Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43 results about "Superconducting solenoid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

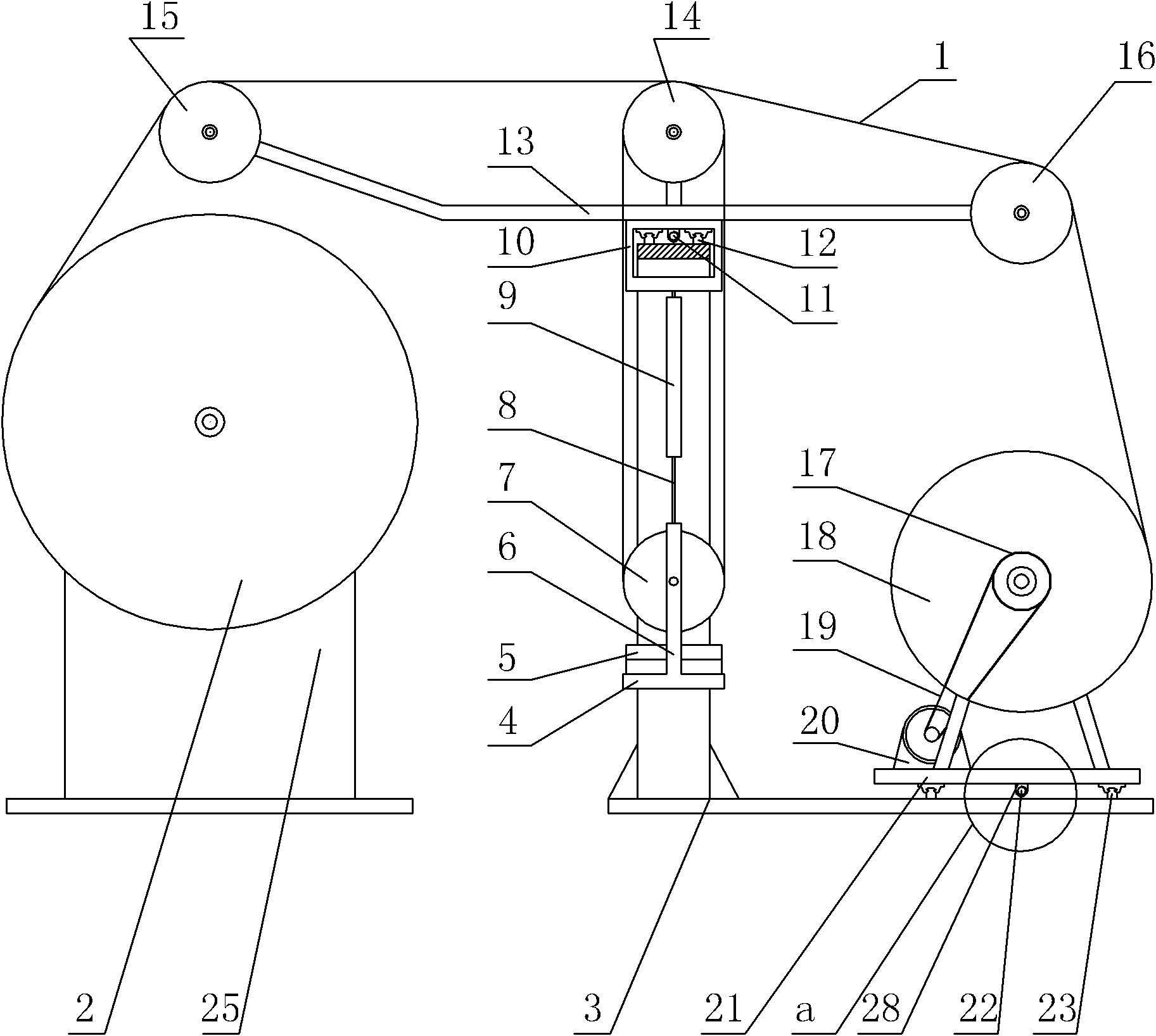

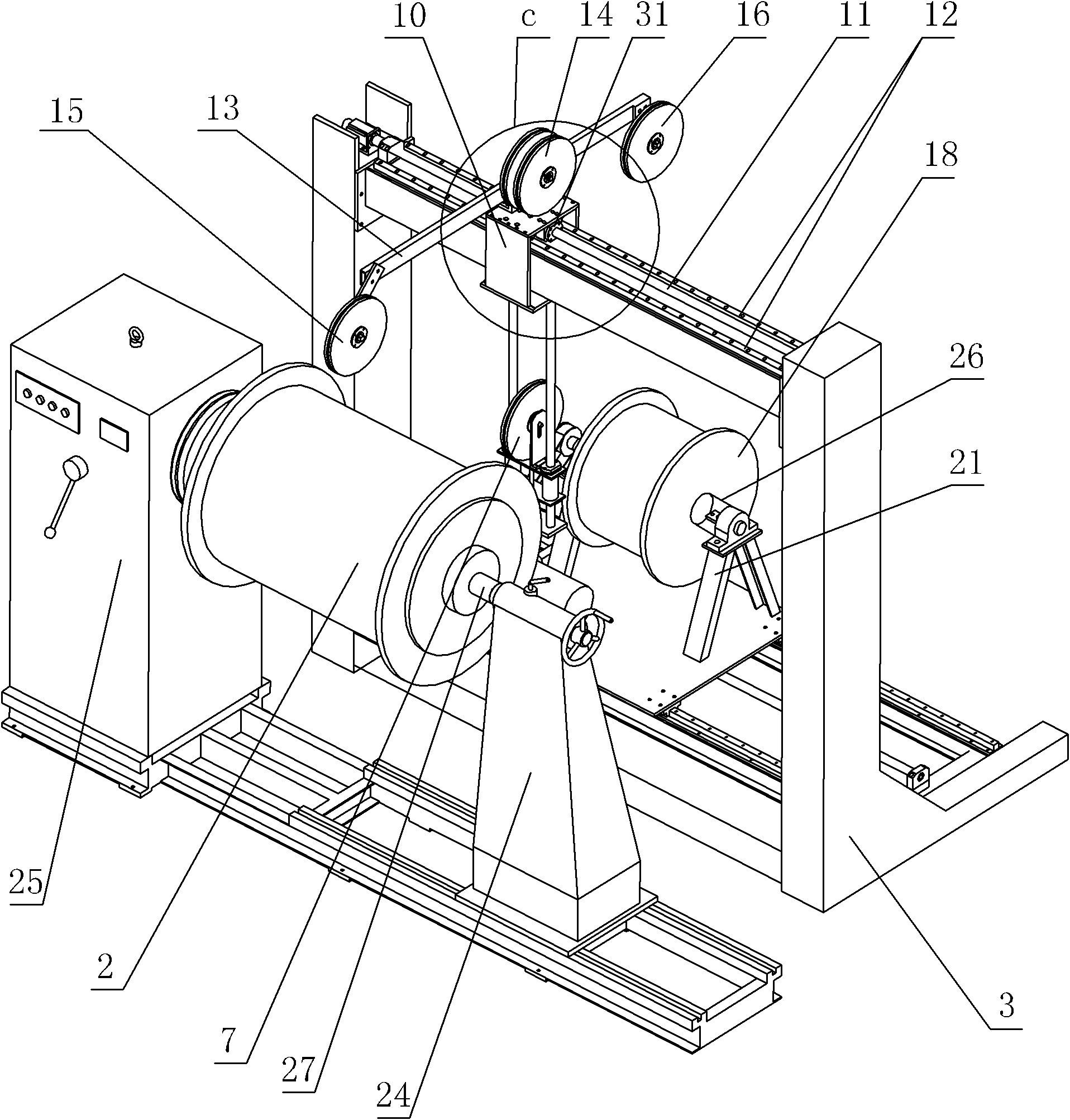

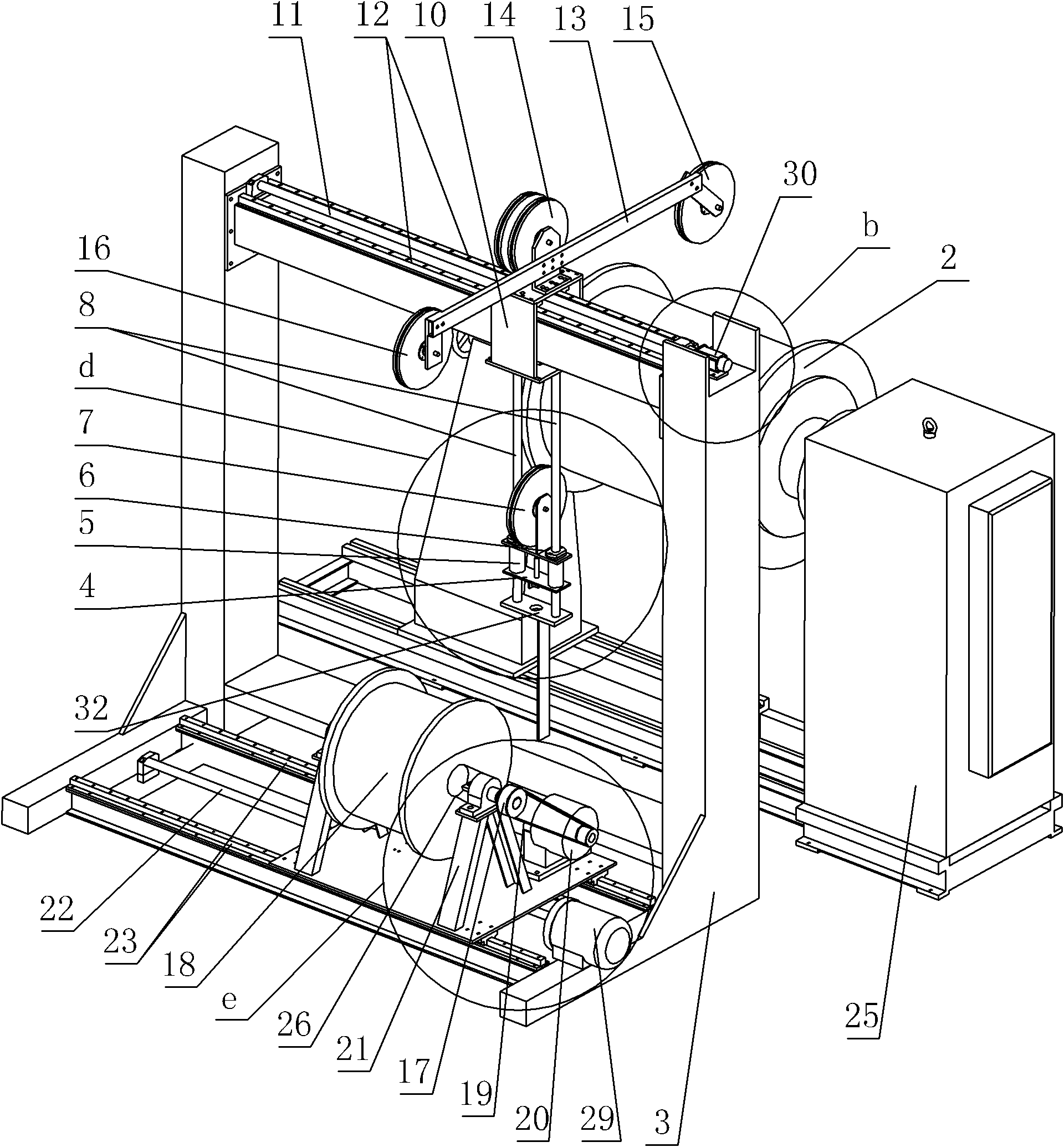

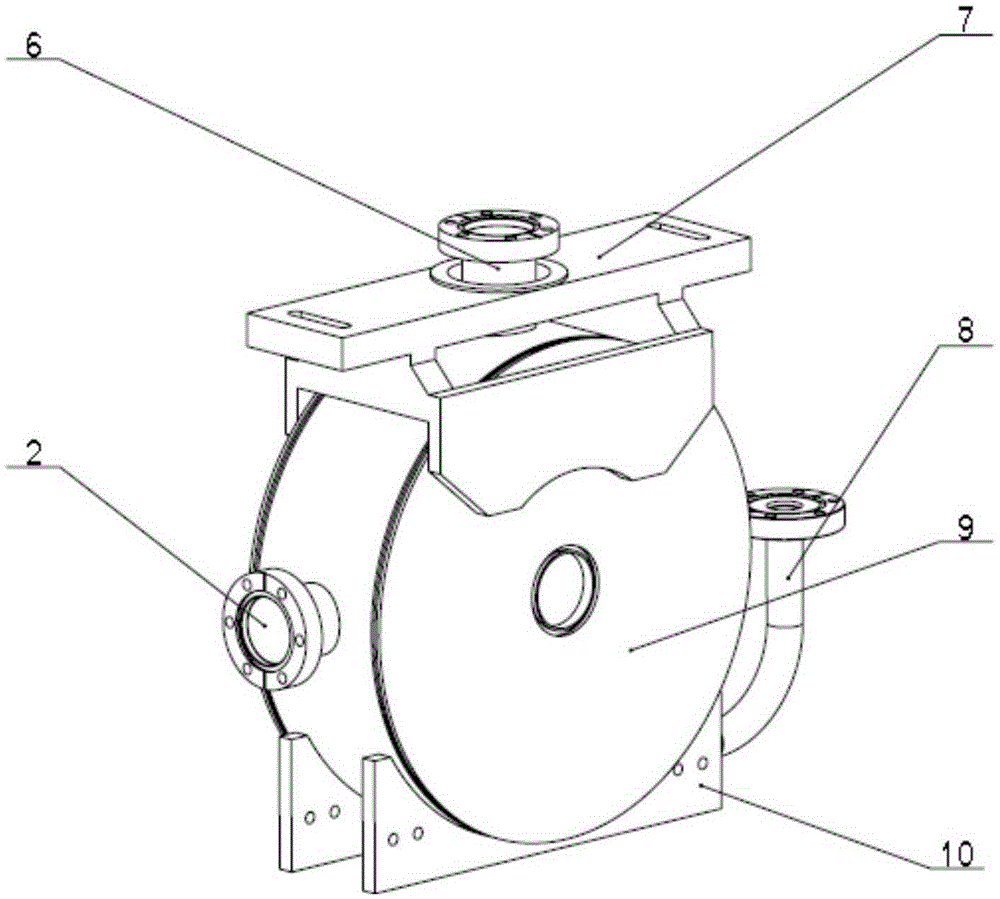

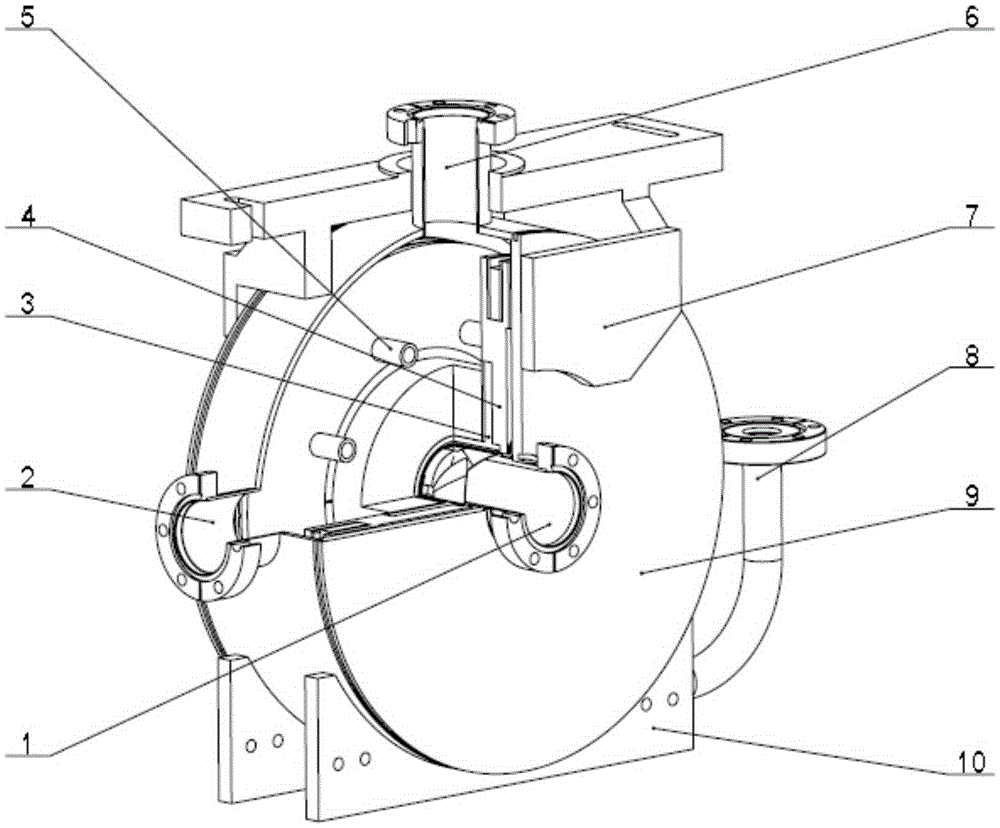

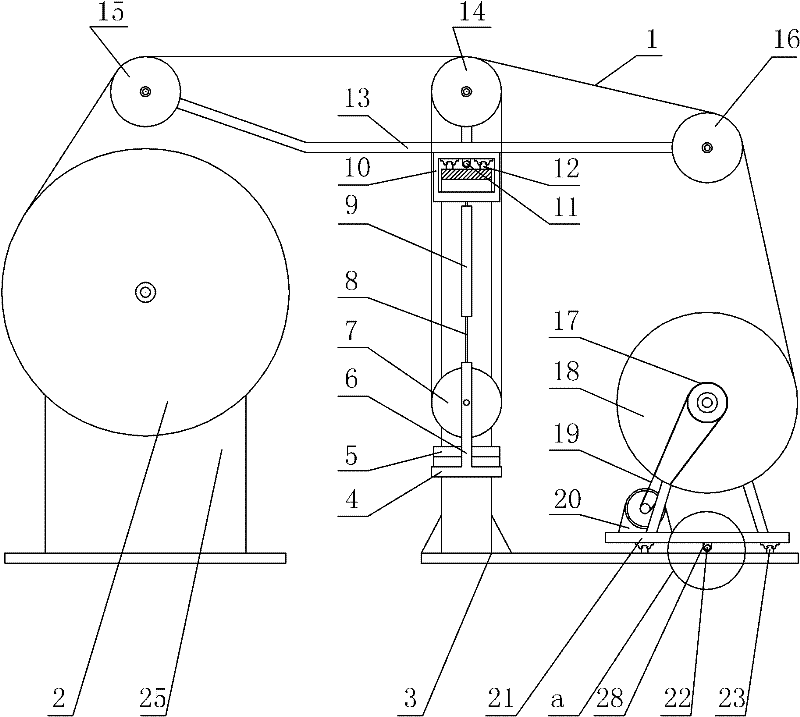

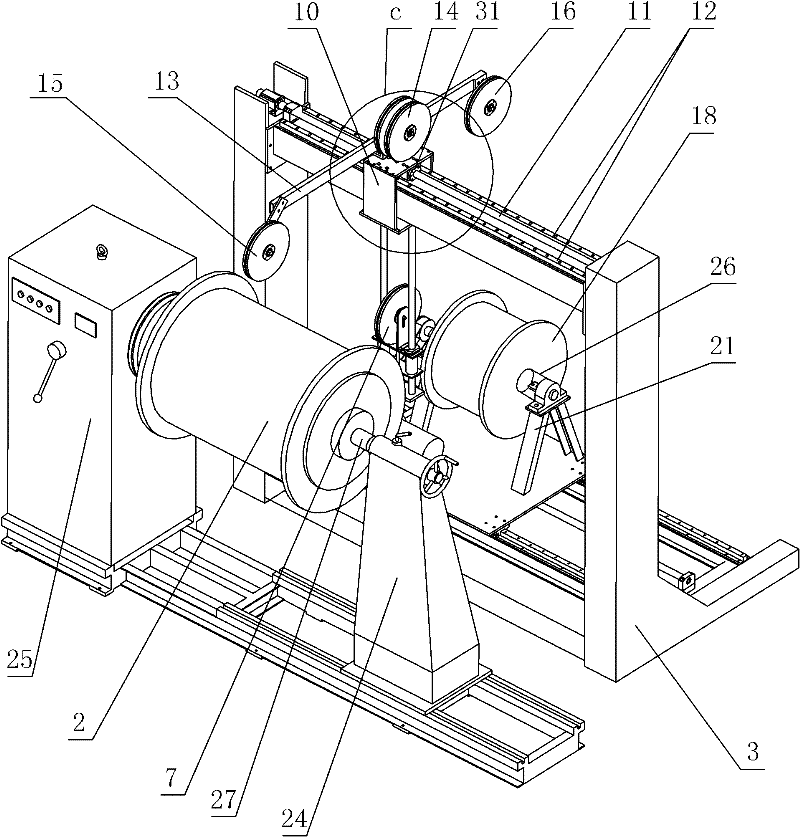

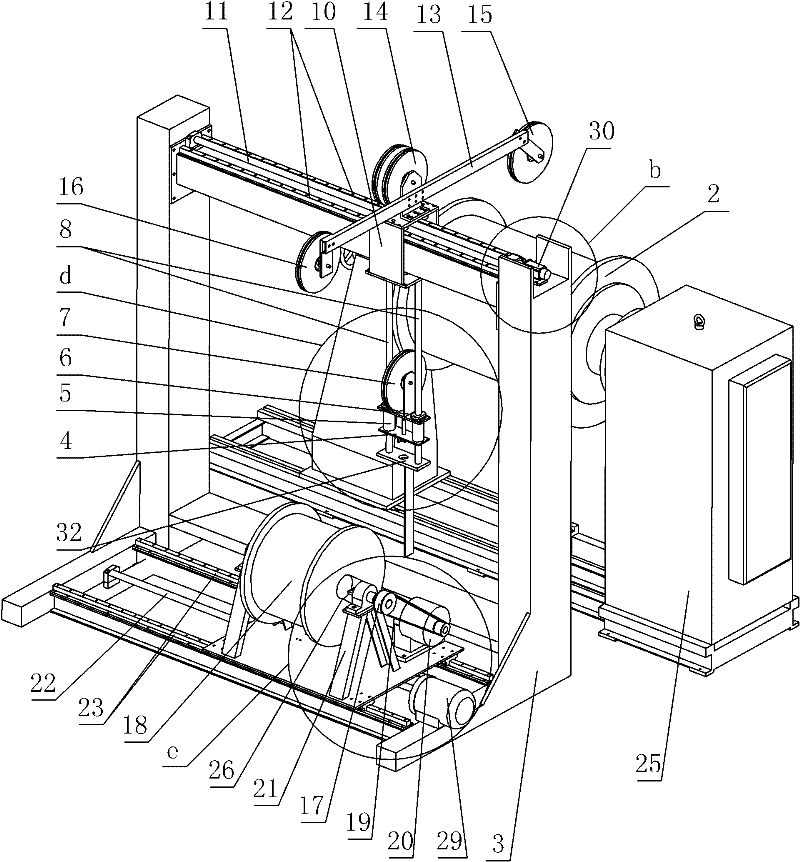

Constant-tension winding machine for niobium titanium-copper superconducting solenoid coils

InactiveCN102030223ACompact space arrangementSmall footprintFilament handlingCoils manufactureWinding machineSuperconducting solenoid

The invention provides a constant-tension winding machine for niobium titanium-copper superconducting solenoid coils, relating to a winding machine for superconducting solenoid coils. The invention solves the problems of complex winding process, high labor intensity of operators and low use ratio of equipment space of the current winding machine for superconducting solenoid coils. In the invention, an L-shaped portal frame is provided with two first slider linear guide rails and a first ball screw, and a double-track pulley is installed on a wiring arm. A wiring support arm of the wiring arm is provided with a wiring pulley, and a wire loading support arm of the wiring arm is provided with a wire loading pulley. A movable pulley is installed on a movable pulley axis support, and a wire loading tray is rotatably installed on a wire loading support. A superconducting solenoid coil to be wound is rotatably installed on a winding support, and a lead wire is led out through the wire loading tray and wound on the superconducting solenoid coil to be wound after moving round the wire loading pulley, one slideway of the double-track pulley, the movable pulley, the other slideway of the double-track pulley and the wiring pulley. The constant-tension winding machine is suitable for winding niobium titanium-copper superconducting solenoid coils.

Owner:HARBIN INST OF TECH

Nuclear magnetic resonance apparatus

InactiveUS7173424B2Magnetic measurementsElectric/magnetic detectionNMR - Nuclear magnetic resonanceSuperconducting solenoid

Owner:HITACHI LTD

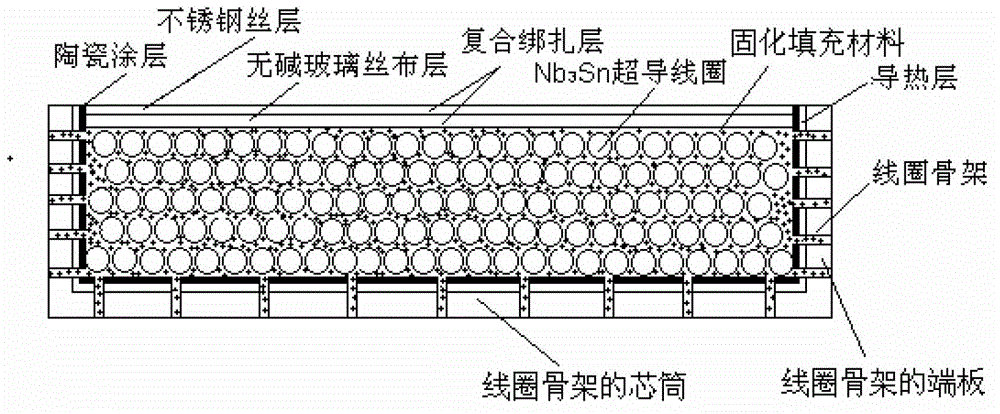

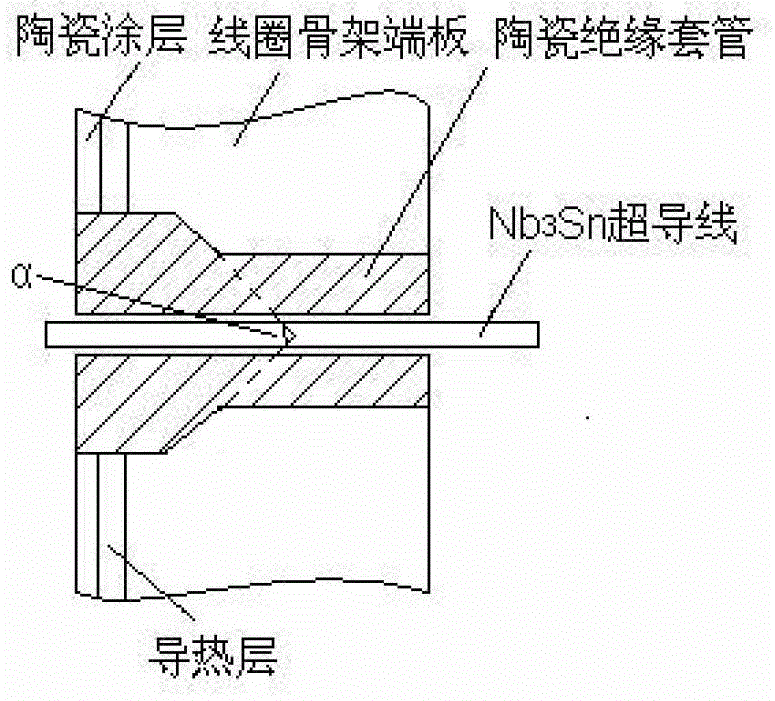

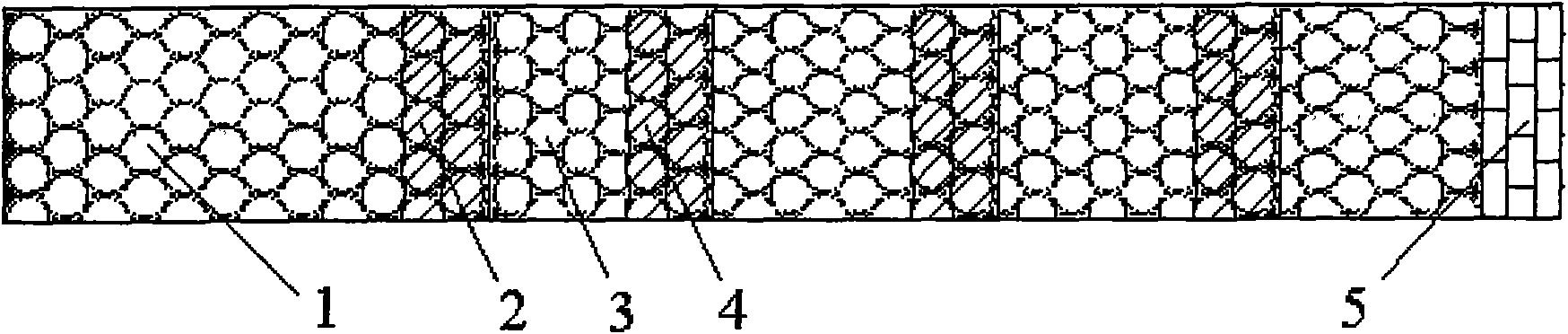

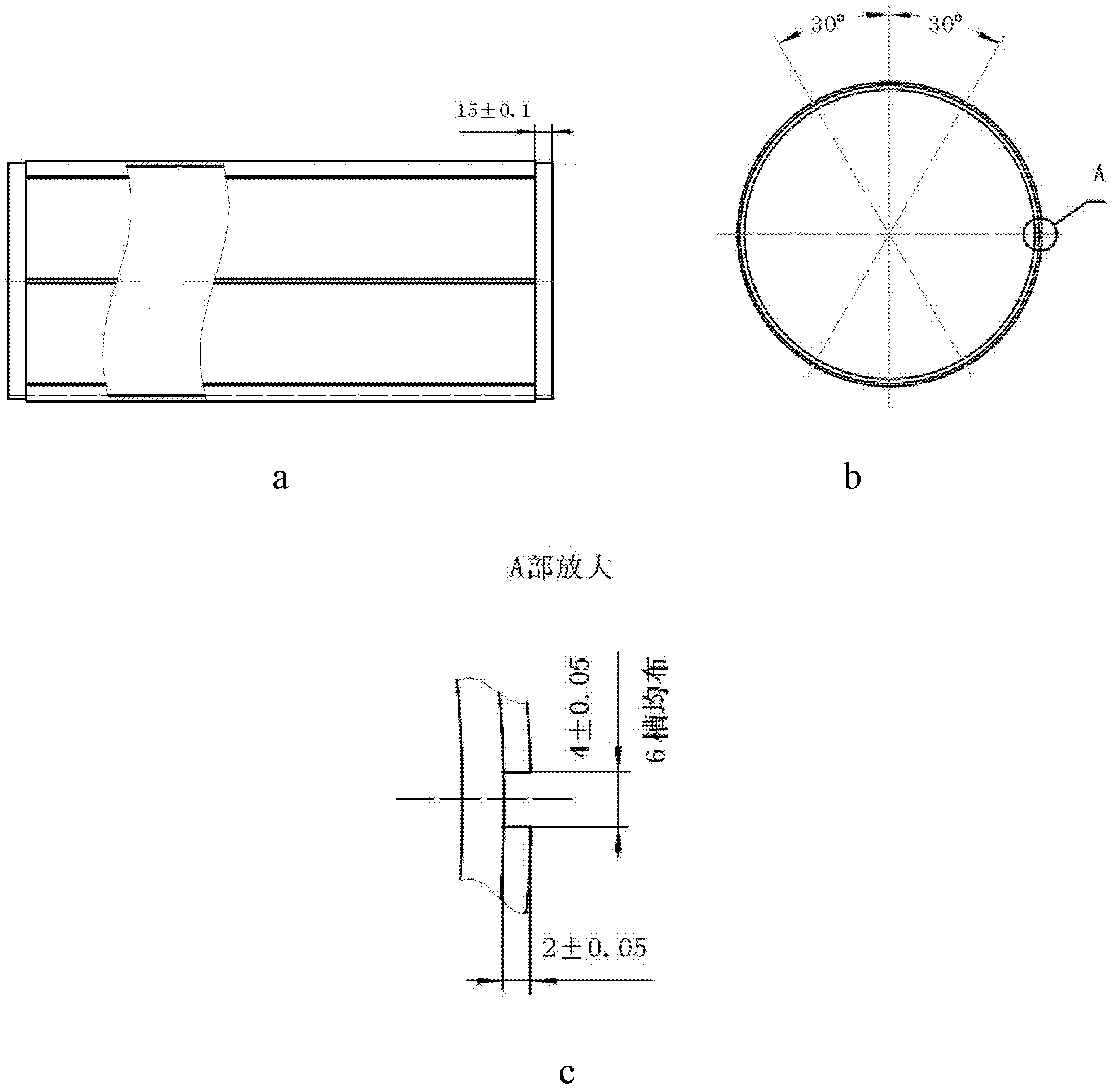

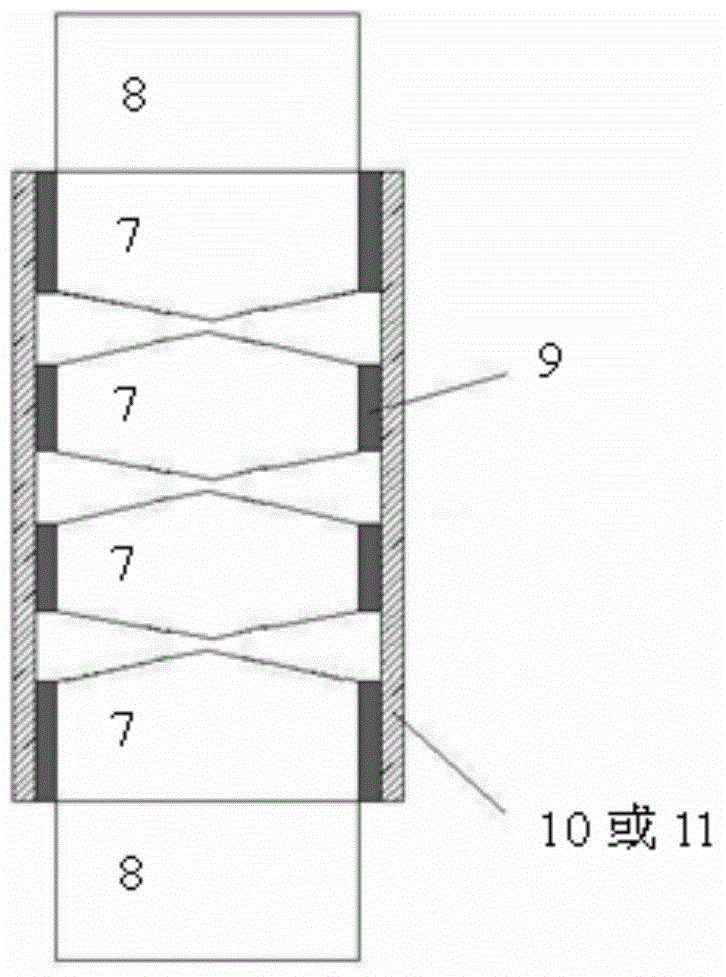

Coil for stainless steel framed Nb3Sn superconducting solenoid

ActiveCN102723162AImprove cooling effectImprove thermal shock resistancePlastic/resin/waxes insulatorsSuperconducting magnets/coilsSuperconducting solenoidCeramic coating

