Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

94 results about "Electromagnetic absorbers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electromagnetic absorbers are specifically chosen or designed materials that can inhibit the reflection or transmission of electromagnetic radiation. For example, this can be accomplished with materials such as dielectrics combined with metal plates spaced at prescribed intervals or wavelengths. The particular absorption frequencies, thickness, component arrangement and configuration of the materials also determine capabilities and uses. In addition, researchers are studying advanced materials such as metamaterials in hopes of improved performance and diversity of applications. Some intended applications for the new absorbers include emitters, sensors, spatial light modulators, infrared camouflage, wireless communication, and use in thermophotovoltaics.

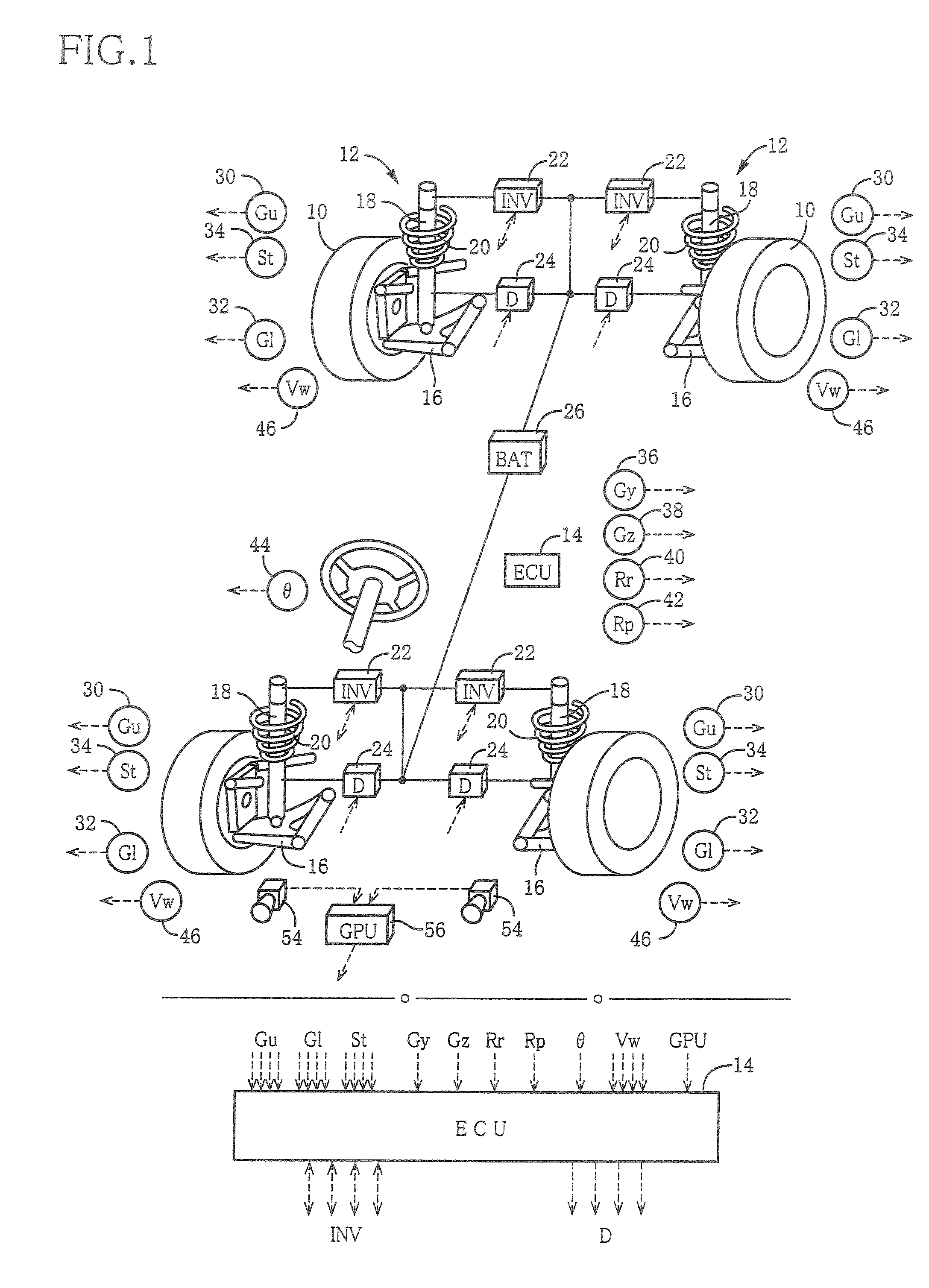

Damping force generation system and vehicle suspension system constructed by including the same

InactiveUS7722056B2High utilityMore roomSpringsVehicle cleaning apparatusElectrical resistance and conductanceElectromagnetic absorbers

It is an object of the invention to improve the utility of an electromagnetic absorber system which is disposed in a suspension system of a vehicle and which generates a damping force by a generation force of a motor. The electromagnetic absorber system 18 is equipped with high-speed-motion responding means, thereby obviating an insufficiency of the damping force and a deterioration of the controllability in a high-speed stroke motion. More specifically, a hydraulic absorber 64 is provided in combination with the electromagnetic absorber system such that the hydraulic absorber 64 operates in the high-speed motion in which an electromotive force of the motor 68 exceeds a power source voltage Further, two motors having mutually different T-N characteristics are provided, and the two motors are selectively operated depending upon a stroke speed. Further, a variable resistor is interposed between the motor and the power source, and a resistance value of the variable resistor is increased in the high-speed motion to realize a decrease in a time constant of the motor, etc. Moreover, to cope with a large extent of unevenness of a road surface, an active stroke motion is performed by a drive force of the motor, thereby preventing the high-speed motion from being performed.

Owner:TOYOTA JIDOSHA KK +1

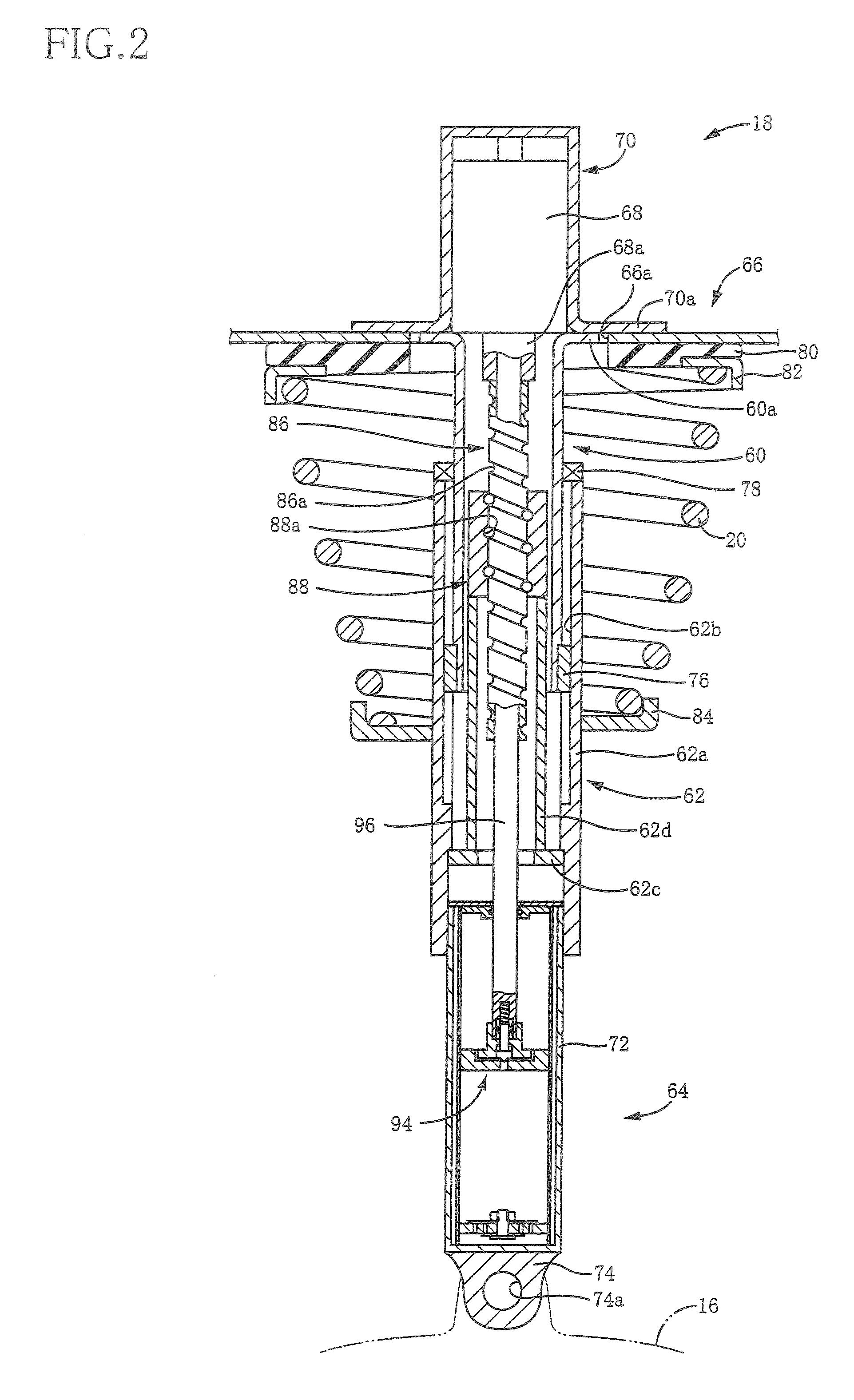

High-performance matched absorber using magnetodielectrics

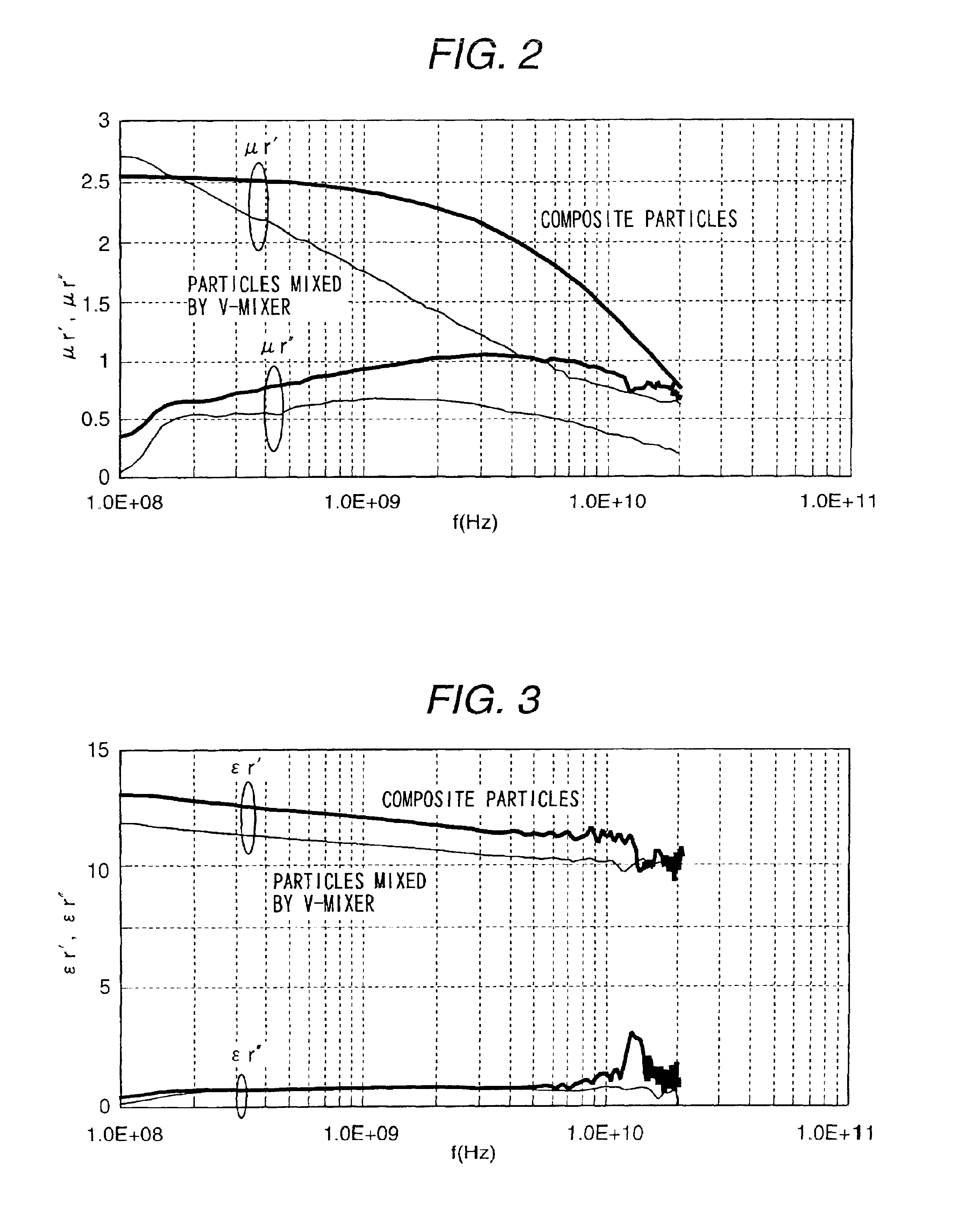

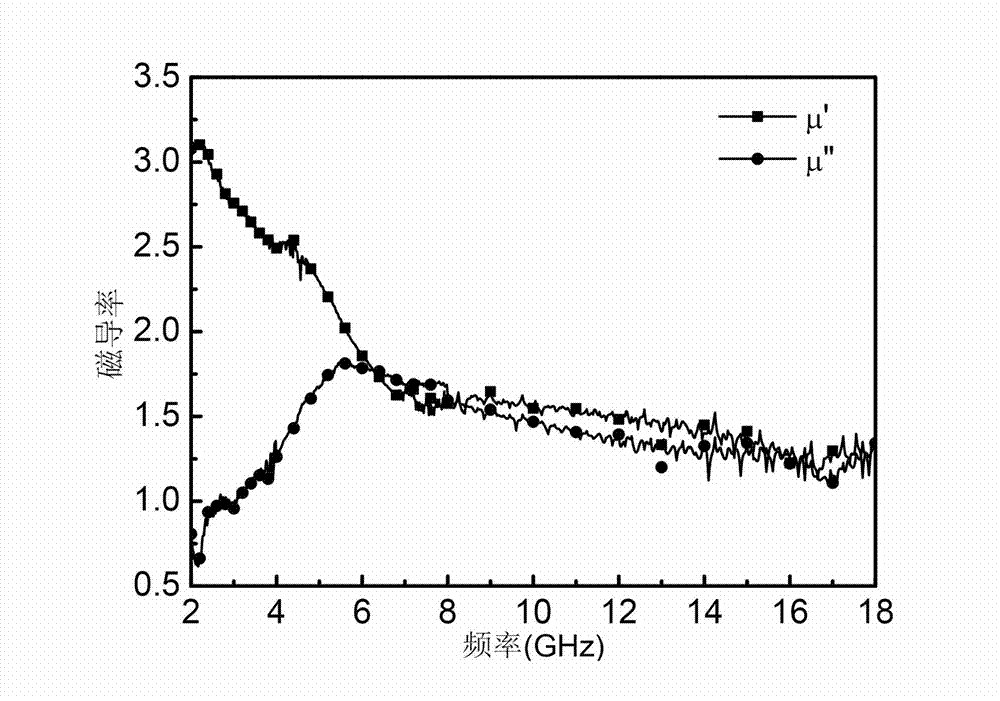

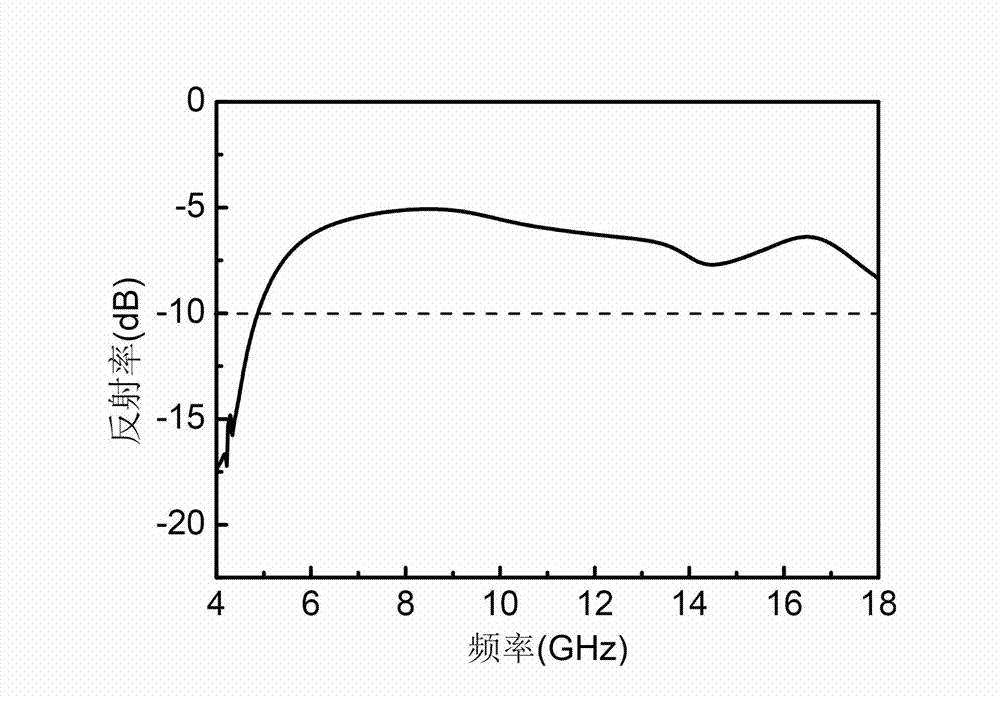

InactiveUS6337125B1Shielding materialsNatural mineral layered productsElectricityElectromagnetic absorbers

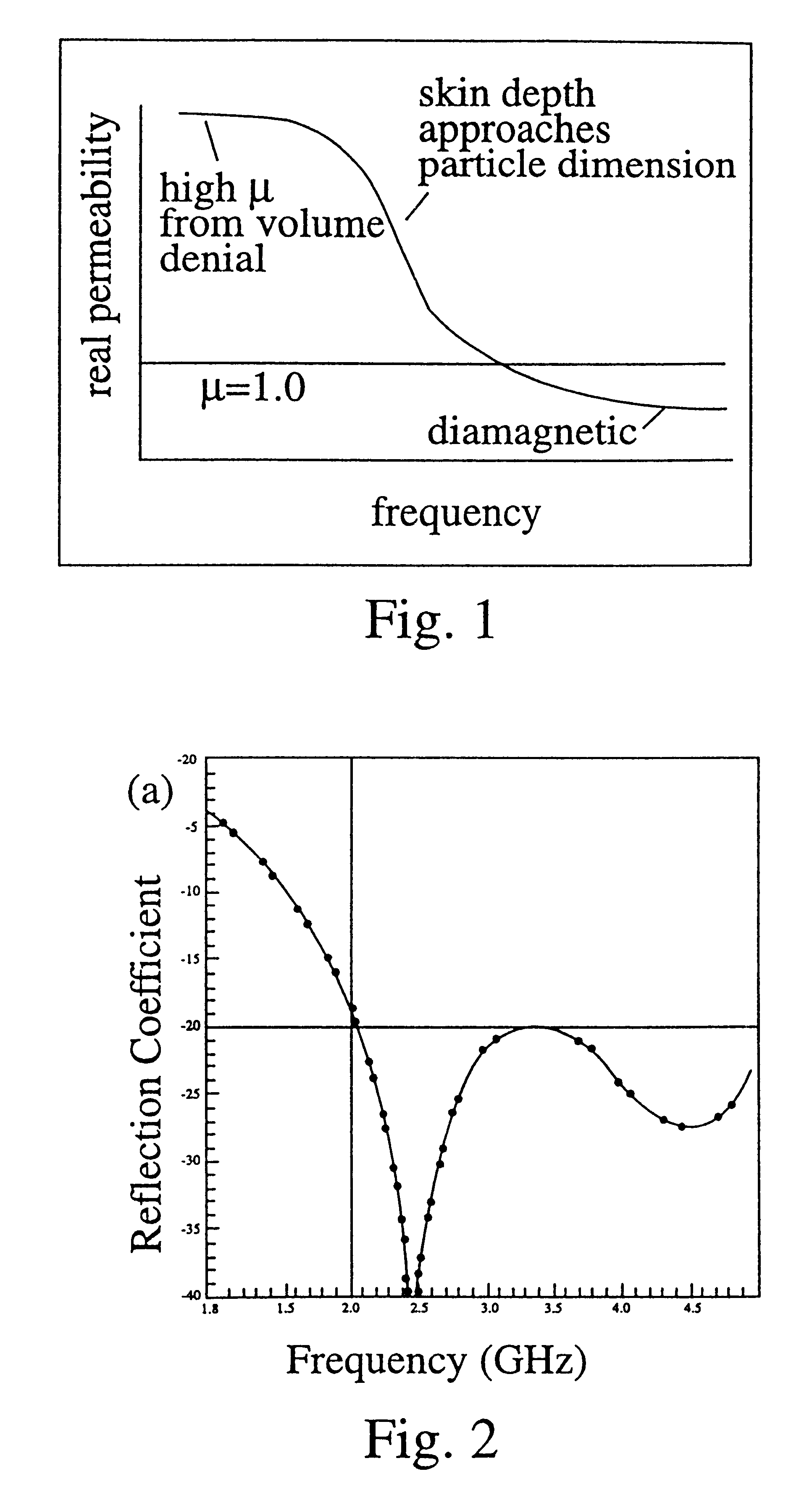

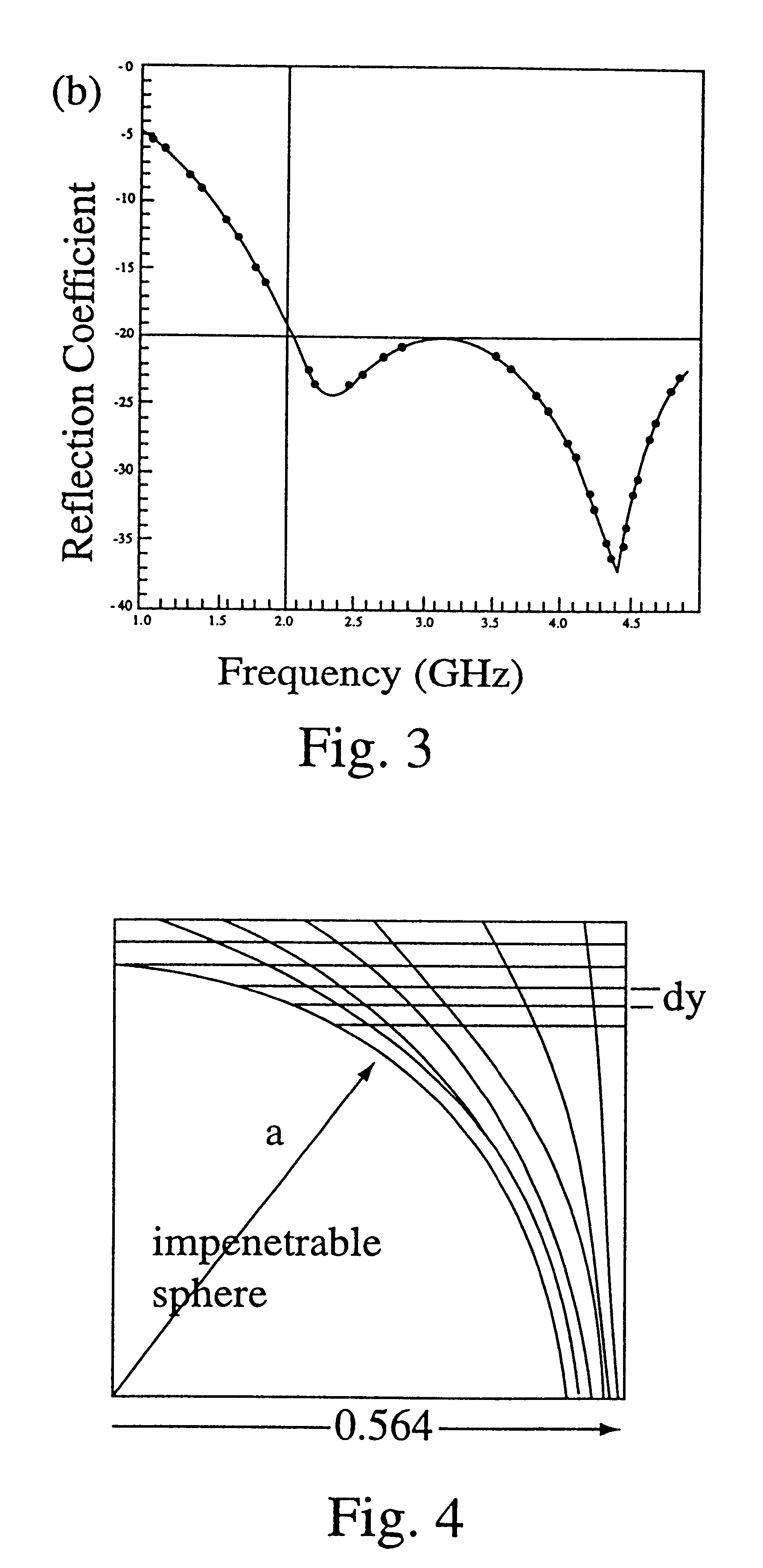

A composite electromagnetic absorber provides increased EMR absorption while being thinner and / or lighter than prior art EMR absorbers. To accomplish this, synthetic dielectric materials are combined with either synthetic magnetic materials or magnetically lossy materials in such a way that the permittivity and permeability of the composite material are substantially matched over the desired range of frequency. The match in the permittivity and permeability allows the majority of the electromagnetic fields to enter the material where the electric and magnetic loss components absorb the electromagnetic energy.

Owner:NORTHROP GRUMMAN SYST CORP

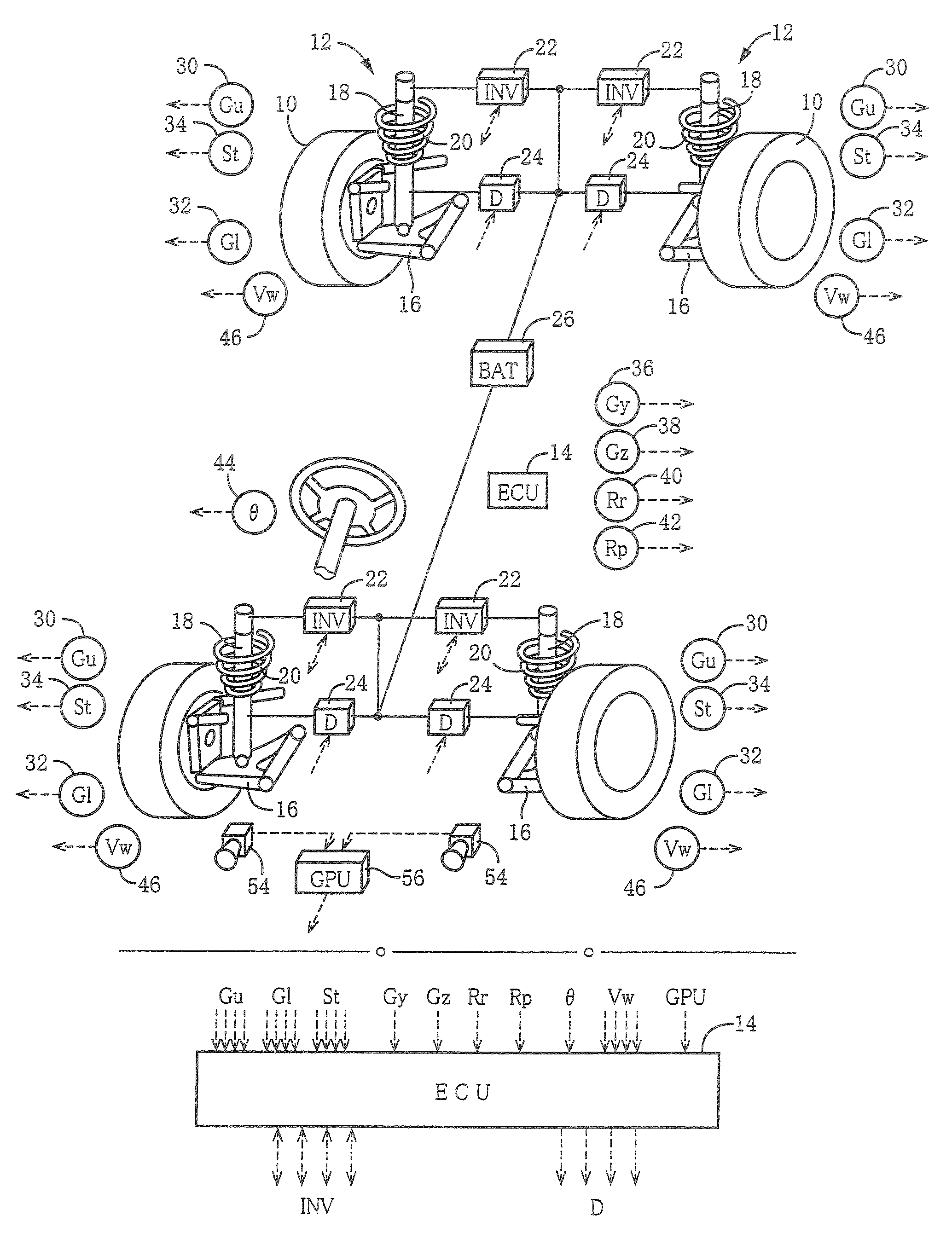

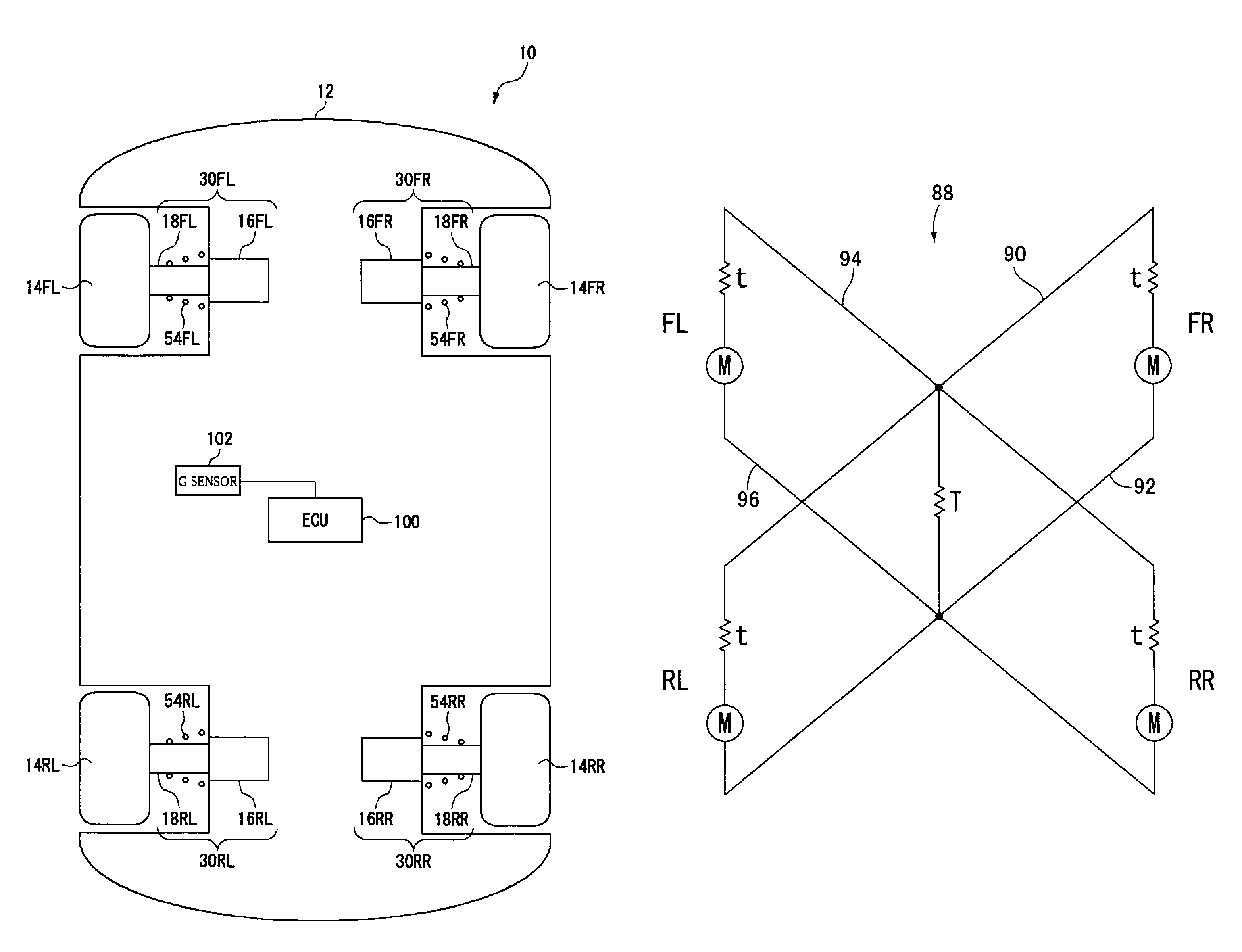

Suspension system for vehicle

ActiveUS20090273147A1Simple structureReduce voltageNon-rotating vibration suppressionDigital data processing detailsElectromagnetic absorbersClosed loop

