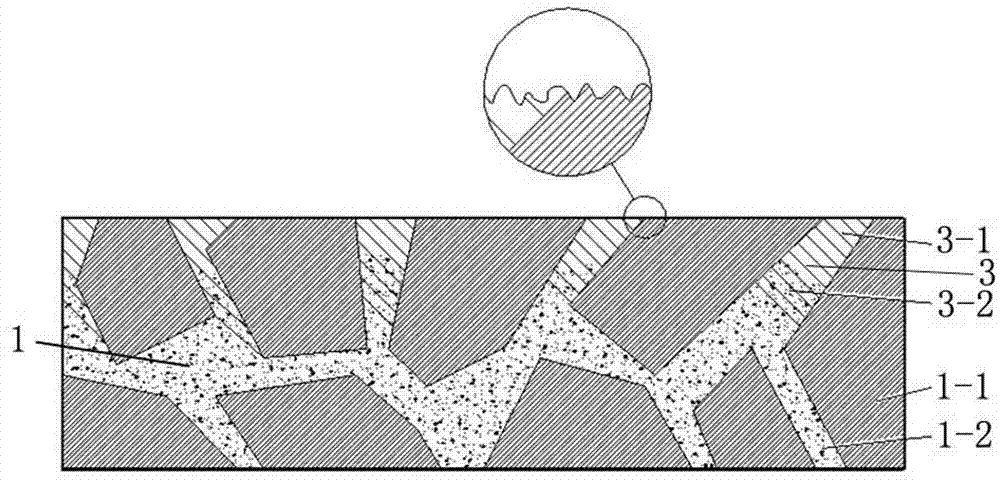

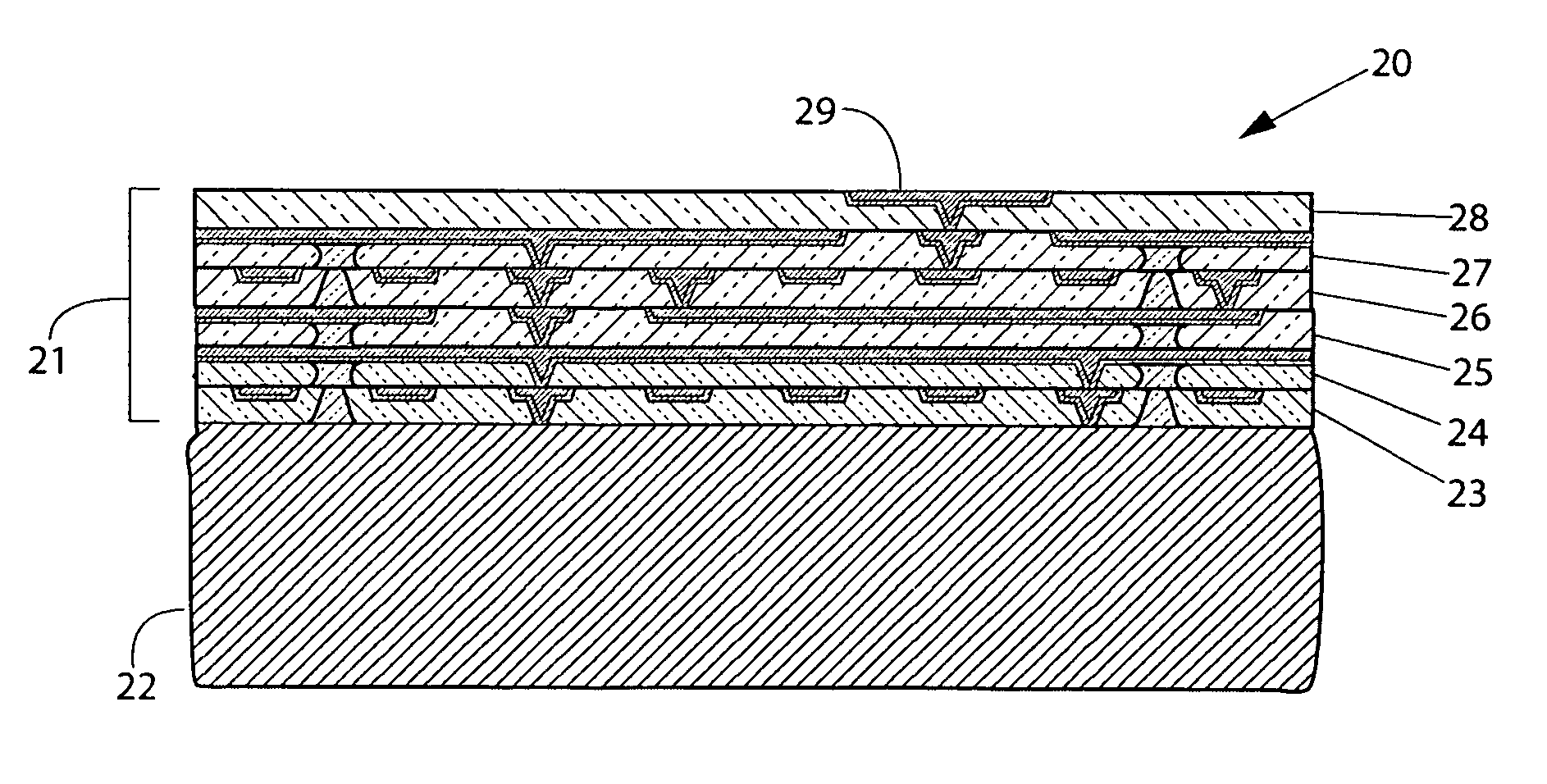

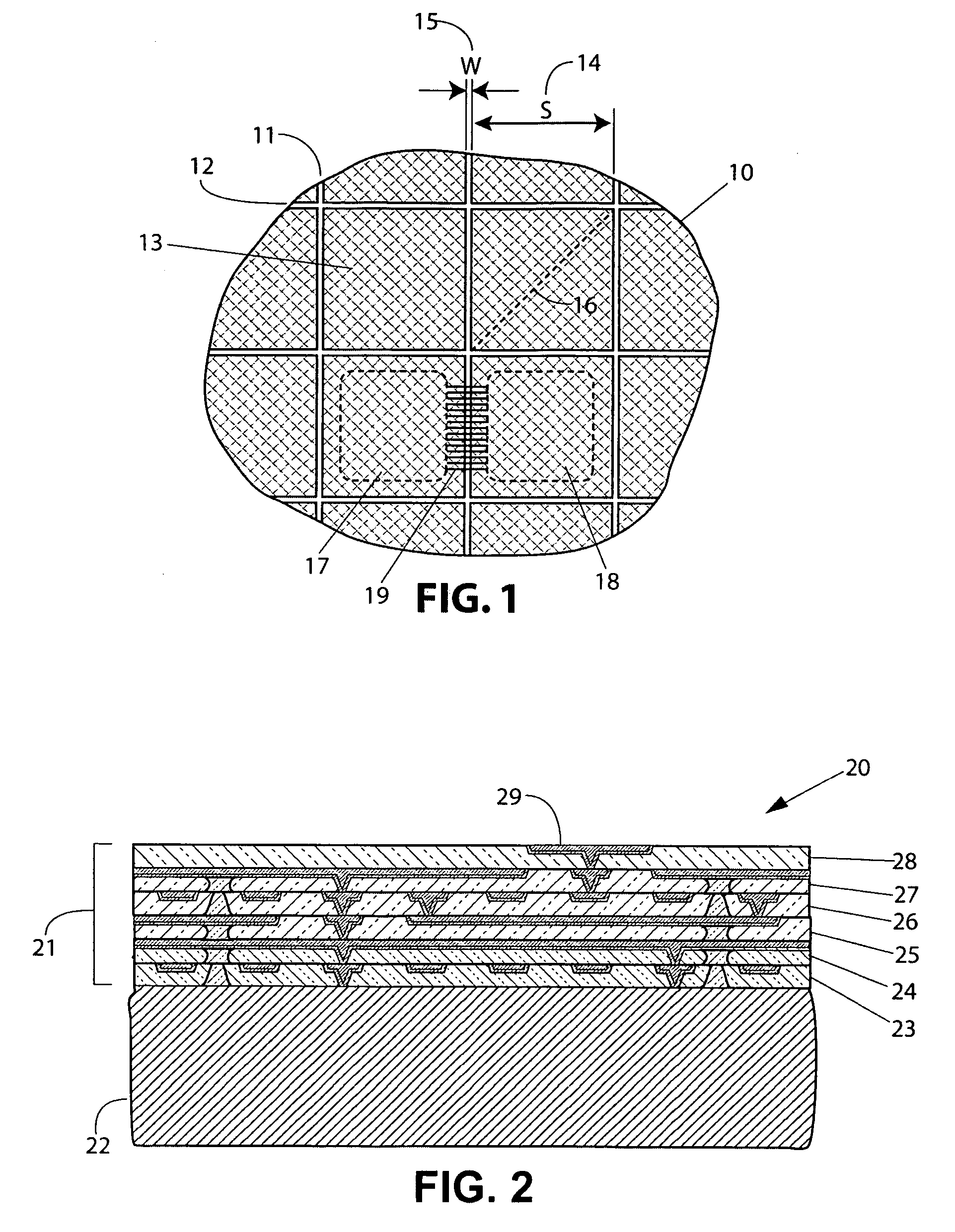

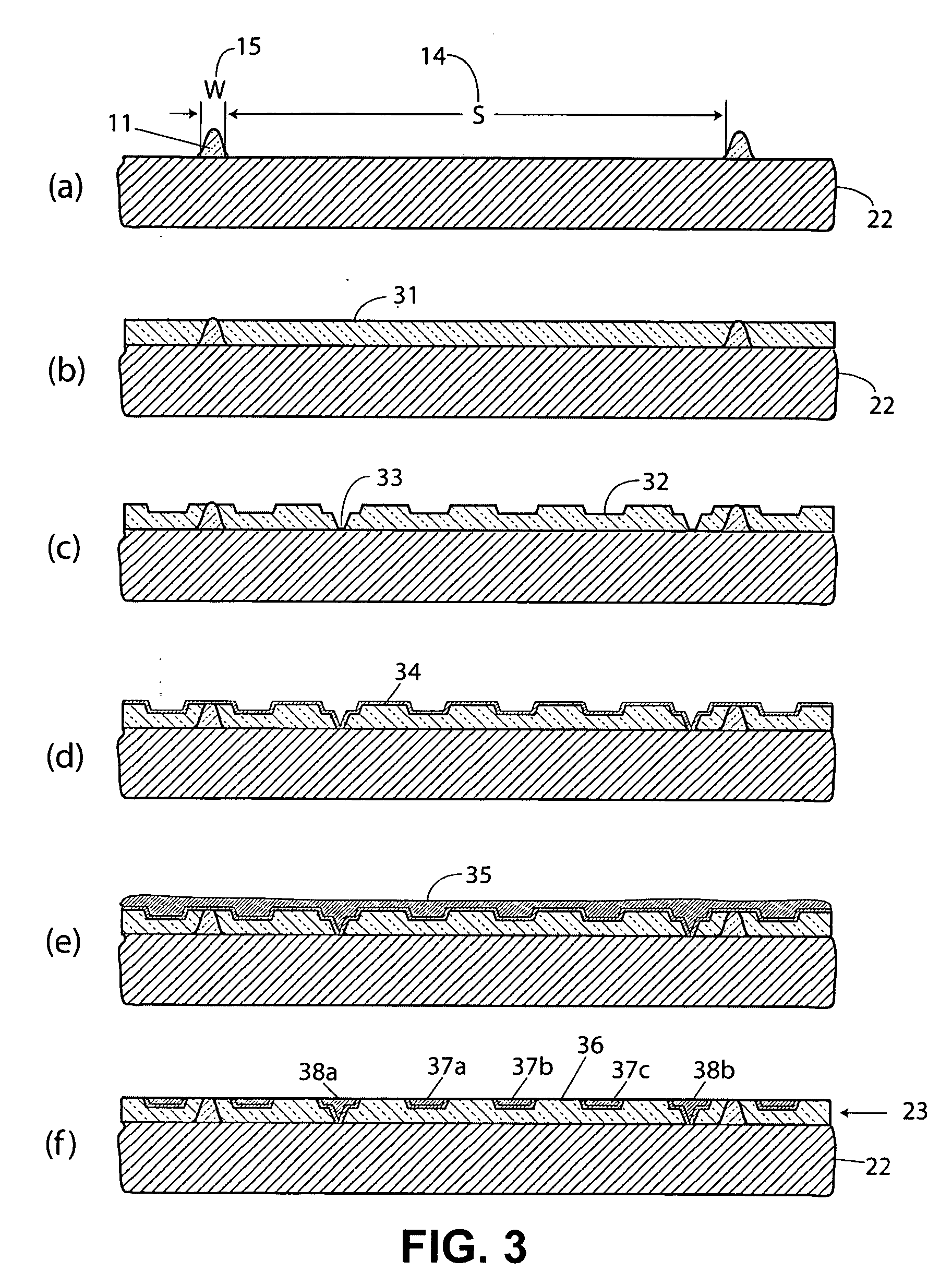

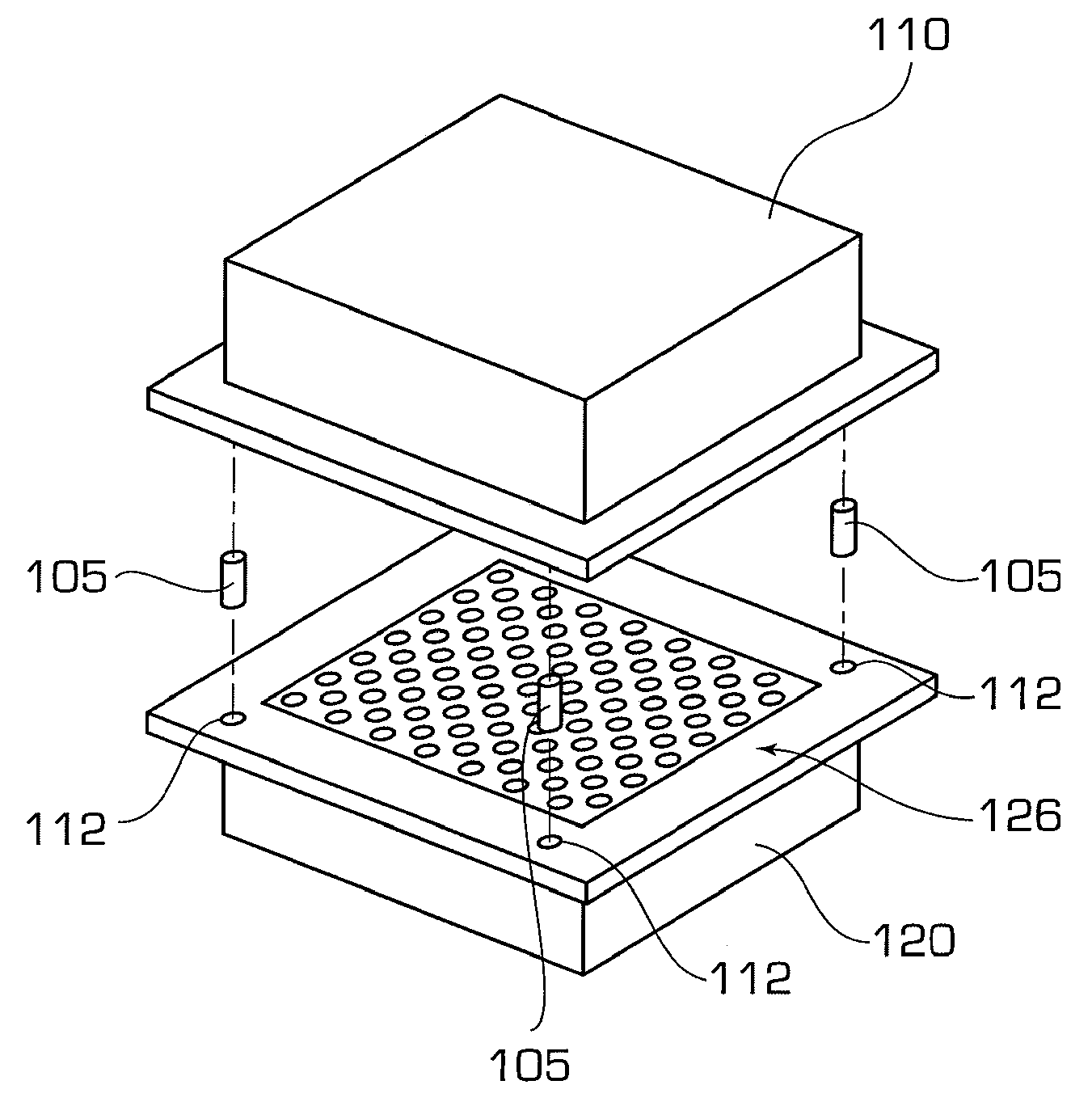

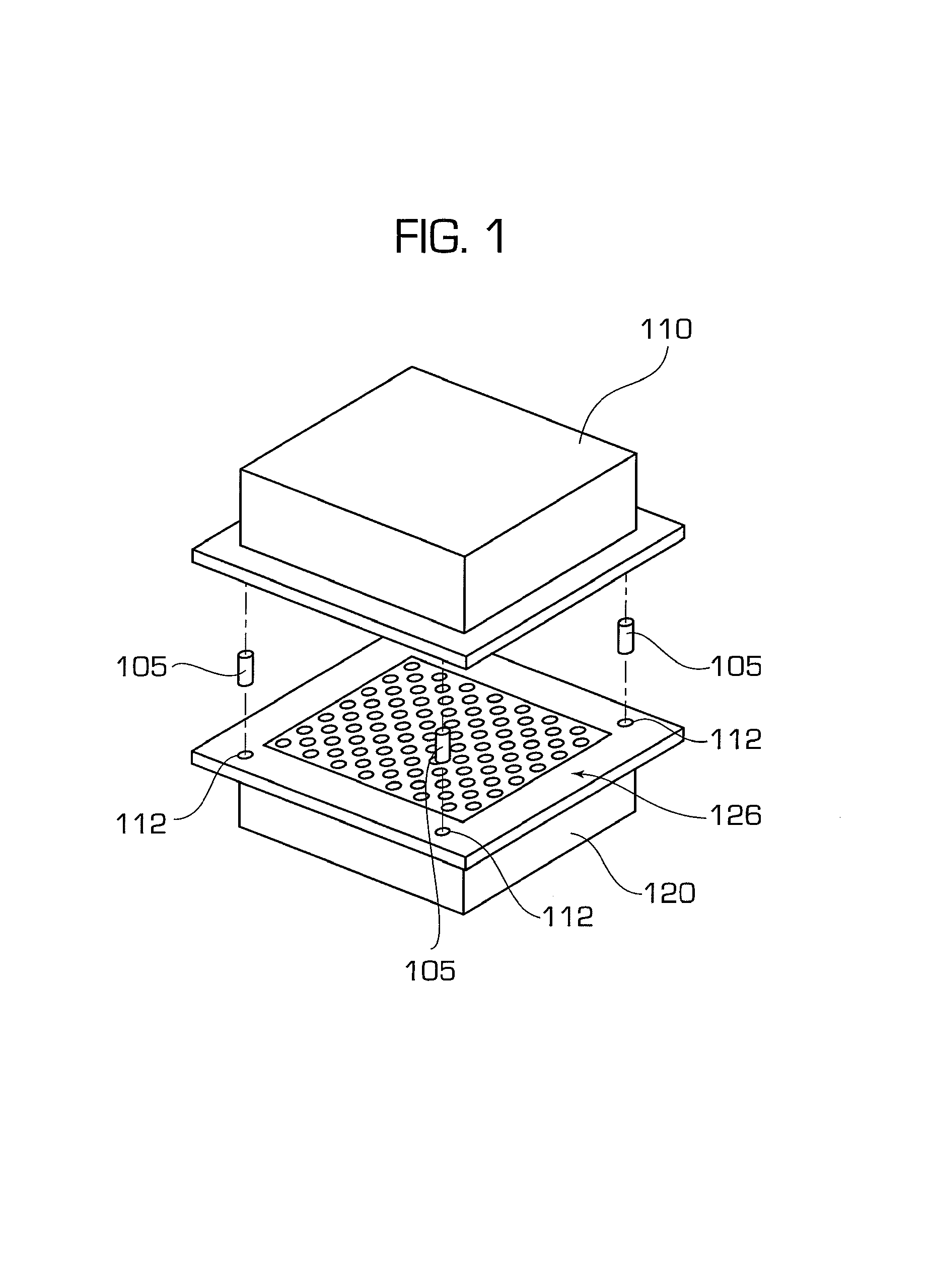

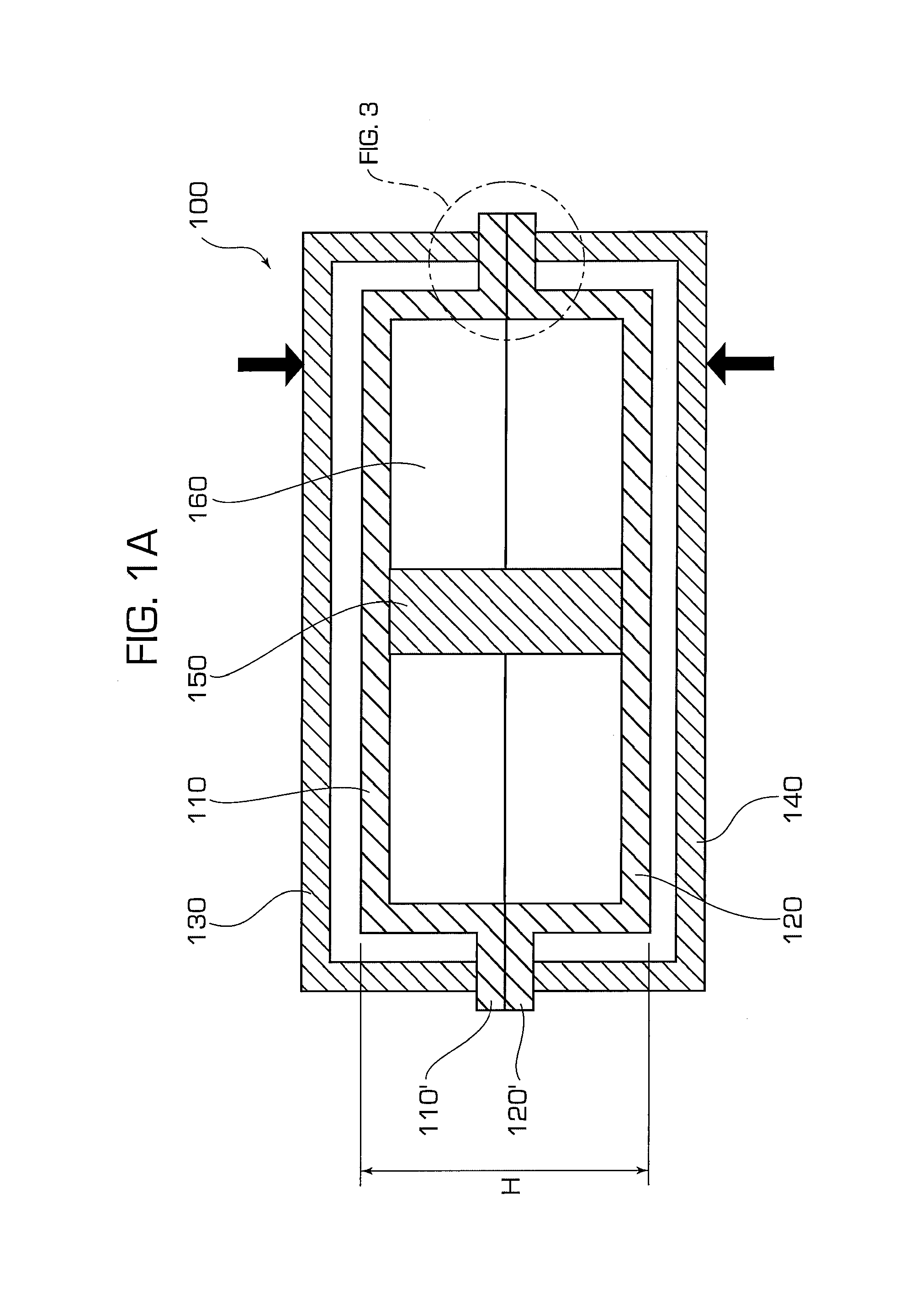

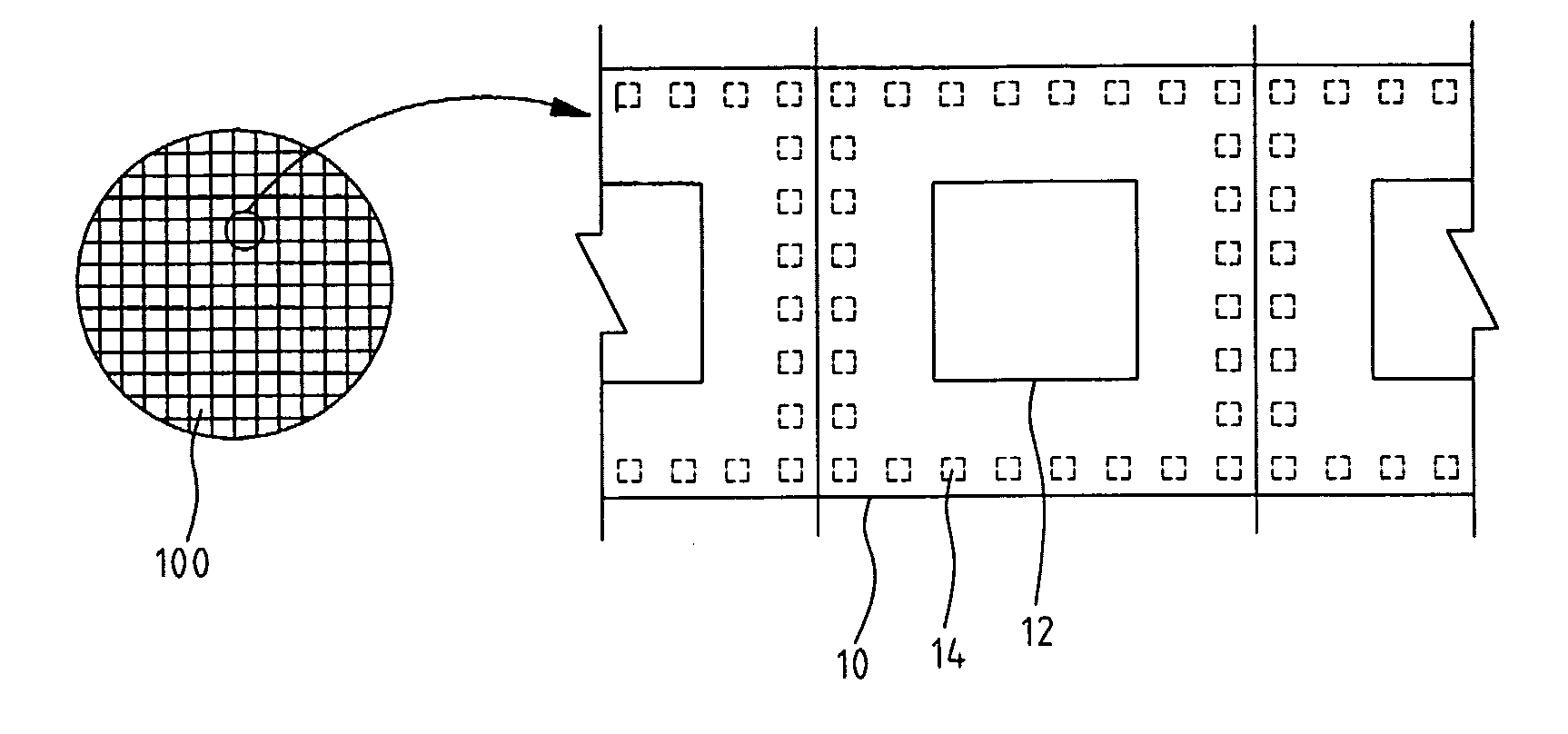

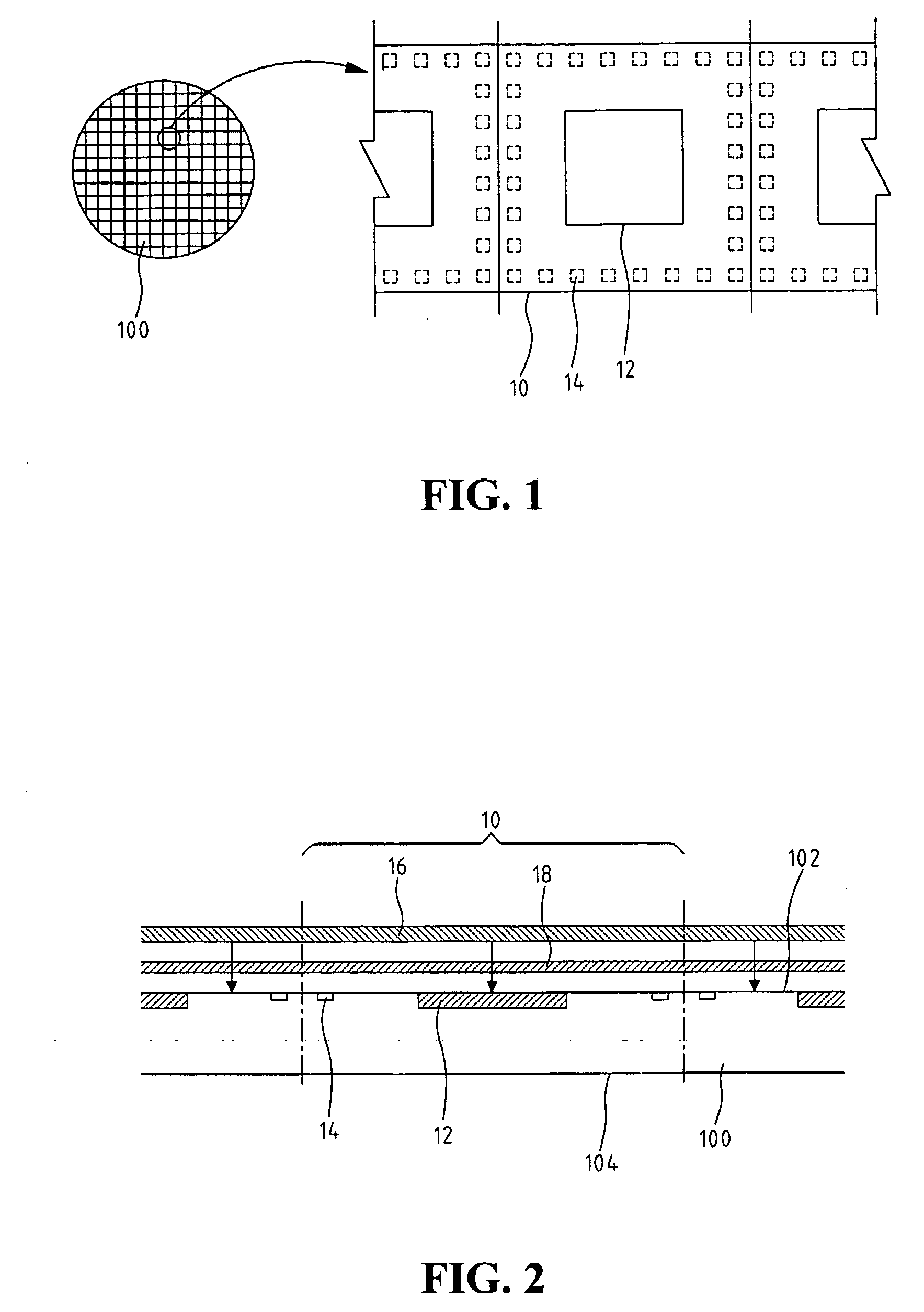

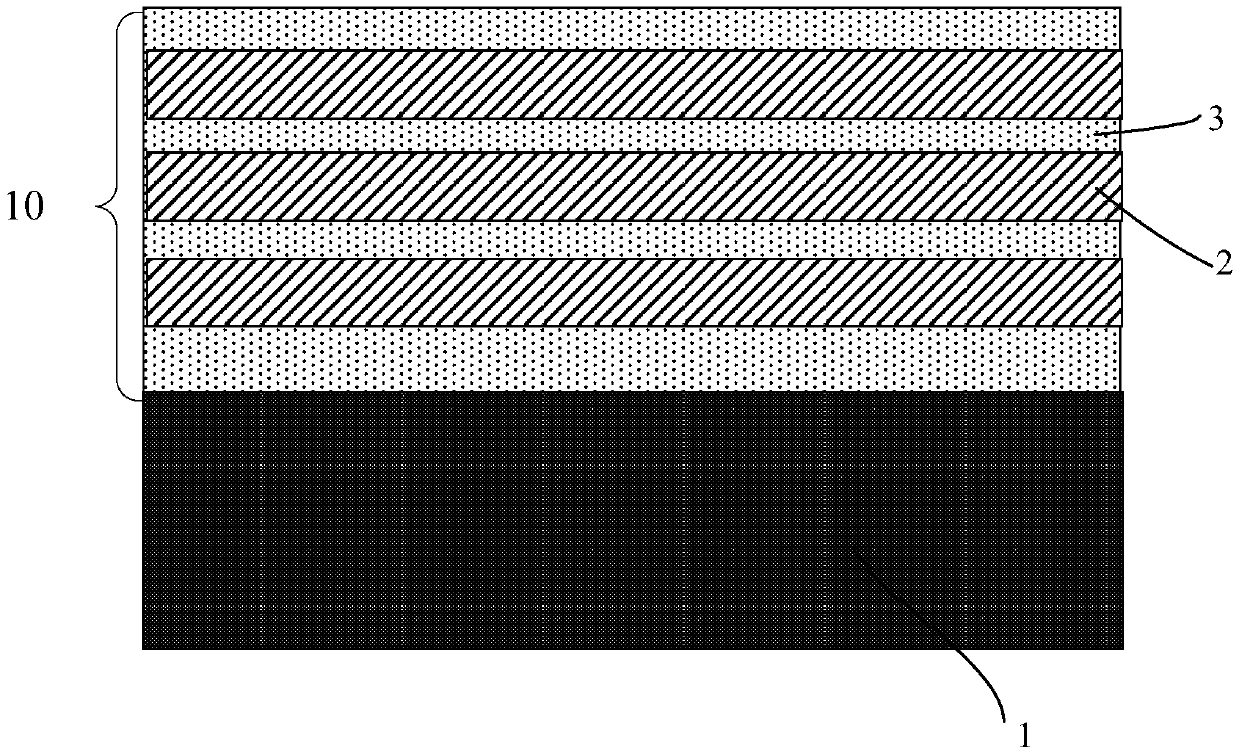

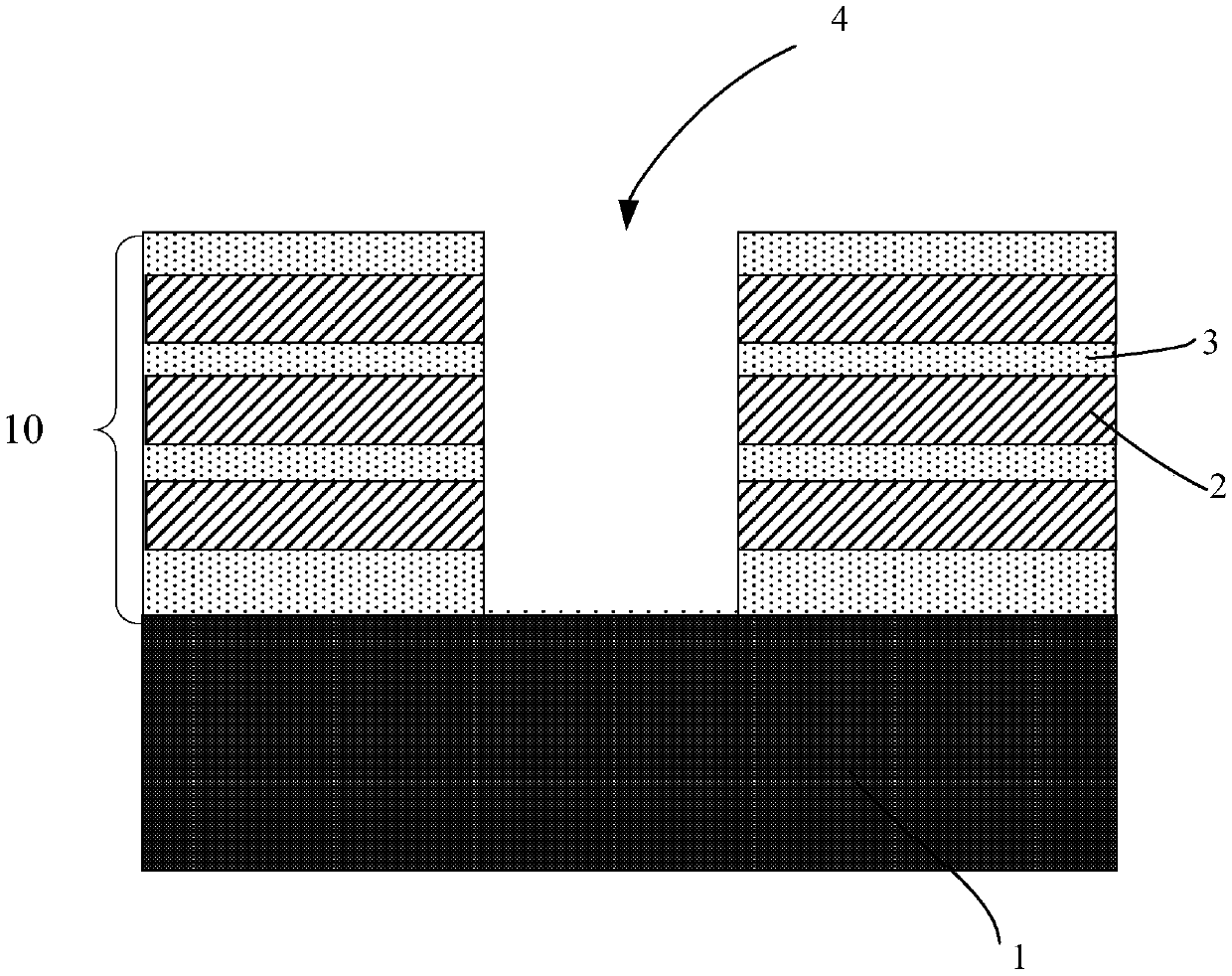

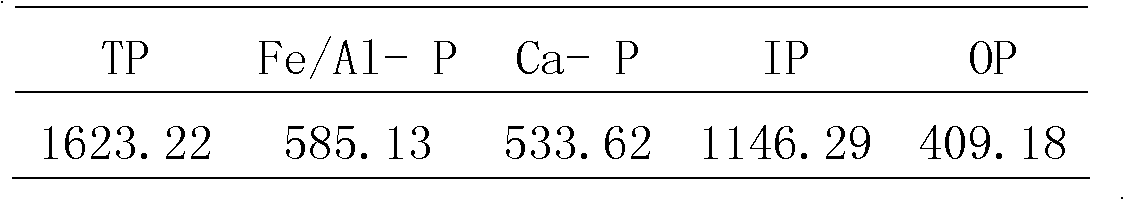