The invention discloses a coil for a stainless steel framed Nb3Sn superconducting solenoid. The coil adopts the structure that a coil frame is made of non-magnetic stainless steel materials and comprises straight tubular core tube and end plates; heat conduction layers and alumina ceramic coating layers are both arranged on the outer surface of the core tube and the inner sides of the end plates, and the heat conduction layers are arranged between the alumina ceramic coating layers and the coil frame; the Nb3Sn superconducting coils are wound outside the ceramic coating layers; a composite binding layer is arranged at the outermost layer of each superconducting coil, and a piece of high-temperature resistant non-alkali fiberglass cloth serves as the inner layer of the composite binding layer, and the outer layer is a non-magnetic stainless steel wire; solidification packing material is fully filled in the gaps among the superconducting coils in a vacuum impregnation manner; through holes are uniformly formed on the coil frame; and ceramic insulation sleeves are installed in the wire-inlet / wire-outlet of the coil frame end plates, and the Nb3Sn superconducting coils pass through the ceramic insulation sleeves to lead outside the coil frame, wherein the ceramic insulation sleeves adopt a similar T-shaped hollow cylindrical structure, and are used for separating and locating the Nb3Sn superconducting coils and the coil frame, so as to maintain the electric insulation.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

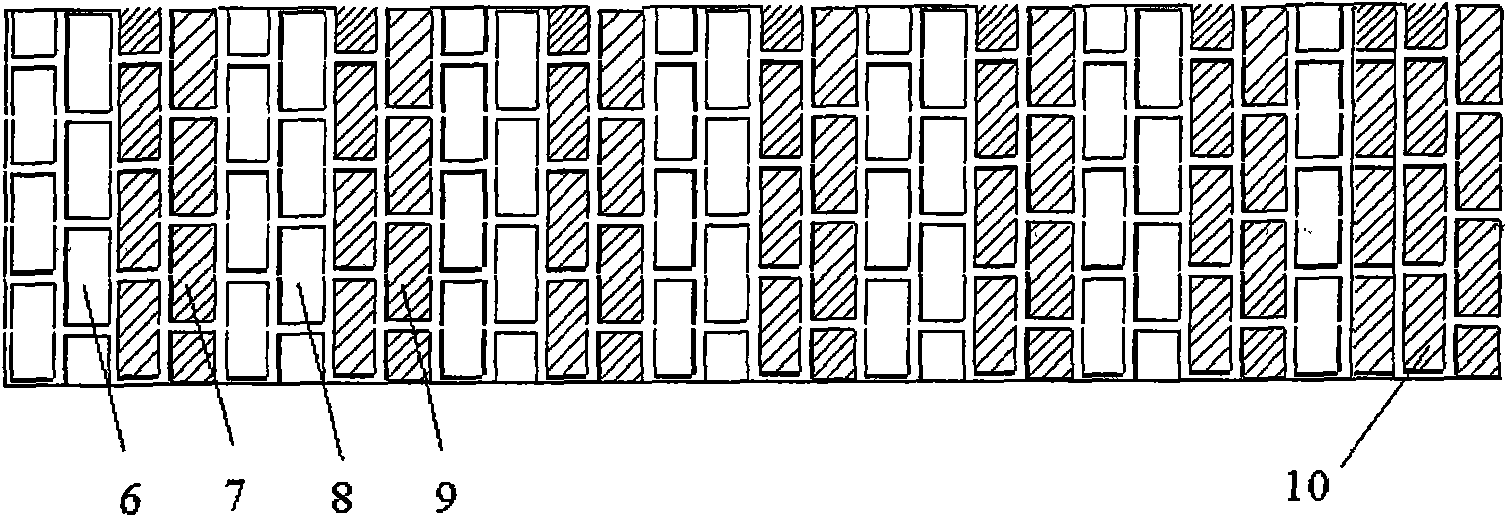

High-field superconducting solenoid coil with dispersive stress and winding method thereof

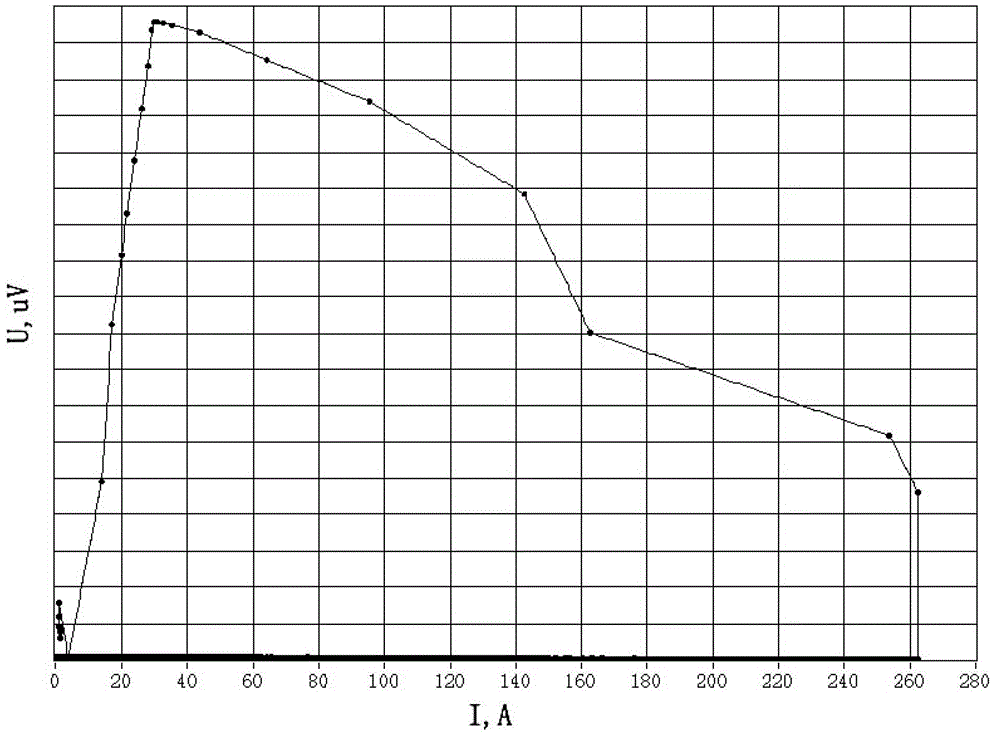

InactiveCN101577166ASuperconducting magnets/coilsCoils manufactureStress concentrationSuperconducting solenoid

The invention discloses a high-field superconducting solenoid coil with dispersive stress and a winding method thereof. The superconducting coil is divided into a plurality of layers by a stainless support layer; the superconducting coil is firstly wound into a superconducting line layer from inside to outside according to a radial direction; the outer surface of the superconducting line layer is wound with stainless steel wires by 1-2 layers, wherein the stainless steel wire is the same as the superconducting line in diameter, therefore, a stainless steel wire support layer is formed. Then alternative winding is carried out in sequence, finally the outermost end of the superconducting coil uses rectangular stainless steel wires to wind a support structure at the end so as to strengthen the whole coil and form the whole superconducting solenoid coil with dispersive stress. The invention not only can reduce the stress concentration in the superconducting winding, but also can greatly reduce the quench exercise times of the coil, and effectively improve the density of running current of the magnet. The coil with the structure is suitable for a high-field superconducting magnet system, in particular to a 25 to 30 T high-field superconducting magnet system.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

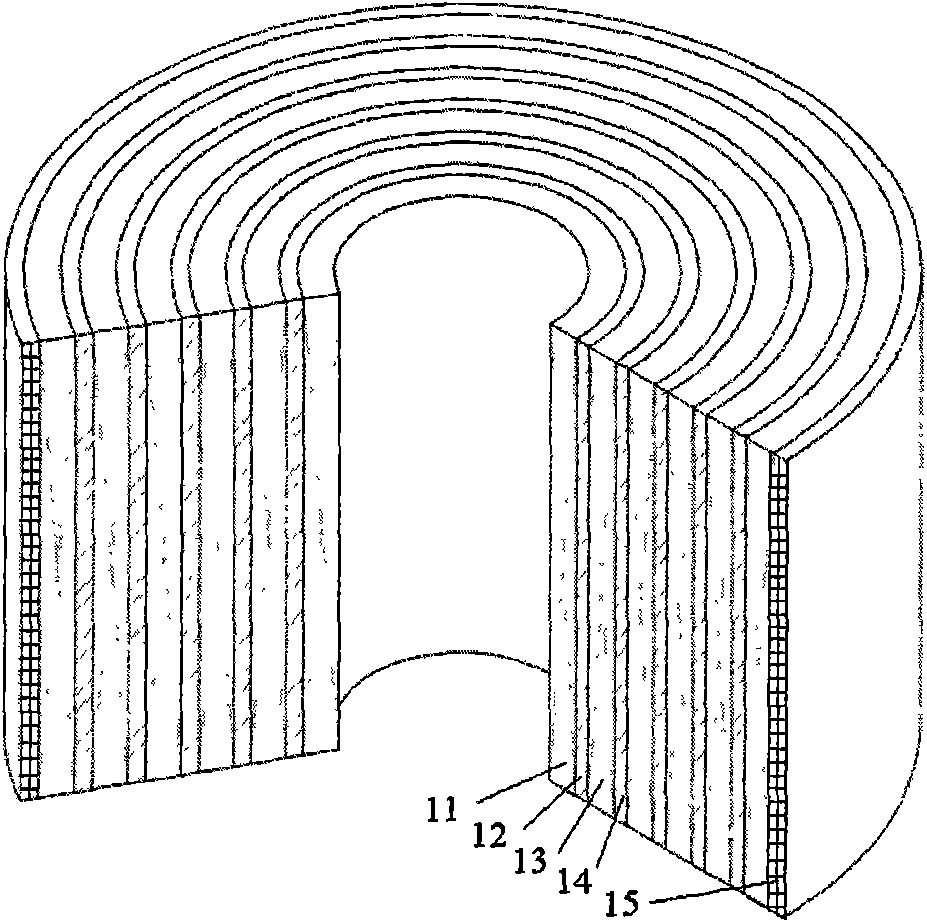

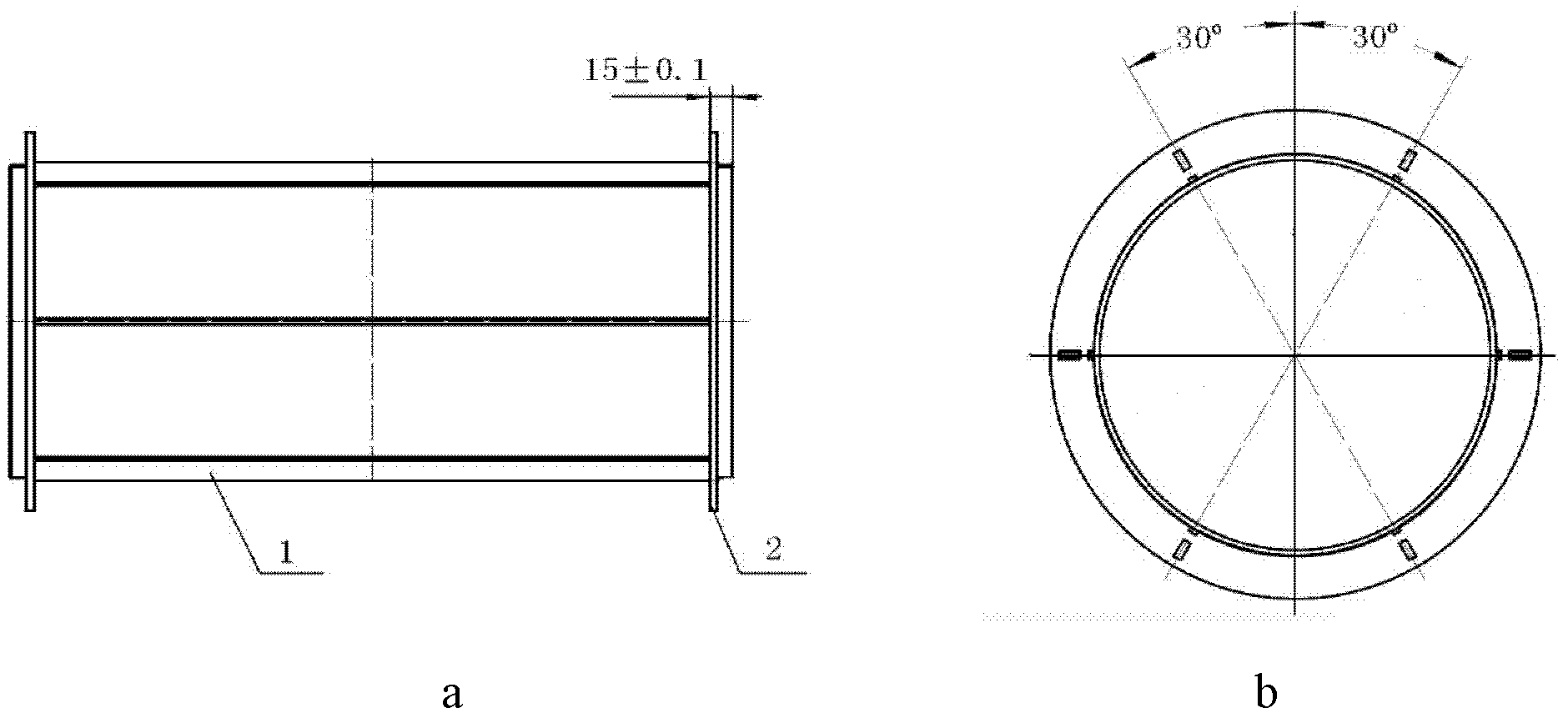

Framework applied to superconductive solenoid magnet

ActiveCN102496439AHigh thermal conductivityGuaranteed uptimeTransformers/inductances coils/windings/connectionsSuperconducting magnets/coilsSuperconducting solenoidCooling down

The invention relates to a framework applied to a superconductive solenoid magnet. The framework is characterized in that two end plates are sleeved on and closely clung to boss structures at two ends of a central cylinder; six rectangular gaps of each end plate are arranged corresponding to six rectangular slots of the central cylinder to form six rectangular holes; the diameters of the two endsof the central cylinder are small diameters and are equal to the diameters of inner through holes of the end plates, and the diameter of each boss is a large diameter and is equal to the inner diameter of a solenoid magnet to be wound. The framework applied to the superconductive solenoid magnet, disclosed by the invention, has a simple structure, is convenient to manufacture; and through adoption of the stainless steel framework device, excellent support is provided for a superconductive solenoid coil and an excellent cooling channel is provided for cooling down the superconductive solenoid coil by using a coolant by utilizing a.

Owner:西部超导材料科技股份有限公司

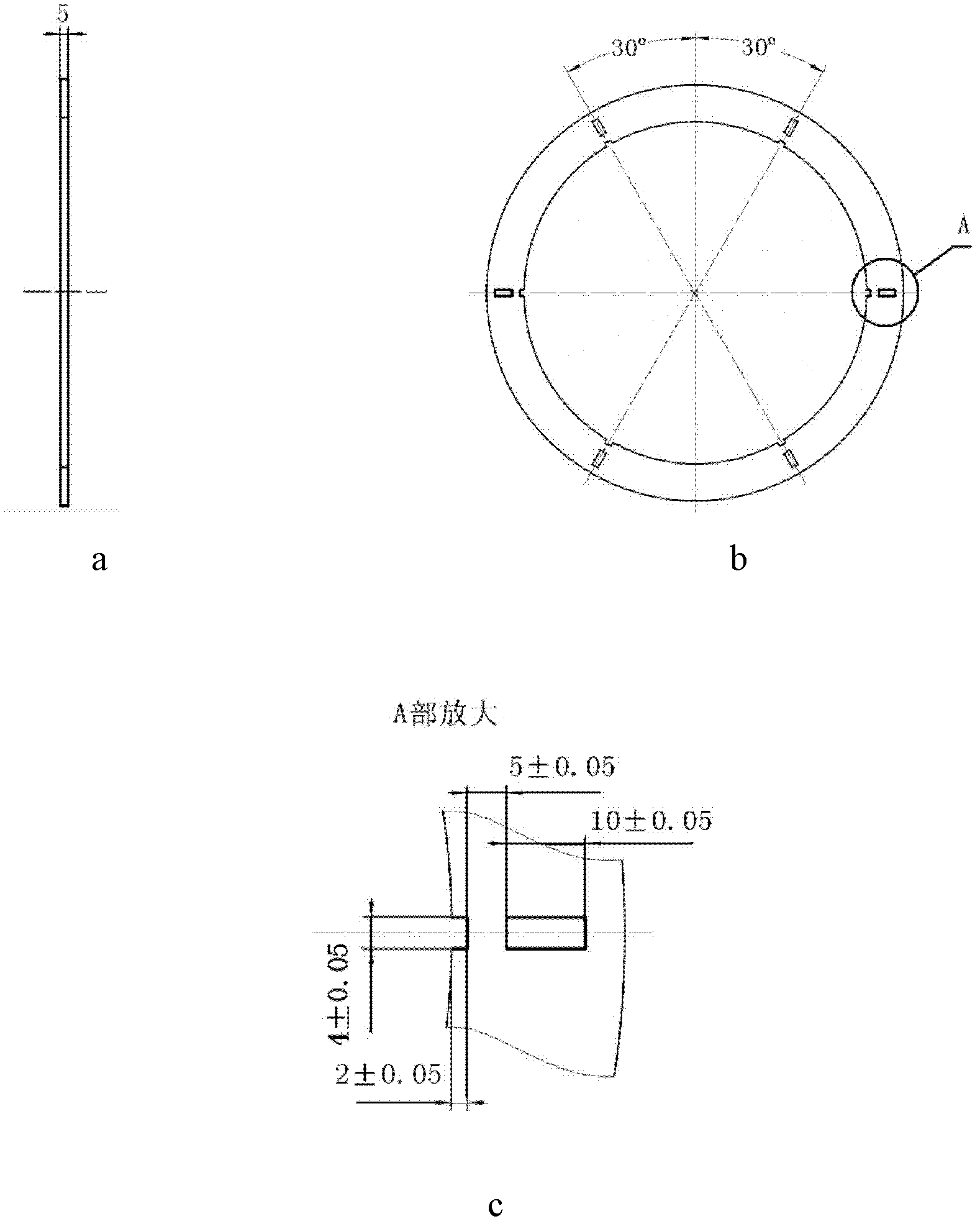

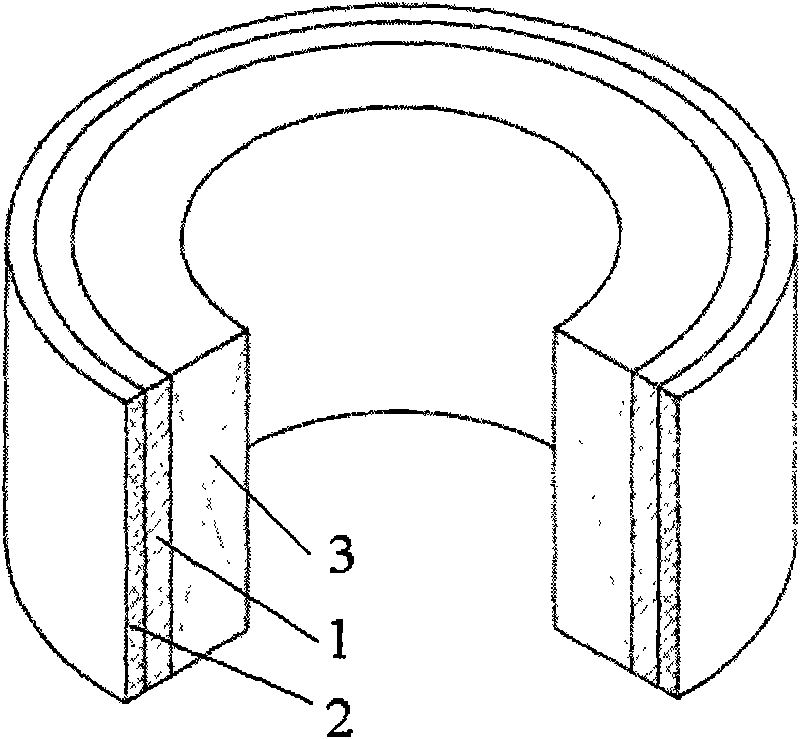

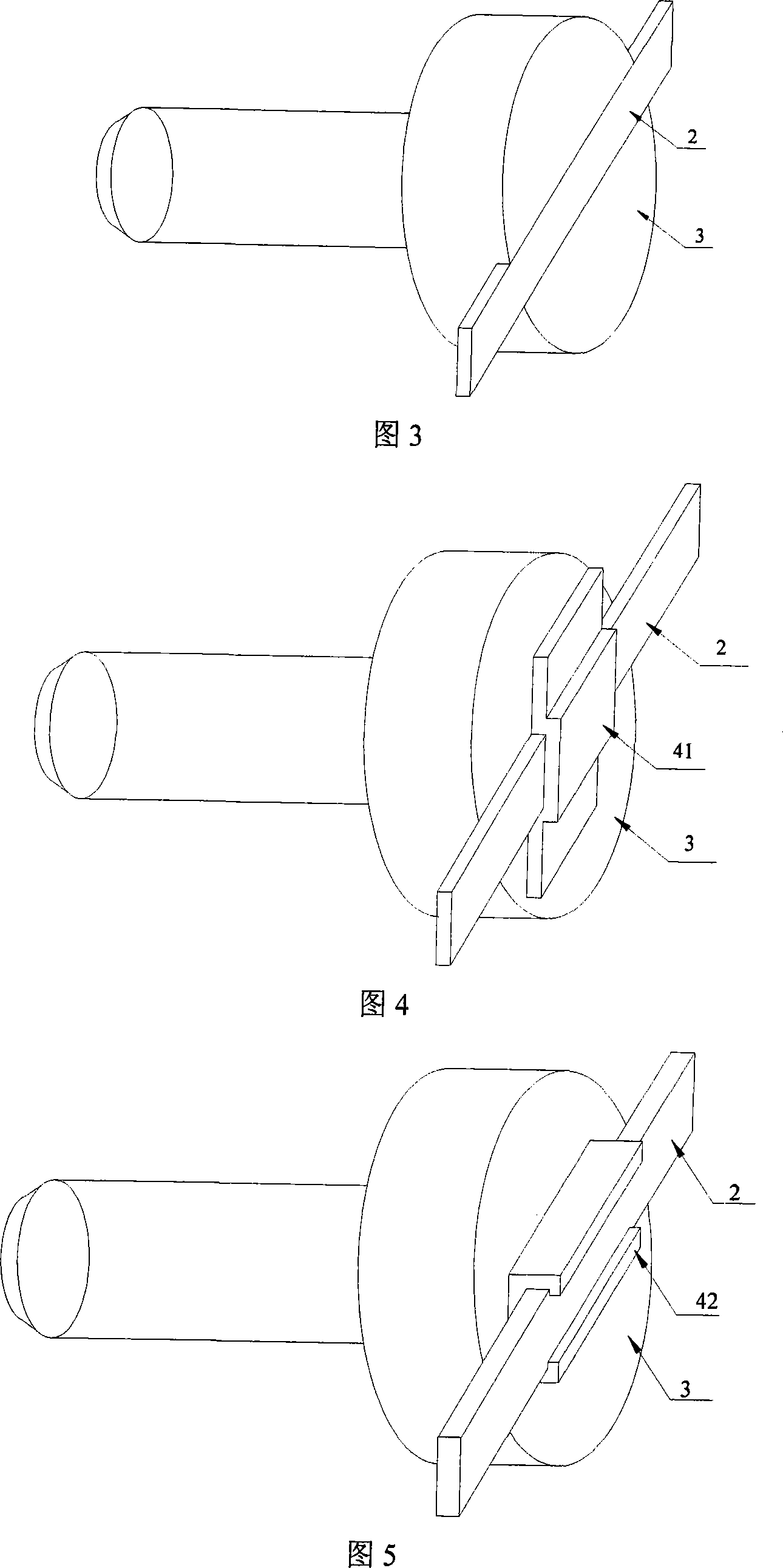

Stress support ring for highfield superconducting solenoid coil and mounting method

InactiveCN101593597AInductances/transformers/magnets manufactureSuperconducting magnets/coilsMetallurgySuperconducting solenoid

The invention provides a stress support ring for a highfield superconducting solenoid coil, which is characterized in that: a support ring (4) consists of an inner aluminium alloy support ring (1) and an outer stainless steel support ring (2). The method comprises the following steps: slowly cooling the inner aluminium alloy support ring (1) to the liquid nitrogen temperature of 77K by cold nitrogen, heating the outer stainless steel support ring (2) to 300 DEG C, and directly sleeving the inner aluminium alloy support ring (1) into the outer stainless steel support ring (2) to form strong bonding force between the stainless steel ring and the aluminium alloy ring so as to form the support ring (4); slowly cooling a superconducting coil (3) to the liquid nitrogen temperature of 77K by cold nitrogen gas; and heating the support ring (4) to 200 DEG C, and directly assembling the superconducting coil (3) into the support ring (4). The stress support ring for the highfield superconducting solenoid coil can effectively inhibit the stress problem of the highfield superconducting coil and reduce quench hardening times of the superconducting coil and degradation of critical current density.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

