Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2565 results about "Magnetostriction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

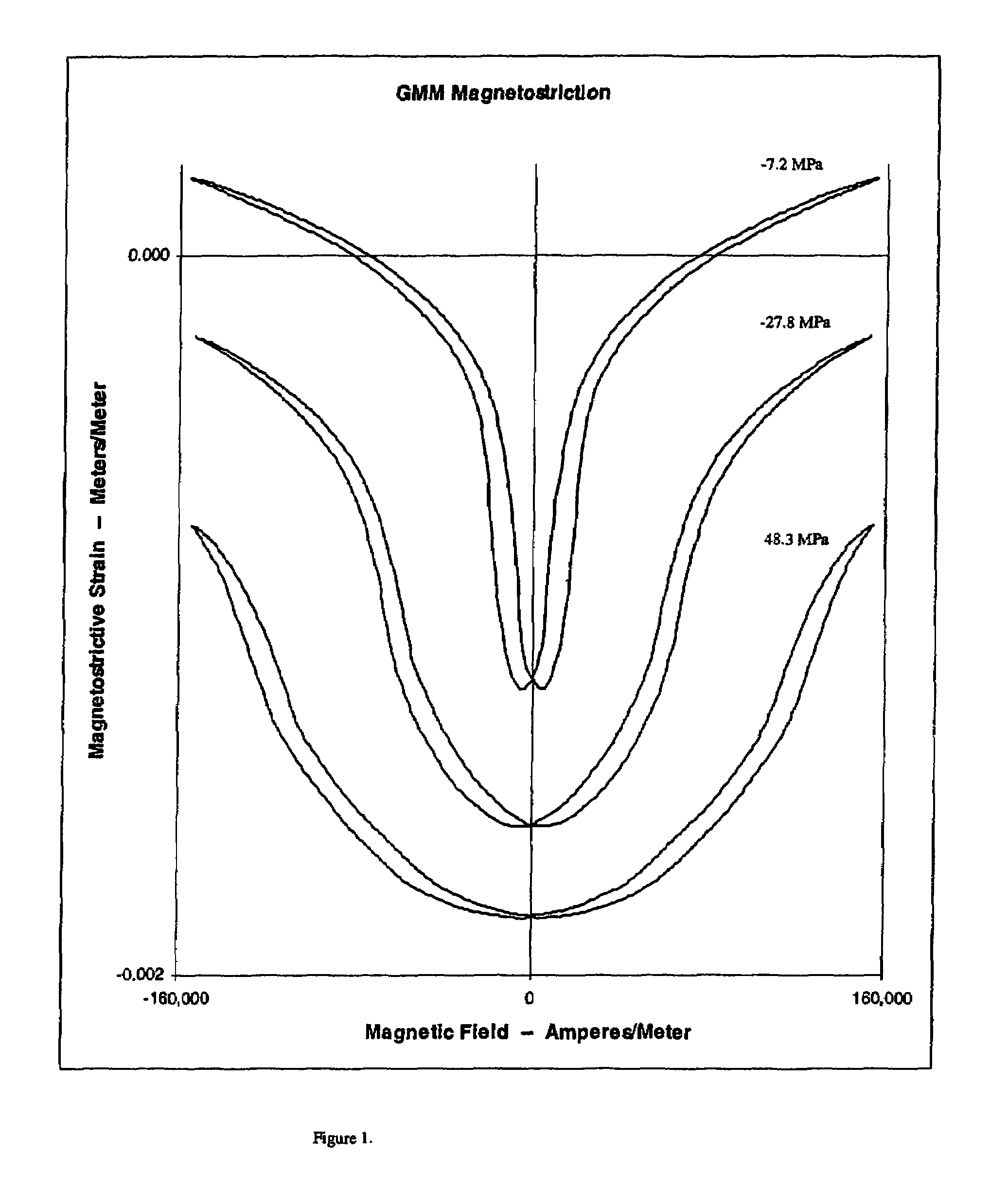

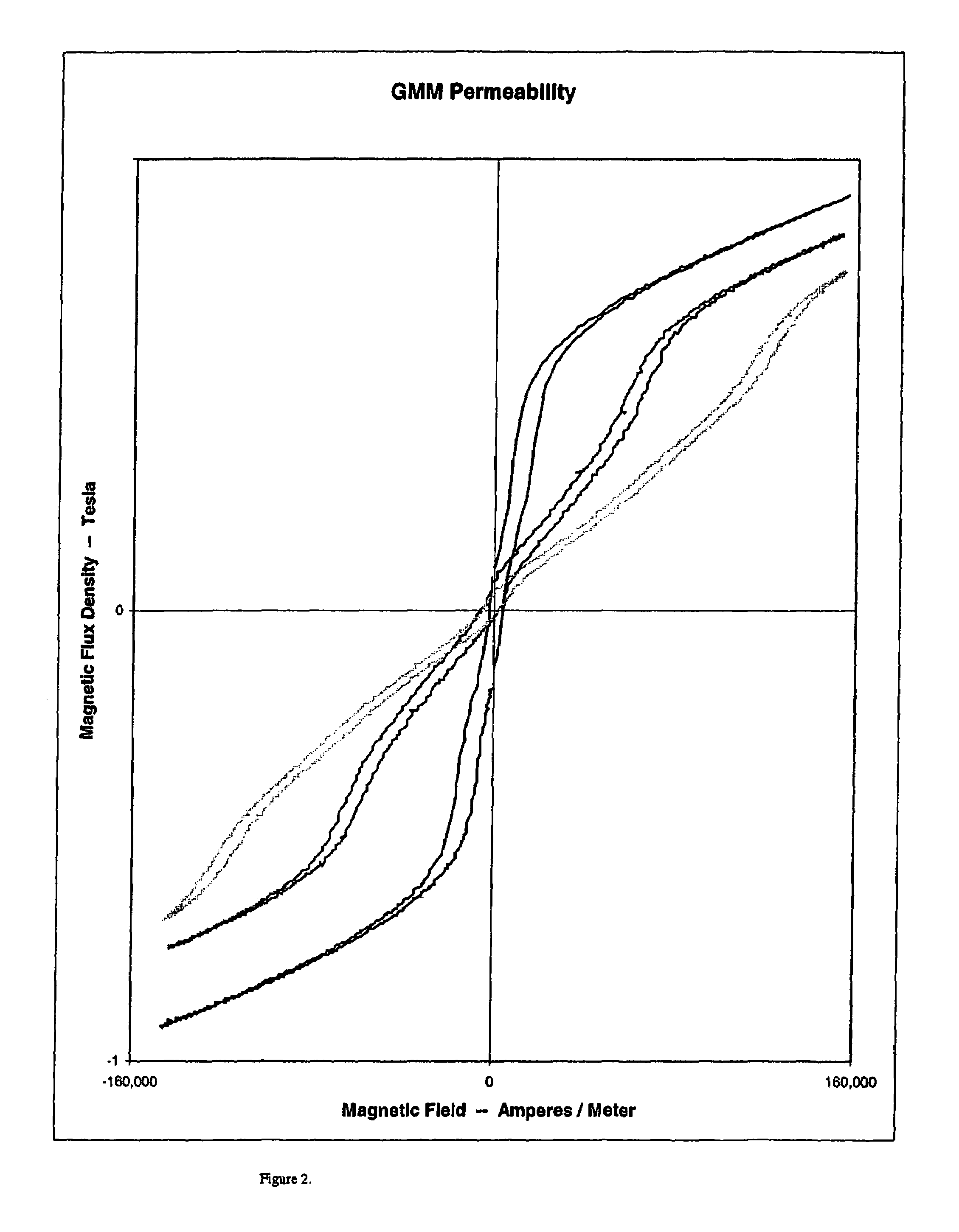

Magnetostriction (cf. electrostriction) is a property of ferromagnetic materials that causes them to change their shape or dimensions during the process of magnetization. The variation of materials' magnetization due to the applied magnetic field changes the magnetostrictive strain until reaching its saturation value, λ. The effect was first identified in 1842 by James Joule when observing a sample of iron.

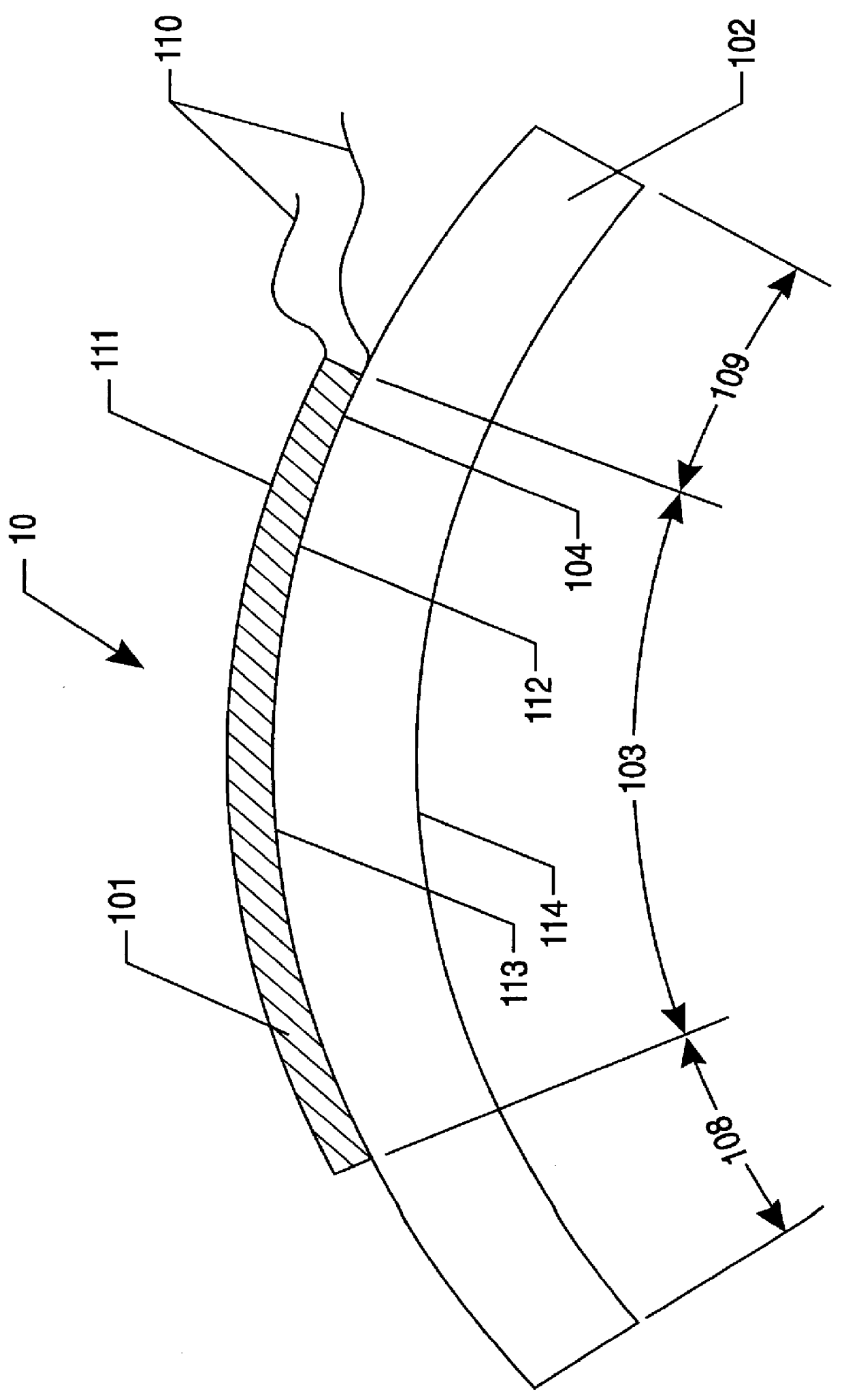

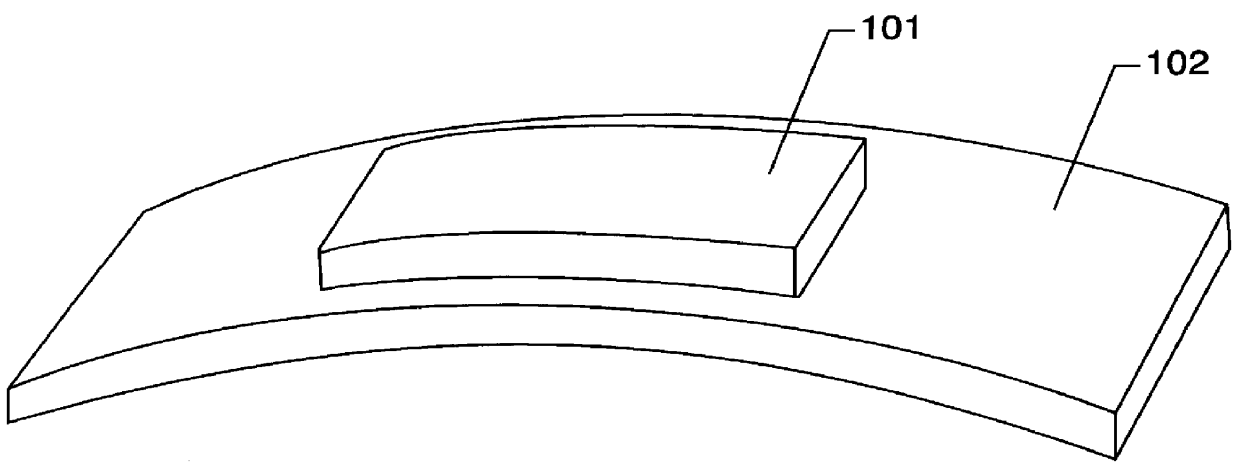

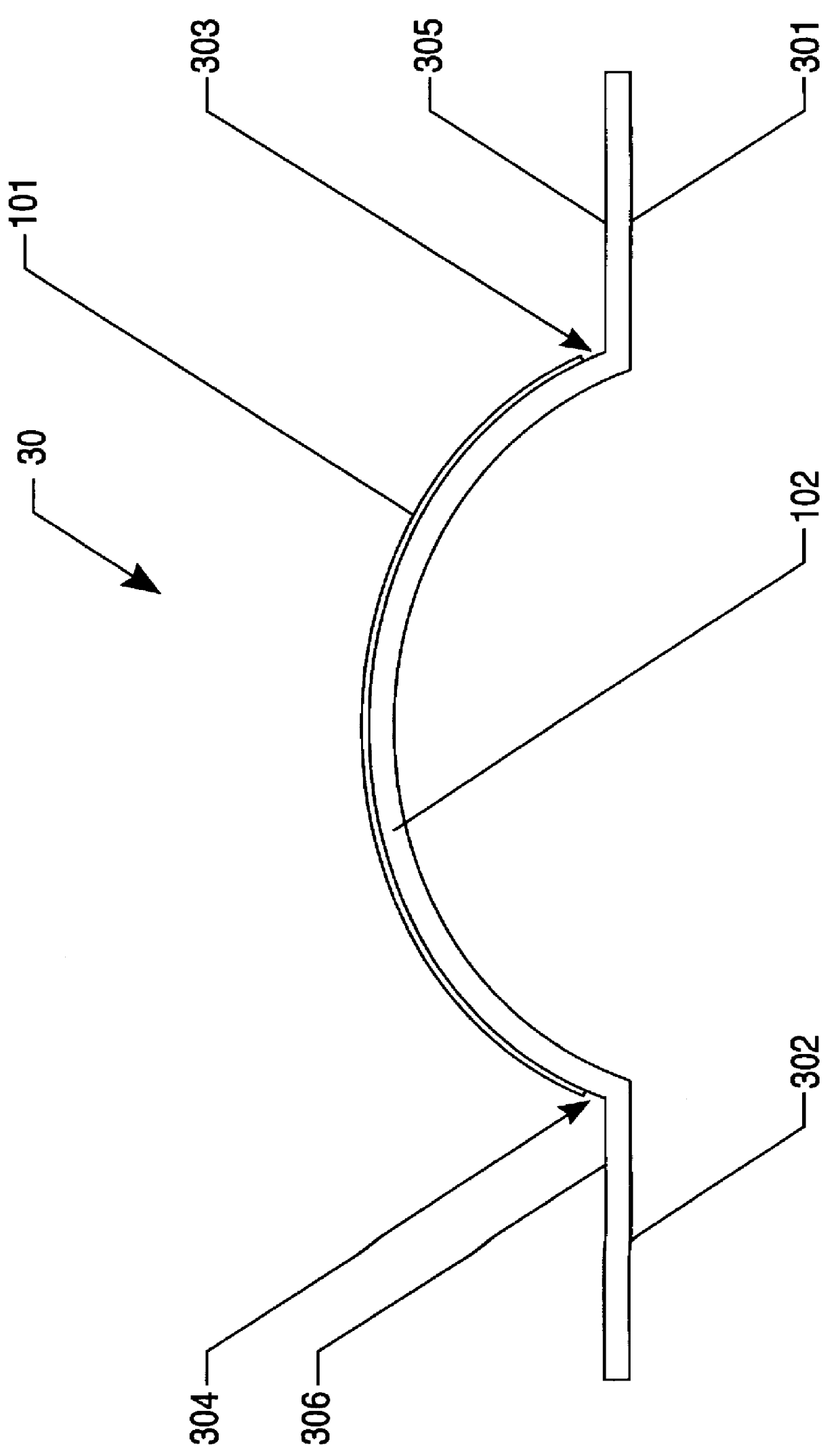

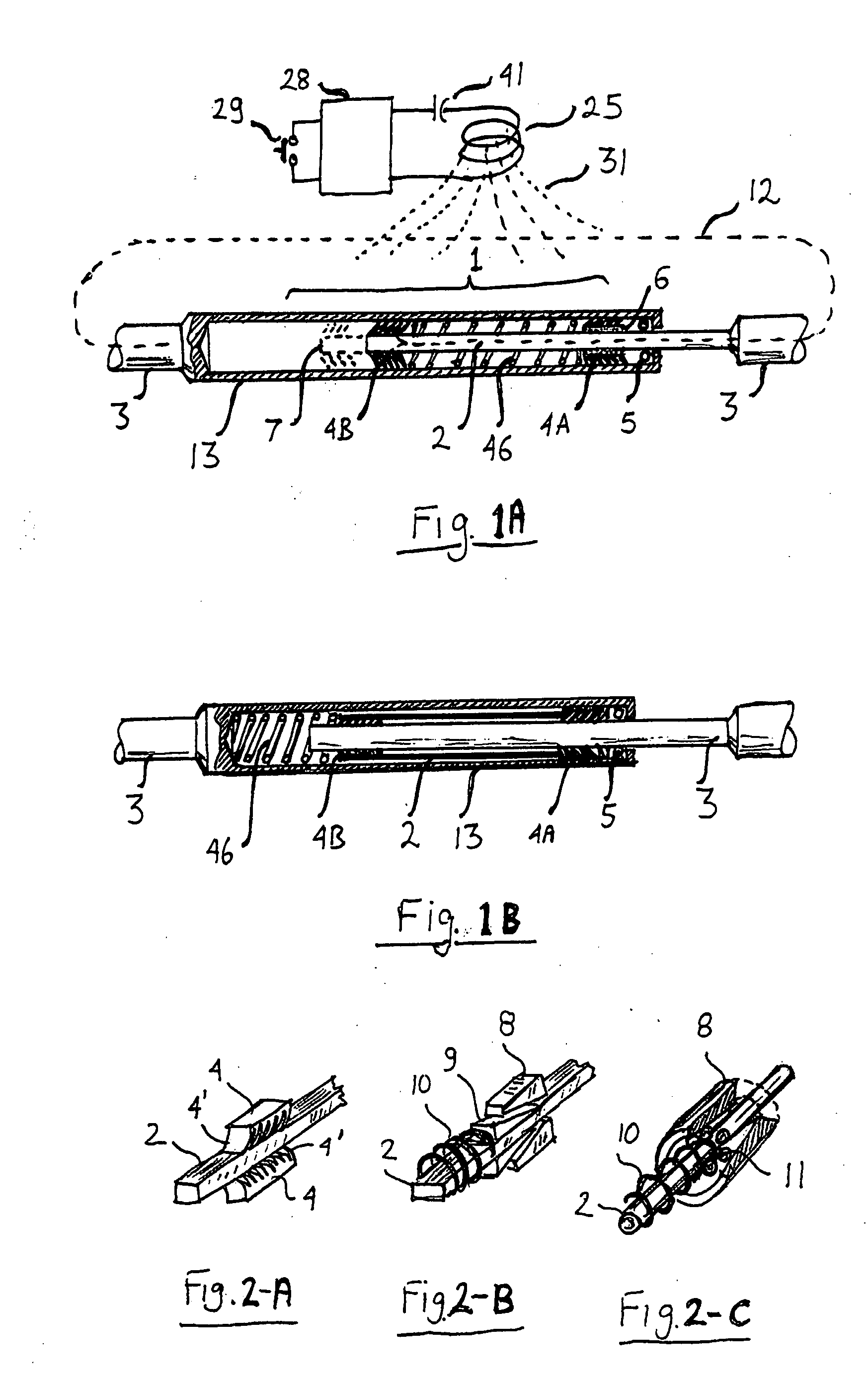

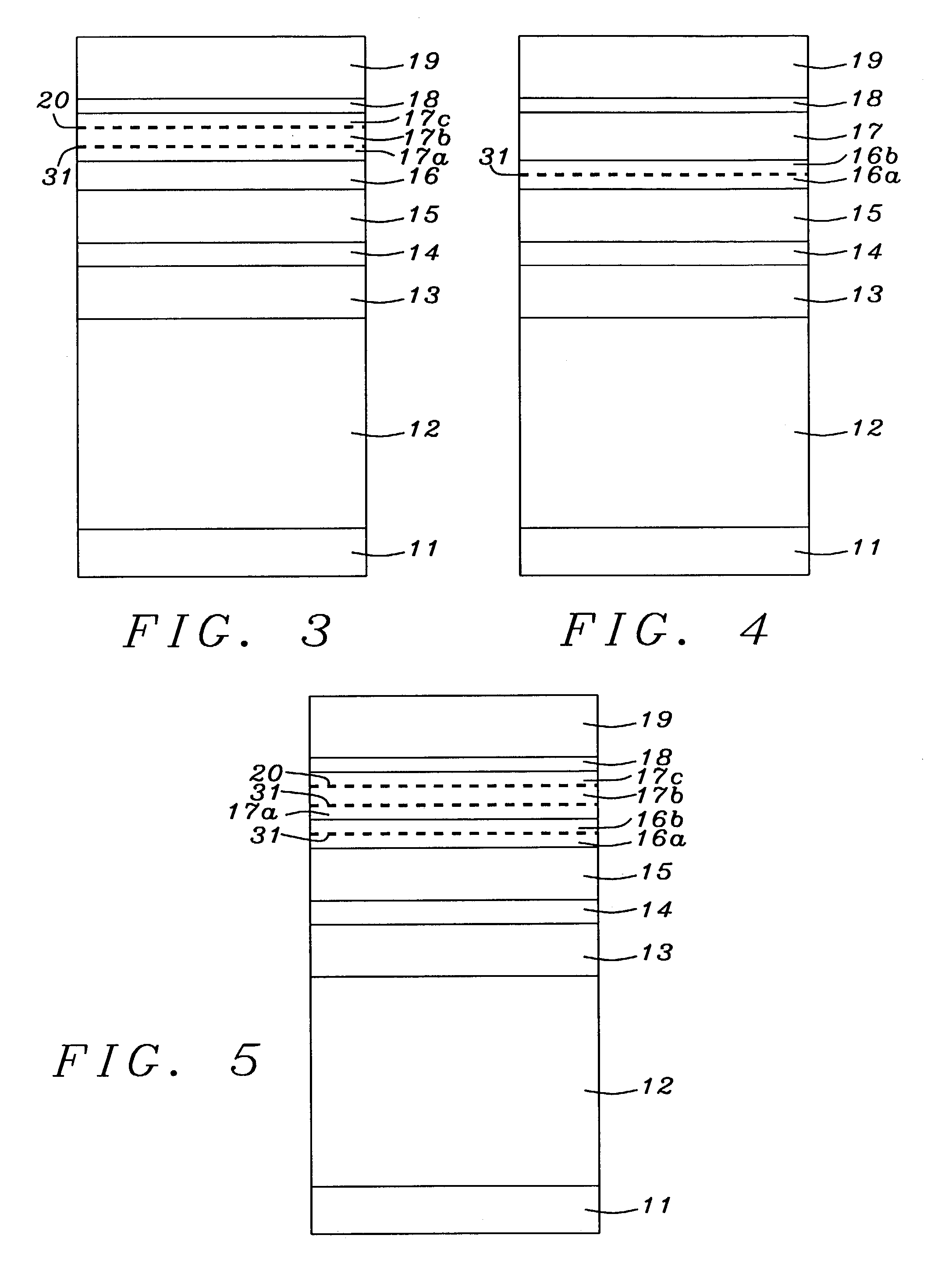

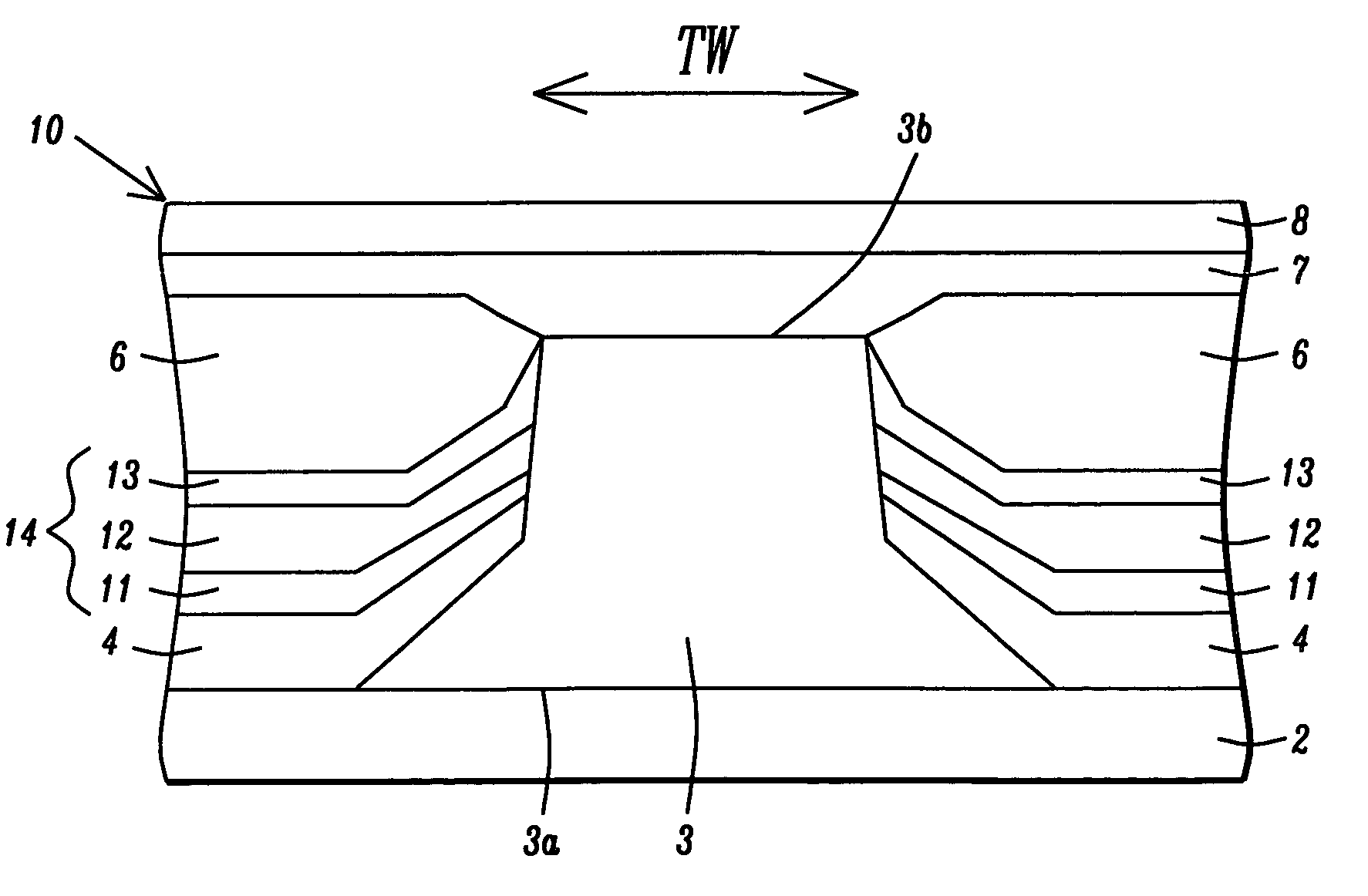

Advanced layered composite polylaminate electroactive actuator and sensor

InactiveUS6060811AImprove efficiencyCancel noisePiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive devicesPre stressPre stressing