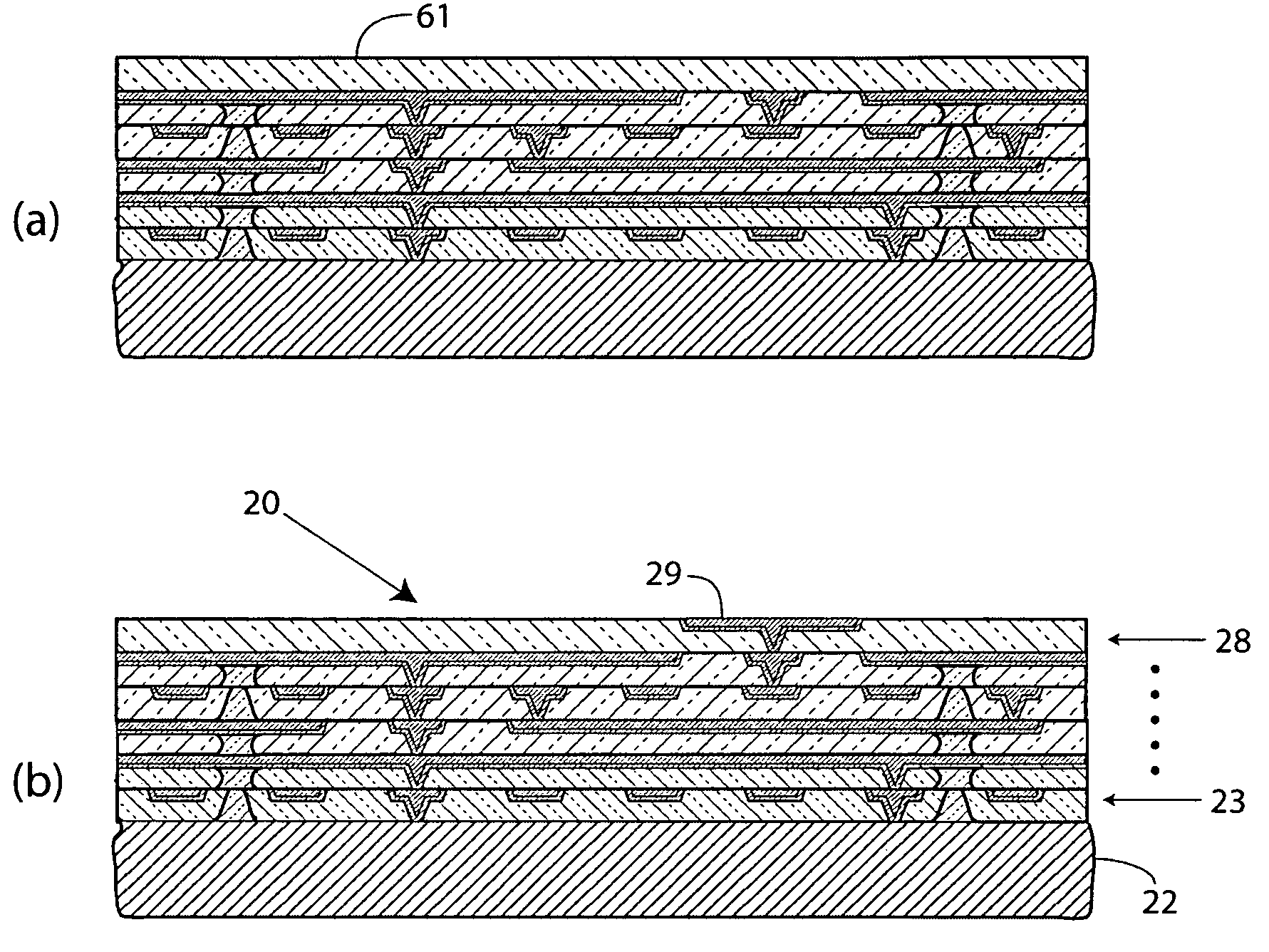

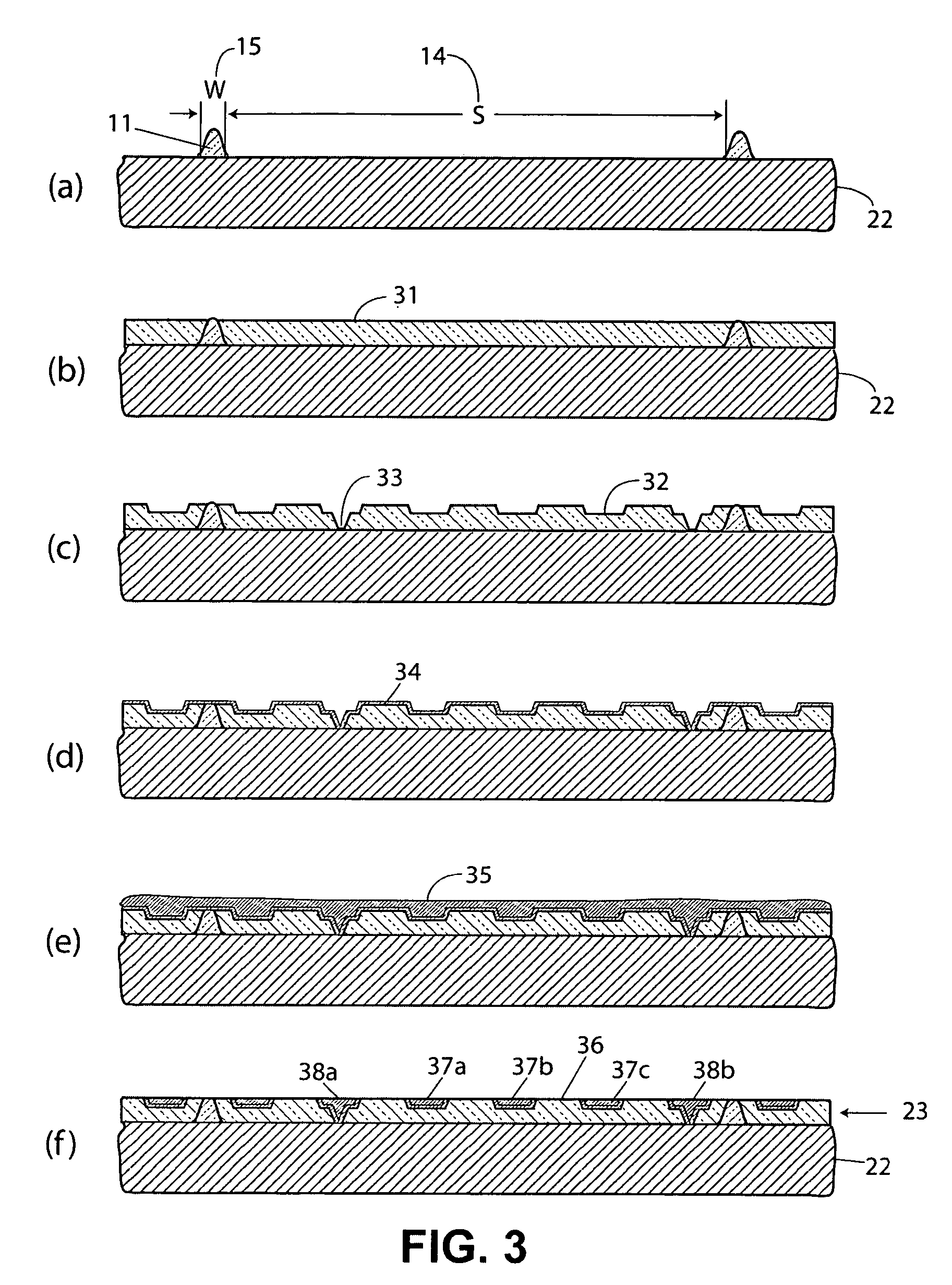

Tiled construction of layered materials

InactiveUS20060103024A1Excellent dielectric propertiesStrong interfaceSemiconductor/solid-state device detailsPrinted circuit aspectsCopperStress Problem

A method is described for combining the diverse strengths of two materials in a tiled film construction. The first material provides a foundation of intersecting grid lines on a substrate and the second material is contained within the grid lines and has a valued property for a particular application. In a preferred embodiment, a tiled dielectric layer has improved low-k dielectric performance while avoiding film stress problems that can lead to delamination or cracking. CTE mismatch is overcome at the cost of an additional masking step. This tiling method and layered binary construction enable Cytop to be used as a high performance low-k dielectric on most substrates including semiconductor wafers and copper panels or foils.