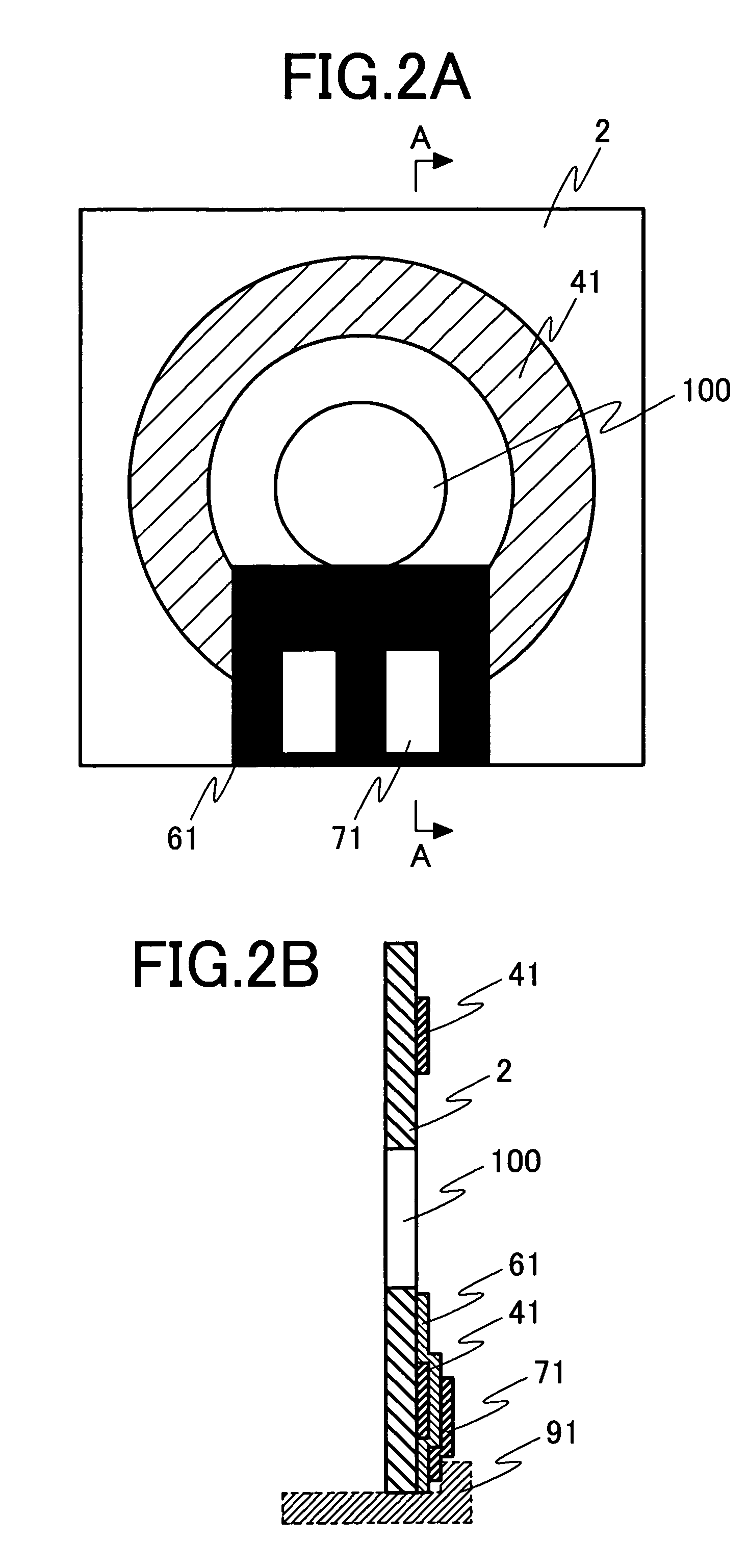

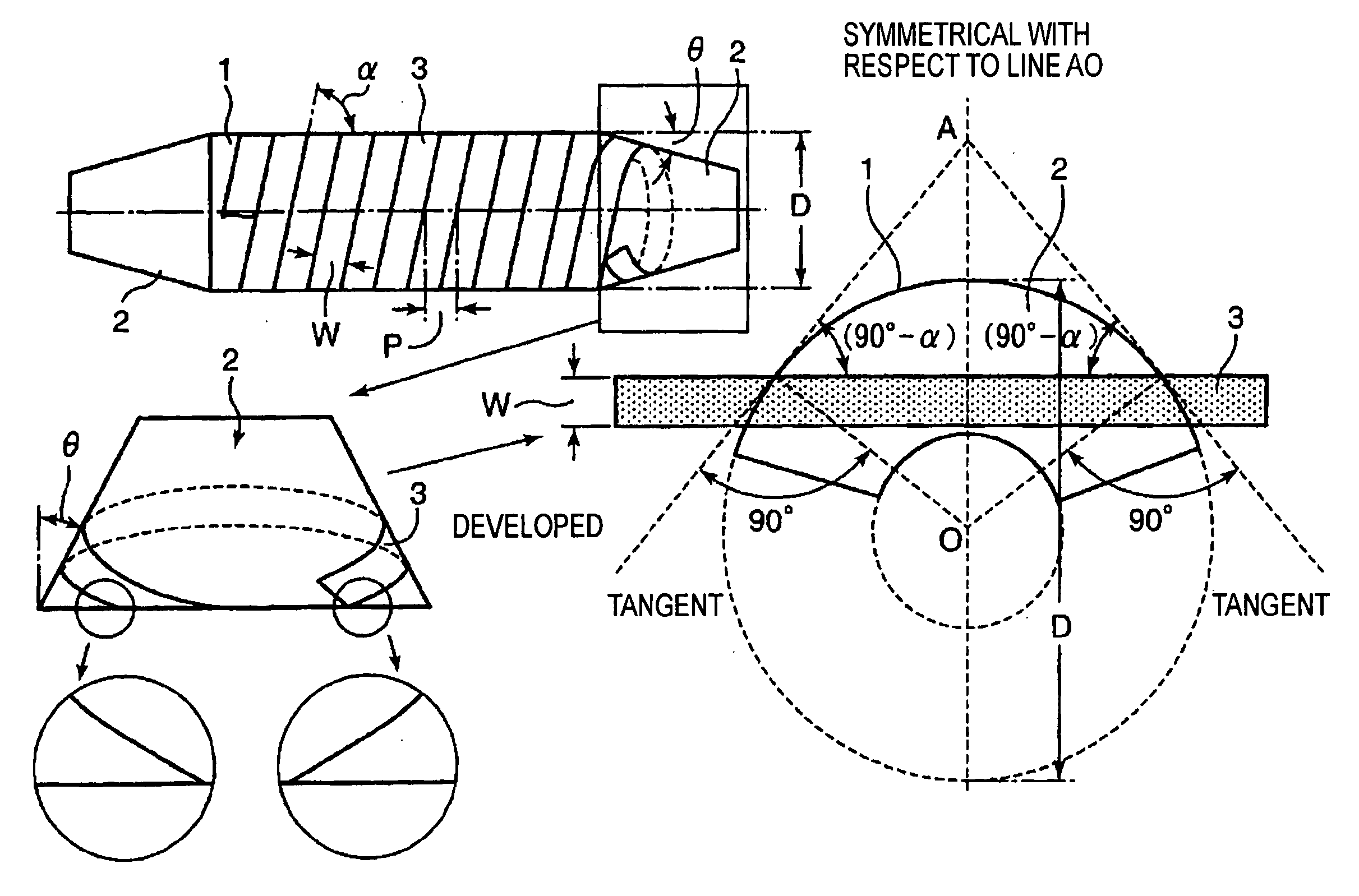

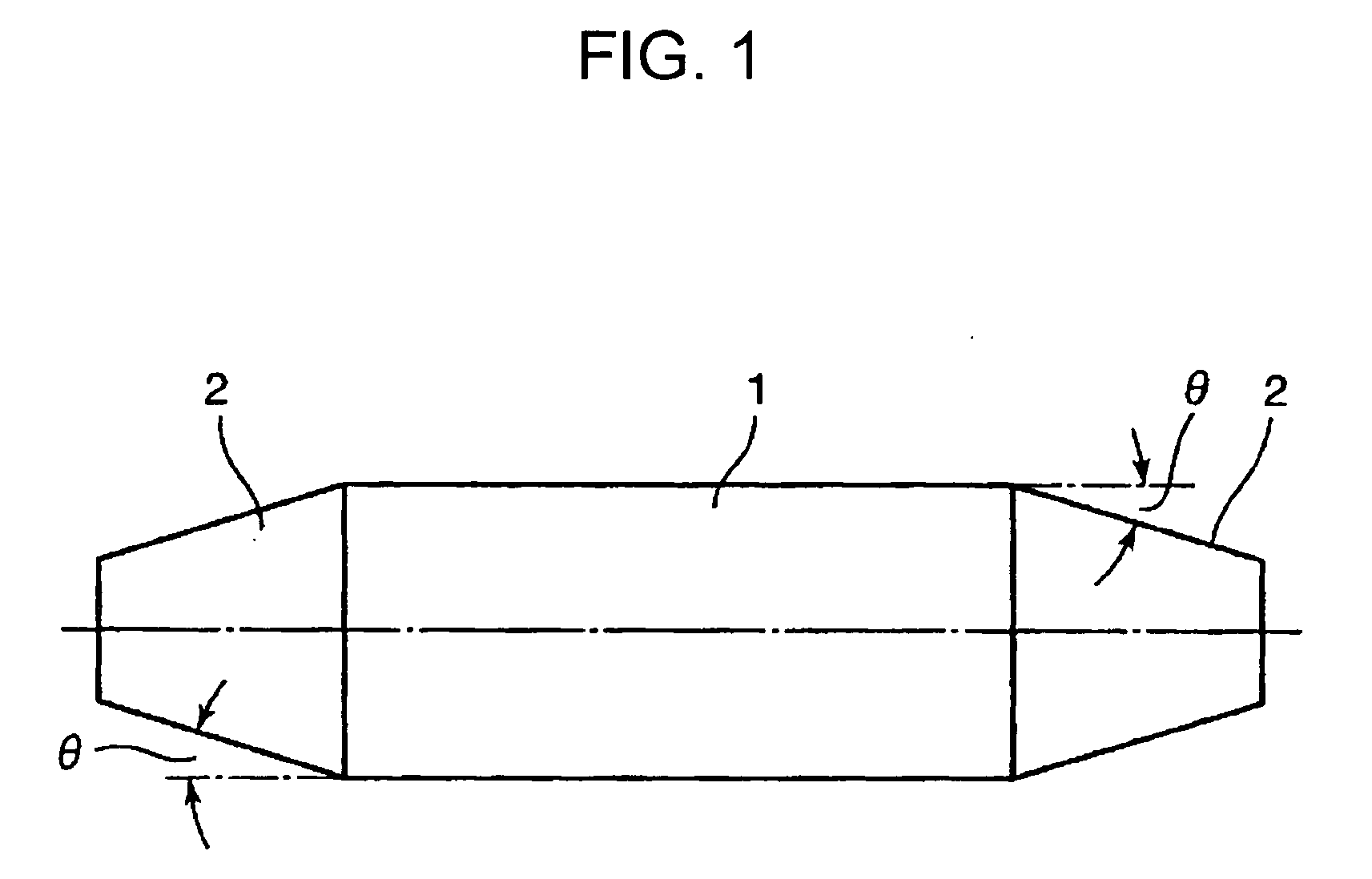

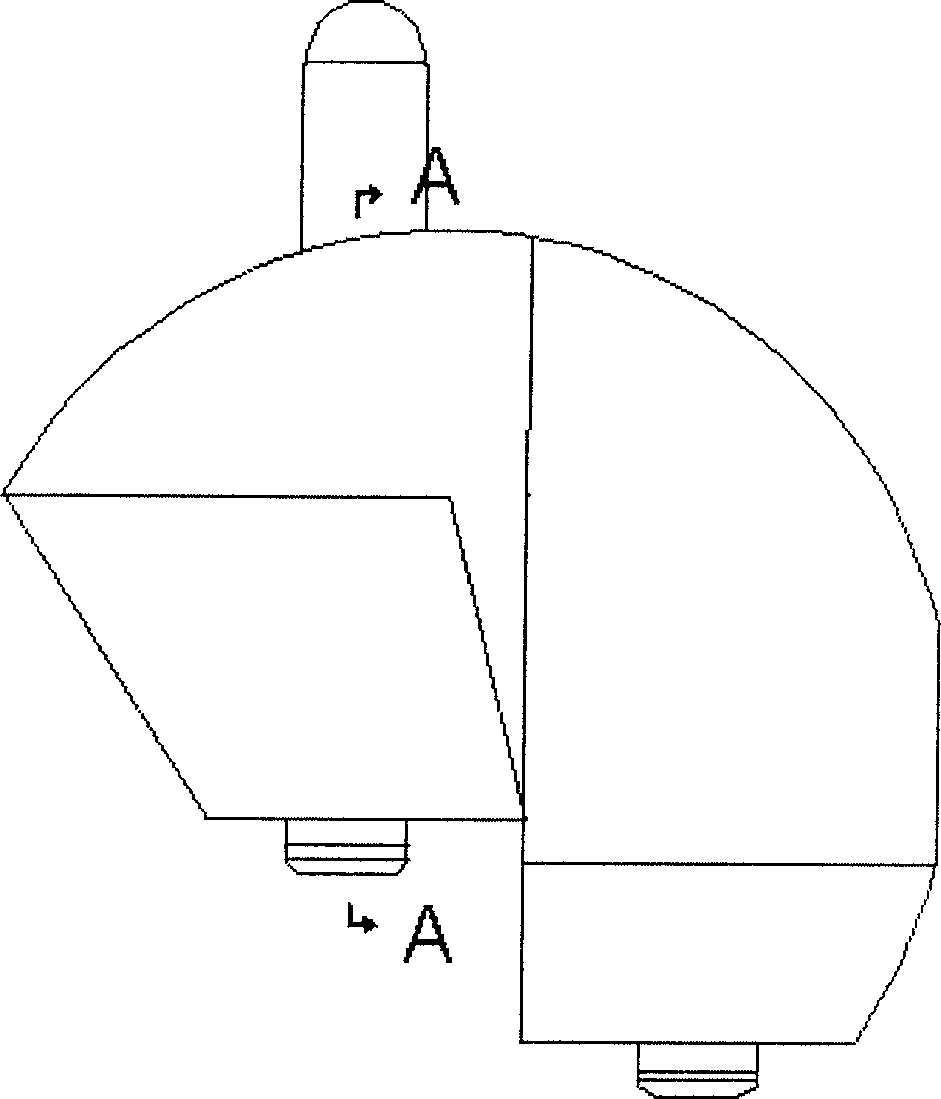

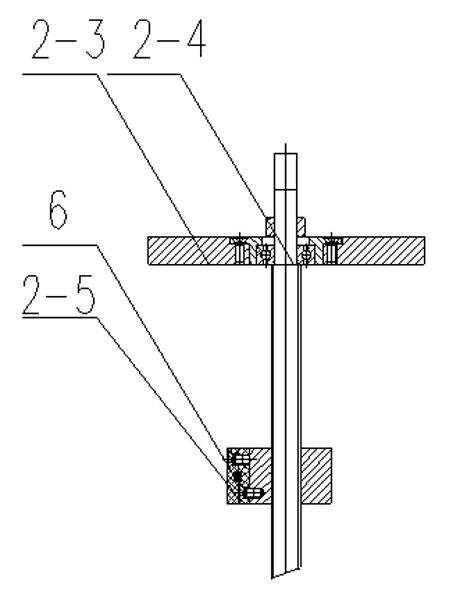

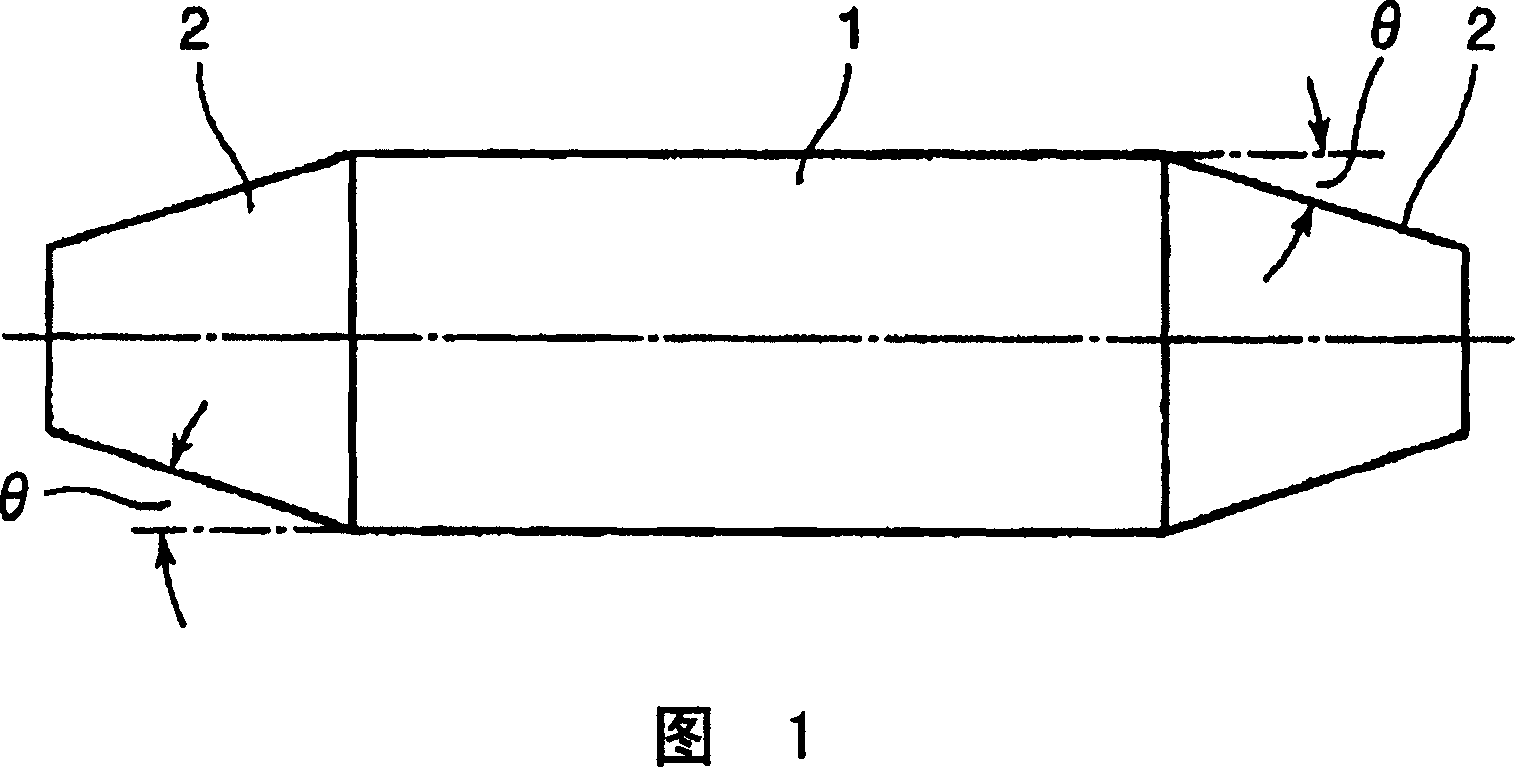

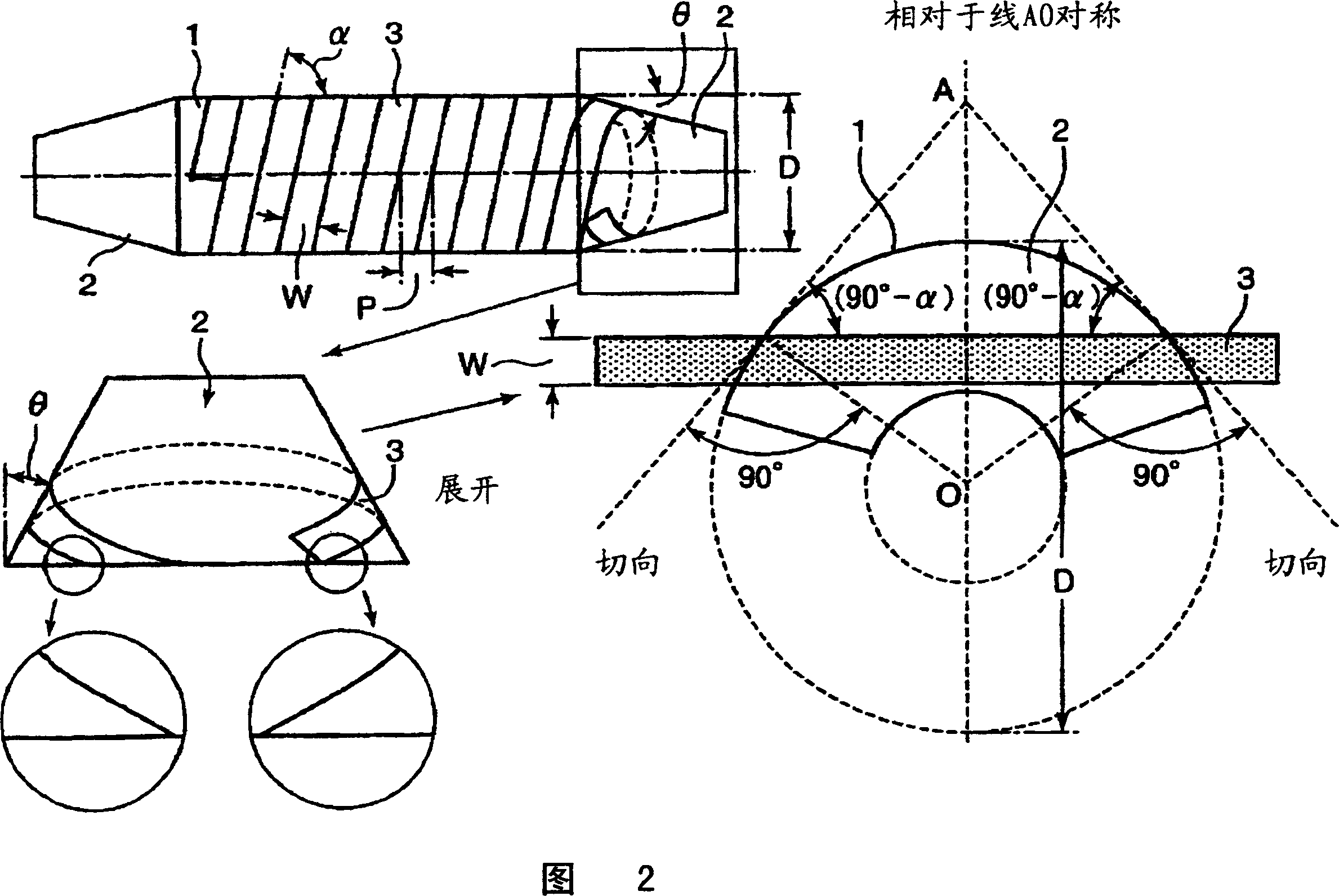

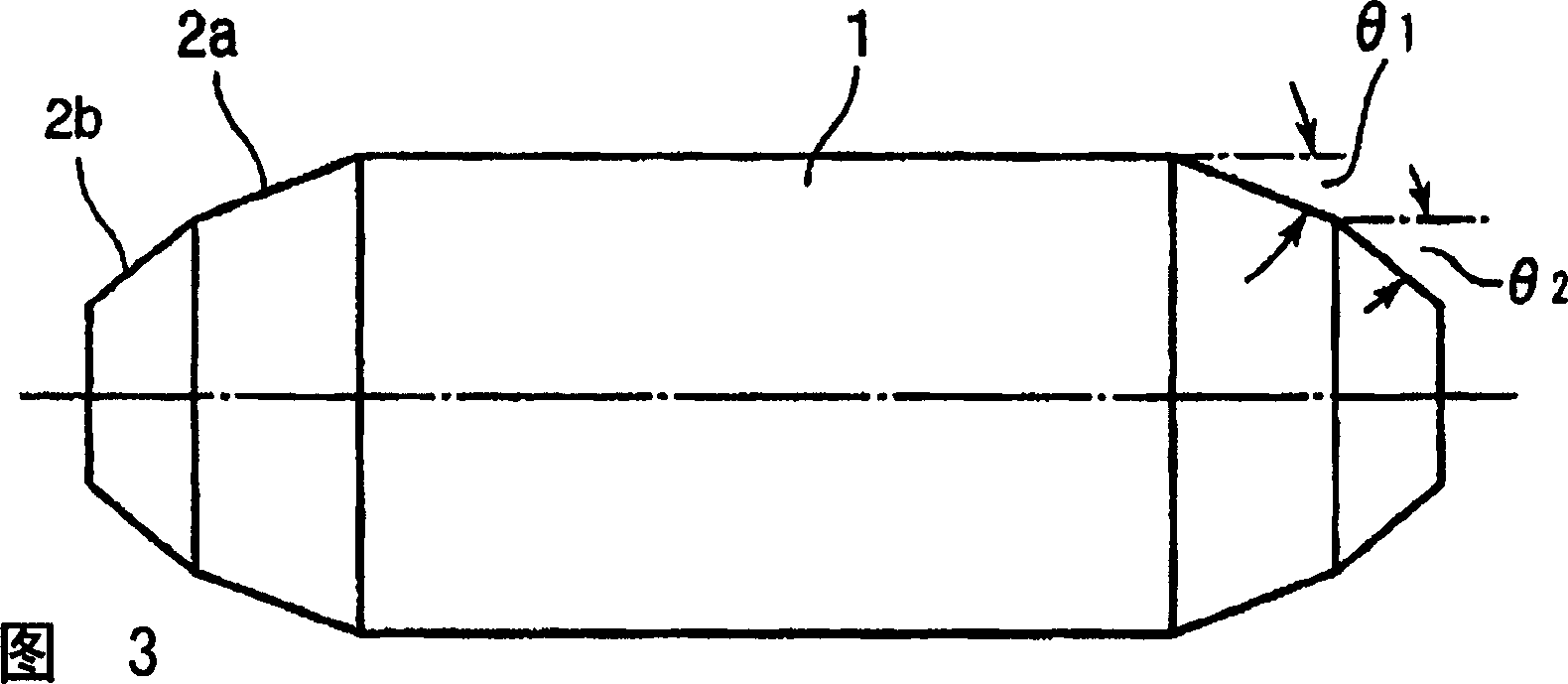

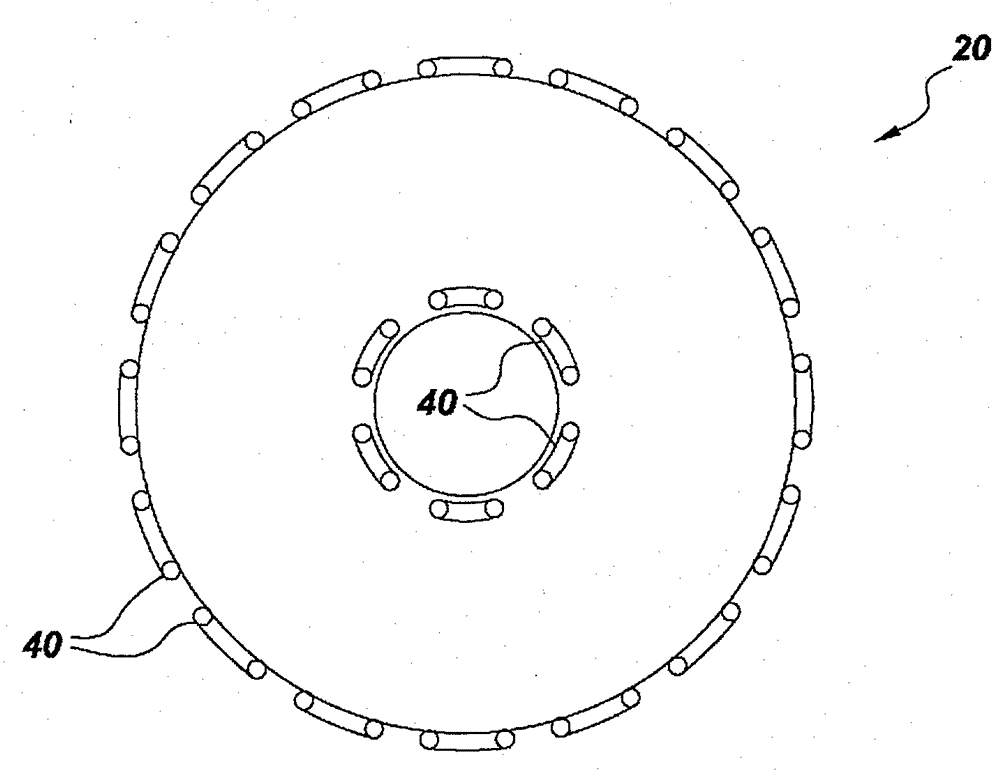

Bobbin for superconducting coil, and superconducting solenoid coil

InactiveUS20070052507A1Simple structureEasily and smoothly and helicallyMagnetic measurementsMagnetsBobbinSuperconducting solenoid

A bobbin for a superconducting coil includes a cylindrical drum, and a tapered portion extending from each end of the drum. A superconducting wire or a precursor of the superconducting wire shaped like a tape is helically wound around the drum in multiple layers. The tapered portion has a tapered surface that is inclined at an arbitrary angle.

Owner:KOBE STEEL LTD

Apparatus and method of superconducting magnet cooling

InactiveUS20100242502A1Reduce manufacturing costReduce operating costsMagnetic measurementsEnergy industrySuperconducting solenoidSuperconducting Coils

Owner:GENERAL ELECTRIC CO

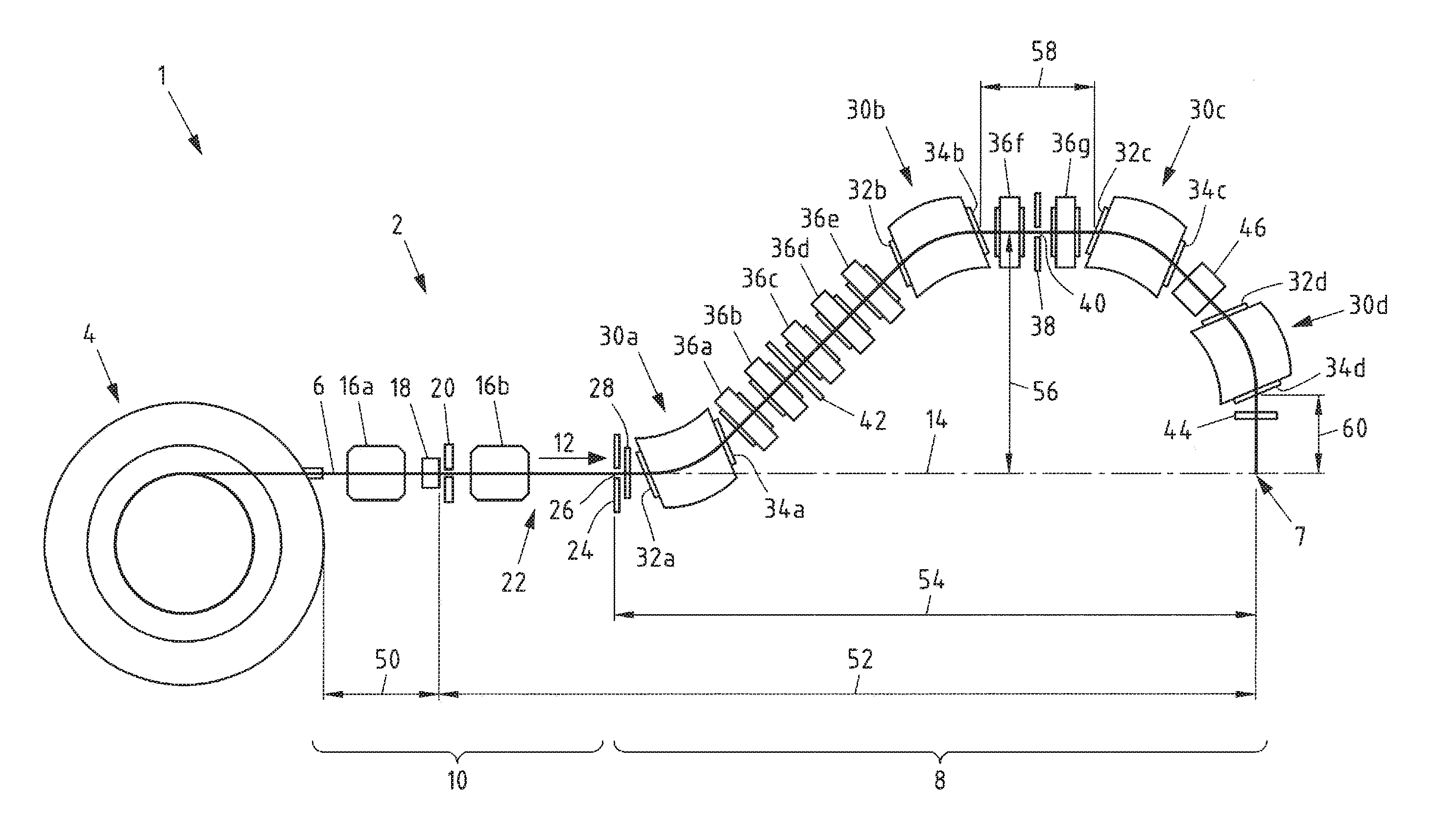

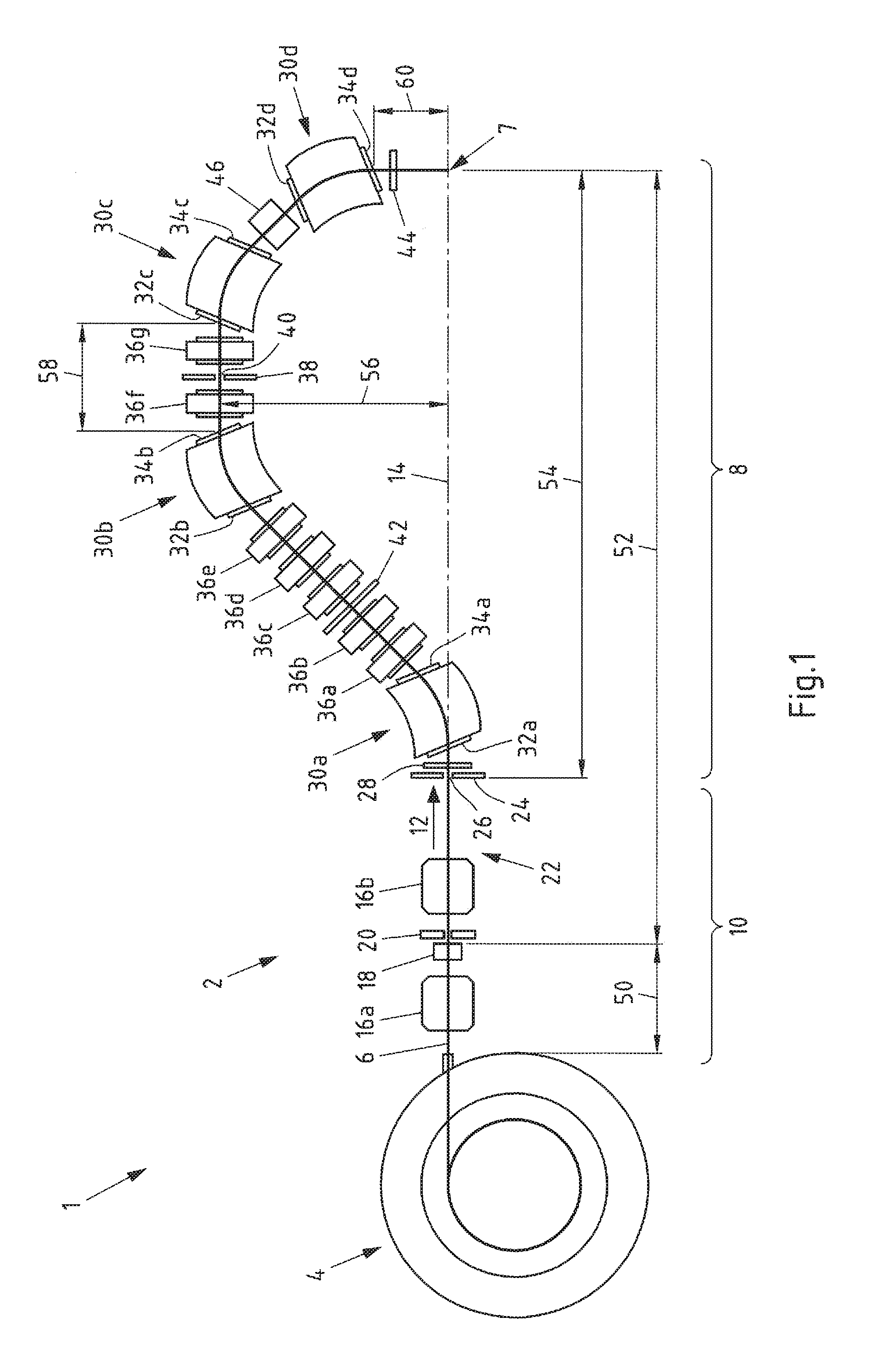

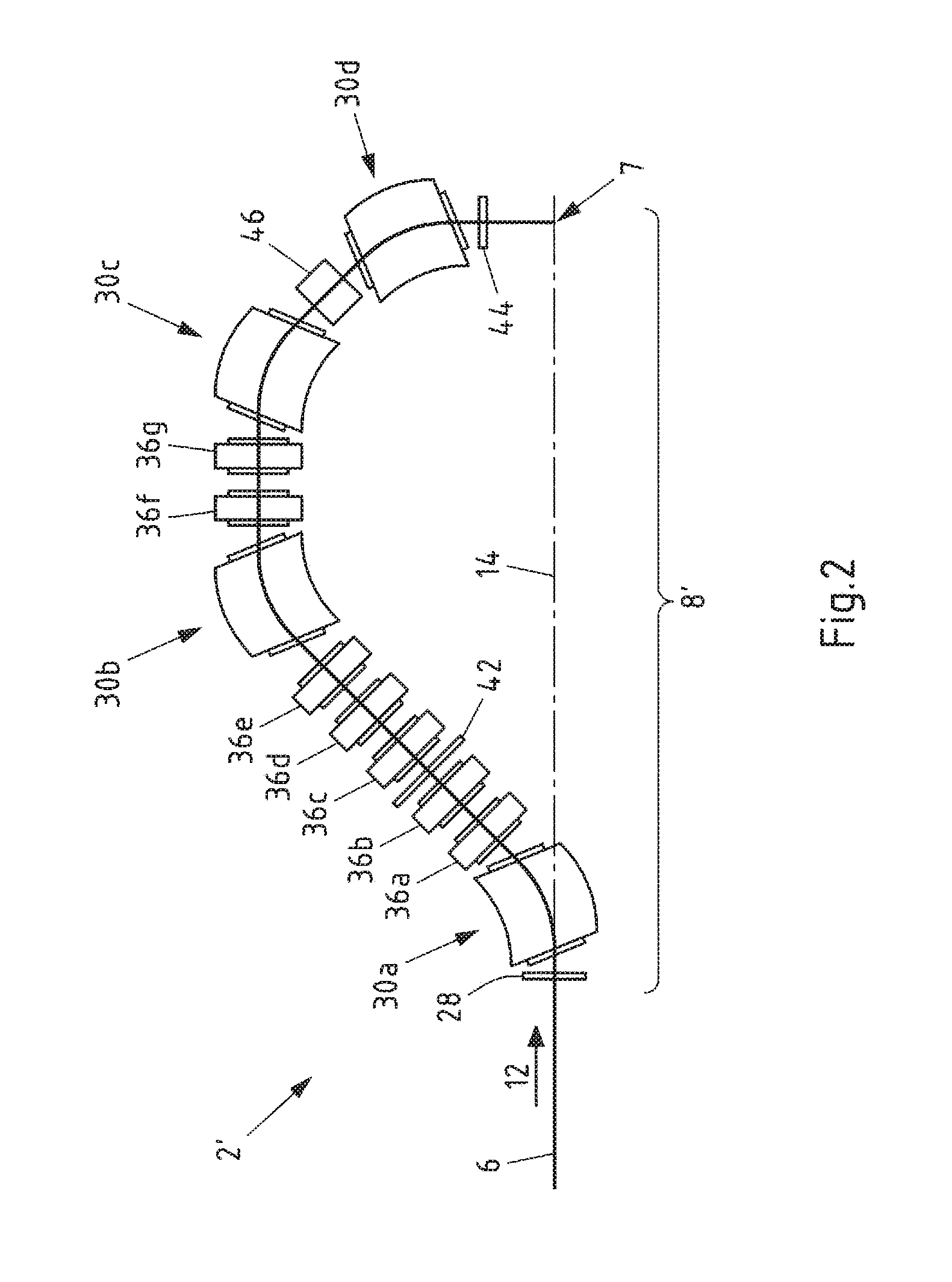

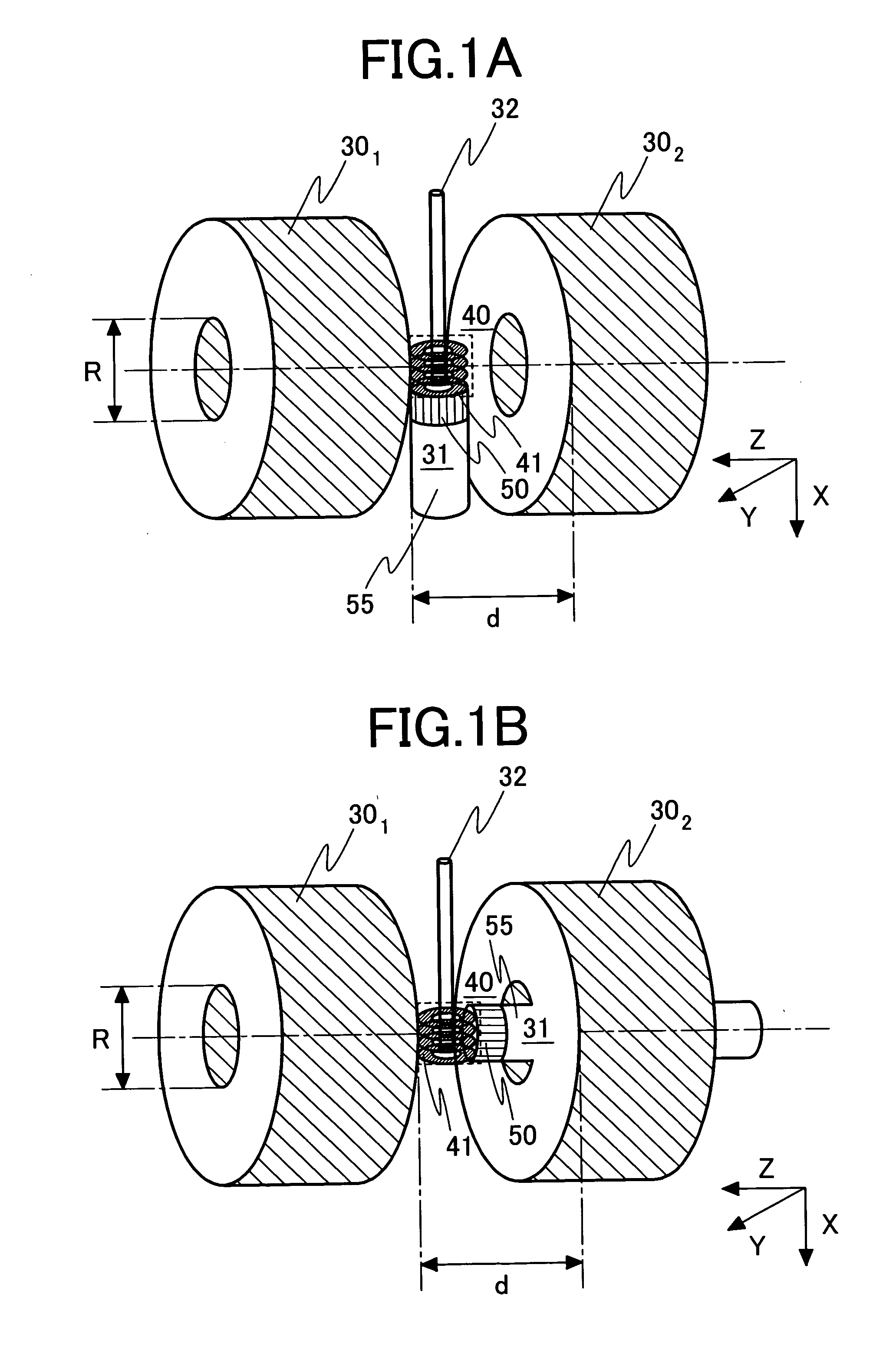

Particle beam treatment system with solenoid magnets

InactiveUS20170007848A1Improve propertiesIncrease spacingRadiation/particle handlingElectric discharge tubesGuidance systemSuperconducting solenoid

A particle beam treatment system having a beam generation unit for generating a beam of charged particles, in particular ions, preferably protons, and having a beam guidance system. The generic beam guidance system takes up less space but can provide comparable or even improved beam properties because, in part, the beam guidance system seen in the direction of the beam of charged particles and behind the beam generation unit has at least one solenoid magnet as a beam shaping unit, and the at least one solenoid magnet of the beam guidance system is a superconducting solenoid magnet.