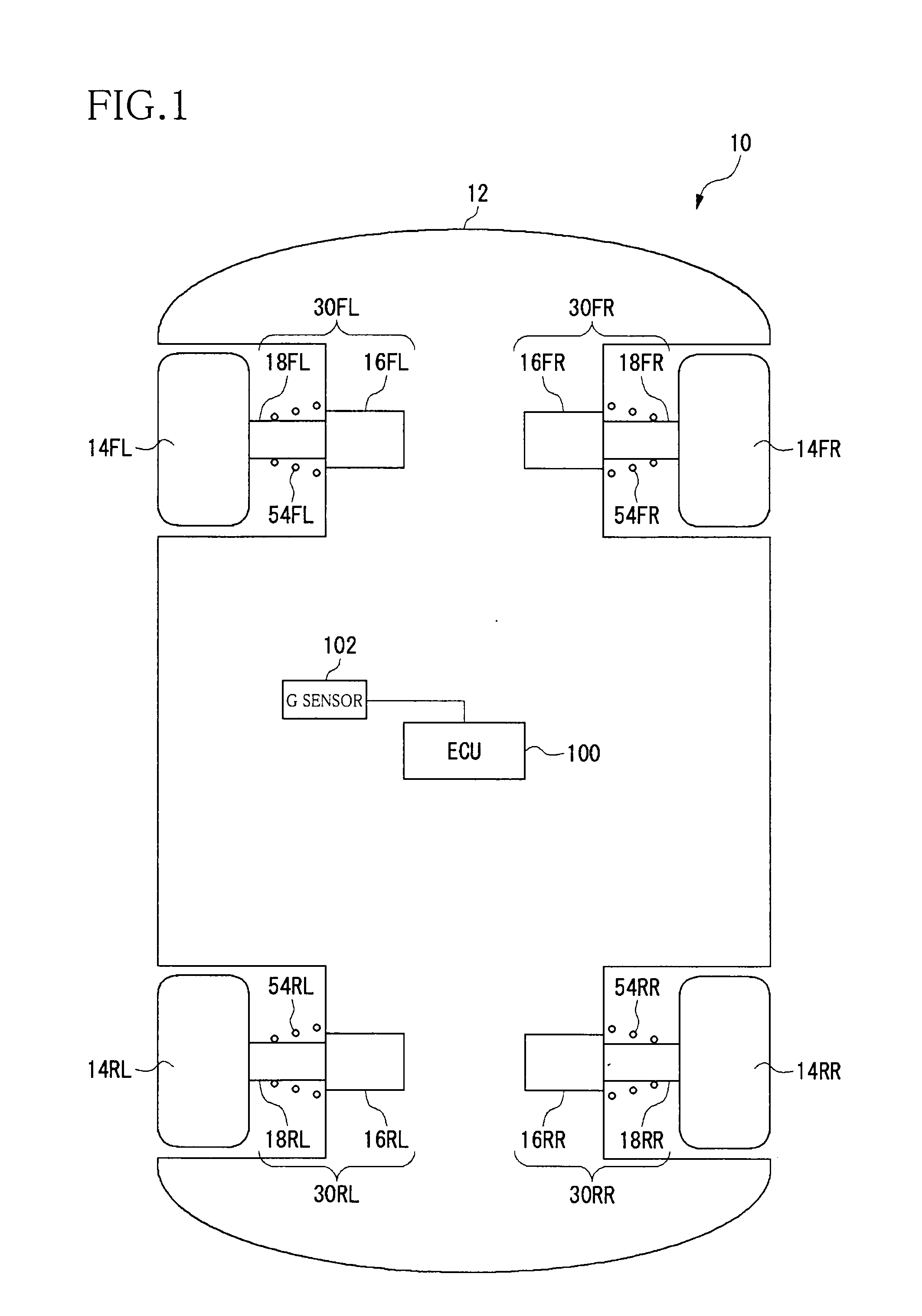

In a system including four electromagnetic absorbers for respective four vehicle wheels, motor coils of two respective electromagnetic absorbers disposed corresponding to two diagonally located wheels are connected forming a closed loop including the coils. A generated damping force magnitude can be made different between an instance directions of respective movements of the diagonally located two wheels with respect to the vehicle body are the same, and an instance the directions are opposite each other. Each electromagnetic absorber includes a resistor cooperating with the corresponding coil forming a closed loop, and selectively establishes: a connected state in which one of the four coils and any of the other three coils are connected to form a closed loop; and a non-connected state in which the one of the four coils is not connected to any other coil. An appropriate vibration suppressing action is exhibited with respect to a coupled motion.

Owner:KYB CORP +2

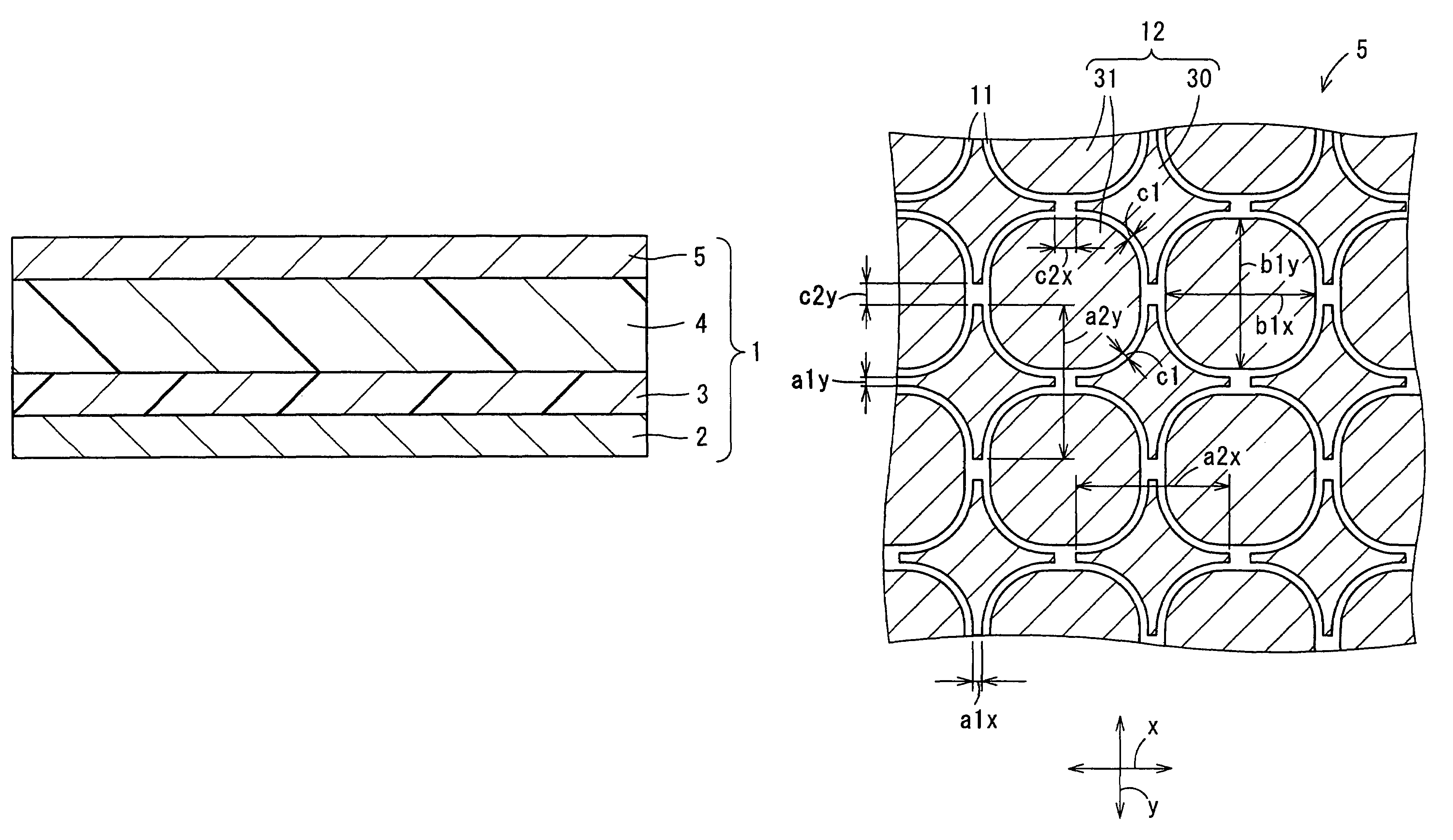

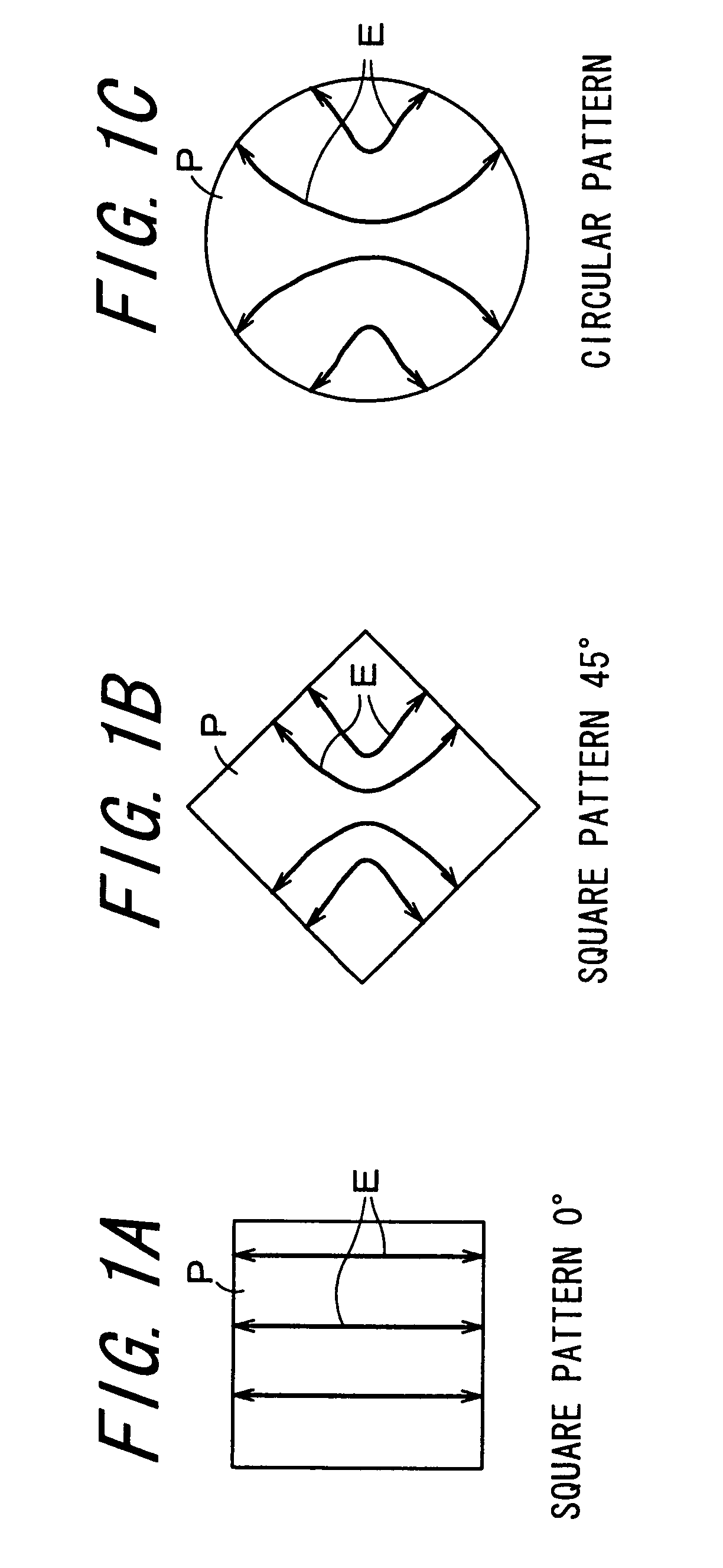

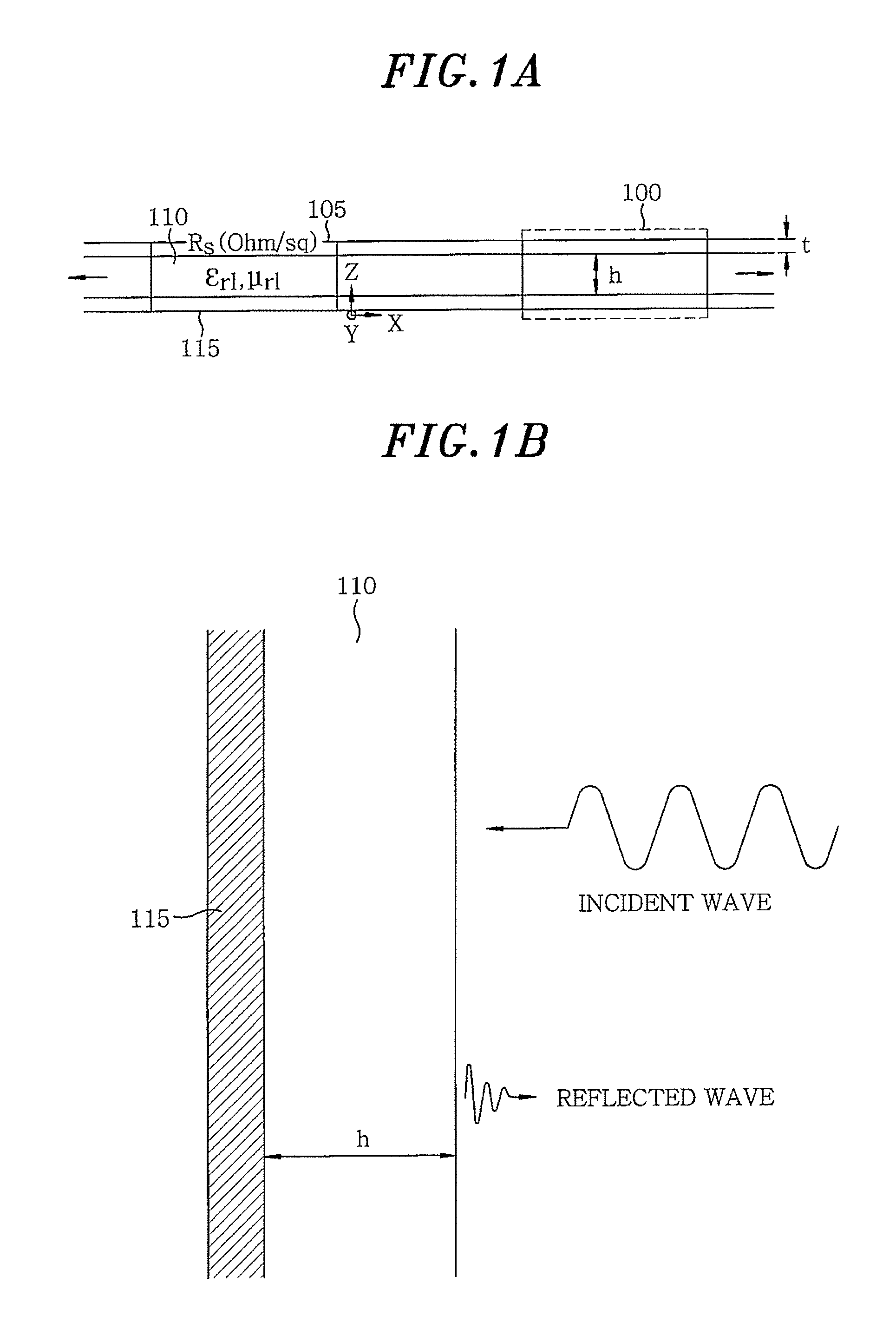

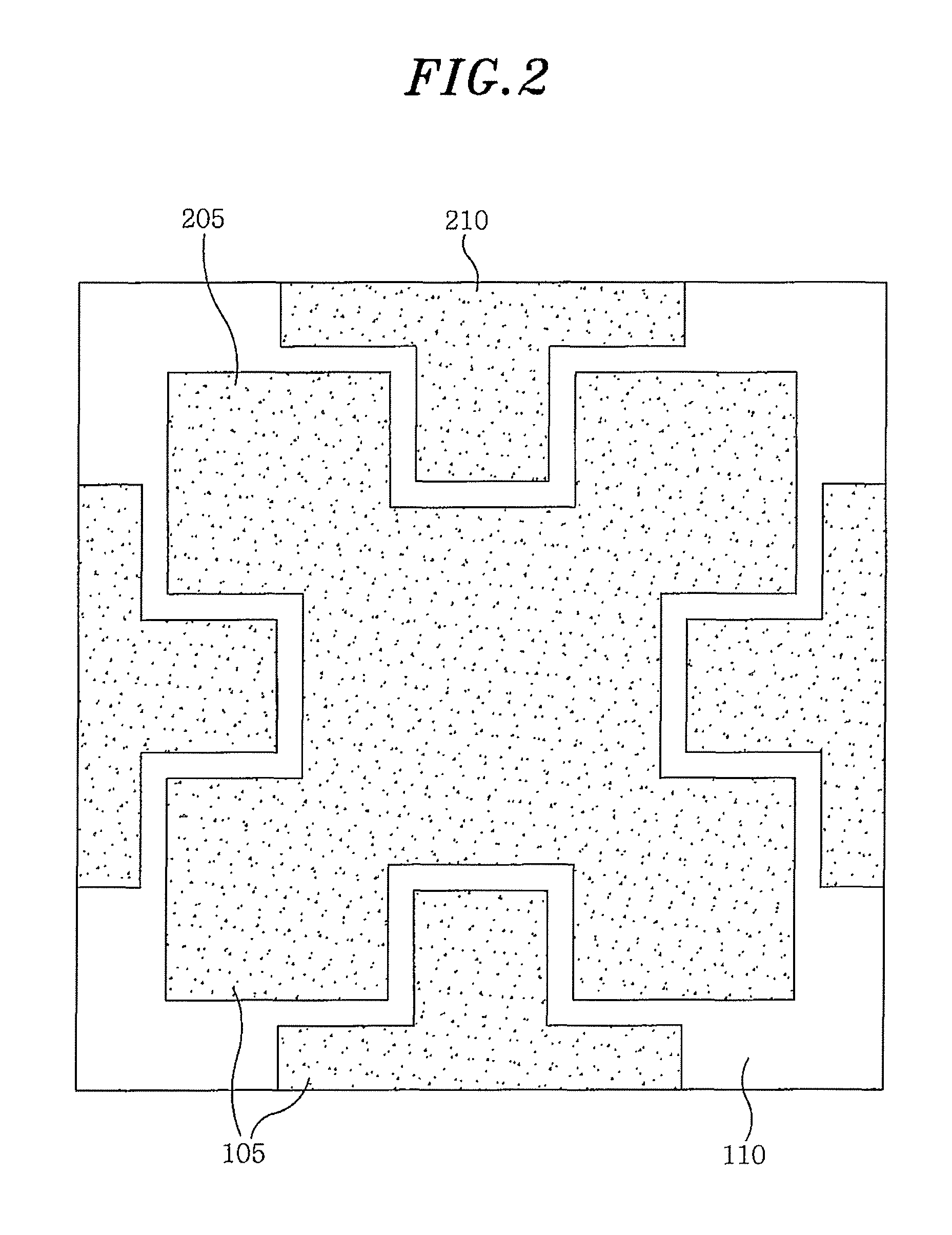

Electromagnetic Wave Absorber

InactiveUS20080257599A1High peak value of absorption amountAvoid large displacementMagnetic/electric field screeningAntennasElectromagnetic wave absorberElectromagnetic absorbers

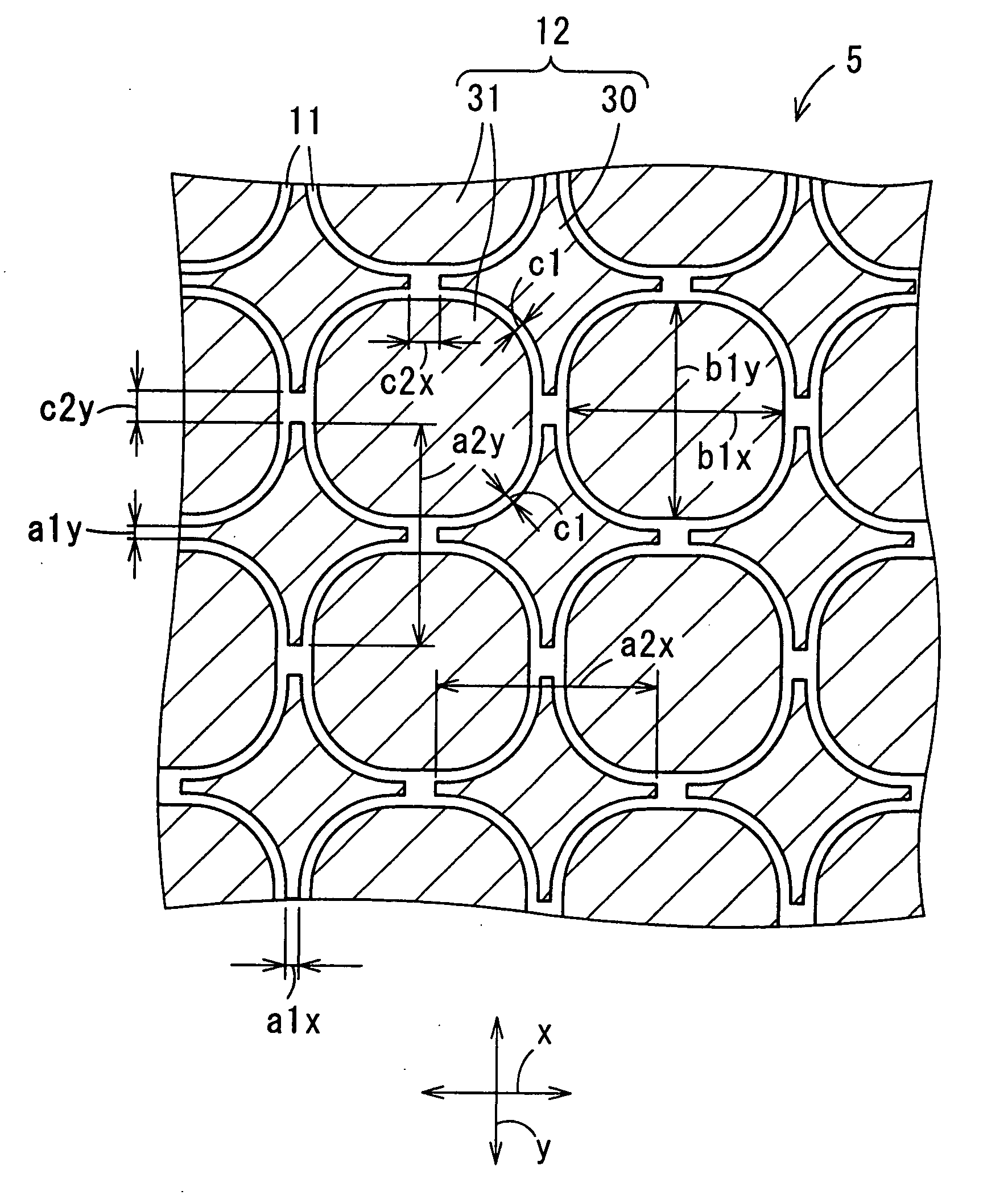

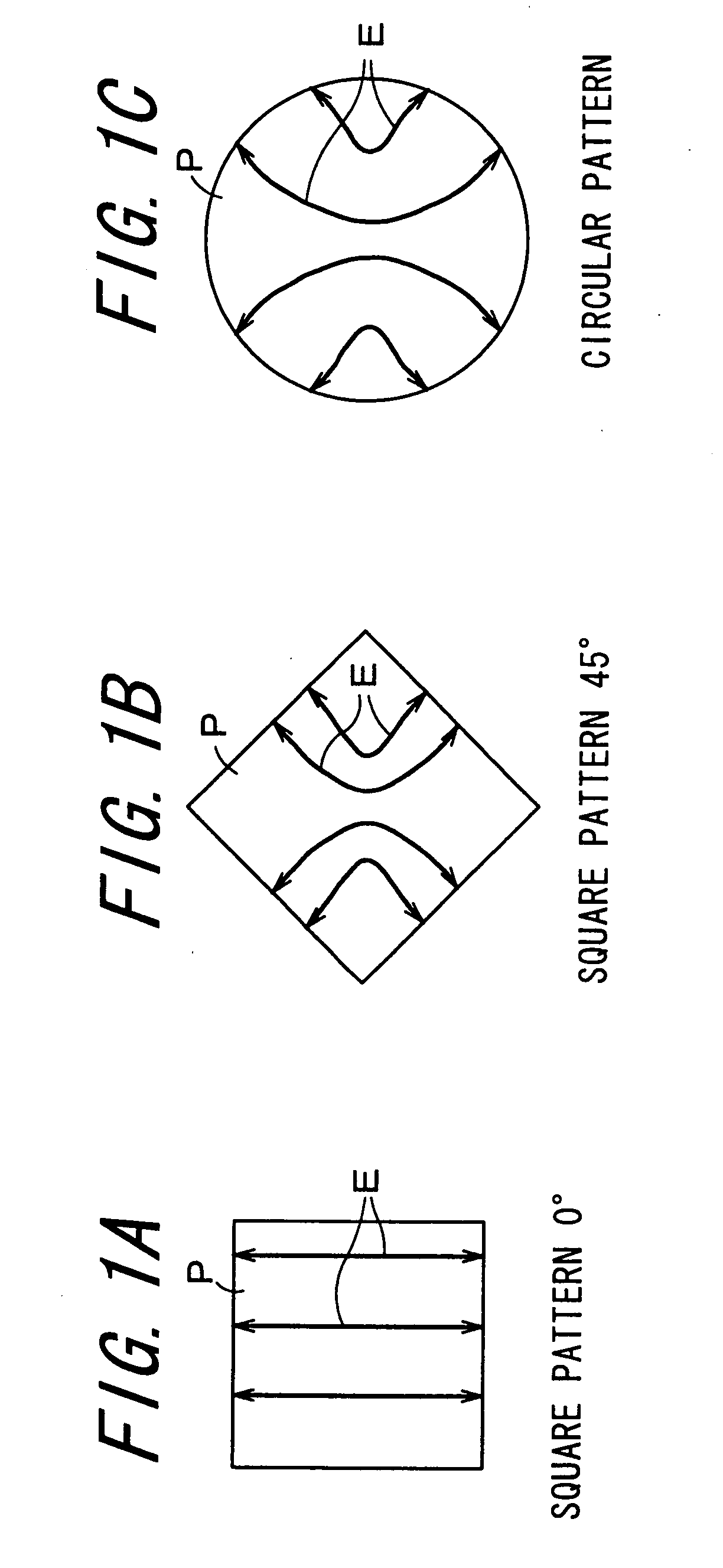

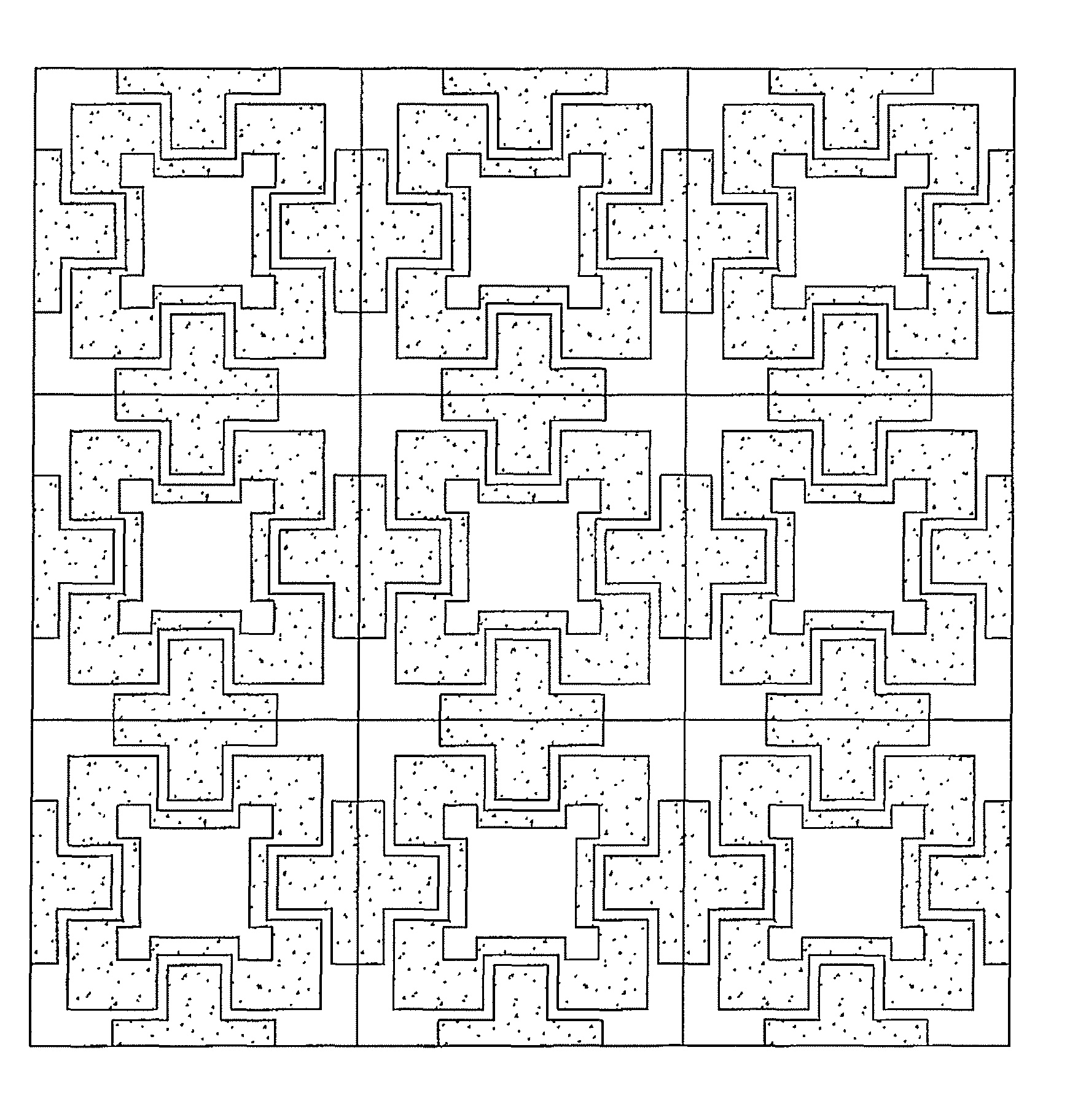

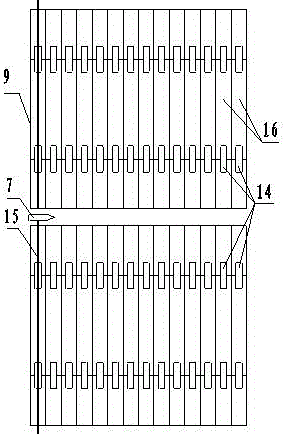

A conductive pattern basically has a substantially polygonal outline shape which is a polygon and can have a high peak value of the electromagnetic wave absorption amount as compared to a case when the conductive pattern has a circular outline shape. Thus, the conductive pattern is basically a polygon and at least one corner portion is shaped in curve. This reduces or even minimizes the shift of the frequency at which the absorption amount becomes a peak value by the polarization direction of the electromagnetic wave. Accordingly, in at least one embodiment, it is possible to realize an electromagnetic absorber having an excellent electromagnetic wave absorption characteristic exhibiting a high peak value of the absorption amount of the electromagnetic wave and a small shift of frequency at which the absorption amount becomes a peak value by the polarization direction of the electromagnetic wave.

Owner:NITTA CORP

Electromagnetic wave absorber

InactiveUS7495181B2Reduce the amount of solutionSmall displacementSparking plugsMagnetic/electric field screeningElectromagnetic wave absorberElectromagnetic absorbers

A conductive pattern basically has a substantially polygonal outline shape which is a polygon and can have a high peak value of the electromagnetic wave absorption amount as compared to a case when the conductive pattern has a circular outline shape. Thus, the conductive pattern is basically a polygon and at least one corner portion is shaped in curve. This reduces or even minimizes the shift of the frequency at which the absorption amount becomes a peak value by the polarization direction of the electromagnetic wave. Accordingly, in at least one embodiment, it is possible to realize an electromagnetic absorber having an excellent electromagnetic wave absorption characteristic exhibiting a high peak value of the absorption amount of the electromagnetic wave and a small shift of frequency at which the absorption amount becomes a peak value by the polarization direction of the electromagnetic wave.

