Preparation method of high temperature resistant flexible fabric material based on coating al2o3 sol-gel

A fabric material, high-temperature flexible technology, applied in textiles, papermaking, fiber processing, etc., can solve problems such as low strength, and achieve the effects of increased strength, good thermal insulation effect, and good thermal performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0025] Specific implementation mode one: this implementation mode is based on coating Al 2 o 3 The preparation method of the high-temperature-resistant flexible fabric material of sol is implemented according to the following steps:

[0026] 1. Aluminum isopropoxide (C 9 h 21 AlO 3 ) into isopropanol ((CH 3 ) 2 CHOH), stirred evenly to obtain a mixed solution;

[0027] 2. Drop the mixed solution obtained in step 1 into a three-necked bottle filled with distilled water, press H+ and Al 3+ The molar ratio is (0.05 ~ 0.1): 1, then drop nitric acid into the there-necked flask, heat in a water bath to evaporate isopropanol, and then heat and reflux for 5 to 8 hours to obtain Al 2 o 3 Sol;

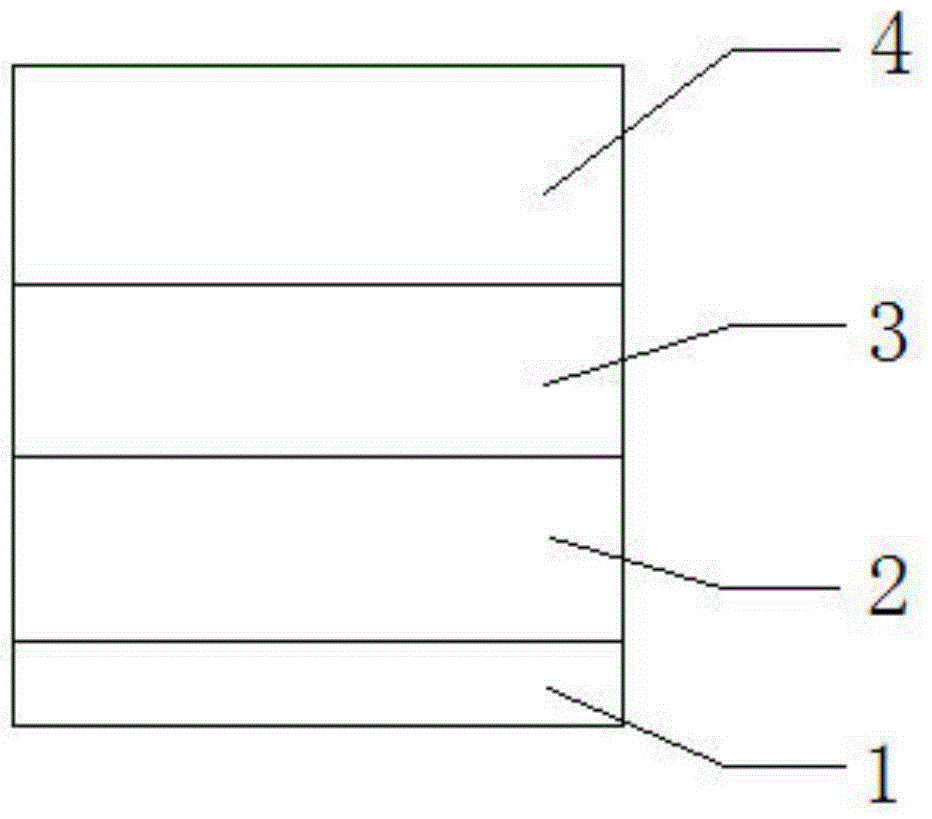

[0028] Three, the Al obtained in step two 2 o 3 The sol was dip-coated on the Kevlar fiber cloth to obtain a coating based on Al 2 o 3 Sol high temperature resistant flexible fabric material.

[0029] In this embodiment, Al 2 o 3 The sol is coated on the Kevlar fiber cloth. Becau...

specific Embodiment approach 2

[0030] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that step 1 adds aluminum isopropoxide to isopropanol according to the molar ratio of isopropanol to aluminum isopropoxide (4-6):1. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0031] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in step 2, nitric acid is added to the three-necked flask, and the isopropanol is evaporated by heating in a water bath at 85-95°C. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com