Owner:CRYOELECTRA

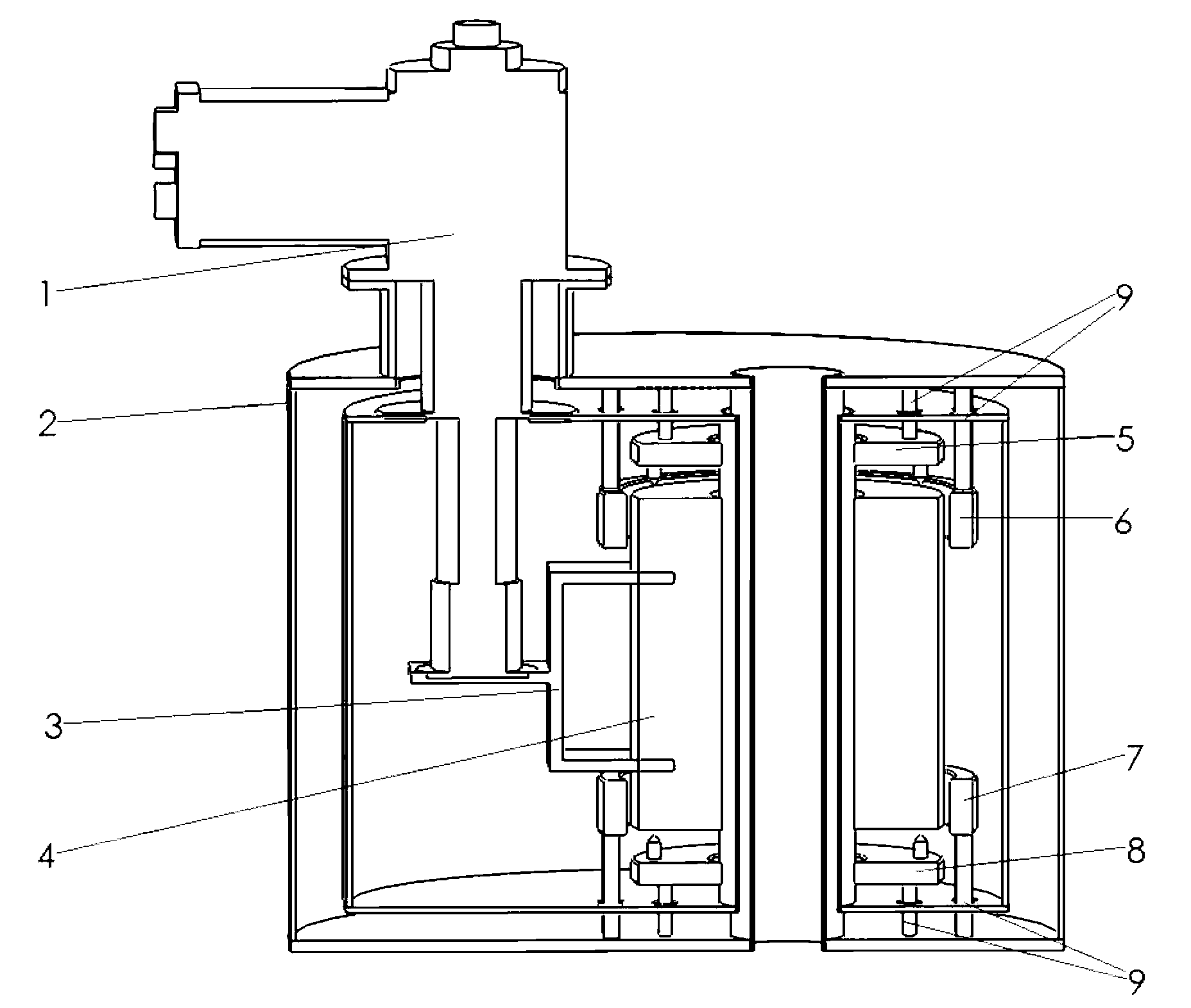

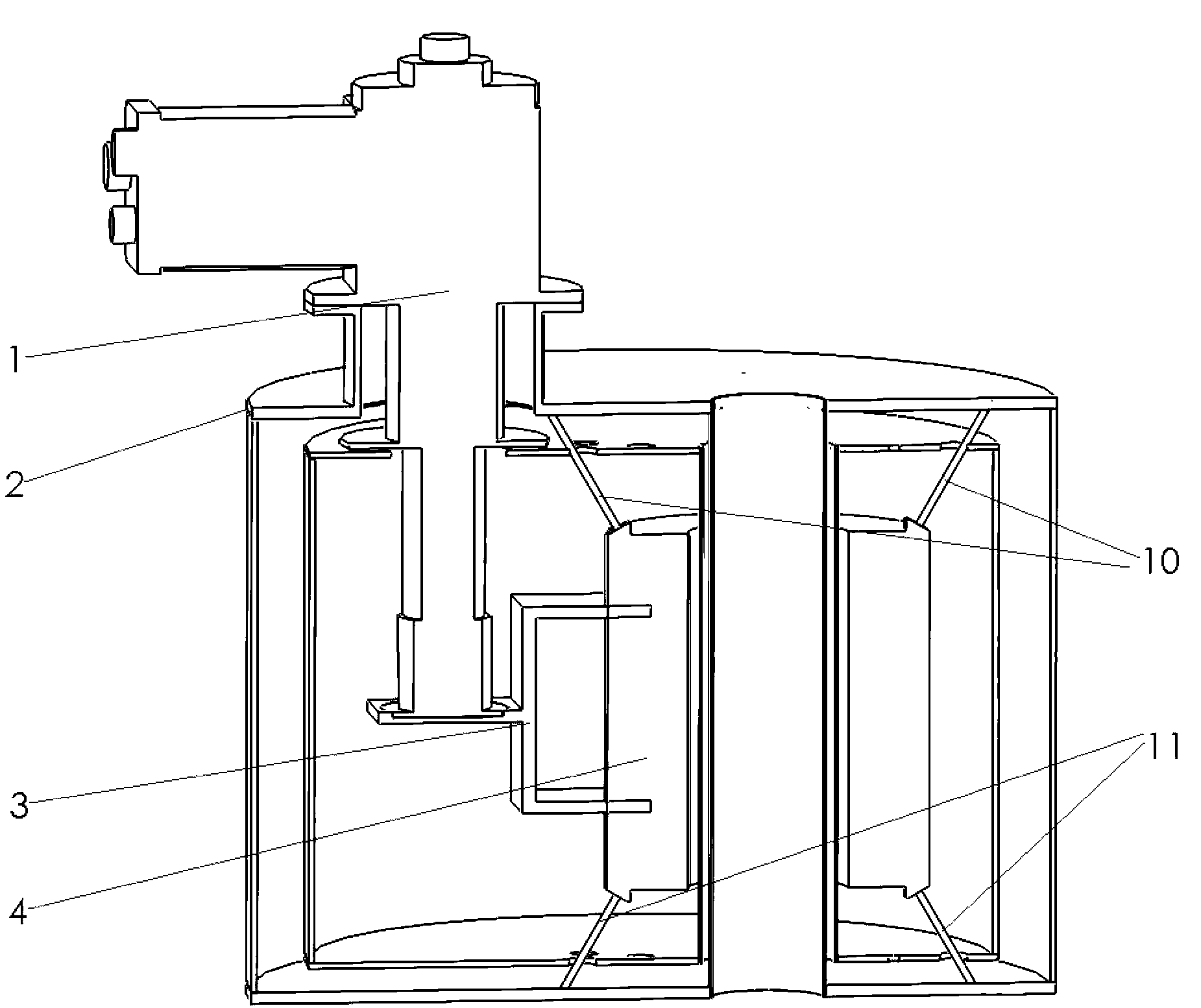

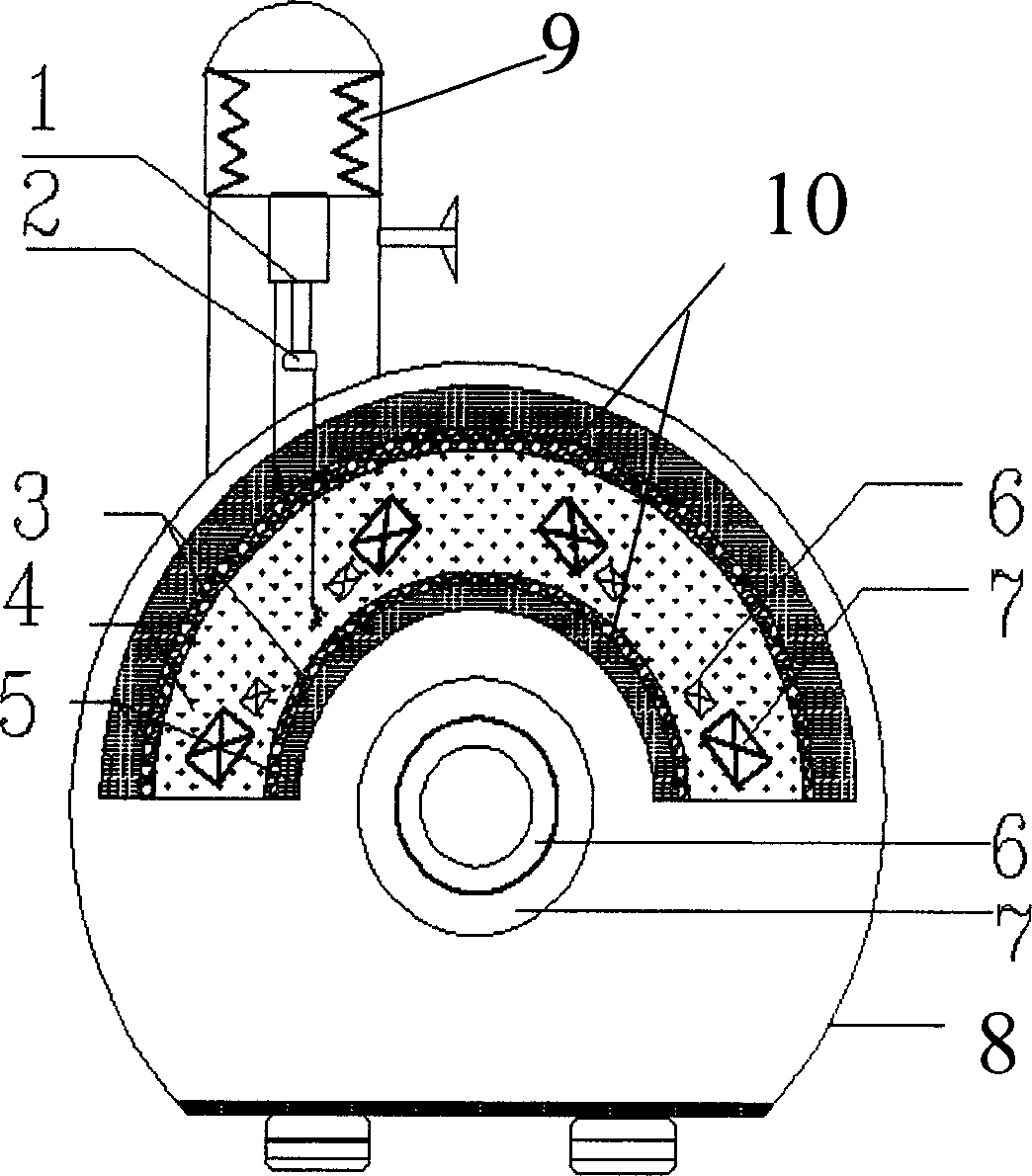

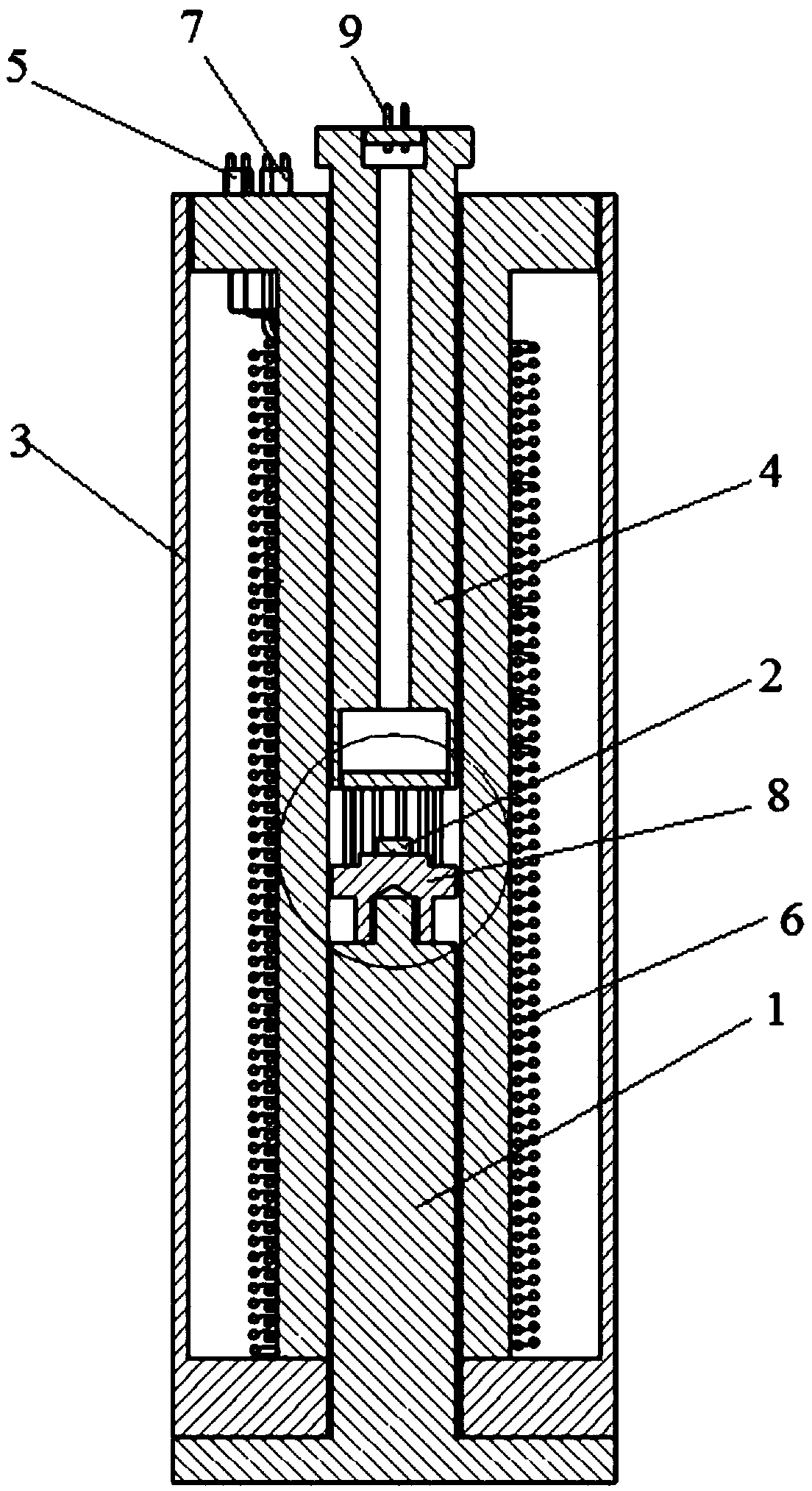

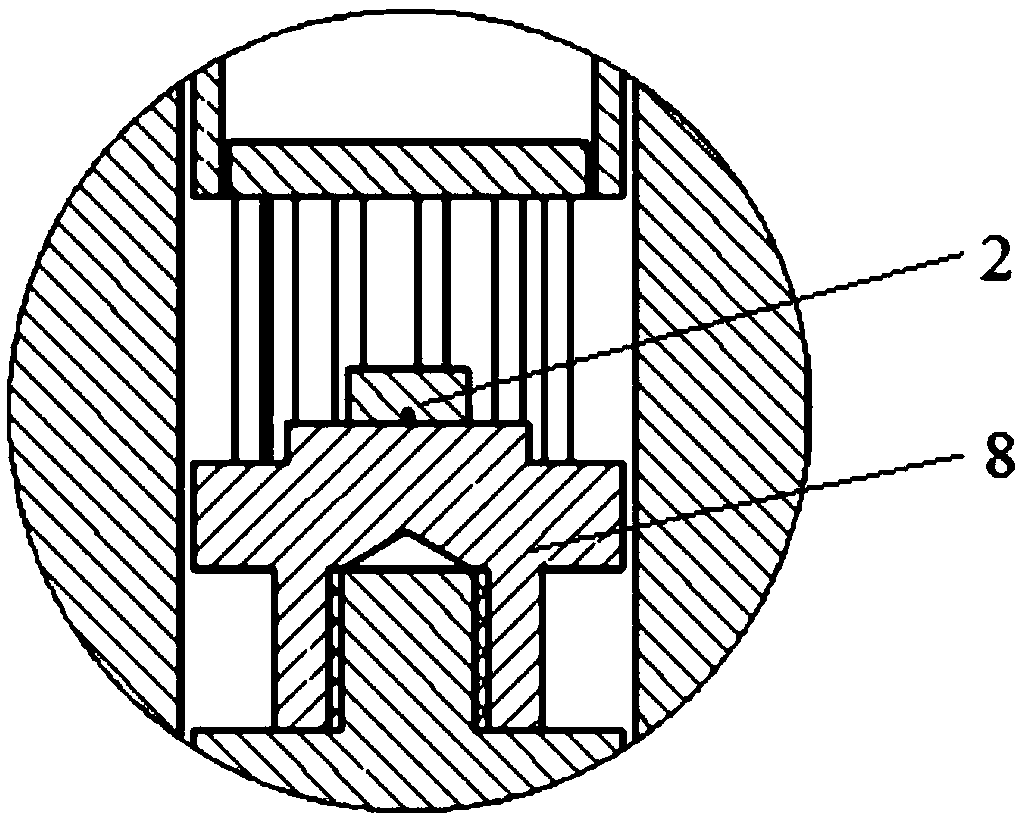

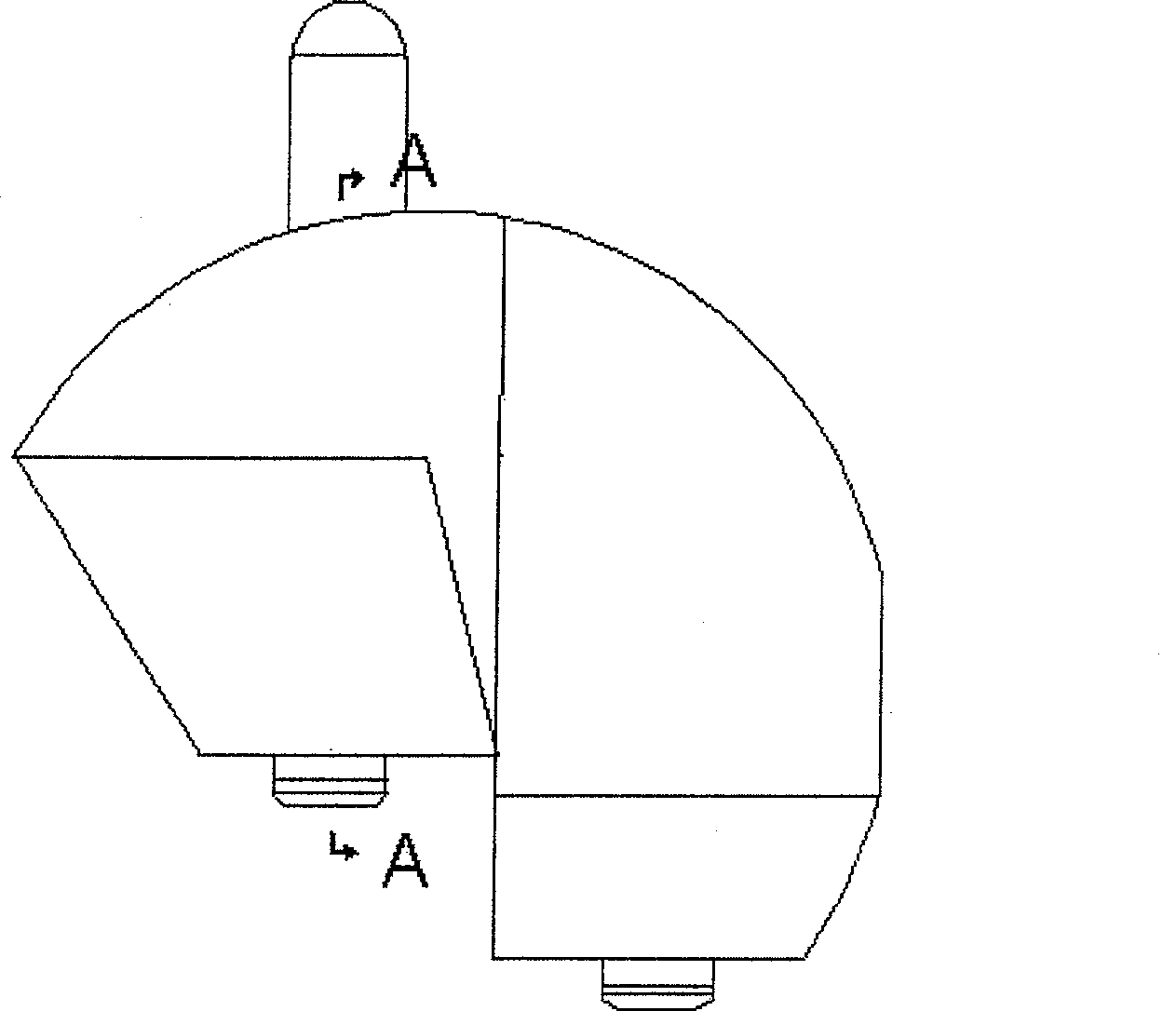

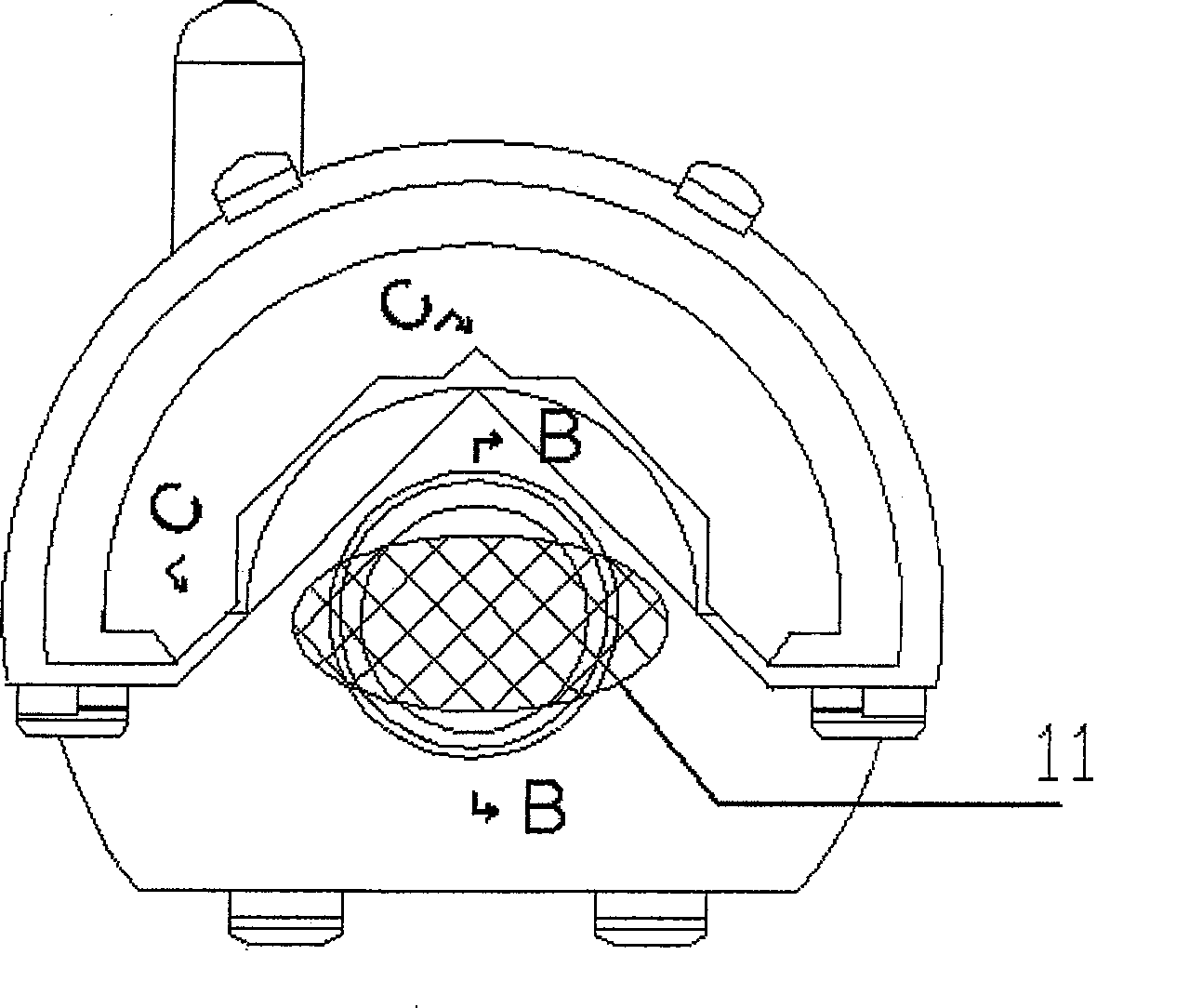

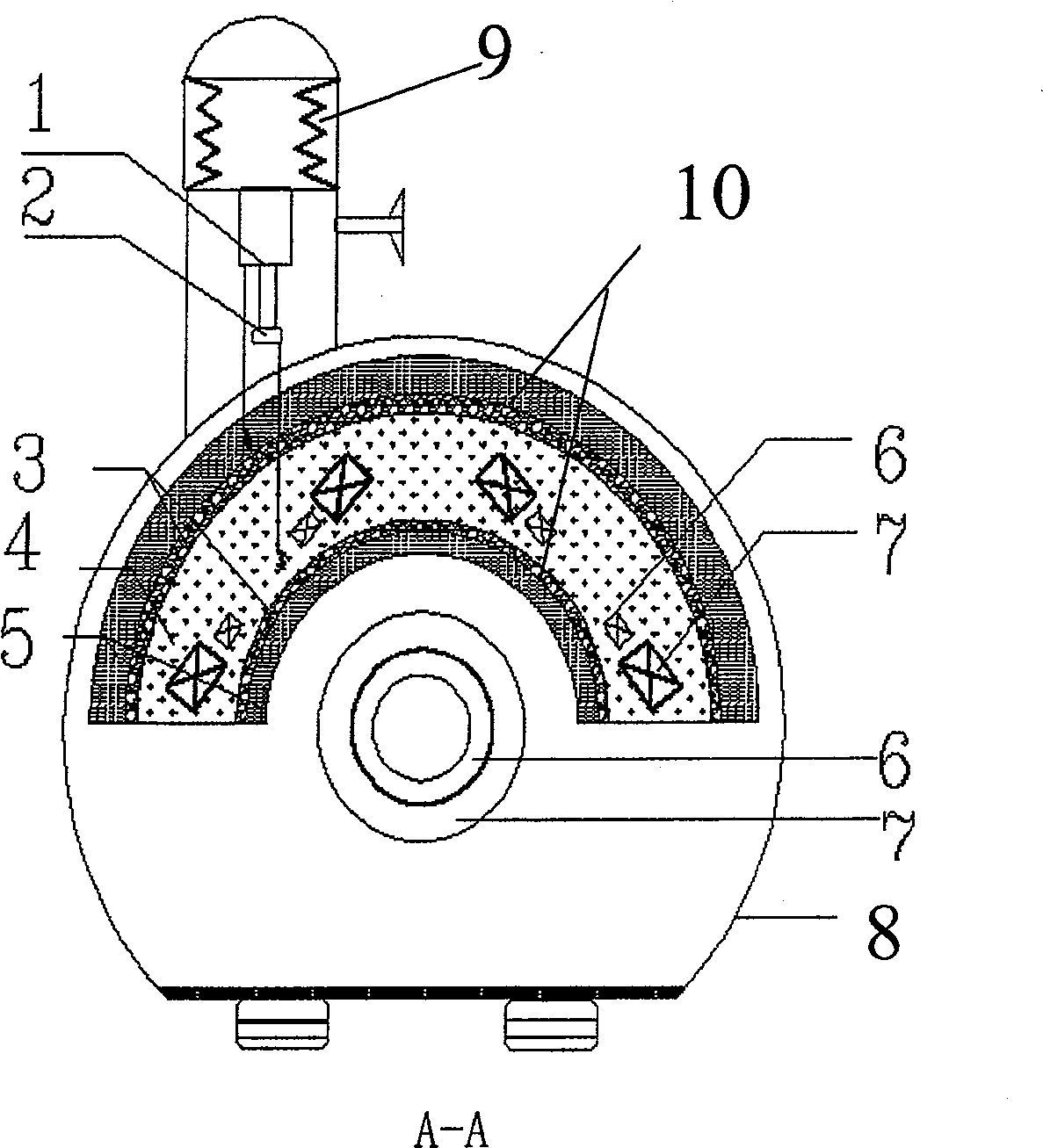

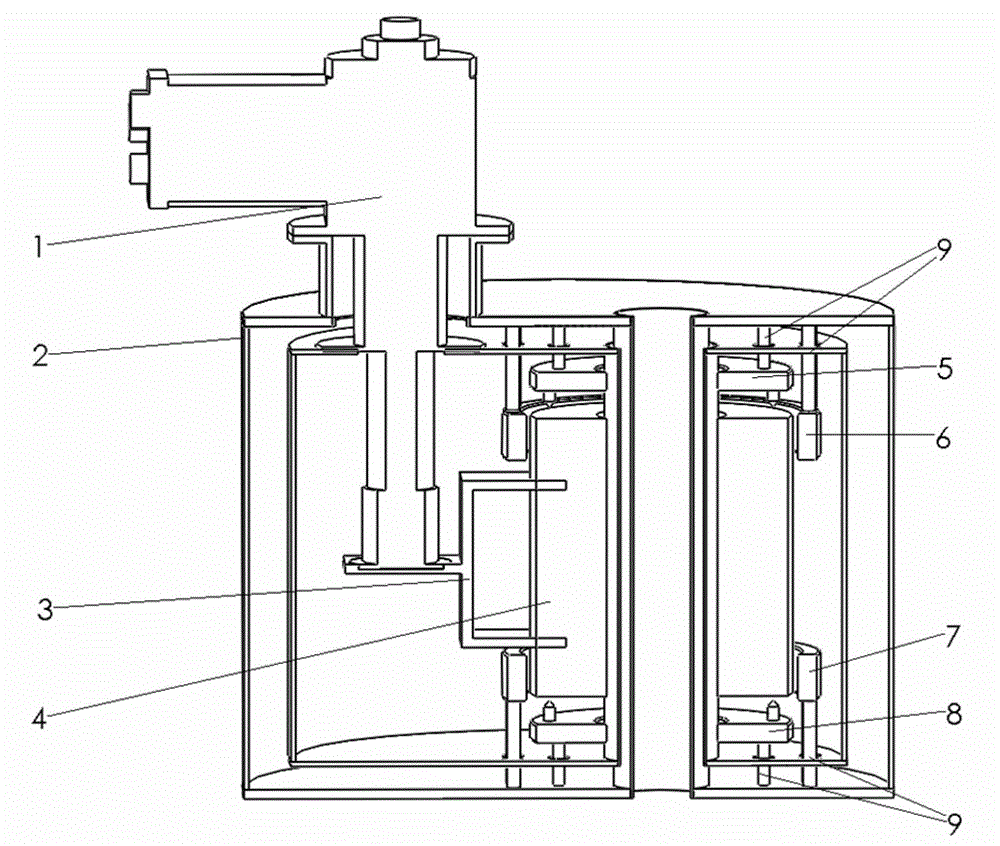

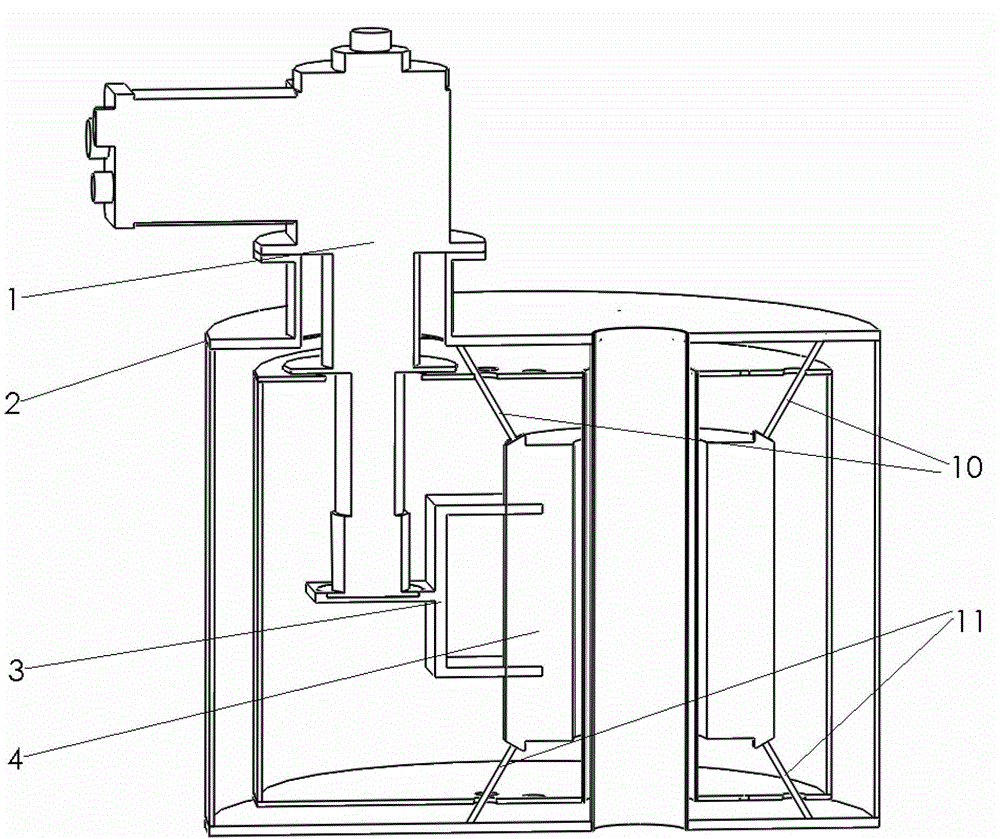

Superconducting magnet supporting and positioning system

ActiveCN103065759AReduce conduction heat leakageLow powerSuperconducting magnets/coilsMagnetic holding devicesSuperconducting solenoidSuperconducting Coils