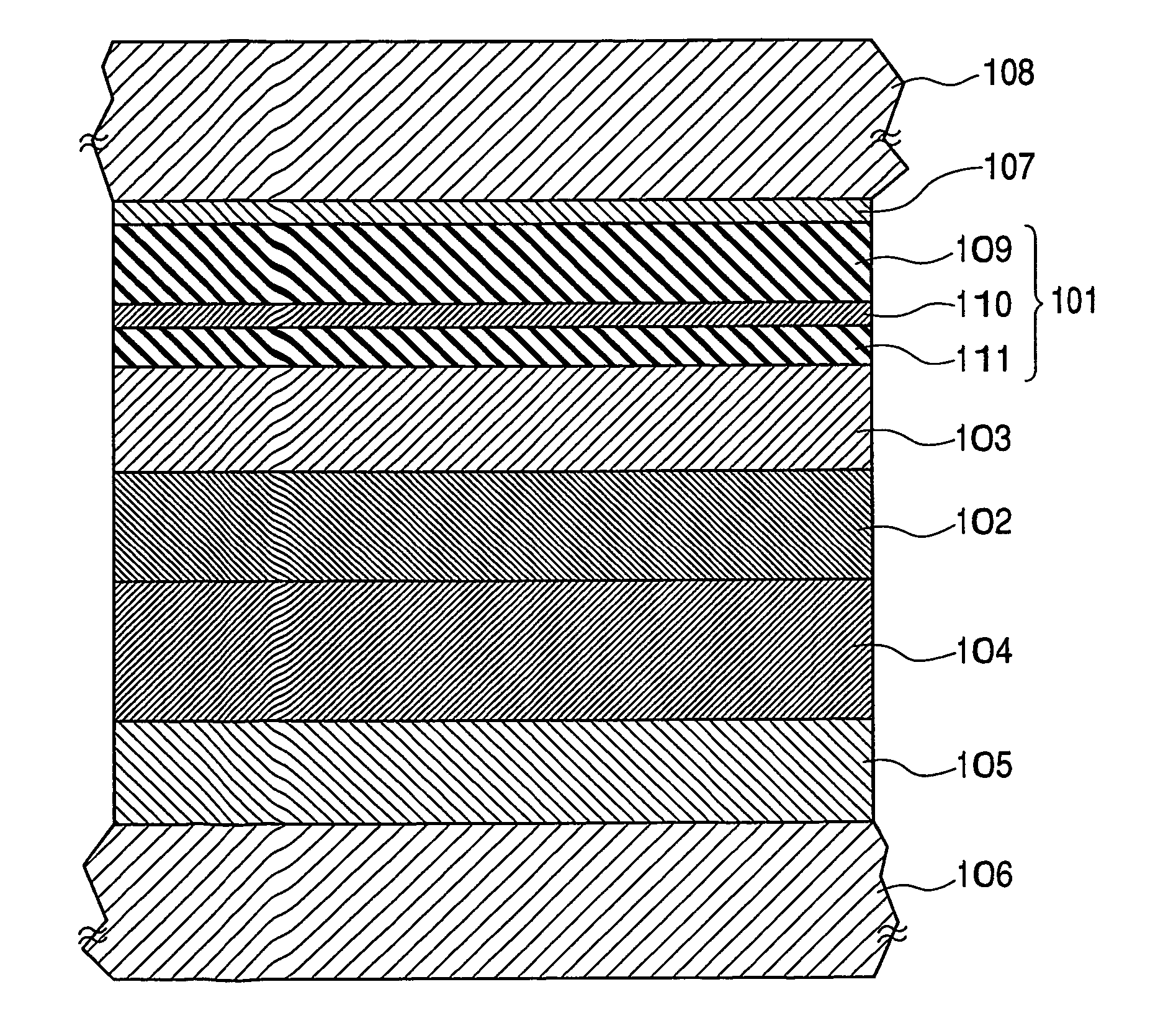

The present invention relates to the mounting of pre-stressed electroactive material in such a manner that large displacement actuators or sensors result. The invention comprises mounting the pre-stressed electroactive material to a support layer. This combination of a pre-stressed electroactive material and support layer may in turn be attached to a mounting surface. The pre-stressed electroactive material may be a ferroelectric, pyroelectric, piezoelectric, or magnetostrictive material. The size, stiffness, mass, and material of the support layer is selected to result in the electroactive device having dynamic response properties, environmental capability characteristics, and the required resilience optimized for a given application. The capacity to connect the support layer to a surface expands the arenas in which the pre-stressed electroactive device may be used. Application for which the invention may be used include actuators, sensors, or as a component in a pumps, switches, relays, pressure transducers and acoustic devices.

Owner:NASA

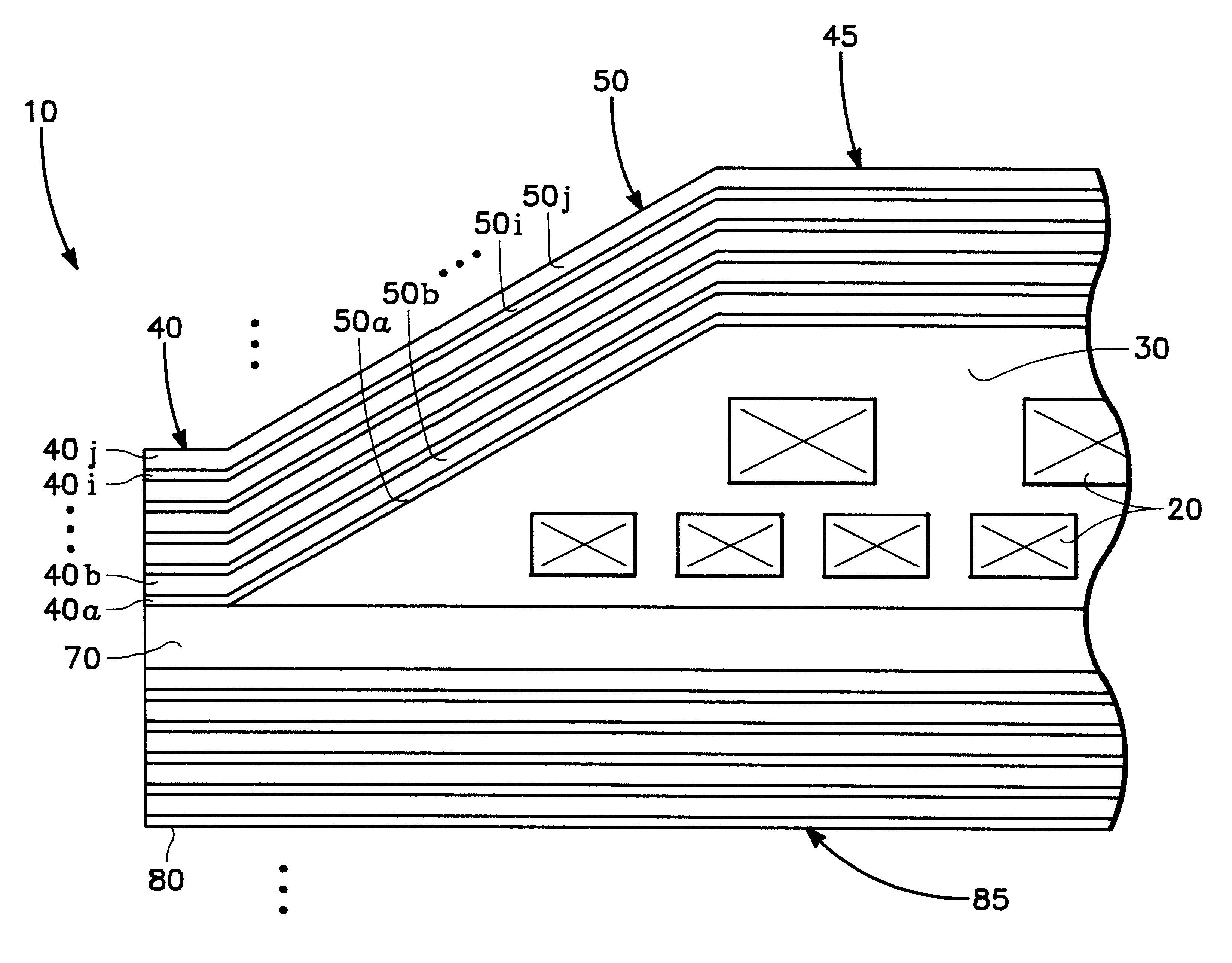

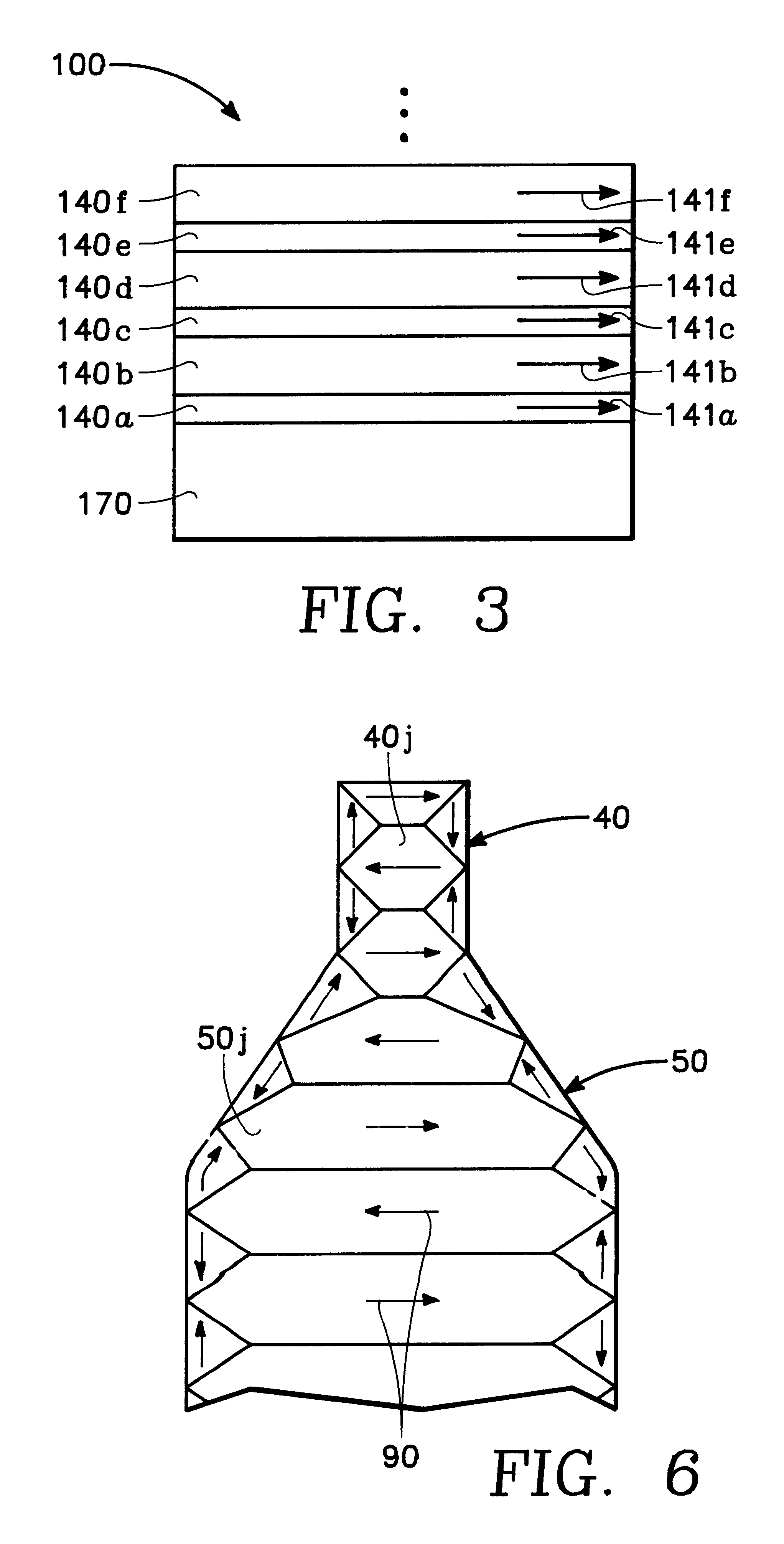

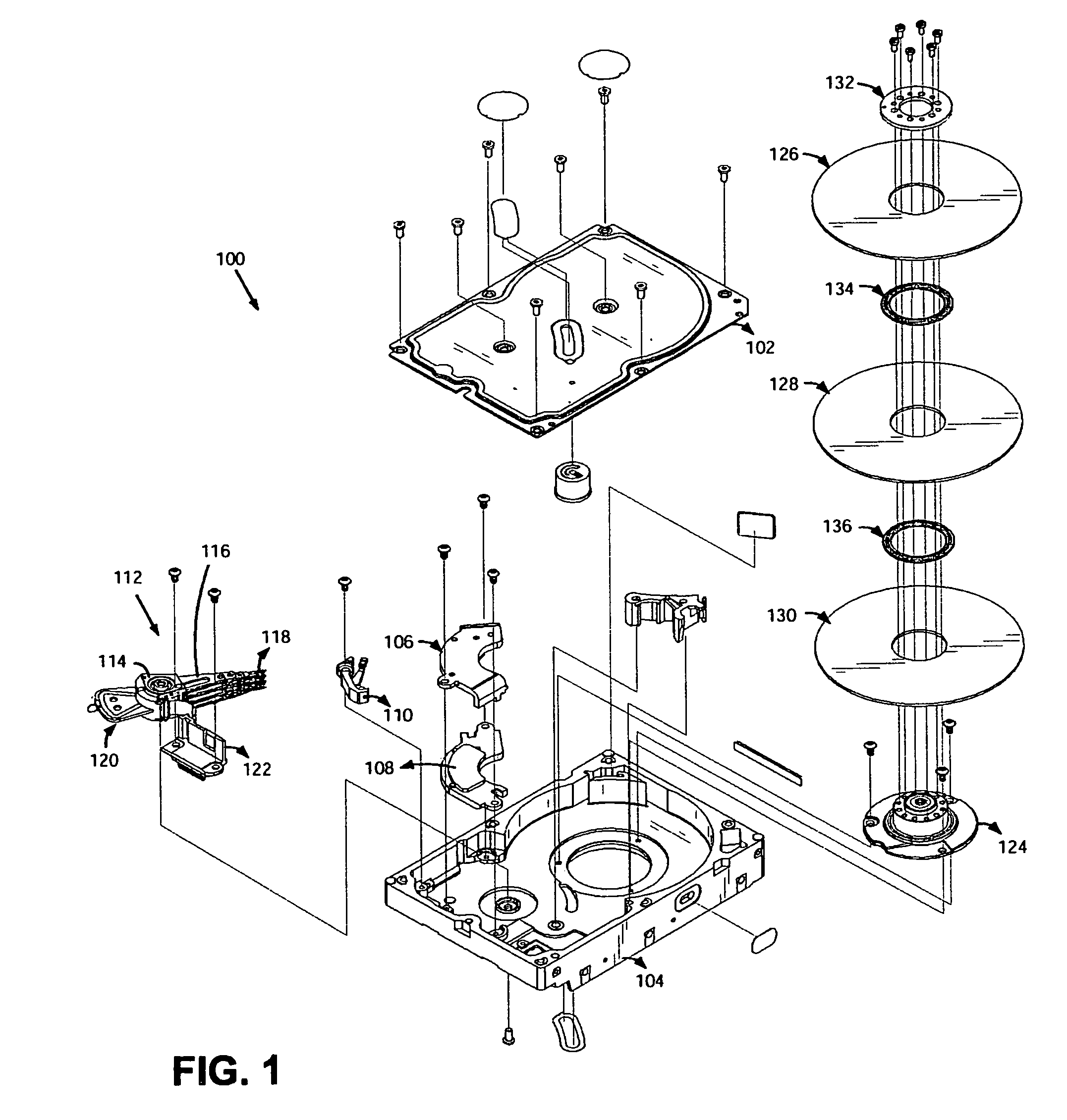

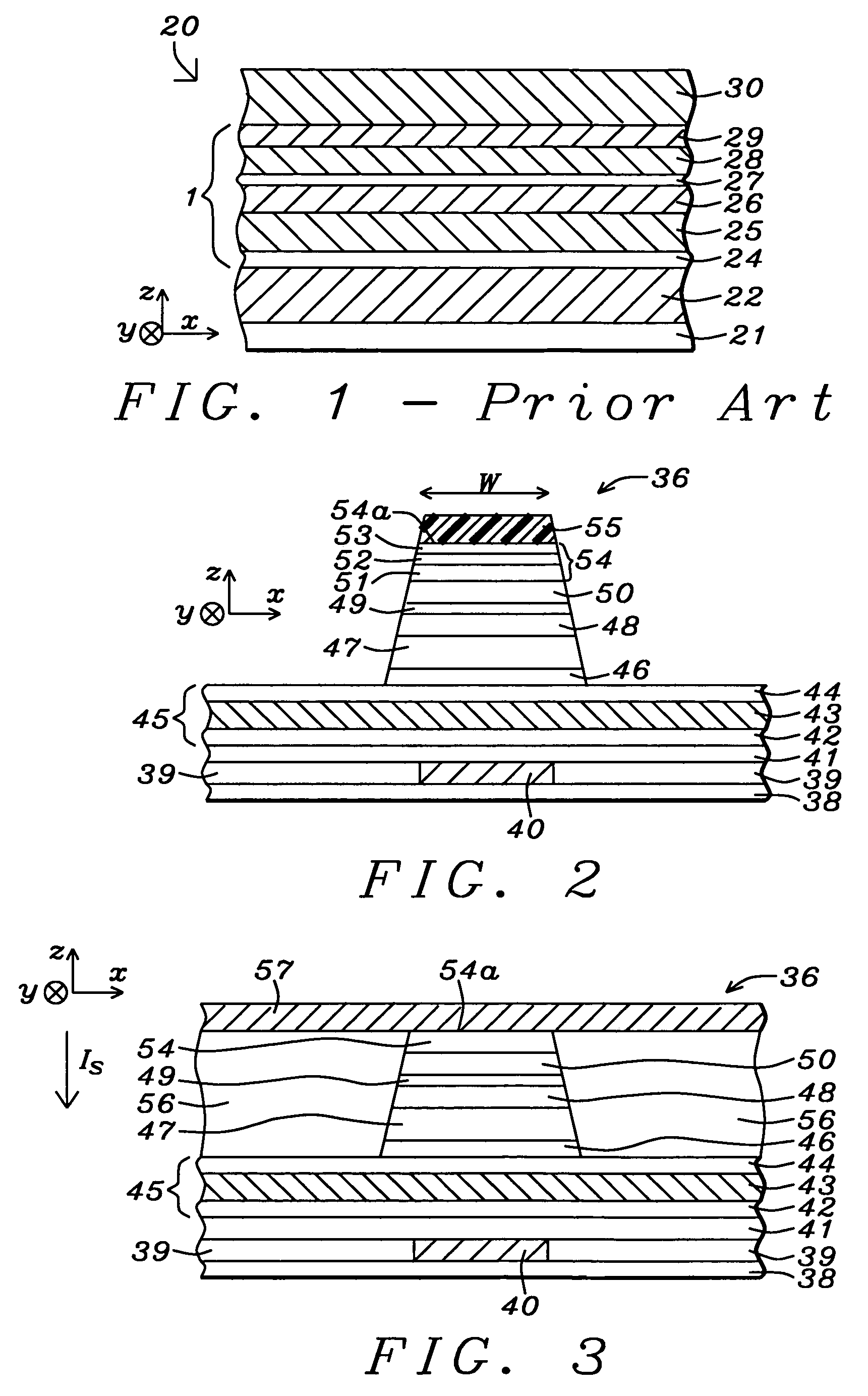

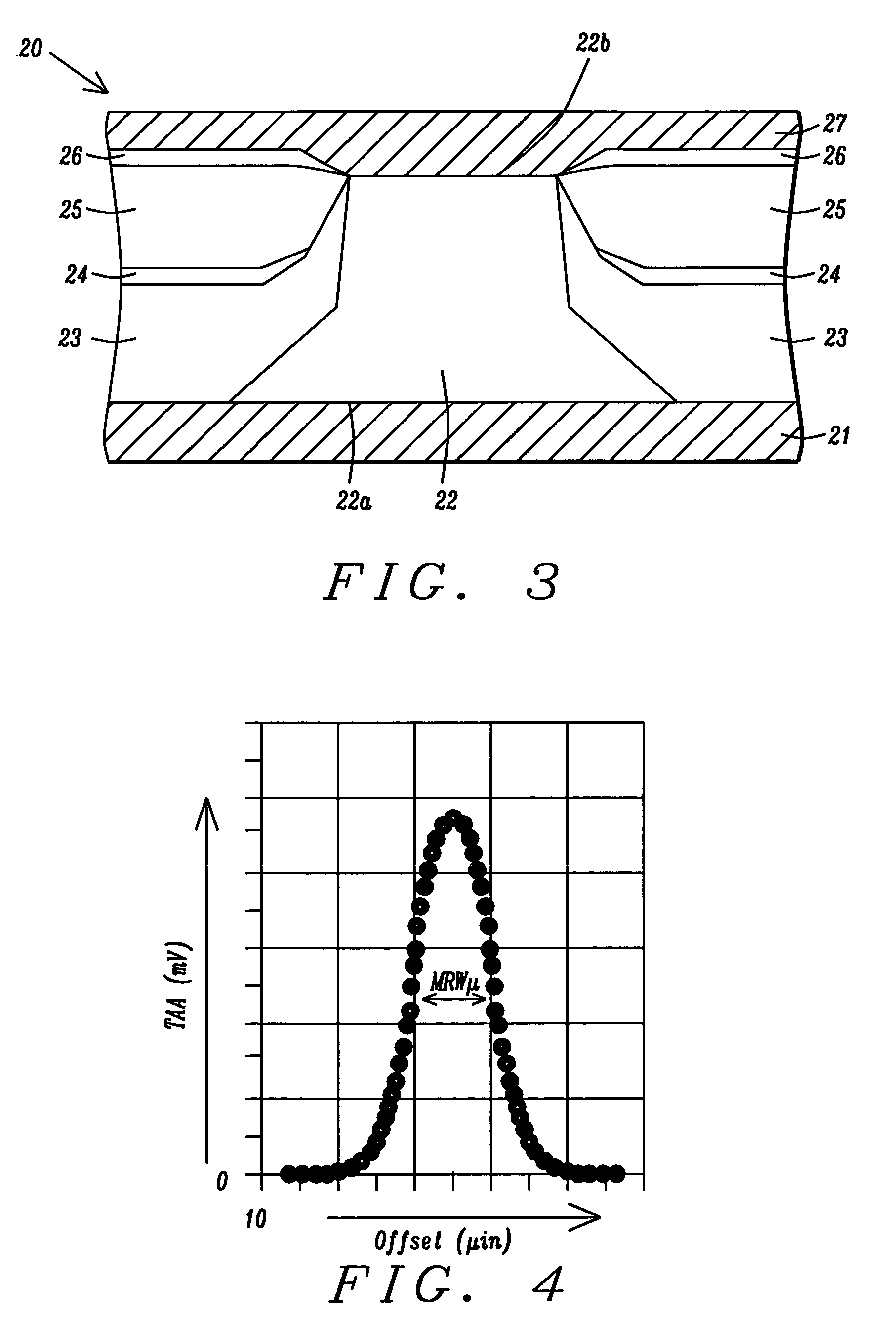

Thin film write head with improved laminated flux carrying structure and method of fabrication

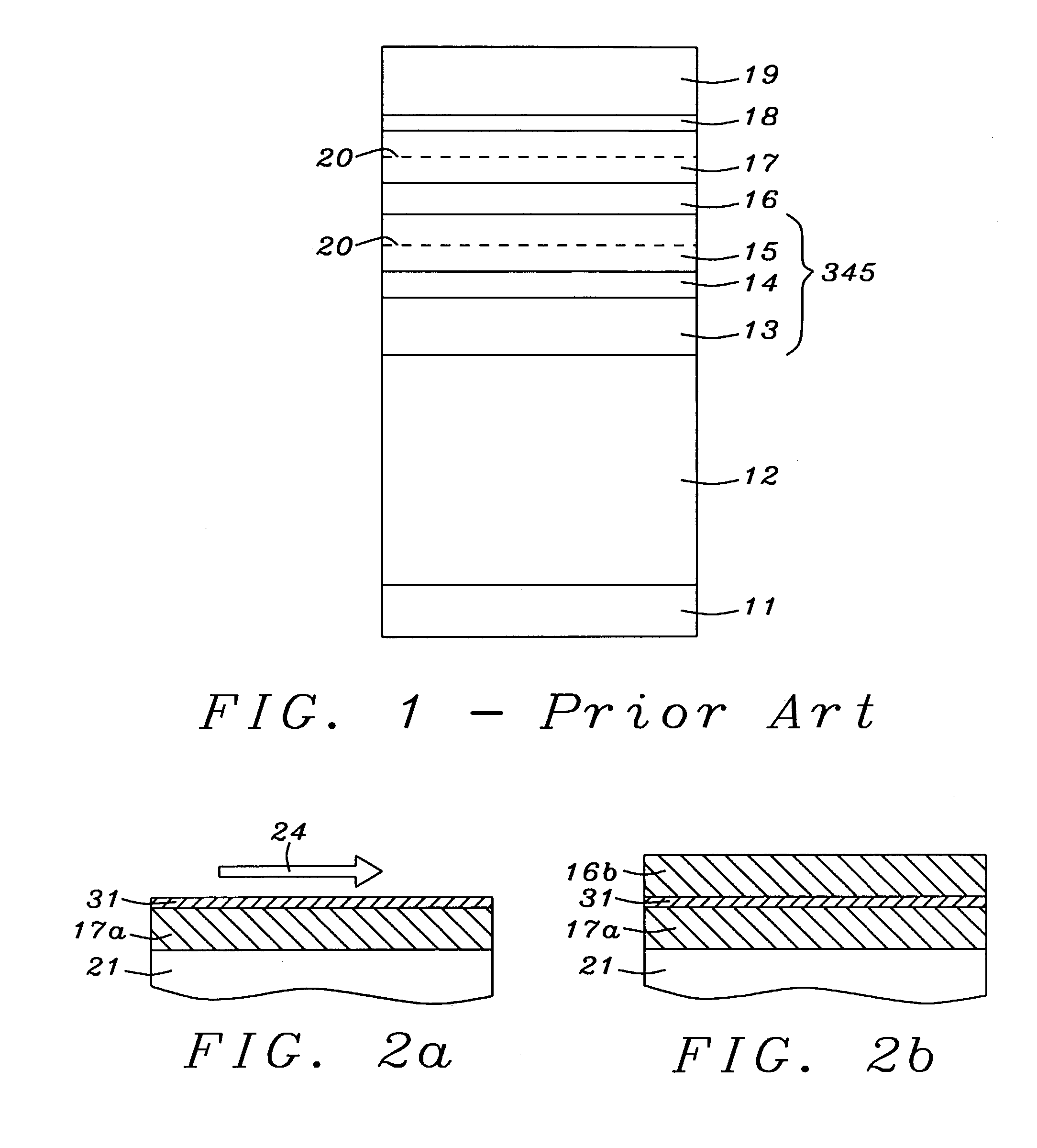

InactiveUS6233116B1High resistivityExcellent soft magnetic propertiesConstruction of head windingsHeads using thin filmsLower poleHigh resistivity

The present invention provides a thin film write head having an improved laminated flux carrying structure and method of fabrication. The preferred embodiment provides laminated layers of: high moment magnetic material, and easily aligned high resistivity magnetic material. In the preferred embodiment, the easily aligned laminating layer induces uniaxial anisotropy, by exchange coupling, to improve uniaxial anisotropy in the high moment material. This allows deposition induced uniaxial anisotropy by DC magnetron sputtering and also provides improved post deposition annealing, if desired. It is preferred to laminate FeXN, such as FeRhN, or other crystalline structure material, with an amorphous alloy material, preferably Co based, such as CoZrCr. In the preferred embodiment, upper and lower pole structures may both be laminated as discussed above. Such laminated structures have higher Bs than structures with insulative laminates, and yokes and pole tips and may be integrally formed, if desired, because flux may travel along or across the laminating layers. The preferred embodiment of the present invention improves soft magnetic properties, reduces eddy currents, improves hard axis alignment while not deleteriously affecting the coercivity, permeability, and magnetostriction of the structure, thus allowing for improved high frequency operation.