Owner:NITTA CORP

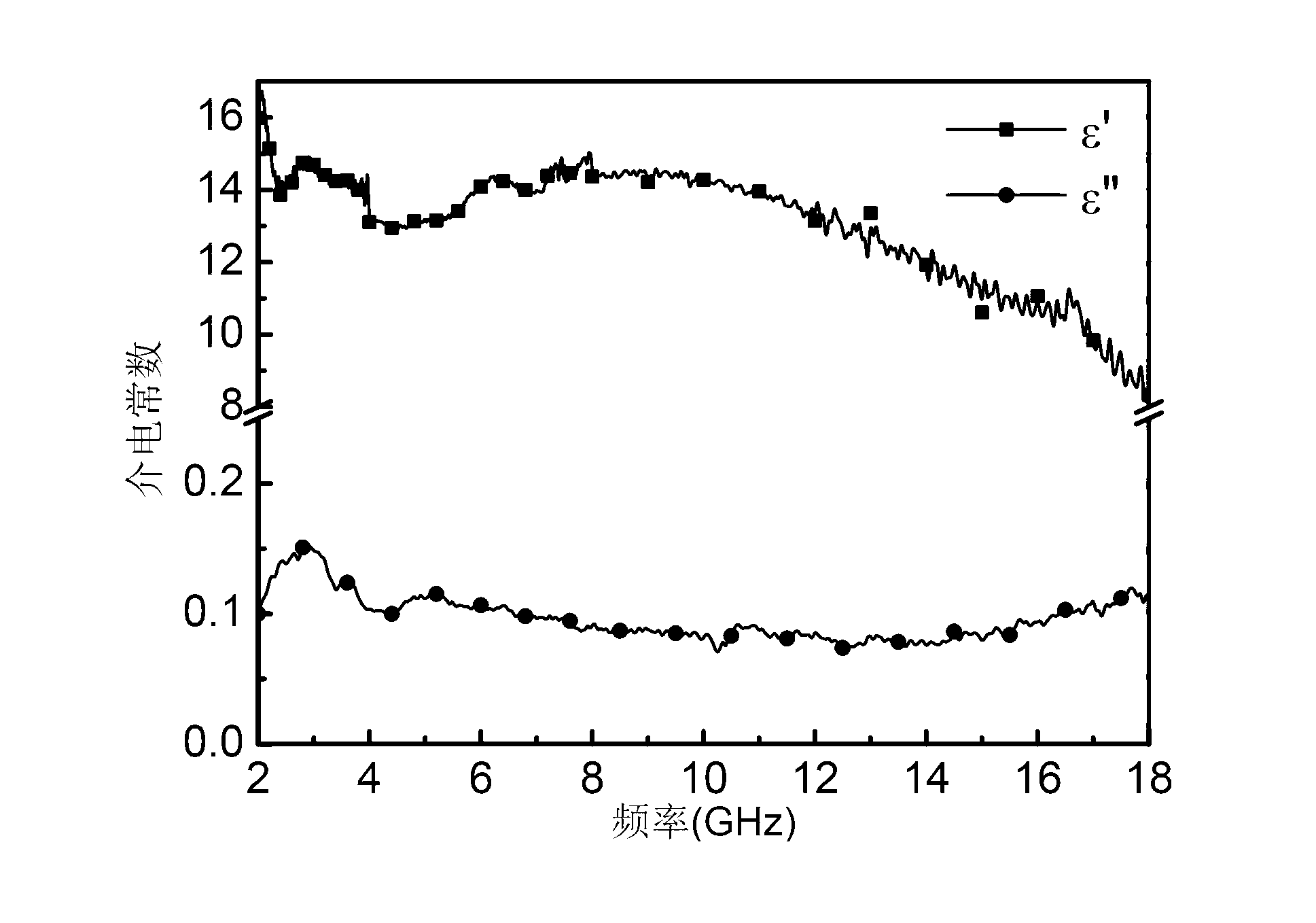

Electromagnetic wave absorbing material with periodic structure, and preparation method thereof

InactiveCN102709708ARaw materials are easy to getSimple structureMagnetic/electric field screeningLaminationDielectricElectromagnetic absorbers

The invention discloses an electromagnetic wave absorbing material with a periodic structure. The electromagnetic wave absorbing material comprises dielectric blocks formed by a magnetic wave absorbing material grid and a dielectric material, wherein the meshes on the magnetic wave absorbing material grid are through holes, and the dielectric blocks are embedded in the through holes of the magnetic wave absorbing material grid according to a certain periodicity. The preparation method of the electromagnetic wave absorbing material comprises the following steps of: selecting a magnetic wave absorbing raw material, and forming periodically arranged embedding holes on the magnetic wave absorbing raw material to obtain the magnetic wave absorbing material grid; then, selecting a dielectric material of which the relative dielectric constant is in a preset range, cutting the dielectric material into the dielectric blocks corresponding to the embedding holes in shape and size; embedding the prepared dielectric blocks in the embedding holes formed on the magnetic wave absorbing material grid one by one, and connecting together by an adhesive to get the electromagnetic wave absorbing material. The preparation method can effectively expand the operation bandwidth of the wave absorbing material without increase of the thickness, and simultaneously, can obviously reduce the volume density of the magnetic wave absorbing material.

Owner:NAT UNIV OF DEFENSE TECH

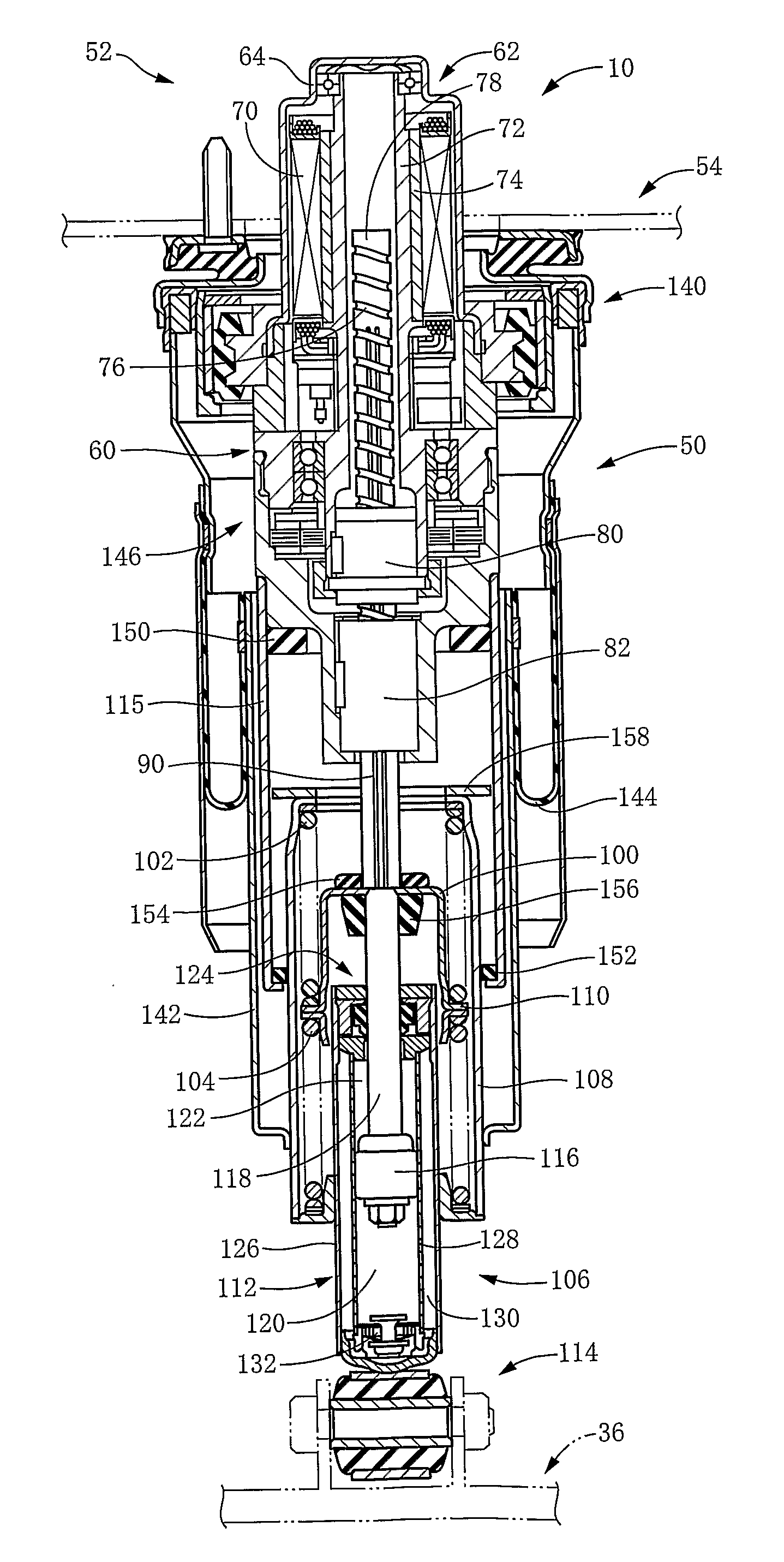

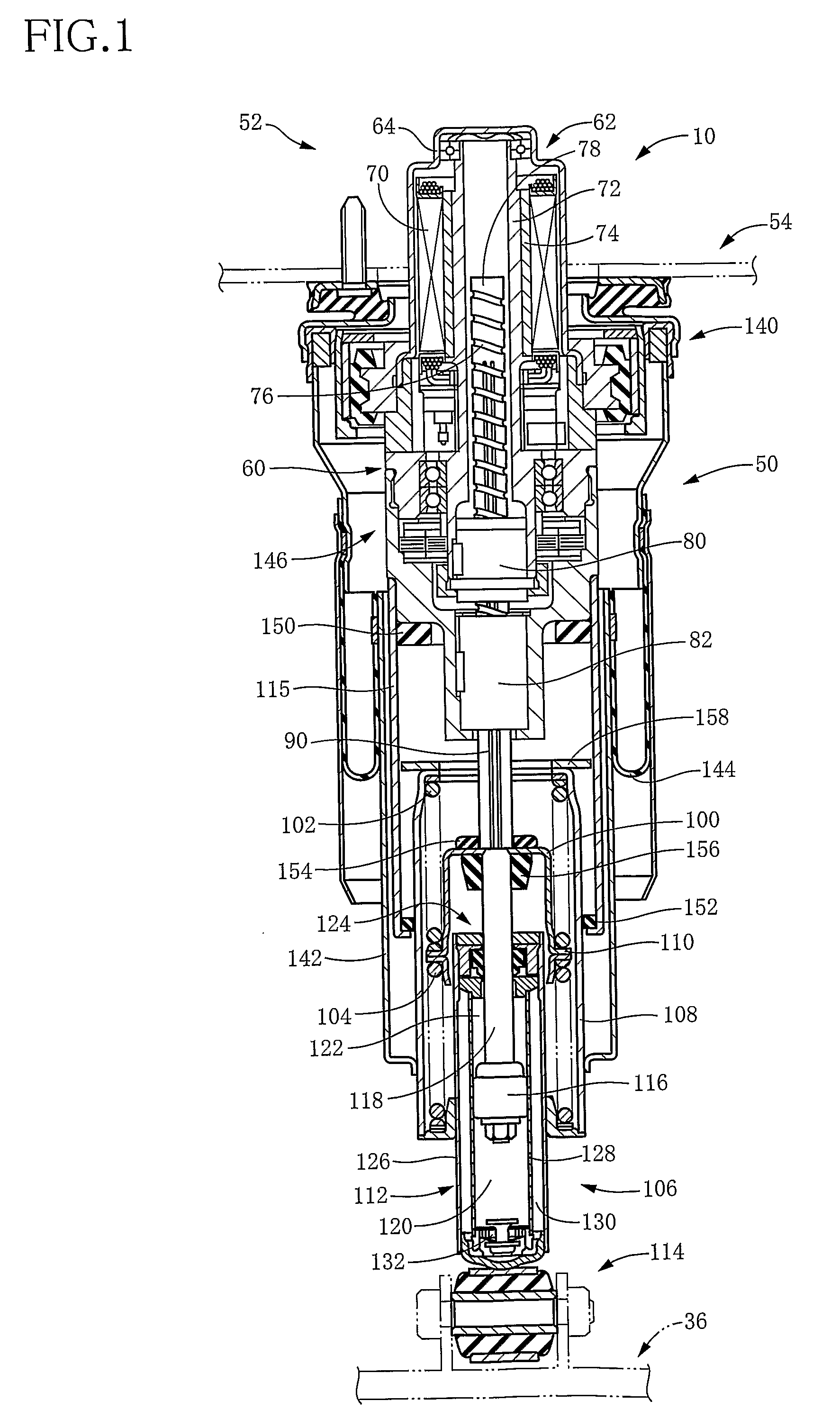

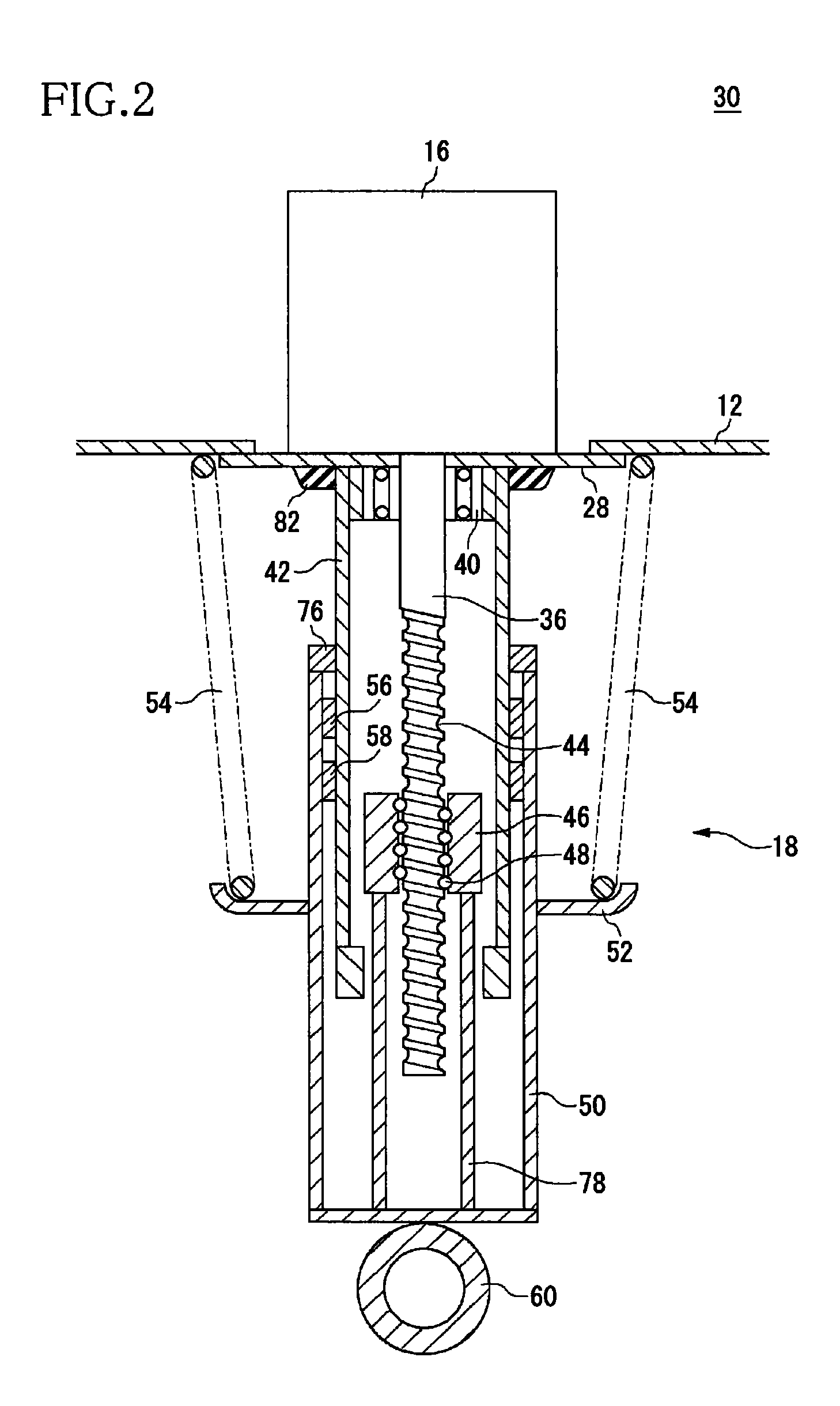

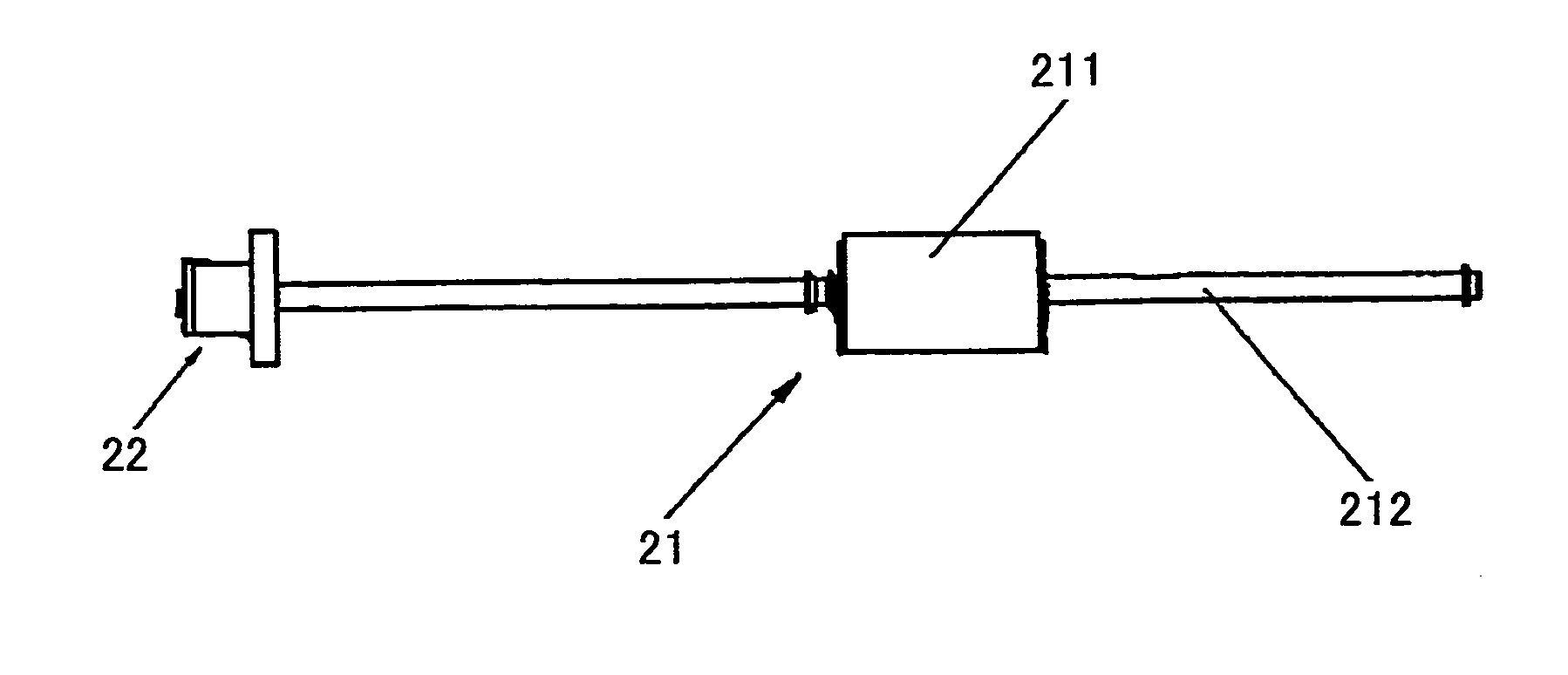

Electromagnetic shock absorber for vehicle

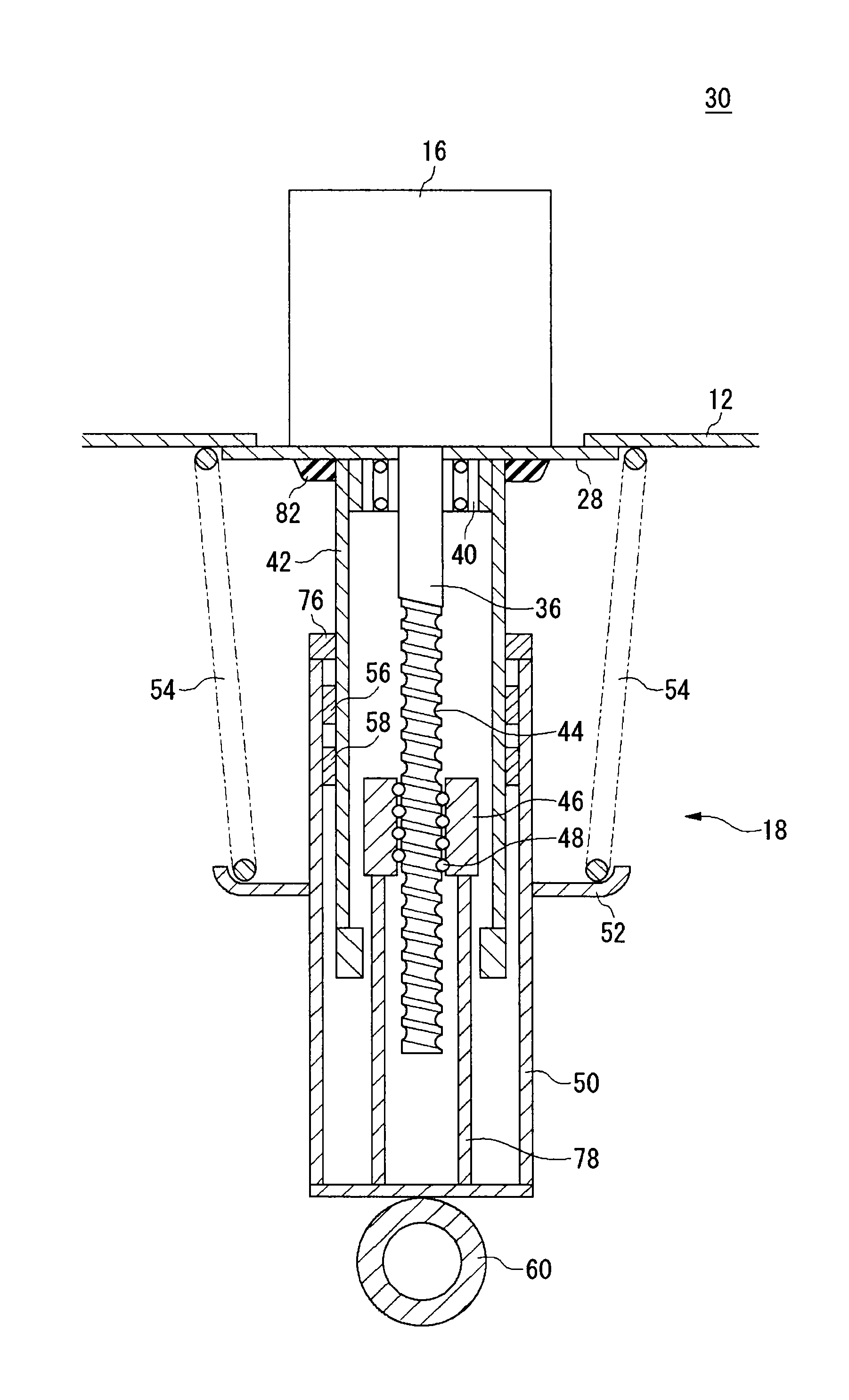

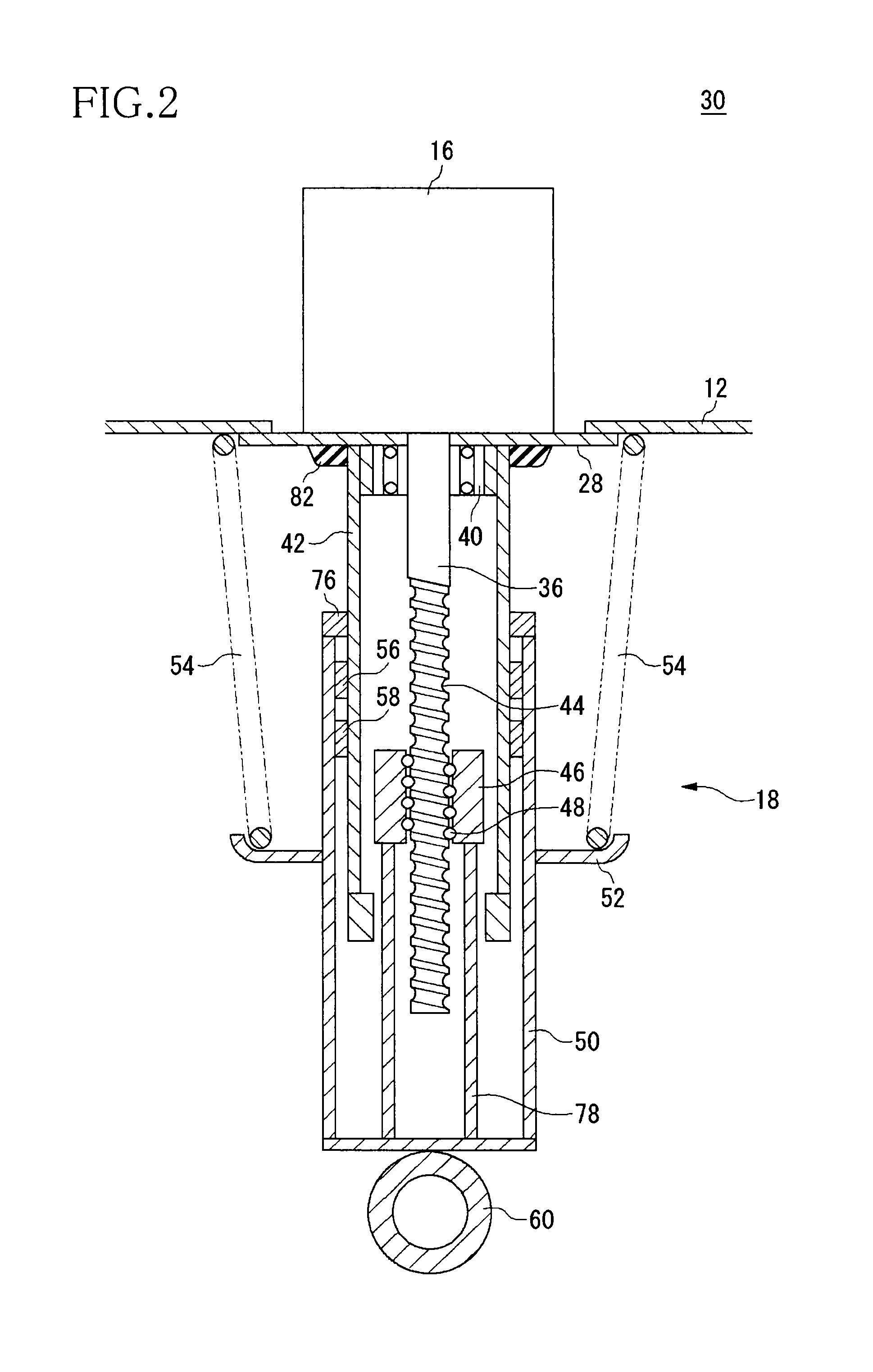

InactiveUS8668060B2Valid conversionIncrease profitVibration dampersSpringsElectromagnetic absorbersScrew thread

An electromagnetic absorber (10) for a vehicle including (a) a threaded rod (78) which is disposed on one of a sprung portion and an unsprung portion and which has a threaded groove (76) formed in its outer circumferential portion and an axial groove (90) extending in its axis direction (b) a nut (80) which is rotatably disposed on the other of the sprung portion and the unsprung portion and which is screwed with the threaded rod and (c) a rod-rotation inhibiting member (82) which includes a fitting portion configured to be fitted in the axial groove and which is disposed on the other of the sprung portion and the unsprung portion, the rod-rotation inhibiting member being configured to inhibit the threaded rod from rotating while permitting the threaded rod to move in the axis direction. In the electromagnetic absorber, the threaded groove is not formed at a section of a fitting range at which the fitting portion is fitted in the axial groove when the fitting portion is located at an end of the fitting range that extends in the axis direction on the outer circumferential portion of the threaded rod.