Owner:SALMON TECH

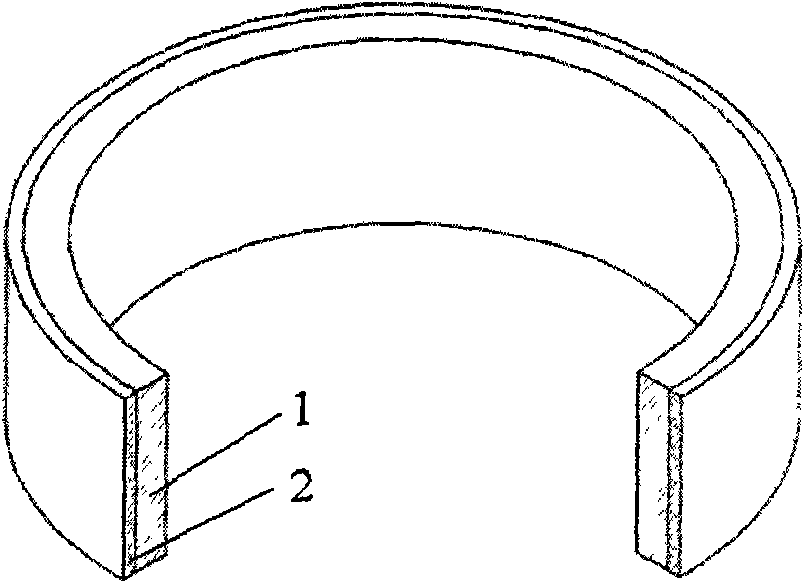

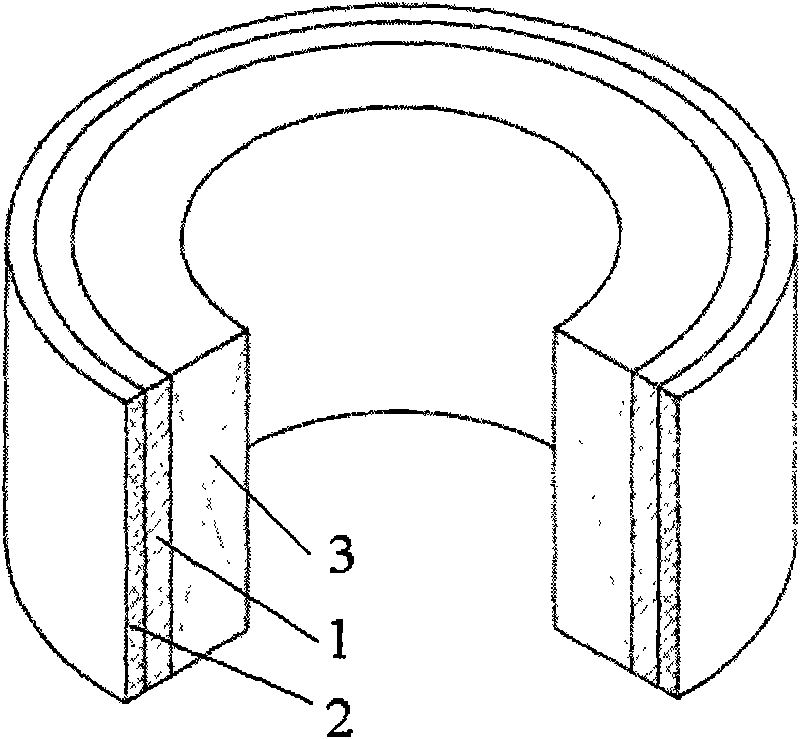

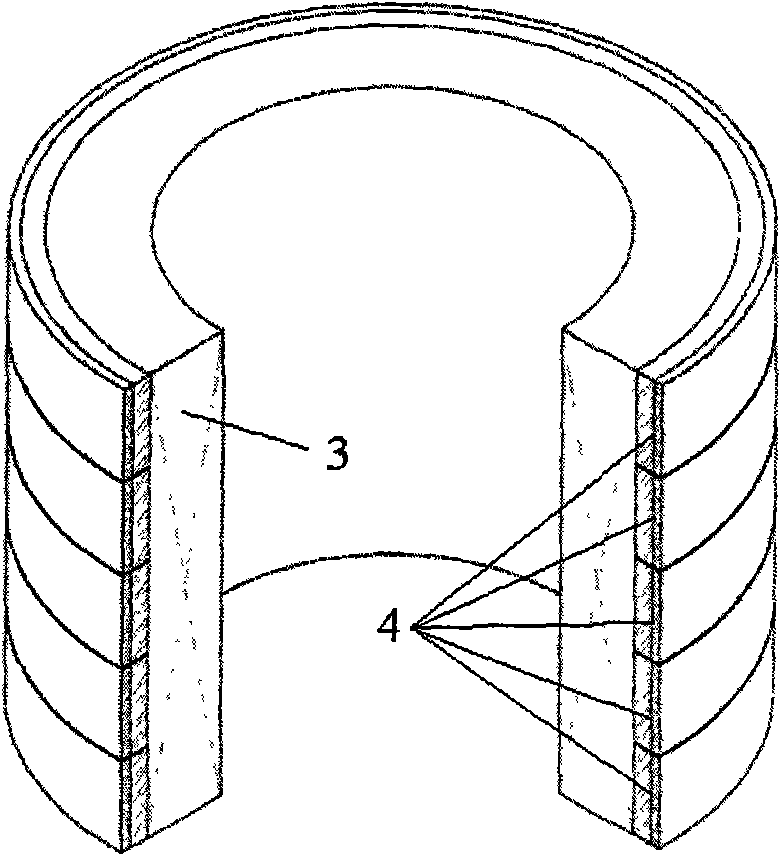

Stress support ring for highfield superconducting solenoid coil and mounting method

InactiveCN101593597AInductances/transformers/magnets manufactureSuperconducting magnets/coilsMetallurgySuperconducting solenoid

The invention provides a stress support ring for a highfield superconducting solenoid coil, which is characterized in that: a support ring (4) consists of an inner aluminium alloy support ring (1) and an outer stainless steel support ring (2). The method comprises the following steps: slowly cooling the inner aluminium alloy support ring (1) to the liquid nitrogen temperature of 77K by cold nitrogen, heating the outer stainless steel support ring (2) to 300 DEG C, and directly sleeving the inner aluminium alloy support ring (1) into the outer stainless steel support ring (2) to form strong bonding force between the stainless steel ring and the aluminium alloy ring so as to form the support ring (4); slowly cooling a superconducting coil (3) to the liquid nitrogen temperature of 77K by cold nitrogen gas; and heating the support ring (4) to 200 DEG C, and directly assembling the superconducting coil (3) into the support ring (4). The stress support ring for the highfield superconducting solenoid coil can effectively inhibit the stress problem of the highfield superconducting coil and reduce quench hardening times of the superconducting coil and degradation of critical current density.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