A superconducting magnet supporting and positioning system comprises a refrigerator (1), a low-temperature container (2), a cold conducting band (3), a superconducting solenoid coil (4), an upper suspension magnet (5), a side upper positioning magnet (6), a side lower positioning magnet (7), a lower suspension magnet (8) and connecting rods (9). After the superconducting solenoid coil (4) is electrified, electromagnetic repulsion is generated between the upper suspension magnet (5) and the lower suspension magnet (8) and the superconducting solenoid coil (4) to enable the superconducting solenoid coil (4) to be suspended in the air, and electromagnetic repulsion is generated between the upper side upper positioning magnet (6) and the side lower positioning magnet (7) and the superconducting solenoid coil (4) to enable the superconducting solenoid coil (4) to be positioned and free of declination. No heat contact exists between the magnets and the superconducting solenoid coil, so that transmission heat leakage of the superconducting solenoid coil can be reduced, and power of the needed refrigerator can be lowered.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

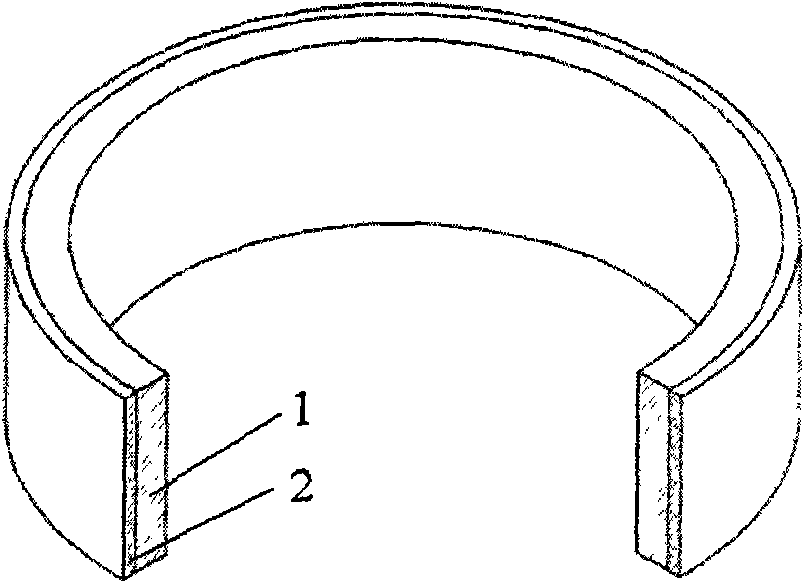

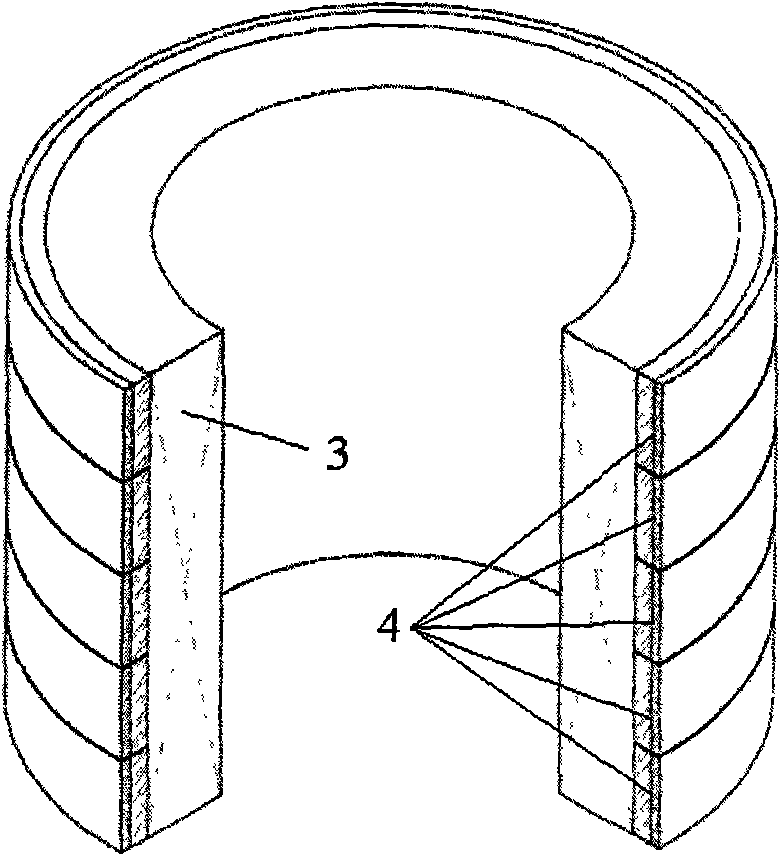

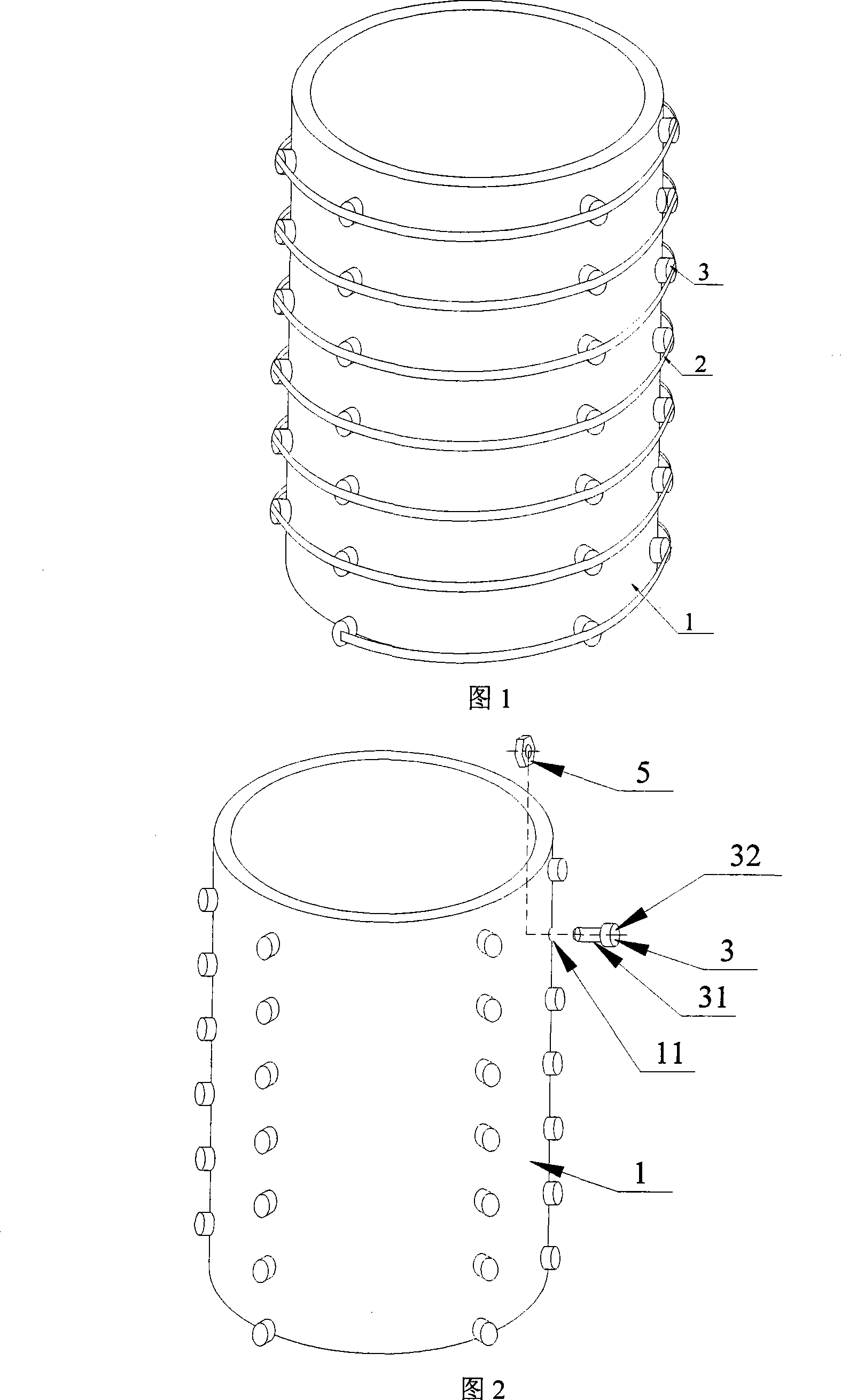

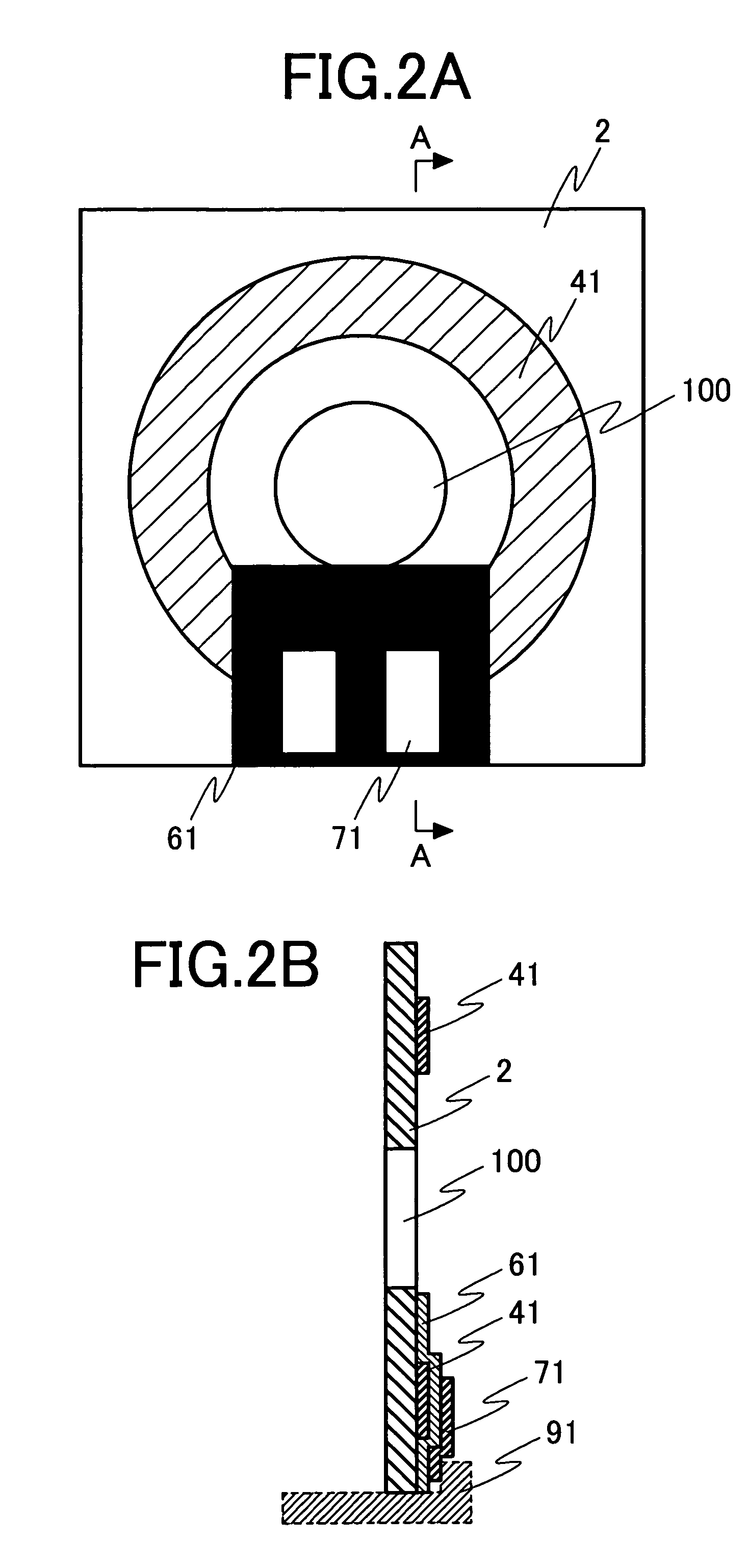

Two-sided immersion superconducting solenoid coil

InactiveCN101183592AImprove heat transfer performanceAvoid performance degradationSuperconducting magnets/coilsCoils manufactureSuperconducting solenoidSuperconducting Coils

The invention relates to a double-side immersed superconducting solenoid coil, comprising a coil frame (1) and a superconducting tape (2); wherein the superconducting tape (2) is winded spirally on the coil frame (1); the superconducting solenoid coil is provided with a supporting piece (3); the supporting piece (3) is arranged between the coil frame (1) and the superconducting tape (2) to support the superconducting tape (2); a gap is arranged between the coil frame (1) and the superconducting tape (2). With the gap between the coil frame (1) and the superconducting tape (2), the invention has the advantages that the two sides of the superconducting tape (2) are both immersed into the liquid nitrogen or the liquid helium, which improves the heat transfer capacity of the superconducting coil and prevents the superconducting coil from performance degradation or being burned out because of the over high heat output under the state of quenching superconductivity.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

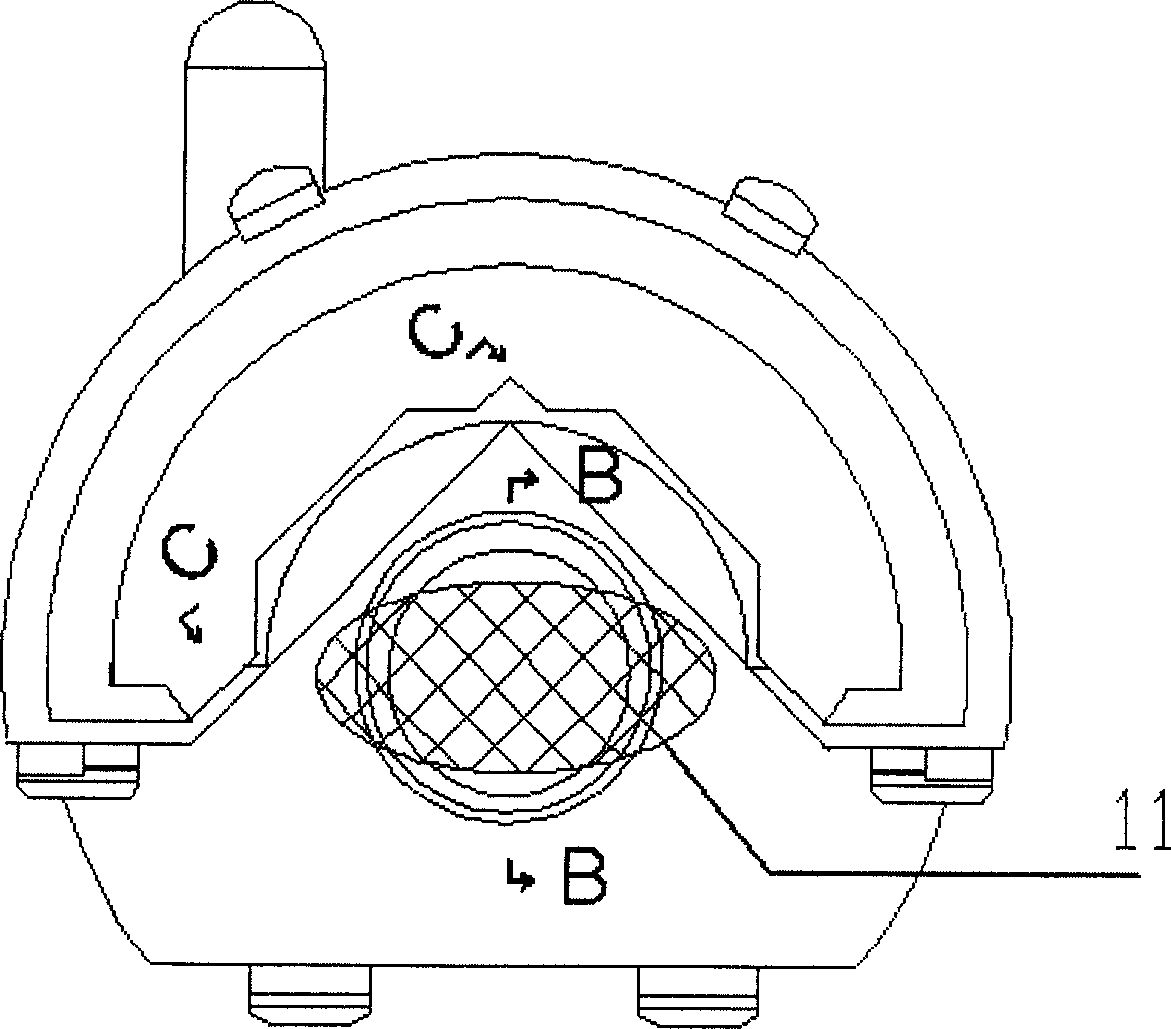

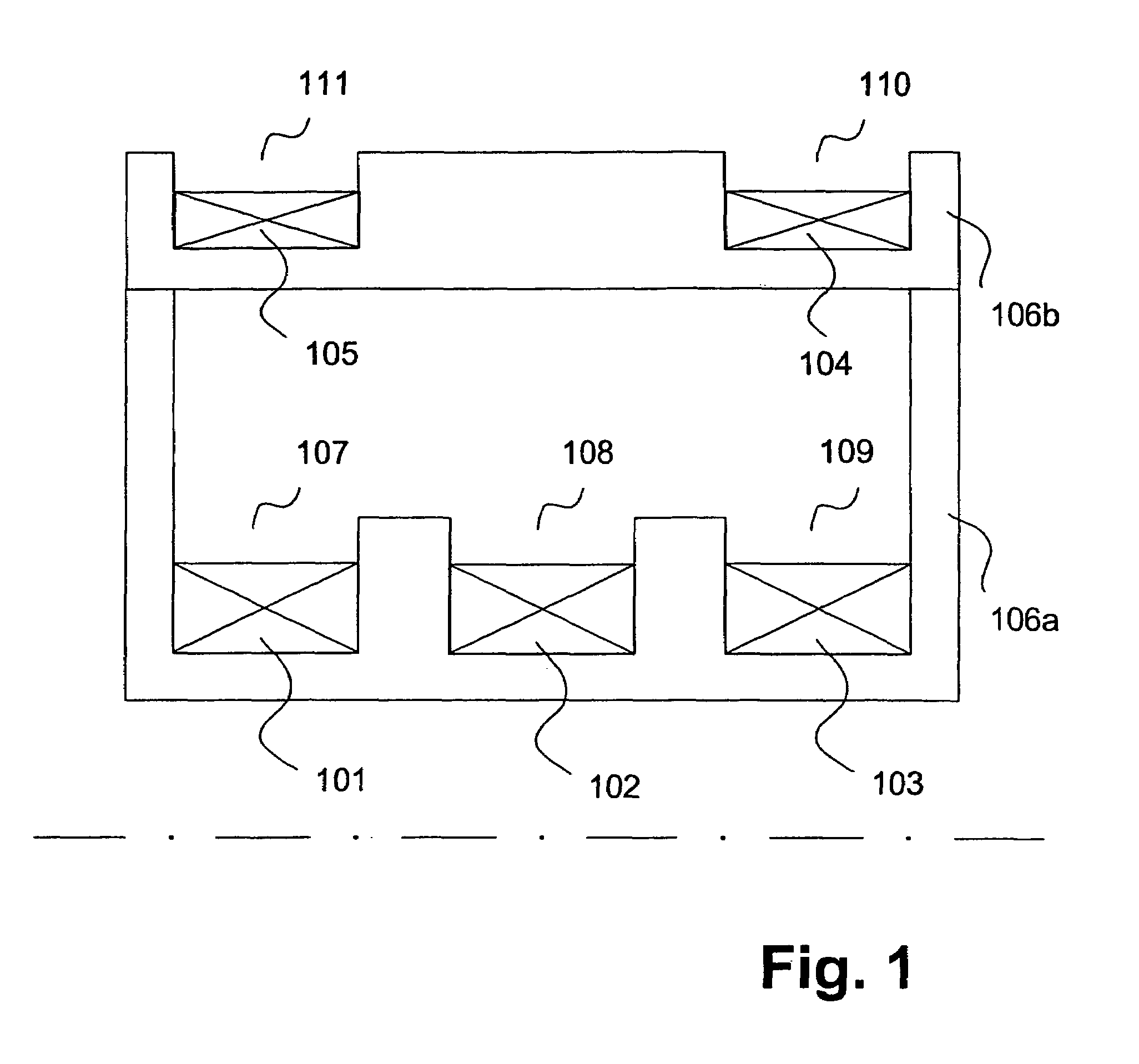

Superconductive magnet system for intercurrent treatment three-dimensional position

ActiveCN1745856ASimple structureGuaranteed uptimeMedical devicesCatheterHigh-temperature superconductivitySuperconducting solenoid

A super-conducting magnetic system for the 3D location in insert therapy is composed of a high-temp super-conducting magnet unit consisting of three pairs of superconducting solenoid coils divided into internal and external layers, a G-M refrigerating unit, a low-temp cylinder, a superconductor-loss protector and a program controlled power supply. The whole magnet unit forms a symmetrical open space. The magnetic system is running in a low-temp system protected by solidified nitrogen.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

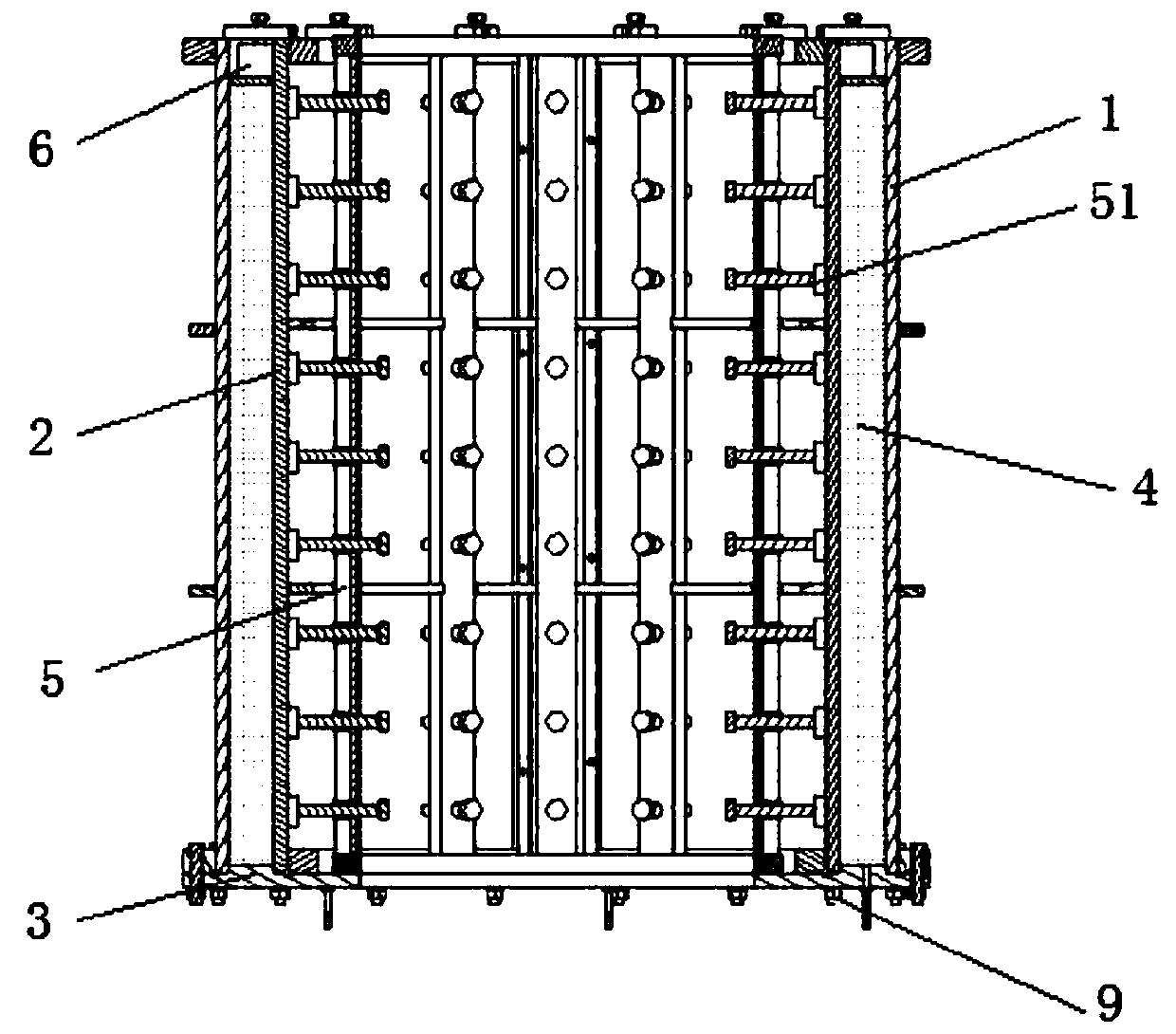

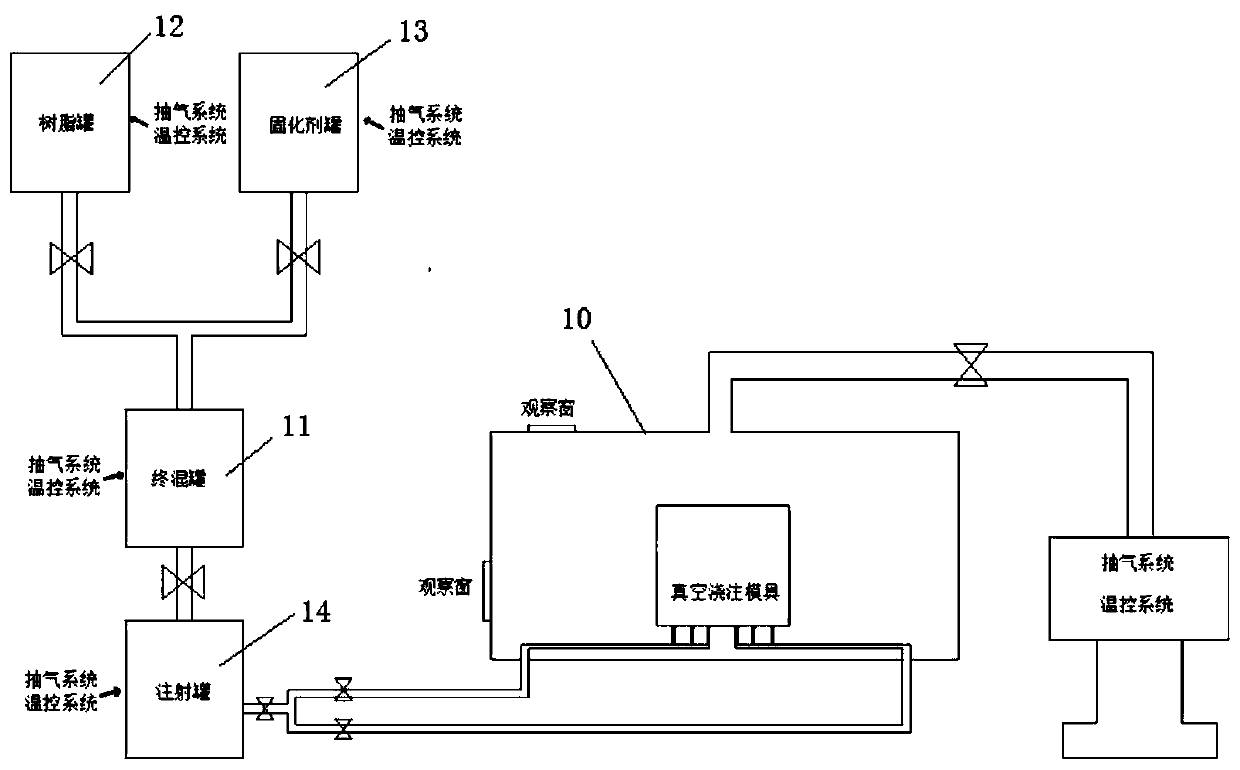

Superconducting CICC solenoid magnet coil vacuum pressure impregnation die and impregnation process

ActiveCN109859944AEasy to assemble and disassembleImprove molding qualityInductances/transformers/magnets manufactureSuperconducting magnets/coilsVacuum pressureElectrical conductor

The invention discloses a superconducting CICC solenoid magnet coil vacuum pressure impregnation die and an impregnation process. The impregnation die comprises a cylindrical outer die; the outer dieis internally and concentrically provided with an inner die; both the outer die and the inner die are formed by assembly of multiple arc segmented dies; the bottom of the outer die and the inner die is positioned and erected on a bottom die; and the bottom of the bottom die is uniformly provided with a plurality of glue injection nozzles communicated with a coil glue injection and molding cavity along a circumferential direction. The impregnation process comprises the step of heating and degassing the coil in the impregnation die. Starting from the particularity of a conductor material in thesuperconducting CICC solenoid magnet coil, the superconducting coil impregnation die and the process are optimized and designed, and the technical problems of large brittleness, easy breaking and large coil size after a Nb3Sn superconducting wire and an S-glass insulating glass ribbon are wound to a coil and are subjected to thermal treatment can be effectively avoided.

Owner:合肥聚能电物理高技术开发有限公司

Device and method for achieving molecule/ion-level separation of homogeneous mixing liquid through magnetizing force

ActiveCN105170316AAchieve separationAchieve enrichmentHigh gradient magnetic separatorsSuperconducting solenoidSuperconducting Coils

The invention provides a device and method for achieving molecule / ion-level separation of homogeneous mixing liquid through magnetizing force. The device comprises a liquid conveying part, a gradient magnetic field separation device and a liquid collection part, wherein the gradient magnetic field separation device can be achieved by permanent magnets or combination of permanent magnets and yokes or electromagnets or superconducting magnets or solenoids or superconducting solenoids and is used for generating a gradient magnetic field in magnetic field space. The liquid conveying part is composed of a liquid storage bottle, a liquid conveying pump and a liquid conveying pipe. Liquid flows in the magnetic field space in a deflection flowing mode, a magnetic screening flowing mode and a magnetic screening and deflection composite flowing mode, and separation or enrichment of paramagnetic and diamagnetic molecules (or ions) in the homogeneous mixing liquid and separation or enrichment of magnetic / paramagnetic particles in the liquid are achieved under the action of the magnetizing force. The device and method have the advantages of being convenient to operate, low in manufacturing cost, low in energy consumption, long in service life, wide in applicability, low in magnetic pollution and the like.

Owner:UNIV OF SCI & TECH BEIJING

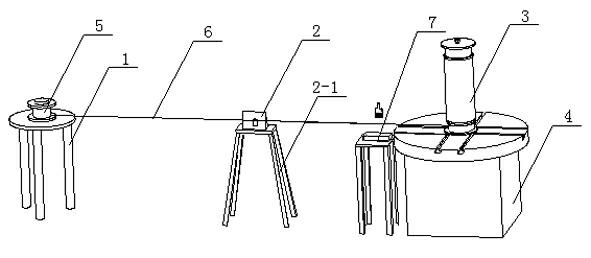

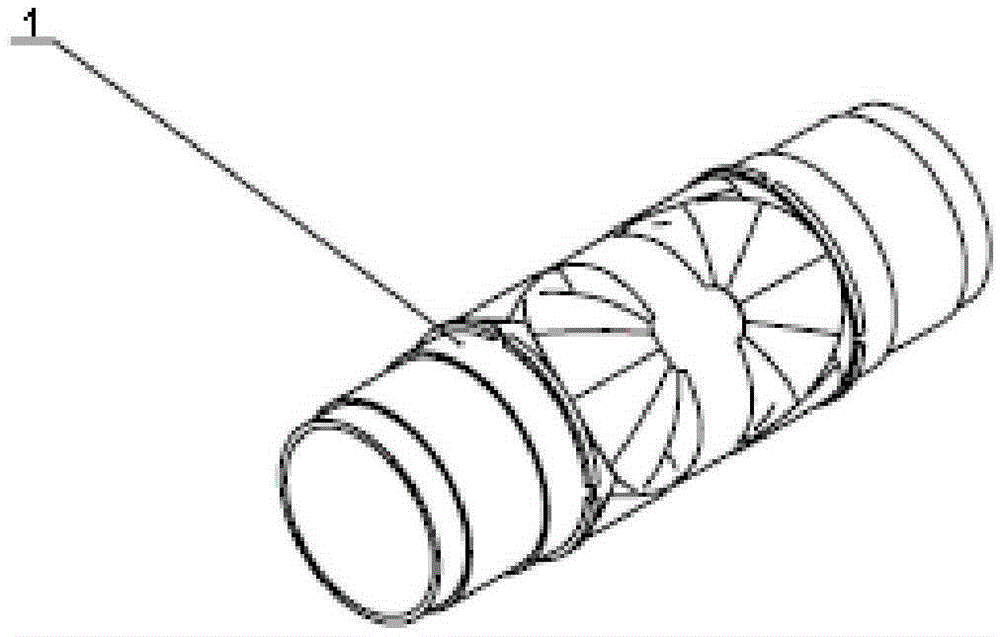

Device and method for winding superconducting solenoid coil

ActiveCN102087904AEasy to operateQuench was not foundSuperconducting magnets/coilsCoils manufactureWinding machineSuperconducting solenoid

The invention relates to a device and method for winding a superconducting solenoid coil. The device comprises a superconducting wire pay-off device, a superconducting solenoid and a vertical winding machine. The device is characterized by also comprising a tension device, wherein the tension device comprises a base; support bars are fixedly installed on the base; a top plate is fixedly installed at the top ends of the support bars; the upper end of an adjusting screw is connected with the top plate, and the lower end of the adjusting screw is installed on the base; a superconducting wire compression block is arranged on the adjusting screw; and a superconducting wire on a superconducting wire coil is connected with the superconducting solenoid installed on the vertical winding machine via the superconducting wire compression block on the adjusting screw. The winding method is reliable and reasonable, can be used for manufacturing the superconducting solenoid, lowers the manufacturing cost and improves the production efficiency, thereby being a supplement to the existing production method and having particularly good practical operability for special-shaped coils.

Owner:INST OF MODERN PHYSICS CHINESE ACADEMY OF SCI

Bobbin for superconducting coil, and superconducting solenoid coil

InactiveCN1933044ASimple structureEasy Spiral WindingMagnetic measurementsTransformers/inductances detailsBobbinSuperconducting solenoid

A bobbin for a superconducting coil includes a cylindrical drum, and a tapered portion extending from each end of the drum. A superconducting wire or a precursor of the superconducting wire shaped like a tape is helically wound around the drum in multiple layers. The tapered portion has a tapered surface that is inclined at an arbitrary angle.