Owner:TOYOTA JIDOSHA KK +2

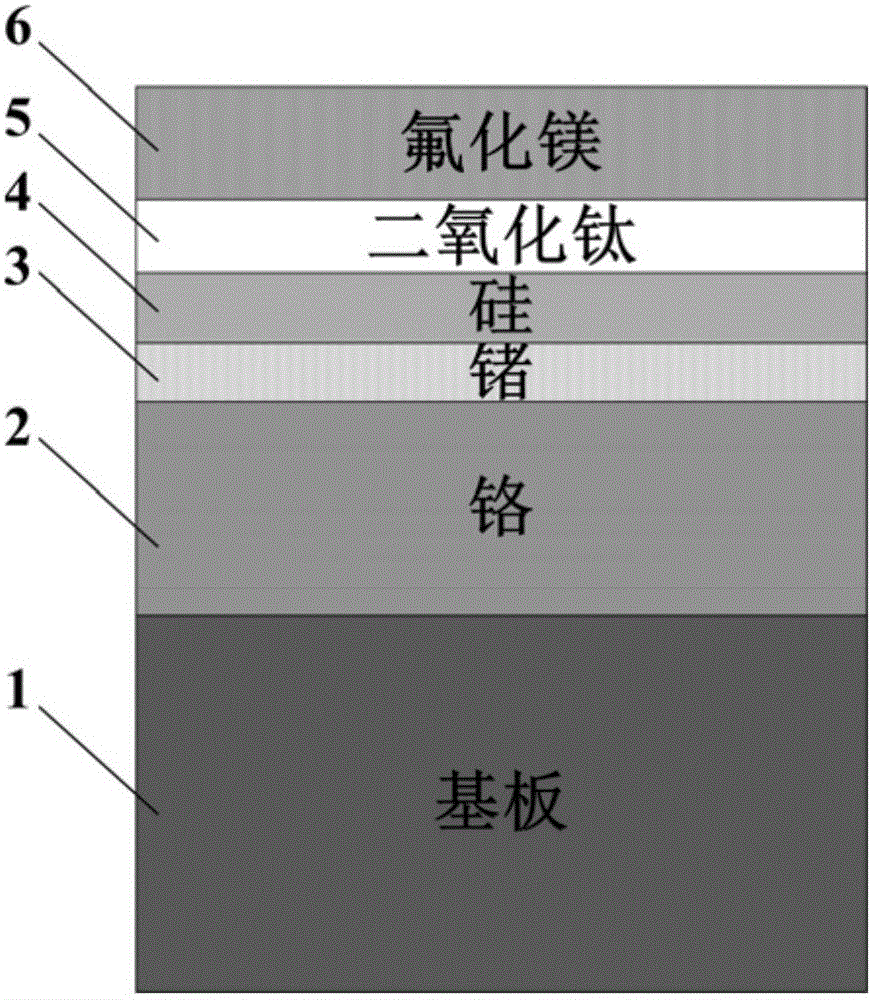

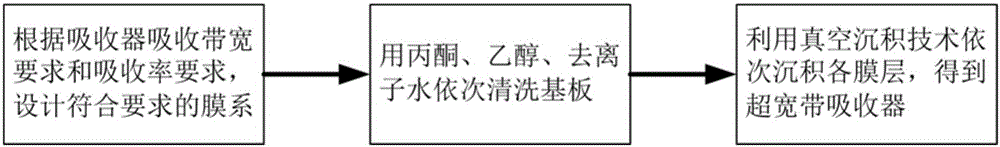

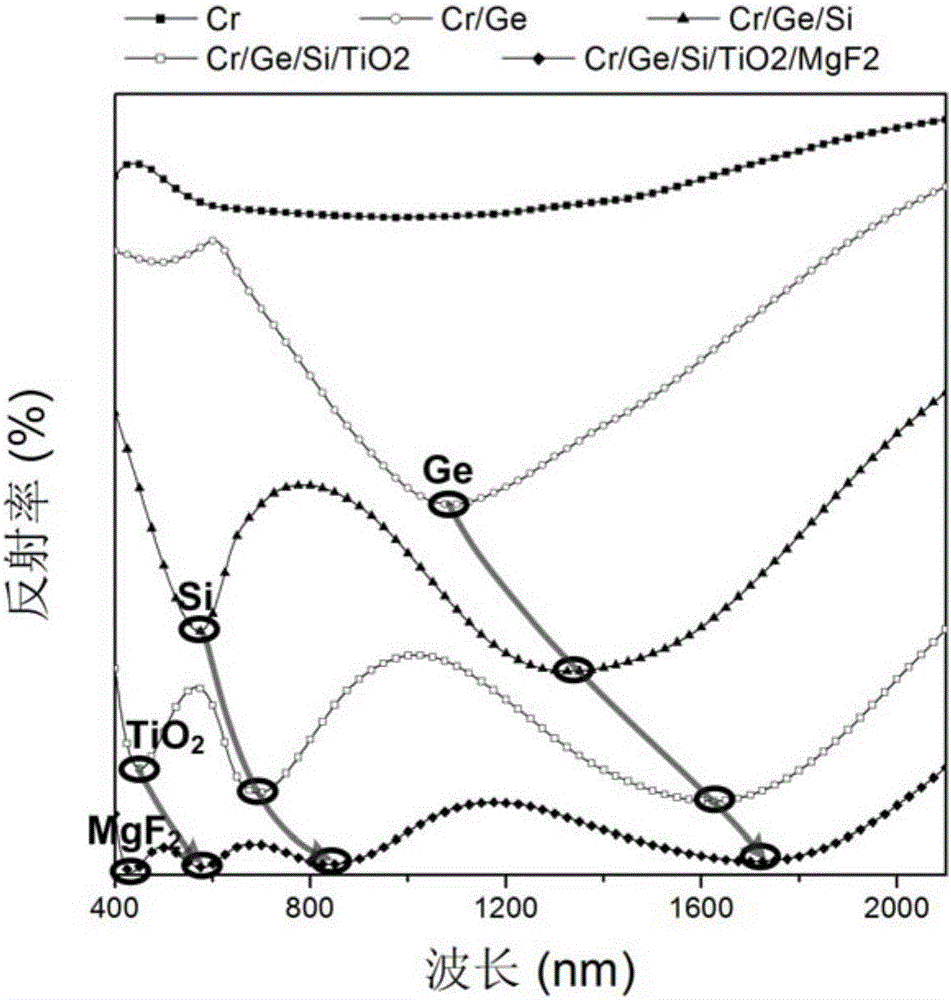

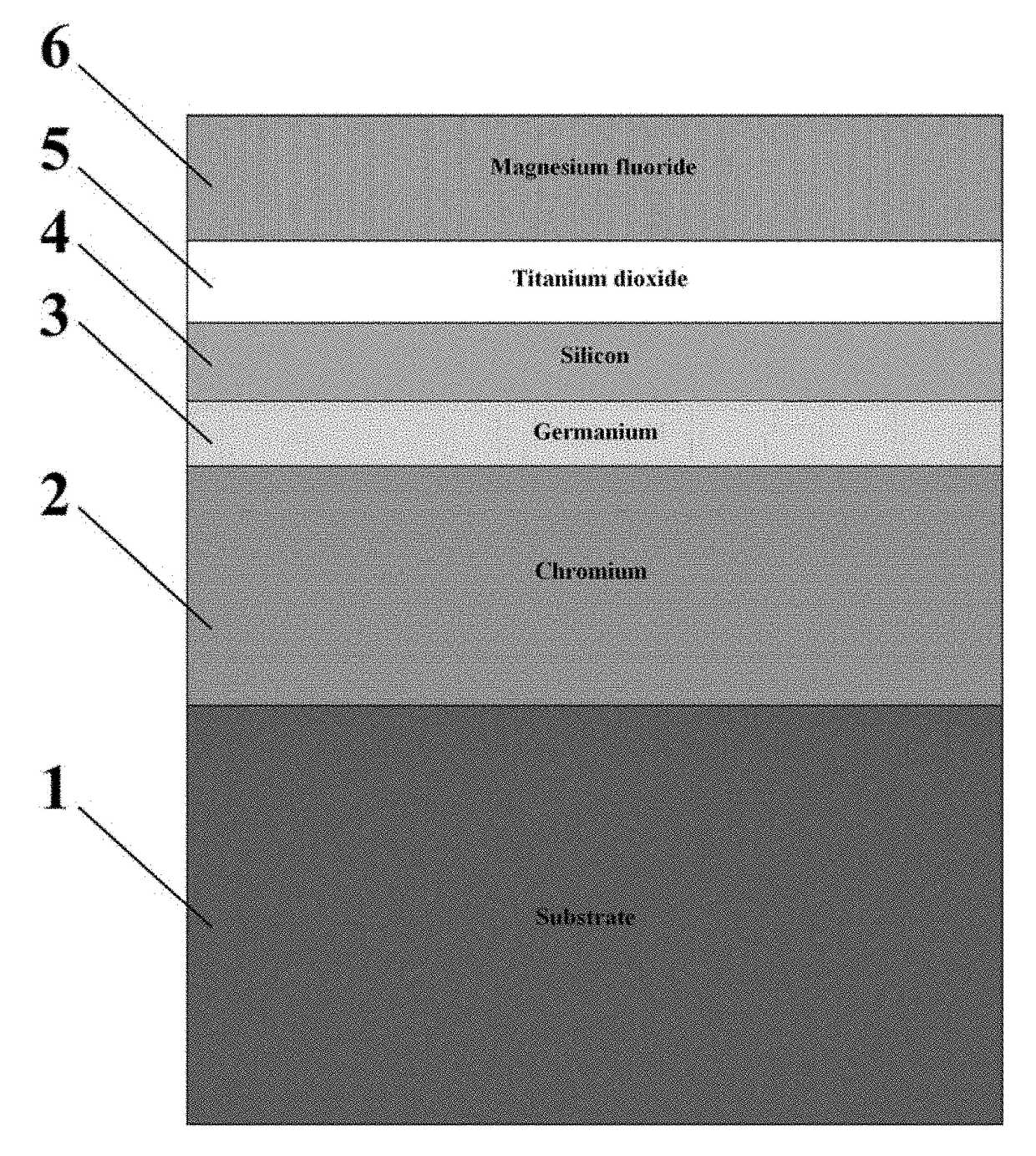

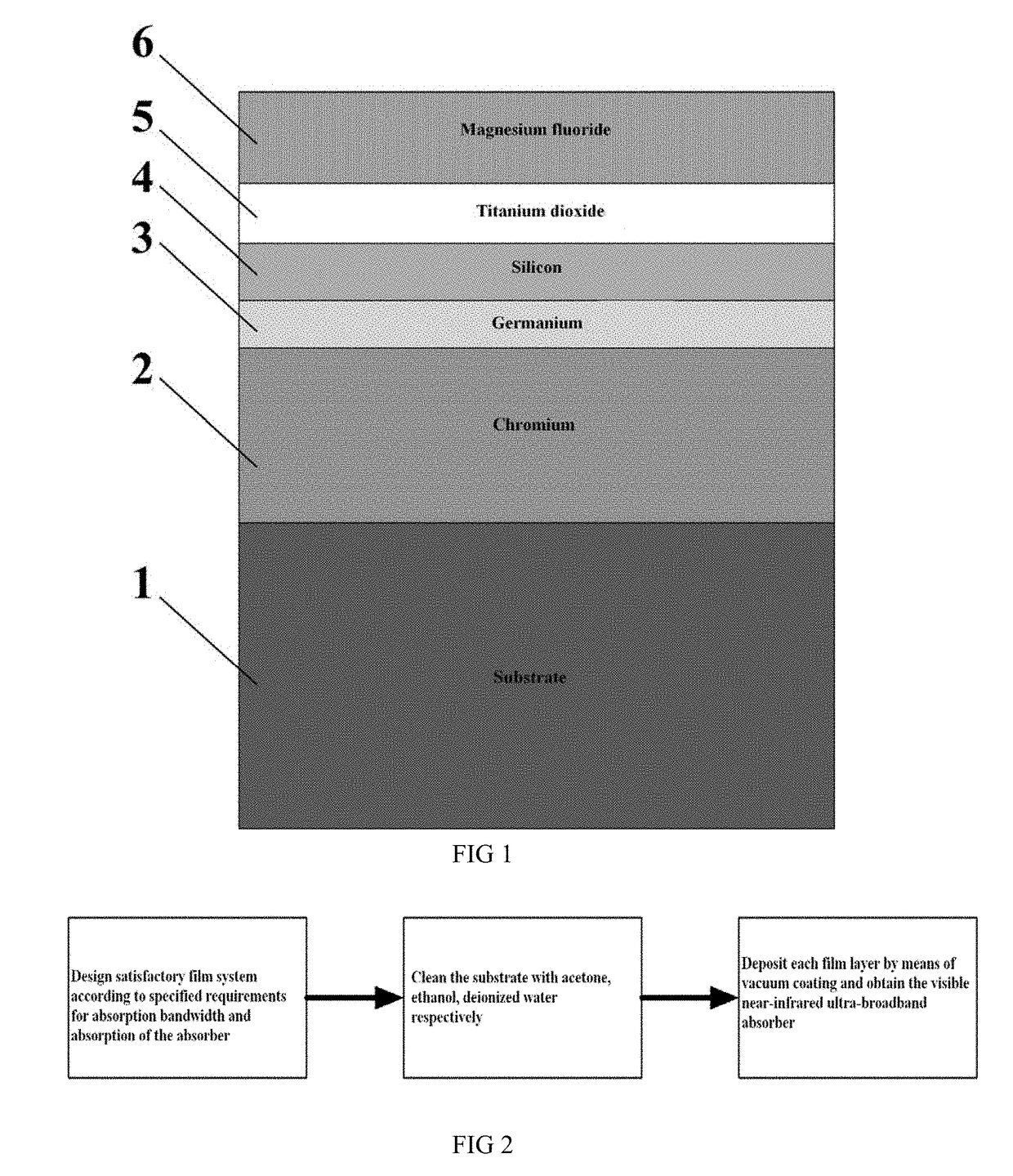

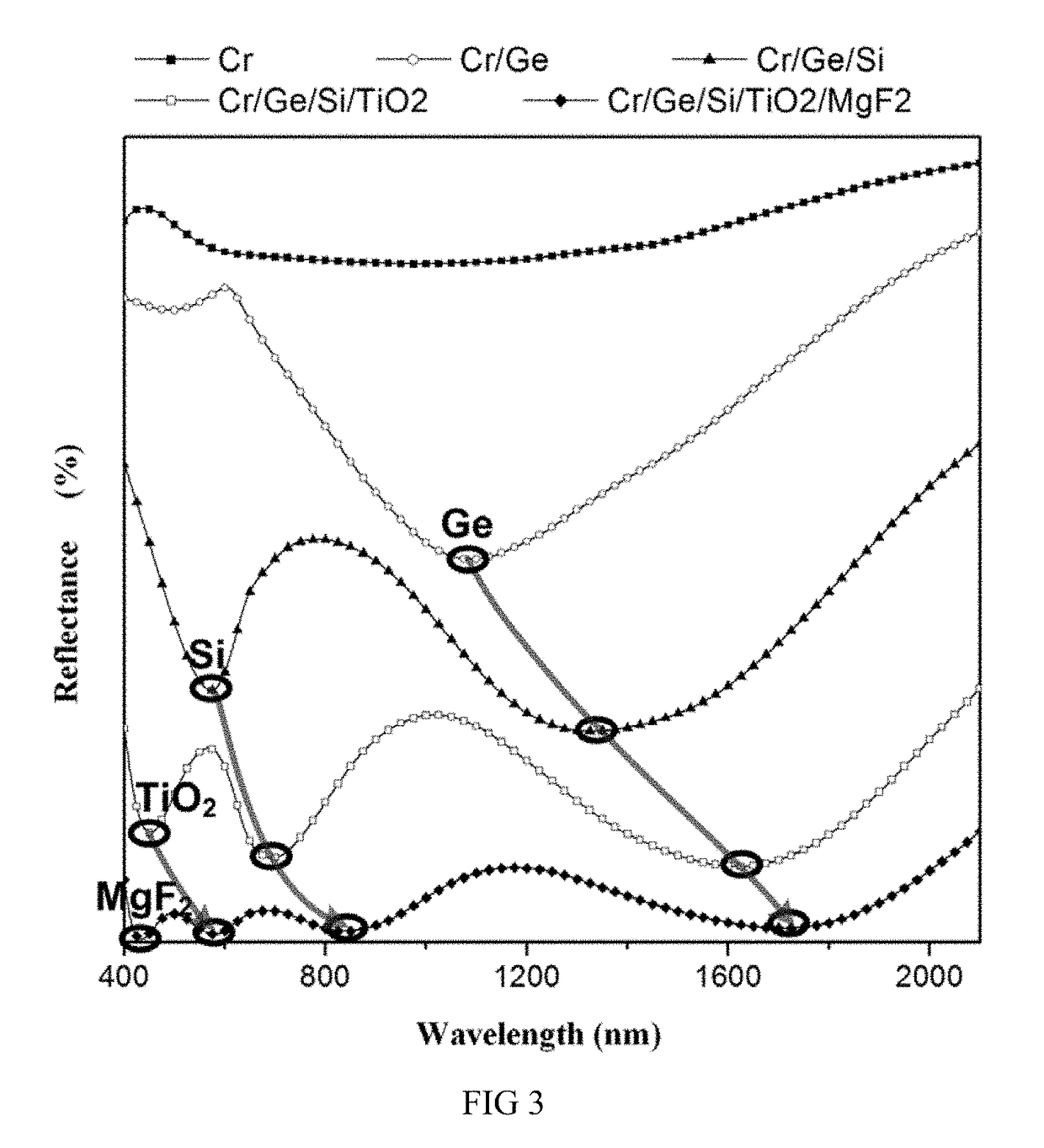

Absorber of ultra wide band of visible and near-infrared band and preparation method thereof

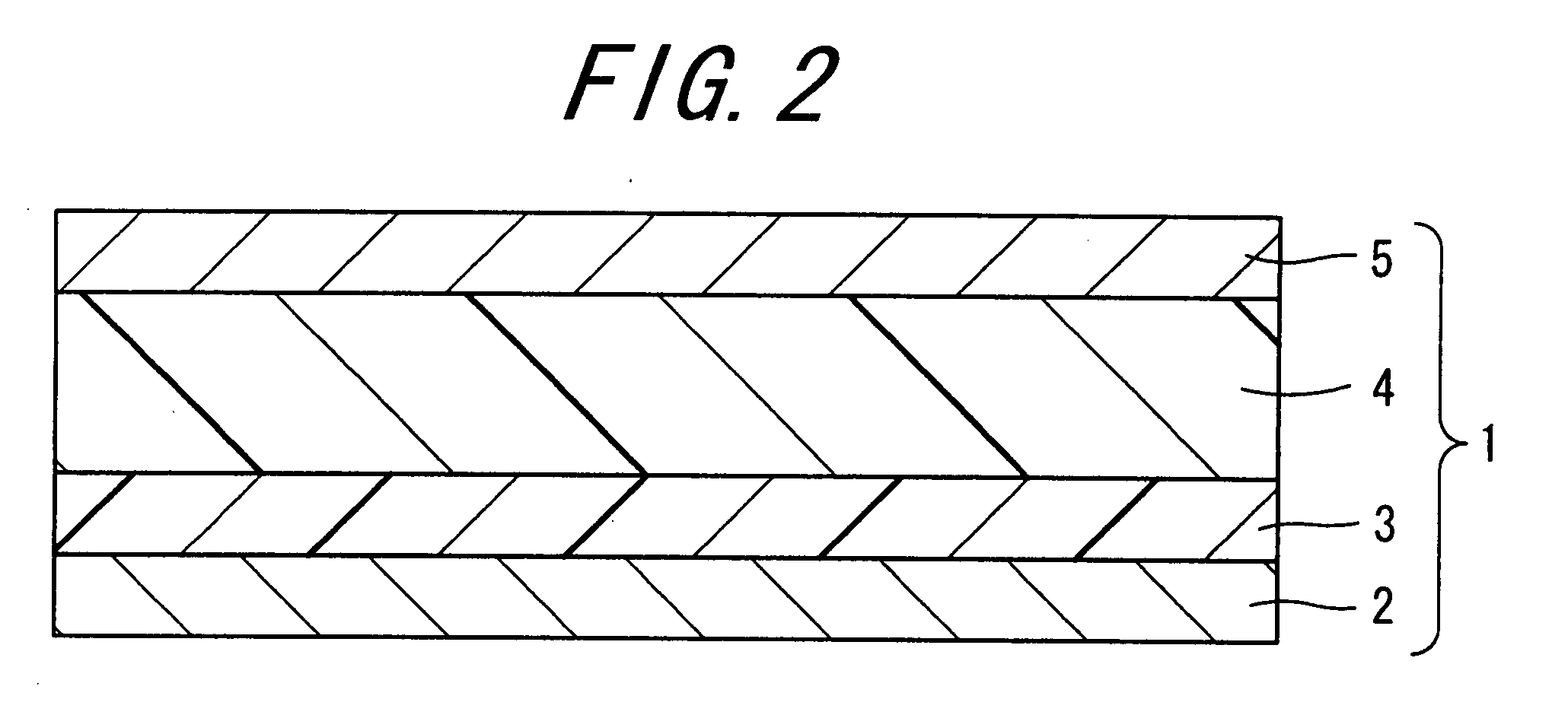

ActiveCN105022106AIncreasing the thicknessEasy to operateOptical elementsElectromagnetic absorbersRefractive index

The present invention discloses an absorber of an ultra wide band of a visible and near-infrared band and a preparation method thereof. The absorber consists of a substrate and five layers of optical thin films, the thin film at the lowest layer being a metal absorption layer, a layer of germanium being above the metal absorption layer, other three layers, which have gradually decreased refractive indexes of materials from bottom up, being above the layer of germanium. The absorber, based on the combination of the incidence resistance effect of the metal absorption layer and a wide band anti-reflection film layer of the layer of germanium, establishes an anti-reflection structure of wide band without transmission, is capable of absorbing ultra wide band of visible and near-infrared band, with high efficiency and insensitive incident angles, and is completely beyond a traditional absorber in performance. Compared with traditional absorbers and artificial electromagnetic absorbers provided in recent years, the absorber provided by the invention employs a compact multi-layer thin film structure which is more simple so as to prevent complicated nanofabrication technology, thereby the absorber provided by the invention is reduced in cost of production, is greatly shorten in the production cycle, and is convenient for large-scale manufacture in batches.

Owner:上海高能煜镀科技有限公司

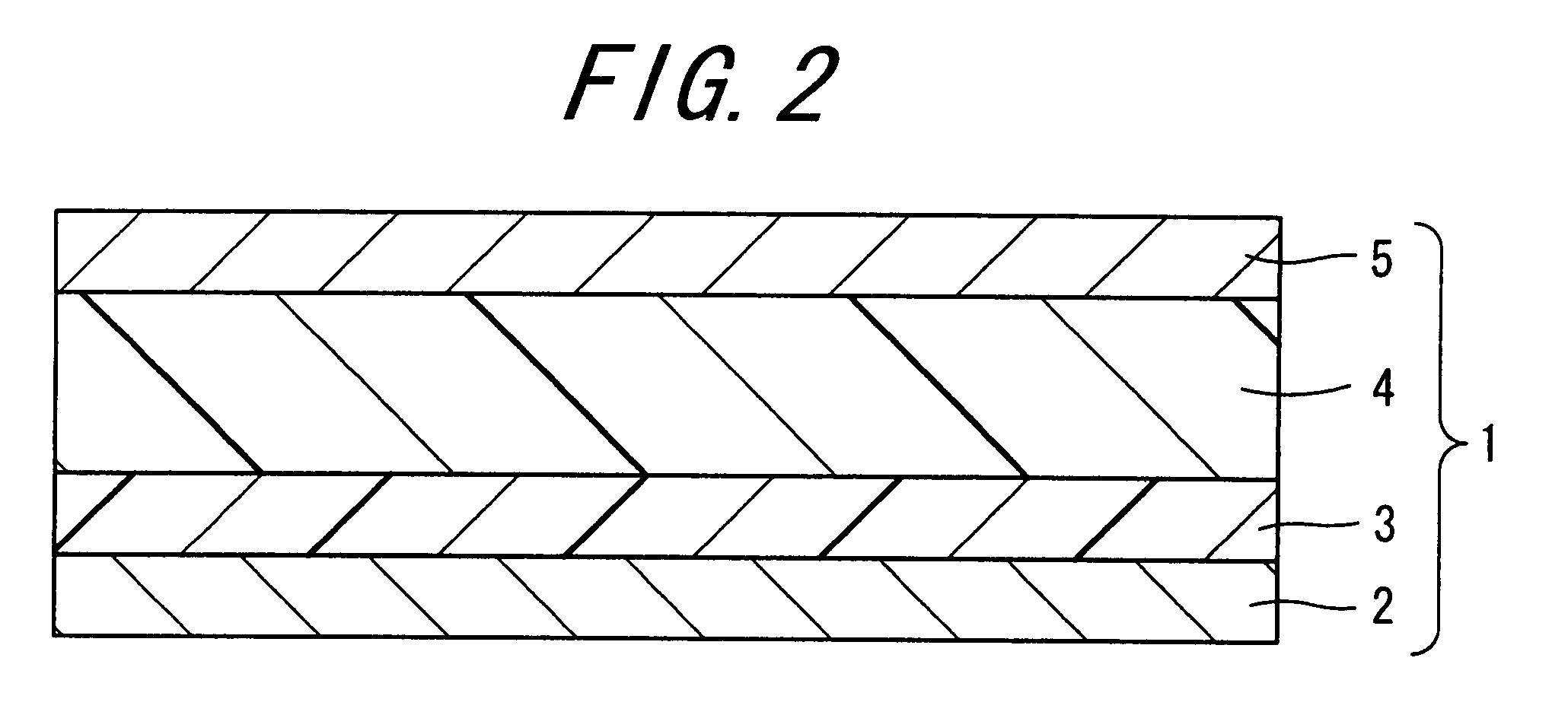

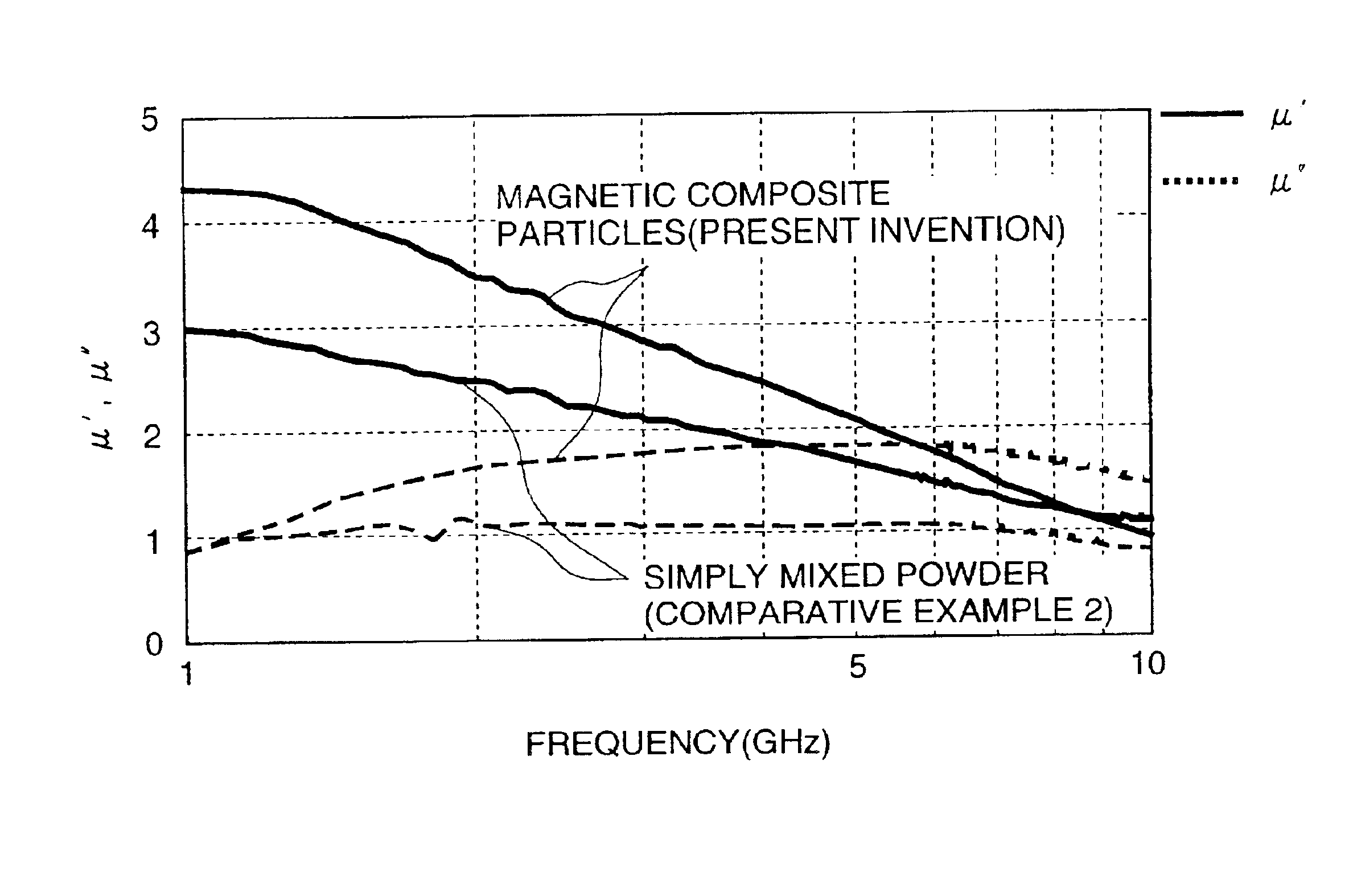

Electromagnetic wave absorber, method of manufacturing the same and appliance using the same

InactiveUS6919387B2Excellent electromagnetic wave absorbing characteristicIncrease heightMagnetic/electric field screeningRoad vehicles traffic controlElectromagnetic wave absorberElectromagnetic absorbers

Owner:HITACHI LTD

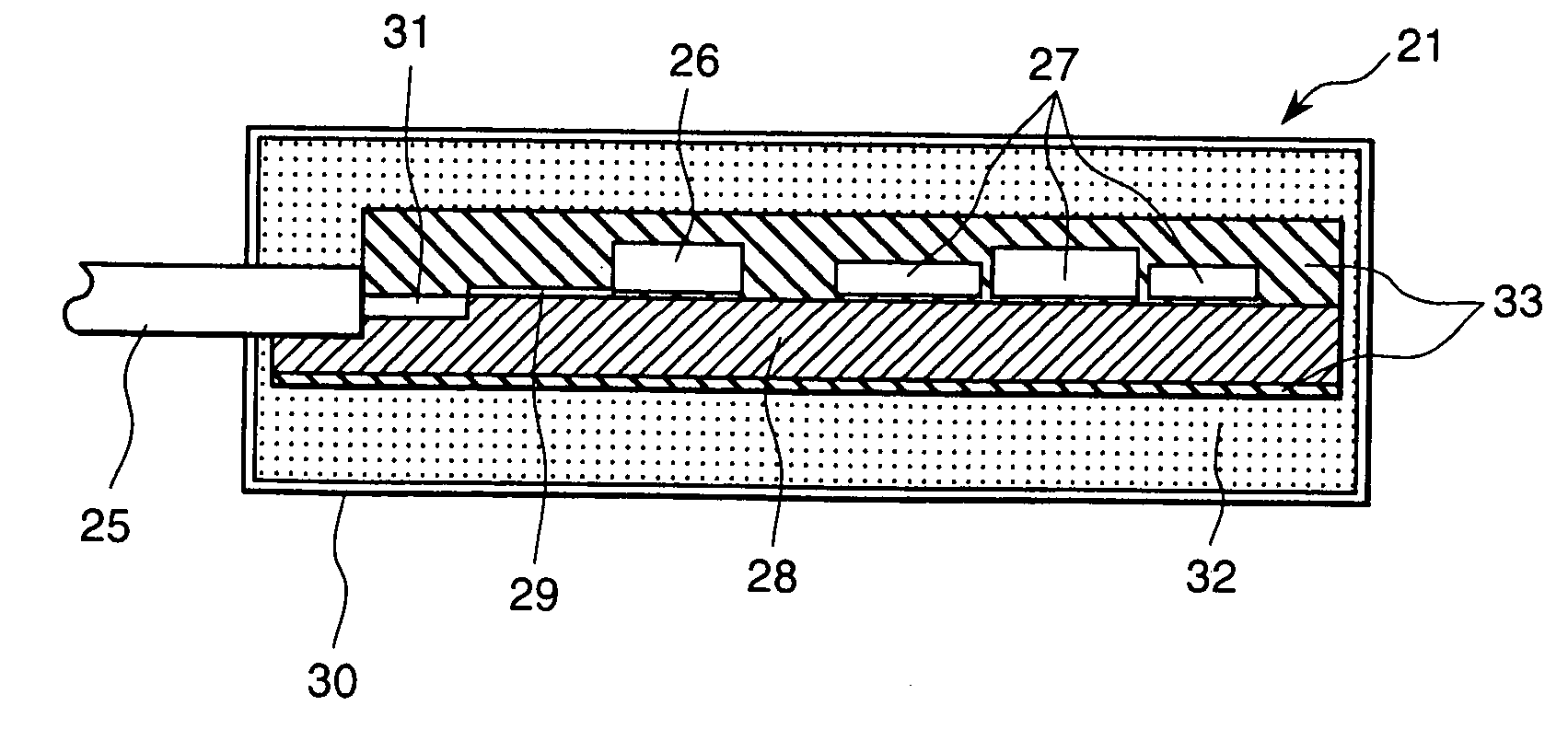

Electromagnetic wave absorber, method of manufacturing the same and appliance using the same

InactiveUS20050140539A1Suppress noise interferenceExcellent electromagnetic wave absorption characteristicMagnetic/electric field screeningCross-talk/noise/interference reductionElectromagnetic wave absorberElectromagnetic absorbers