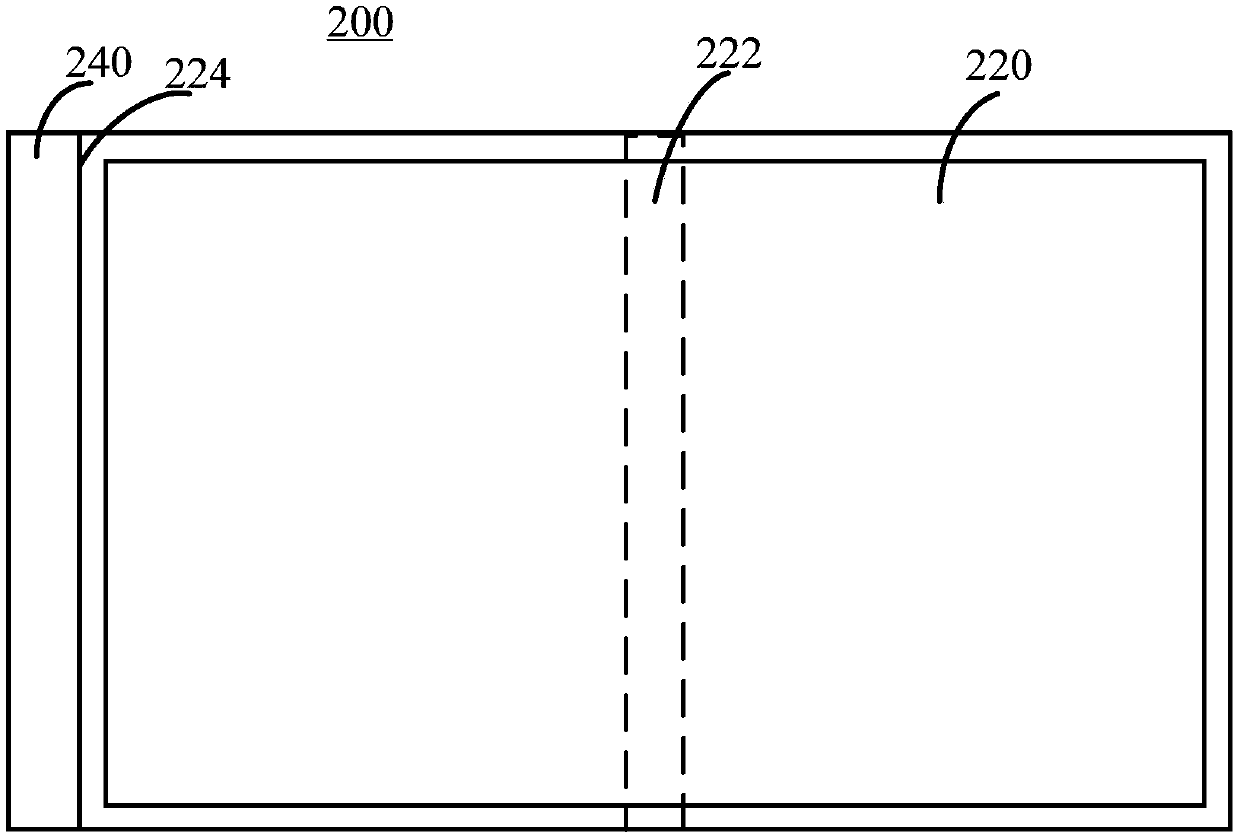

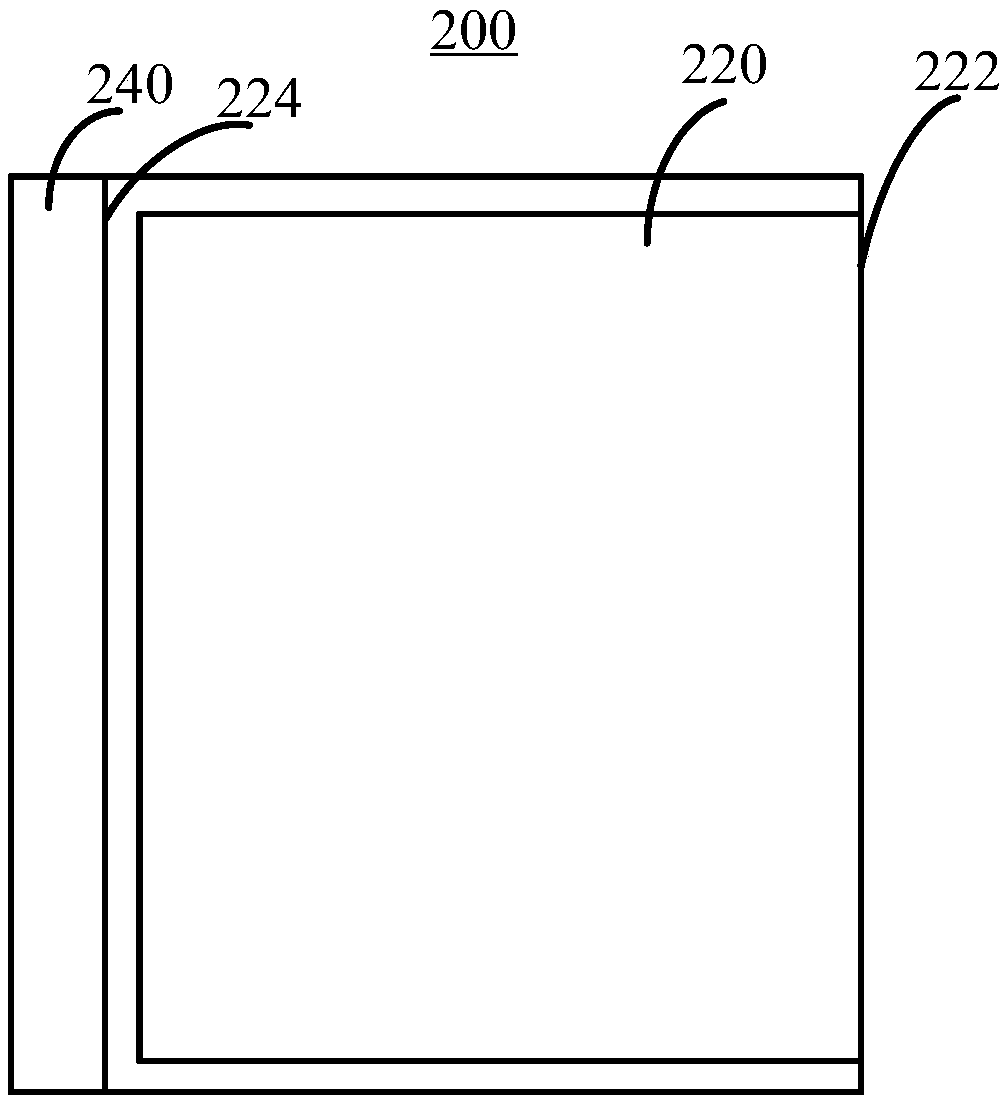

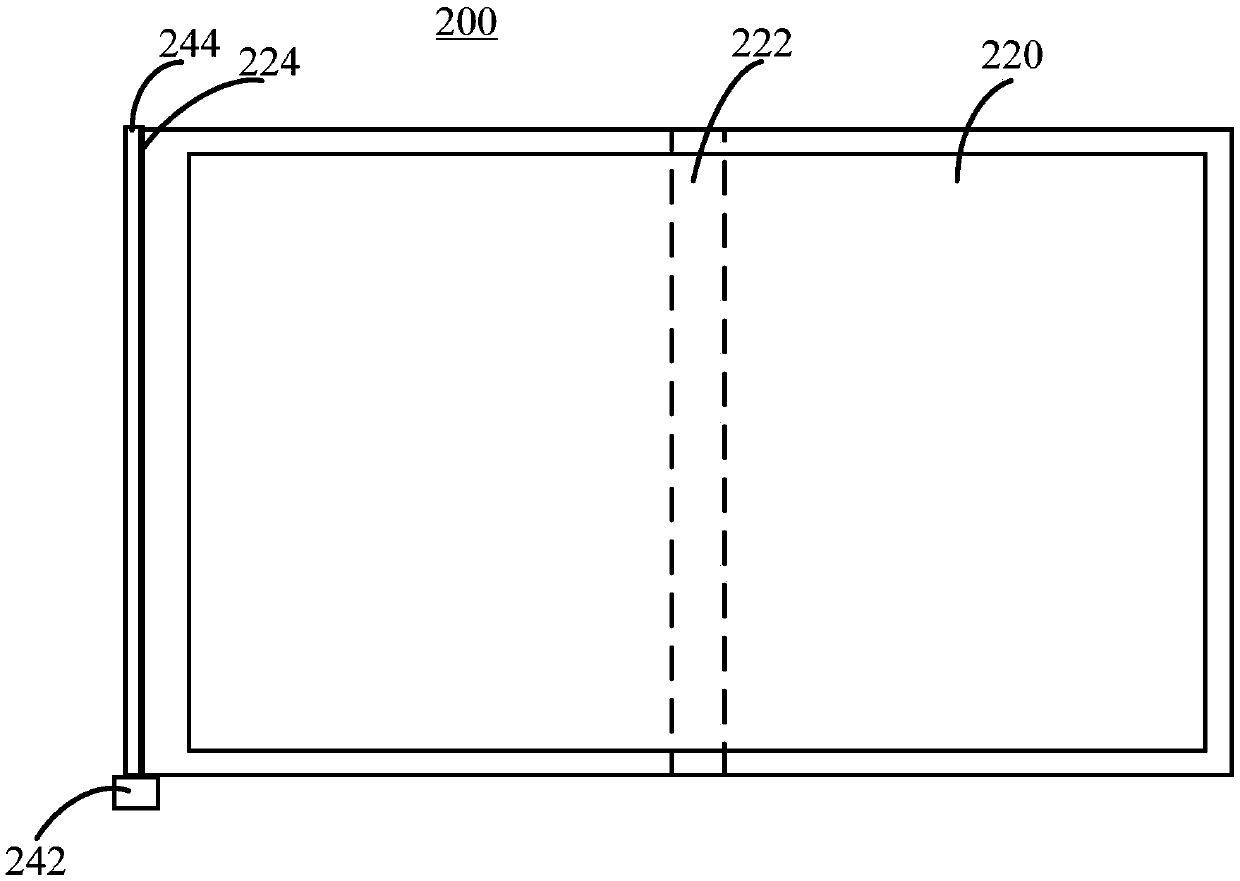

Flexible display module

The invention relates to a flexible display module. The flexible display module is provided with a bent zone and an extending zone located at the end of the flexible display module. The flexible display module comprises a first superposed layer and a second superposed layer which are superposed, and the first superposed layer and the second superposed layer are non-fixedly connected in at least part of bent zone and are fixedly connected in the extending zone. On one hand, the first superposed layer and the second superposed layer are non-fixedly connected in the bent zone, so that when the flexible display module is bent, the first superposed layer and the second superposed layer can be freely bent in the bent zone, and the stress problem caused by a bonding material to the two superposedlayers during traditional bending is avoided; on the other hand, the first superposed layer and the second superposed layer are fixedly connected in the extending zone, and relative slippage of the superposed layers during bending is avoided. The whole flexible display module is not likely damaged in the bending process.

Owner:GUANGZHOU GOVISIONOX TECH CO LTD

Semiconductor device manufacturing method based on double patterning

ActiveCN103779187ANo deformationSimple methodSemiconductor/solid-state device manufacturingPhotomechanical coating apparatusSurface layerGas phase

The invention relates to a semiconductor device manufacturing method based on double patterning. The method comprises the following steps: a semiconductor substrate and a mask layer located on the substrate are provided; a patterned photoresist layer is formed on the mask layer, wherein the patterned photoresist layer is photoresist cores separated through openings; a crosslinked top surface layer is formed on the patterned photoresist layer; a part of the photoresist layer sidewall is removed to thin the photoresist cores and reduce the critical size of the photoresist cores; spin coating is performed on the inner sidewall material layer, and the crosslinked top surface layer is covered; the etch back operation is performed on the inner sidewall material layer to form inner sidewalls on the photoresist cores; and the remaining crosslinked top surface layer and remaining photoresist cores are removed to form a double-patterned mask. The method of the invention is more simple, the stress problem caused by inner sidewall material chemical vapor deposition does not exist, and etch steps are reduced, so the cost is greatly reduced, and the product yield can be further improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

High temperature isostatic pressure bonding of hollow beryllium pressure vessels using a bonding flange

InactiveUS7163121B1High strength jointHigh strengthLarge containersDomestic vesselsThermal expansionHigh pressure

A bond joint and process of bonding metal parts to one another to form seamless, hollow metal articles, particularly made from beryllium. Tooling is assembled to the parts, prior to hot pressing, to cause pressure to be applied to flanges that extend peripherally from the parts. The parts, assembled together with the tooling, are then subjected to hot isostatic pressing of the flanges at a temperature of about 1700° F. to 1750° F., and at a pressure of about 2000 psi to 2500 psi, for around 3 hours. The tooling surrounding the metal parts functions to limit the amount of compression of the flanges. Articles formed by this process are particularly useful in space flight applications because they are formed of a homogeneous material. This means that the articles can operate under high pressure despite being subjected to temperature cycling. Strength of the bond joint is enhanced because no filler metal is used. The absence of a filler metal also eliminates any thermal stress problems as a result of differences in coefficients of thermal expansion.

Owner:NORTHROP GRUMMAN INNOVATION SYST INC

Method for wafer level package of sensor chip

InactiveUS20070224728A1Reduce packaging costsOvercomes drawbackSemiconductor/solid-state device detailsSolid-state devicesManufacturing cost reductionElectrical connection

A method for wafer level package (WLP) of sensor chips is provided, including the steps of: providing a wafer, the wafer including a plurality of die regions, each the die region on a first surface of the wafer comprising an active area and a pad surrounding the active area; bounding a transparent protective layer to the first surface of the wafer; forming a stress buffer on a second surface of the wafer; using etching or laser drill to form a via hole at the location between two neighboring die regions through the stress buffer and the wafer to expose the pad or a conductive line between two neighboring pads; and forming a plurality of bump electrodes on the stress buffer for electrical connection to the pads through the via holes. The method can prevent pollution of the die, improve the convenience of package, reduce the manufacture cost, increase the package reliability, and solve the stress problem caused by attaching the die directly to the PCB.

Owner:NAT TAIWAN UNIV

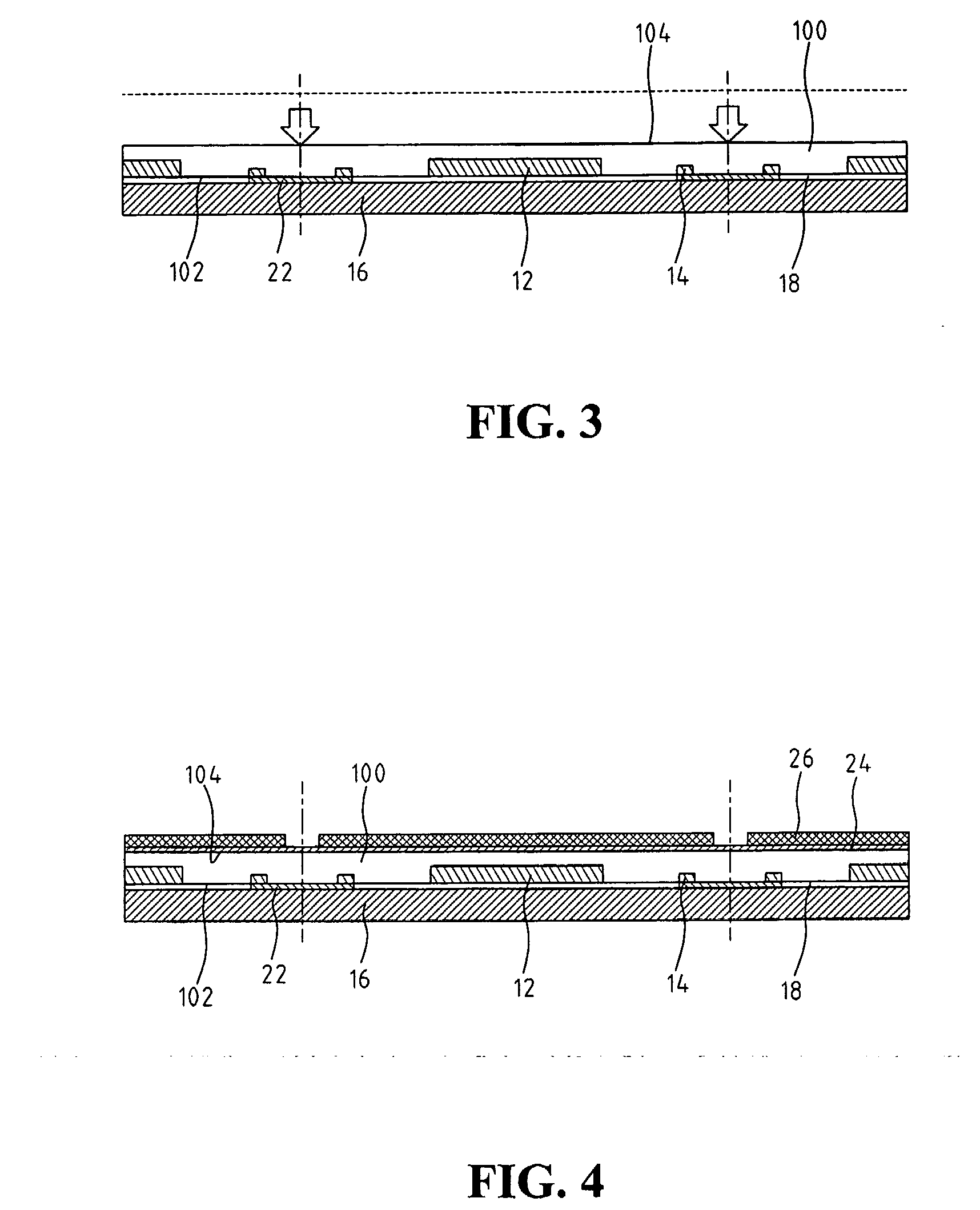

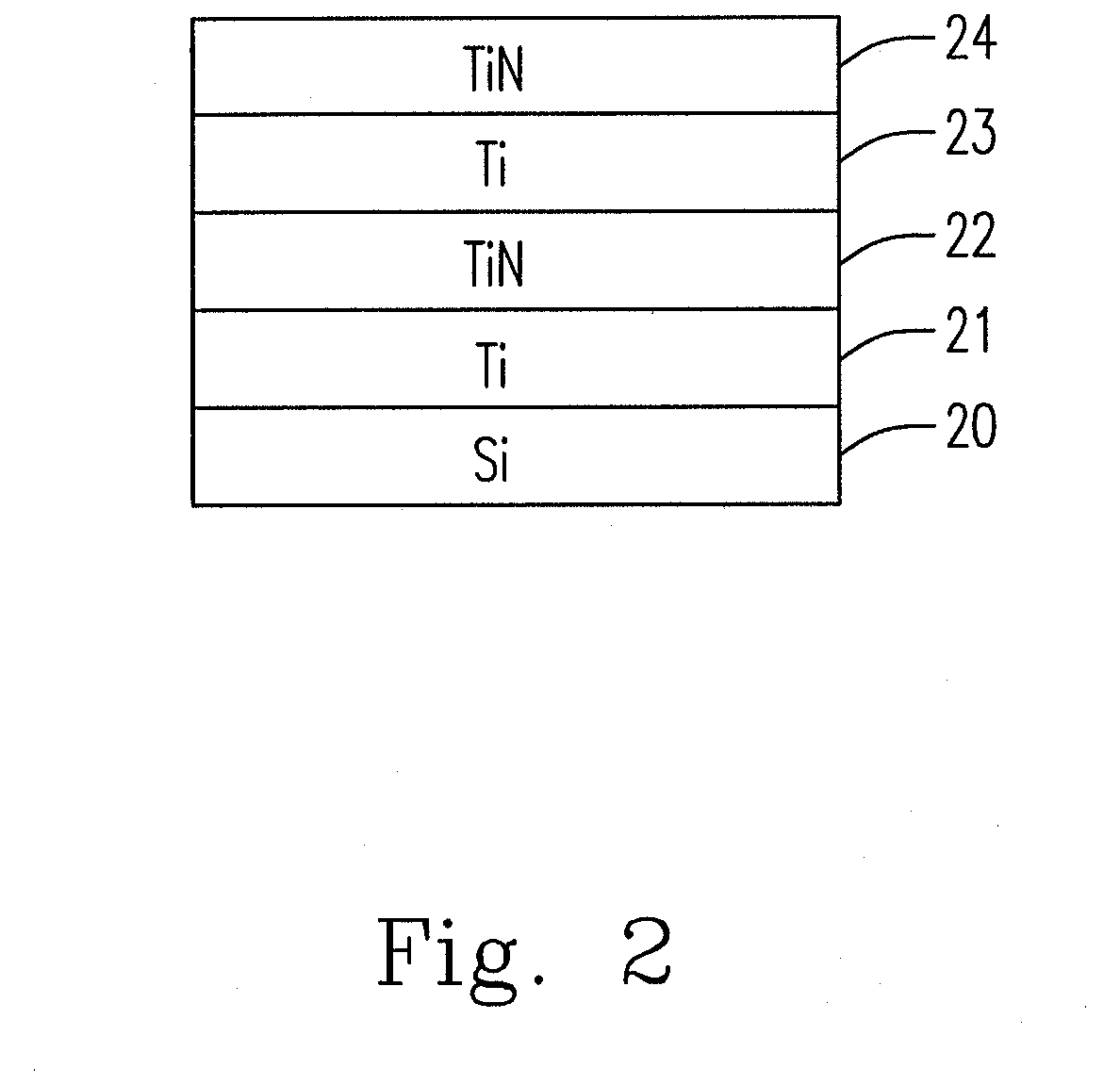

Method of forming multi metal layers thin film on wafer

InactiveUS20100240214A1Shorten cycle timeIncrease in production capacityVacuum evaporation coatingSemiconductor/solid-state device manufacturingStress ProblemCycle time

A method of forming the multi metal layers thin film has Ti sputtered on top surface of a substrate by PVD first. Then, Ti is transformed into TiN via CVD. Thus, by skipping the extra process steps of wafer cleaning and surface treating, the method not only solves the stress problems between two different metal layers but also improves the cycle time and particle performance for the production without any yield impact.