Owner:KOBE STEEL LTD

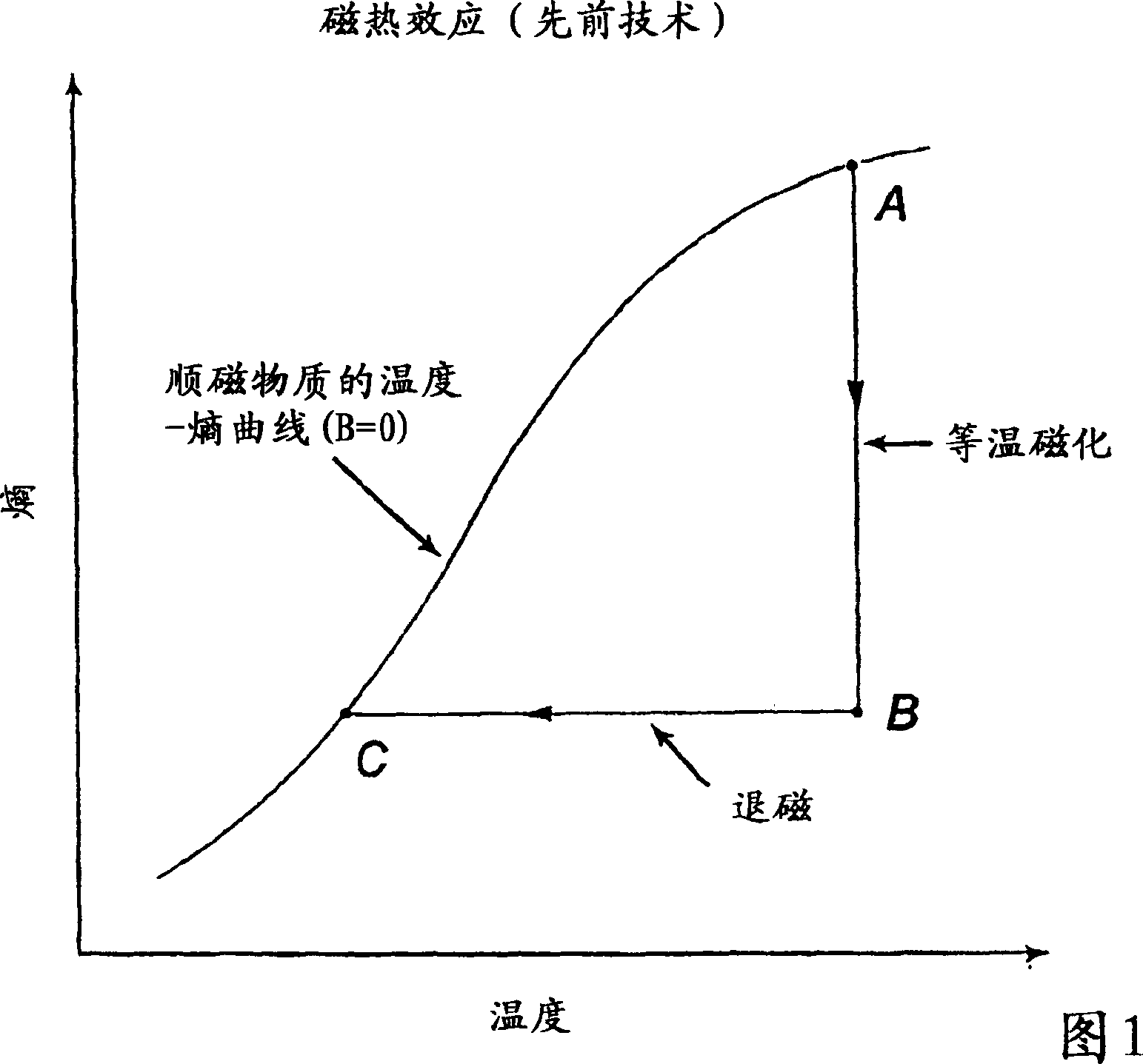

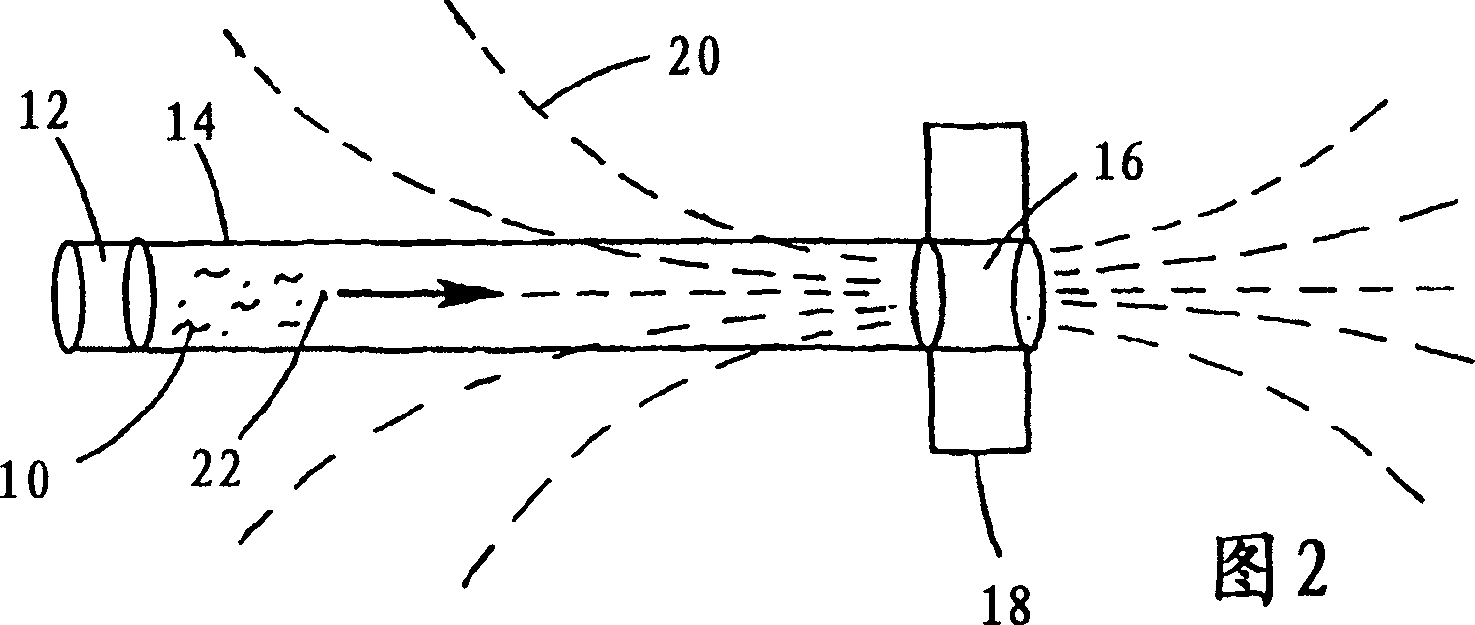

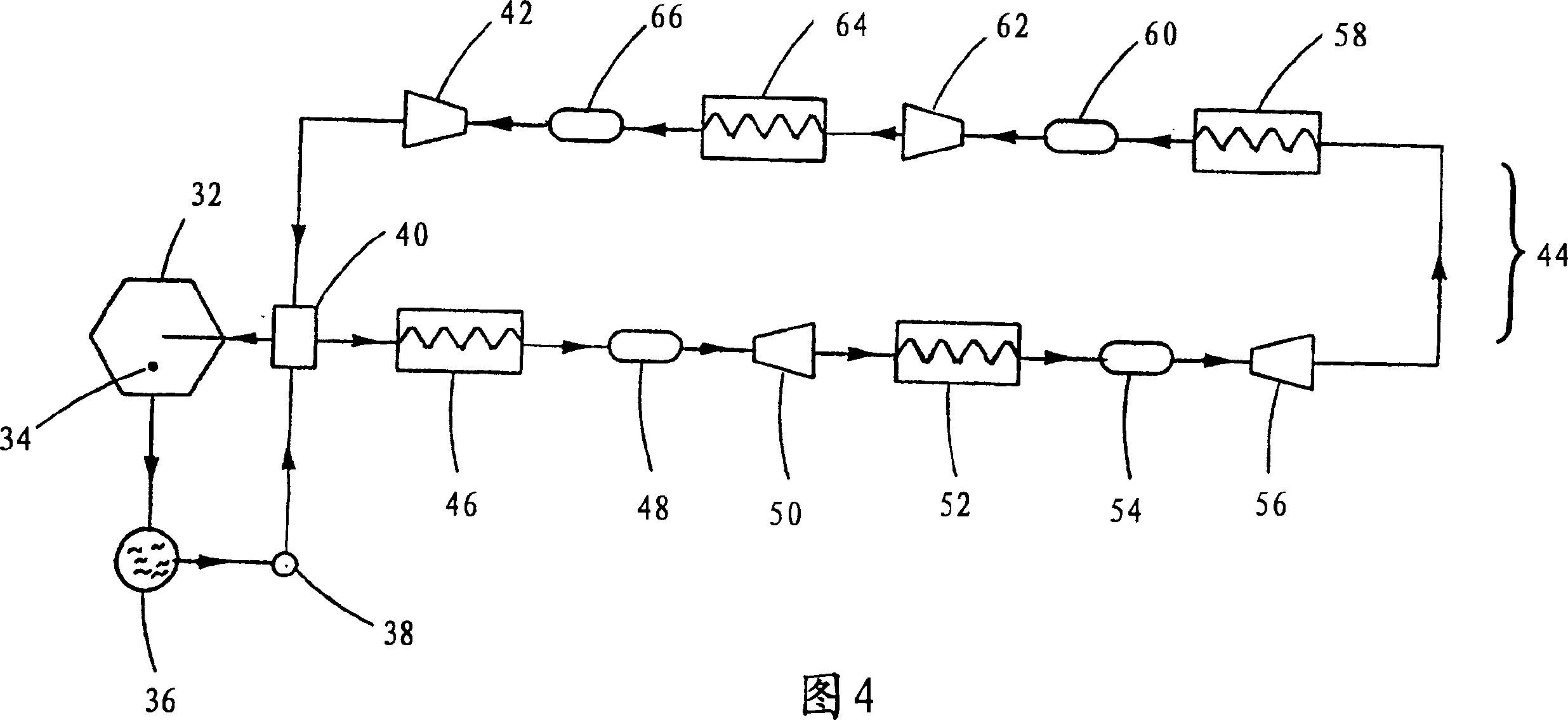

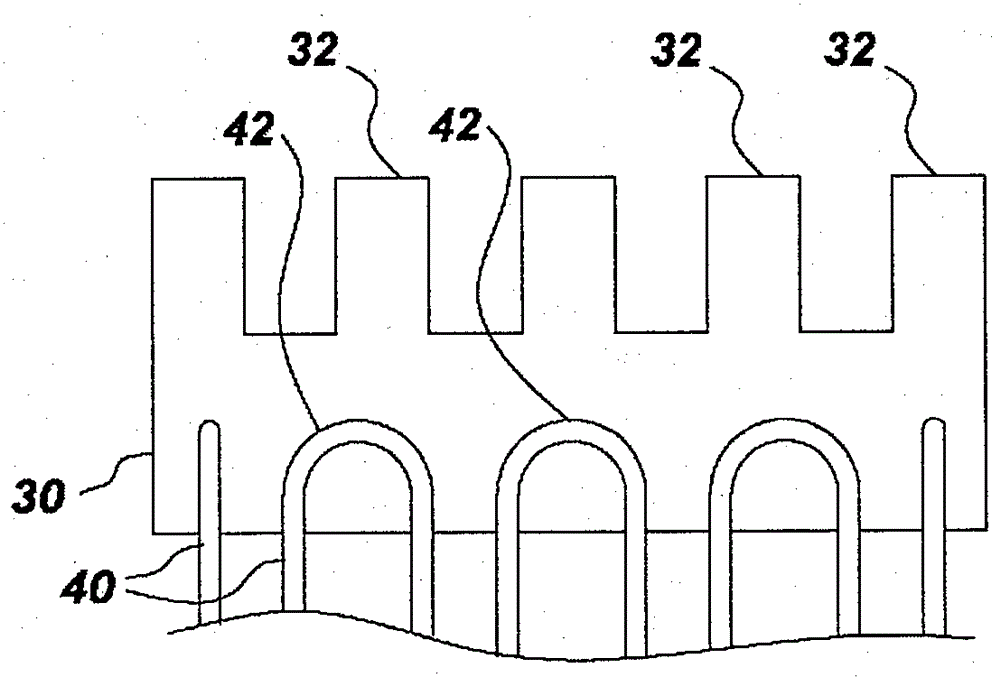

Magnetic condensing system for cryogenic engines

InactiveCN1662780ACompression machines with non-reversible cycleEnergy efficient heating/coolingSuperconducting solenoidMagnetization

A method and apparatus is provided for generating an artificial heat sink below ambient temperature for a cryogenic condenser (32) by isothermally magnetizing a paramagnetic fluid and removing the magnetic field thereby creating a temperature drop in the fluid by the magentocaloric effect. The heat of magnetization is converted into mechanical work by initially placing the fluid inside a sealed chamber with a door (76) that opens to a conduit leading into the bore of a superconducting solenoid (72). When the solenoid (72) is energized with current, it creates a strong axial magnetic field that exerts magnetic attractive forces on the fluid inside the chamber. When the fluid is released by opening the door (76), it is accelerated through the conduit (70) toward the superconducting solenoid where it becomes magnetized by the increasing strength of the magnetic field. By mounting a non-magnetic turbine (120) inside the conduit between the solenoid and the chamber, the kinetic energy of the accelerating flow stream, which is equal to the heat of magnetization, is converted into mechanical work thereby achieving isothermal magnetization. By removing the magnetic field after the fluid enters the bore of the solenoid, a temperature reduction is achieved thereby enabling the fluid to absorb heat in a cryogenic condenser.

Owner:迈克尔・A・米诺维奇

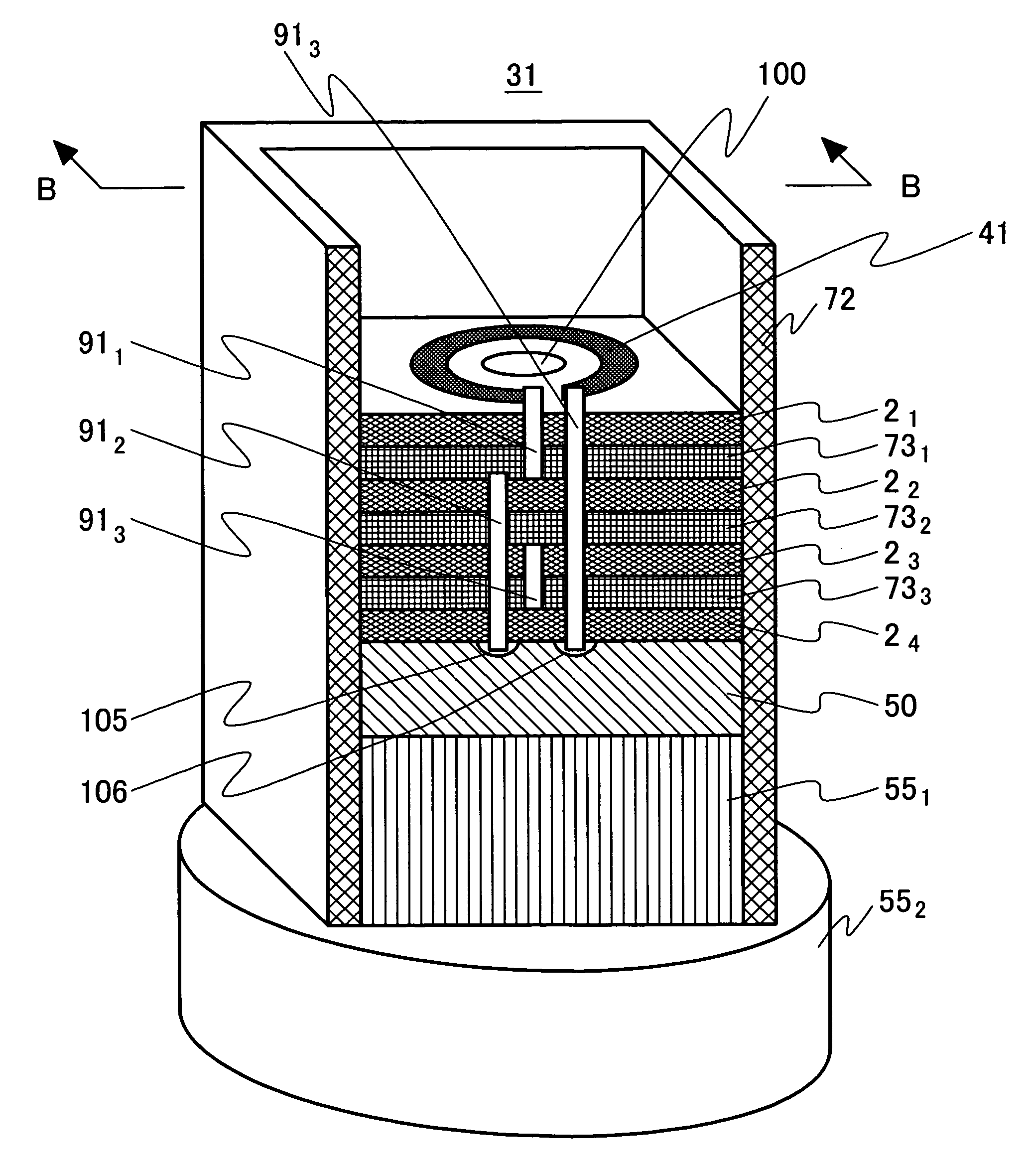

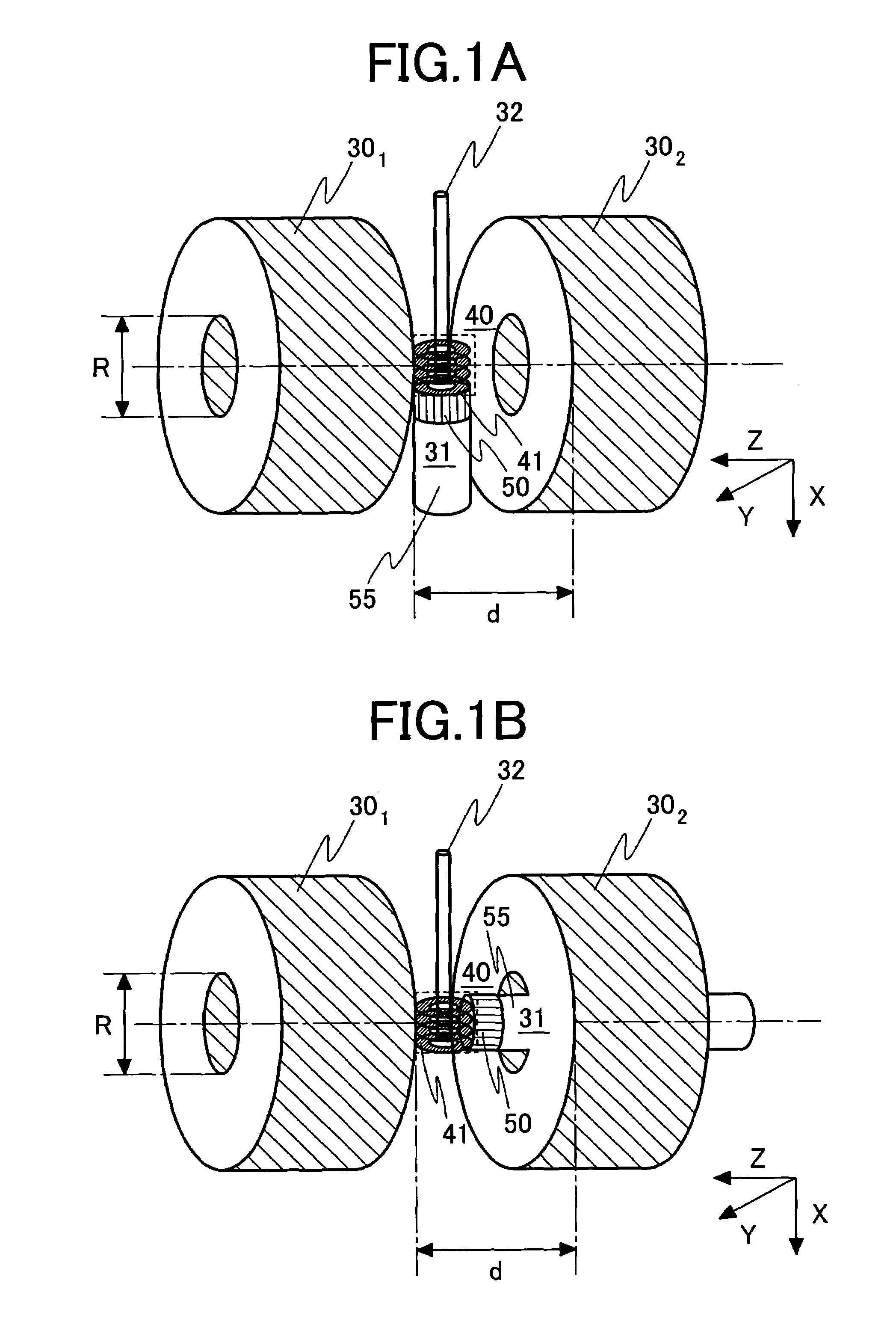

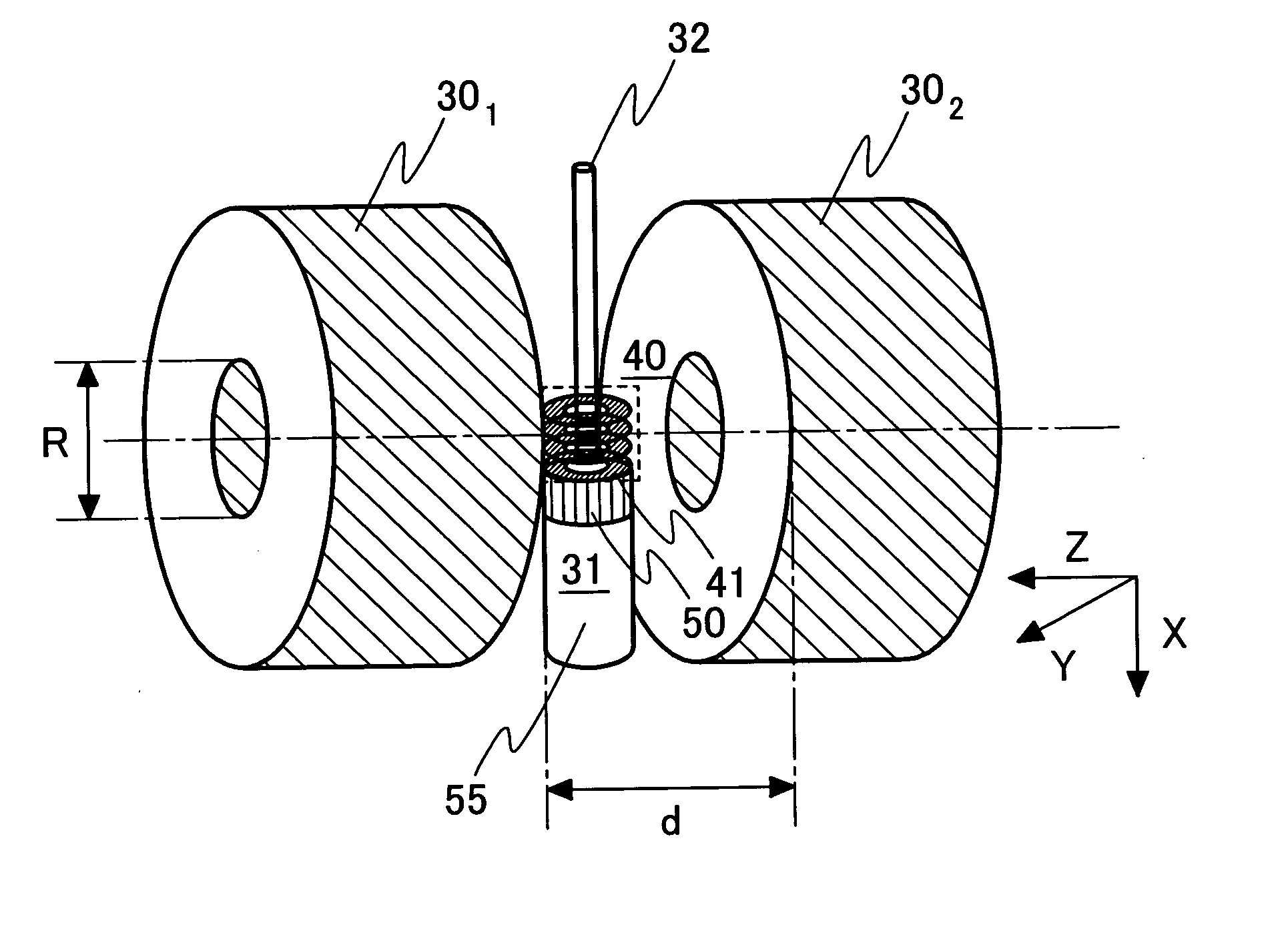

Nuclear magnetic resonance apparatus

InactiveUS20060033498A1Easy constructionMagnetic measurementsElectric/magnetic detectionNMR - Nuclear magnetic resonanceSuperconducting solenoid

A configuration of an NMR apparatus is provided. In the NMR apparatus, a magnetic field space of higher uniformity is generated by split superconducting magnets. At the same time, it is provided with a cryo probe excellent in cooling capability and sensitivity between two superconducting solenoid coils constructed in very close proximity to each other. For this purpose, a probe coil provided between the two superconducting solenoid coils is so constructed that the following is implemented: a certain distance is ensured between a substrate with a coil formed thereon and another, and the substrates and spacer substrates for cooling are alternately laminated. The spacer substrates are cooled by a cold head of sapphire. When the probe coil is inserted in the same direction as a sample tube (direction perpendicular to the static magnetic field), the spacer substrates cannot be coupled directly by the cold head of sapphire. Therefore, they are cooled through a fixed substrate for thermal conduction of sapphire coupled with the cold head.