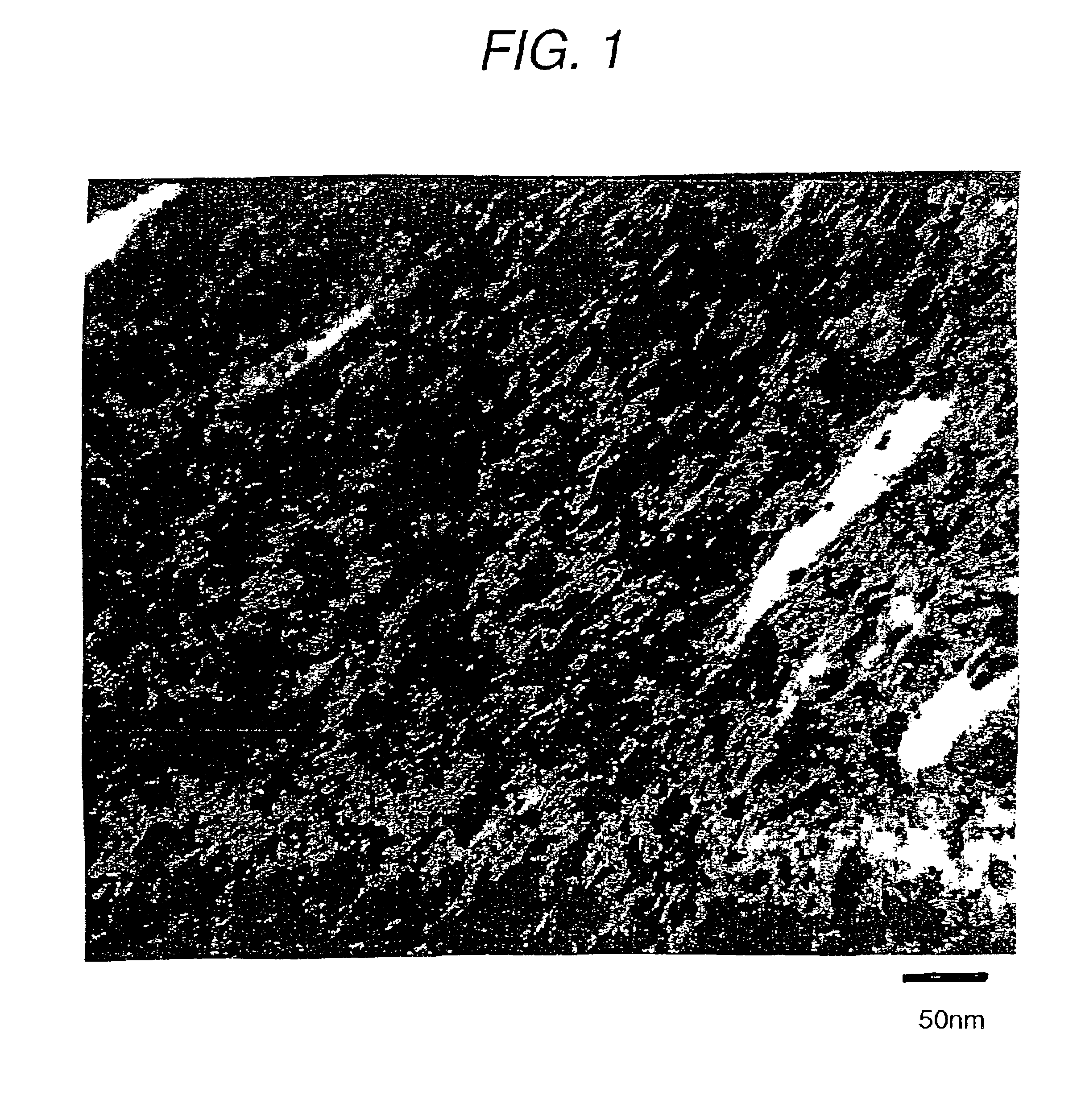

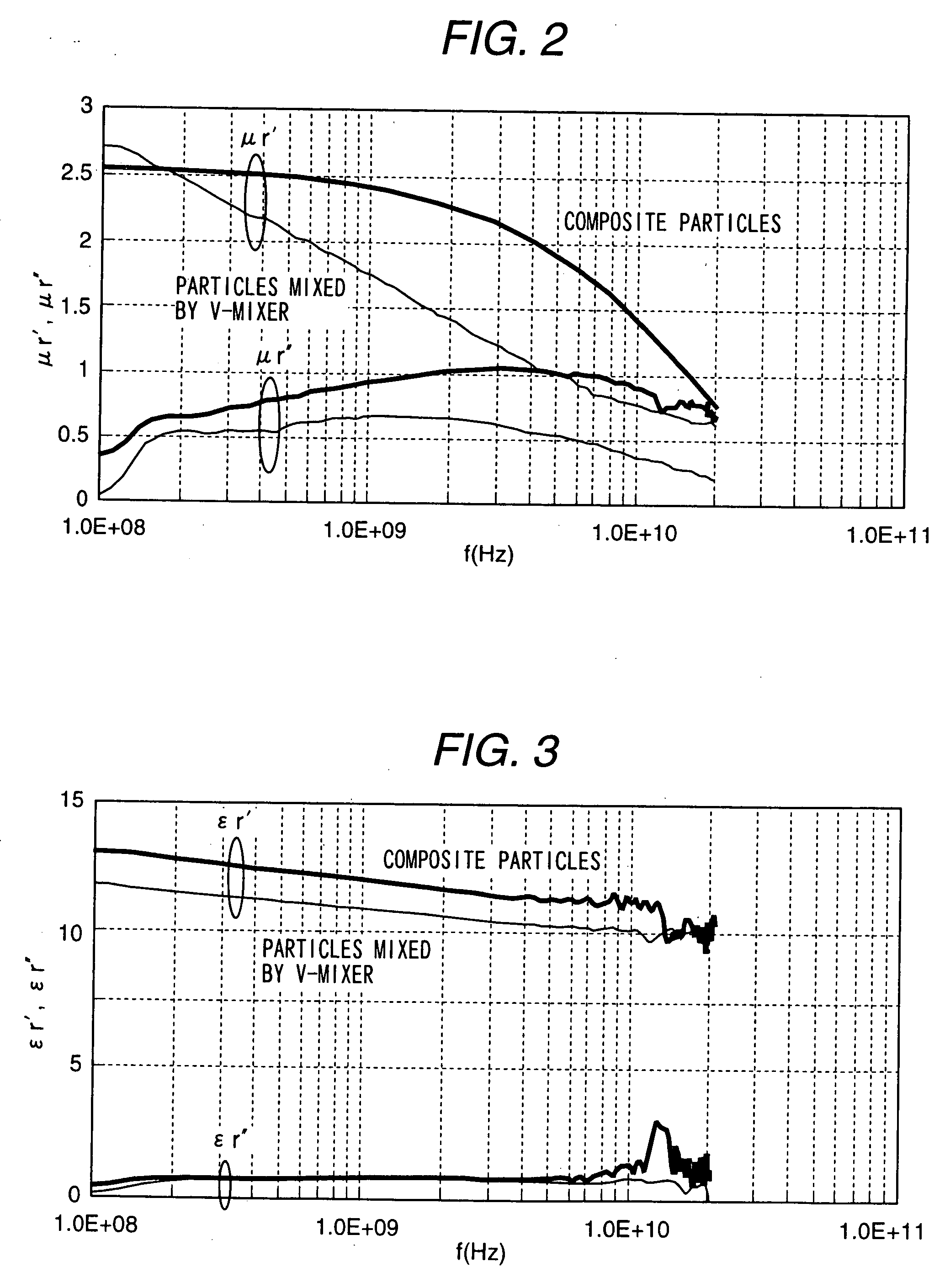

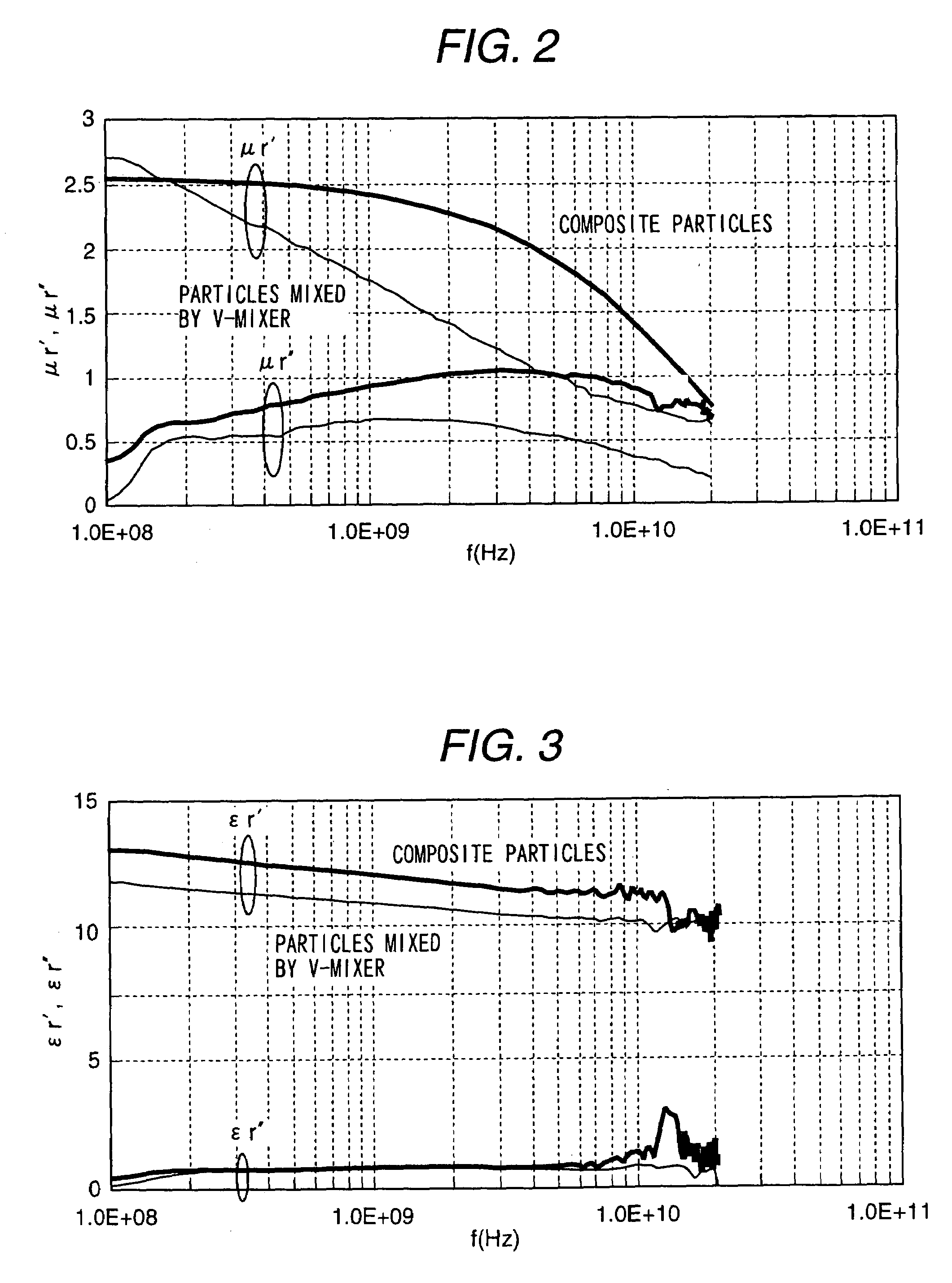

An electromagnetic wave absorber for use in the high frequency range above 1 Ghz and a composite member are characterized by the fact that magnetic metal grains are covered with ceramic above 20 volume %. Further, a method of manufacturing the electromagnetic absorber and the composite member is characterized by the fact that composite magnetic particles, in which a plurality of magnetic metal grains and ceramic are unified, are formed through a mechanical alloying method applied to a composite powder composed of magnetic metal powder and ceramic powder. The electromagnetic wave absorber can be used in a semiconductor device, an optical sending module, an optical receiving module, an optical sending and receiving module, an automatic tollgate in which erroneous operation due to electromagnetic wave disturbance is provided by use of the electromagnetic wave absorber.

Owner:HITACHI LTD

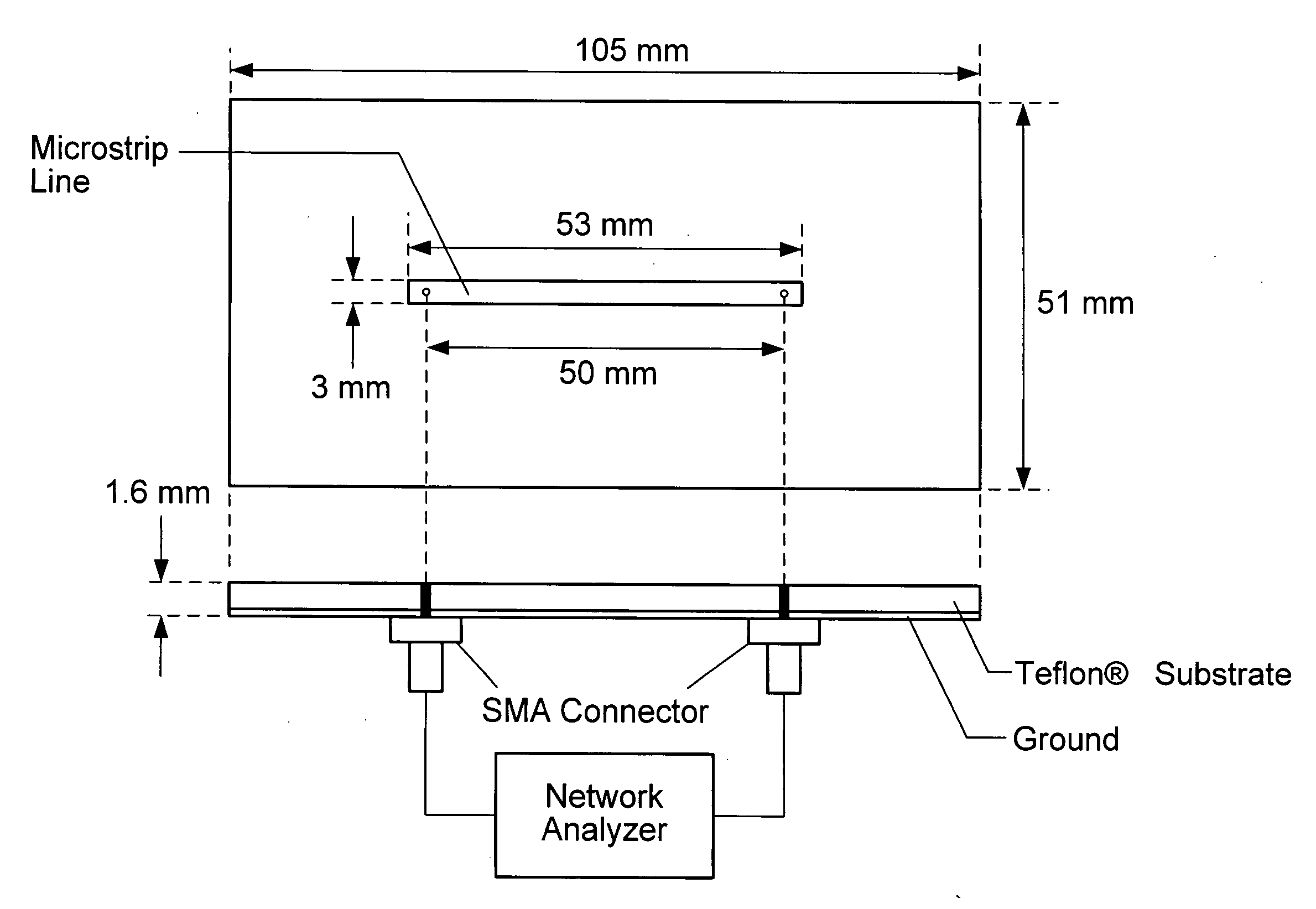

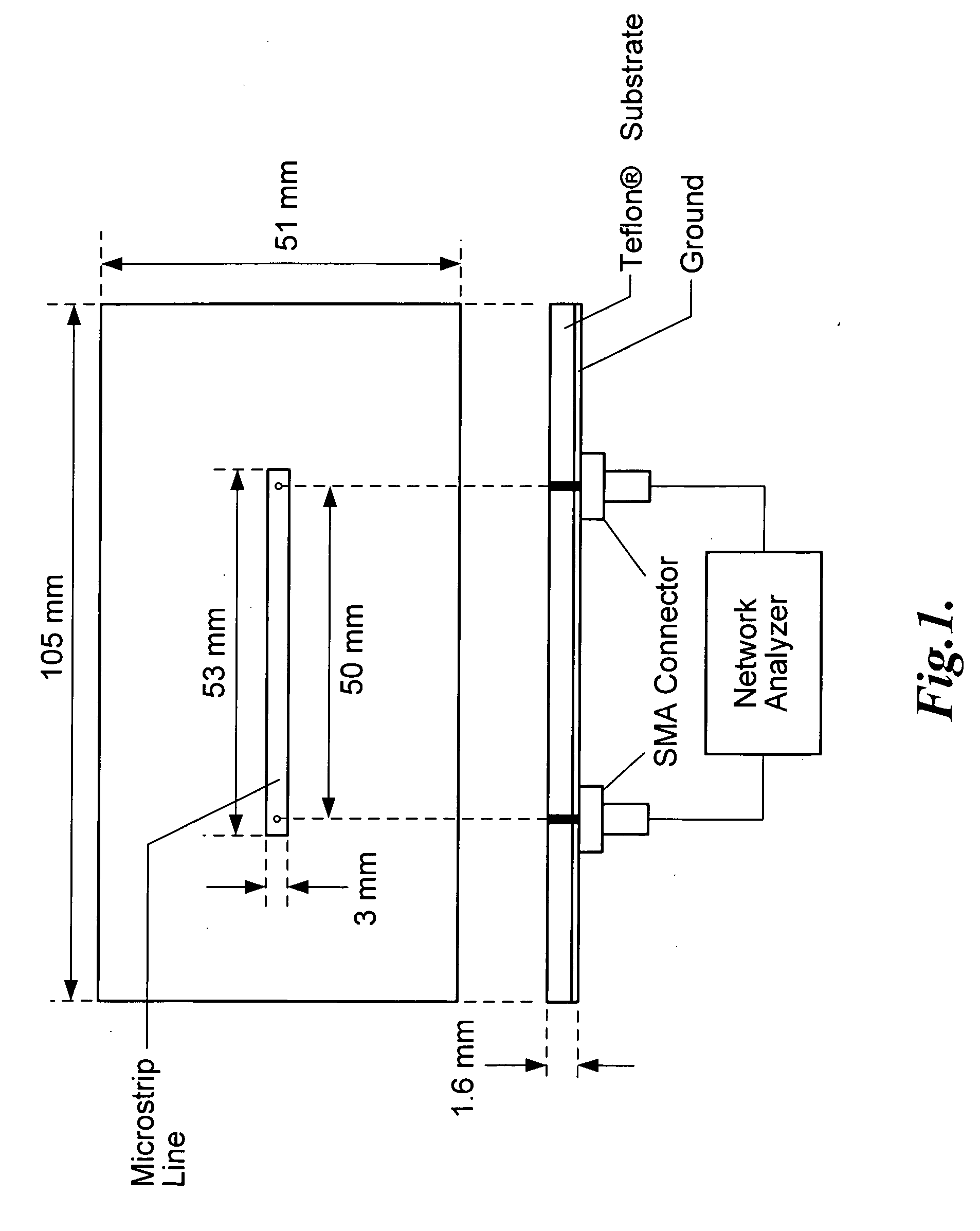

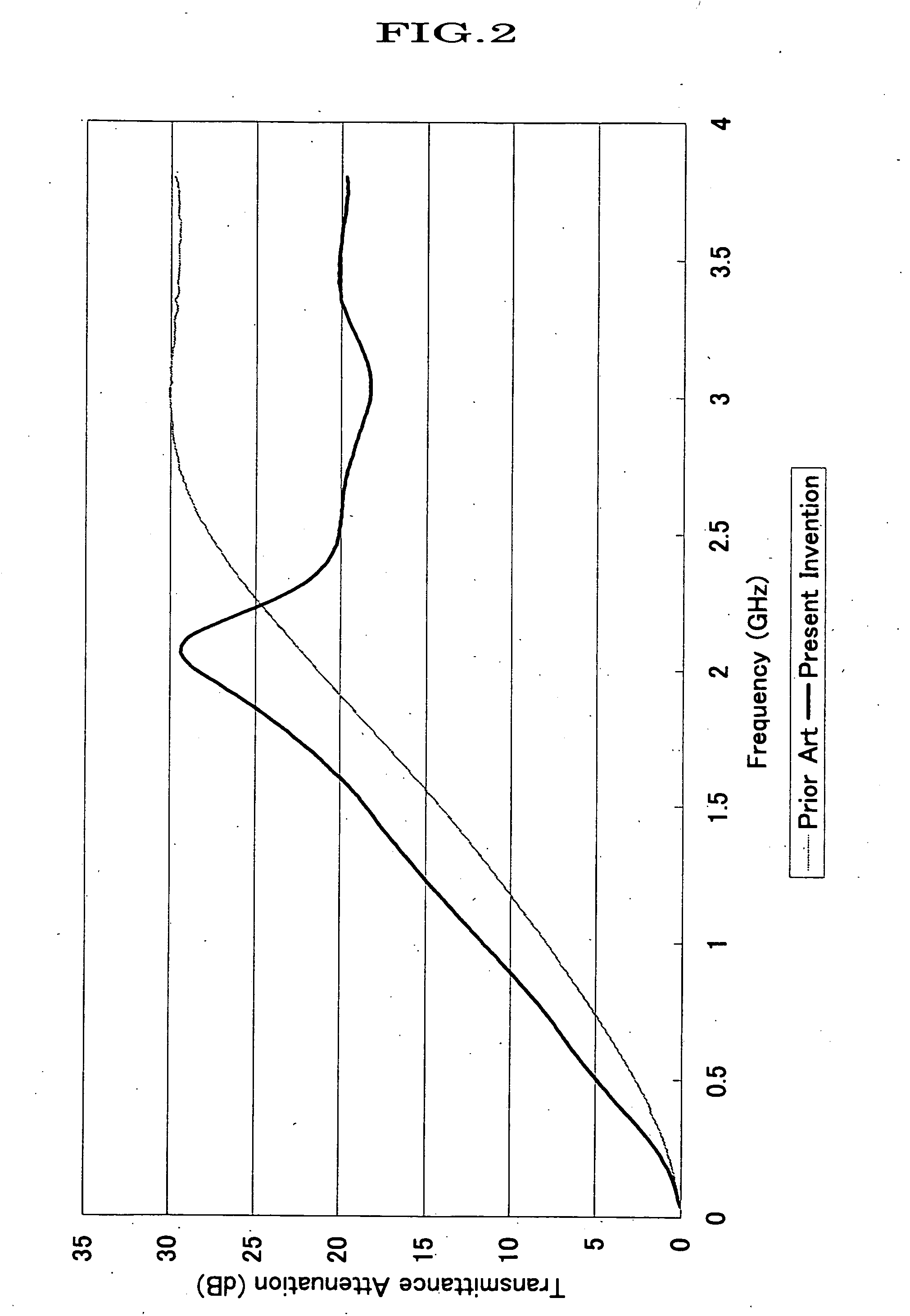

Electromagnetic absorber using resistive material

An electromagnetic absorber using resistive material includes a ground plane of a conductive material; a dielectric layer formed on the ground plane; and a pattern layer in which specific unit cell patterns made of a resistive material are periodically arranged on the dielectric layer. The electromagnetic absorber is applied to an electronic toll collection system, a transportation device, a building structure, an electronic device and an anechoic chamber.

Owner:ELECTRONICS & TELECOMM RES INST

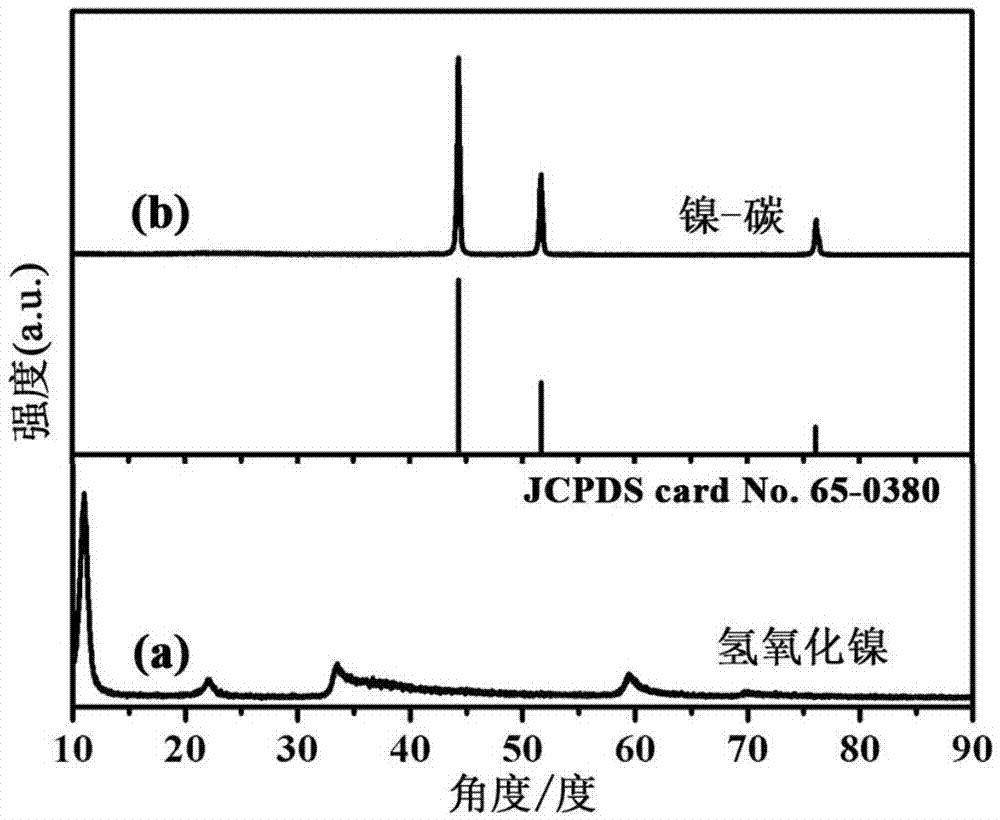

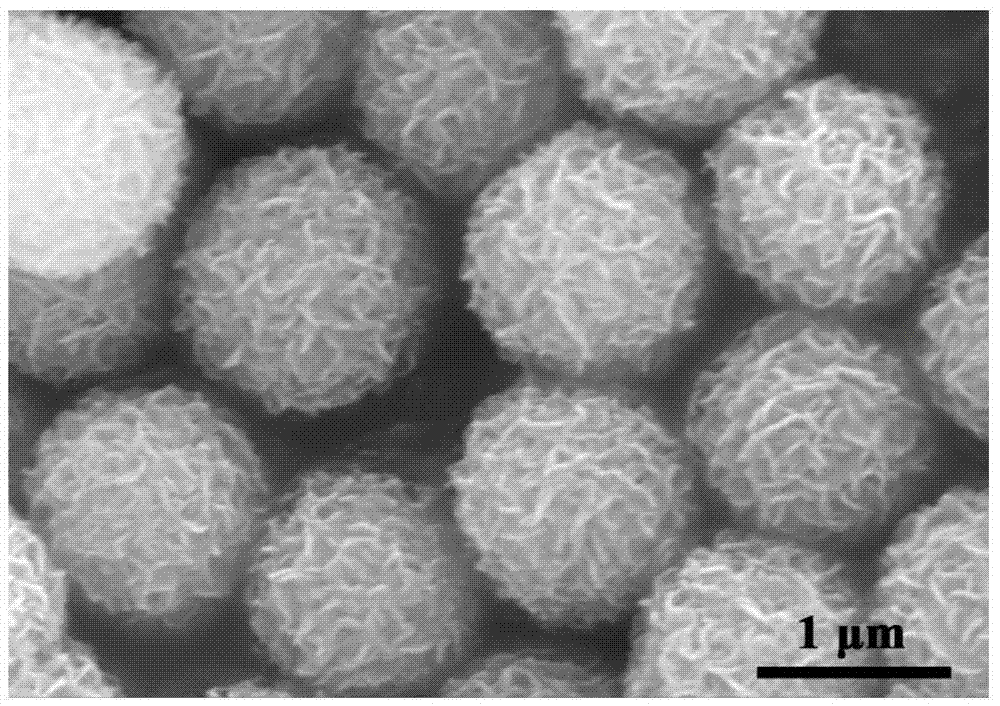

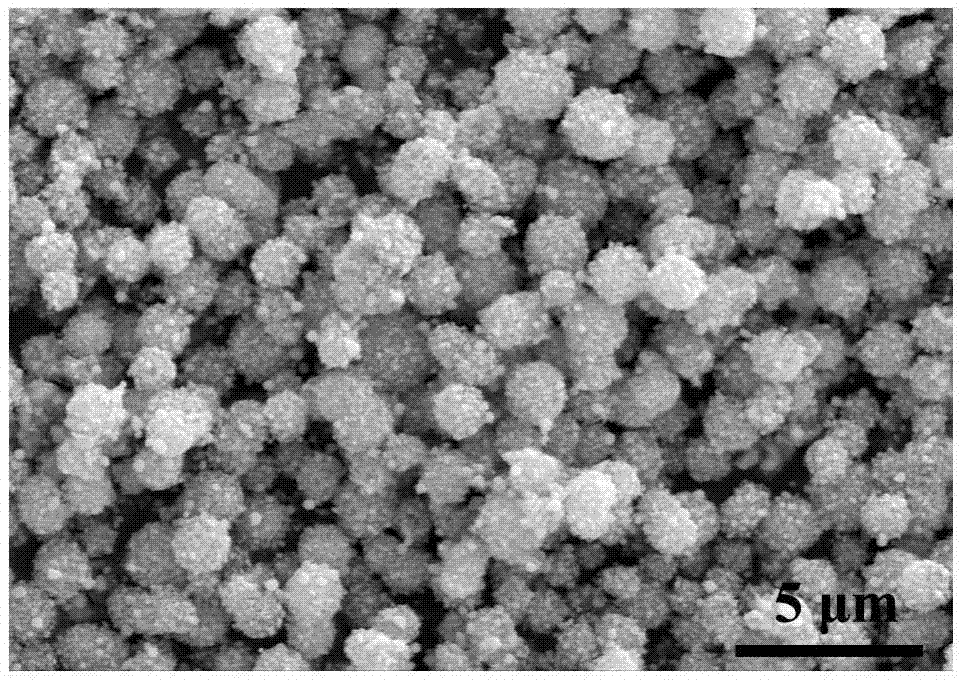

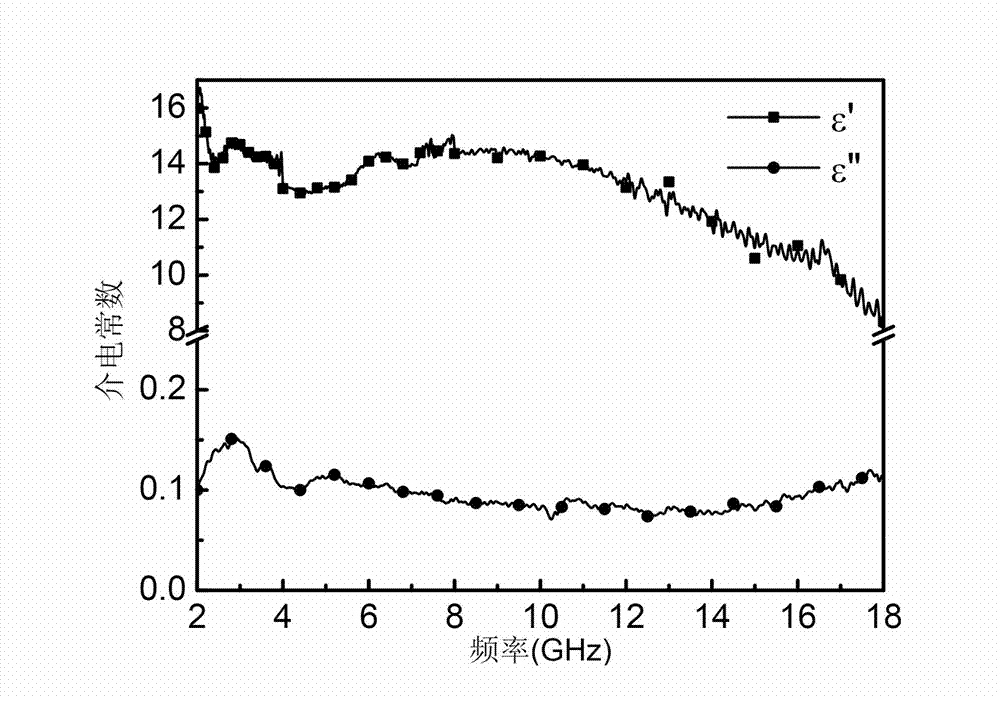

Porous nickel-carbon nano-composite microsphere electromagnetic wave absorbing material and preparation method and application thereof

ActiveCN105436498AHigh saturation susceptibilityImprove coercive forceTransportation and packagingMetal-working apparatusElectromagnetic absorbersMicrosphere

The invention relates to a porous nickel-carbon nano-composite microsphere electromagnetic wave absorbing material and a preparation method and application thereof. A porous nickel-carbon nano-composite microsphere is a multiphase nano-composite powder body composed of carbon and nickel and a porous-structure monodisperse microsphere with the diameter being 1.2-3.0 microns. The preparing method comprises the steps that nickel acetate, other precursors, polyvinyl alcohol and other surfactant are dissolved in an alcohol solvent and react, and nickelous hydroxide is obtained; after being processed through dehydroxylation, the nickelous hydroxide is mixed with pyrrole, pyridine or acrylonitrile, and then the mixture is directly synthesized into the porous nickel-carbon nano-composite microsphere in a sealed reaction kettle under the condition of 500 DEG C-600 DEG C. The obtained porous nickel-carbon nano-composite microsphere is good in stability and uniformity, has the characteristics of being good in electromagnetic wave absorbility, wide in absorbing and covering frequency range, high in corrosion resistance and oxidation resistance and low in cost and is used for manufacturing electromagnetic absorbers.

