Flexible polyimide-based composite dielectric film material and preparation method and application thereof

A composite dielectric film and polyimide-based technology, applied in the field of dielectric materials, can solve problems such as not meeting the requirements of dielectric materials, achieve low thermal expansion coefficient, good cycle stability, and increase the effect of dielectric coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

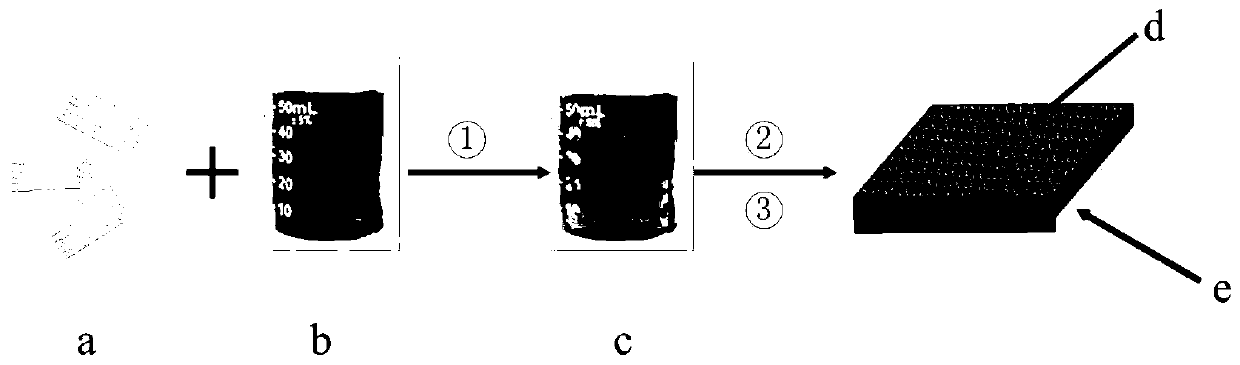

[0032] 1. Stir and react pyromellitic dianhydride (PMDA) and 4,4-diaminodiphenyl ether (ODA) in a molar ratio of 1:1 at room temperature to generate polyamic acid (PAA);

[0033] 2. Put Ti 3 C 2 It is mixed with PAA at a mass ratio of 1:100, rolled on the cellulose ether film, and chemically imidized at 220°C to obtain a flexible polyimide-based composite dielectric film material.

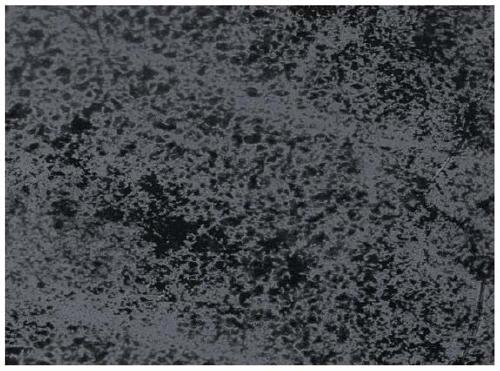

[0034] The average thickness of the dielectric film obtained above is 15 μm, the dielectric constant is 8.73, and the thermal expansion coefficient is 0.51. It can still maintain good interface integrity after 5000 cycles as a supercapacitor dielectric material, and the mass loss is only 0.08%. figure 2 Ti of this embodiment 3 C 2 SEM photographs from figure 1 It can be clearly seen that Ti 3 C 2 The layered structure contributes to the increase of the dielectric constant in PI materials. image 3 The photo of the flexible polyimide composite dielectric material prepared for this embodiment...

Embodiment 2

[0036] 1. Will Stirring reaction at room temperature generates polyamic acid PAA in a molar ratio of 1:4;

[0037] 2.Nb 3 C 2 Mix it with PAA at a mass ratio of 1:1000, apply it on a stainless steel metal mesh by pulling method, and chemically imidize it at 400°C to obtain a flexible polyimide-based composite dielectric film material.

[0038] The average thickness of the obtained dielectric film is 25 μm, the dielectric constant is 9.74, the thermal expansion coefficient is 0.87, the maximum reflection loss as an electromagnetic absorbing material is 14.3%, and the absorption frequency is 0.01-10000 Hz.

Embodiment 3

[0040] 1. Will Stirring reaction at room temperature generates polyamic acid PAA in a molar ratio of 1:0.1;

[0041] 2.Ta 3 C 2 Mix it with PAA at a mass ratio of 1:500, spray it on the graphene film, and chemically imidize it at 320°C to obtain a flexible polyimide-based composite dielectric film material.

[0042] The average thickness of the dielectric film obtained by the test is 20 μm, the dielectric constant is 10.74, and the thermal expansion coefficient is 0.66. As a dielectric material for integrated circuit packaging, it can still maintain good interface integrity after 5000 cycles, and the mass loss is only 0.08%. The maximum reflection The loss is 12.3%, and the absorption frequency is 0.01-1000Hz.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| absorption frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com