Owner:HITACHI LTD

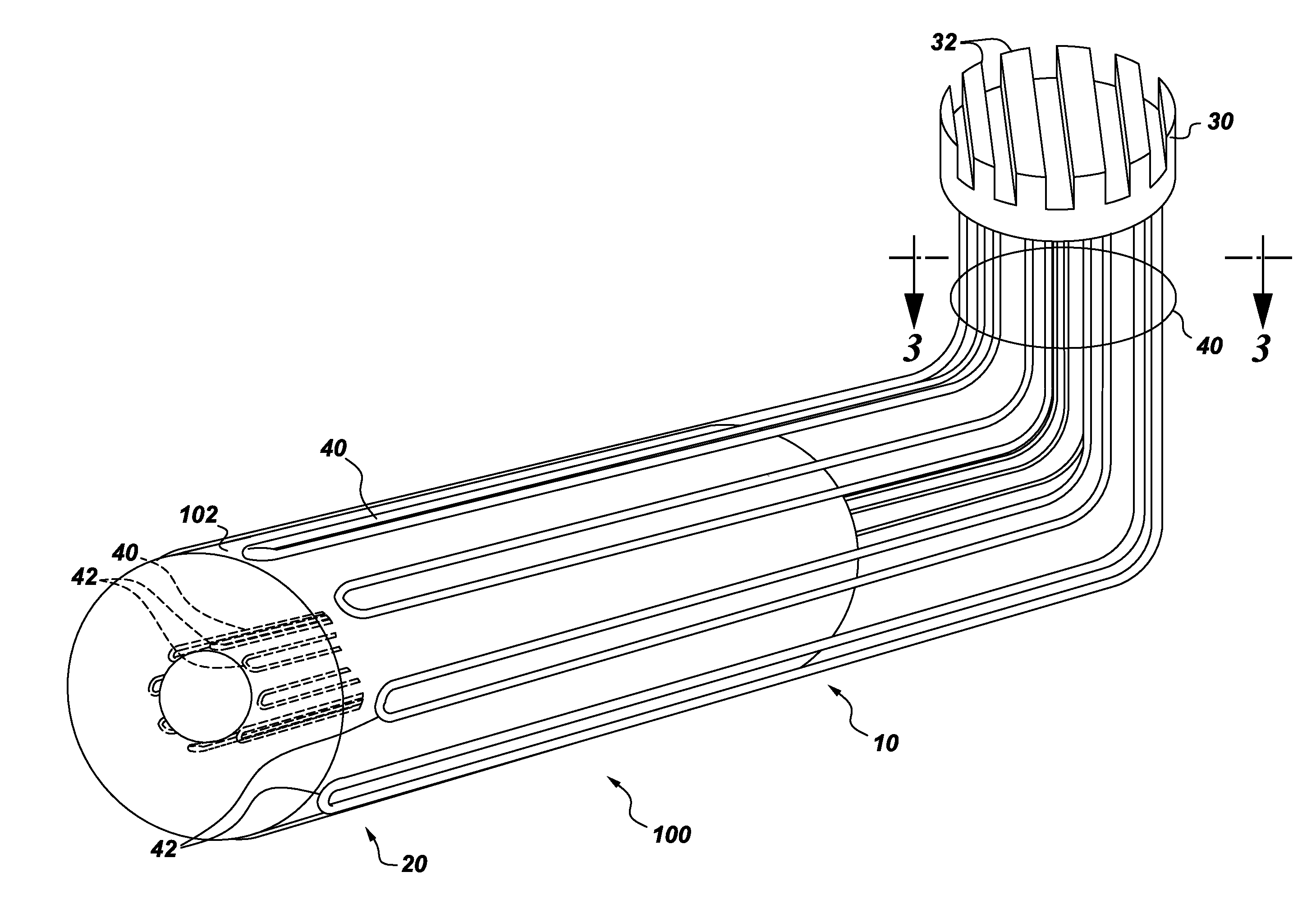

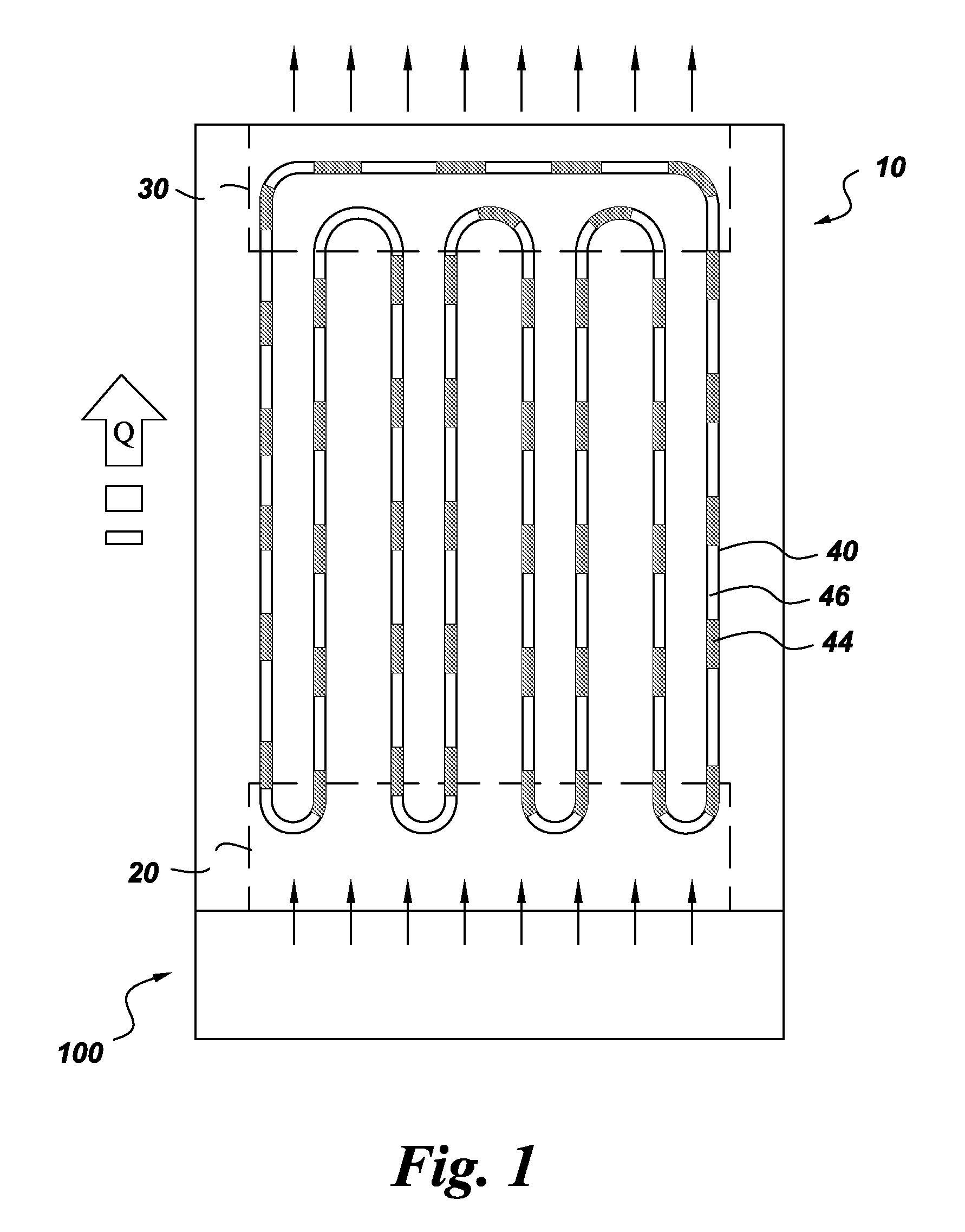

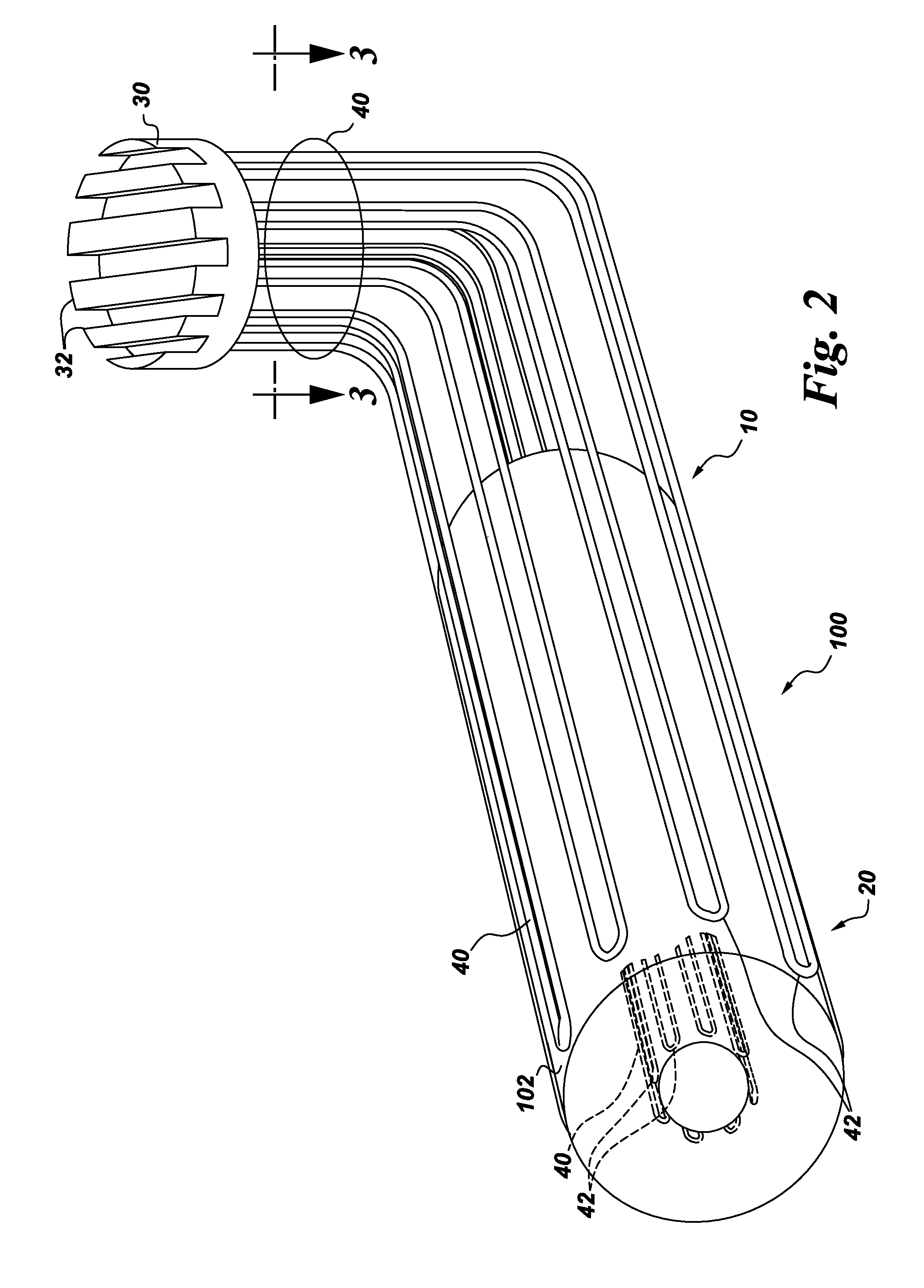

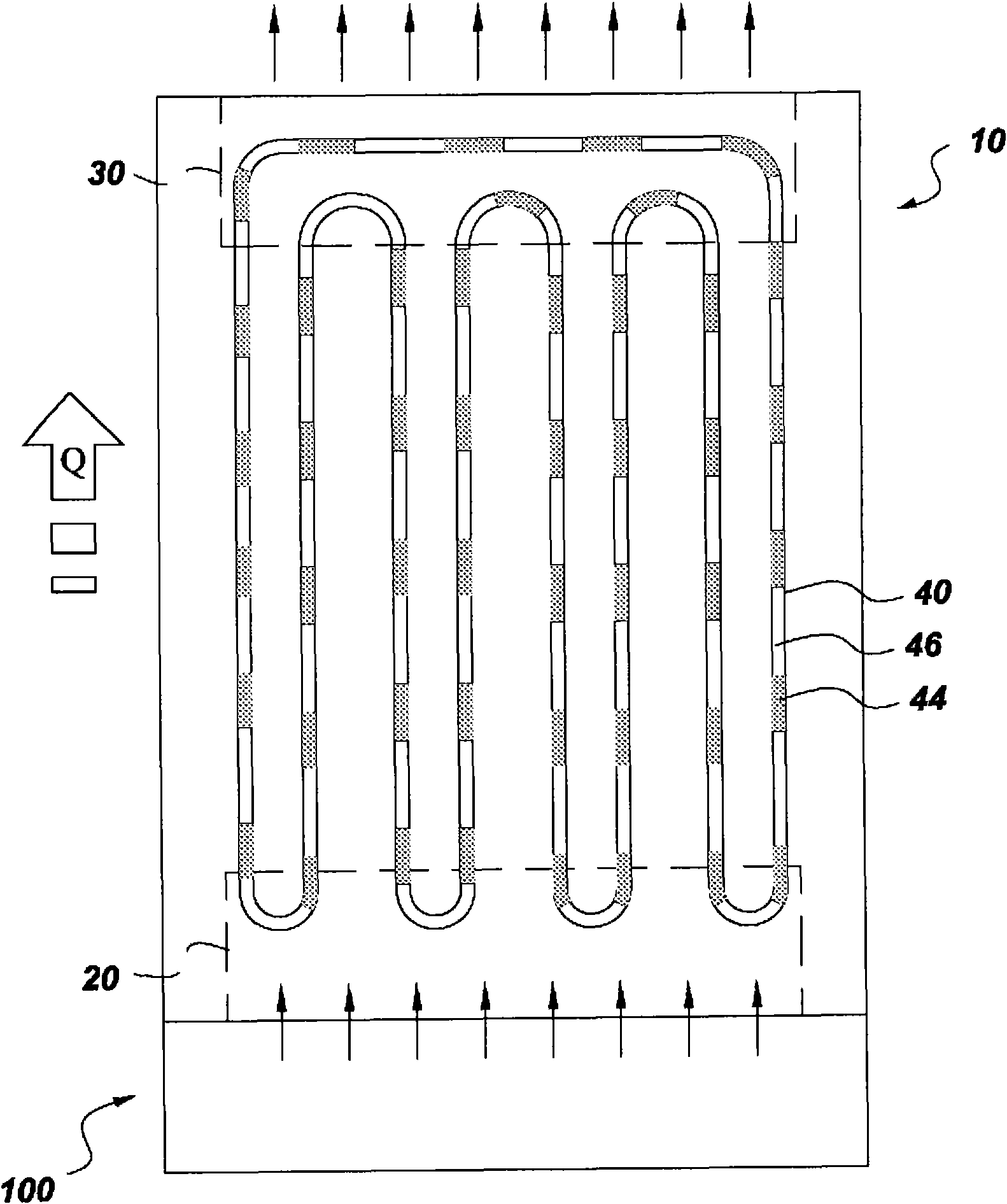

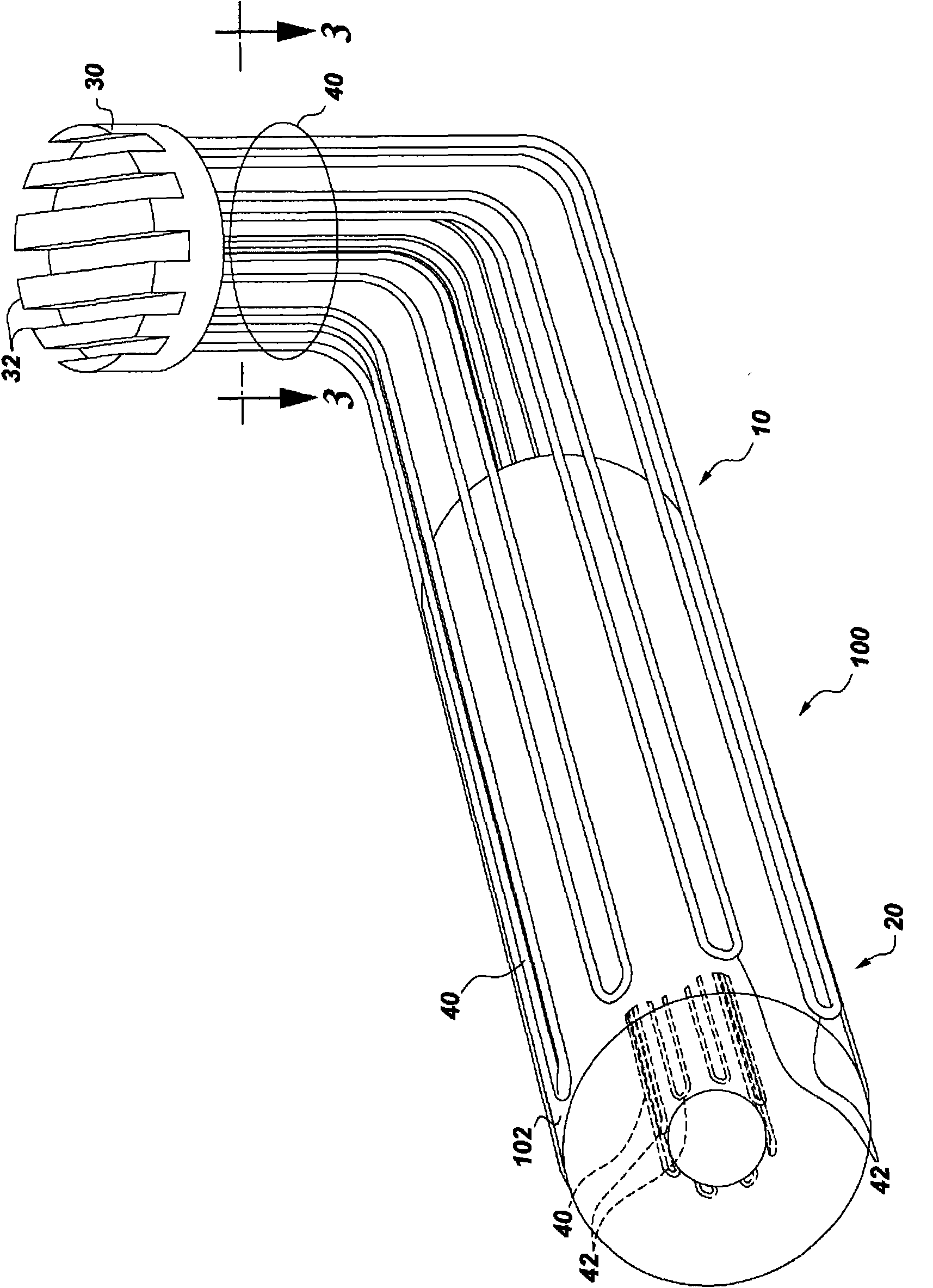

Apparatus and method of superconducting magnet cooling

InactiveCN101859624AMagnetic measurementsEnergy industrySuperconducting solenoidSuperconducting Coils

A superconducting magnet assembly 100 and method of cooling a superconducting magnet assembly 100 includes thermally connecting a pulsating heat pipe (10) to the superconducting magnet assembly 100 and adding a liquid cryogen to the pulsating heat pipe 10. The superconducting magnet assembly 100 also includes a thermally conductive coil former 102, at least one superconducting solenoid magnet comprising at least one superconducting winding wrapped about the coil former 102 and configured to generate a magnetic field, and at least one pulsating heat pipe 10 thermally connected to the at least one superconducting solenoid magnet.

Owner:GENERAL ELECTRIC CO

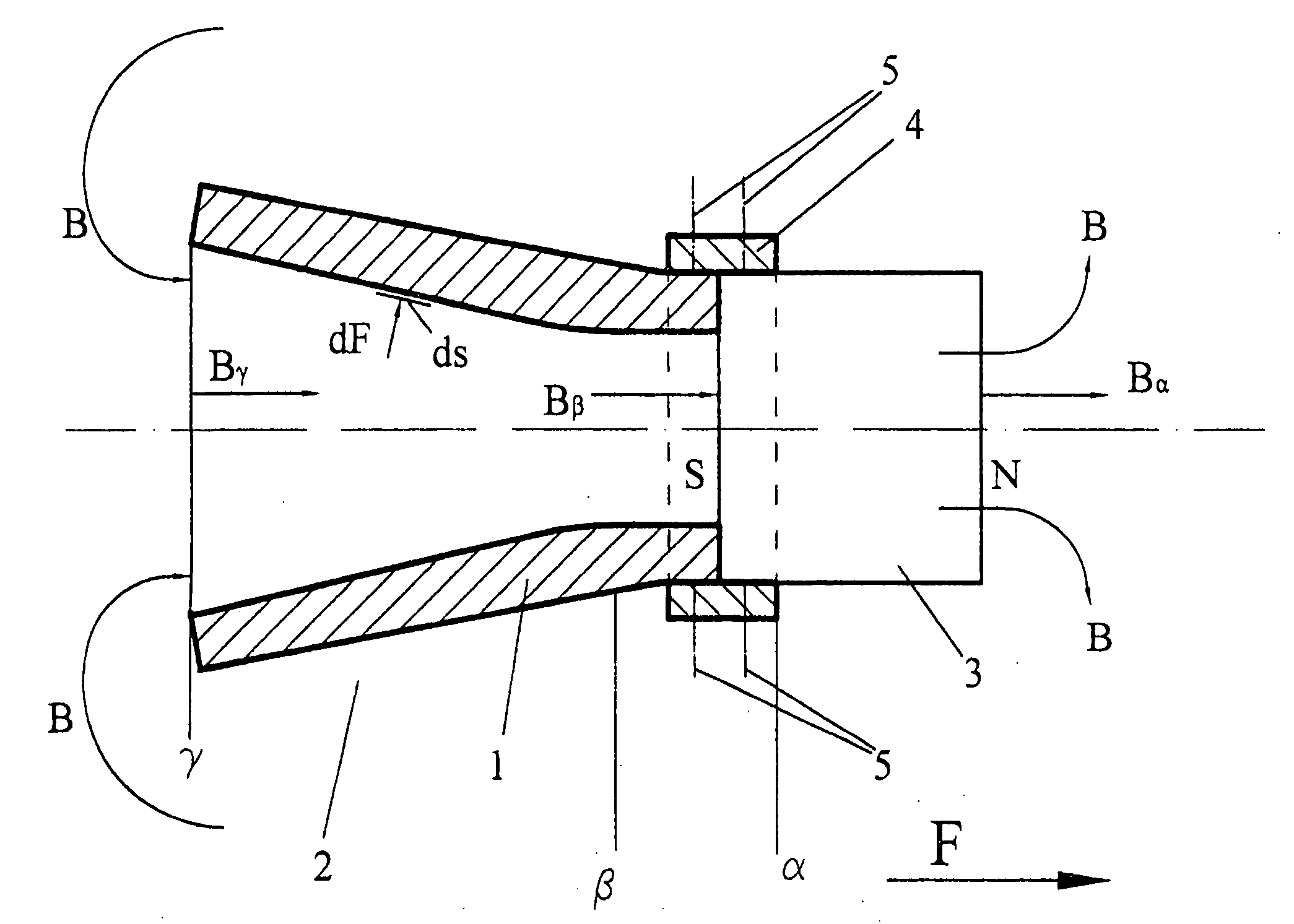

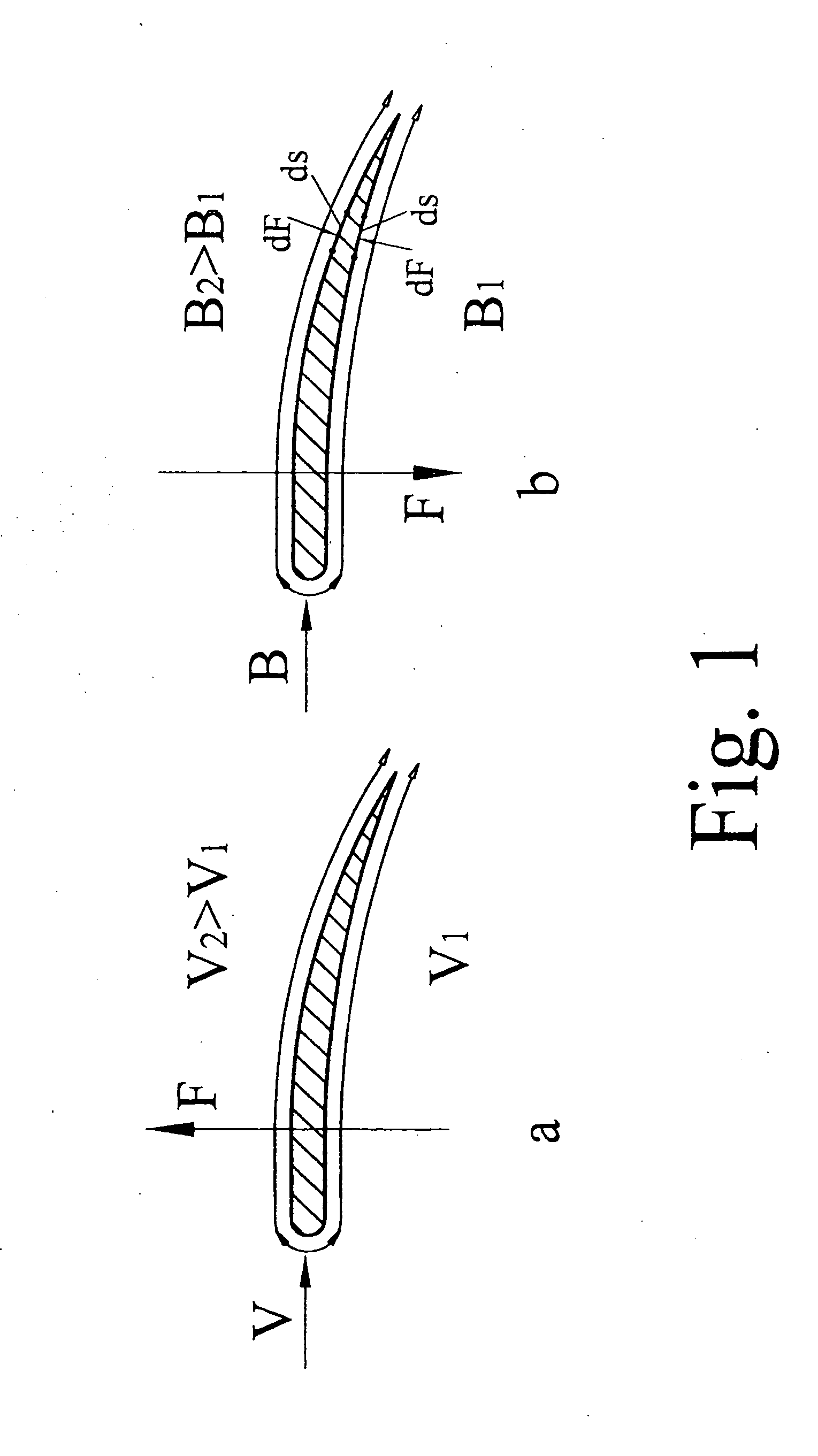

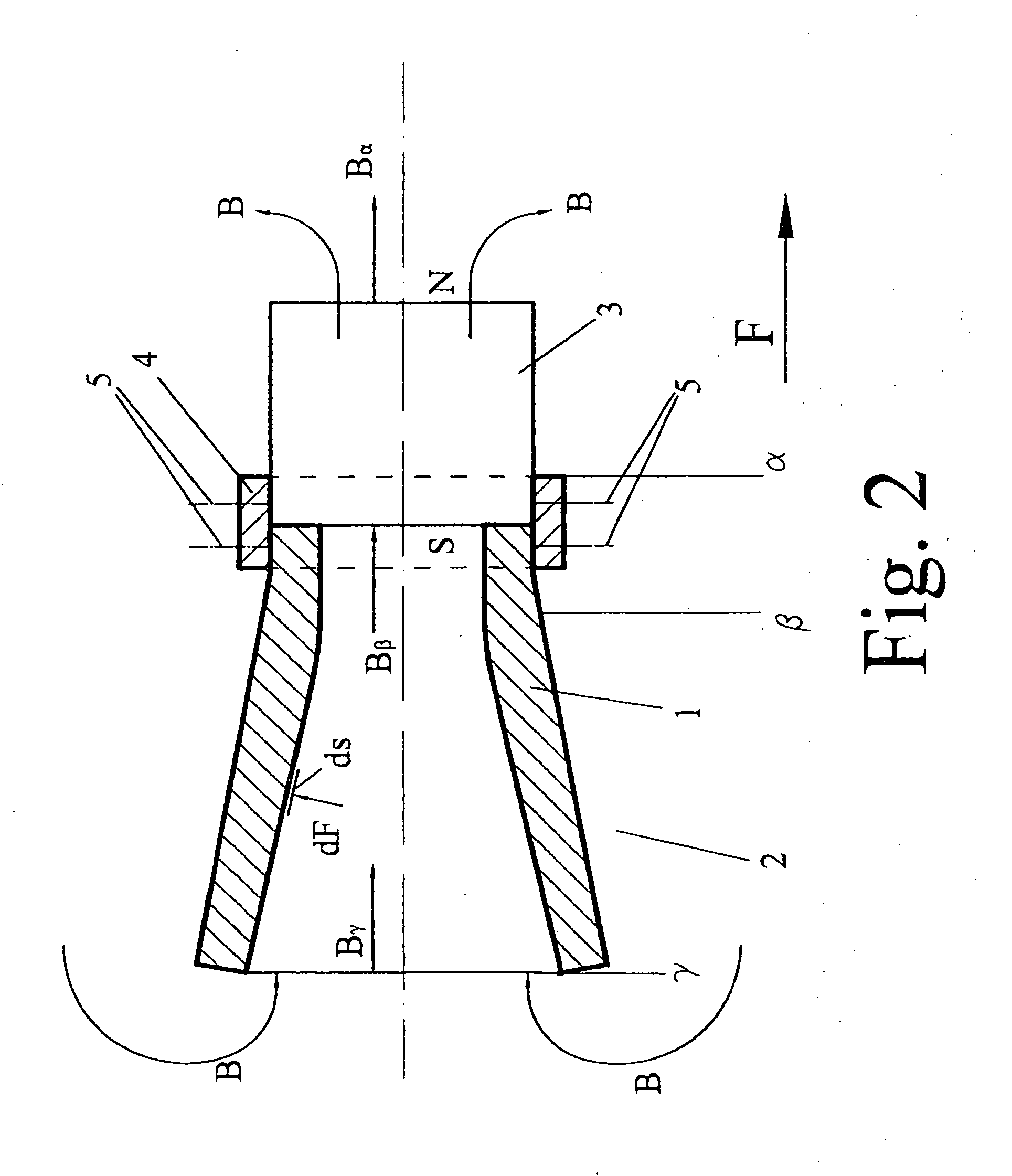

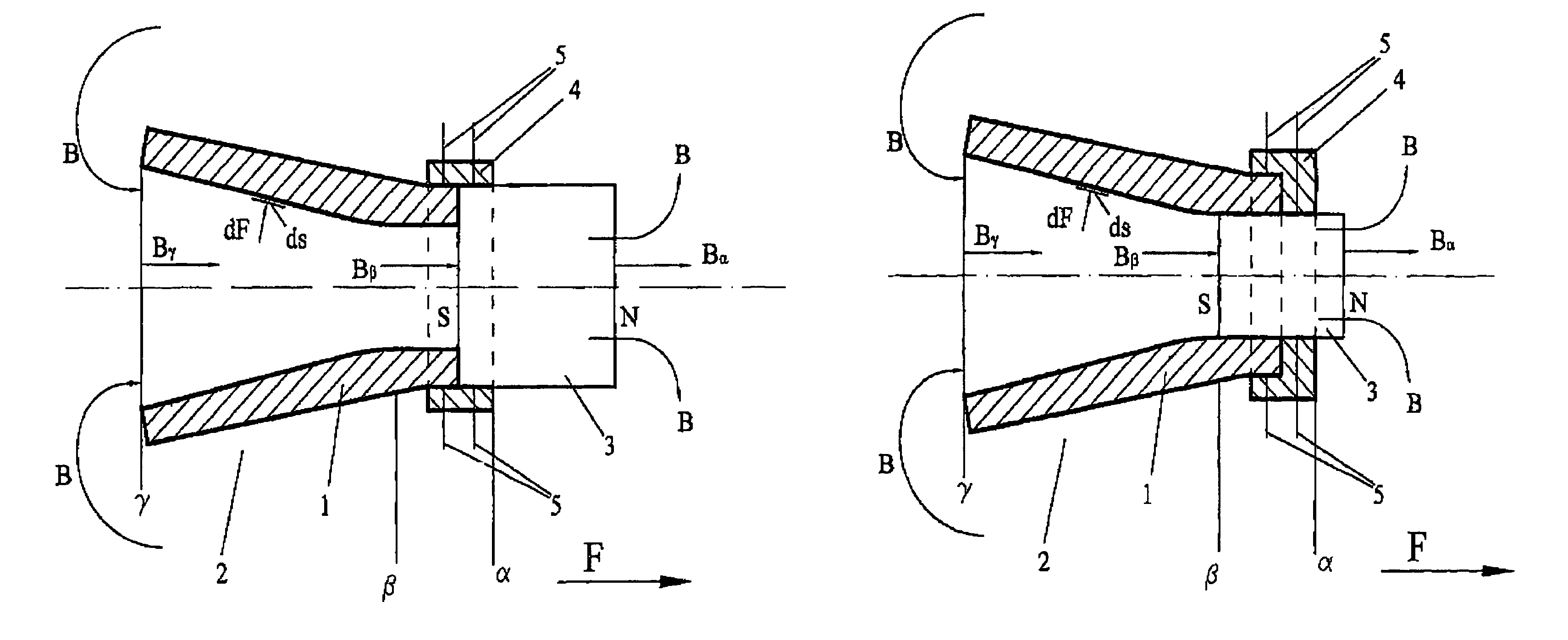

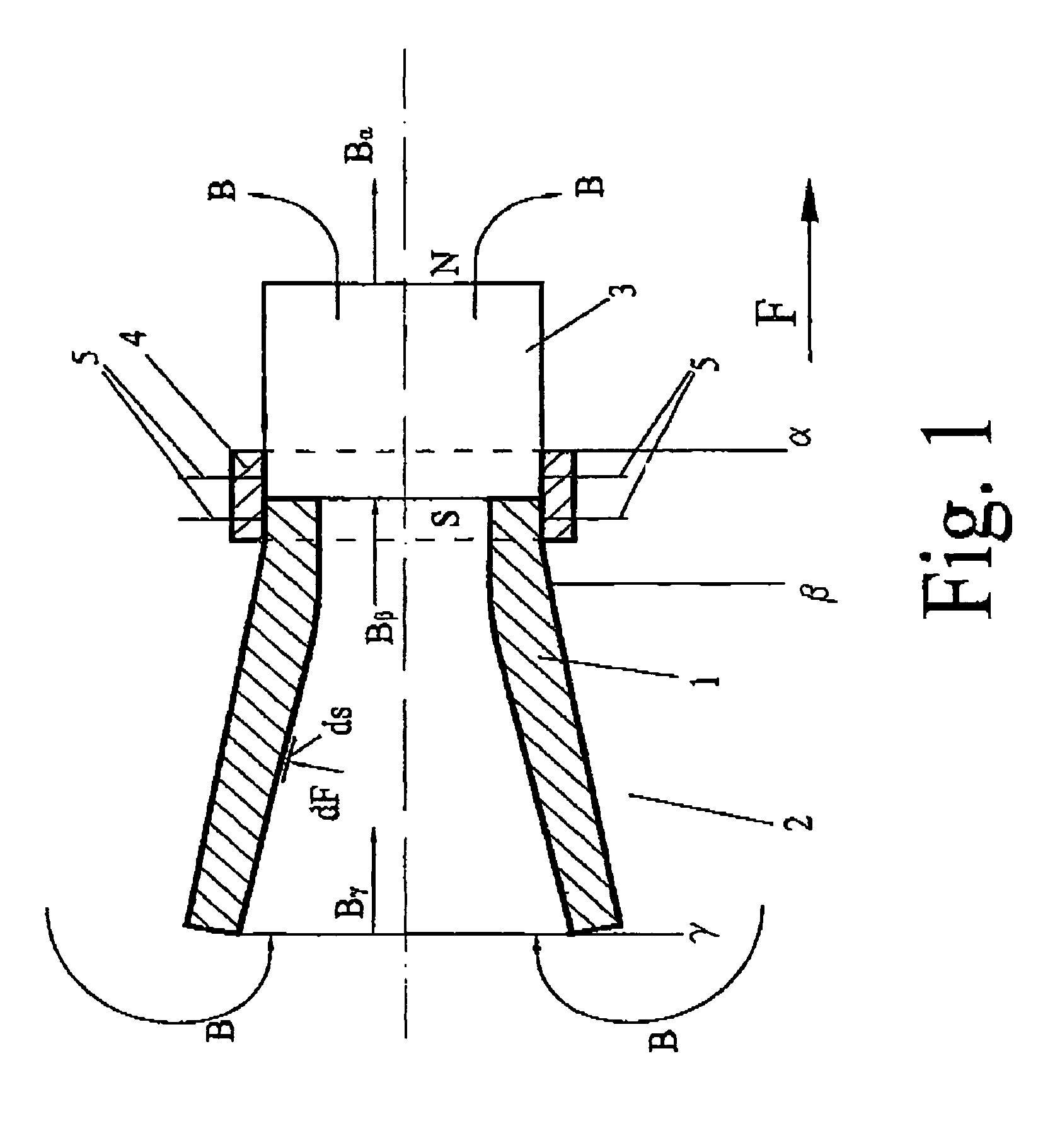

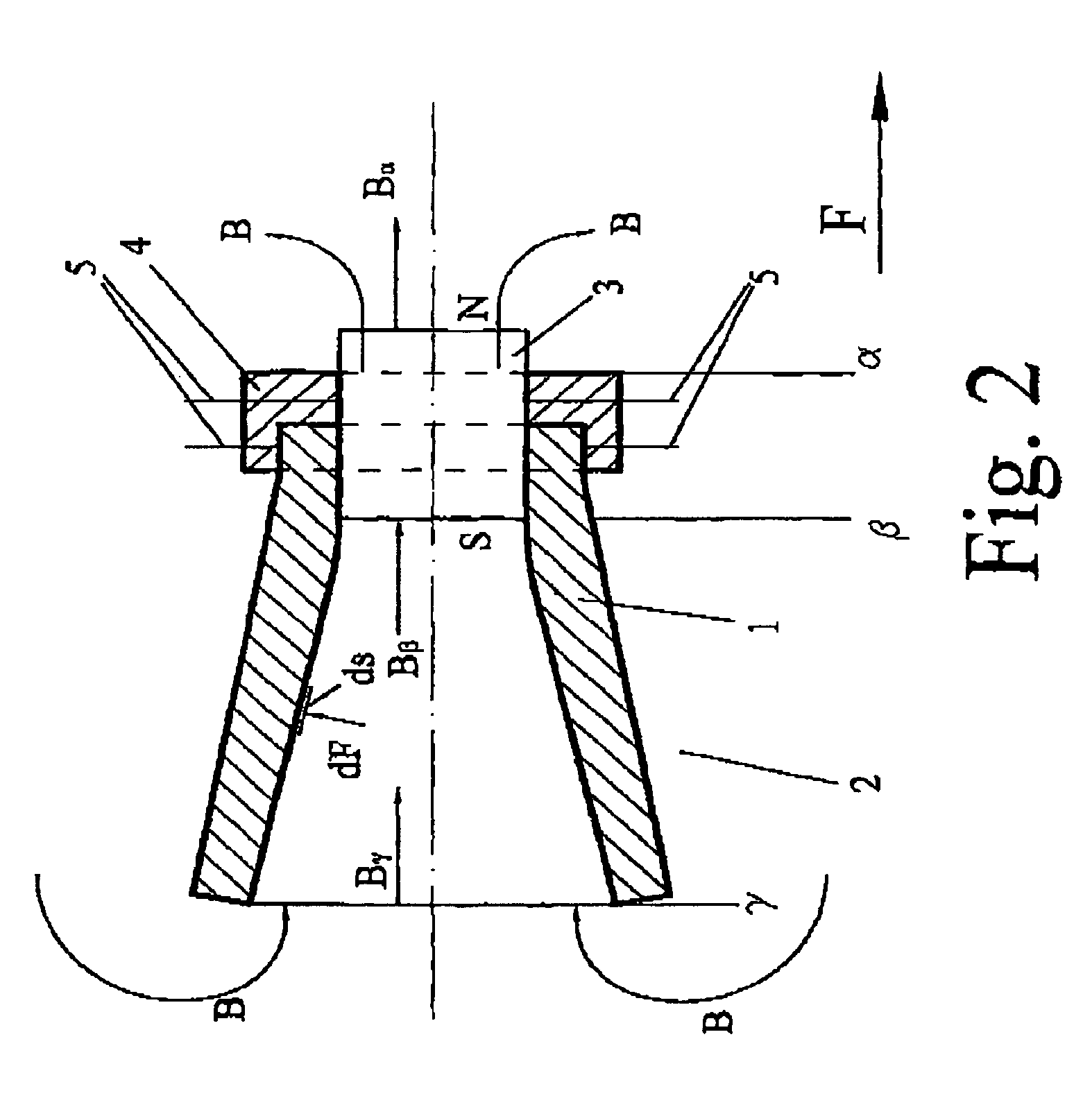

Magnetic propulsion method and mechanism using magnetic field trapping superconductors

A method for the creation of propulsive force and a mechanism for implementing the method comprising a magnet (3), like a permanent magnet or a superconductive solenoid, located at the output of a mechanism (2) inside which the propulsive force is developed and whose solid parts are those of a hydrodynamic machine made of a superconductor, like a type II superconductor, e.g. a superconductor Sm—Ba—Cu—O with high magnetic field trapping ability. The magnetic field generated by the interaction of magnet (3) with mechanism (2) acts in the form of pressure on mechanism (2) thereby creating the intended propulsion. Mechanism (2) may be a converging nozzle made from a superconductor (1), which conjointly with the magnet (3) act as self-propulsion mechanism with direction towards the converging area. The propulsive force being developed may be used for the propulsion required in any machine or vehicle, as well as in the production of energy.