Owner:WESTERN DIGITAL TECH INC +1

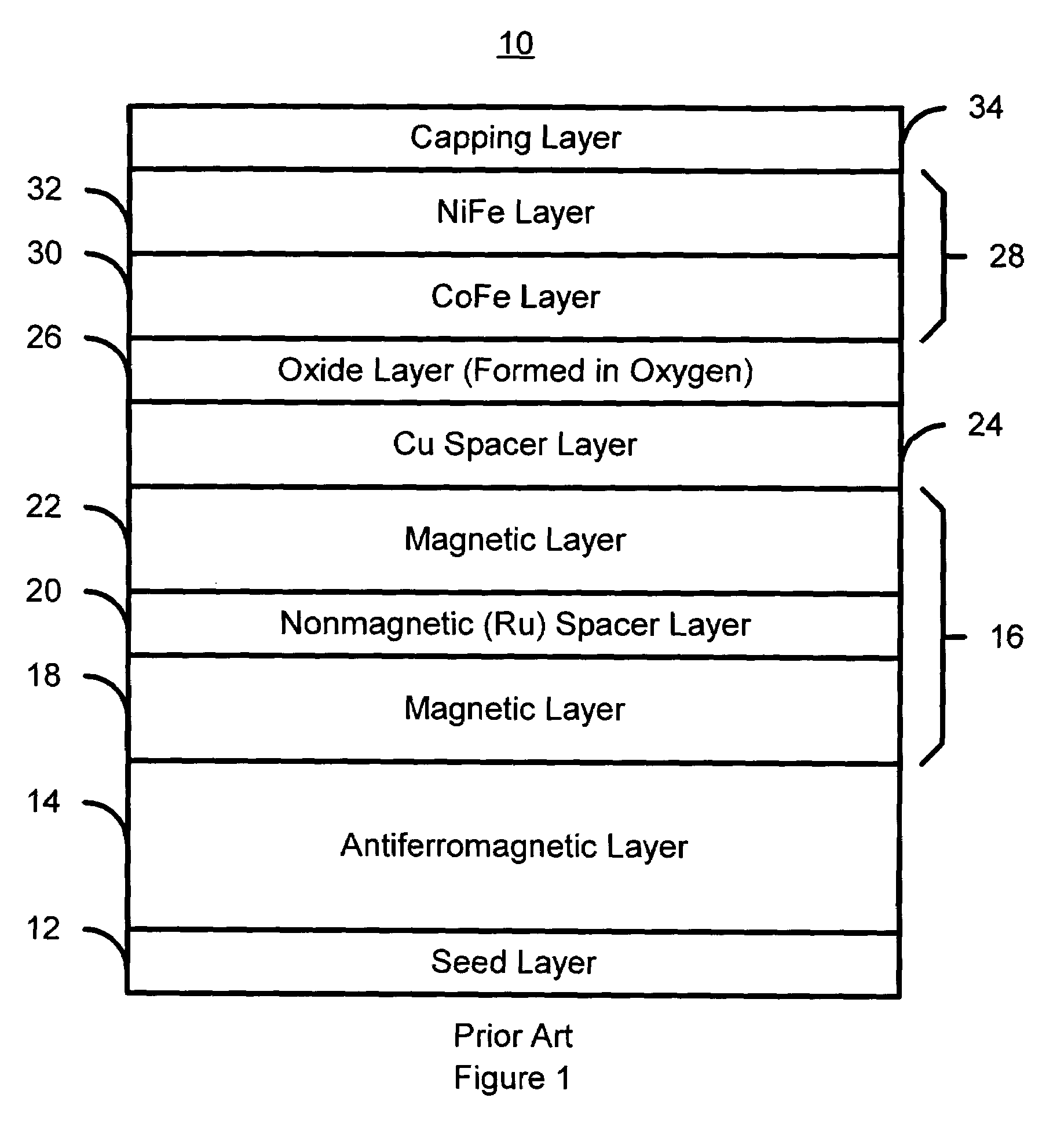

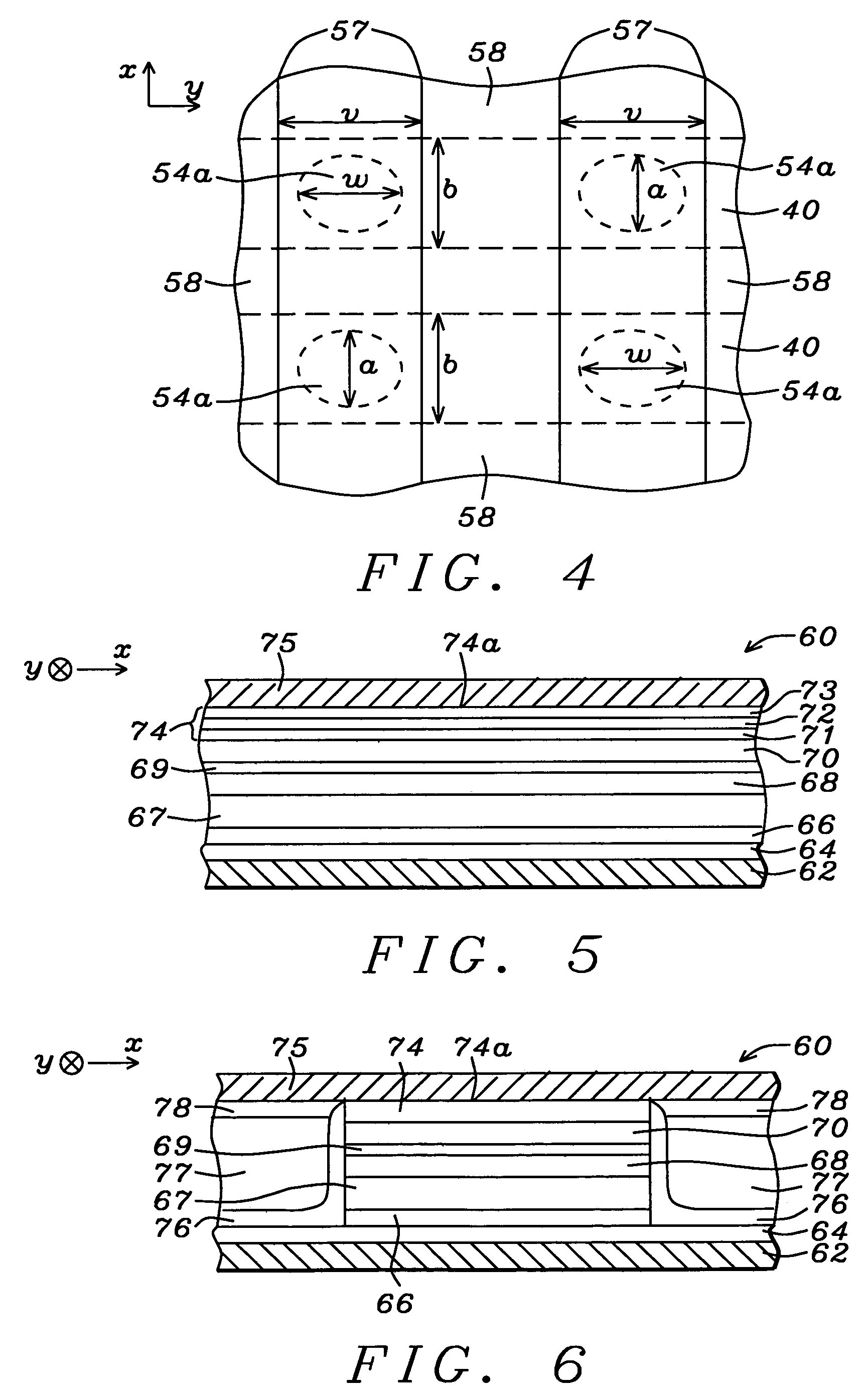

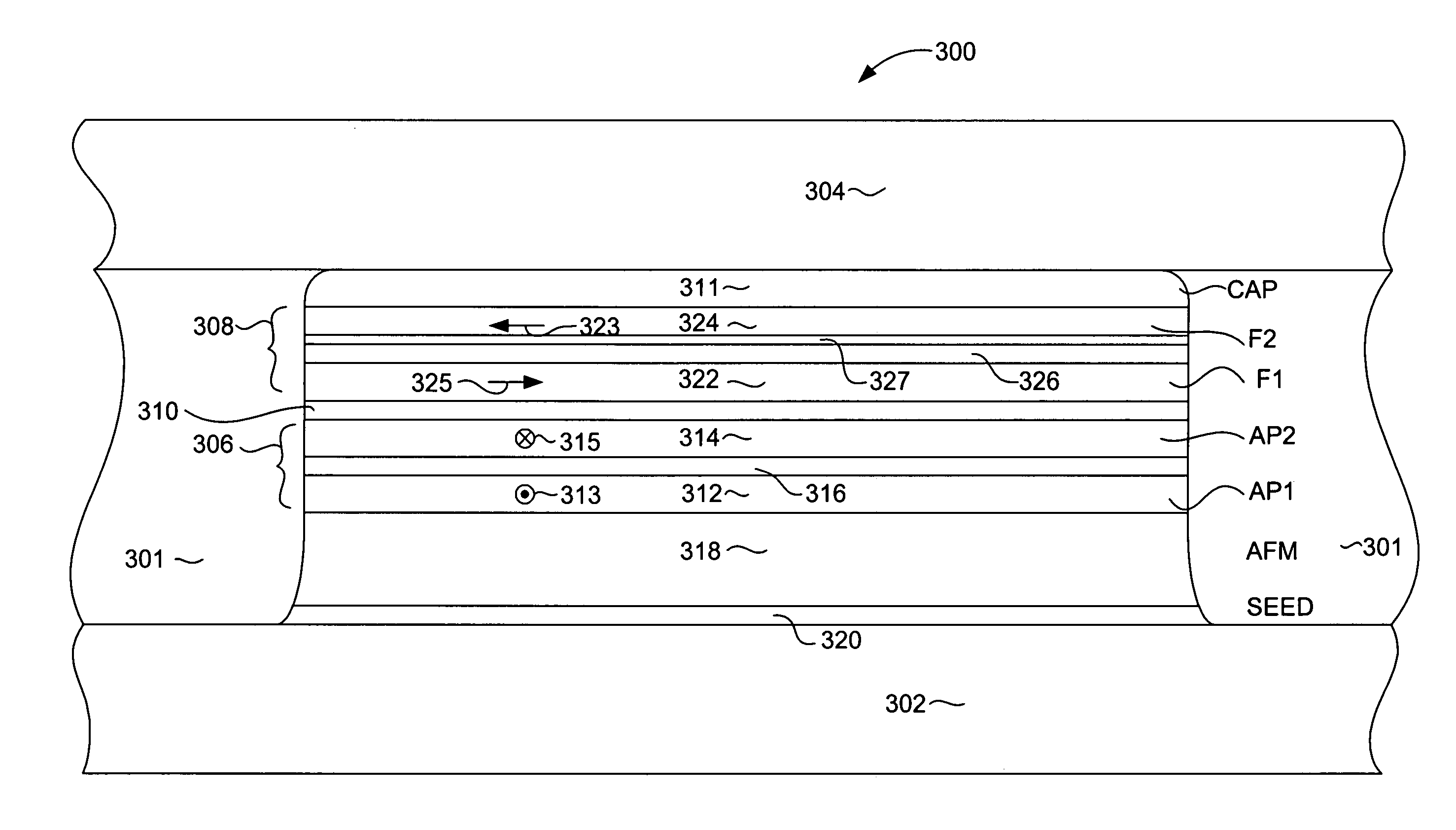

Top spin valve with improved seed layer

InactiveUS6687098B1Improved exchange bias fieldNanostructure applicationNanomagnetismEngineeringHigh resistivity

The present invention provides an improved top spin valve and method of fabrication. In the preferred embodiment of the top spin valve of the present invention, a seed layer is formed of non-magnetic material having the elements Ni and Cr. In the preferred embodiments, the seed layer material has an ion milling rate comparable to that of the free layer material. This allows free layer sidewalls to be formed with shorter tails, improving free layer-to-magnetic bias layer junction, thus improving free layer domain structure and track width. In one embodiment, the seed layer may have NiFeCr, with Cr from about 20% to 50%. In another embodiment, the seed layer may have NiCr, with about 40%. Some embodiments may have the seed layer formed on an optional Ta pre-seed layer. Such embodiments provide an improved fcc (111) texture particularly for NiFe and for NiFe / CoFe free layers grown on a seed layer improving spin valve performance, and especially in embodiments having very thin NiFe free layers, ultra thin NiFe free layers, and free layers without NiFe, such as a free layer of CoFe. Such a seed layer can improve AFM pinning layer texture to improve the exchange bias, thus providing better thermal stability. Such a seed layer also provides high resistivity and can improve the magnetostriction of adjacent NiFe free layer material or improve the soft properties of an adjacent CoFe free layer.

Owner:WESTERN DIGITAL TECH INC

Novel capping structure for enhancing dR/R of the MTJ device

InactiveUS20050276099A1Well controlled magnetizationWell controlled switching characteristicNanomagnetismNanoinformaticsElectrical conductorOxygen