Owner:SHANDONG UNIV

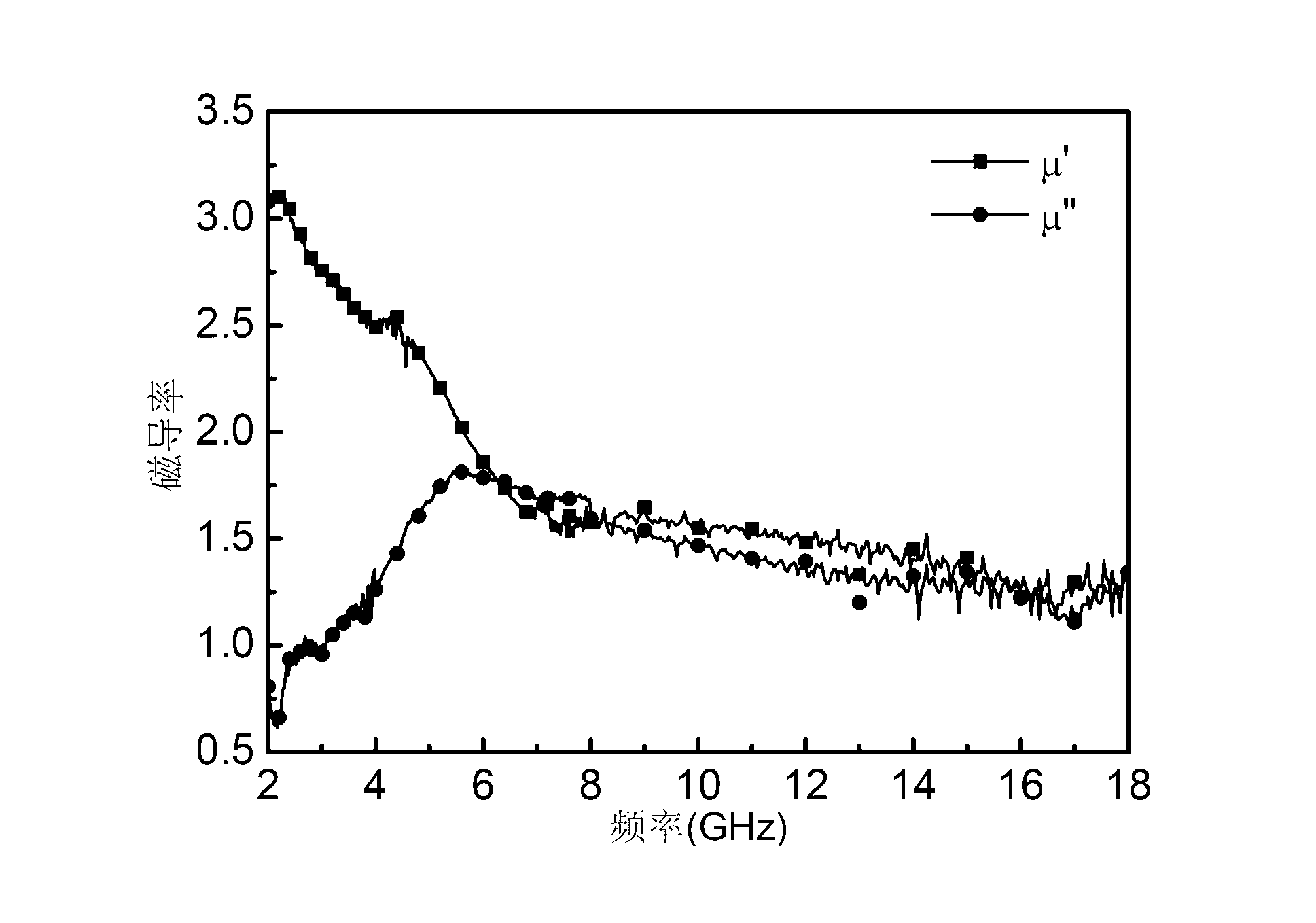

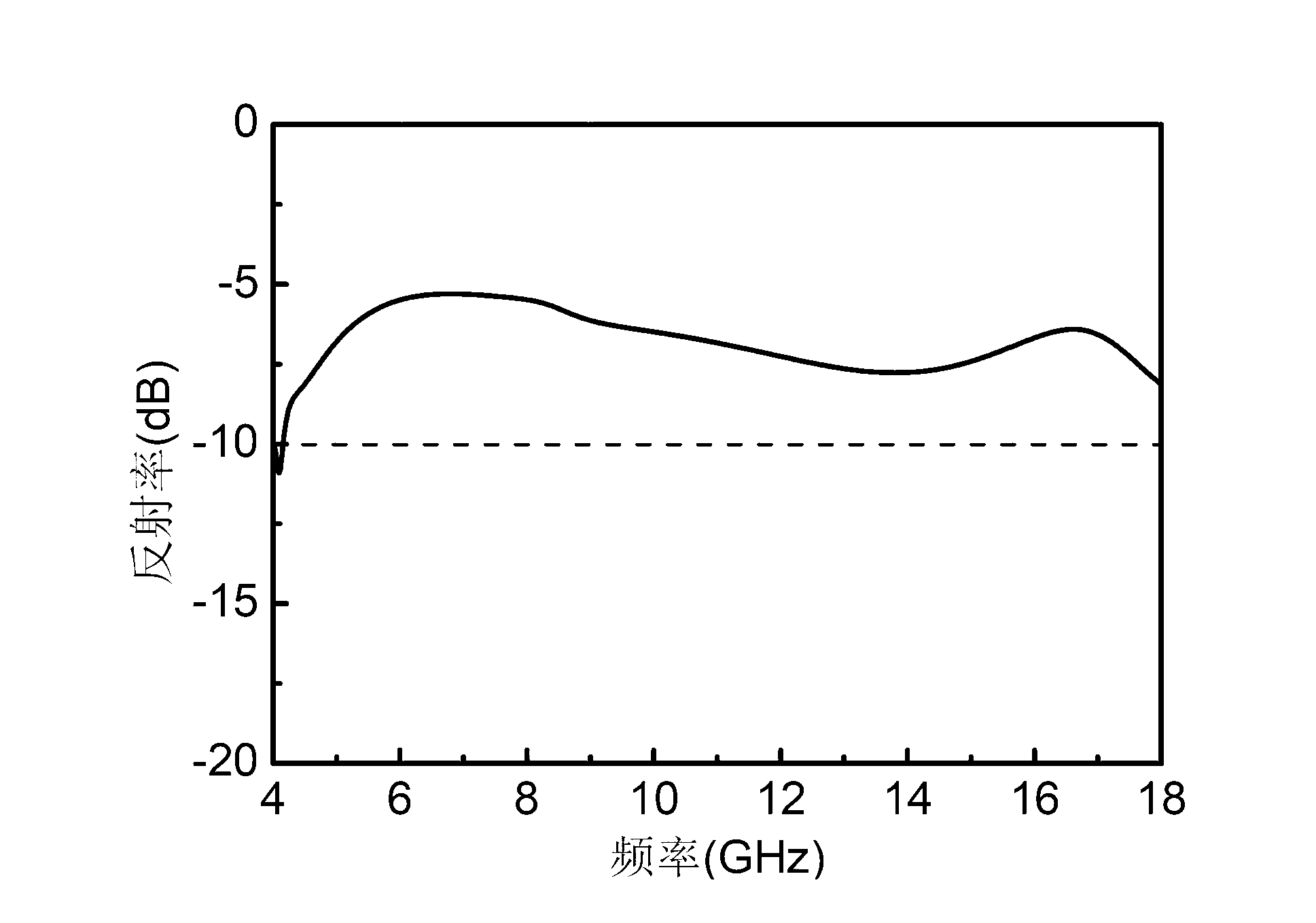

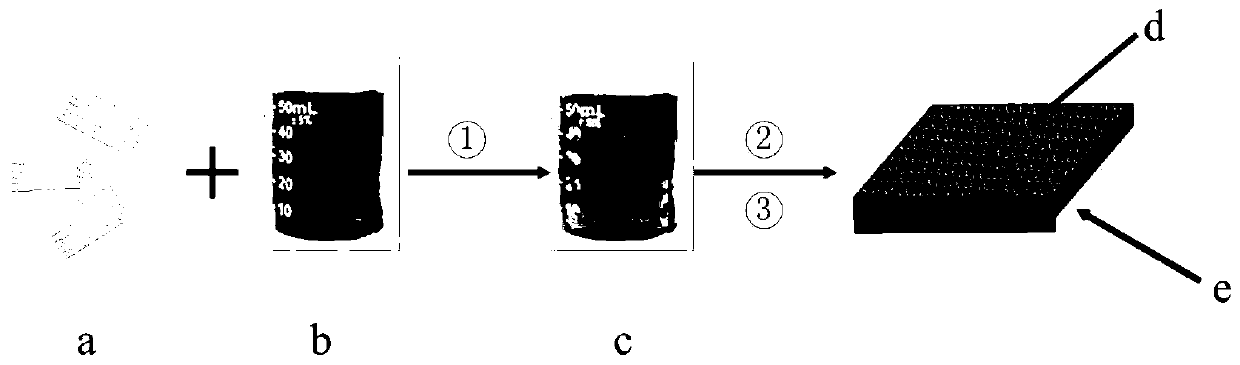

Electromagnetic-wave absorption-material having periodic structure, and preparation method thereof

InactiveCN102732210ARaw materials are easy to getSimple structureOther chemical processesDielectricElectromagnetic absorbers

The present invention discloses an electromagnetic-wave absorption-material having a periodic structure. The material comprises magnetic-wave absorption-blocks and a dielectric material grid, wherein meshes on the dielectric material grid are through holes, and the magnetic-wave absorption-blocks are embedded in the through holes of the dielectric material grid according to a certain periodicity. The preparation method for the electromagnetic-wave absorption-material comprises the following steps: selecting a magnetic-wave absorption-raw material, and cutting the magnetic-wave absorption-raw material into a desired shape and a desired size to prepare into magnetic-wave absorption-blocks; selecting a dielectric material with a dielectric constant in a preset requirement range, arranging insert holes on the dielectric material in a periodic arrangement manner to obtain a dielectric material grid; and individually embedding the magnetic-wave absorption-blocks into the insert holes arranged on the dielectric material grid, and adopting an adhesive to connect the magnetic-wave absorption-blocks and the dielectric material grid into the integration to obtain the electromagnetic-wave absorption-material having the periodic structure. According to the present invention, the work bandwidth of the wave absorption material can be effectively expanded without increase of the thickness, and the volume density of the magnetic-wave absorption-material can be substantially reduced.

Owner:NAT UNIV OF DEFENSE TECH

Electromagnetic wave absorber, method of manufacturing the same and appliance using the same

InactiveUS7218266B2Excellent electromagnetic wave absorbing characteristicIncrease heightMagnetic/electric field screeningSemiconductor/solid-state device detailsElectromagnetic wave absorberElectromagnetic absorbers

An electromagnetic wave absorber for use in the high frequency range above 1 Ghz and a composite member are characterized by the fact that magnetic metal grains are covered with ceramic above 20 volume %. Further, a method of manufacturing the electromagnetic absorber and the composite member is characterized by the fact that composite magnetic particles, in which a plurality of magnetic metal grains and ceramic are unified, are formed through a mechanical alloying method applied to a composite powder composed of magnetic metal powder and ceramic powder. The electromagnetic wave absorber can be used in a semiconductor device, an optical sending module, an optical receiving module, an optical sending and receiving module, an automatic tollgate in which erroneous operation due to electromagnetic wave disturbance is provided by use of the electromagnetic wave absorber.

Owner:HITACHI LTD

Flexible polyimide-based composite dielectric film material and preparation method and application thereof

ActiveCN110330646ASmall coefficient of thermal expansionHigh electromagnetic absorption efficiencyDielectricReflection loss

The invention belongs to the field of dielectric materials and discloses a flexible polyimide-based composite dielectric film material and a preparation method thereof. The flexible polyimide-based composite dielectric film material is prepared by stirring MXene and polyamic acid formed by dianhydride and diamine at room temperature to obtain a mixed solution of MXene / PAA, coating a base materialwith the mixed solution of MXene / PAA, and amidating at 150-550 DEG C, wherein the MXene is Mn+1Xn, X is selected from C or N, M is selected from Sc, Ti, Zr, Hf, V, Nb, Ta, Cr, Mo AND Mn transition metal elements. The preparation method of the flexible polyimide-based composite dielectric material is simple, the thickness is uniform and controllable, and the dielectric property is good; and as a supercapacitor device or an electromagnetic wave absorbing material, the flexible polyimide-based composite dielectric material has the characteristics of higher electromagnetic absorption efficiency, good cycle stability, small maximum reflection loss, wide absorption frequency range and the like.

Owner:GUANGDONG UNIV OF TECH +1

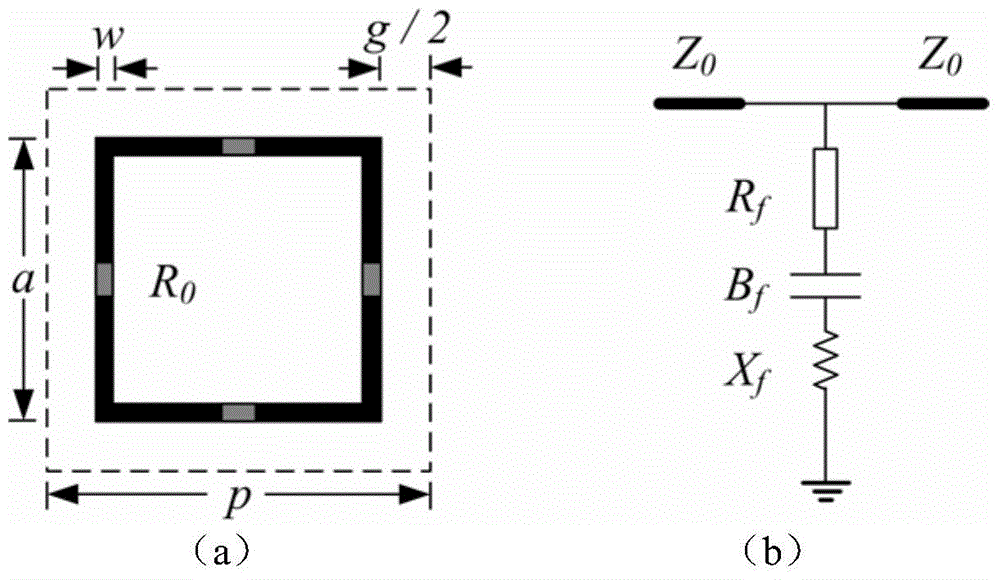

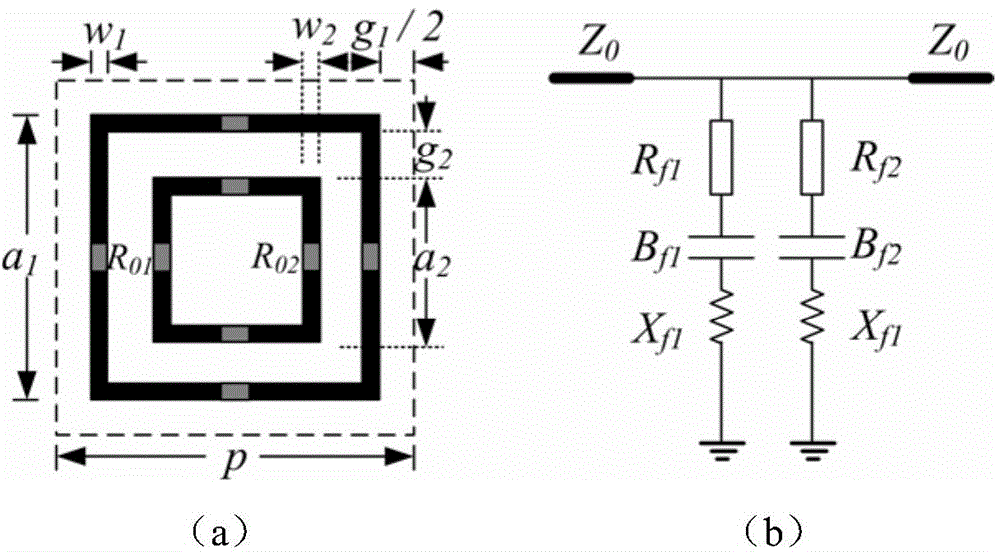

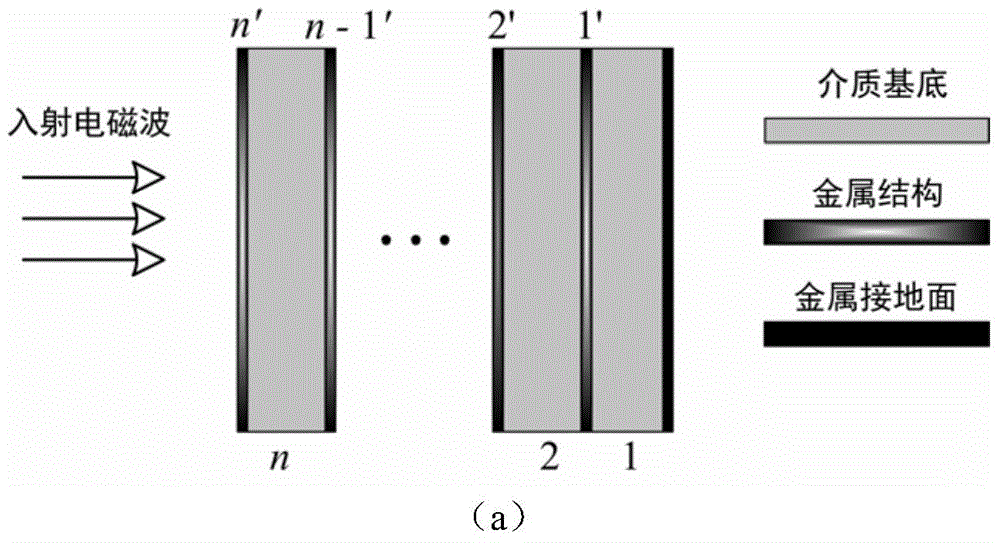

Design method for square ring array electromagnetic absorber integrating equivalent circuit with genetic algorithm

InactiveCN104809270ARapid designShorten the timeSpecial data processing applicationsElectrical resistance and conductanceElectromagnetic absorbers

The invention provides a method for designing a square ring array based absorber rapidly and efficiently, namely, a square ring array equivalent circuit combined genetic algorithm. The method comprises the steps of: firstly introducing two parameters, namely, resistance loss and equivalent dielectric constant on the basis of an equivalent circuit model of a loss-free square ring array so as to obtain a single / double ring array equivalent circuit model and calculation formula of centrally uploaded lumped resistance; then combining with a transmission line theory to finally elicit an equivalent circuit m of an absorber in a multilayered structure; finally, on the basis of the equivalent circuit, optimizing the performance of the structure by adopting a genetic algorithm to form a complete optimized design process. According to the method, the square ring array based multilayered absorber can be designed, a design goal can be defined based on the practical demand, and a broadband low-profile absorber can be designed freely. With adoption of the method for designing the absorber, short time is taken, the error is small, and the efficiency is high.

Owner:NANJING UNIV OF SCI & TECH

Multi-pore hollow iron nano spherical electromagnetic wave absorption material as well as preparation method and application thereof

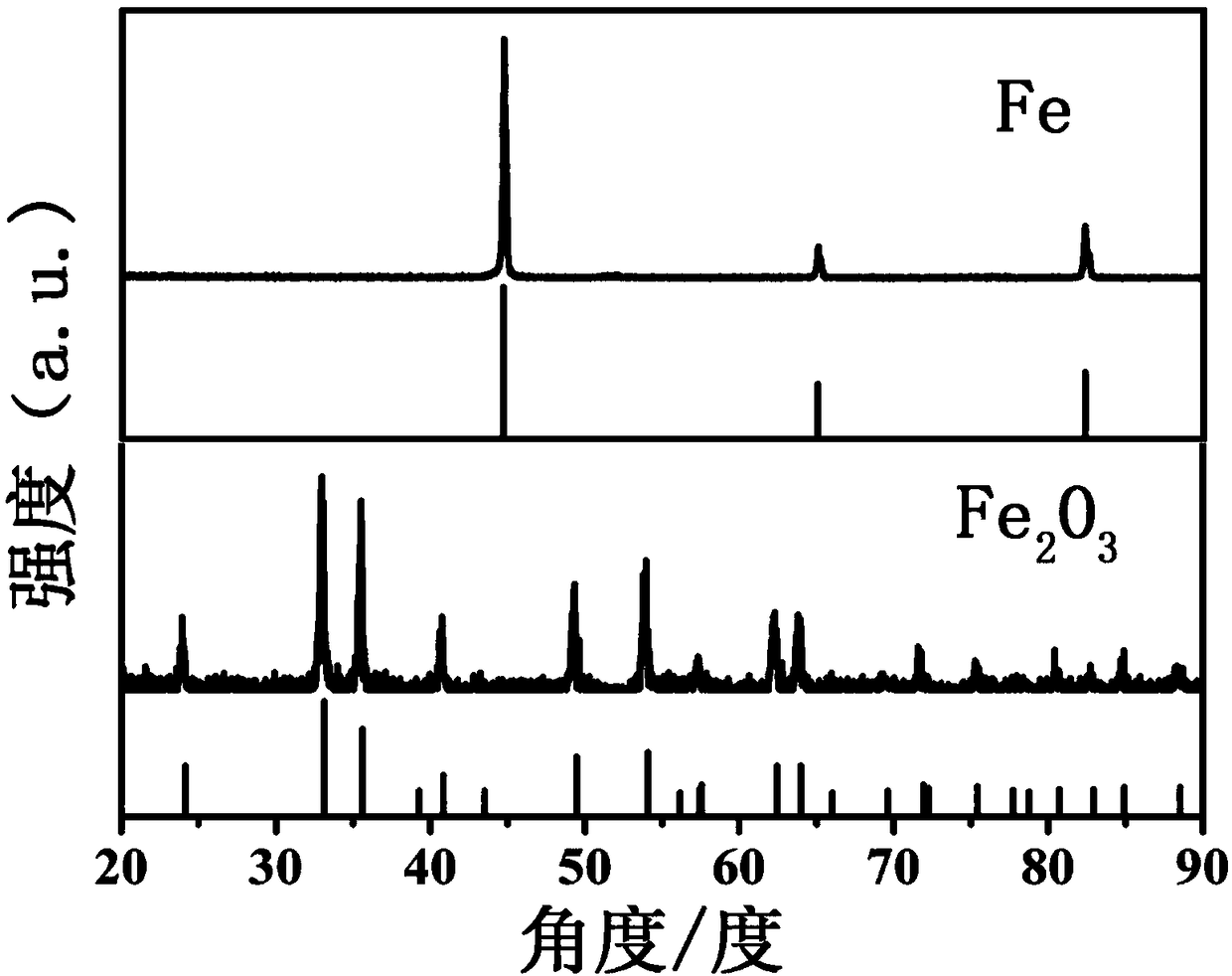

ActiveCN108124413AHigh saturation susceptibilityImprove coercive forceNanomagnetismMagnetic/electric field screeningElectromagnetic absorbersHydrogen atmosphere

The invention relates to a multi-pore hollow iron nano spherical electromagnetic wave absorption material as well as a preparation method and the application thereof. The electromagnetic wave absorption material is a hollow sphere of which the diameter is 500-600nm. The preparation method comprises the following steps: dissolving a precursor salt such as ferric nitrate and surfactants such as polyvinylpyrrolidone into an alcohol solvent, further adding a small amount of deionized water, performing a thermal reaction on the solvent so as to obtain a precursor, performing calcining treatment, further reducing in the presence of a hydrogen atmosphere, and performing direct reduction at 400-500 DEG C, so as to obtain a multi-pore hollow iron nano sphere. The obtained multi-pore hollow iron nano sphere has the characteristics of good stability and uniformity, good electromagnetic wave absorption performance, wide absorption cover frequency range, small corrosion and low cost, and can be adopted to manufacture an electromagnetic absorber.

Owner:SHANDONG UNIV

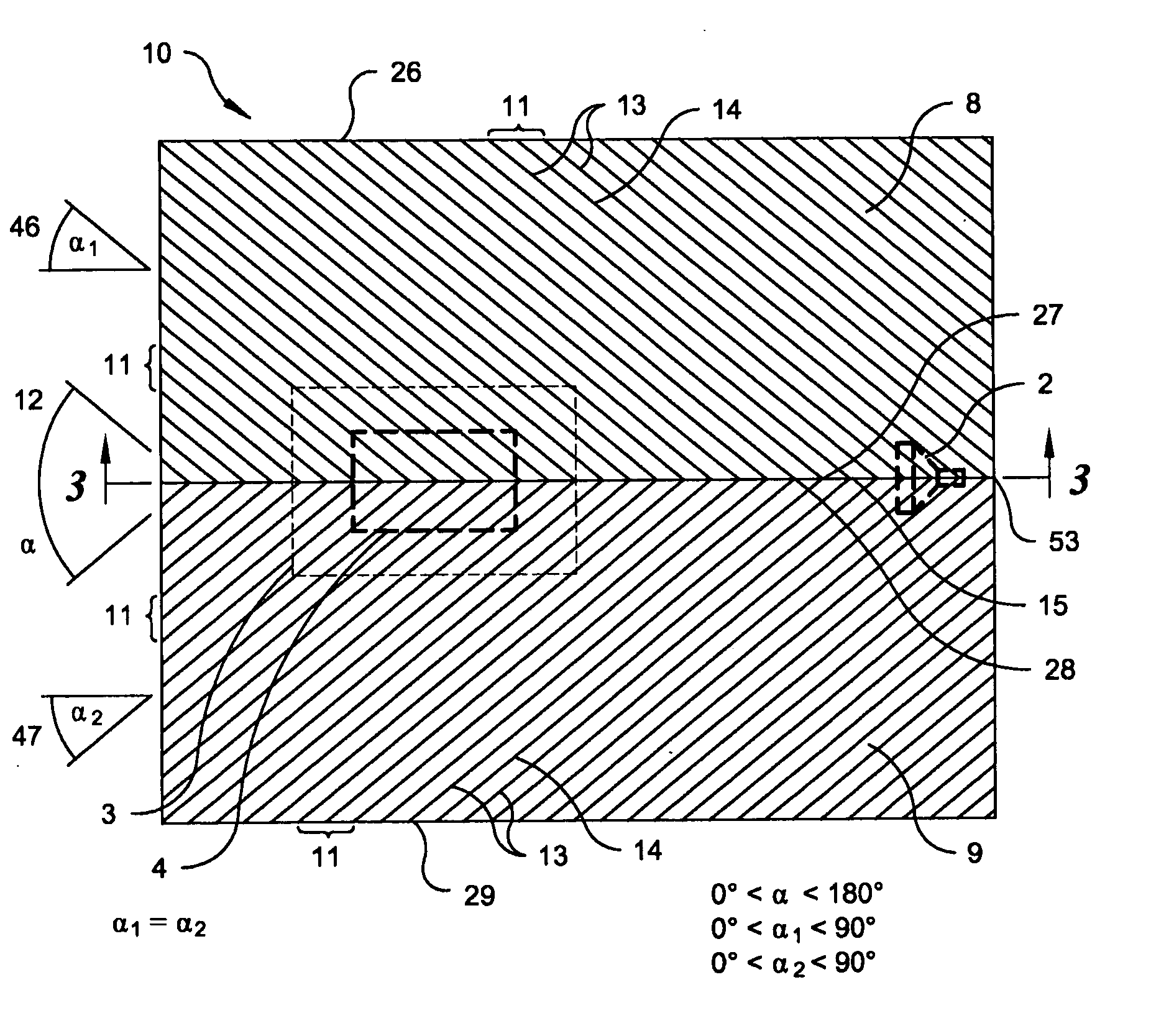

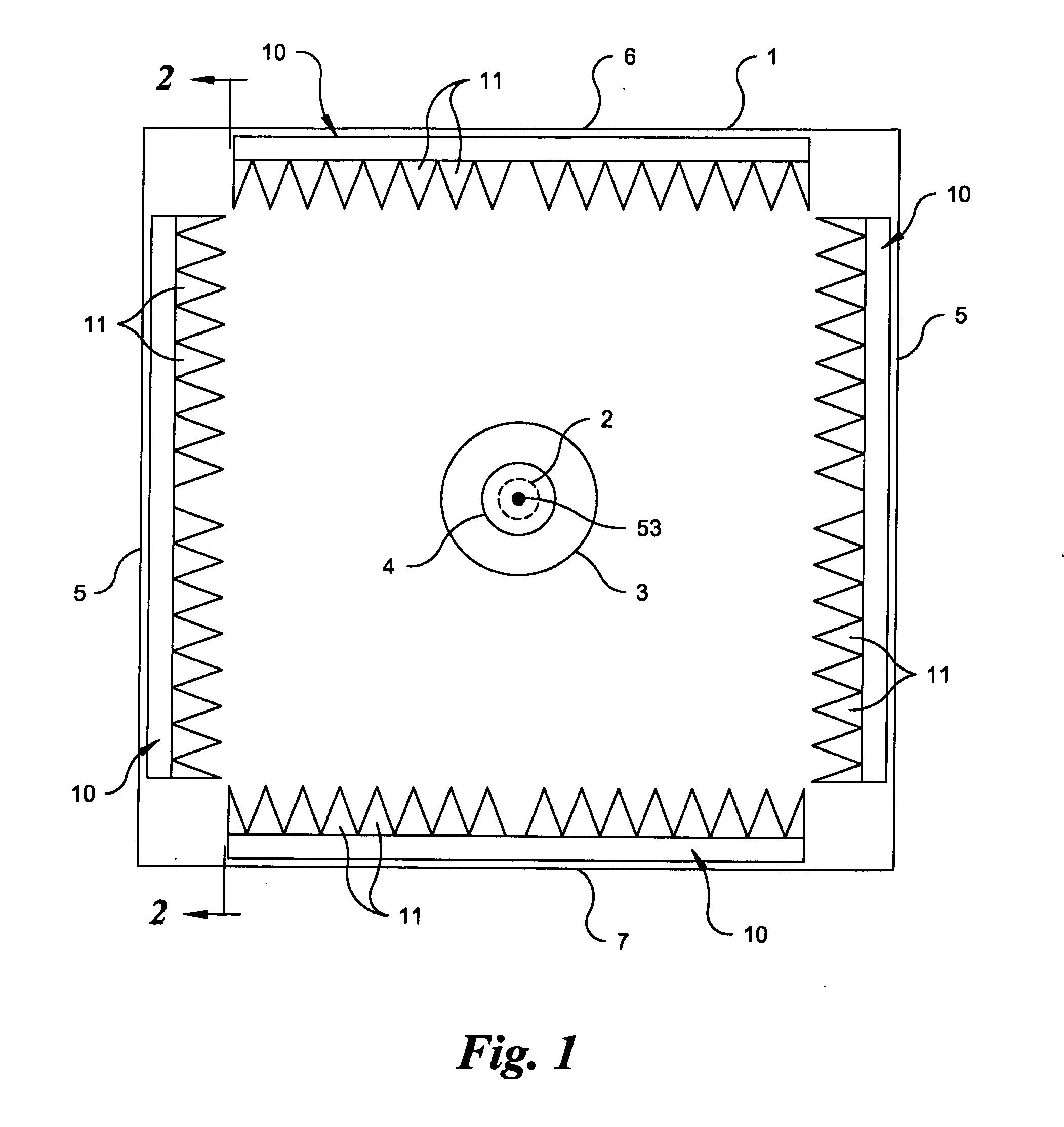

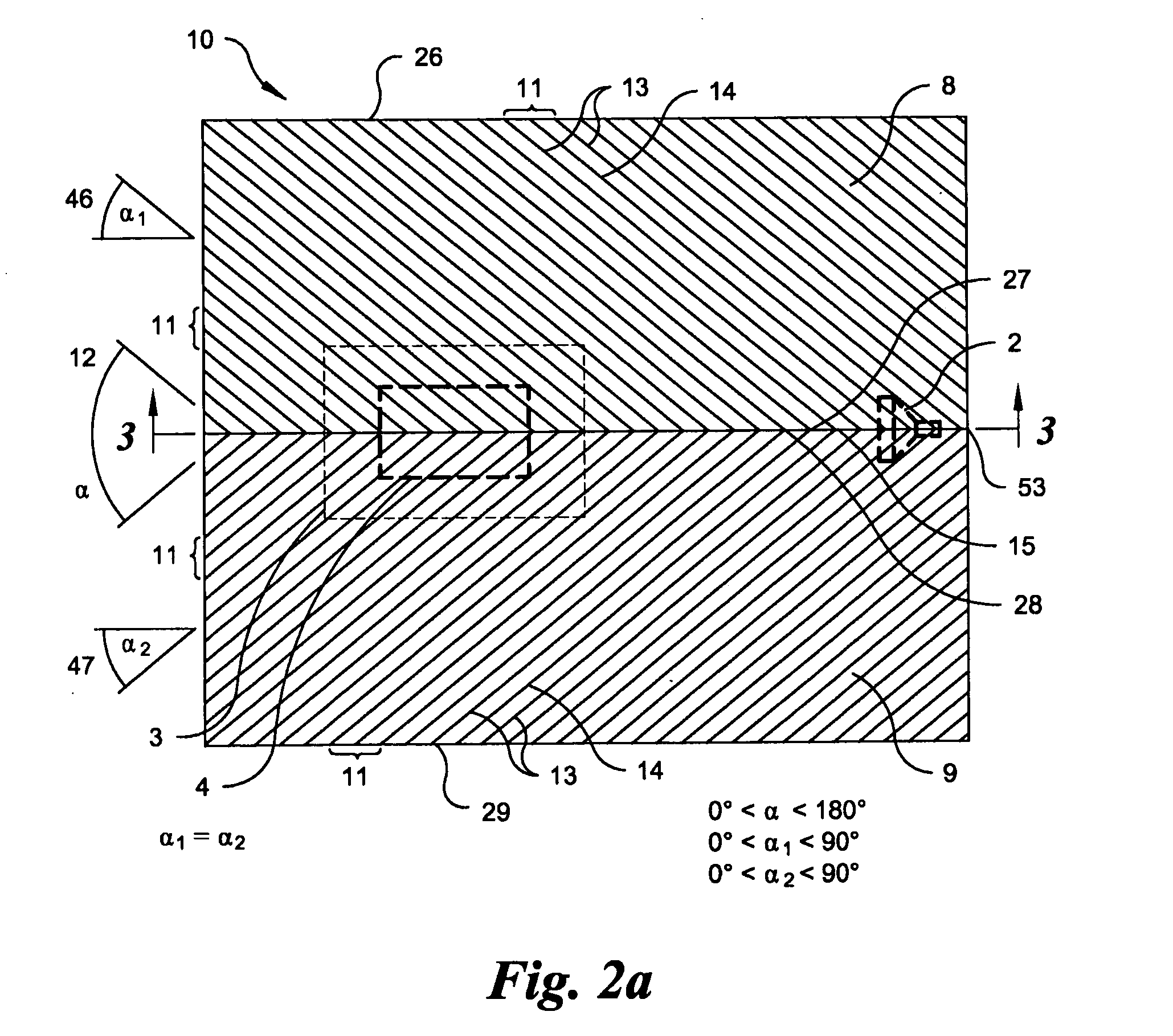

Absorber Assembly for an Anechoic Chamber

InactiveUS20110095932A1Minimises levelExtensive testingScreening rooms/chambersAntennasElectromagnetic absorbersTest chamber

An electromagnetic absorber assembly (10) capable of minimizing reflectivity caused by reflected and diffracted waves within a test chamber (1) is presented. The absorber assembly (1) includes a plurality of first wedges (11) and a plurality of second wedges (11) disposed in a symmetrical arrangement so as to form a continuous and smoothly changing v-shaped pattern along one or more walls (5-7) of an anechoic test chamber (1). Each wedge (11) has a triangular-shaped first end (26) and second end (27) formed by a pair of side walls (16, 18, or 19) and a base wall (17). One second end (27) of each first wedge (11) contacts and covers one first end (26) of each second wedge (11) along a contact plane (15). First and second wedges (11) are disposed at a first angle (46) and a second angle (47), respectively, about the contact plane (15) in a symmetrical arrangement. The assemblies described could be installed on a flat or shaped absorber base (44) or wall (20) to divert reflected and refracted fields away from a quiet zone (3). Interplay between the shaped absorber base (44) or wall (20) and intersecting wedges (11) facilitates minimization of clutter and secondary scattering.