Owner:NASSIKAS ATHANASSIOS A

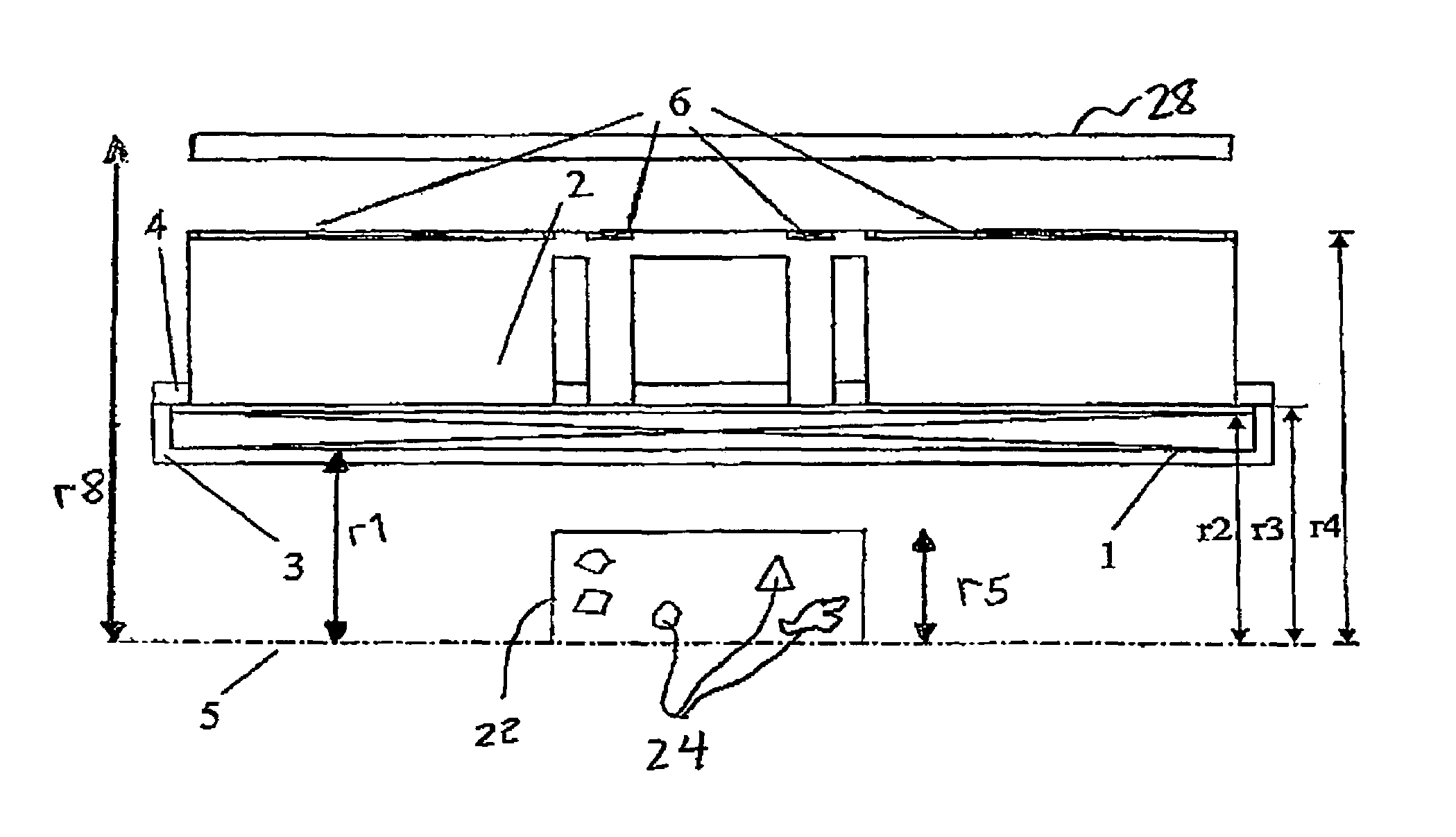

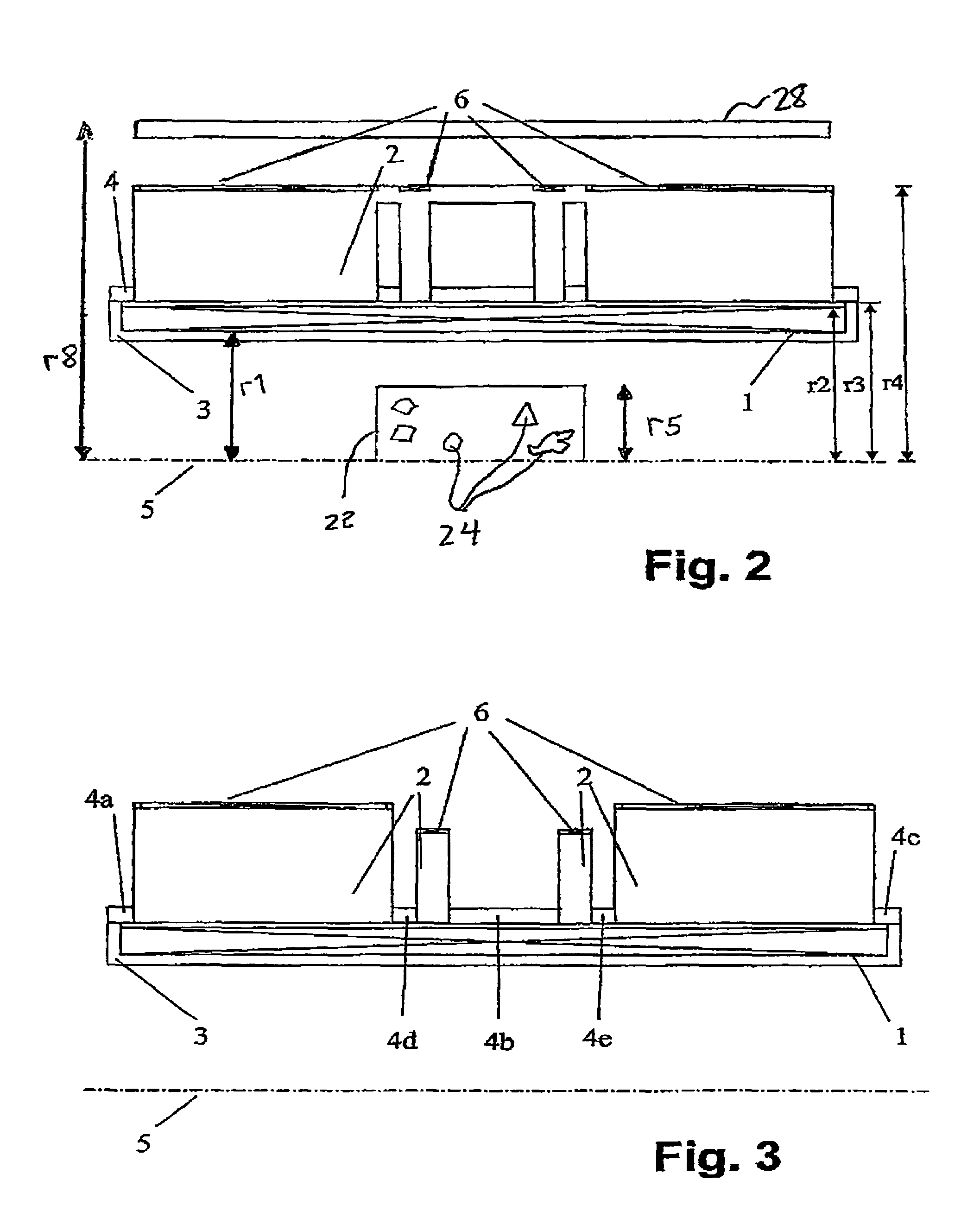

Hybrid magnet configuration

ActiveUS7365540B2High strengthIncrease field strengthMagnetic measurementsElectric/magnetic detectionResonanceSuperconducting solenoid

A co-axial magnet configuration for the production of a magnetic field and investigational volume which is suitable for measurement of magnetic resonance has at least one superconducting solenoid coil or solenoid coils which are radially nested within each other, wherein the windings of the solenoid coil(s) in a radial region about the axis of the magnetic configuration are disposed between r1 and r2, wherein r1<r2 is characterized in that the windings are surrounded by at least one rotationally symmetric magnet body made from ferromagnetic material which extends over a radial region between r3 and r4 wherein r3<r4 wherein r2<r3<1.3 r2 and r4>1.3 r3, wherein the rotationally symmetric magnet body or bodies are structured, dimensioned and positioned in such a fashion that the magnetic field is homogenized in the investigational volume and the magnetic fringe field outside the magnet configuration is essentially suppressed to permit the production of strong magnetic fields of high homogeneity without requiring notches in the coil configuration.

Owner:BRUKER BIOSPIN

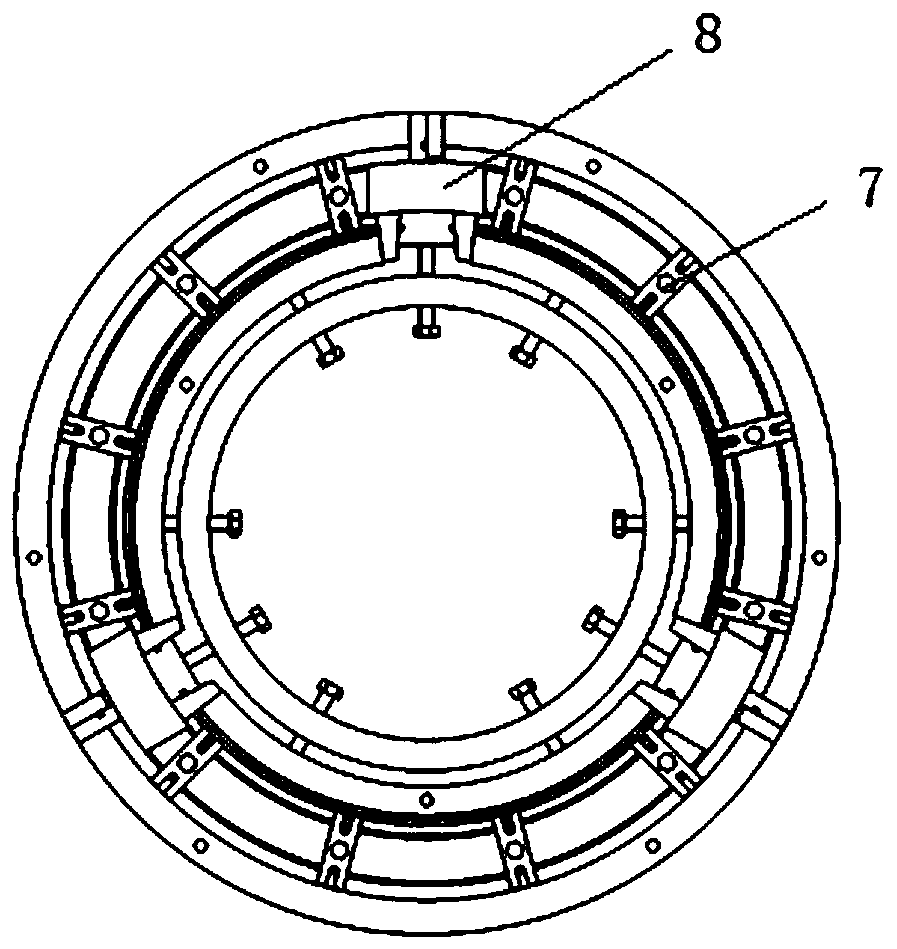

Helium groove of compound superconducting solenoid magnet coil

ActiveCN105261438ACompact structureAvoid normal weldingSuperconducting magnets/coilsSuperconducting solenoidHorizontal and vertical

The invention relates to the technical field of a particle accelerator superconducting solenoid magnet, in particular to a helium groove of a compound superconducting solenoid magnet coil. The helium groove is characterized by comprising a superconducting solenoid magnet coil frame, wherein the superconducting solenoid magnet coil frame is packaged in the helium groove and comprises a beam passage tube, the beam passage tube serves as two pairs of horizontal and vertical runway-type coil frames, a main magnetic field coil frame sleeves the beam passage tube, two shielding magnetic field coil frames are arranged at the two ends of the main magnetic field coil frame, distances tubes are correspondingly arranged between the main magnetic field coil frame and the shielding magnetic field coil frames, helium groove end plates are arranged outside the shielding magnetic field coil frames, and a liquid helium outlet, a liquid helium inlet and a current lead interface are further arranged on the helium groove. The helium groove has the characteristics of compact structure, strong magnetic field and low stray field, is easy to manufacture and convenient to assemble, and is simple in positioning and low in welding workload and welding deformation, the processing accuracy is easily guaranteed, and the assembly accuracy can be effectively ensured to reach requirement.

Owner:INST OF MODERN PHYSICS CHINESE ACADEMY OF SCI

Magnetic propulsion device using superconductors

A device for the creation of propulsive force comprising a magnet, such as a permanent magnet or a superconductive solenoid, fixedly mounted at the narrow end of a converging nozzle made of a superconductor, such as a type II superconductor, e.g. like the rare earth Ba—Cu—O superconductors Sm—Ba—Cu—O or Y—Ba—Cu—O. The magnetic field generated by the interaction of the magnet with the superconducting nozzle due to Meissner effect, acts in the form of pressure on nozzle thereby producing a propulsive force directed toward the nozzle's converging end. The propulsive force being developed may be used for propelling or actuating any machine or vehicle, as well as in the production of energy.

Owner:NASSIKAS ATHANASSIOS A

Constant-tension winding machine for niobium titanium-copper superconducting solenoid coils

InactiveCN102030223BCompact space arrangementSmall footprintFilament handlingCoils manufactureWinding machineSuperconducting solenoid

The invention provides a constant-tension winding machine for niobium titanium-copper superconducting solenoid coils, relating to a winding machine for superconducting solenoid coils. The invention solves the problems of complex winding process, high labor intensity of operators and low use ratio of equipment space of the current winding machine for superconducting solenoid coils. In the invention, an L-shaped portal frame is provided with two first slider linear guide rails and a first ball screw, and a double-track pulley is installed on a wiring arm. A wiring support arm of the wiring arm is provided with a wiring pulley, and a wire loading support arm of the wiring arm is provided with a wire loading pulley. A movable pulley is installed on a movable pulley axis support, and a wire loading tray is rotatably installed on a wire loading support. A superconducting solenoid coil to be wound is rotatably installed on a winding support, and a lead wire is led out through the wire loading tray and wound on the superconducting solenoid coil to be wound after moving round the wire loading pulley, one slideway of the double-track pulley, the movable pulley, the other slideway of the double-track pulley and the wiring pulley. The constant-tension winding machine is suitable for winding niobium titanium-copper superconducting solenoid coils.

Owner:HARBIN INST OF TECH

Quantum resistance standard device

PendingCN109596871ABase element modificationsElectrical resistance and conductanceSuperconducting solenoid

The invention provides a quantum resistance standard device. The quantum resistance standard device comprises a superconducting solenoid coil, a quantum hall resistance chip, a heat conduction mechanism and a metal shell, wherein the quantum hall resistance chip is arranged in the superconducting solenoid coil; when the superconducting solenoid coil is electrified, the quantum hall resistance chipis located in a magnetic field; one end of the heat conduction mechanism is connected to the quantum hall resistance chip; and the metal shell is buckled on the superconducting solenoid coil and theheat conduction mechanism, and the other end of the heat conduction mechanism extends out of the metal shell. The quantum resistance standard device is small in size, convenient to use, easy to achieve working requirements and beneficial to popularization and application.

Owner:NAT INST OF METROLOGY CHINA

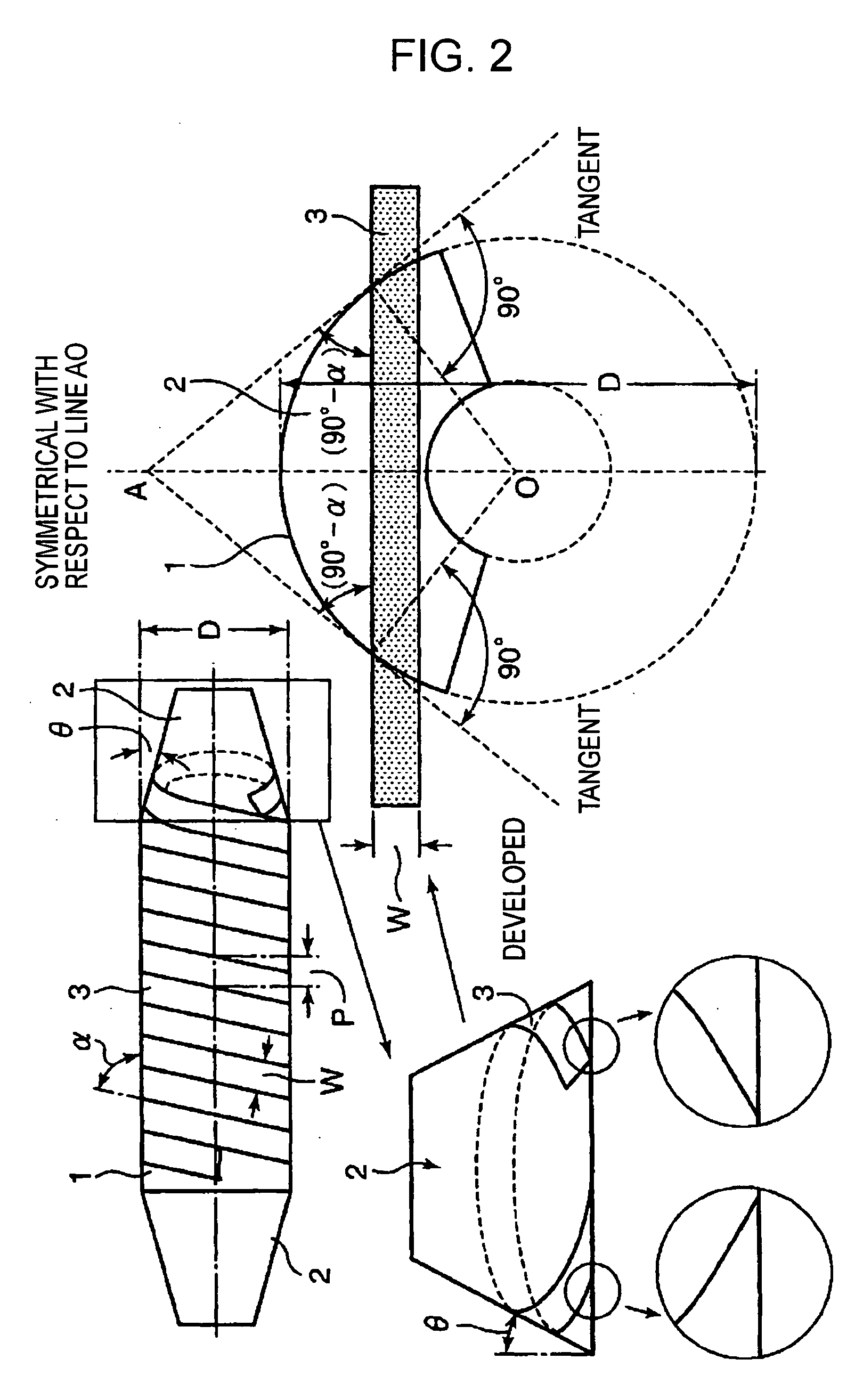

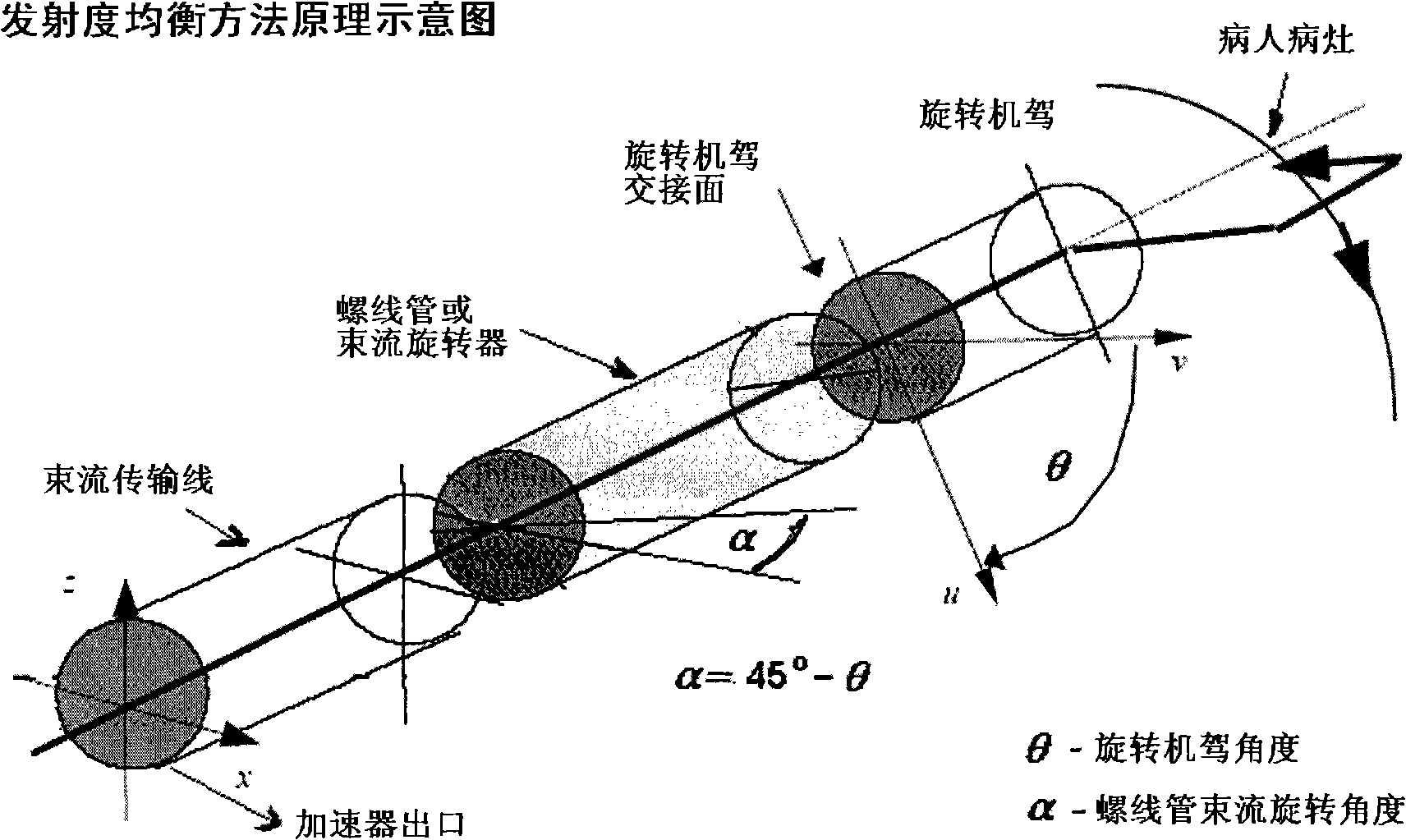

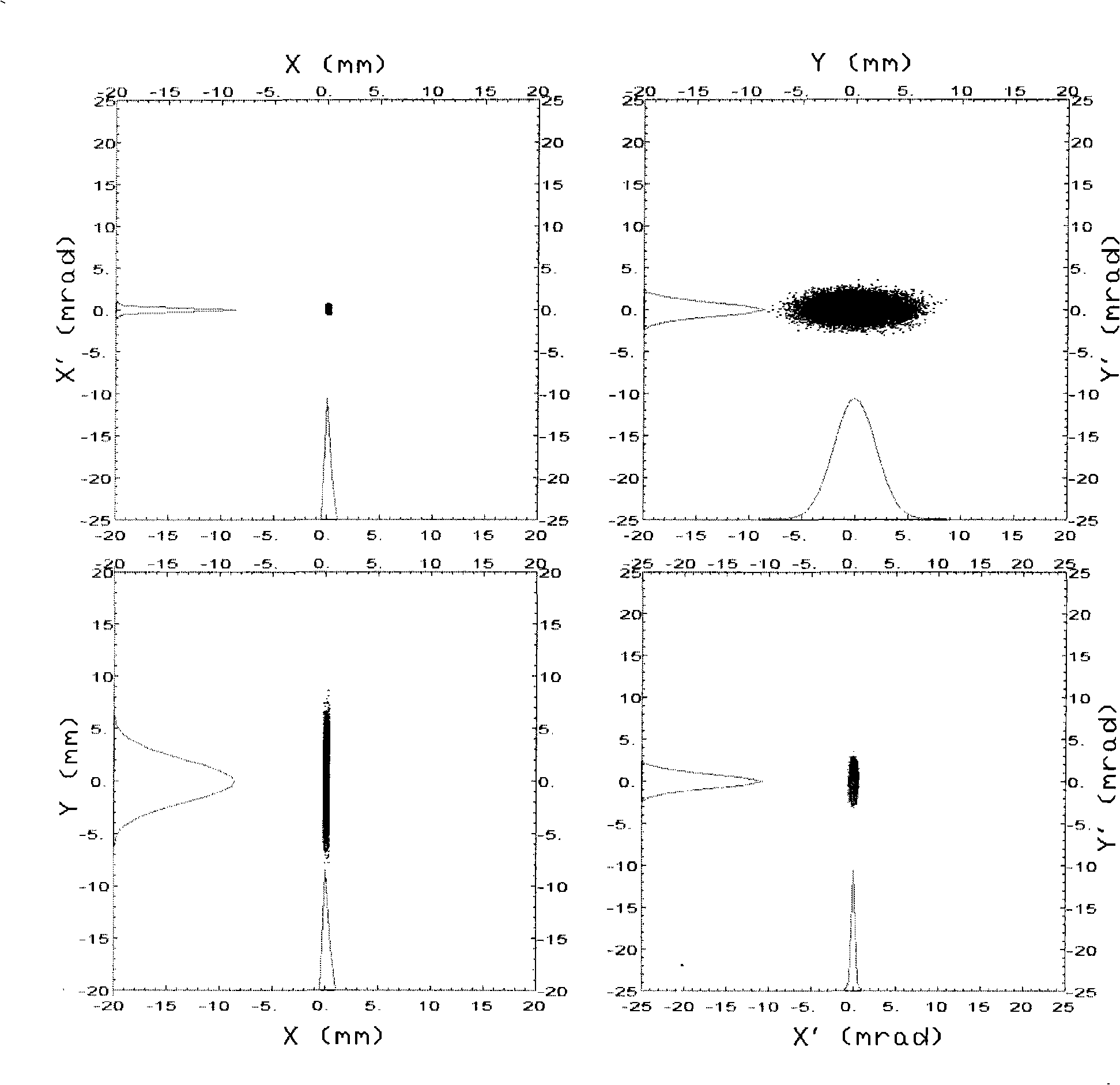

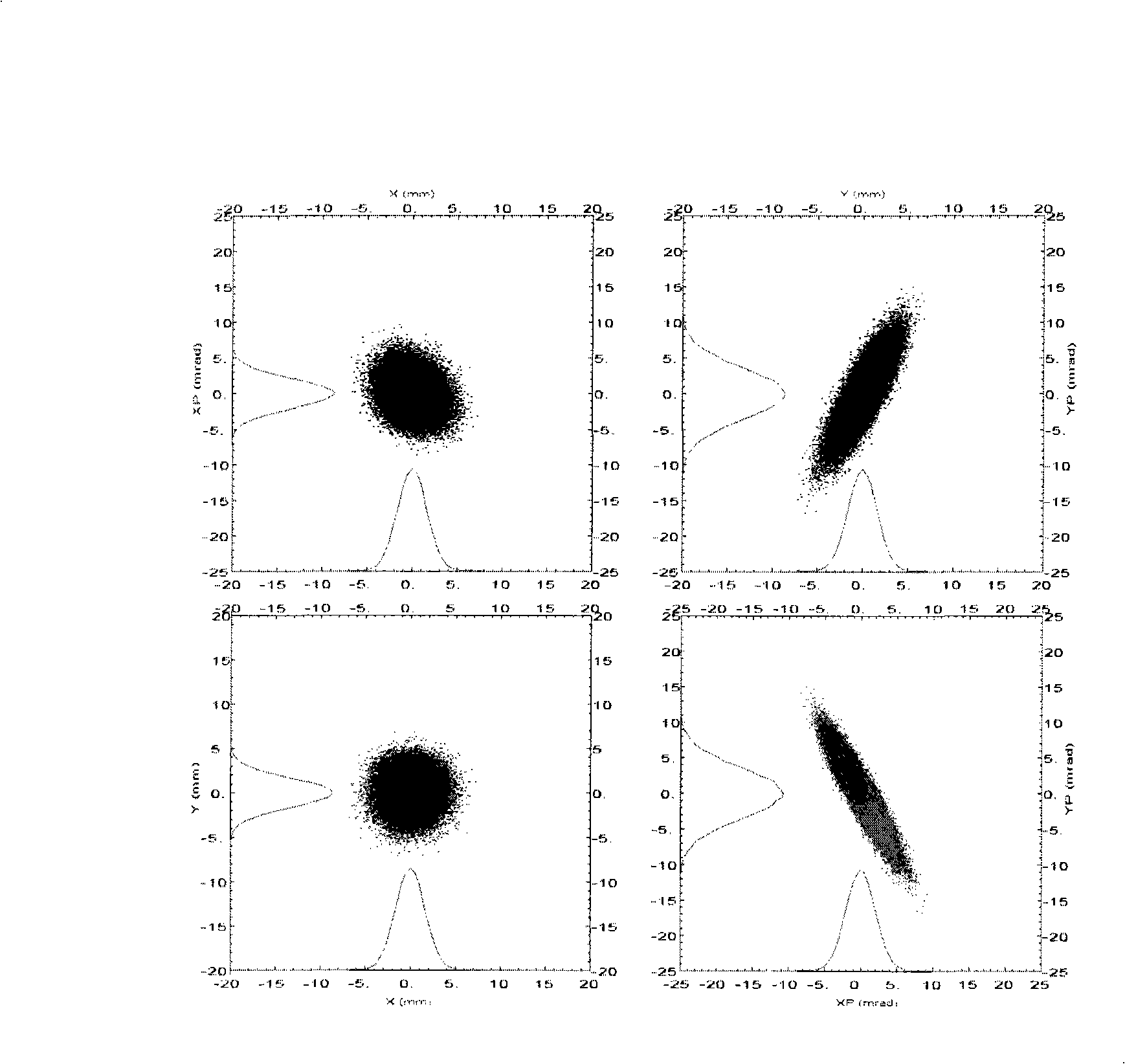

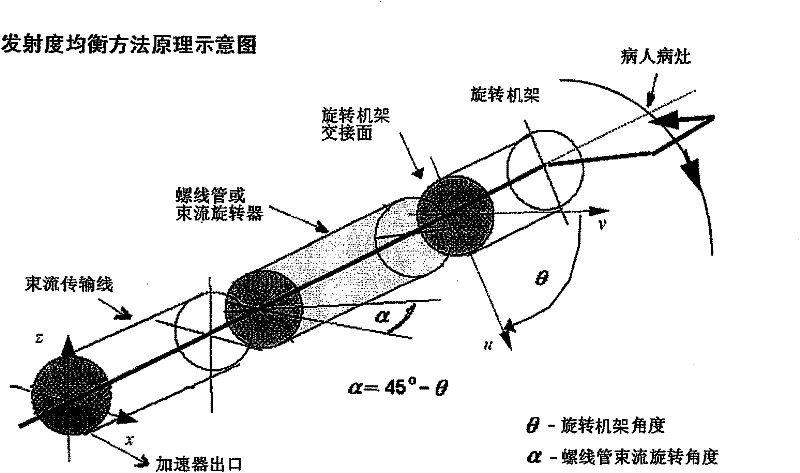

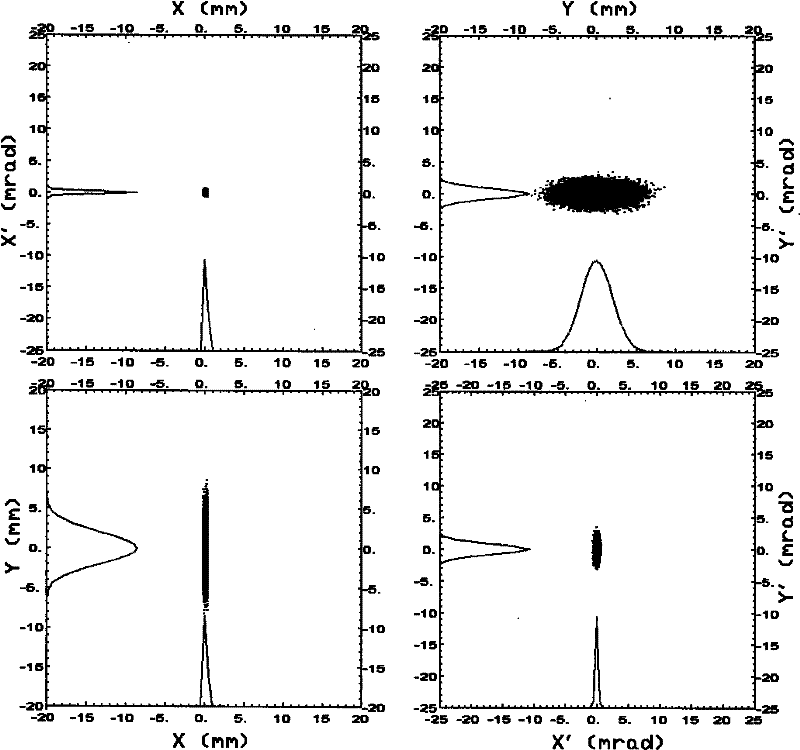

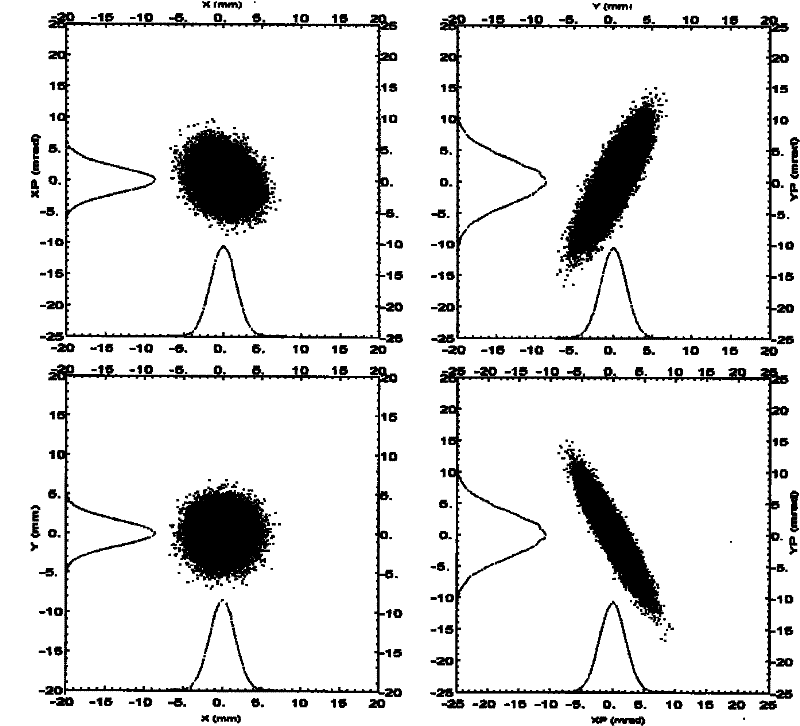

Equalizing method of beam emittance

InactiveCN101515484AReduce weightSmall beam emittanceRadiation/particle handlingX-ray/gamma-ray/particle-irradiation therapyBeam angleSuperconducting solenoid

The invention discloses an equalizing method of beam emittance, including the followings: according to the beam type and energy, one of plain solenoid, superconducting solenoid and beam gyrator is used as an emittance equalizing unit; the mounting space of the emittance equalizing unit is arranged on the beam transmission line; the inlets of the emittance equalizing unit and the gyrator respectively carries out matching of TWISS parameters so that the TWISS parameters in horizontal phase space and vertical phase space are equal; a required beam angle of rotation is set for the emittance equalizing unit; normal beam spot size matching is carried out, and the matching of beam slope angle in real space X-Y phase plane of beam cross-section is carried out; and when the energy of curing beam is changed, the magnetic setting of the beam emittance equalizing unit is simultaneously adjusted with the whole beam transmission system. The application of the invention can carry out equalizing process for beam emittance in horizontal and vertical directions so that the beam optics remains the same in the gyrator.

Owner:INST OF HIGH ENERGY PHYSICS CHINESE ACADEMY OF SCI

Equalizing method of beam emittance

InactiveCN101515484BReduce weightSmall beam emittanceRadiation/particle handlingX-ray/gamma-ray/particle-irradiation therapyBeam angleSuperconducting solenoid

The invention discloses an equalizing method of beam emittance, including the followings: according to the beam type and energy, one of plain solenoid, superconducting solenoid and beam gyrator is used as an emittance equalizing unit; the mounting space of the emittance equalizing unit is arranged on the beam transmission line; the inlets of the emittance equalizing unit and the gyrator respectively carries out matching of TWISS parameters so that the TWISS parameters in horizontal phase space and vertical phase space are equal; a required beam angle of rotation is set for the emittance equalizing unit; normal beam spot size matching is carried out, and the matching of beam slope angle in real space X-Y phase plane of beam cross-section is carried out; and when the energy of curing beam is changed, the magnetic setting of the beam emittance equalizing unit is simultaneously adjusted with the whole beam transmission system. The application of the invention can carry out equalizing process for beam emittance in horizontal and vertical directions so that the beam optics remains the same in the gyrator.

Owner:INST OF HIGH ENERGY PHYSICS CHINESE ACAD OF SCI

Superconductive magnet system for intercurrent treatment three-dimensional position

ActiveCN100509077CSimple structureGuaranteed uptimeMedical devicesCatheterSuperconducting solenoidRectangular coordinates

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Superconducting magnet supporting and positioning system

ActiveCN103065759BReduce conduction heat leakageLow powerSuperconducting magnets/coilsMagnetic holding devicesSuperconducting solenoidSuperconducting Coils

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Apparatus And Method Of Superconducting Magnet Cooling

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com