Owner:HEADWAY TECH INC +1

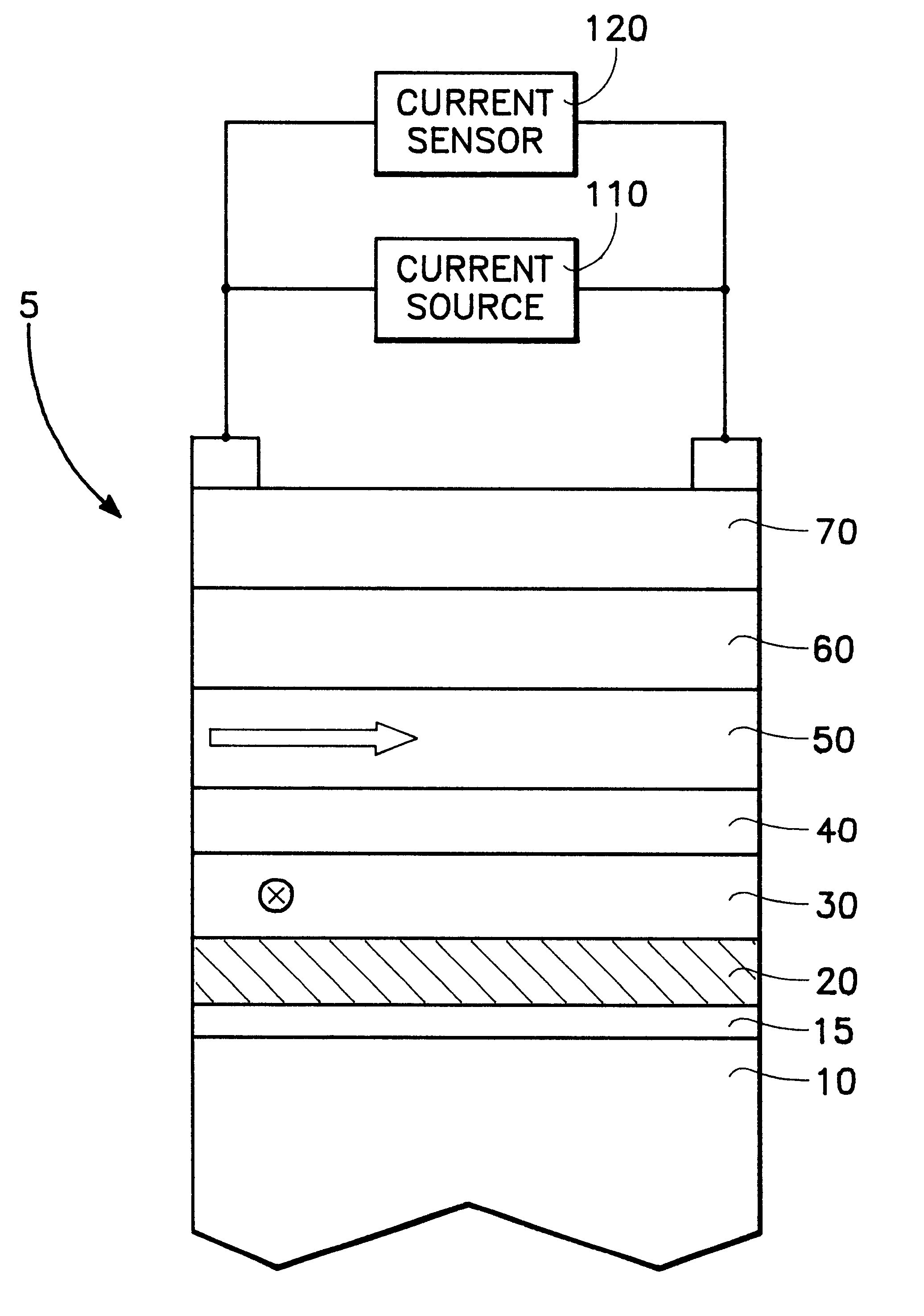

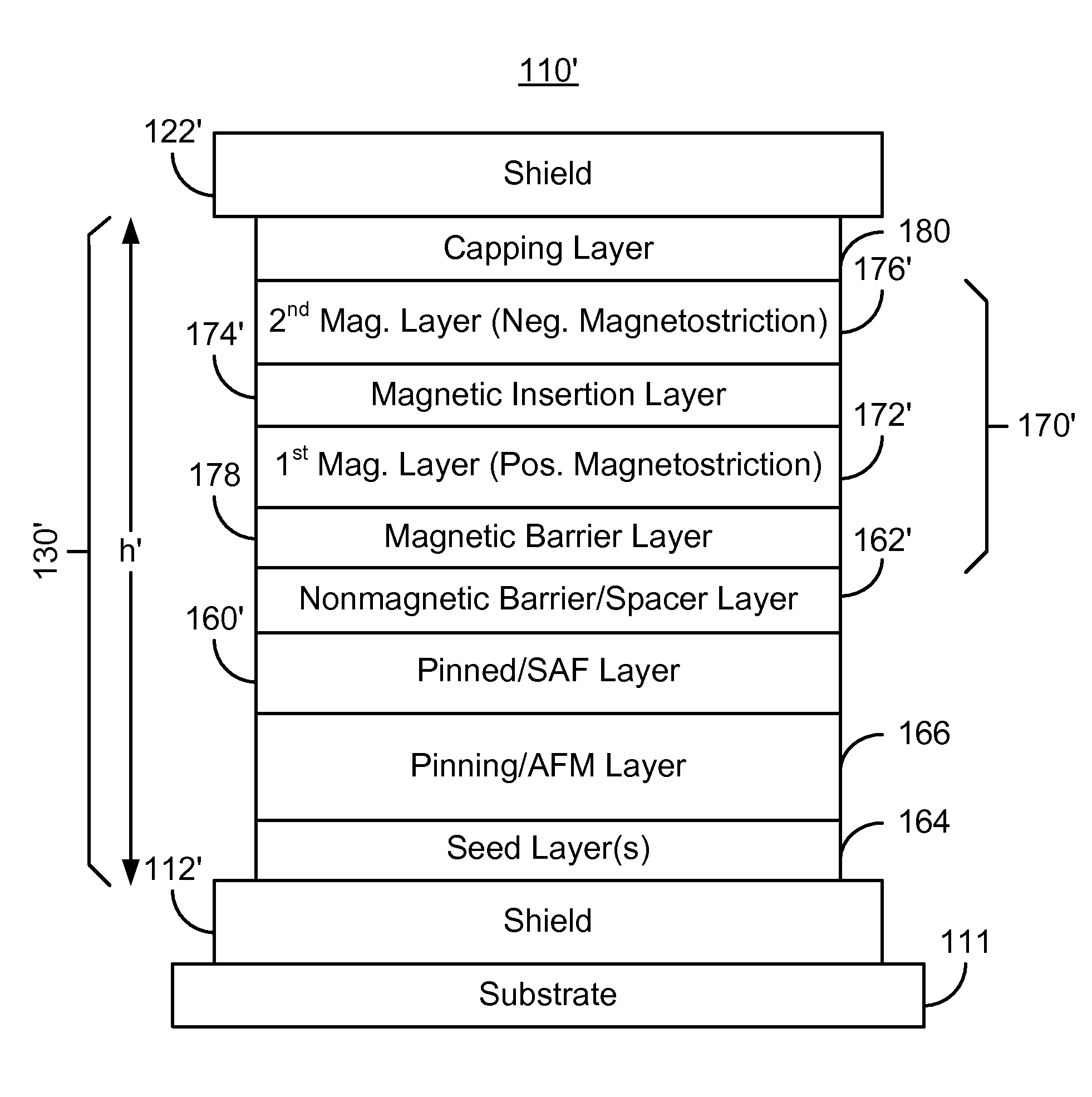

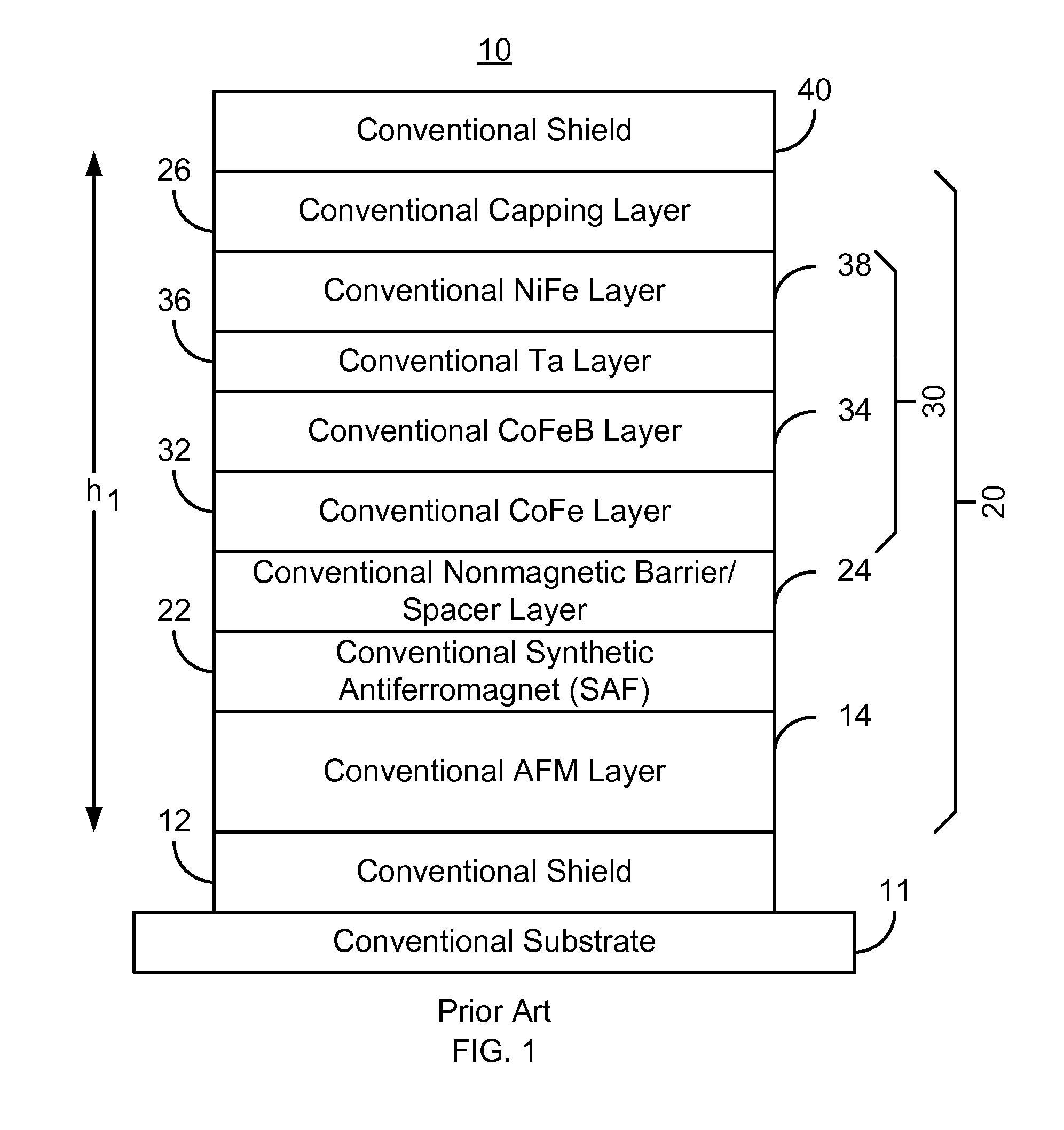

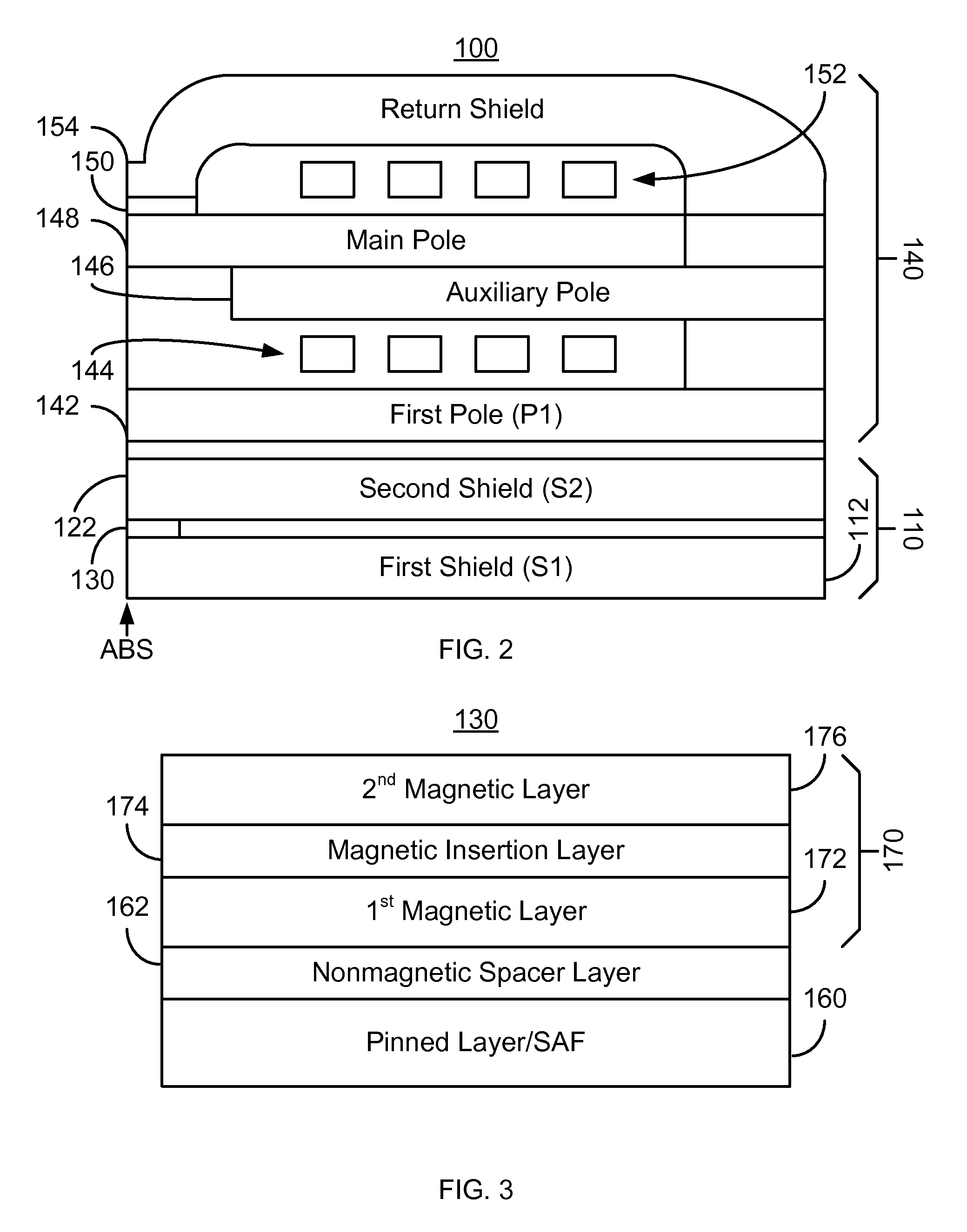

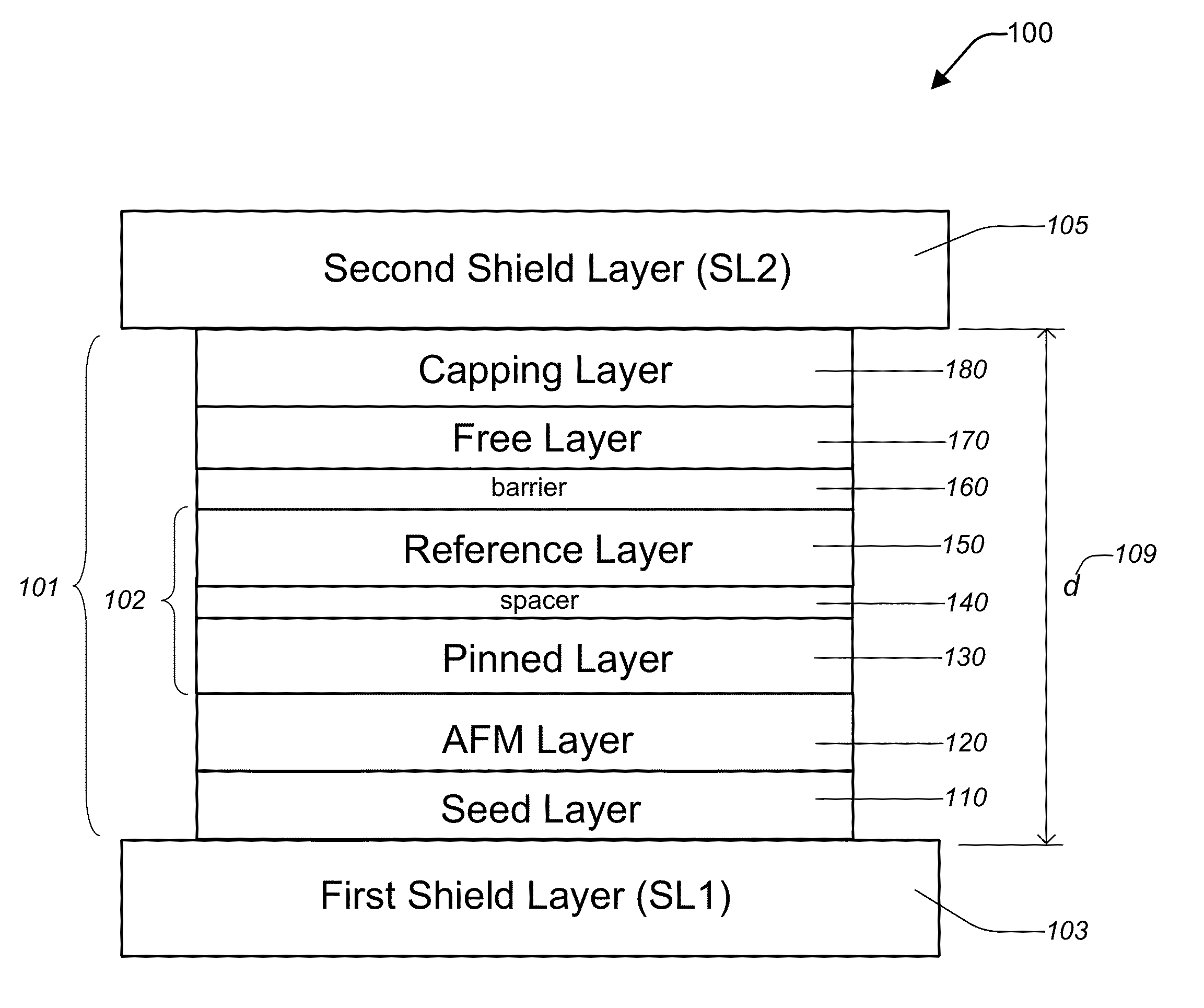

Method and system for providing a read sensor having a low magnetostriction free layer

ActiveUS8194365B1Magnetic measurementsMagnetic-field-controlled resistorsMagnetic transducersMagnetic layer

A method and system for providing a magnetic structure in magnetic transducer is described. The magnetic structure includes a pinned layer, a nonmagnetic spacer layer, and a free layer. The nonmagnetic spacer layer is between the pinned layer and the free layer. The free layer includes a first magnetic layer, a second magnetic layer, and a magnetic insertion layer between the first magnetic layer and the second magnetic layer. The first magnetic layer has a first magnetostriction. The second magnetic layer has a second magnetostriction opposite to the first magnetostriction. The magnetic insertion layer provides a growth texture barrier between the first magnetic layer and the second magnetic layer.

Owner:WESTERN DIGITAL TECH INC

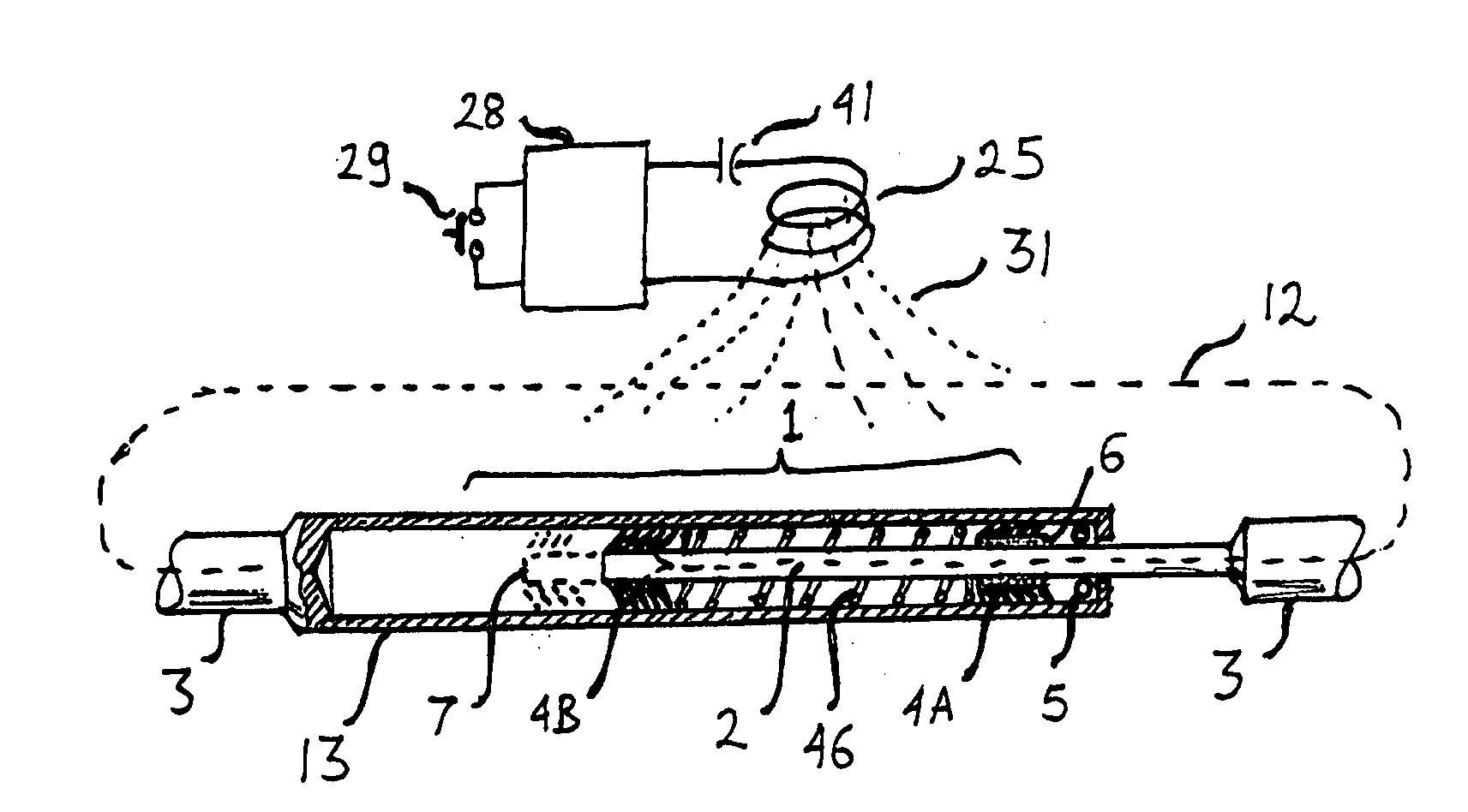

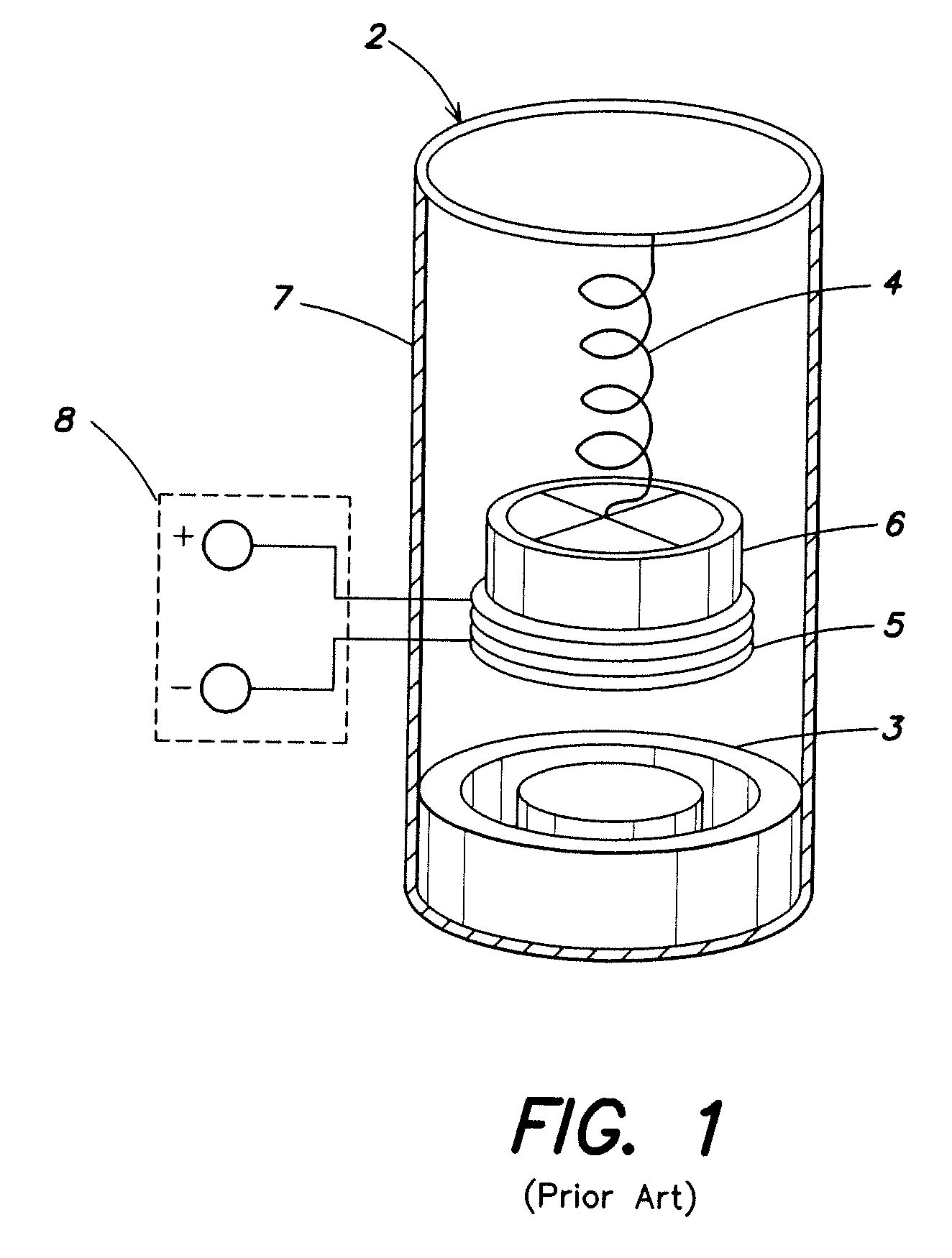

System for mechanical adjustment of medical implants

A system for mechanically adjusting medical implants uses an external coil to set up a magnetic field. The magnetic field causes an actuator inside the implant to move in small steps, allowing fine adjustment. The element responding to the magnetic field can be magnetostrictive or SMA based. Large motions are made up from small steps by using two one-way clutches allowing the active element to move small increments in one direction. For SMA based devices, short burst of AC magnetic field are used. For magnetostrictive devices short pulse of unipolar magnetic field are used.

