Super-hard abrasive grinding wheel with head face having abrasives in phyllotaxis arrangement and production method thereof

A super-hard abrasive, face grinding technology, applied in abrasives, bonded grinding wheels, grinding devices, etc., can solve the problems of low grinding efficiency, grinding instability, etc., and achieve small grinding force and specific energy consumption. , The effect of improving the surface integrity of the workpiece and improving the comprehensive grinding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

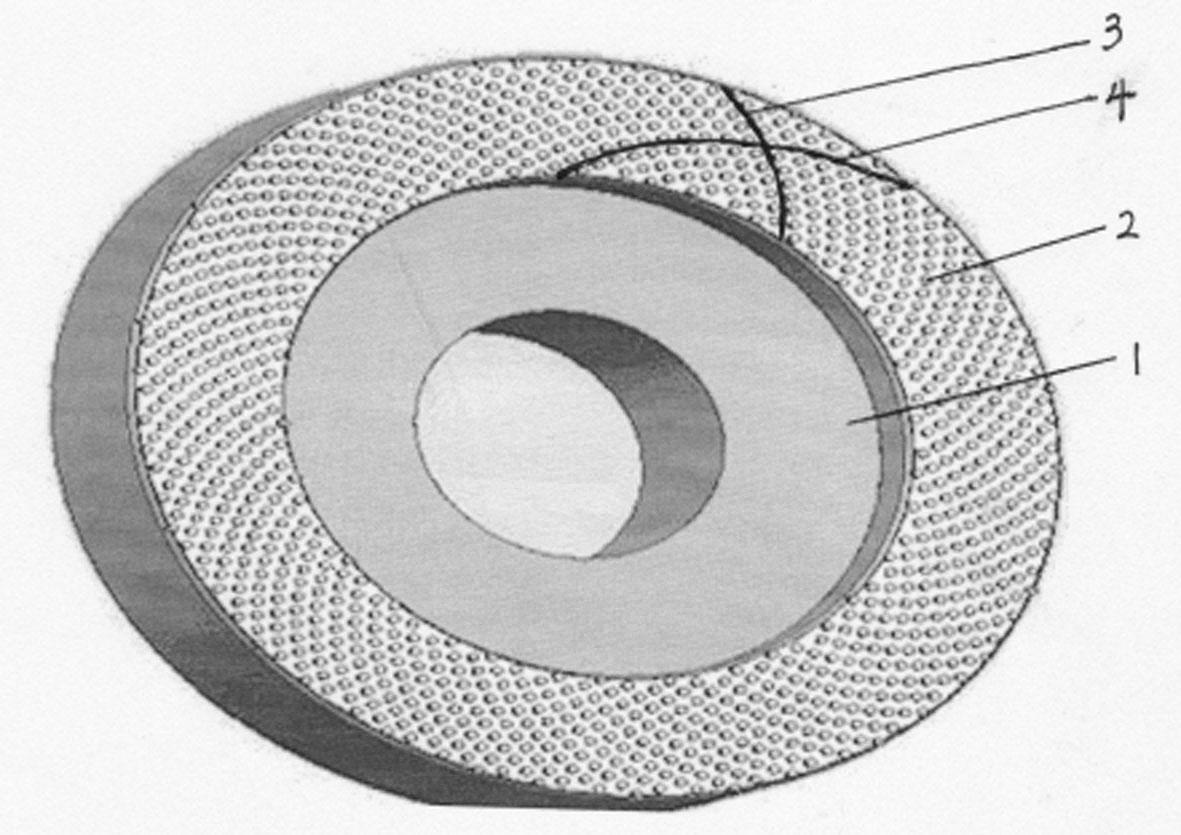

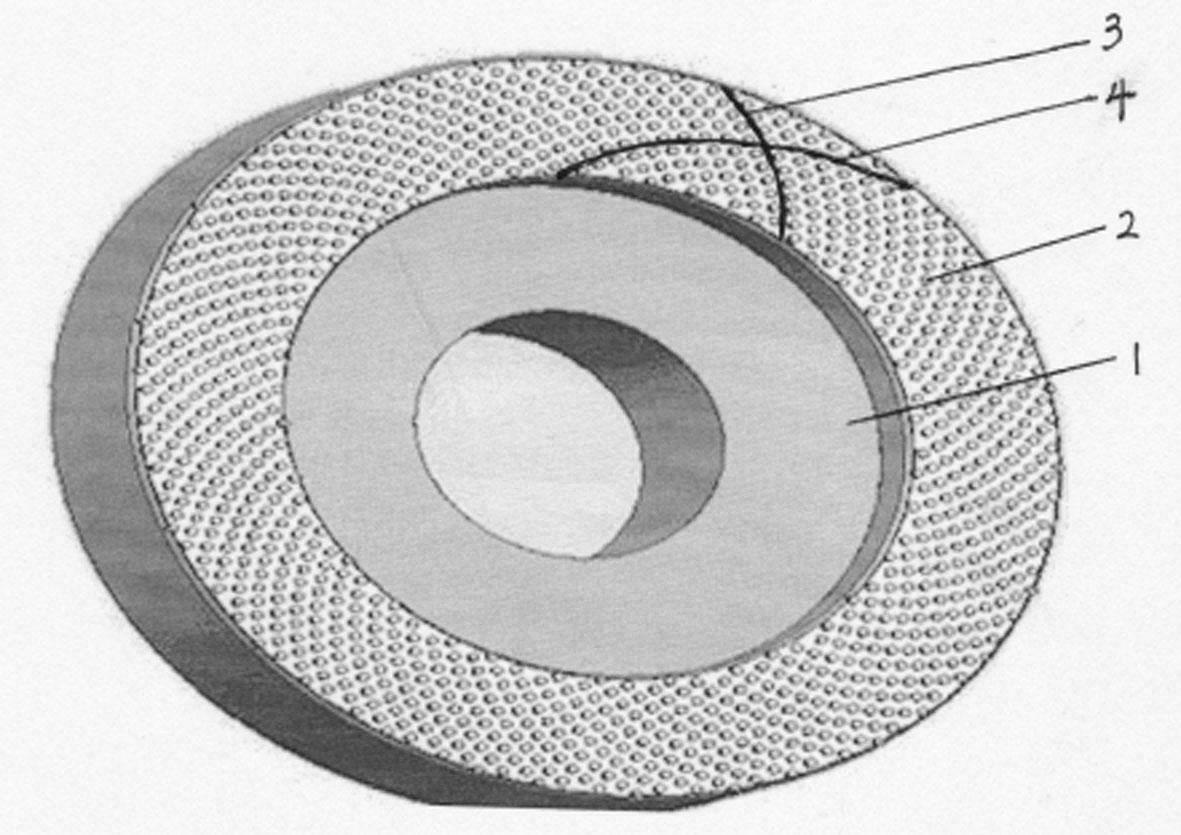

[0012] The superabrasive grinding wheel with phyllotaxy arrangement abrasive end face of the present invention comprises a grinding wheel base body 1, the working surface of the grinding wheel base body 1 has a plurality of abrasive grains 2 conforming to the biological phyllotaxy theory, and the plurality of abrasive grains 2 are fixed on the surface by a nickel bond On the grinding wheel substrate 1. A plurality of abrasive grains 2 form a plurality of counterclockwise alignment grooves 3 and a plurality of clockwise alignment grooves 4 according to the biological phyllotaxy theory.

[0013] Biological phyllotaxy theory H. Vogel model, that is, the polar coordinate angle of the plant grain satisfies , the radial position of the polar coordinates of the grain block satisfies . where n is the ordinal number of the kernel and k is the growth coefficient. The H. Vogel model is a typical model describing the structure and arrangement of sunflower seeds. The arrangement of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com