Owner:ORBIT ADVANCED TECH INC

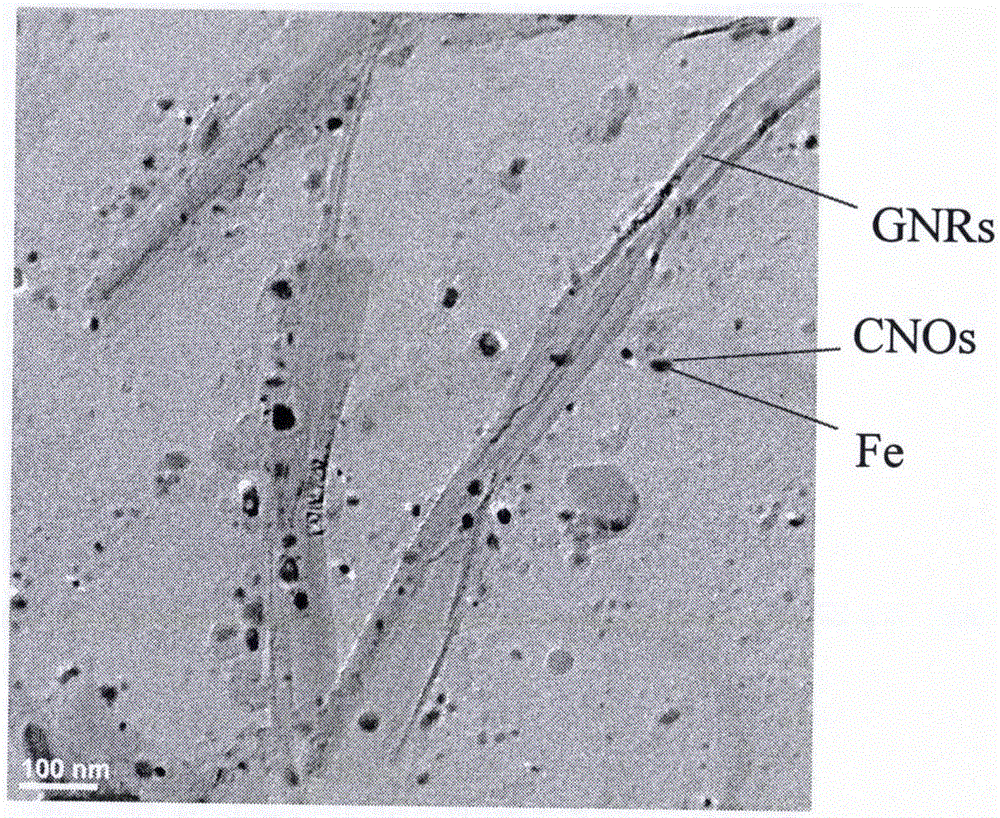

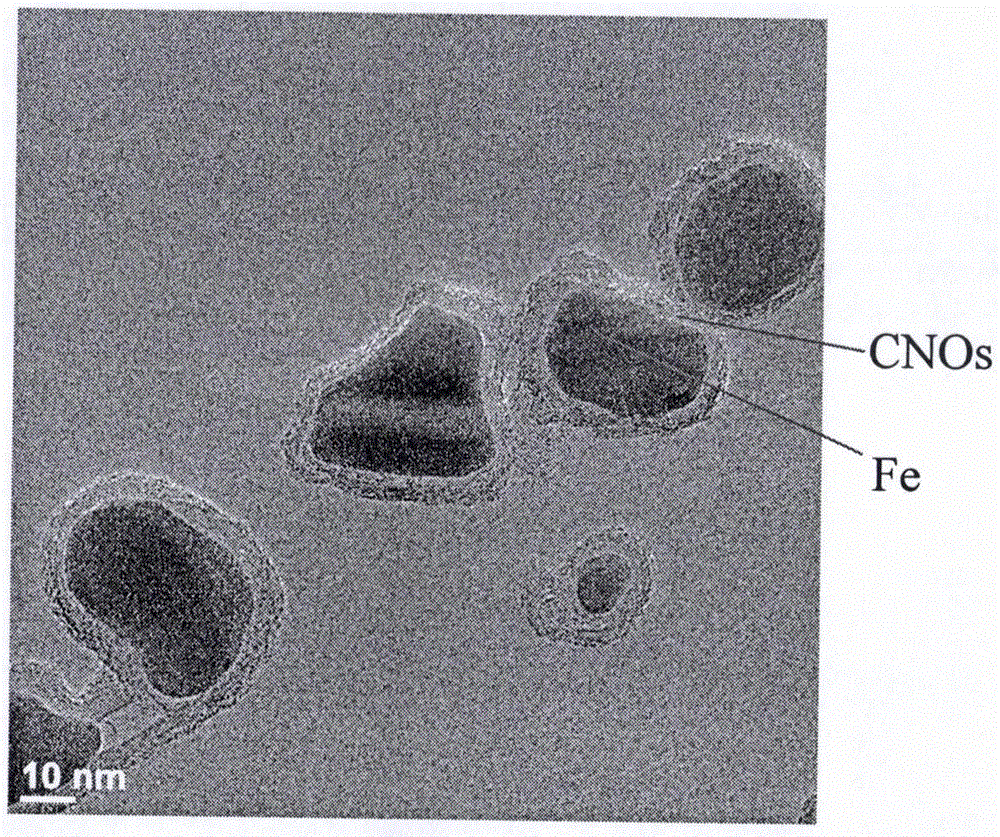

Preparation method for magnetic graphene nanobelt/graphene composite film

ActiveCN106191804ALow costSimple processLiquid/solution decomposition chemical coatingChemical vapor deposition coatingComposite filmOptical transparency

The invention provides a preparation method for a magnetic graphene nanobelt / graphene composite film. According to the preparation method, ferromagnetic metal nanoparticles wrapped with carbon nano onions grow on the surface of the graphene nanobelt and the surface of the graphene composite film in an in-situ growth manner through a two-step chemical vapor deposition method. The graphene composite film can be transferred to a target matrix without the assistance of a polymer during the transfer process and has the beneficial effects of strong in magnetism, high in optical transparency and high in hole / electron mobility. In addition, the ferromagnetic metal nanoparticles are wrapped with shells of the carbon nano onions so that oxidation, acidification, shedding and the like of the ferromagnetic metal nanoparticles can be avoided, so that the graphene composite film has high strength and good stability. By the adoption of the preparation method, the magnetic graphene composite film can be obtained through macroscopic preparation by the adoption of the two-step chemical vapor deposition method; by the adoption of the method, the technological process is simple, the cost is low, and large-scale production is facilitated; and the method can be widely applied to graphene spintronic devices, electromagnetic wave absorbing materials, flexible graphene film electronic devices and the like.

Owner:重庆锦添翼新能源科技有限公司

Suspension system for vehicle

ActiveUS8103408B2Simple structureReduce voltageNon-rotating vibration suppressionDigital data processing detailsElectromagnetic absorbersClosed loop

In a system including four electromagnetic absorbers for respective four vehicle wheels, motor coils of two respective electromagnetic absorbers disposed corresponding to two diagonally located wheels are connected forming a closed loop including the coils. A generated damping force magnitude can be made different between an instance directions of respective movements of the diagonally located two wheels with respect to the vehicle body are the same, and an instance the directions are opposite each other. Each electromagnetic absorber includes a resistor cooperating with the corresponding coil forming a closed loop, and selectively establishes: a connected state in which one of the four coils and any of the other three coils are connected to form a closed loop; and a non-connected state in which the one of the four coils is not connected to any other coil. An appropriate vibration suppressing action is exhibited with respect to a coupled motion.

Owner:KYB CORP +2

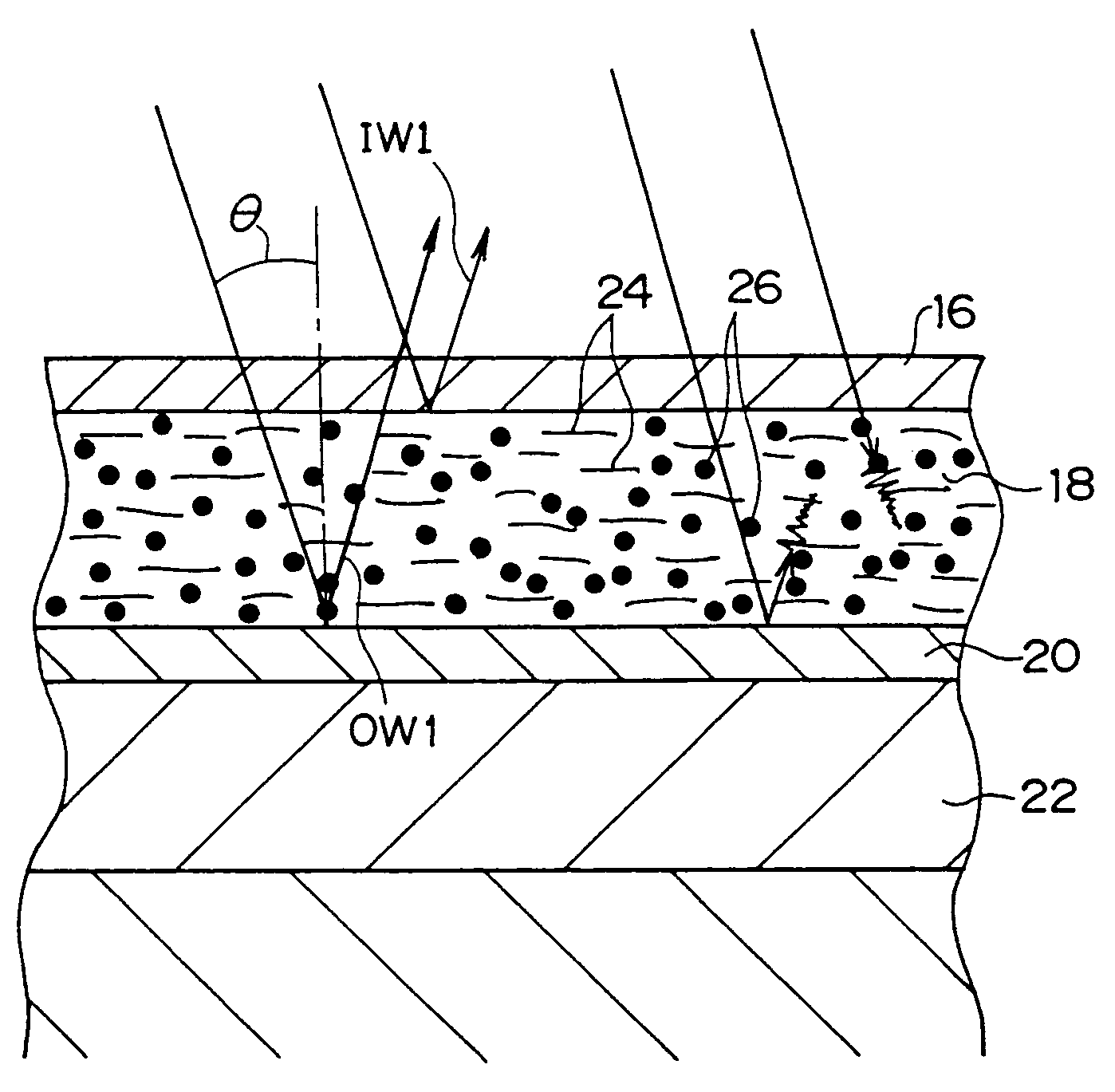

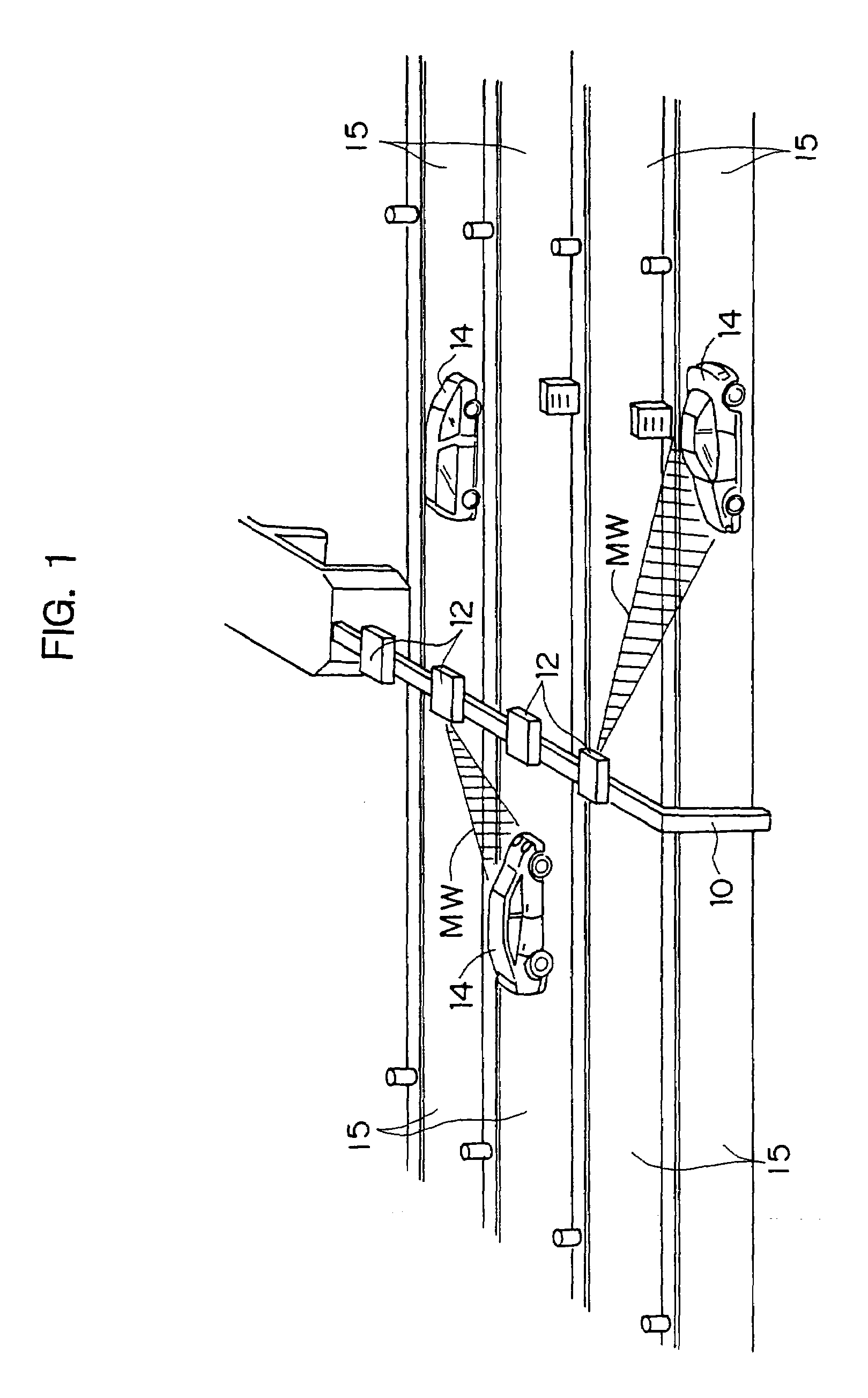

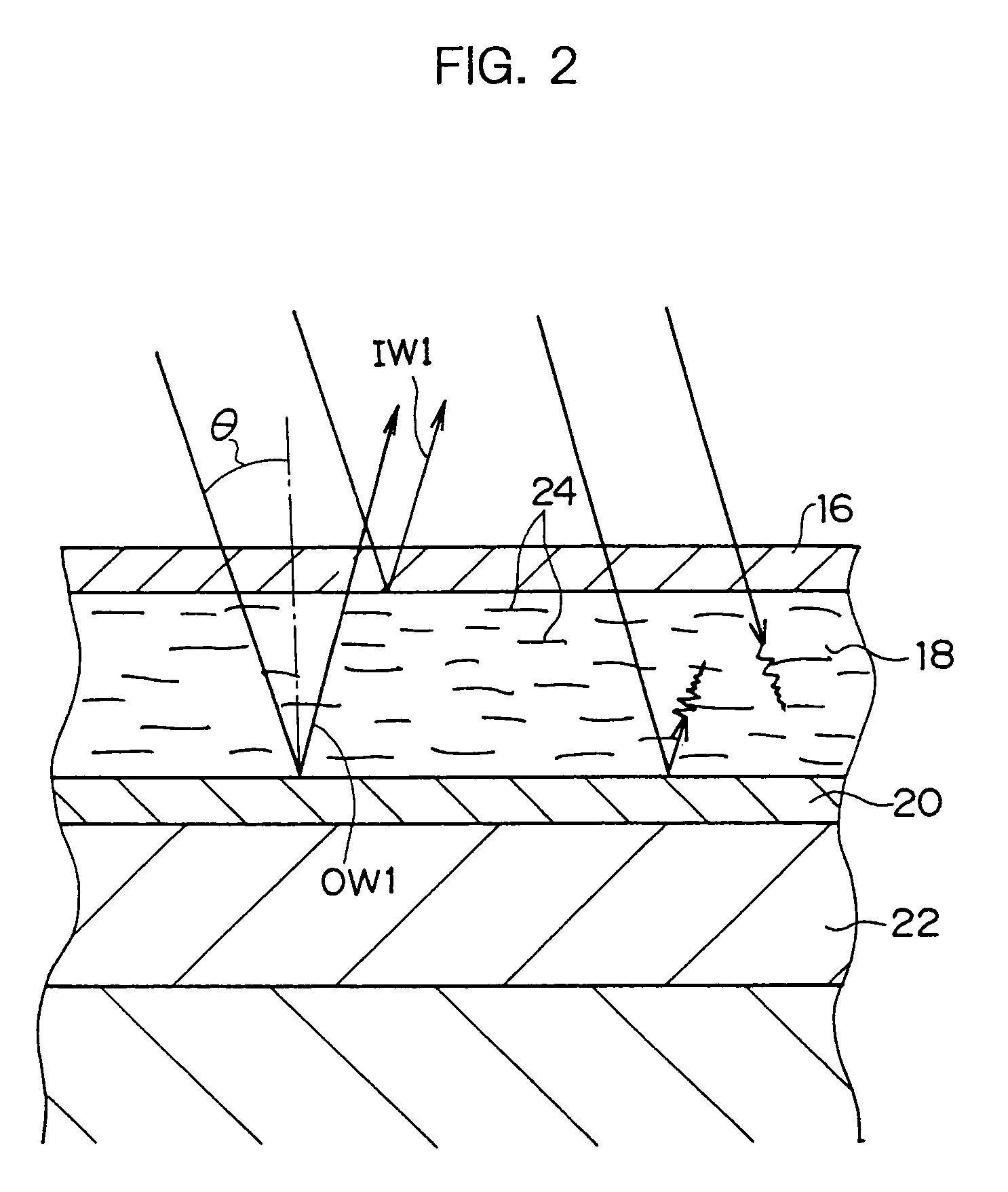

Paving material for absorbing electromagnetic wave and pavement structure using it

InactiveUS7160049B2Absorbed more effectivelyEffective absorptionPaving reinforcementsIn situ pavingsElectricityFiber

An electromagnetic absorber formed of conductive fiber or the like, such as carbon fiber having an overall length corresponding to the wavelength of electromagnetic waves to be absorbed, is mixed into a base material to form an electromagnetic wave-absorbing pavement material. The electromagnetic wave-absorbing pavement material is used to form a pavement having an electromagnetic wave absorbing course. Further, an electromagnetic wave reflecting course is disposed under the electromagnetic wave absorbing course, and the electric length of the electromagnetic wave reflecting course is set to a predetermined value in relation to the dielectric constant so that electromagnetic waves reflecting off the surface of the electromagnetic wave absorbing course and electromagnetic waves reflecting off the electromagnetic wave reflecting course have opposite phases and thereby cancel each other out, whereby the electromagnetic waves are absorbed well.

Owner:TAKENAKA KOMUTEN CO LTD +2

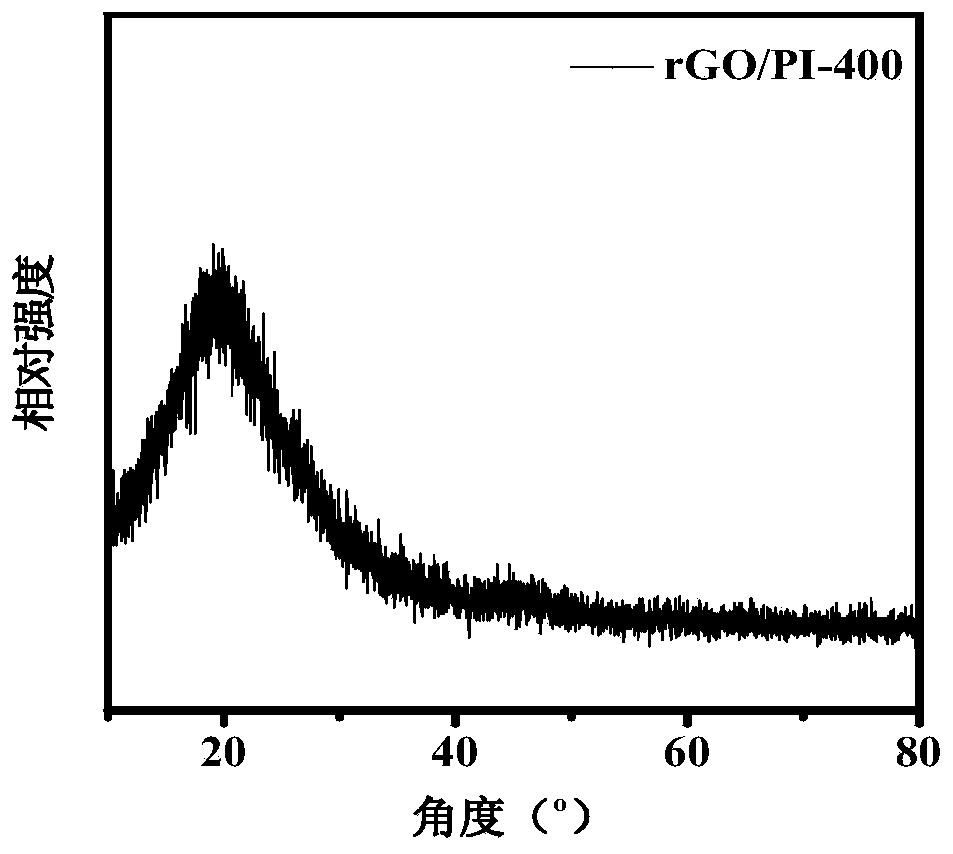

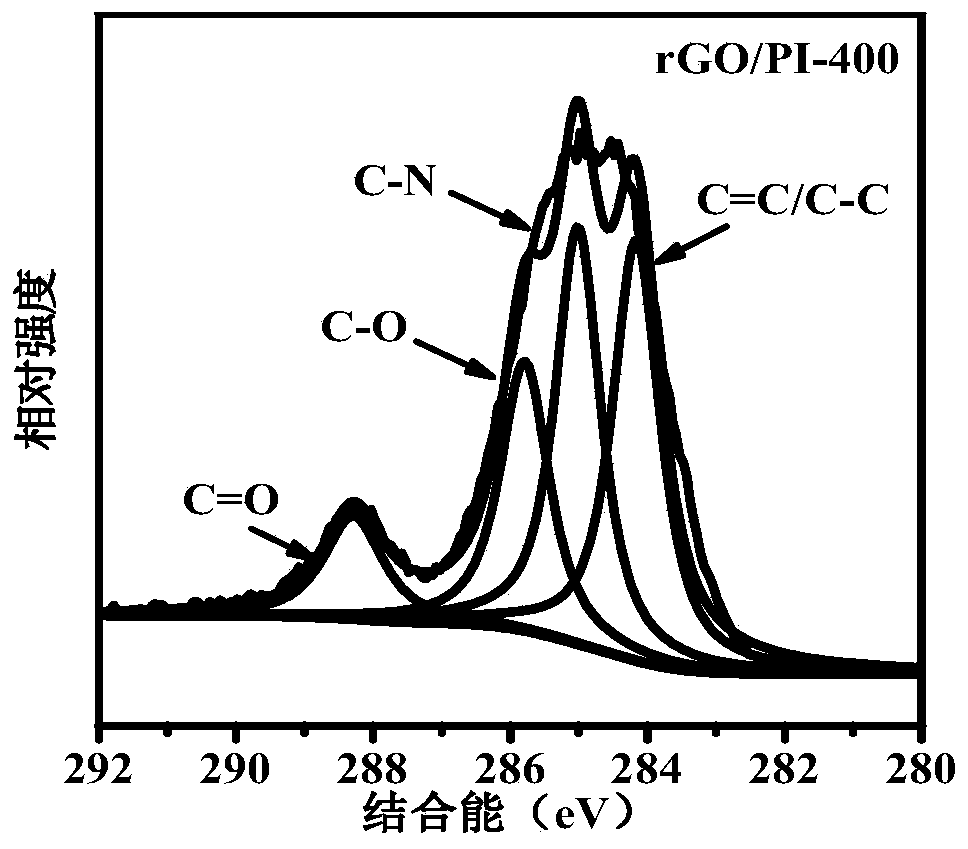

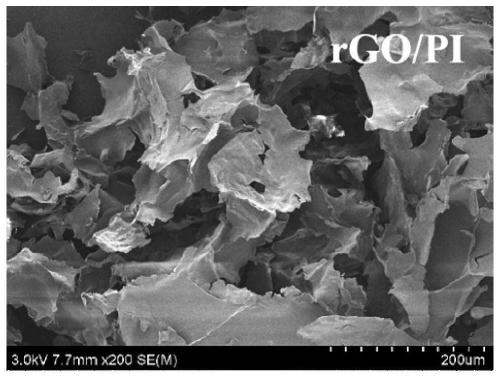

RGO/polyimide composite aerogel, preparation method and application thereof

InactiveCN111218112AImprove mechanical propertiesIncreased load-bearing capacityOther chemical processesImidePolymer science

The invention discloses an rGO / polyimide composite aerogel. The composite aerogel is a three-dimensional conductive network structure formed by interpenetrating rGO of a sheet structure, and polyimideserves as a supporting framework and is located among the sheet structure rGO. The rGO / polyimide composite aerogel is microscopically a two-dimensional lamellar adhesion structure and macroscopicallyhas a porous structure, lamellar structure rGO adheres to each other to provide an effective transmission path for electron transmission, and the porous structure plays a decisive role in light weight and heat resistance of the material; polyimide calcined at a proper temperature endows the composite material with better mechanical properties, so that the bearing capacity and compression resistance of the composite material are effectively improved; due to the introduction of porous rGO, and the electrical conductivity of the composite aerogel is improved, thus facilitating use of the composite aerogel as an electromagnetic wave absorbing material to absorb and attenuate electromagnetic waves.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