Owner:KARDIUM

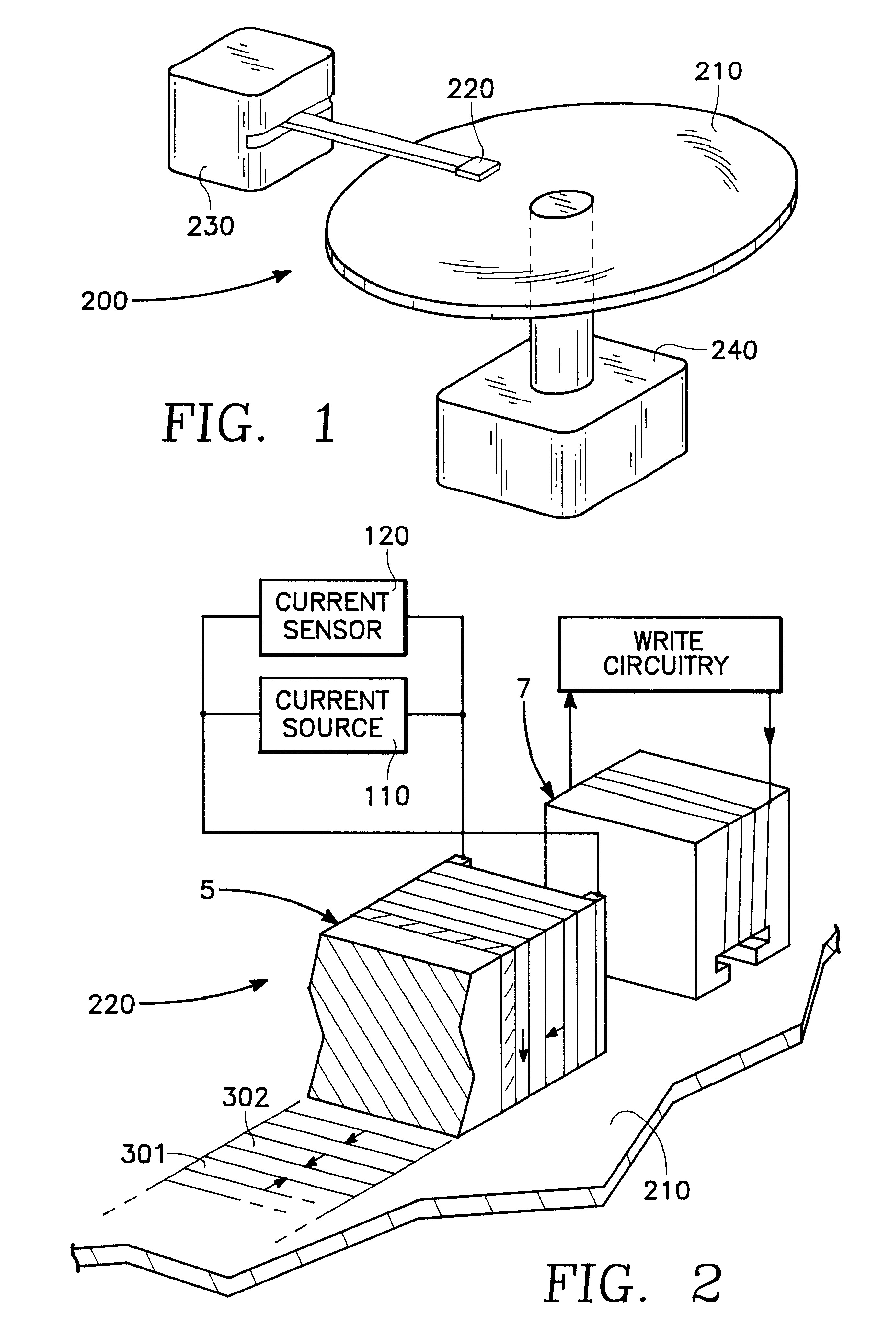

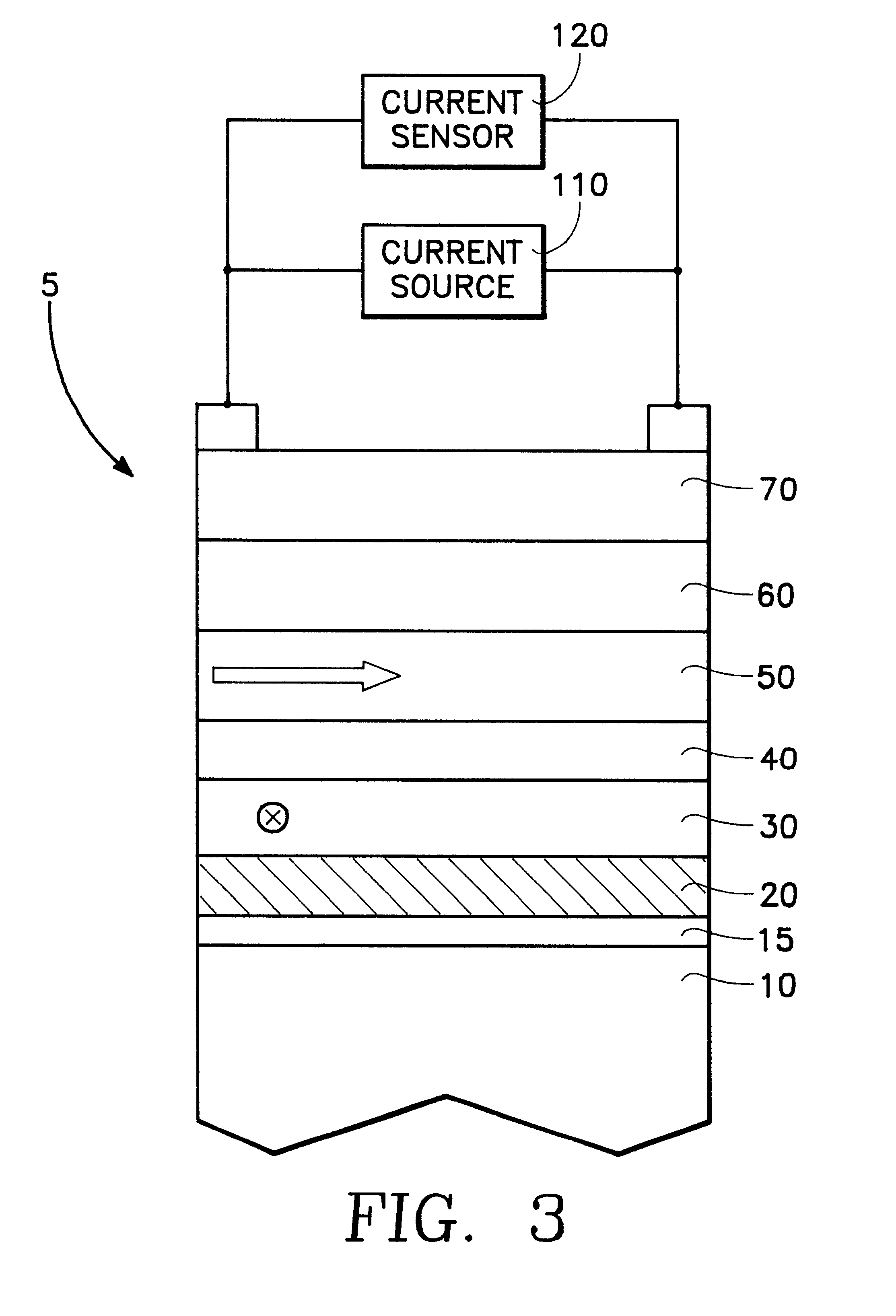

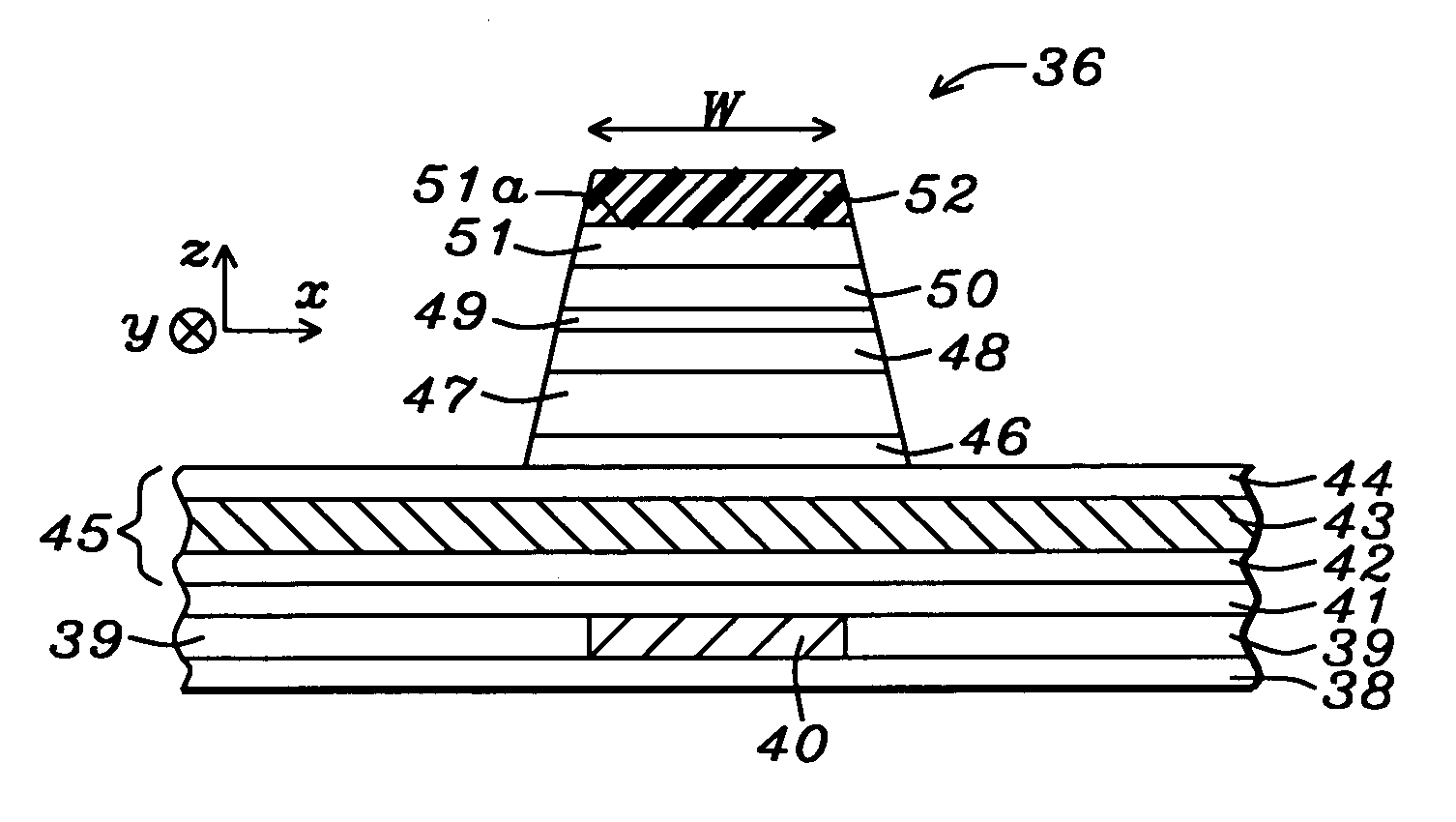

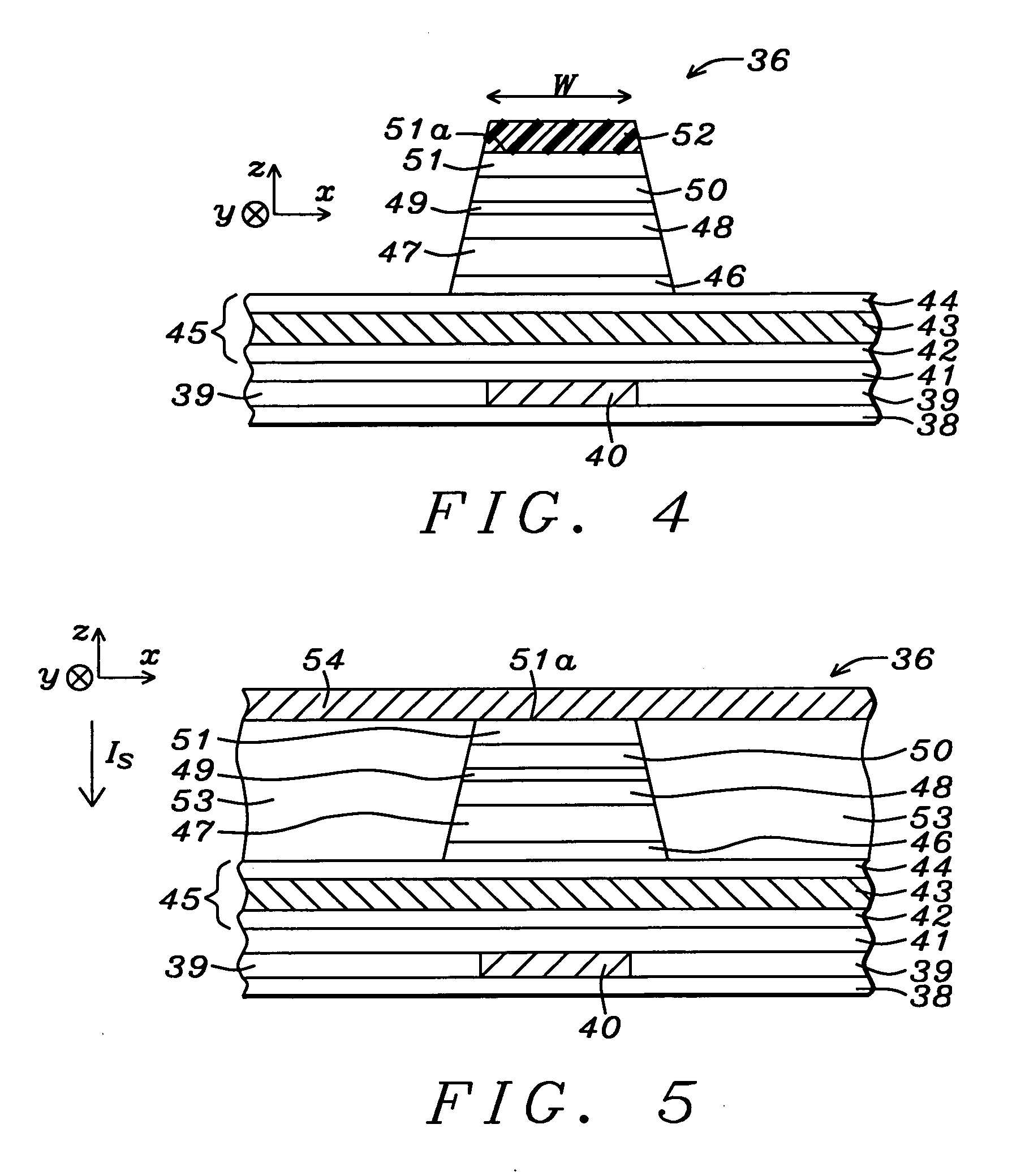

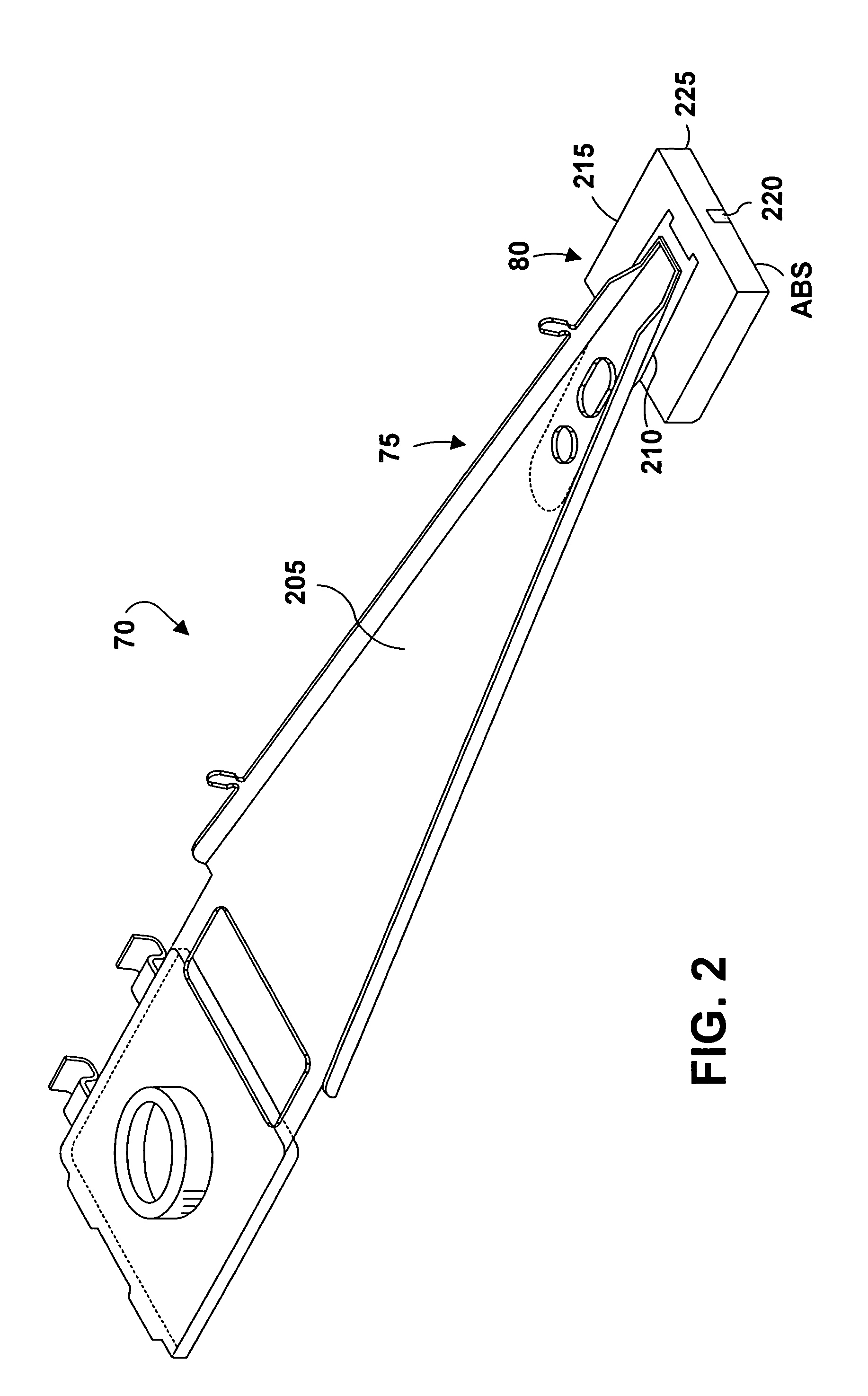

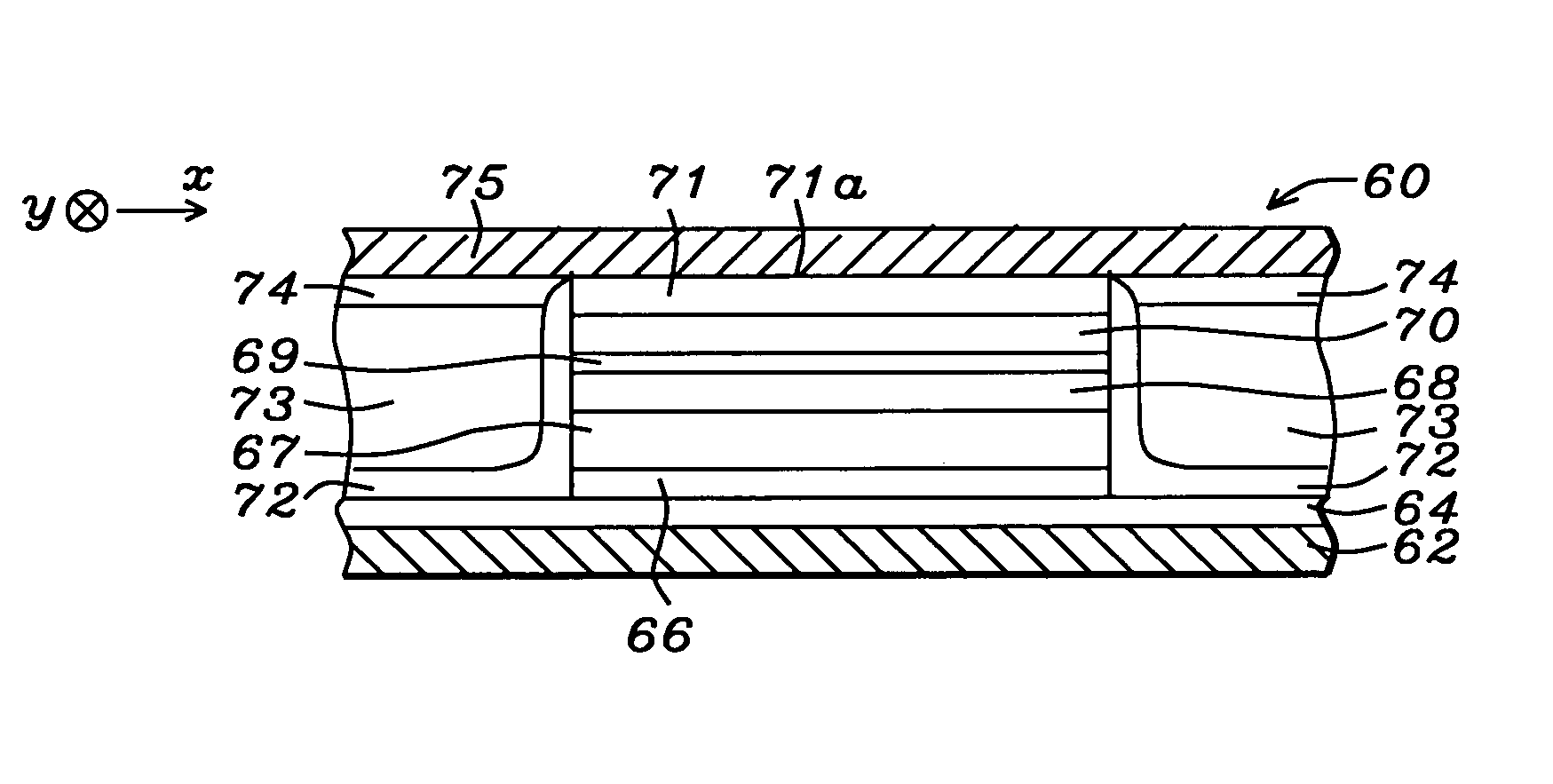

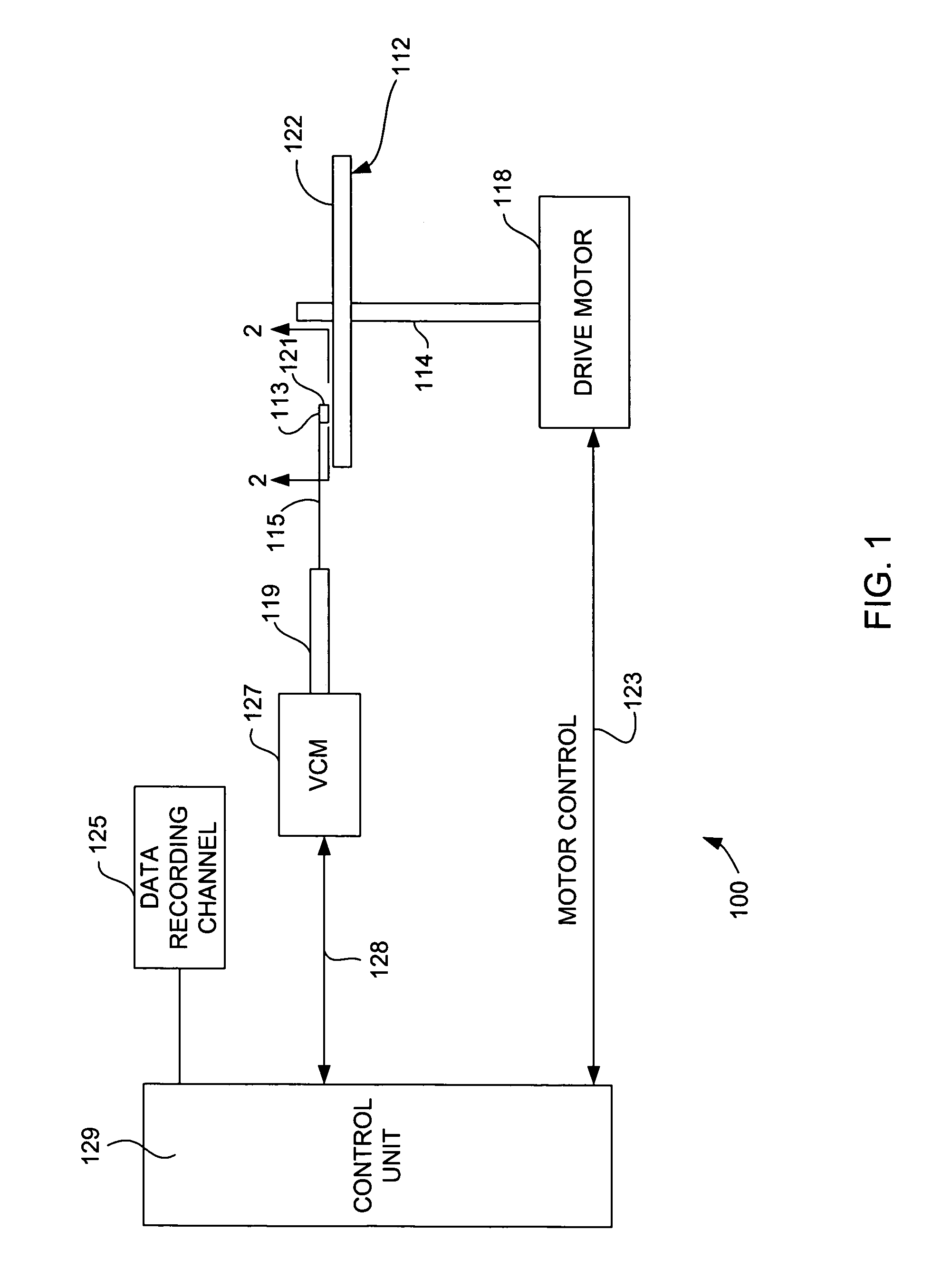

Read/write head with dynamic flying height control by magnetostriction

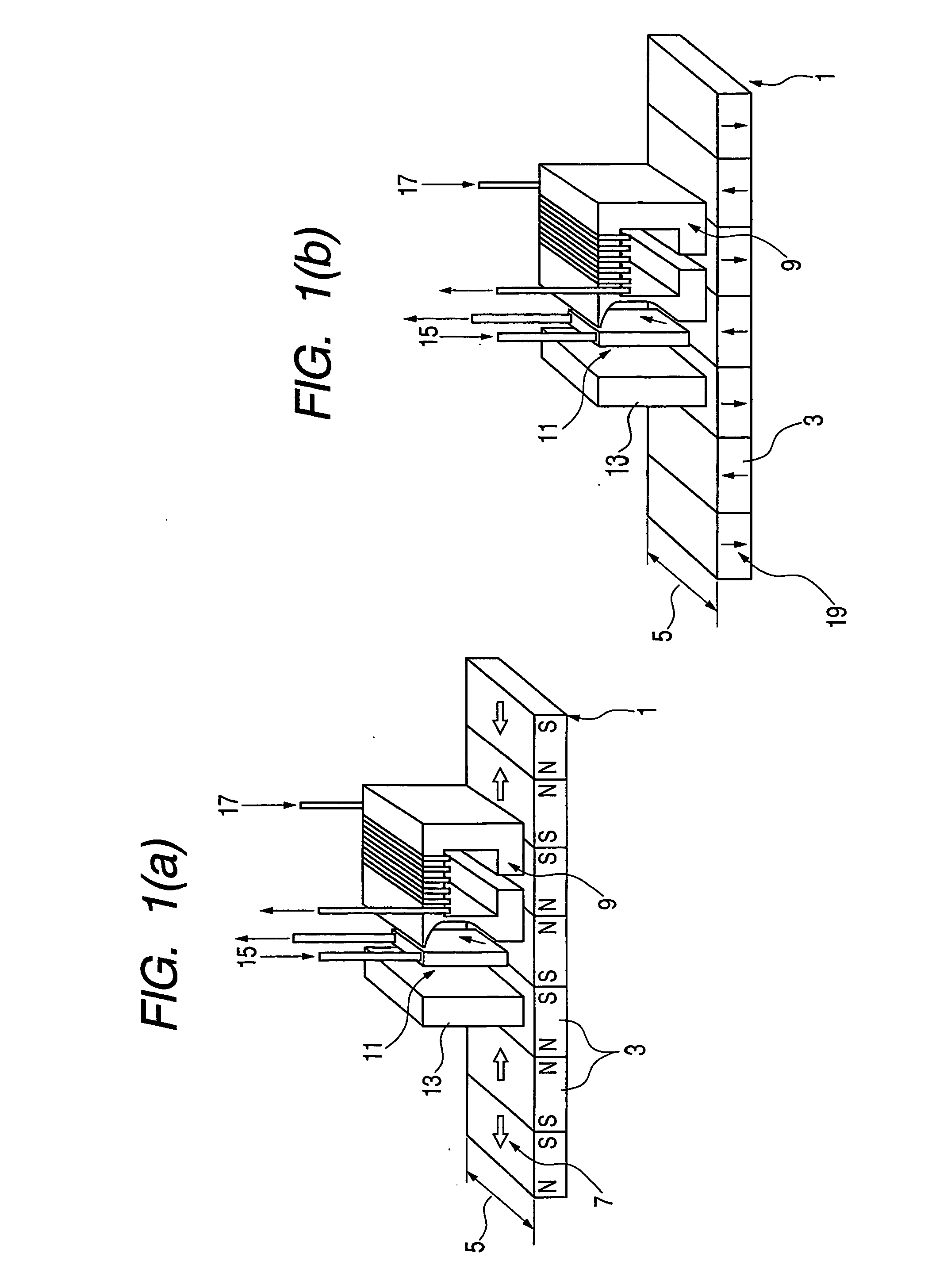

InactiveUS7660080B1Easy to controlDisposition/mounting of recording headsRecord information storageFlying heightData recording

A read / write head for use in a data storage device to control the low dynamic flying height in order to achieve high data recording storage capacity of magnetic hard drives. The read / write head is designed for use in a data storage device that includes a storage medium having a recording surface. The head comprises a pole tip region and an actuator. In turn, the actuator includes an excitation source for generating a magnetic field, and a magnetostrictive plate for expanding in response to the magnetic field, resulting in a protrusion in a section of the pole tip region along a direction towards the recording surface, so that the head flies above the recording surface at a flying height lower than a nominal flying height.

Owner:WESTERN DIGITAL TECH INC

Magnetoresistive sensors having an improved free layer

ActiveUS8498084B1Reduce thicknessGilbert damping constantMagnetic measurementsRecord information storageSpin polarizationCobalt

A magnetoresistive sensor having a novel free layer and a method of producing the same are disclosed. The magnetoresistive sensor comprises a pinned layer, a barrier layer disposed over the pinned layer, and a free layer disposed over the barrier layer. The free layer comprises a first magnetic layer disposed over the barrier layer. The first magnetic layer has a positive spin polarization, a positive magnetostriction, and a polycrystalline structure. The free layer further comprises a second magnetic layer disposed over the first magnetic layer. The second magnetic layer has a negative magnetostriction and comprises at least cobalt (Co) and boron (B).

Owner:WESTERN DIGITAL TECH INC

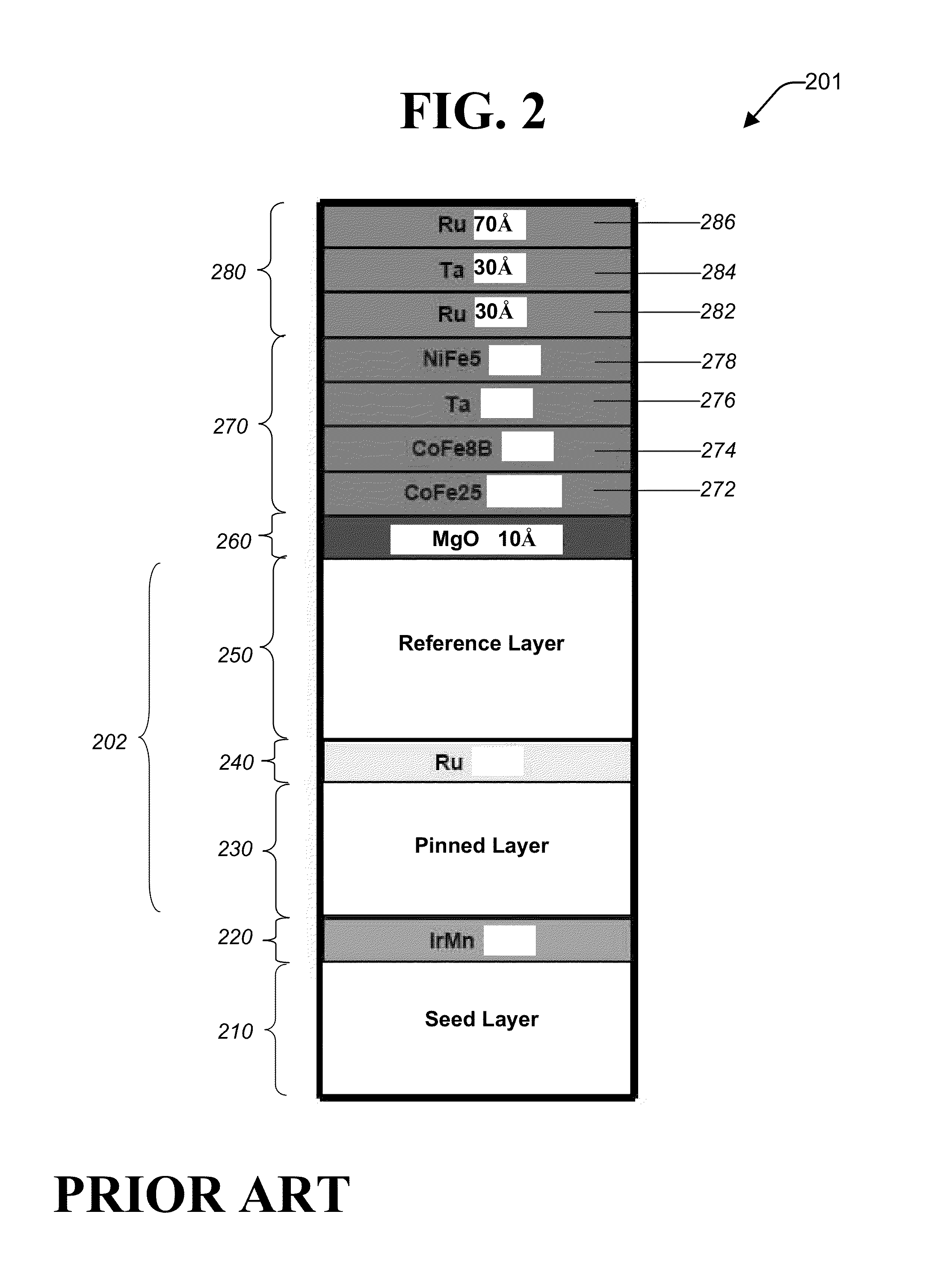

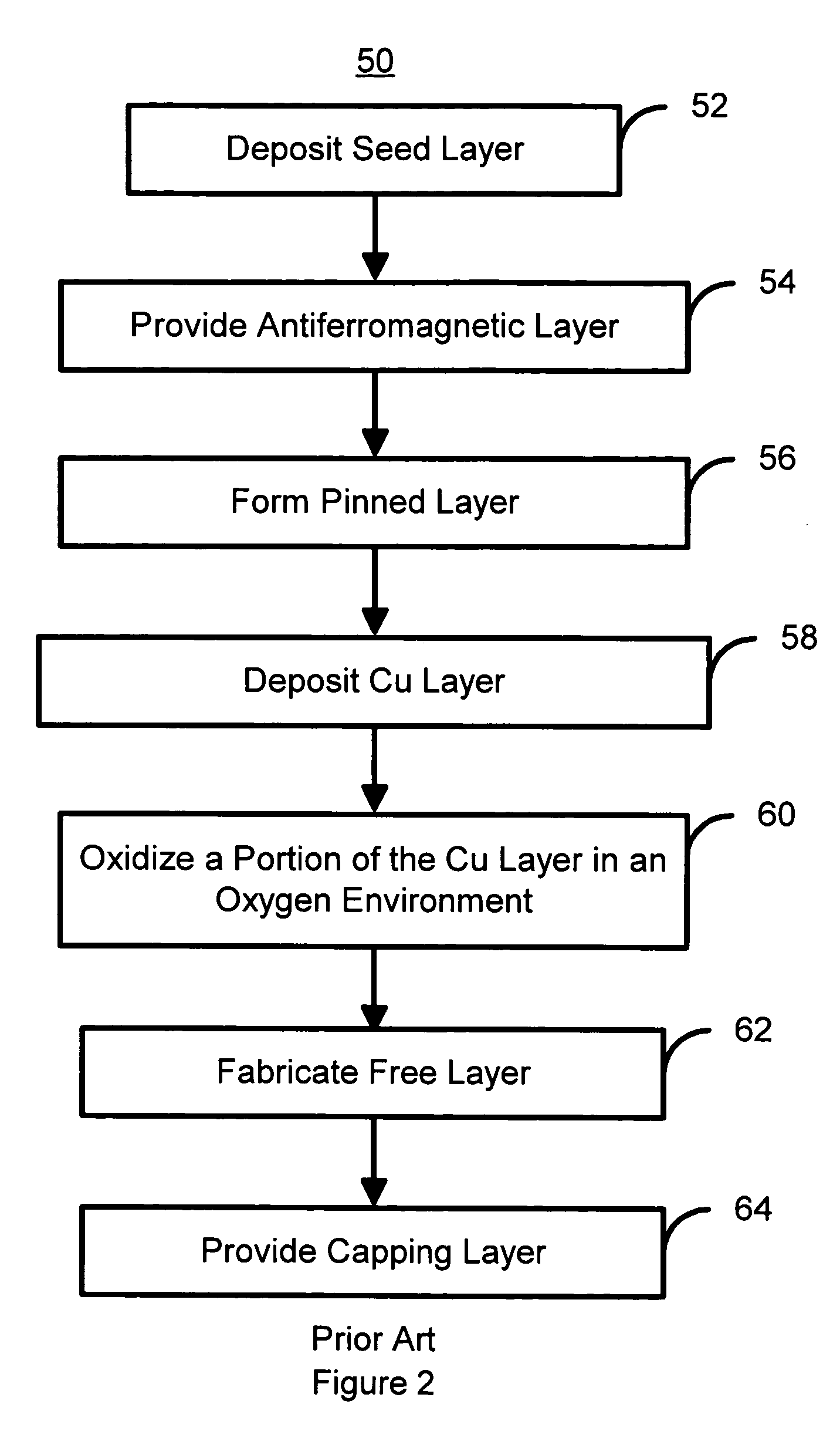

Method and apparatus for controlling magnetostriction in a spin valve sensor

A method and system for providing a magnetic element are described. The method and system include providing a pinned layer, fabricating a metallic spacer layer and oxidizing a portion of the spacer layer in an environment including at least oxygen and a gas inert with respect to the spacer layer to provide an oxide layer. The method and system also include creating a free layer. The oxide layer is between a remaining metallic portion of the spacer layer and the free layer. In one aspect, the system includes a chamber and a gas diffusion apparatus within the chamber. The gas diffusion apparatus includes a plurality of nozzles and defines a plane. The gas exits each of the plurality of nozzles in a cone having an apex angle. The nozzles are directed at a nozzle tilt angle of at least half of the apex angle from the plane and the spacer layer.