Owner:NAN YA TECH

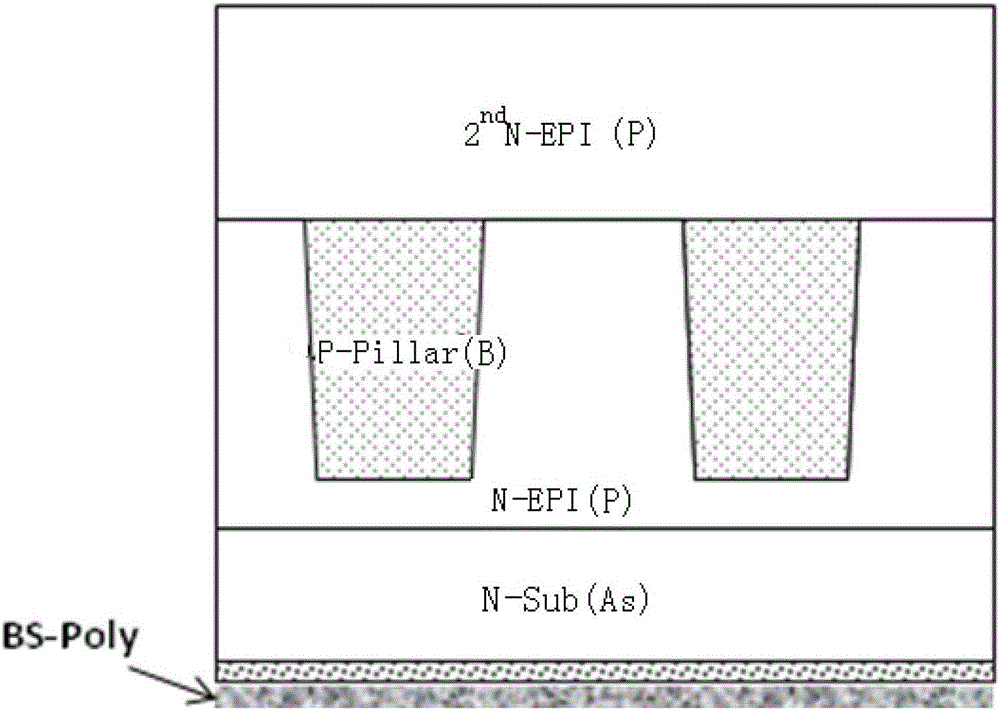

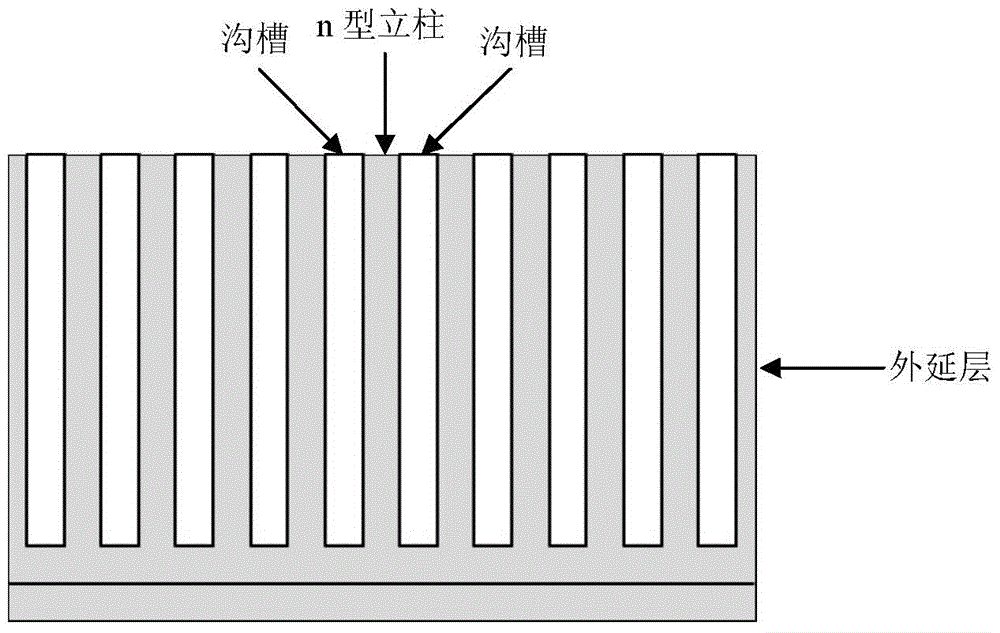

A method for manufacturing a deep-groove type super junction device

InactiveCN105702710AImprove electrical characteristics such as reverse breakdown voltageSolve the problem of doping and external expansionSemiconductor devicesEngineeringStress Problem

The invention discloses a method for manufacturing a deep-groove type super junction device. A back-seal of a substrate is changed from the structure of Poly+LTO into LTO+Poly so as to prevent back-seal LTOs exposed outside from being removed by wet method technology. During growth of a second N-type epitaxial layer, the LTOs still exist owing to the protection by Poly. Elements heavily doped in the substrate will not spread and will not lead to abnormity of doping of the second N-type epitaxial layer. Under a condition that stress problems will not occur, problems of doping spreading in the substrate in a high-temperature growing process of the second N-type epitaxial layer can be solved, and electrical properties such as reverse breakdown voltages of the deep-groove type super junction device can be effectively improved.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Wear-resistant coating and preparation method thereof, cutter ring of shield hobbing cutter, shield hobbing cutter and shield tunneling machine

ActiveCN110468406ARelieve heat stressInhibition of germinationMetallic material coating processesTunnelsHobbingAlcohol

The invention provides a wear-resistant coating and a preparation method thereof, a cutter ring of a shield hobbing cutter, the shield hobbing cutter and a shield tunneling machine. The wear-resistantcoating comprises at least two brazing filler metal coatings basically identical in structure. Each brazing filler metal coating comprises, by mass part, 3-10 parts of diamond micro-powder, 2-6 partsof an alcohol solvent, 1-5 parts of sodium fluoride and 81-93 pars of nickel-based brazing filler metal. According to the wear-resistant coating, a gradient transition coating is formed by the multi-pass basically identical thin coatings, the thermal stress problem generated when a thick coating is prepared through a surfacing welding method is relieved, and initiation and extension of cracks areinhibited to a certain degree; and meanwhile, the uniform distribution degree of the hard phase diamond micro-powder can be improved, and the advantages of being small in thermal injury, uniform in hard phase distribution and not likely to fall off are achieved. According to the shield hobbing cutter, the surface of the cutter ring is coated with the wear-resistant coating, the wear resisting performance of the cutter ring is effectively improved, and the service life of the cutter ring is prolonged.

Owner:CHINA INNOVATION ACADEMY OF INTELLIGENT EQUIP CO LTD +1

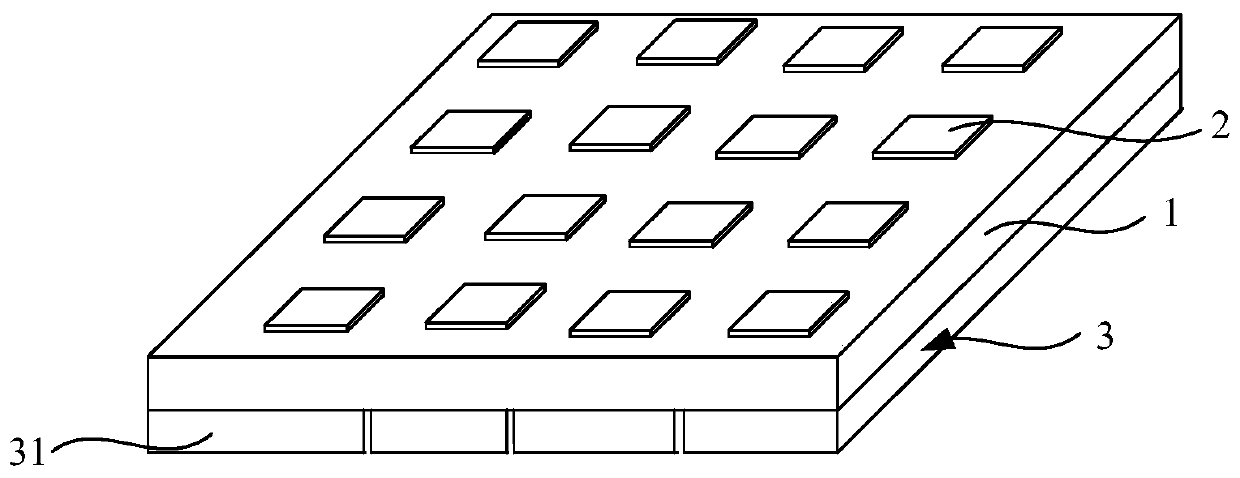

Lamp panel, backlight module and display device

ActiveCN110534020AGuaranteed flatnessLight mixing distance unchangedIdentification meansFlexible circuitsDisplay device

The invention relates to the technical field of display equipment, and discloses a lamp panel, a backlight module and a display device. The lamp panel comprises a flexible circuit board which comprises a first side face and a second side face; a light source which is positioned on the first side surface of the flexible circuit board; a supporting plate which is located on the second side face of the flexible circuit board and comprises a plurality of supporting parts capable of being spliced in sequence, each supporting part is of a strip-shaped structure, and the side, close to the flexible circuit board, of each supporting part is connected with the second side face of the flexible circuit board; wherein the flexible circuit board can be bent in the arrangement direction of the pluralityof supporting parts; when the flexible circuit board is in a flattened state, the sides, away from the flexible circuit board, of the multiple supporting parts are flatly spliced. When the flexible circuit board is in a bent state, the sides, away from the flexible circuit board, of the multiple supporting parts are disconnected. According to the lamp panel, the bending stress can be reduced, good attachment between the lamp panel and the back plate is guaranteed, the light source light mixing distance is not changed, and then the problem that the display brightness of the curved display panel is uneven due to the bending stress problem is solved.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

Process for assembling and welding ultralong hollow shafting auger flight

ActiveCN101412156ASolve the problem that flame preheating cannot be usedSolve the warm-up problemArc welding apparatusFurnace typesCombustionHelical blade

The invention provides an assembly welding process for an ultra-long hollow shaft helical blade, which mainly comprises two assembly welding processes, namely the pre-heating welding of the helical blade on the ultra-long hollow shaft and the overlaying welding of the antiwear layer on the helical blade and a process of the overall annealing of overlaying welding. In the assembly welding processes, the small-pore tubing negative pressure siphoning type air supply combustion-supporting gas heating is utilized to solve the problem of preheating the high-carbon equivalent material; by evaluating the welding processes of a plurality of overlaying welding materials, the welding method, the welding material and the welding condition are finally determined; and the result meets the hardness(HRC54 to 06) of the antiwear layer required in the design, which is the necessary hardness obtained after annealing, and solves the new welding stress problem generated due to the overlaying welding after annealing. Moreover, the process has the advantages of easily obtained material, simple preparation, time conservation and labor conservation, and low cost.

Owner:CITIC HEAVY INDUSTRIES CO LTD

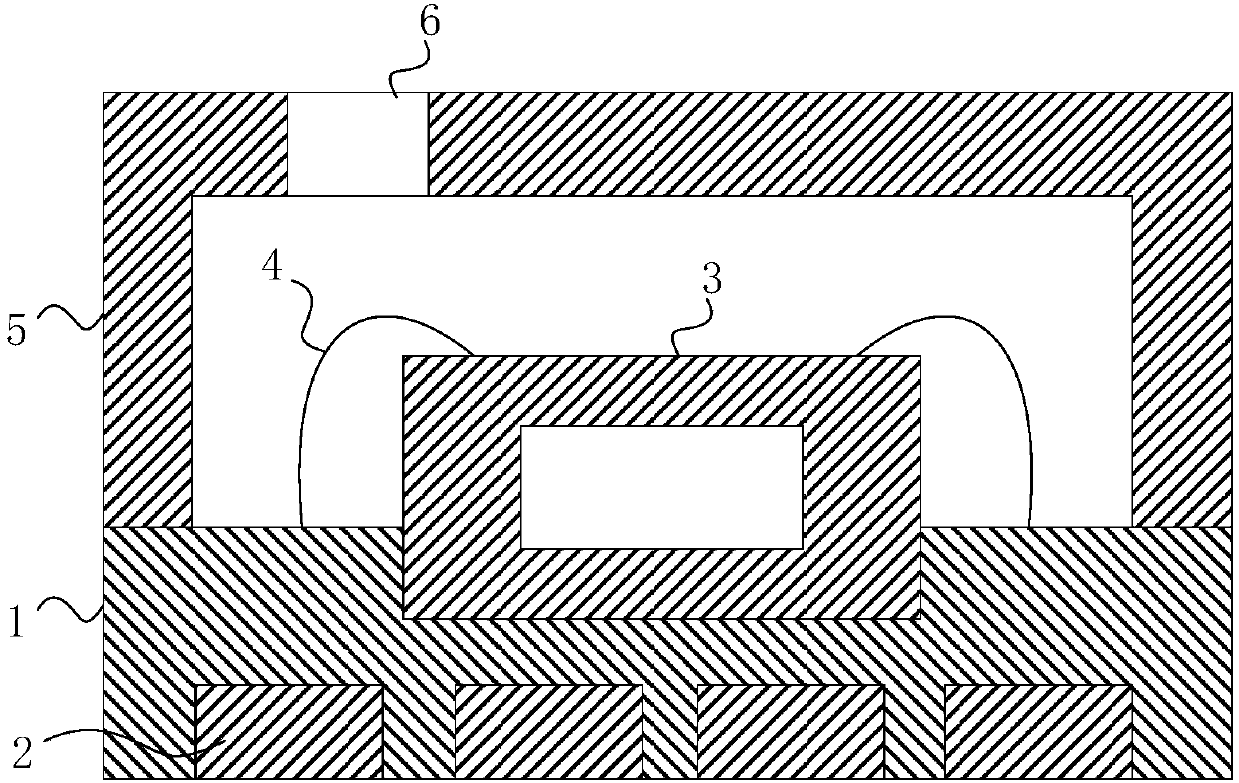

Pressure sensor chip and manufacturing method thereof

ActiveCN107894297ALow costPerformance impactFluid pressure measurement using ohmic-resistance variationEngineeringStress Problem

The invention discloses a pressure sensor chip and a manufacturing method thereof. According to the technical scheme, designed is a new accommodation space formed by a first cavity, a second cavity and separation grooves, which are communicated mutually, and used for accommodating pressure sensitive components; and the outer walls of the accommodation space are provided with pressure leading holesto enable the accommodation space to be communicated with the external gas environment. The novel stress isolation structure can reduce the influence of environment stress on the performance of the pressure sensor chip, solves the lead wire protection problem, surface flexible glue coating problem and packaging stress and welding thermal stress problem of the pressure sensor chip in plastic package in the prior art, and can meet low-cost and high-efficiency all-mold plastic package requirements of a pressure sensor.