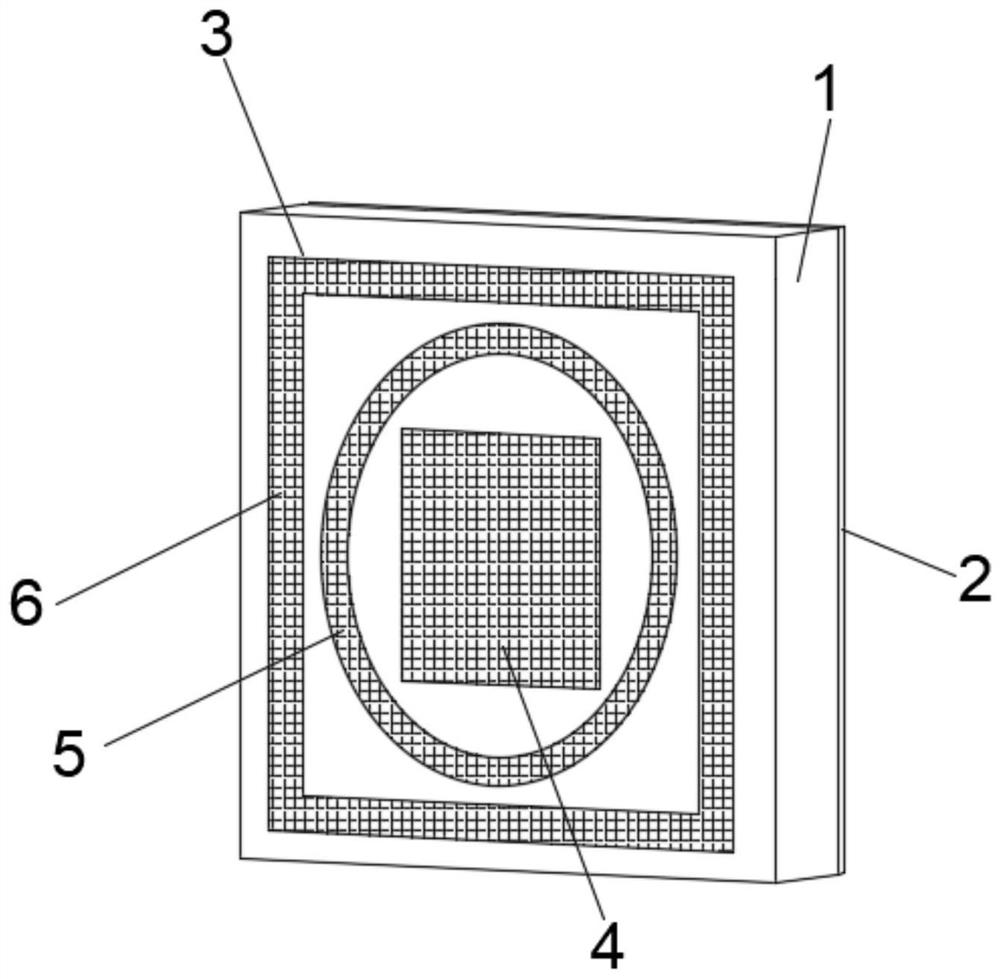

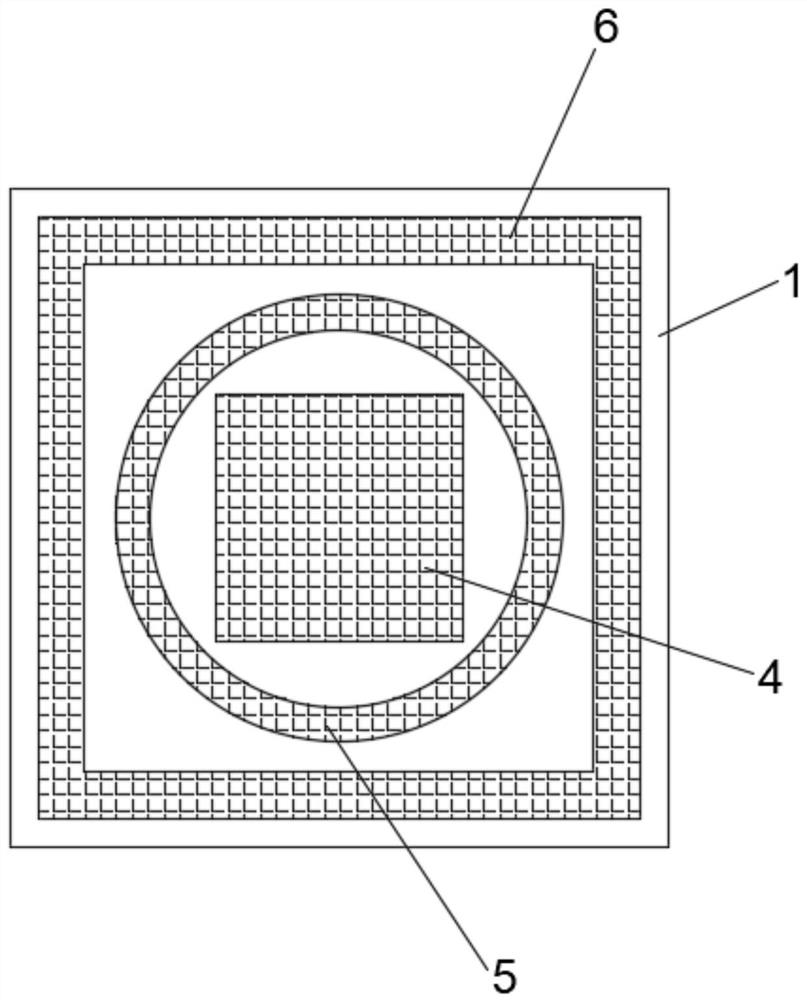

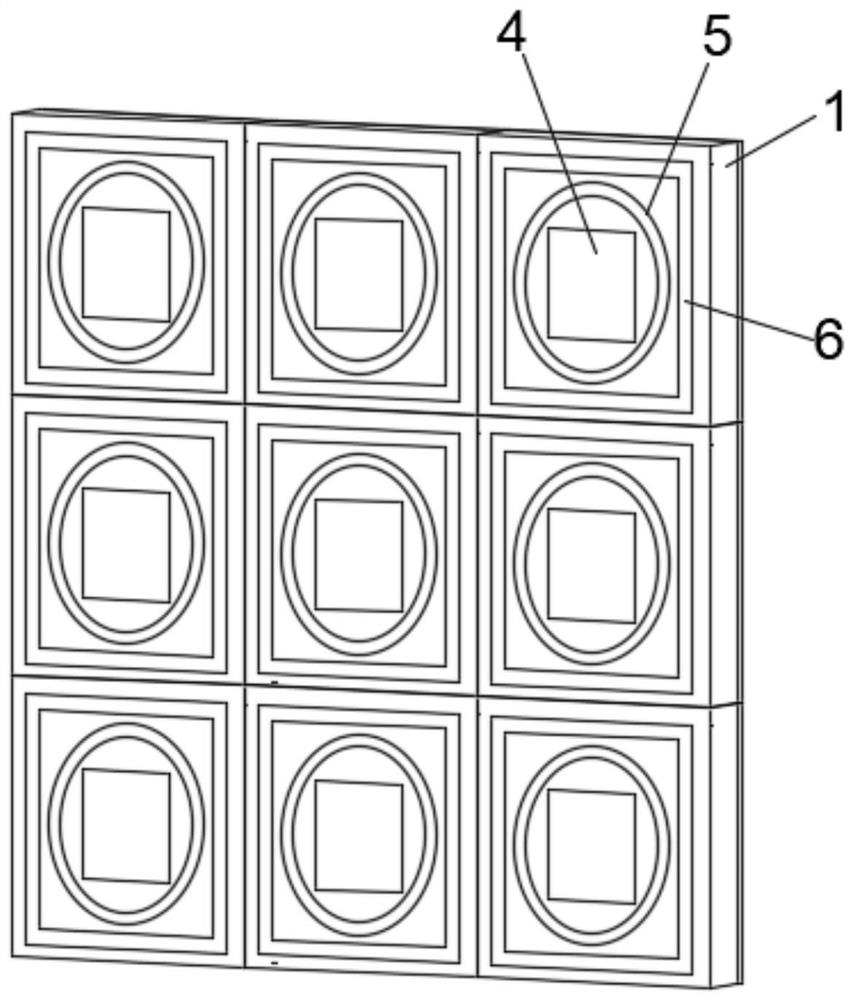

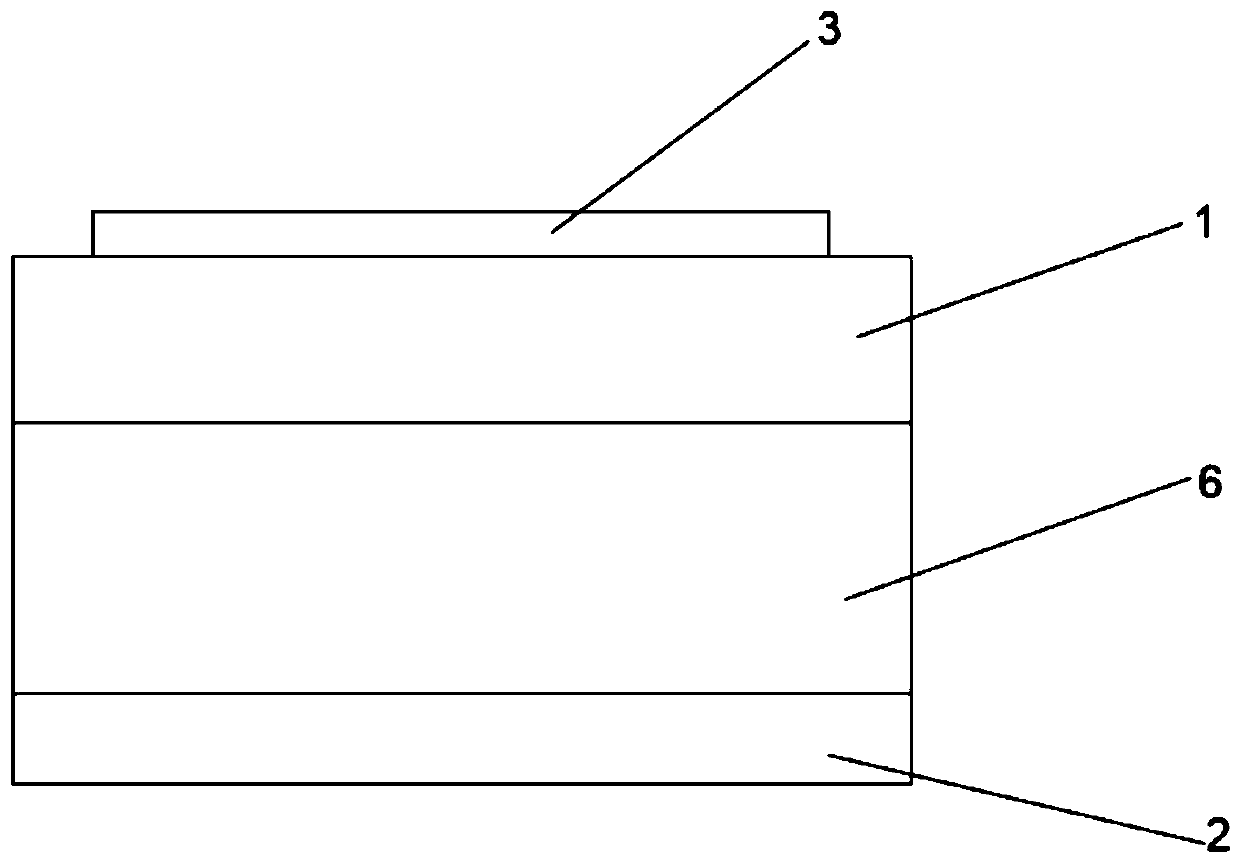

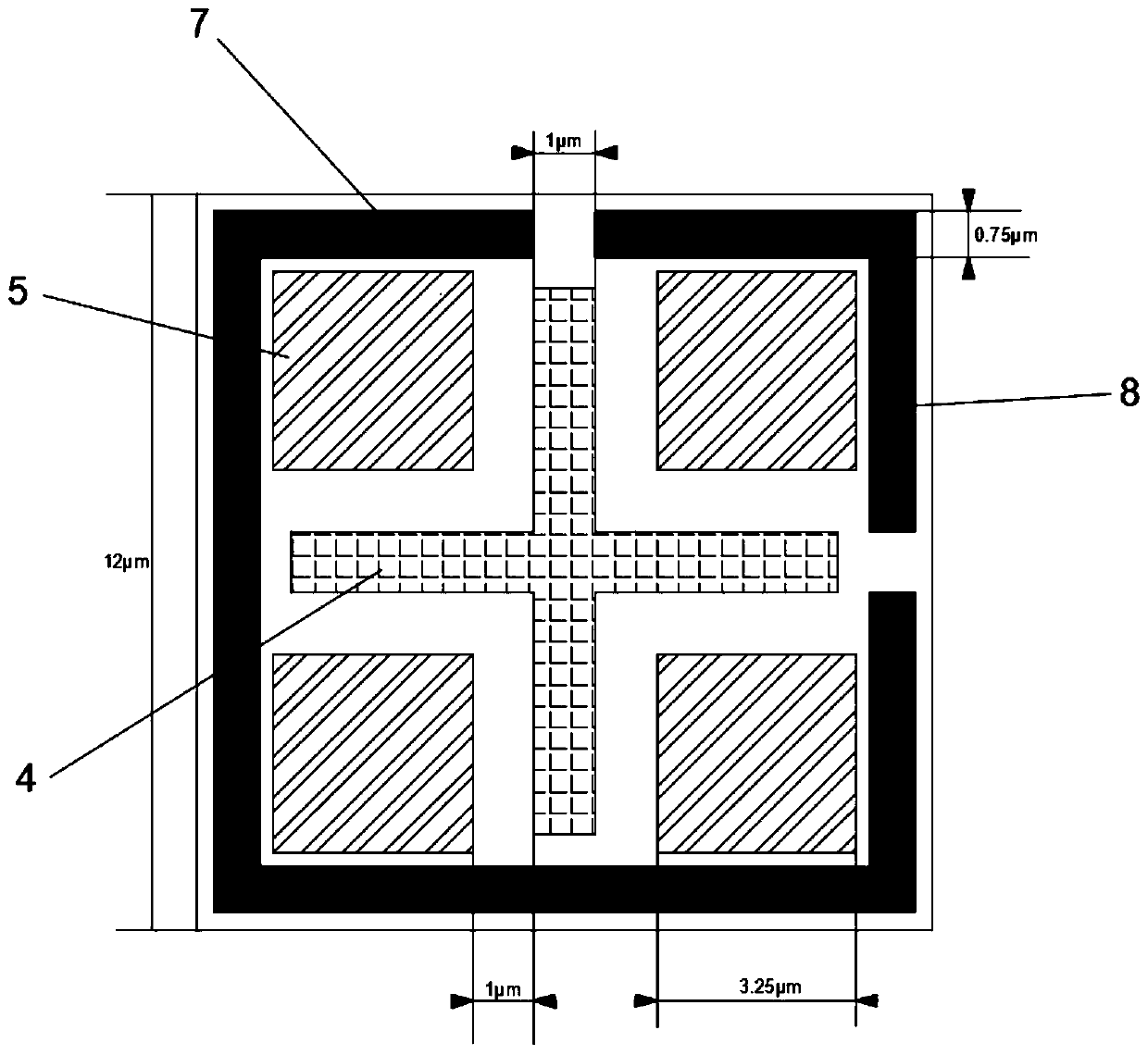

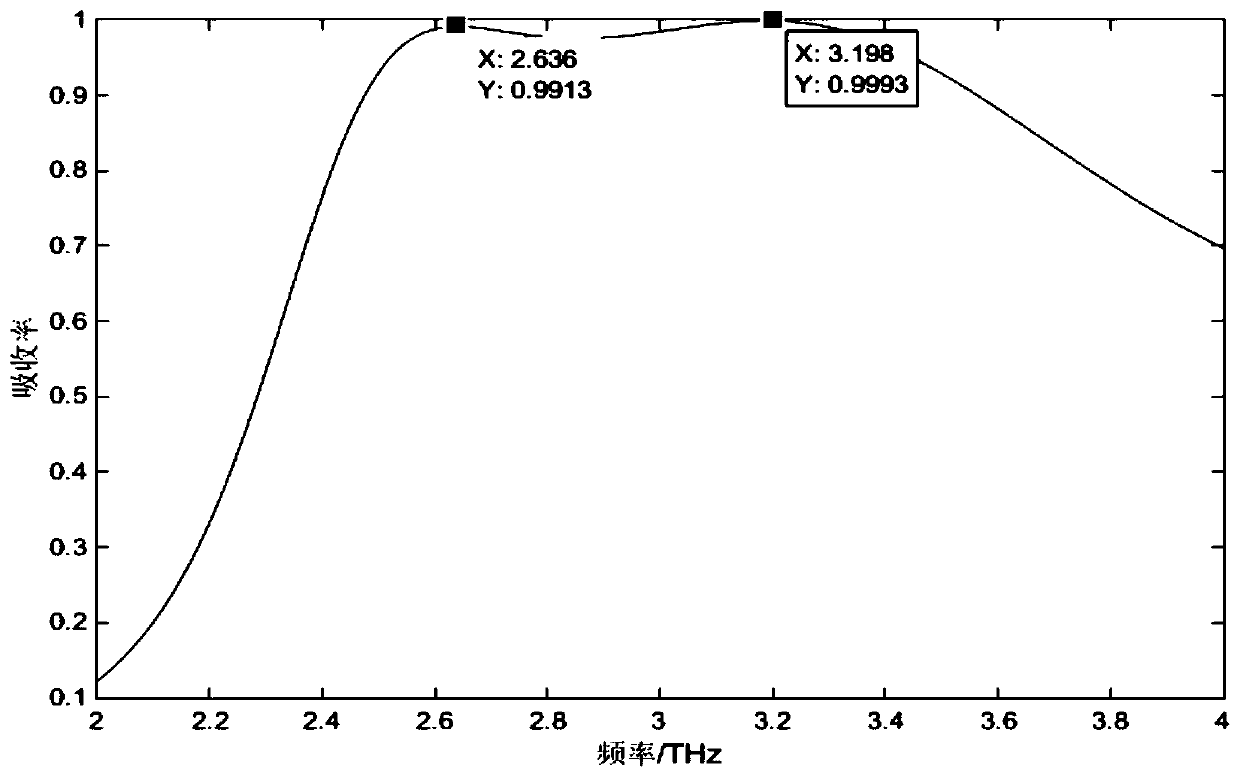

Terahertz electromagnetic absorber based on metamaterial

ActiveCN111883936APromote absorptionIncrease absorption peakAntennasOptical elementsIndiumElectromagnetic absorbers

The invention discloses a terahertz electromagnetic absorber based on metamaterial, and the terahertz electromagnetic absorber comprises a dielectric layer with a square section in the horizontal direction, and an absorption bottom layer is arranged on the bottom surface of the dielectric layer; a patch layer made of indium tin oxide is arranged on the surface of the dielectric layer; the patch layer comprises a square patch arranged in the center of the surface of the dielectric layer, an annular patch concentric with the square patch is arranged on the outer side of the square patch, and a square frame-shaped patch concentric with the annular patch is arranged on the outer side of the annular patch. The terahertz wave absorber has excellent absorption performance on terahertz waves and has the characteristic of wide absorption frequency band.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Metamaterial terahertz electromagnetic absorber

InactiveCN111048910AStrong absorption capacityWide range of bandwidthAntennasOptical elementsElectromagnetic absorbersEngineering

The invention discloses a metamaterial terahertz electromagnetic absorber. The metamaterial terahertz electromagnetic absorber is characterized by comprising a dielectric layer with a square section in a horizontal direction, a foam layer connected to the bottom surface of the dielectric layer, and a metal grounding layer arranged on the bottom surface of the foam layer; a metal patch layer is arranged on the surface of the dielectric layer; the metal patch layer comprises a regular-cross-shaped patch arranged in the center of the surface of the dielectric layer; square patches are arranged atthe four corners of the regular-cross-shaped patch respectively; a first patch frame and a second patch frame are arranged at the peripheries of the regular-cross-shaped patch and the square patches;and the first patch frame and the second patch frame are two parts which are reserved after two adjacent sides of a square frame are cut by two cuboids respectively. The terahertz wave absorber has excellent terahertz wave absorption capacity, polarization insensitivity and wide-angle characteristic.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Preparation method of magnetic graphene composite film

ActiveCN106191805AIncrease the areaQuality improvementChemical vapor deposition coatingOptical transparencyComposite film

The invention provides a preparation method of a magnetic graphene composite film. According to the preparation method, a two-step chemical vapor deposition method is adopted to enable nano ferromagnetic metal particles covered with a carbon nano onion to grow on the surface of a carbon nano tube and graphene composite film. The graphene composite film can be transferred to a target substrate without the assistance of polymer during the transferring process, and has the characteristics of strong magnetism, high optical transparency, high hole / electronic mobility and the like. In addition, the ferromagnetic metal particles are covered by a carbon nano onion outer shell so that oxidization, acidification, falling and the like of the nano ferromagnetic metal particles can be avoided, and the graphene composite film has high strength and good stability. According to the preparation method, the two-step chemical vapor deposition method can be adopted to prepare and obtain the magnetic graphene composite film in macroscopic quantity; the technological process is simple, the cost is low, mass production is facilitated, and the magnetic graphene composite film can be widely applied to graphene spin-electron devices, electromagnetic wave absorption materials, flexible graphene film electronic devices and the like.

Owner:重庆锦添翼新能源科技有限公司

A visible near-infrared ultra-broadband absorber and its preparation method

ActiveUS20170242162A1Broad absorptionPromote absorptionMetal layered productsOptical elementsBroadband absorptionElectromagnetic absorbers

The present invention discloses a visible near-infrared ultra-broadband absorber and its preparation method, comprising a substrate and a five-layer optical film, wherein the bottom film is a bottom metal absorbing layer; a top germanium layer is provided on the top of the bottom metal absorbing layer; and remaining three layers are provided on the top of the top germanium layer with gradually decreasing refractive indexes from the bottom to the top. The present invention is based on the blocking effect of the metal absorbing layer and broadband anti-reflection film stack of the germanium layer, which has realized visible near-infrared ultra-broadband absorption with high efficiency and good angle insensitivity, and has fully surpassed traditional absorbers in terms of performances. Compared with conventional broadband absorbers and artificial electromagnetic absorbers proposed in recent years, the compact multilayer film structure in the present invention is simpler and avoides complicated nano-fabrication techniques. Therefore, it can significantly reduce production cost and shorten the production cycle, and is thus suitable for large-scale mass production.

Owner:ZHEJIANG UNIV

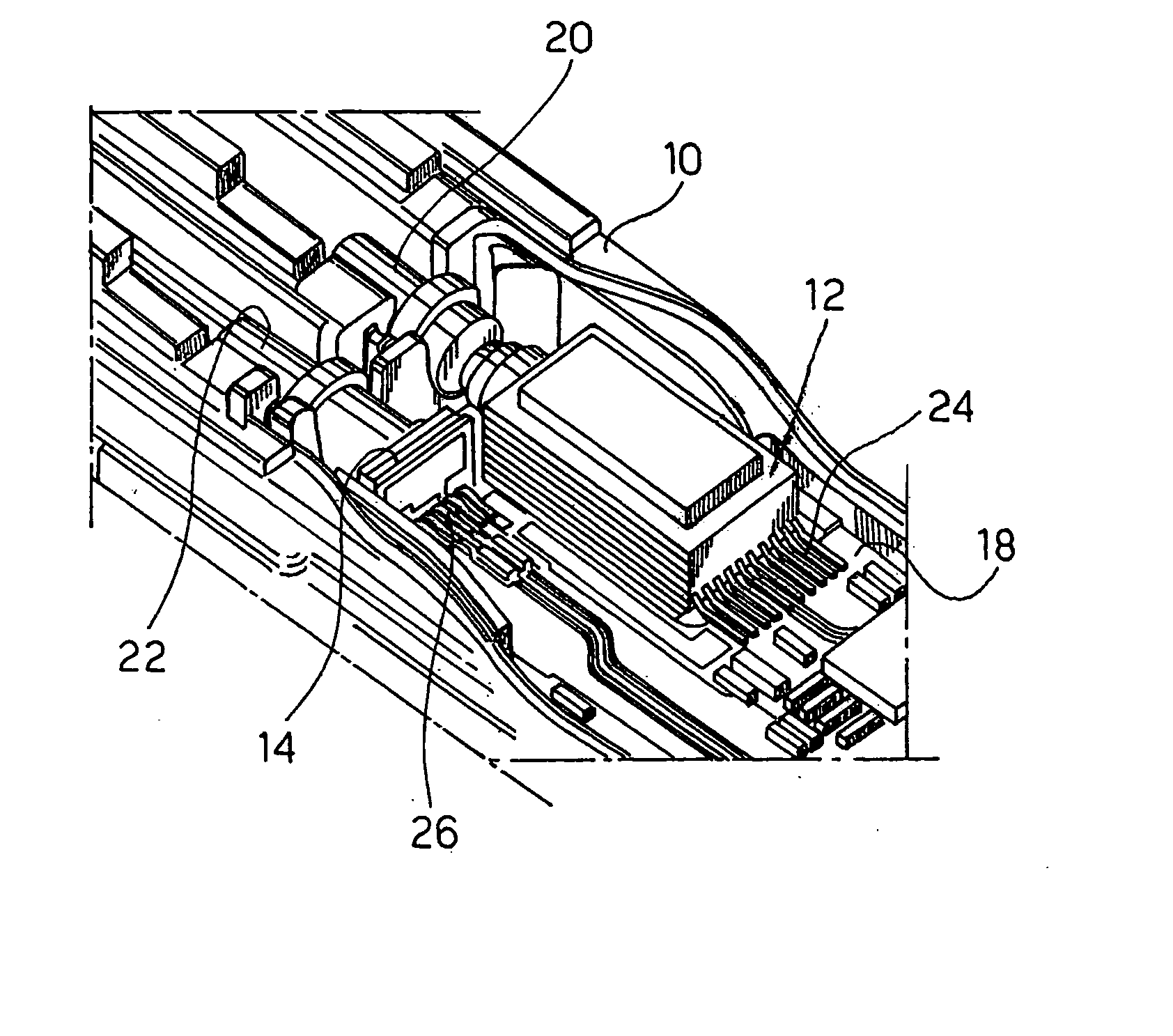

Connection arrangement for optical communication systems

InactiveUS20050213895A1Easy to produceReduce the impactCoupling for high frequencyCoupling light guidesElectromagnetic absorbersElectrical connection

An arrangement including: an electrical subassembly, an optical subassembly, the electrical subassembly and the optical subassembly having an associated electrical connection including at least one electrical lead extending therebetween, and an electrically non-conductive electromagnetic absorber body arranged to at least partly cover the electrical lead.

Owner:AVAGO TECH WIRELESS IP SINGAPORE PTE

Tire wire automatic welding machine for manufacturing high-performance steel shots

The invention provides a tire wire automatic welding machine for manufacturing high-performance steel shots. The tire wire automatic welding machine is composed of a rack, a roller motor, a conveying belt, extrusion rollers, a distributor, a distribution brush, an initial positioning mechanism, a chain material plate, a position sensor, a contact mechanism and a control system. A tire wire is arranged on the conveying belt through an electromagnetic absorber, the tire wire is stretched and straightened on the conveying belt through the extrusion rollers and enters the distributor, and even distribution is conducted through the electromagnetic absorber. Multiple grooves are formed in the chain material plate, and multiple wheels are arranged in the grooves. The tire wire enters the grooves and is arranged on the wheels, through re-positioning of the initial positioning mechanism and the position sensor and along with the continuous movement of the tire wire, when the tire wire makes contact with the contact mechanism, butt welding is achieved, along with the continuous movement of the tire wire fater the tire wire is heated, groove openings are perpendicularly downward, the tire wire disengages from the grooves, and automatic feeding, automatic distribution, automatic positioning, welding, and automatic blanking are achieved.

Owner:于海双

Near-field electromagnetic wave absorber

InactiveUS20070052575A1Easy to prepareReduce manufacturing costLoop antennasElectromagnetic wave absorberElectromagnetic absorbers

An object of the present invention is to provide a near field electromagnetic absorber that is capable of expressing an effective electromagnetic wave absorption characteristic in a broad range of frequency bands by using conductive material that conductively acts on the electrical field component of an electromagnetic wave. The present invention discloses a near-filed electromagnetic wave absorber consisting essentially of conductive material, wherein the near-field electromagnetic wave absorber absorbs an electromagnetic wave within one wavelength from the electromagnetic wave source by the conductive material, which conductively acts on the electrical field component of the electromagnetic wave.

Owner:NISCA KK

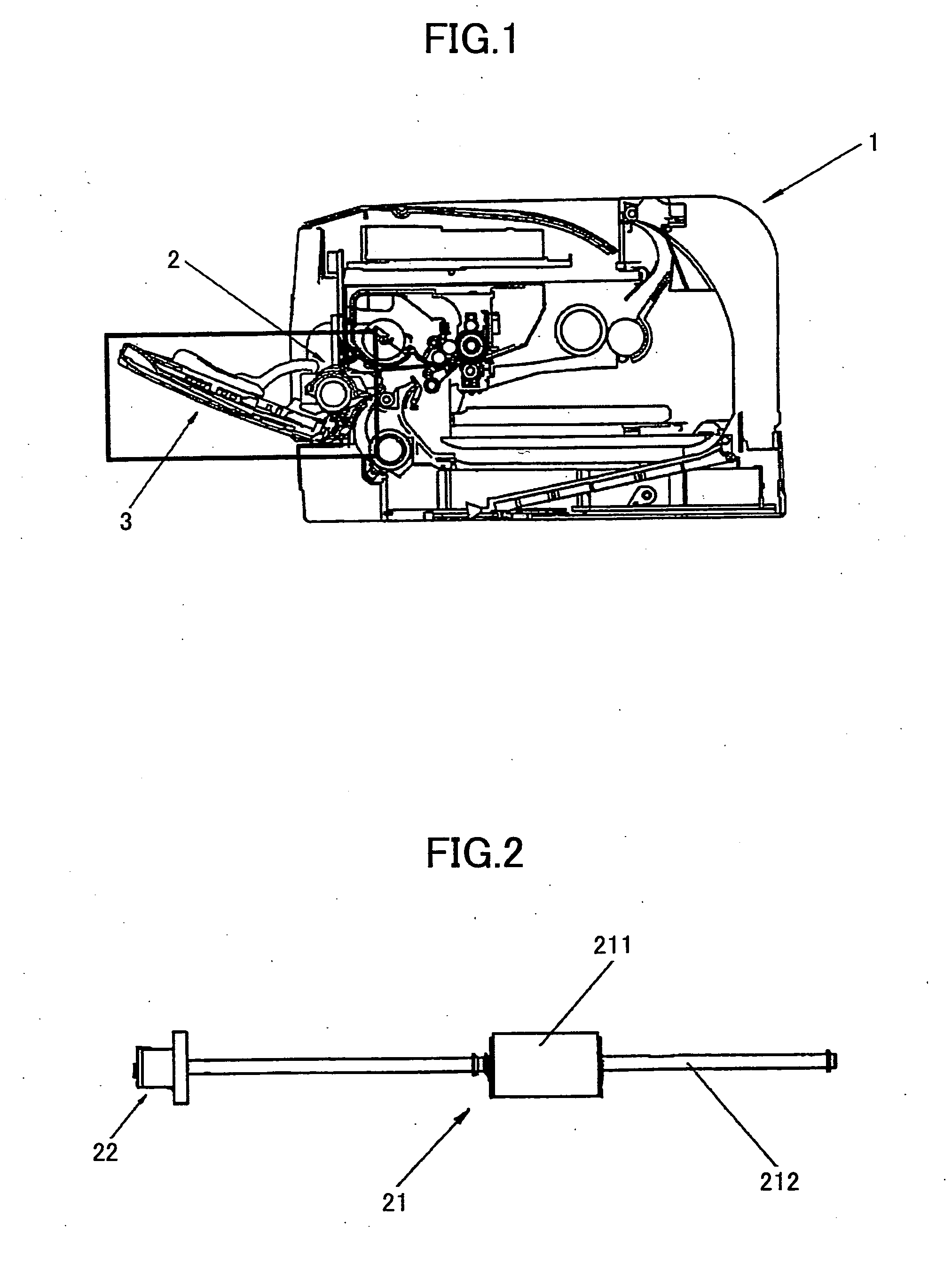

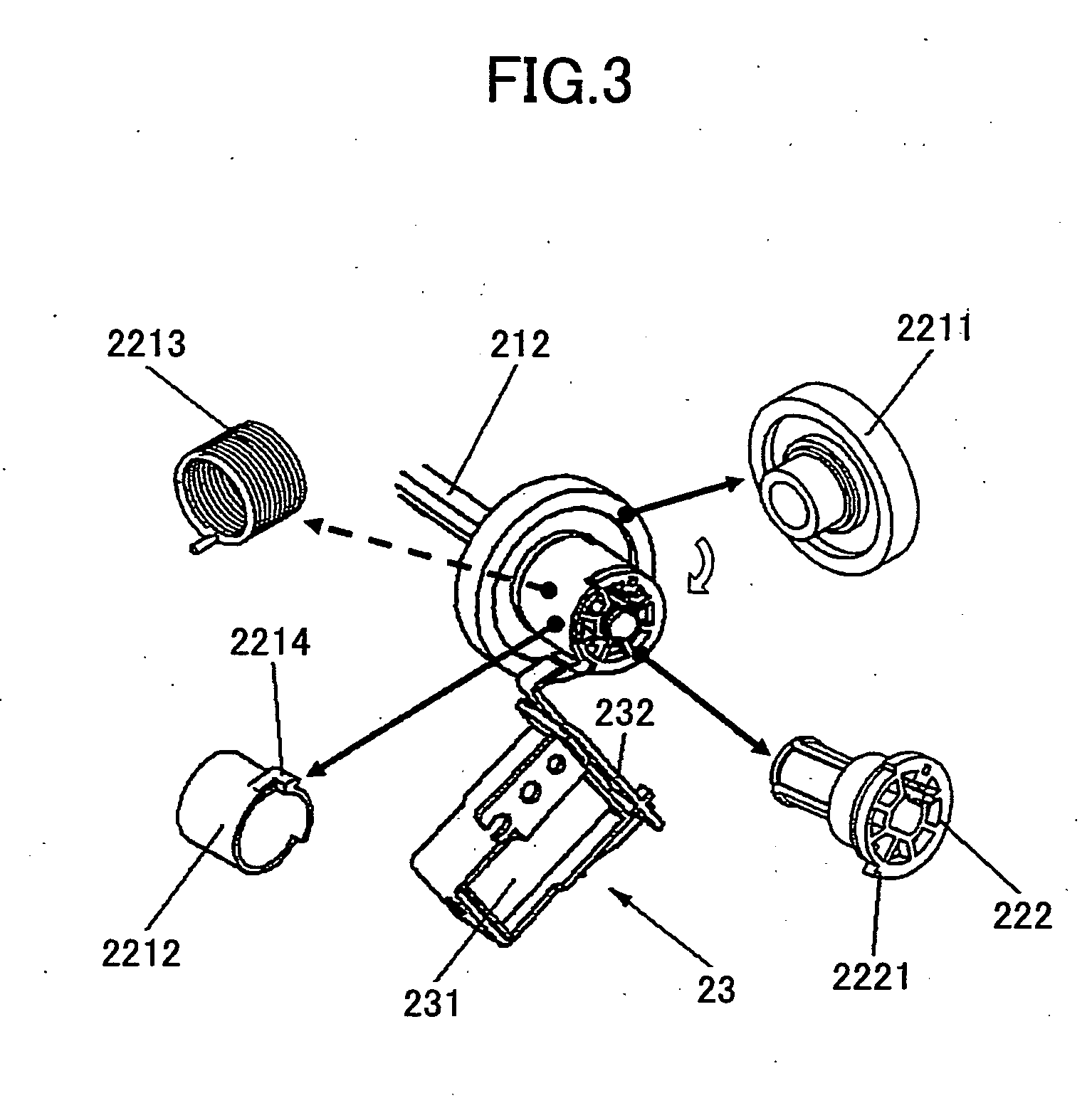

Paper feed device and image formation apparatus using the same

InactiveUS20110164911A1Shortening of life duration can be avoidedEasy to controlElectrographic process apparatusOther printing apparatusDetentElectromagnetic absorbers

Disclosed are a paper feed device and an image formation apparatus using the same. The device comprises a drive transmission unit disposed on one end of a rotation shaft, including a clutch gear, a control unit, and a spring; a control unit stopper fixedly disposed on the control unit; and an electromagnetic absorber including a detent. When the detent is located at a brake-off position, the detent and the control unit stopper are separated. When the detent is located at a braking position, the detent makes contact with the control unit stopper, and stops the rotation of the control unit.

Owner:RICOH KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com