mosi 2 -sio 2 -Borosilicate high temperature resistant high emissivity coating and its preparation method and application

A mosi2-sio2-, 1.mosi2-sio2- technology is applied in the field of MoSi2-SiO2-borosilicate high temperature resistant and high emissivity coating and its preparation, which can solve the problem that the quality and purity of powder are difficult to guarantee and difficult to apply In the ultra-high temperature field, there is no problem of high temperature oxidation resistance, so as to achieve the effect of lowering temperature, superior high temperature resistance and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] MoSi 2 -SiO 2 -A method for preparing a borosilicate high-temperature-resistant high-emissivity coating, comprising the following steps:

[0042] (1) MoSi 2 -SiO 2 Preparation of composite powder: weigh MoO with a mass percentage of 63% 2 Powder, 37% Si powder, add ethanol as a solvent, grind in a planetary mill for 12 hours, then dry in an oven at 80°C for use; then take an appropriate amount of mixed powder in a graphite crucible, protect it with Ar gas, and sinter Heating in the furnace to 1300°C and holding it for 30min to obtain MoSi2-SiO2 composite powder; the prepared MoSi 2 -SiO 2 Composite powders were initially pulverized with a mortar, and then ground in a planetary mill for 12 hours, and the MoSi 2 -SiO 2 The composite powder is ground to D 50 =5 μm, dried in an oven at 80°C for use.

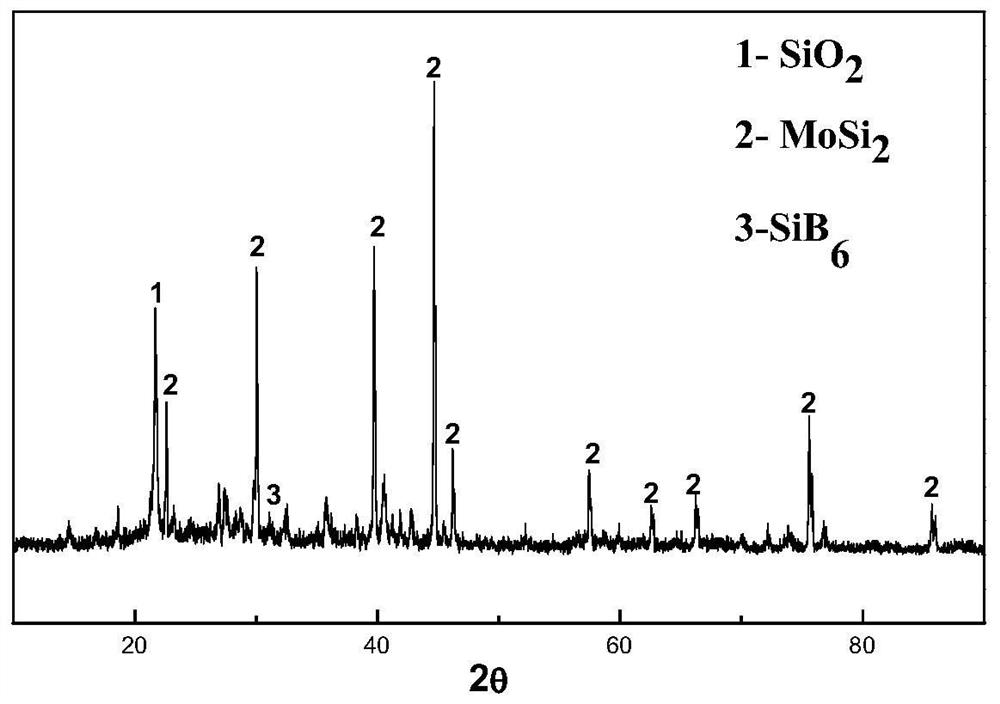

[0043] (2) Weigh MoSi with a mass ratio of 20% 2 -SiO 2 Composite powder, 78% borosilicate glass powder, 2% SiB 6 Put the powder in a ball mill jar, add ethanol as...