Owner:WESTERN DIGITAL TECH INC

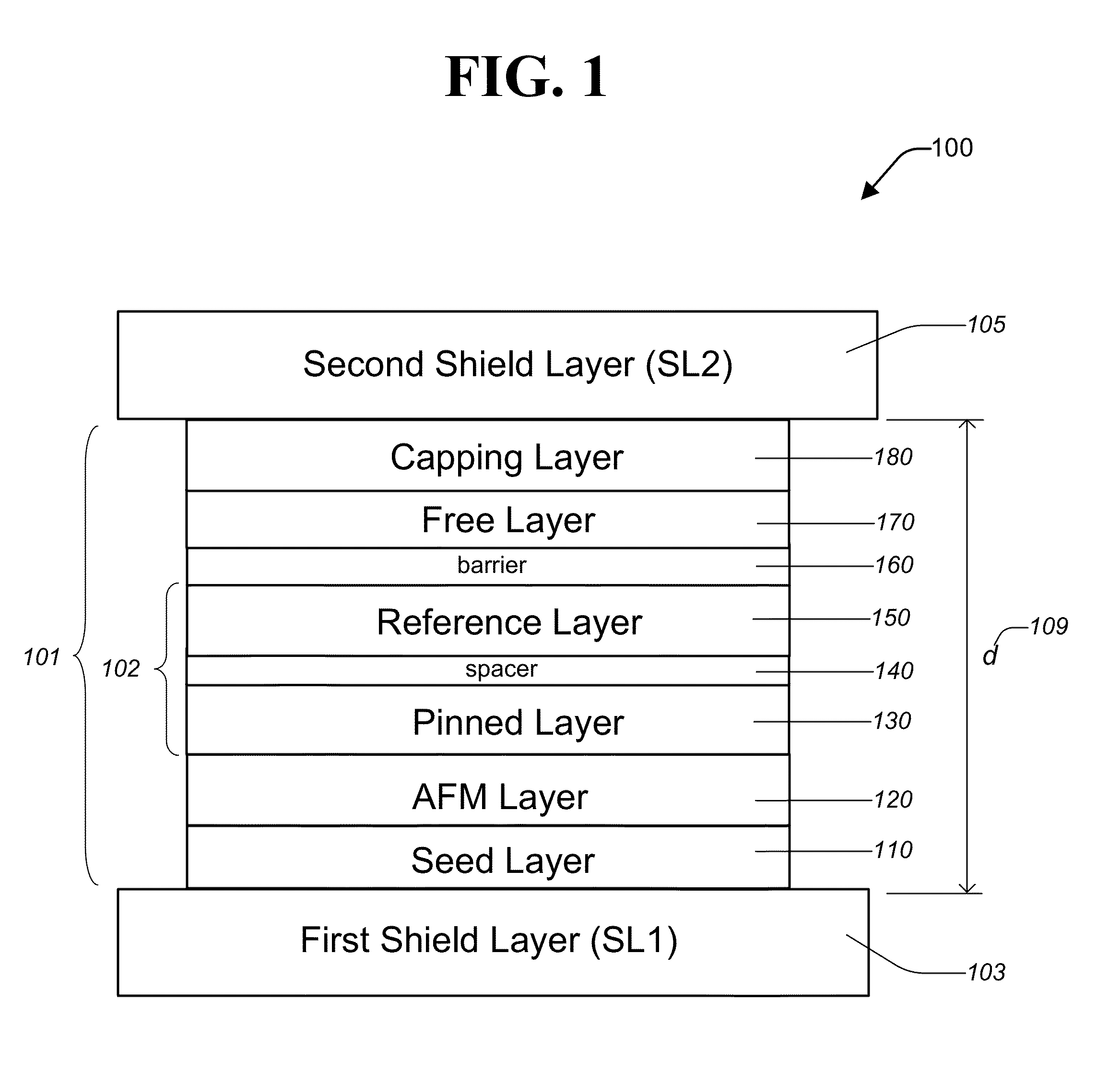

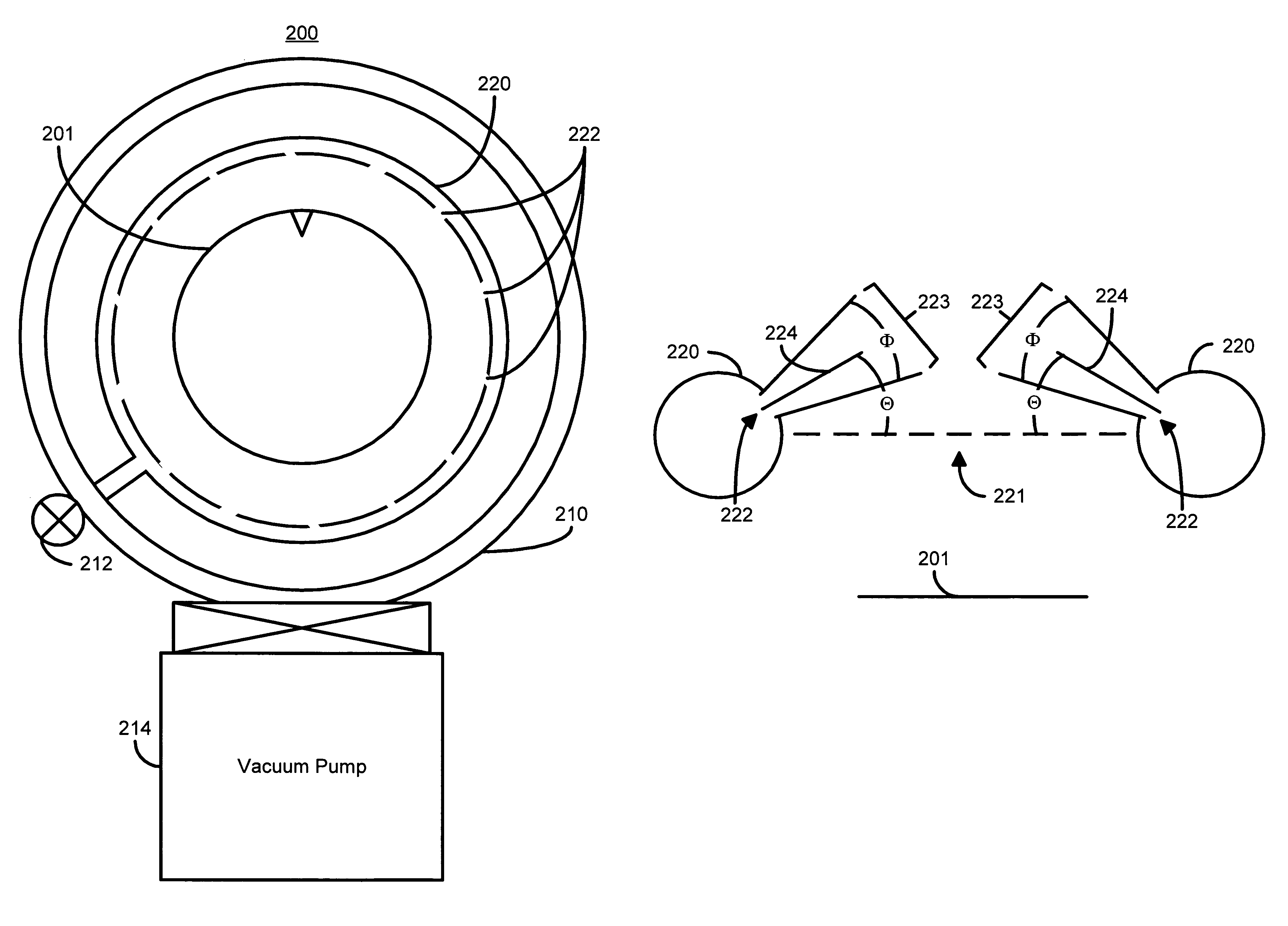

Capping structure for enhancing dR/R of the MTJ device

An MTJ in an MRAM array or in a TMR read head is comprised of a capping layer with a lower inter-diffusion barrier layer, an intermediate oxygen gettering layer, and an upper metal layer that contacts a top conductor. The composite capping layer is especially useful with a moderate spin polarization free layer such as a NiFe layer with a Fe content of about 17.5 to 20 atomic %. The capping layer preferably has a Ru / Ta / Ru configuration in which the lower Ru layer is about 10 to 30 Angstroms thick and the Ta layer is about 30 Angstroms thick. As a result, a high dR / R of about 40% is achieved with low magnetostriction less than about 1.0 E−6 in an MTJ in an MRAM array. Best results are obtained with an AlOx tunnel barrier layer formed by an in-situ ROX process on an 8 to 10 Angstrom thick Al layer.

