Liquid-solid phase loaded catalyst used in production of acetic acid and preparation method thereof

A supported catalyst, liquid-solid phase technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, organic compound/hydride/coordination complex catalyst, etc., can solve poor stability, loss of precious metals, deactivation, etc. problem, to achieve the effect of low cost, stable catalytic activity, and not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

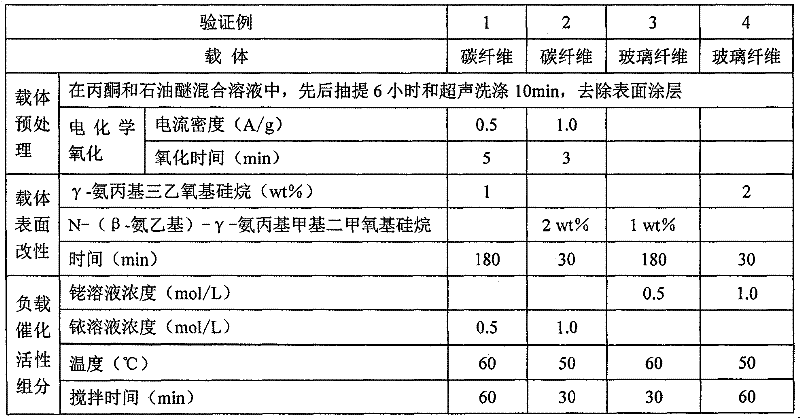

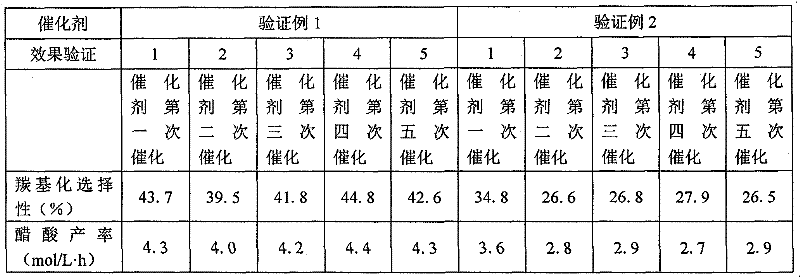

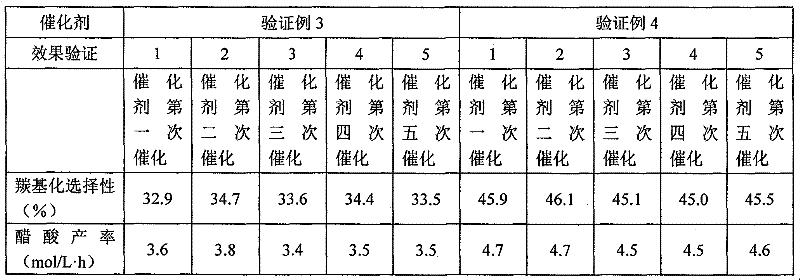

[0018] The invention relates to a supported catalyst for producing acetic acid in liquid-solid phase. It is a catalyst used for producing acetic acid by methanol carbonylation. Its catalytic active component is rhodium or iridium, and the carrier for loading rhodium or iridium is solid. The carrier of the present invention is carbon fiber or glass fiber after coupling reaction with silane coupling agent. The supported catalyst is prepared through the following steps:

[0019] (1) Carrier pretreatment

[0020] Immerse the carbon fiber or glass fiber in a mixed solution of acetone and petroleum ether with a volume ratio of 1:1, successively undergo extraction and ultrasonic washing, and the time is to remove the surface coating; then, dry at 80°C to 100°C ;

[0021] Separate electrochemical oxidation of carbon fiber: In 5wt% ammonium bicarbonate aqueous solution, carbon fiber is used as anode, metal platinum sheet is used as cathode, current density is 0.5 ~ 1A / g, time is 3 ~ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com