Embodiment 2

[0046] MoSi 2 -SiO 2 -A method for preparing a borosilicate high-temperature-resistant high-emissivity coating, comprising the following steps:

[0047] (1) MoSi 2 -SiO 2 Preparation of composite powder: weigh MoO with a mass percentage of 62% 2 Powder, 38% Si powder, add ethanol as a solvent, grind in a planetary mill for 12 hours, then dry in an oven at 80°C for use; then take an appropriate amount of mixed powder in a graphite crucible, protect it with Ar gas, and sinter Heating in the furnace to 1350°C and holding it for 30 minutes to obtain MoSi 2 -SiO 2 Composite powder; prepared MoSi 2 -SiO 2 Composite powders were initially pulverized with a mortar, and then ground in a planetary mill for 12 hours, and the MoSi 2 -SiO 2 The composite powder is ground to D 50 =5 μm, dried in an oven at 80°C for use.

[0048] (2) Weigh MoSi with a mass ratio of 40% 2 -SiO 2 Composite powder, 56% borosilicate glass powder, 4% SiB 6 Put the powder in a ball mill jar, add etha...

Embodiment 3

[0051] MoSi 2 -SiO 2 -A method for preparing a borosilicate high-temperature-resistant high-emissivity coating, comprising the following steps:

[0052] (1) MoSi 2 -SiO 2 Preparation of composite powder: weigh MoO with a mass percentage of 61% 2 Powder, 39% Si powder, add ethanol as a solvent, grind in a planetary mill for 12 hours, then dry in an oven at 80°C for use; then take an appropriate amount of mixed powder in a graphite crucible, protect it with Ar gas, and sinter Heating in the furnace to 1350°C and holding it for 40 minutes to obtain MoSi 2 -SiO 2 Composite powder; prepared MoSi 2 -SiO 2 Composite powders were initially pulverized with a mortar, and then ground in a planetary mill for 12 hours, and the MoSi 2 -SiO 2 The composite powder is ground to D 50 =5 μm, dried in an oven at 80°C for use.

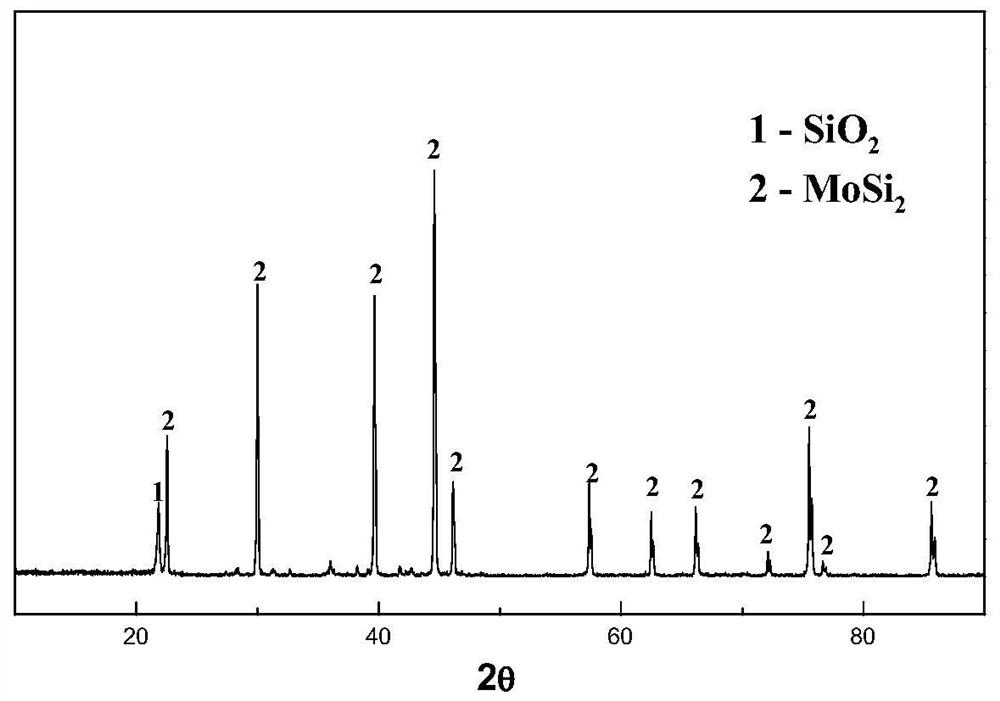

[0053] figure 1 is made of MoSi 2 -SiO 2 The XRD diffraction pattern of the composite powder shows that the composite powder is MoSi 2 , SiO 2 two phases. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com