Owner:HEADWAY TECH INC +1

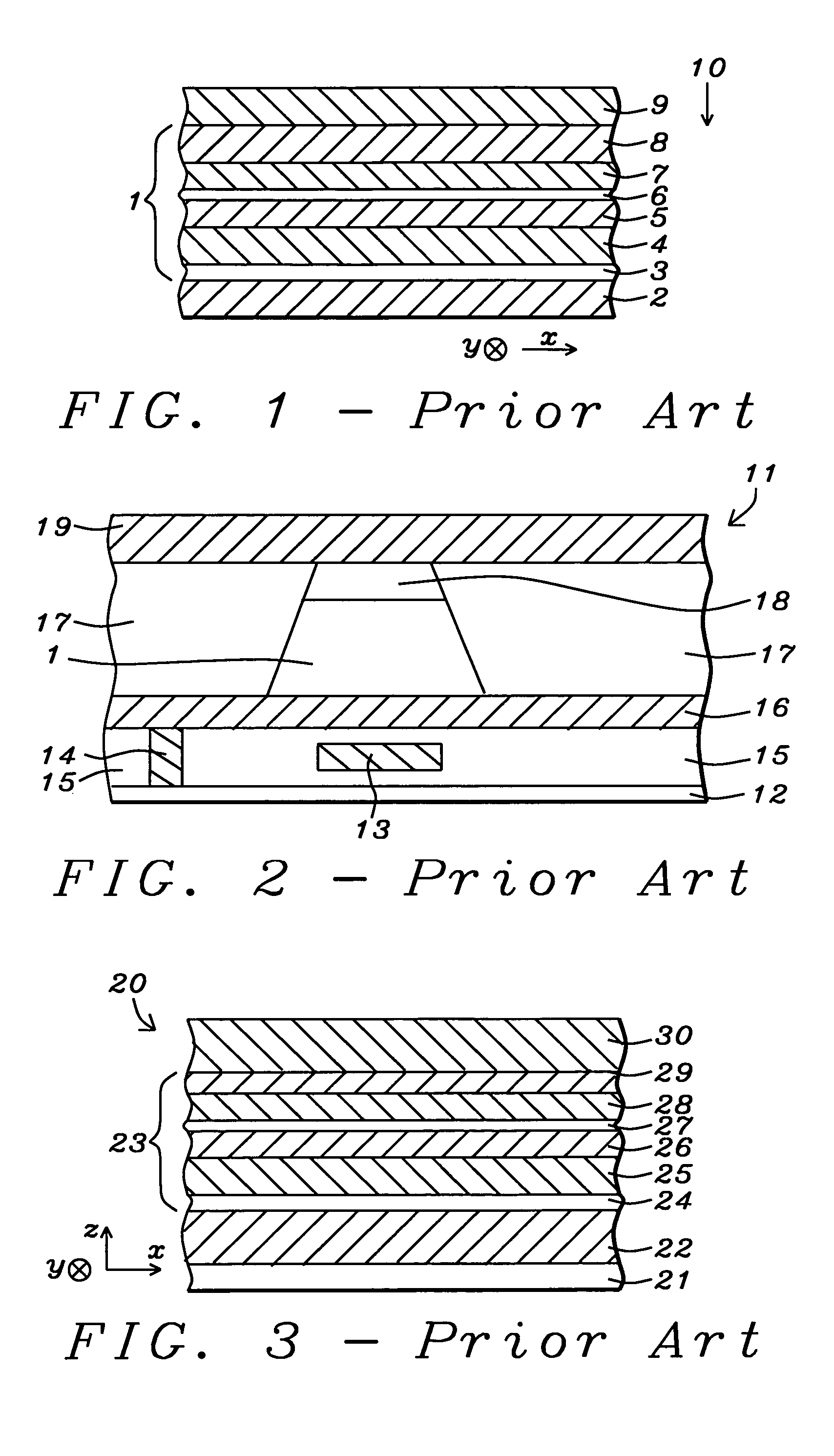

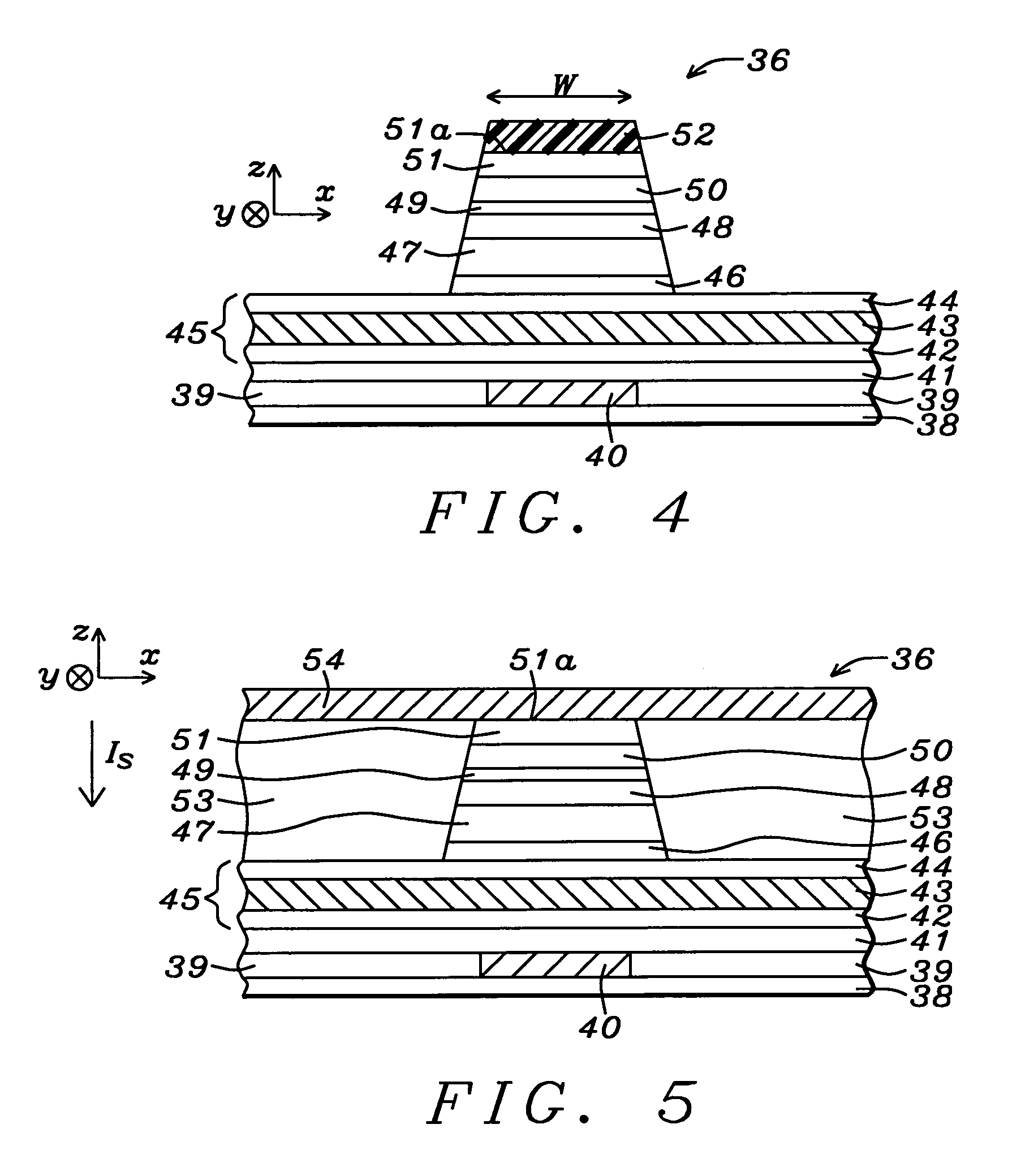

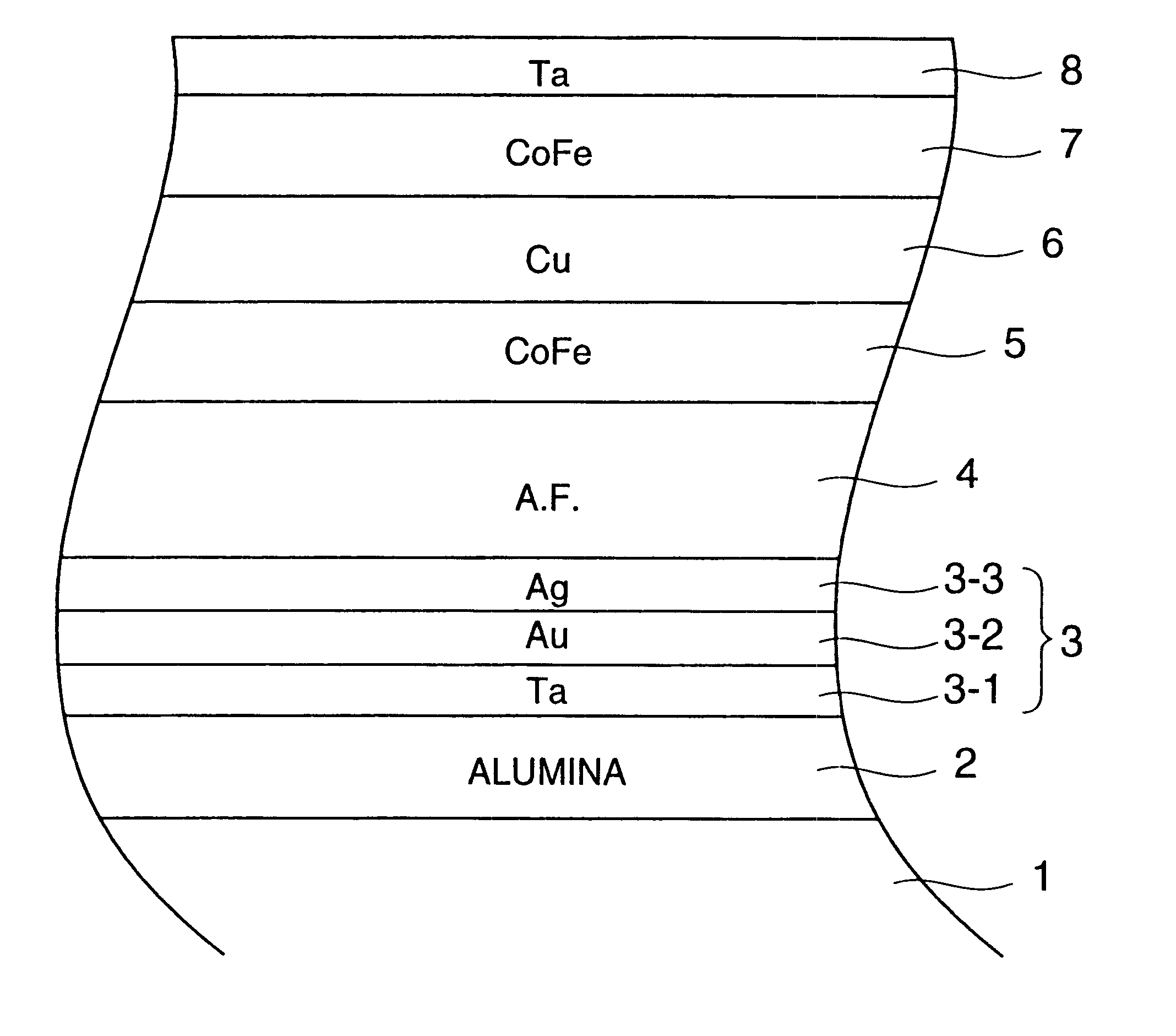

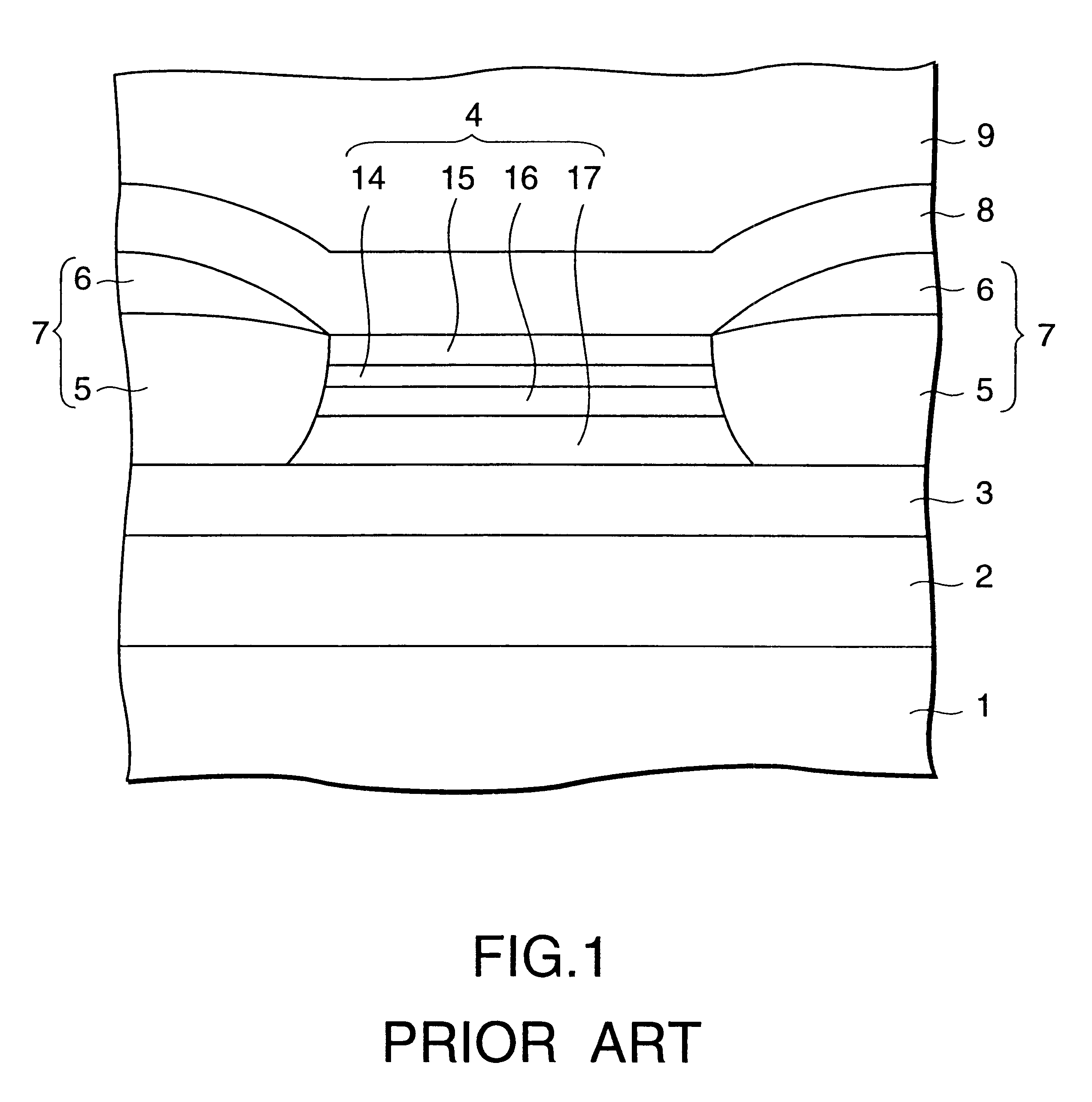

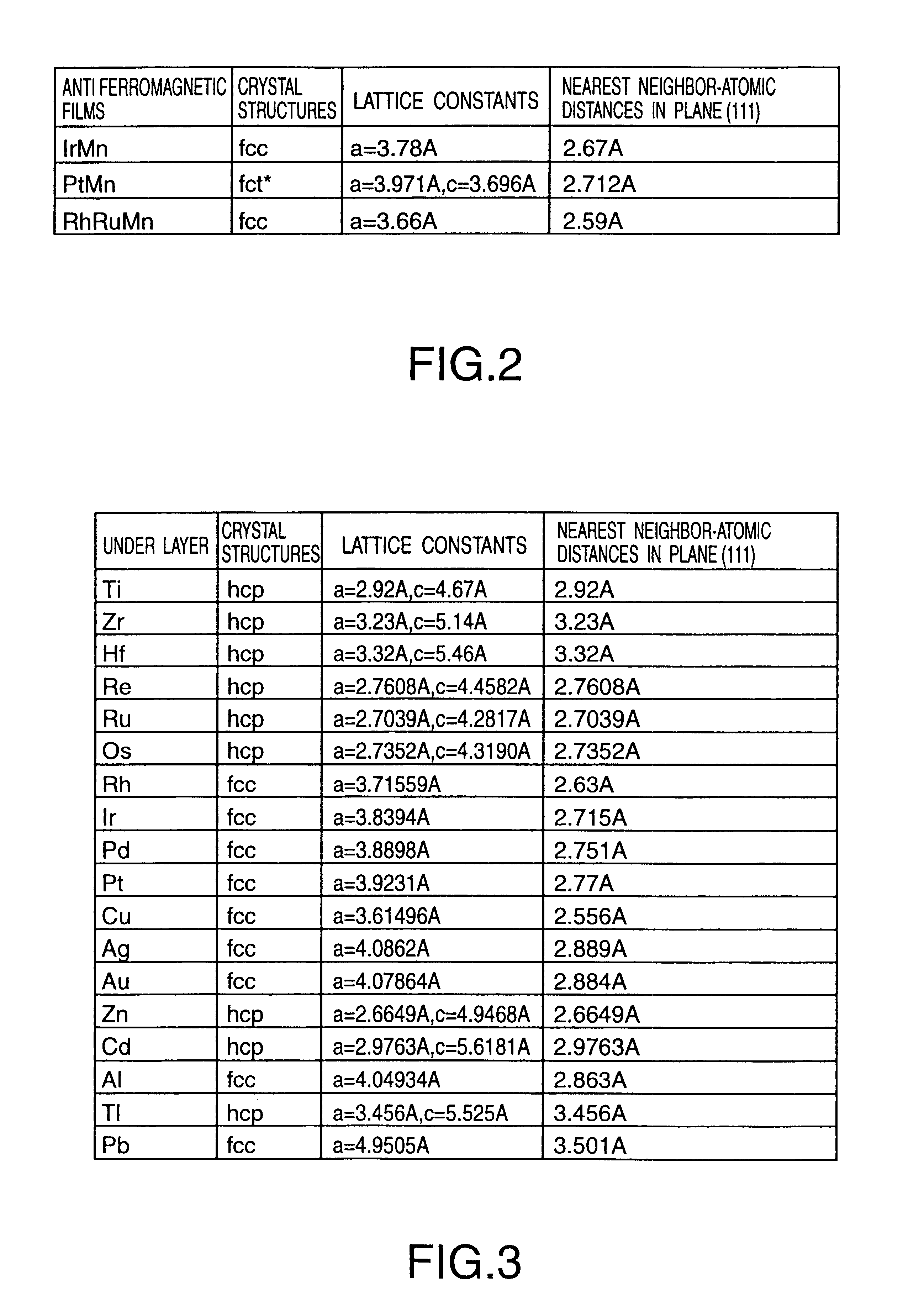

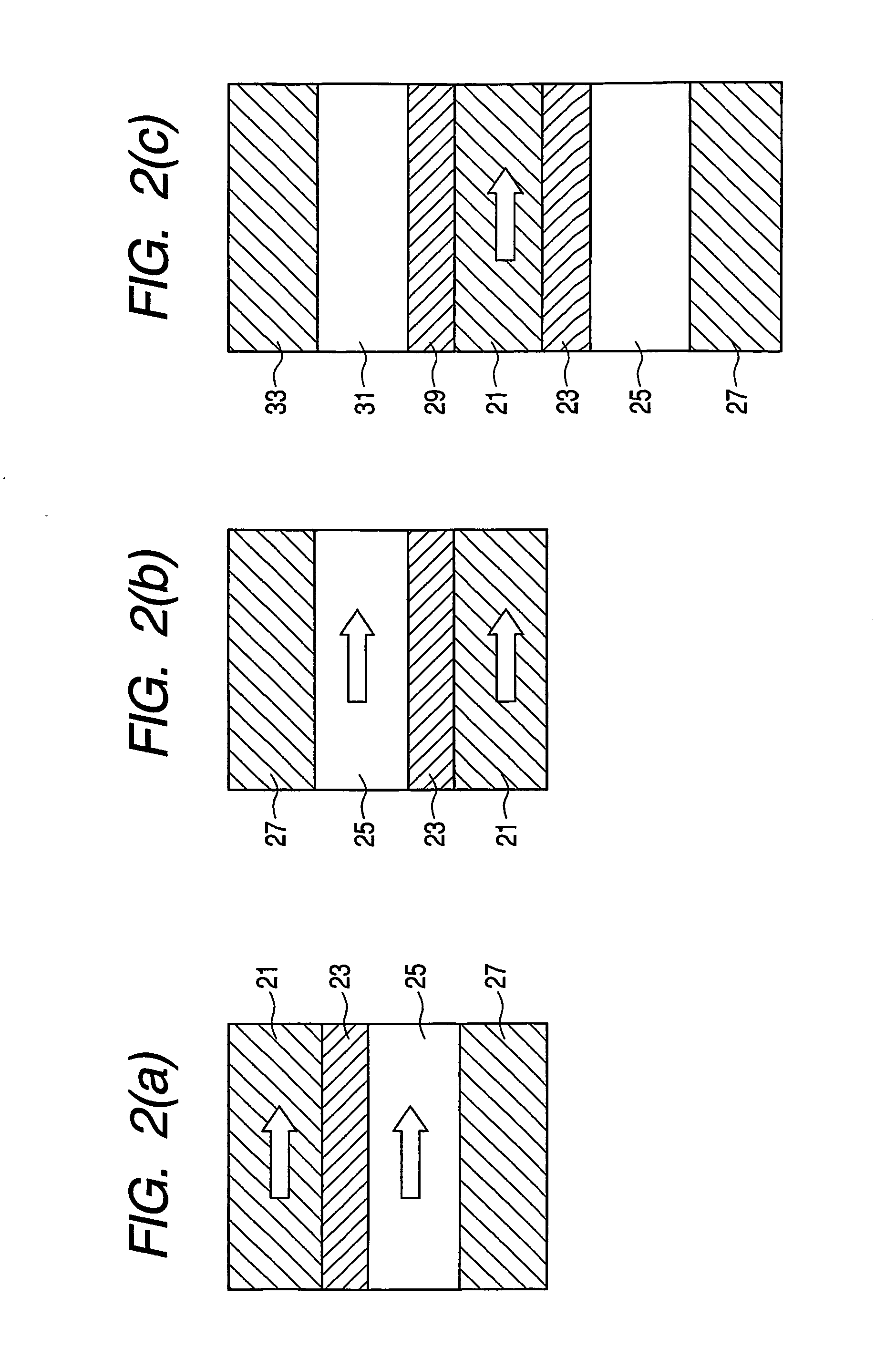

Laminated magnetorestrictive element of an exchange coupling film, an antiferromagnetic film and a ferromagnetic film and a magnetic disk drive using same

InactiveUS6313973B1Stable output voltageRaise the ratioNanomagnetismNanoinformaticsGiant magnetoresistanceCoupling

A magnetoresistive element comprises an exchange coupling film having a under layer, an antiferromagnetic film and a ferromagnetic film, which are laminated in that order, the under layer including a metal having a face centered cubic crystal structure or hexagonal closest packing crystal structure which have a longer nearest neighbor atomic distance than that of the antiferromagnetic film. With this construction, it is possible to improve the exchange coupling field and to satisfy a stable output over a long period of time. A magnetoresistive element having a dual spin valve structure has a magnetization adjusting layer, which is antiferromagnetically connected to a pinned layer via an anti-parallel connection layer, to adjust the value of the product of the saturation magnetization of each of the magnetization adjusting layer and the pinned layer by the thickness thereof. Moreover, a magnetoresistance head use a giant magnetoresistance effect, and has at least one pair of pinned layer and free layer arranged via a non-magnetic spacer layer. The pinned layer has a pair of ferromagnetic layers which have different compositions and different coercive forces and which are antiferromagnetically connected to each other via a connection layer, so that the effective exchange coupling field of the pinned layer is 200 Oe or more.

Owner:KK TOSHIBA

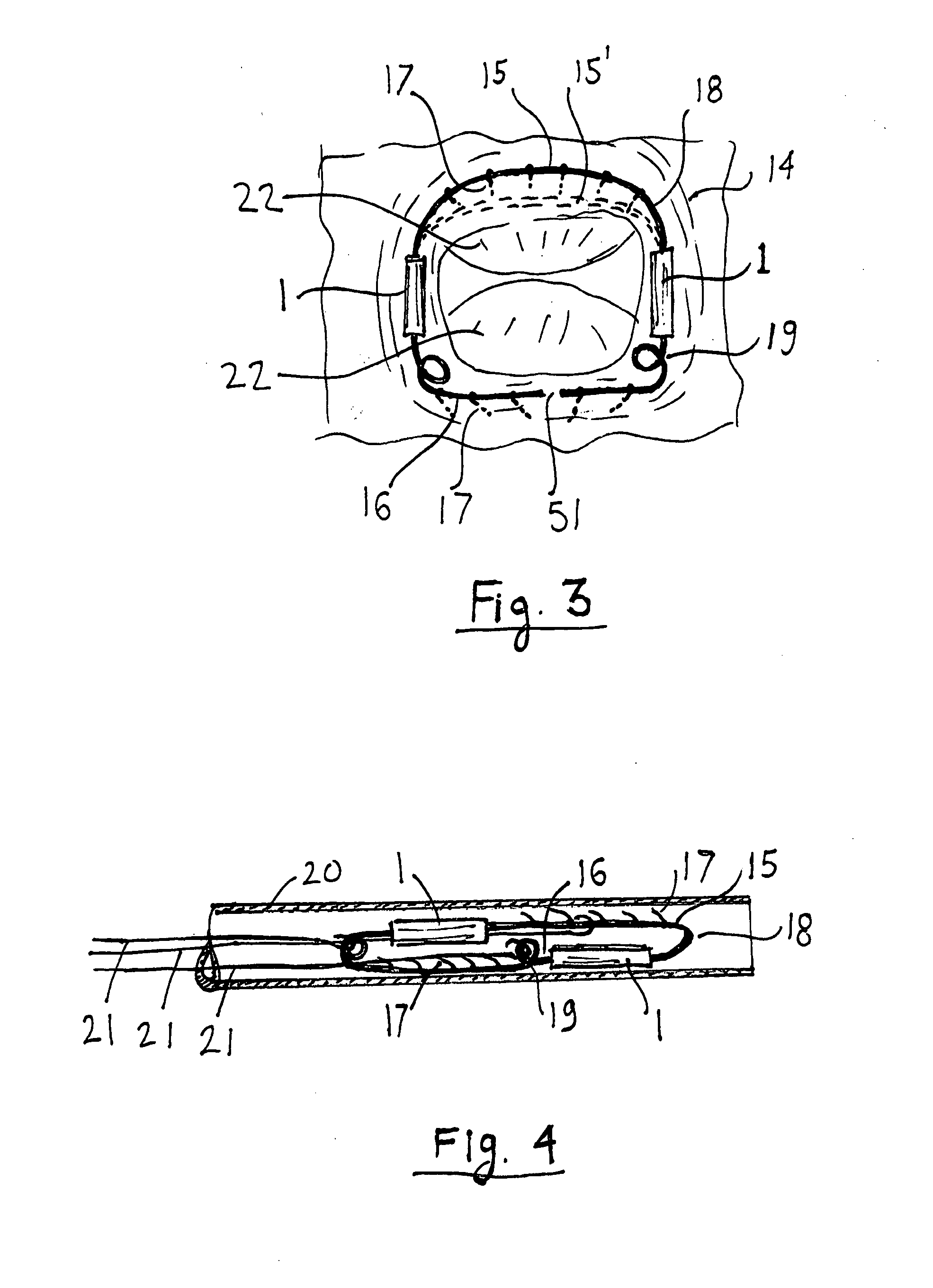

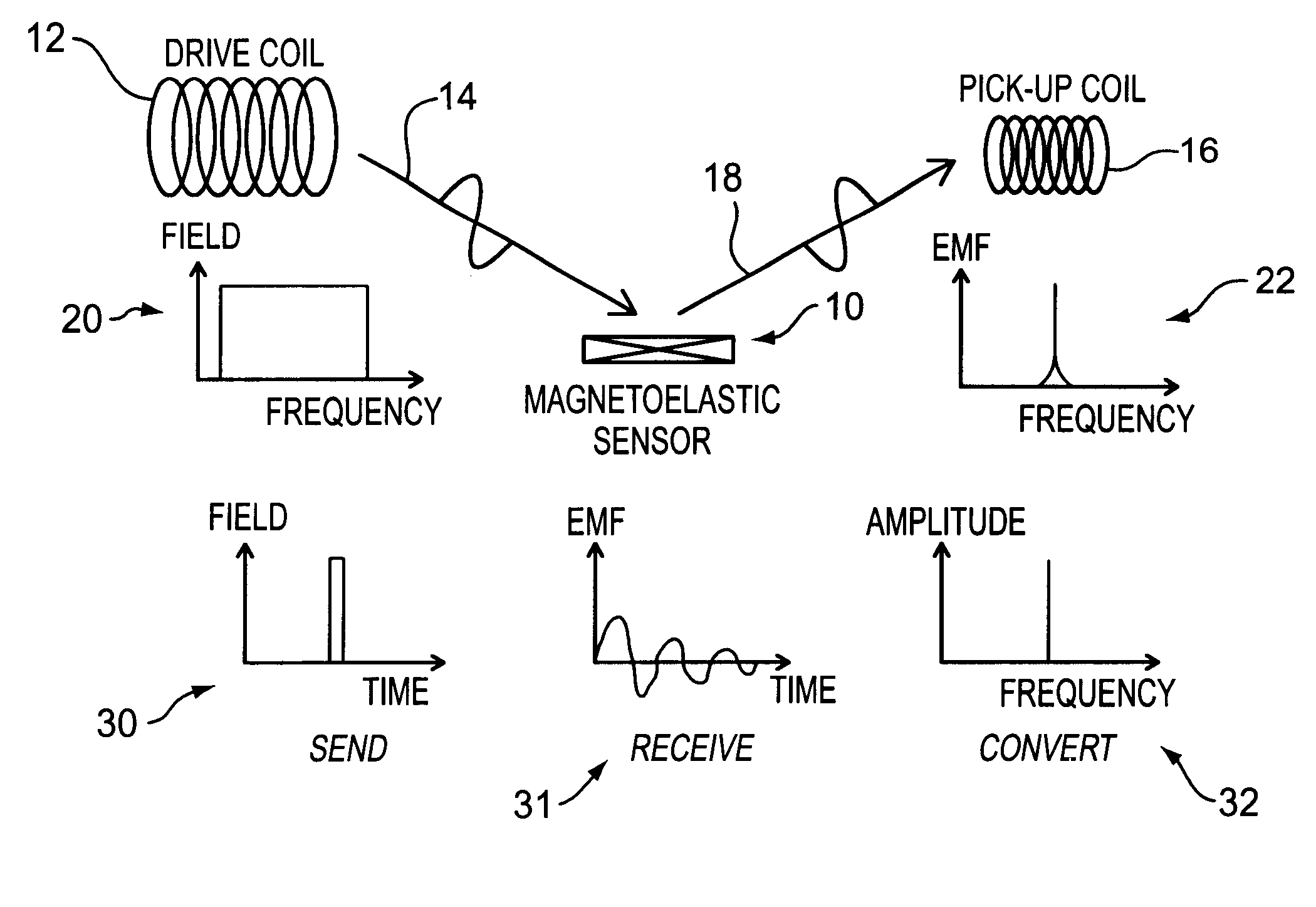

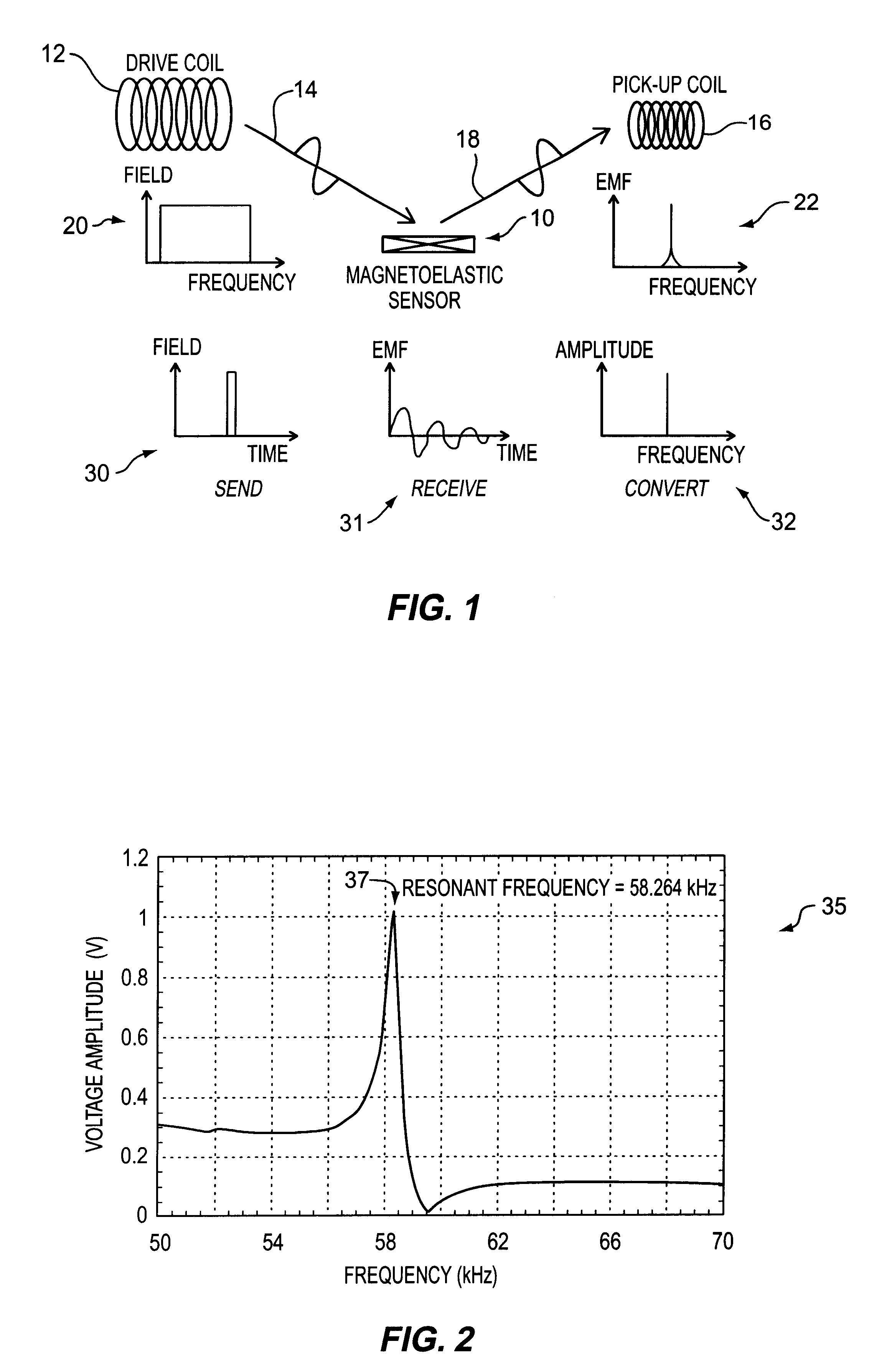

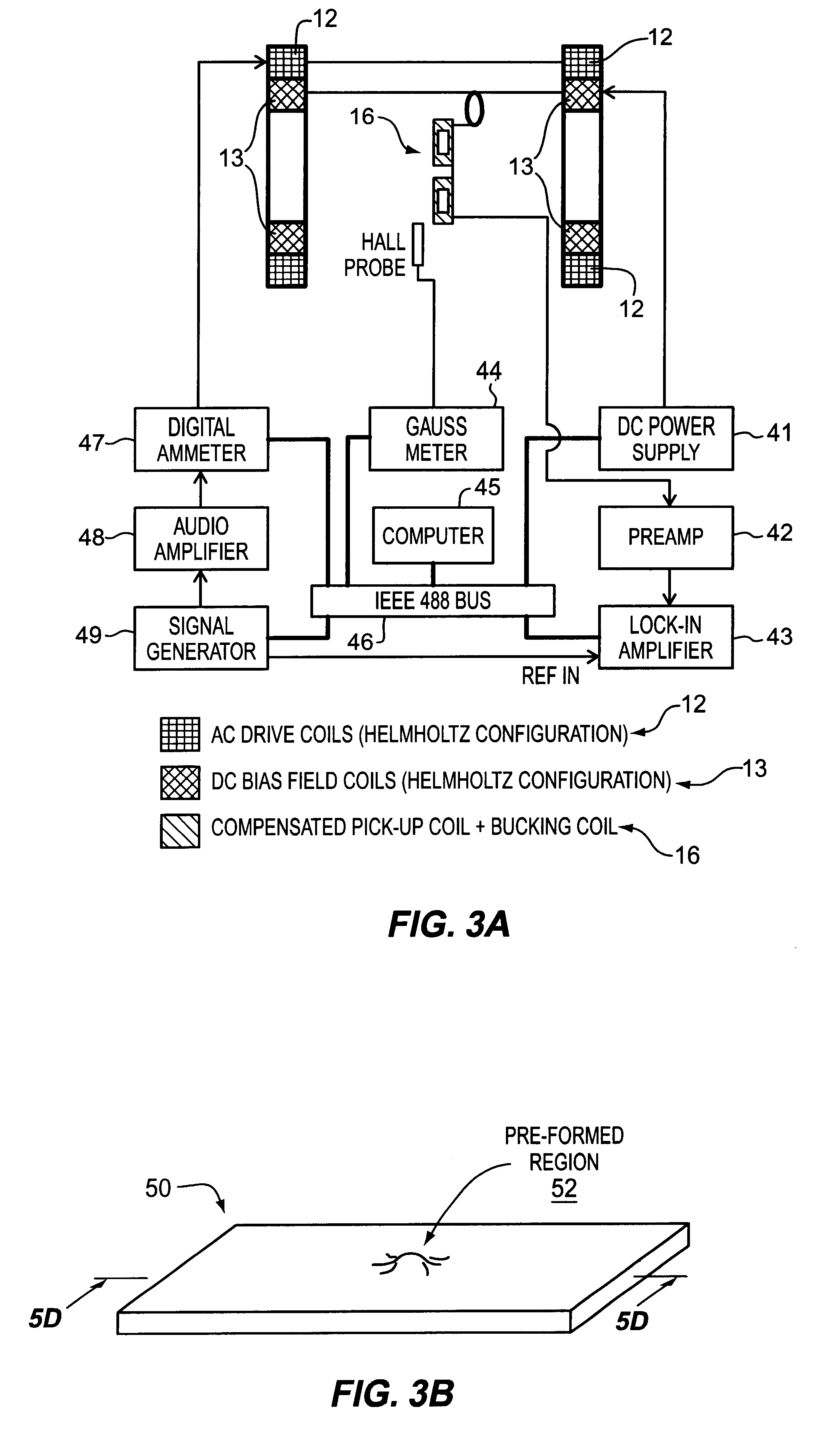

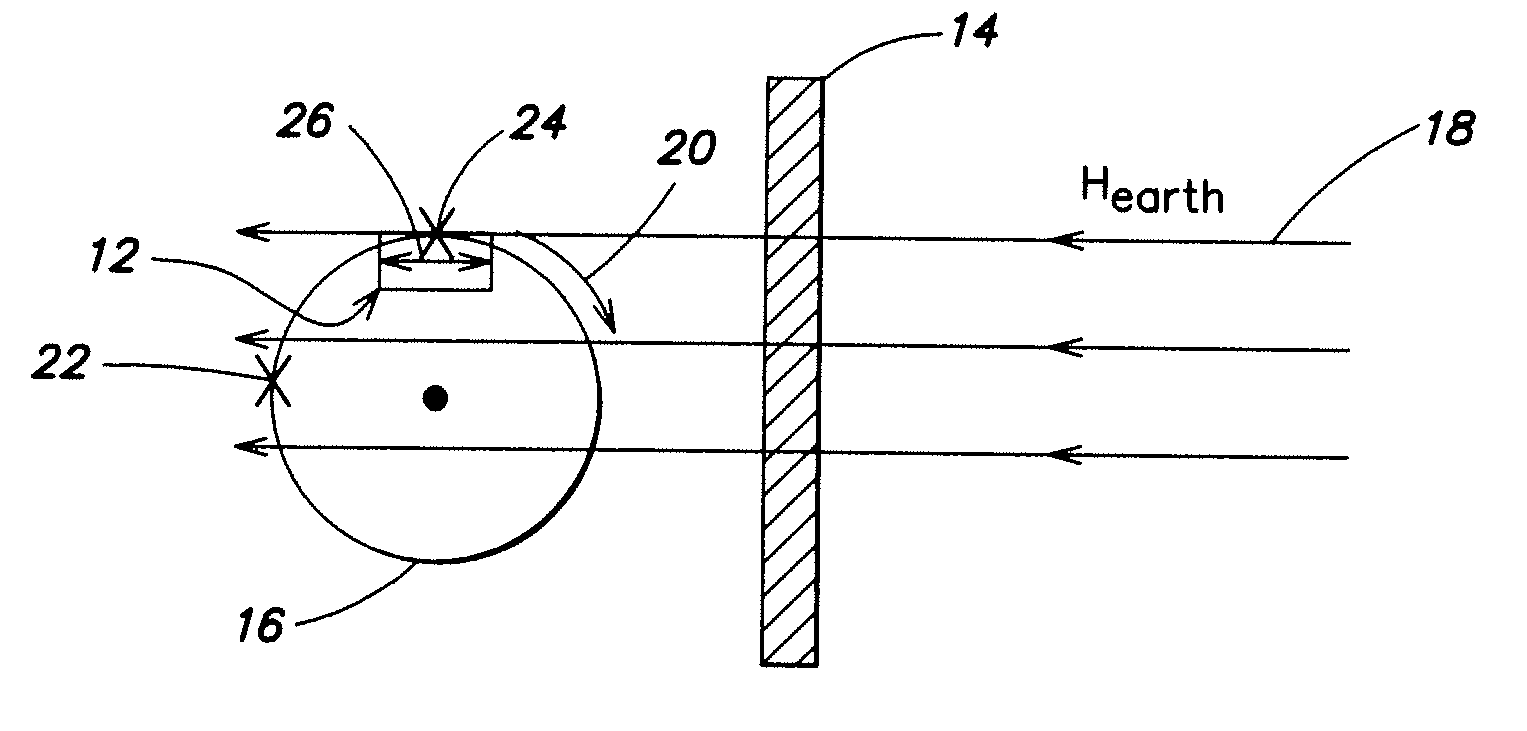

Magnetoelastic sensing apparatus and method for remote pressure query of an environment

InactiveUS6393921B1Fluid pressure measurement using inductance variationFluid pressure measurement using magnet displacementMagneto elasticPressure sense

A pressure sensing apparatus for operative arrangement within an environment, having: a sensor comprising a hermetically-sealed receptacle, at least one side of which has an flexible membrane to which a magnetically hard element is attached. Enclosed within the receptacle is a magnetostrictive element that vibrates in response to a time-varying magnetic field. Also included is a receiver to measure a plurality of successive values for magneto-elastic emission intensity of the sensor taken over an operating range of successive interrogation frequencies to identify a resonant frequency value for the sensor. Additional features include: (a) the magnetically hard element may be adhered to an inner or outer side of, or embedded within, the membrane; (b) the magnetostrictive element can include one or more of a variety of different pre-formed, hardened regions; (c) the magneto-elastic emission may be a primarily acoustic or electromagnetic emission; and (d) in the event the time-varying magnetic field is emitted as a single pulse or series of pulses, the receiver unit can detect a transitory time-response of the emission intensity of each pulse (detected after a threshold amplitude value for the transitory time-response is observed). A Fourier transform of the time-response can yield results in the frequency domain. Also, an associated method of sensing pressure of an environment is included that uses a sensor having a magnetostrictive element to identify a magneto-elastic resonant frequency value therefore. Using the magneto-elastic resonant frequency value identified, a value for the pressure of the environment can be identified.