Owner:安徽京芯传感科技有限公司

Electronic equipment

The embodiment of the invention provide electronic equipment. A foldable screen component comprises a foldable screen and a driving mechanism, wherein the foldable screen comprises a bending part, anda first end part which is located at one end of the foldable screen; the foldable screen is unfolded or folded through the bending part; the driving mechanism is connected with the first end part; when the foldable screen is in an unfolded state, the driving mechanism drives the first end part to get away from the bending part; and when the foldable screen is in the folded state, the driving mechanism drives the first end part to move toward the bending part. Through adoption of the electronic equipment, the stress problem of the folded screen in the unfolded state and the folded state is solved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

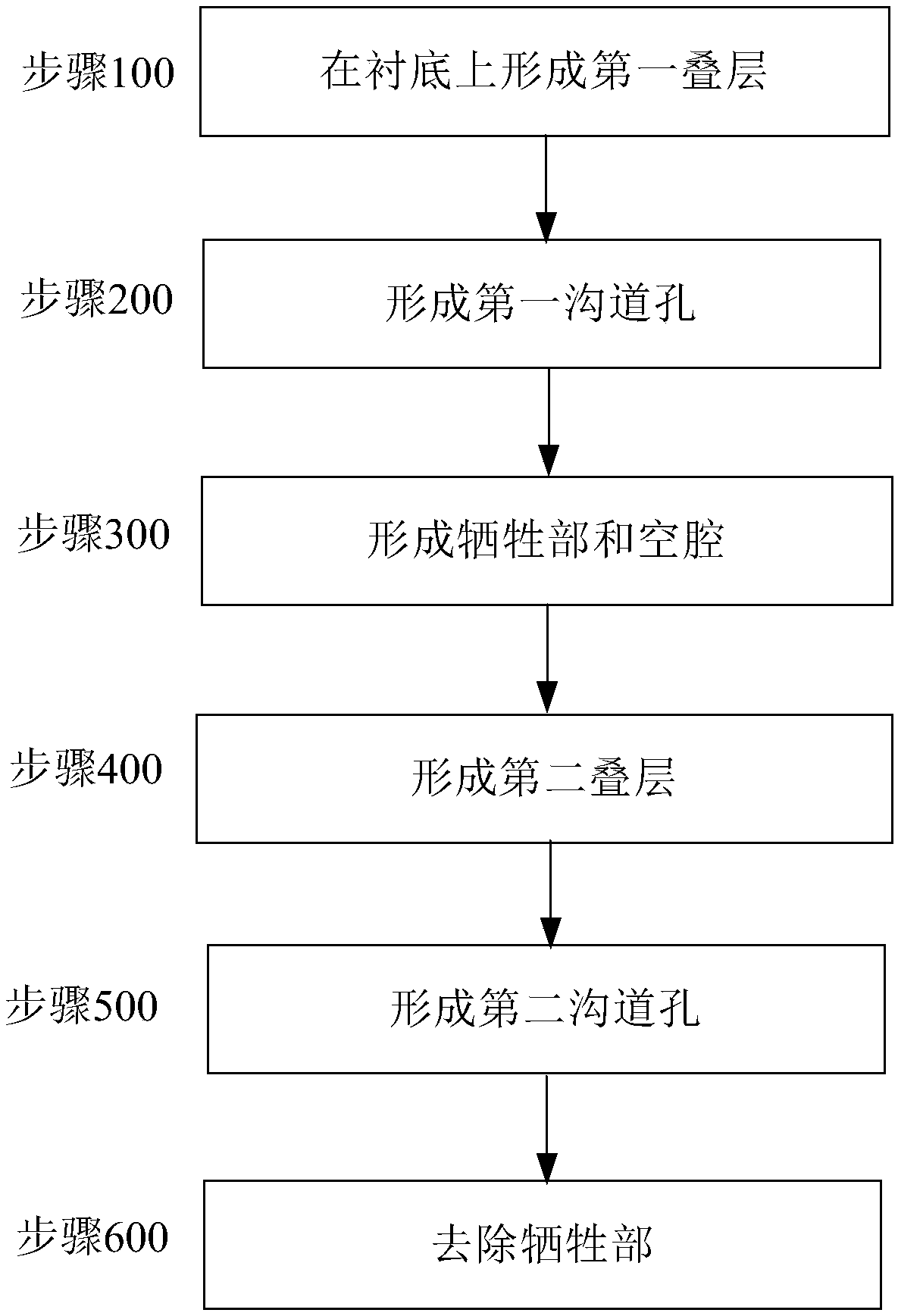

Method of fabricating three-dimensional memory and preparation method of semiconductor structure

ActiveCN108682674ASmall sizeEasy to makeSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor structureStress Problem

A method of fabricating a three-dimensional memory comprises steps of: forming a first stack formed by alternately stacking a first layer and a second layer on a substrate; forming a first channel hole penetrating through the first stack and reaching the substrate; forming a sacrificial portion in the first channel hole, and forming a cavity between the sacrificial portion and a sidewall and a bottom portion of the first channel hole; forming a second stack by alternately stacking a third layer and a fourth layer on the first stack; forming a second channel hole penetrating through the secondstack and reaching the sacrificial portion; and removing the sacrificial portion. The method for fabricating the three-dimensional memory provided by the present invention arranges the sacrificial portion, and forms the cavity formed between the sacrificial portion and the sidewall and the bottom portion of the channel hole, so that the material of the sacrificial portion can be made less, the sacrificial portion is easier to produce and remove, and the contamination and stress problems caused by the material of the sacrificial portion are solved.

Owner:YANGTZE MEMORY TECH CO LTD

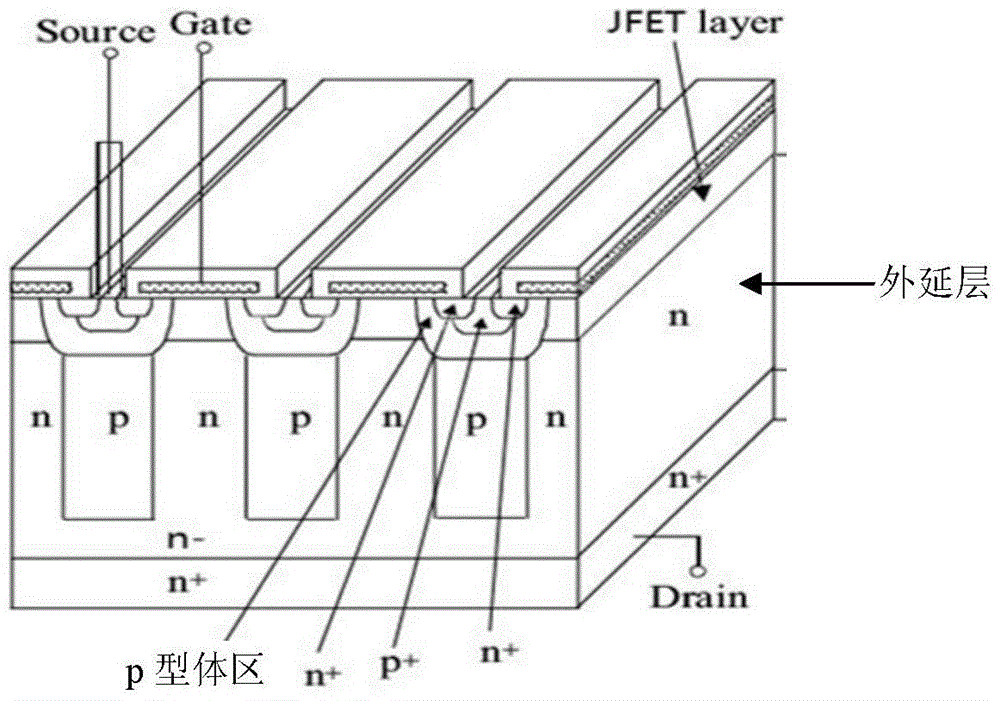

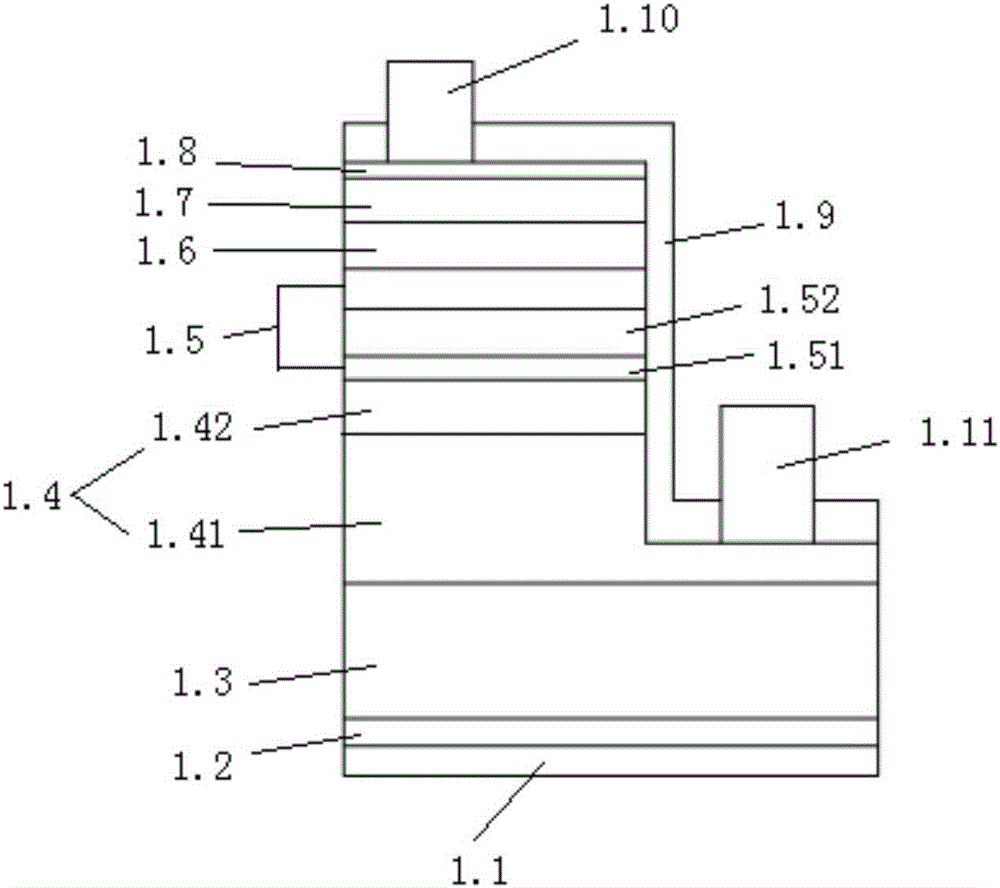

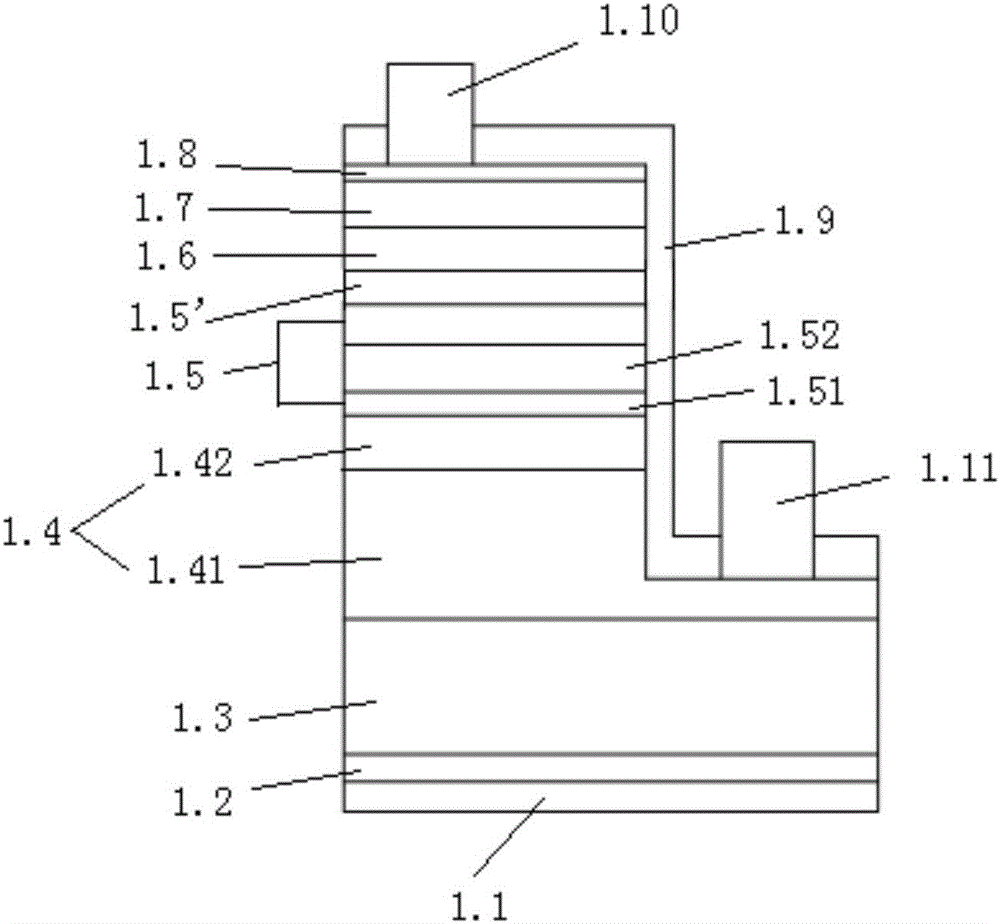

LED epitaxial structure and growing method thereof

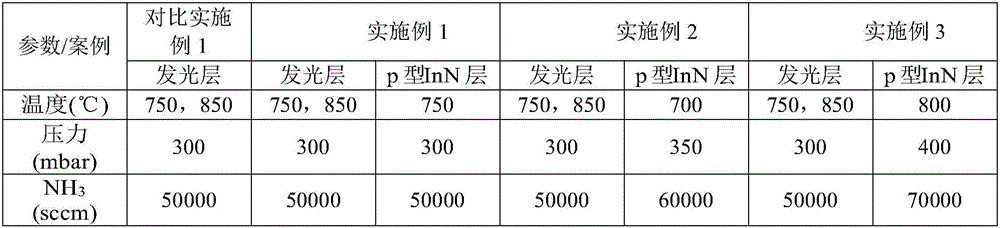

InactiveCN106384764AImprove crystal qualityImprove injection efficiencySemiconductor devicesMacro levelOptoelectronics

The invention provides an LED epitaxial structure comprising a sapphire substrate, a low-temperature buffer layer, a non-doped GaN layer, a Si-doped n-type GaN layer, a light emitting layer, a p-type InN layer, a p-type AlGaN layer and a magnesium-doped p-type GaN layer, which are stacked in turn. By arranging the p-type InN layer between the light emitting layer and an electron blocking layer, the following effects are achieved: on one hand, the p-type InN material helps to solve the stress problem properly, a smooth energy band is more suitable for hole injection, the hole injection efficiency is increased, and the light efficiency of LED devices is increased on a macro level; and on the other hand, the p-type InN layer increases the distance between a GaN epitaxial layer and the electron blocking layer and effectively blocks the diffusion of Mg atoms in the electron blocking layer, the concentration of Mg impurity atoms in the light emitting layer is reduced, the crystal quality of the light emitting layer is improved to a certain degree, and the light efficiency of LED devices can be further improved. The invention further discloses a growing method of the LED epitaxial structure, which includes simple steps and is advantageous for industrialization production.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

