Method for manufacturing crystal array of gamma-ray detector

A technology of crystal arrays and manufacturing methods, applied in the field of gamma-ray detection and imaging, can solve the problems of long working hours, increased production costs, processing difficulty and increased production costs, so as to reduce labor force and time consumption, increase mechanical stability, The effect of improving process yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

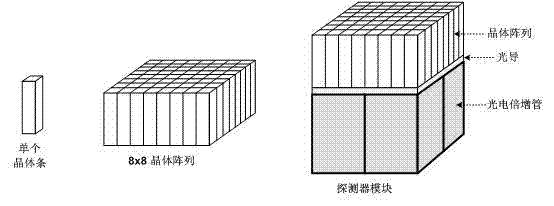

[0037] Steps to make a gamma ray detector:

[0038] 1. Making scintillation crystal array:

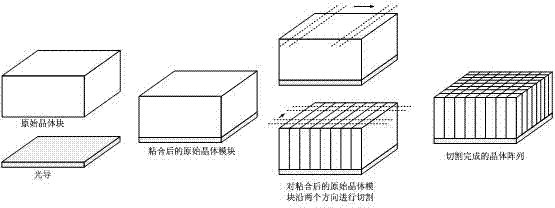

[0039] 1. According to the size of the crystal array to be fabricated, the original crystal material is cut to form a whole rectangular original crystal block. And perform mechanical surface treatment on the rectangular original crystal block as required, such as grinding and polishing.

[0040] 2. Prepare the light guide material with corresponding size according to the requirements of the detector module. As an example, figure 2 The light-guiding medium shown has the same cross-sectional dimensions as the original crystal block. In practical cases, the two need not be the same size.

[0041] 3. Bond the light-guiding medium to the lower surface of the original crystal block to form a complete original crystal module. Adhesives include, but are not limited to, UV-curable optical glues, self-curing optical glues, and adhesive polymers with optically transparent properties. A pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com