Photoelectric thin film capable of strengthening adhesive force and application of photoelectric thin film

A technology that enhances adhesion and photoelectric thin films, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of great harm to the human body and the environment, achieve the effect of improving adhesion and overcoming easy fall-off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] In a specific embodiment, the preparation method of the present invention includes the following specific steps: select a high-transparency glass substrate, first clean the glass surface with a cleaning process, then roughen the glass surface with NaOH solution, and then dry it. Then, the interface modification layer is deposited by coating technology, dried or annealed, and then the metal layer is vacuum-coated.

[0024] Preferably, the metal or metal alloy thin film layer can be prepared by magnetron sputtering, vacuum thermal evaporation, electron beam evaporation and laser deposition, and can also be prepared by printing, printing and spin coating. For preparing the photoelectric thin film layer, first cover one, two or more interface modification layers on the substrate, and then vacuum deposit the metal thin film layer. In order to improve the adhesion between the substrate and the interface modification layer, the interface modification layer and the metal film l...

Embodiment 1

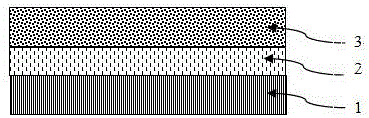

[0030] Such as figure 1 As shown, the photoelectric thin film with enhanced adhesion in this embodiment includes a substrate 1 , an interface modification layer 2 and a metal thin film layer 3 in sequence from bottom to top. Wherein, the substrate 1 is glass, the interface modification layer 2 is aluminum oxide, and the metal thin film layer 3 is silver film. A single specific material is given in this embodiment, which does not limit the choice of other materials, but is just an example to illustrate the present invention. The glass surface of the substrate 1 is subjected to surface roughening and / or surface plasma treatment, an alumina precursor is prepared by a sol-gel method, and then an alumina interface modification layer 2 is coated on the substrate, followed by thermal evaporation or magnetron sputtering Deposit silver film 3. The structure of the product prepared in this embodiment is Glass / AlOx / Ag. The photoelectric thin film prepared in this embodiment can be use...

Embodiment 2

[0032] Such as figure 2As shown, the transparent conductive film of this embodiment includes a substrate 1 , a first interface modification layer 21 , a second interface modification layer 22 and a metal thin film layer 3 from bottom to top. Wherein, the substrate 1 is glass, the first interface modification layer 21 is a silicon oxide layer, the second interface modification layer 22 is a titanium oxide layer, and the metal thin film layer 3 is a silver film layer or a silver-titanium alloy. This embodiment gives a single specific material, does not limit the choice of other materials, and is just to illustrate the present invention. Manufacturing process is with embodiment 1. The glass surface of the substrate 1 is subjected to surface roughening and / or surface plasma treatment, and silicon oxide and titanium oxide precursors are prepared by using a sol-gel method, and then silicon oxide is respectively coated on the substrate as the first layer 21 of interface modificatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com