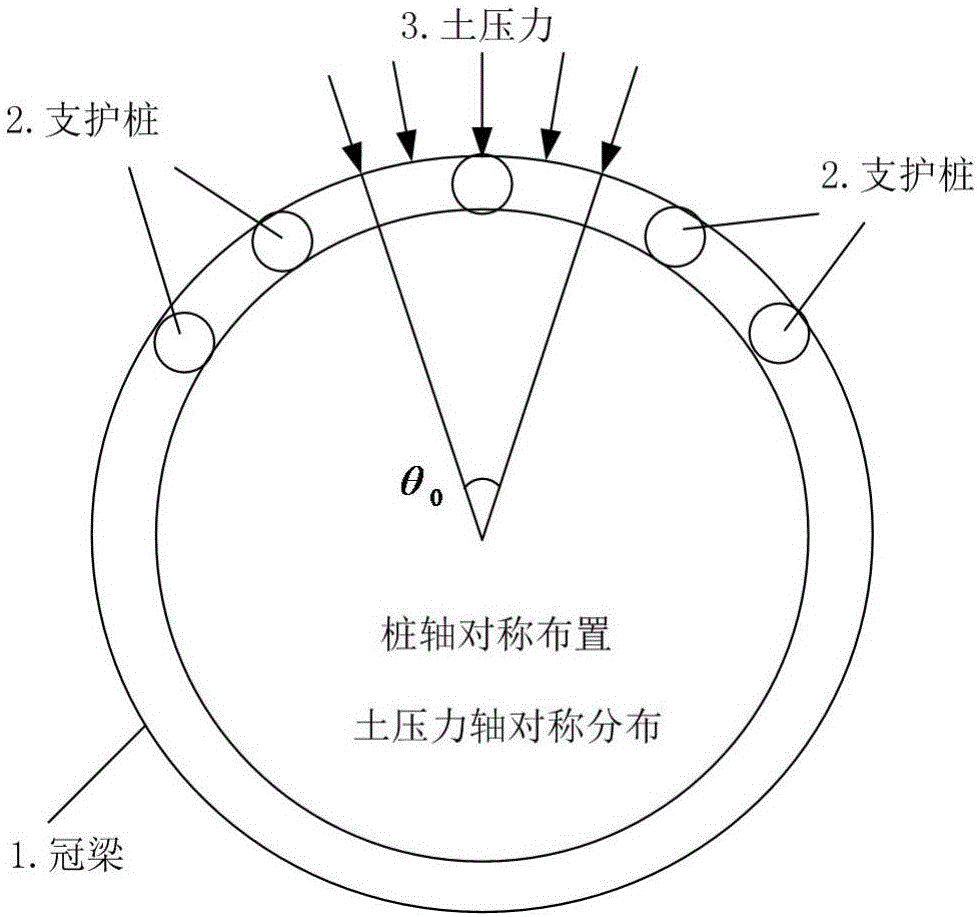

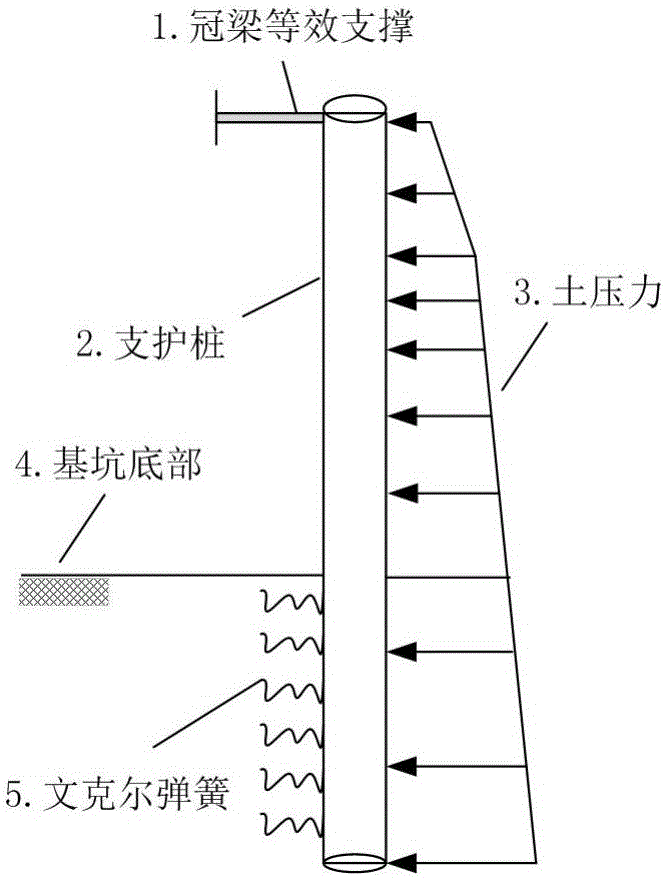

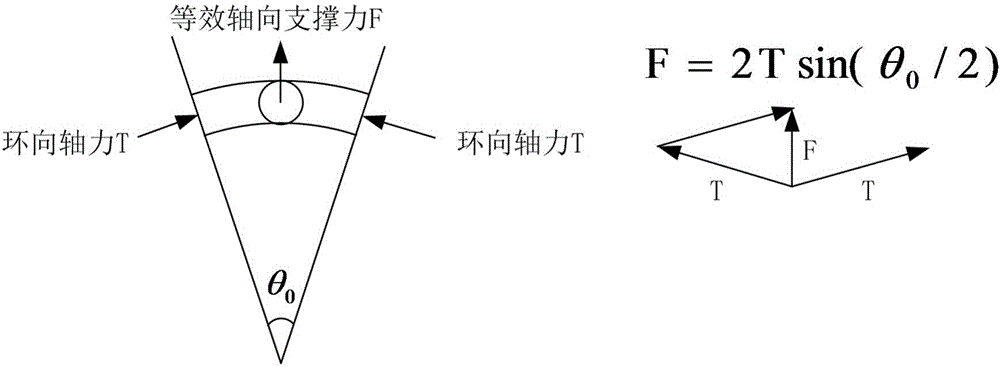

Method for computing horizontal lateral stiffness of pile top crown beam of support pile of cylindrical foundation pit

ActiveCN106570221AAvoid physical supportReflect deformationGeometric CADSpecial data processing applicationsSocial benefitsSupporting system

The invention provides a method for computing horizontal lateral stiffness of a pile top crown beam of a support pile of a cylindrical foundation pit. Through simplifying a cylindrical support system into an axial symmetry stress problem, establishing a computational formula of the horizontal lateral stiffness of the pile top crown beam of the support pile of the cylindrical foundation pit and computing to obtain the horizontal lateral stiffness of the pile top crown beam, the conventional elastic resistance method can be adopted to analyze and design a support structure of the cylindrical foundation pit, the deformation state and the stress state of the support pile can be more really reflected, the spatial effect of the cylindrical foundation pit is fully utilized, the tangible support of the cylindrical foundation pit is reduced and even avoided, the earth excavation of the foundation pit is facilitated, the engineering construction period and cost are saved, the energy consumption is reduced, and the method has larger economic benefit and social benefit.

Owner:WUHAN SURVEYING GEOTECHN RES INST OF MCC

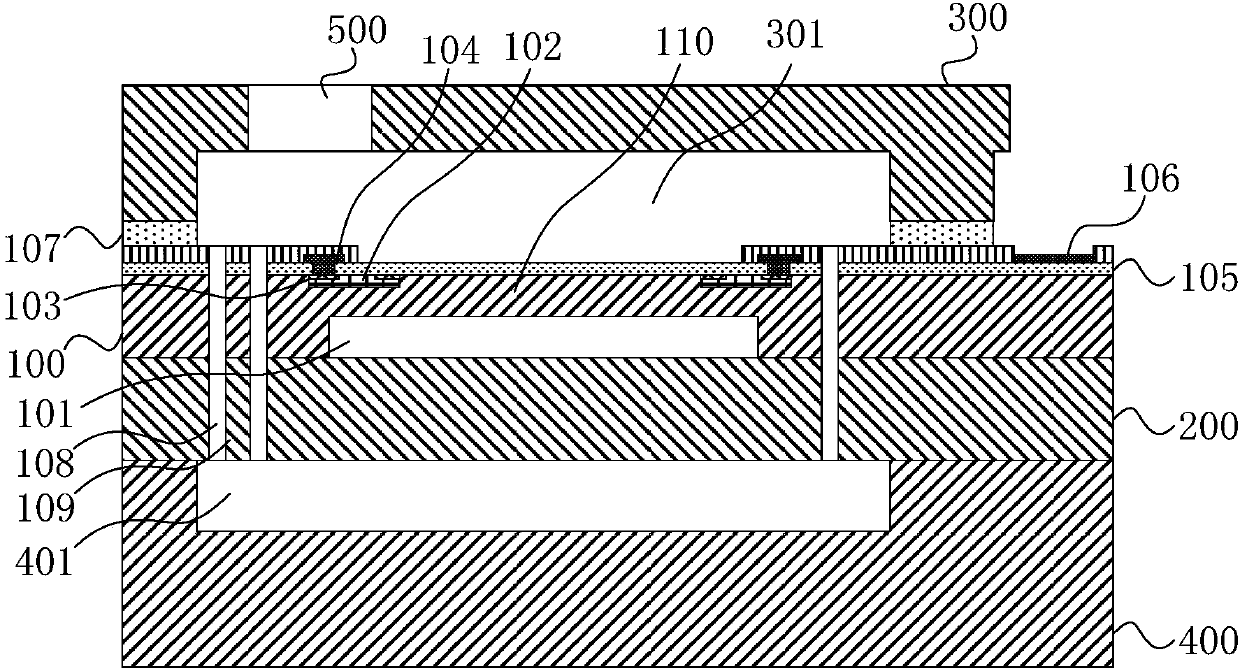

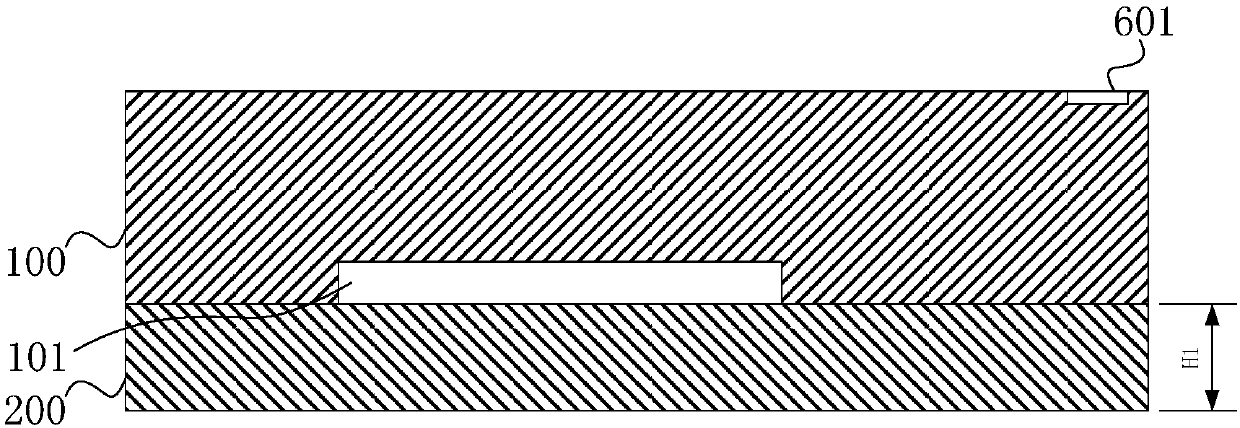

Backside illuminated image chip module structure and fabrication method thereof

InactiveCN105023931ASimple circuit designLow costRadiation controlled devicesSurface mountingStress Problem

The invention discloses a backside illuminated image chip module structure and a fabrication method thereof. The fabrication method comprises the following steps of: 1) backside illuminated (BSI) chip packaging, in which a non through silicon vias (TSV) wafer level packaging process is used for BIS chip package; 2) analog-digital converter / image single processor (ISP) chip package; 3) BSI chip and ADC / ISP chip lamination, in which an inversed packaging technique and a surface mounting technology are used for laminating the packaged BIS chip, a soft board and some auxiliary small devices on the ADC / ISP chip or a silicon-base substrate; and 4) lens module installation to finally form an image chip module. By the backside illuminated image chip module structure and the fabrication method thereof, the stress problem between the BSI chip and the soft board is solved, the volume of the whole module is shortened, the circuit design of the soft board is simplified, and the comprehensive cost of the module is reduced.

Owner:NAT CENT FOR ADVANCED PACKAGING

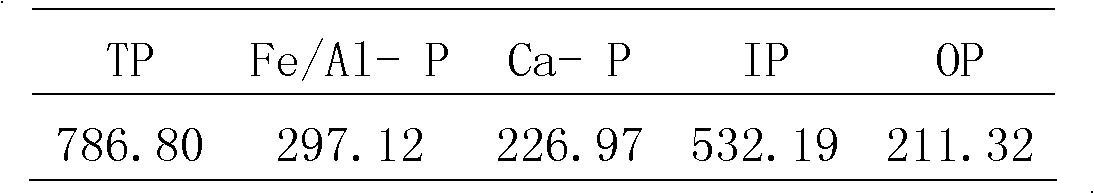

Method for processing phosphorus in sediment by combining photocatalytic reduction with submerged plants

ActiveCN102329046AEasy to operateEasy to handleWater/sewage treatment by irradiationMultistage water/sewage treatmentEnvironmental resistancePhotocatalytic reaction

The invention discloses a method for processing phosphorus in sediment by combining photocatalytic reduction with submerged plants. The method comprises the following steps: 1) screening out the submerged plants adapted to local climate and water area conditions; 2) planting the submerged plants into a glass ware containing the sediment and laying a layer of novel environment-friendly filter balls loaded with a nano-semiconductor photocatalyst thin film on the sediment; 3) injecting overlying water which is from a water column at a sediment sampling point; 4) performing intermittent irradiation by using an external light source at the growth initial stage and the decline stage of the submerged plants, wherein the external light source not only enables a photocatalyst to perform photocatalytic reaction, but also meets the light irradiation required for the growth of the submerged plants; and 5) collecting sediment samples at set time intervals and determining the change situation of the phosphorus in all forms in the sediment. The method is easy to operate and simple and convenient to operate; by adopting the method, the phosphorus in the sediment in an eutrophic water body can be removed with high efficiency and the phosphorus stress problem during the process of restoration and reconstruction of the submerged plants can also be effectively solved.

Owner:INST OF AQUATIC LIFE ACAD SINICA

Tiled construction of layered materials

InactiveUS7535107B2Excellent dielectric propertiesStrong interfaceSemiconductor/solid-state device detailsPrinted circuit aspectsCopperStress Problem

A method is described for combining the diverse strengths of two materials in a tiled film construction. The first material provides a foundation of intersecting grid lines on a substrate and the second material is contained within the grid lines and has a valued property for a particular application. In a preferred embodiment, a tiled dielectric layer has improved low-k dielectric performance while avoiding film stress problems that can lead to delamination or cracking. CTE mismatch is overcome at the cost of an additional masking step. This tiling method and layered binary construction enable Cytop to be used as a high performance low-k dielectric on most substrates including semiconductor wafers and copper panels or foils.

Owner:SALMON TECH

Modeling method and manufacture method of auricular support capable of exposure prevention, and auricular support

The invention provides a modeling method and manufacture method of an auricular support capable of exposure prevention, and the corresponding auricular support. Based on an artificial ear support, ear support data is collected; data modeling is conducted; ear support and skin data is introduced; finite element analysis is used to simulate force bearing states of each part after implantation of the ear support; and finally, simulation results are compared with clinical results, and stress concentration parts are adjusted, so that carving of the support can be guided, and exposure of the support caused by stress problems can be prevented effectively.

Owner:SOUTHERN MEDICAL UNIVERSITY

Lead welding technique for packaging semiconductor power device

ActiveCN105458434ANo stress damageIncrease flow resistanceWelding/cutting media/materialsMetal working apparatusManufacturing technologyStress Problem

The invention discloses a lead welding technique for packaging a semiconductor power device and belongs to the technical field of semiconductor power device packaging and manufacturing. According to the technique, lead connection is achieved through a brazing technique, and the brazing process is achieved through lasers, wherein lead connection refers to the completion of the welding process of a lead and a chip and the welding process of the lead and two welding points of a frame. In the welding process, the lead, the frame and a chip welding pad are preheated through direct laser spot radiation, the diameter of laser spots is 1 mm, and laser radiation time is 10 ms; and a brazing wire is heated through direct laser spot radiation, the diameter of the laser spots is 1 mm, and laser radiation time is 10 ms. By the adoption of the technique, the wet aluminum pad and the frame can be melted directly to achieve stable and reliable connection of the lead, the chip and the frame, the aluminum pad and the frame cannot be melted due to the fact that the temperature does not reach the melting point, and the aluminum pad and the frame are just preheated, so that the surfaces are stretched fully to assist in combination of the aluminum pad and liquid brazing filler metal and combination of the frame and the liquid brazing filler metal, and therefore mechanical damage, thermal damage and the stress problem existing in a traditional routing technique are avoided.

Owner:王伟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com