Owner:UNIV OF KENTUCKY RES FOUND

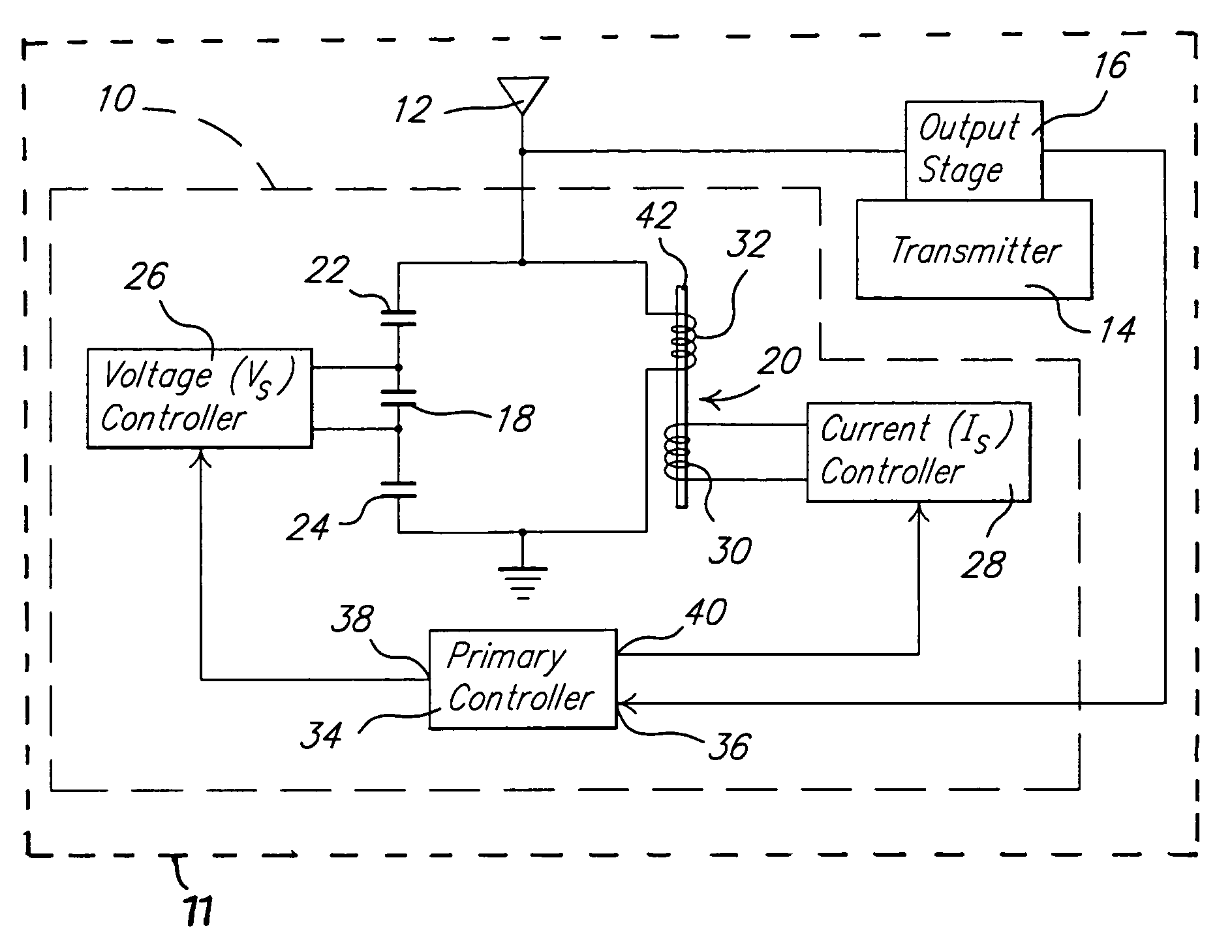

Electrically tuned resonance circuit using piezo and magnetostrictive materials

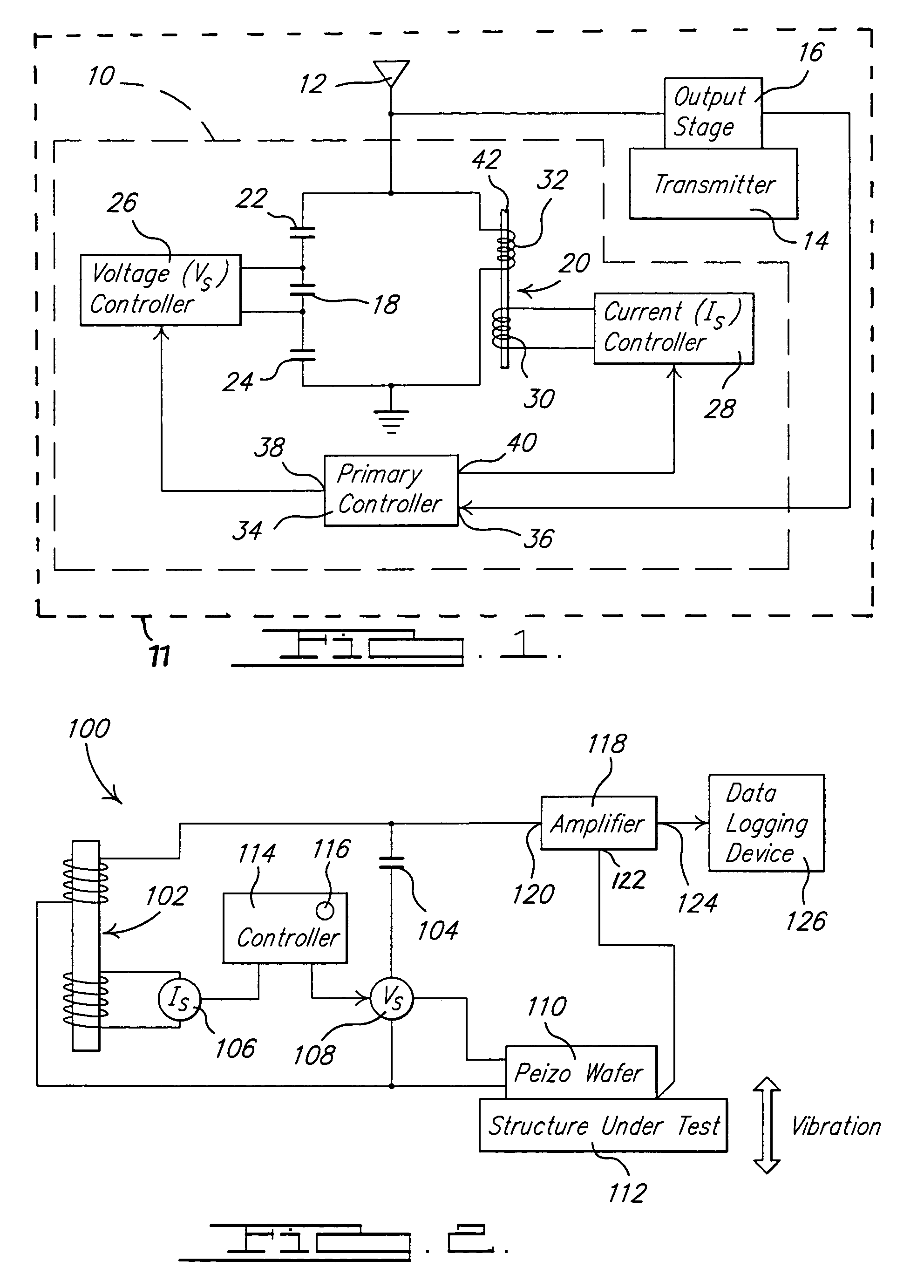

An impedance tuning system, especially for a cellular telephone system. The system can be used to match the impedance of an antenna element with that of an output stage of a transmitter driving the antenna element. The system includes a piezo capacitor in parallel with the magnetostrictive inductor to form an LC circuit. A voltage controller applies a voltage bias signal to the piezo capacitor and a current controller applies a current bias signal to the inductor. A primary controller monitors the frequency of the output signal from the transmitter and controls the voltage and current controllers as needed to alter the impedance of the system as needed to match the impedance of the antenna element with that of the output stage of the transmitter. In an alternative form an ultrasonic sensor is provided.

Owner:THE BOEING CO

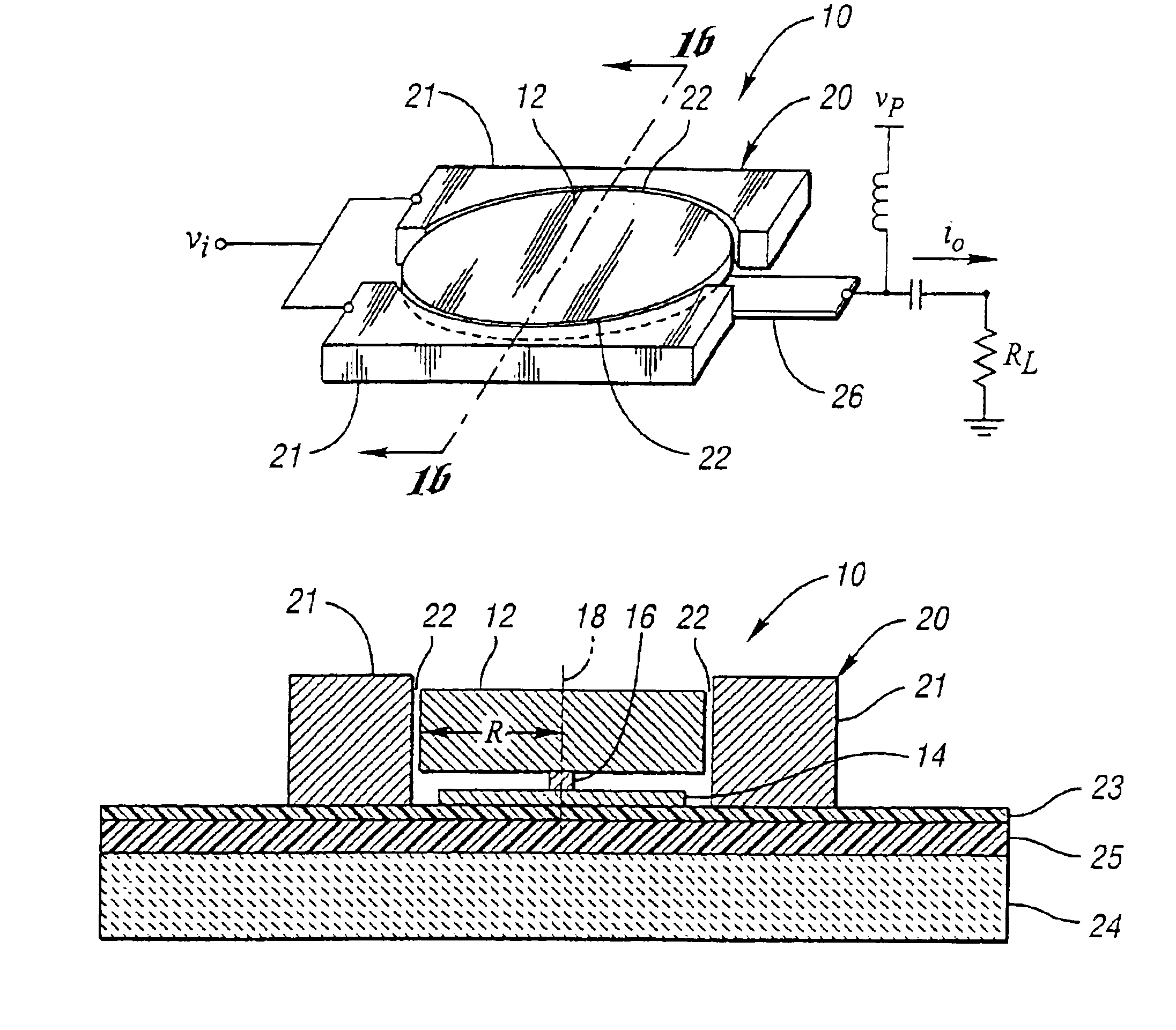

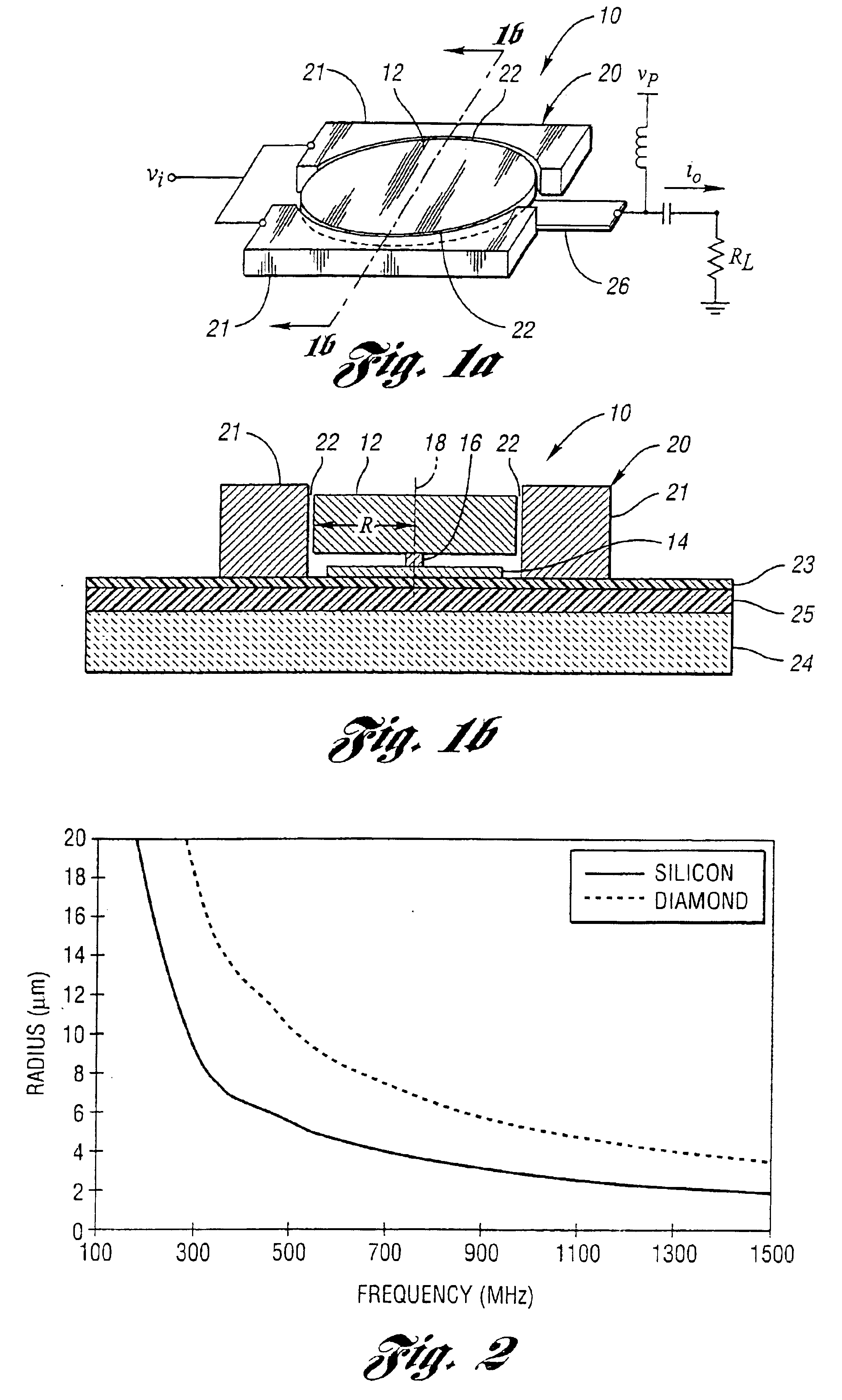

Micromechanical resonator device and micromechanical device utilizing same

InactiveUS6856217B1Improving QHigh Power Handling CapabilityPiezoelectric/electrostriction/magnetostriction machinesImpedence networksWireless transceiverTransceiver

A micromechanical resonator device and a micromechanical device utilizing same are disclosed based upon a radially or laterally vibrating disk structure and capable of vibrating at frequencies well past the GHz range. The center of the disk is a nodal point, so when the disk resonator is supported at its center, anchor dissipation to the substrate is minimized, allowing this design to retain high-Q at high frequency. In addition, this design retains high stiffness at high frequencies and so maximizes dynamic range. Furthermore, the sidewall surface area of this disk resonator is often larger than that attainable in previous flexural-mode resonator designs, allowing this disk design to achieve a smaller series motional resistance than its counterparts when using capacitive (or electrostatic) transduction at a given frequency. Capacitive detection is not required in this design, and piezoelectric, magnetostrictive, etc. detection are also possible. The frequency and dynamic range attainable by this resonator makes it applicable to high-Q RF filtering and oscillator applications in a wide variety of communication systems. Its size also makes it particularly suited for portable, wireless applications, where, if used in large numbers, such a resonator can greatly lower the power consumption, increase robustness, and extend the range of application of high performance wireless transceivers.

Owner:RGT UNIV OF MICHIGAN

Composed free layer for stabilizing magnetoresistive head having low magnetostriction

A magnetoresistive read head includes a spin valve having at least one free layer spaced apart from at least one pinned layer by a spacer. The free layer includes a thin CoFeOx lamination layer in the CoFe, and an optional Cu layer. The amount of oxygen is below 10% of total gas. The pinned layer is a single layer, or a synthetic multi-layered structure having a spacer between sub-layers, and may have the foregoing low-magnetostriction material. As a result, low magnetostriction is obtained to improve read quality and / or improve the pinned field of the pinned layer. Other parameters are not adversely affected.

Owner:TDK CORPARATION

Amorphous and nanocrystalline glass-covered wires

InactiveUS6270591B2Prevent oxidationAvoid fragmentationInorganic material magnetismYarnGlass coverMetalloid

The invention refers to amorphous and nanocrystalline magnetic glass-covered wires. The wires consist of a metallic amorphous or nanocrystalline core with diameters by the order of 10-6 m, having compositions based on transition metal-metalloids and other additional metals and a glass cover, having a thickness of the wall by the same order of magnitude. The wires present high or medium saturation inducation, positive, negative or nearly zero magnetostriction and values of the coercive field and of the magnetic permeability in function of the requested applications in a field of electronics and electrotechnics to achieve sensors, transducers, inductive coils, trnasformers, magnetic shields, devices working on the basis of the correlation between the magnetic properties of the metallic core and the optical properties of the glass cover.

Owner:INSTL DE FIZICA TEHNICA IASI

Method of adjusting CoFe free layer magnetostriction

InactiveUS6998150B2Low constantLow coercivityNanostructure applicationNanomagnetismCopperOXYGEN EXPOSURE

It has been found that the insertion of a copper laminate within CoFe, or a CoFe / NiFe composite, leads to higher values of CPP GMR and DRA. However, this type of structure exhibits very negative magnetostriction, in the range of high −10−6 to −10−5. This problem has been overcome by giving the copper laminates an oxygen exposure treatment When this is done, the free layer is found to have a very low positive magnetostriction constant. Additionally, the value of the magnetostriction constant can be adjusted by varying the thickness of the free layer and / or the position and number of the oxygen treated copper laminates.

Owner:HEADWAY TECH INC

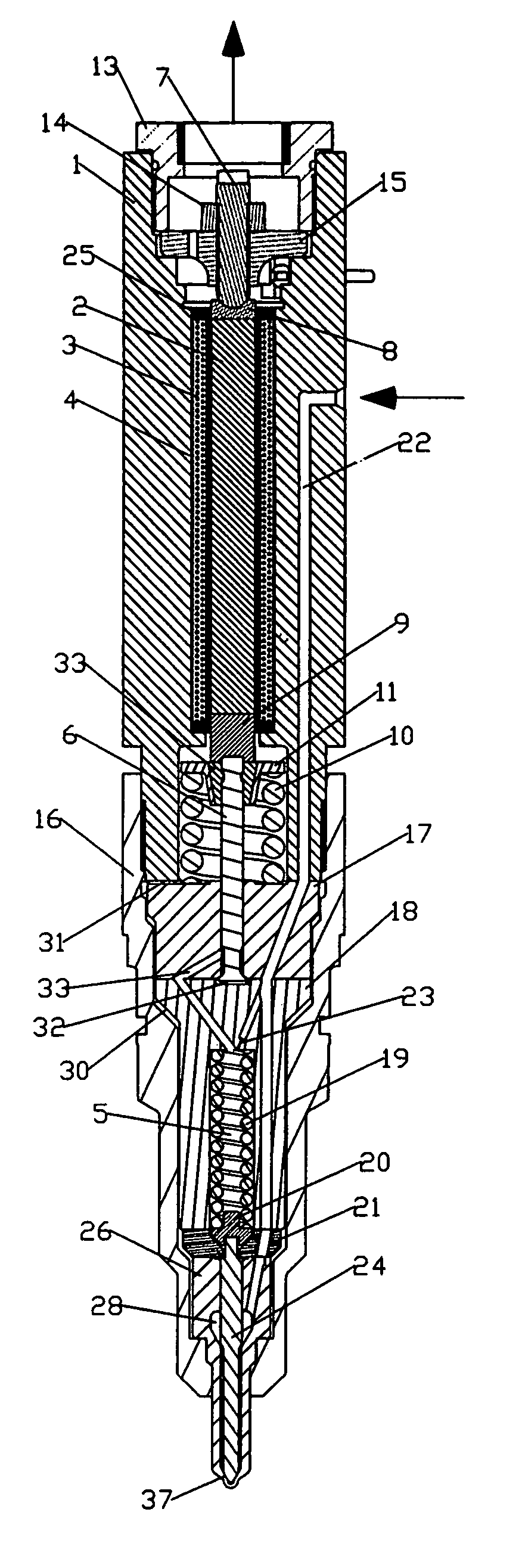

Very high speed rate shaping fuel injector

ActiveUS7255290B2Simple processMinimize formationOperating means/releasing devices for valvesPiezoelectric/electrostriction/magnetostriction machinesParticulatesCombustion chamber

Owner:QUANTUM CONTROL WORKS L C

Differential spin valve sensor having both pinned and self-pinned structures

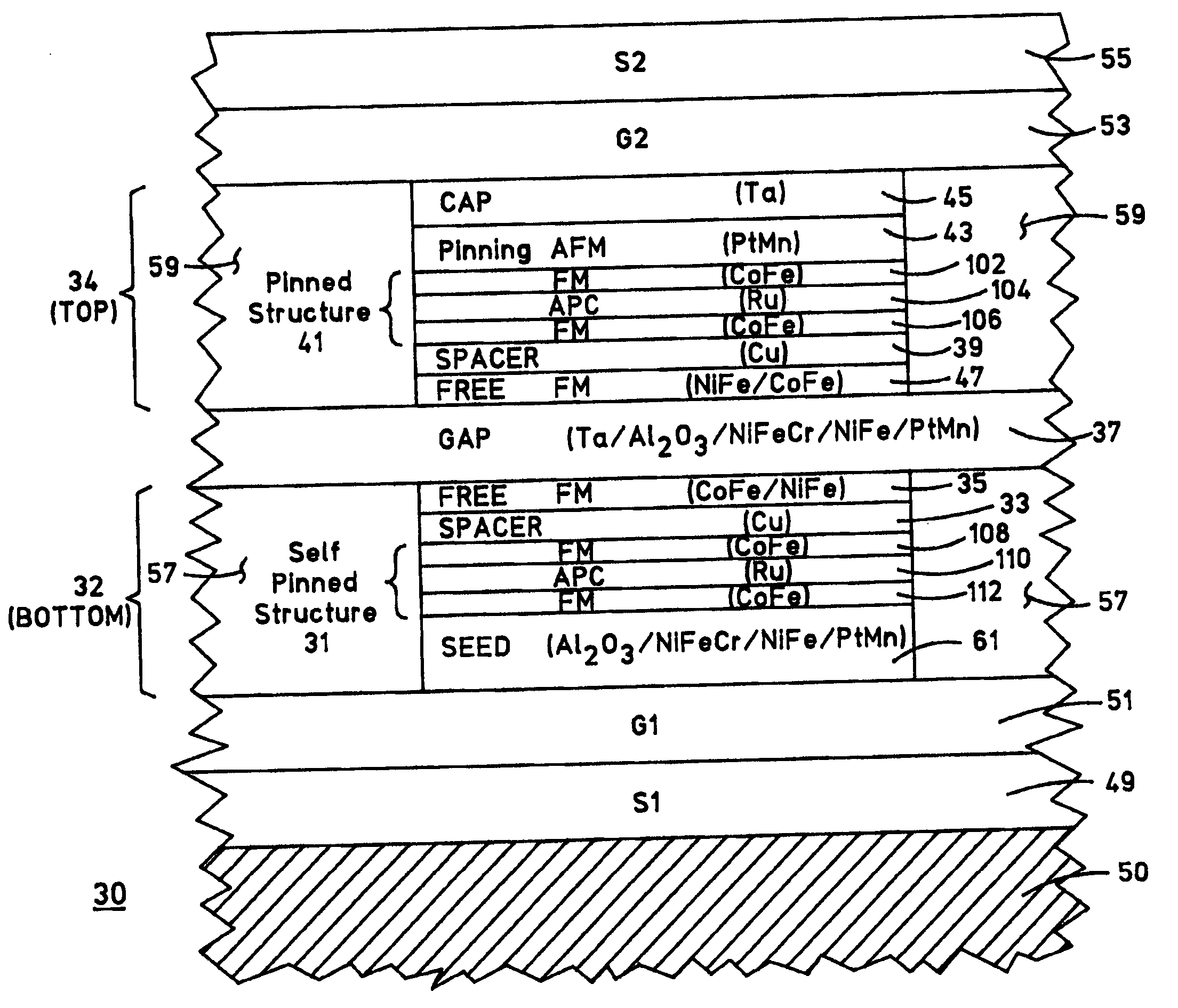

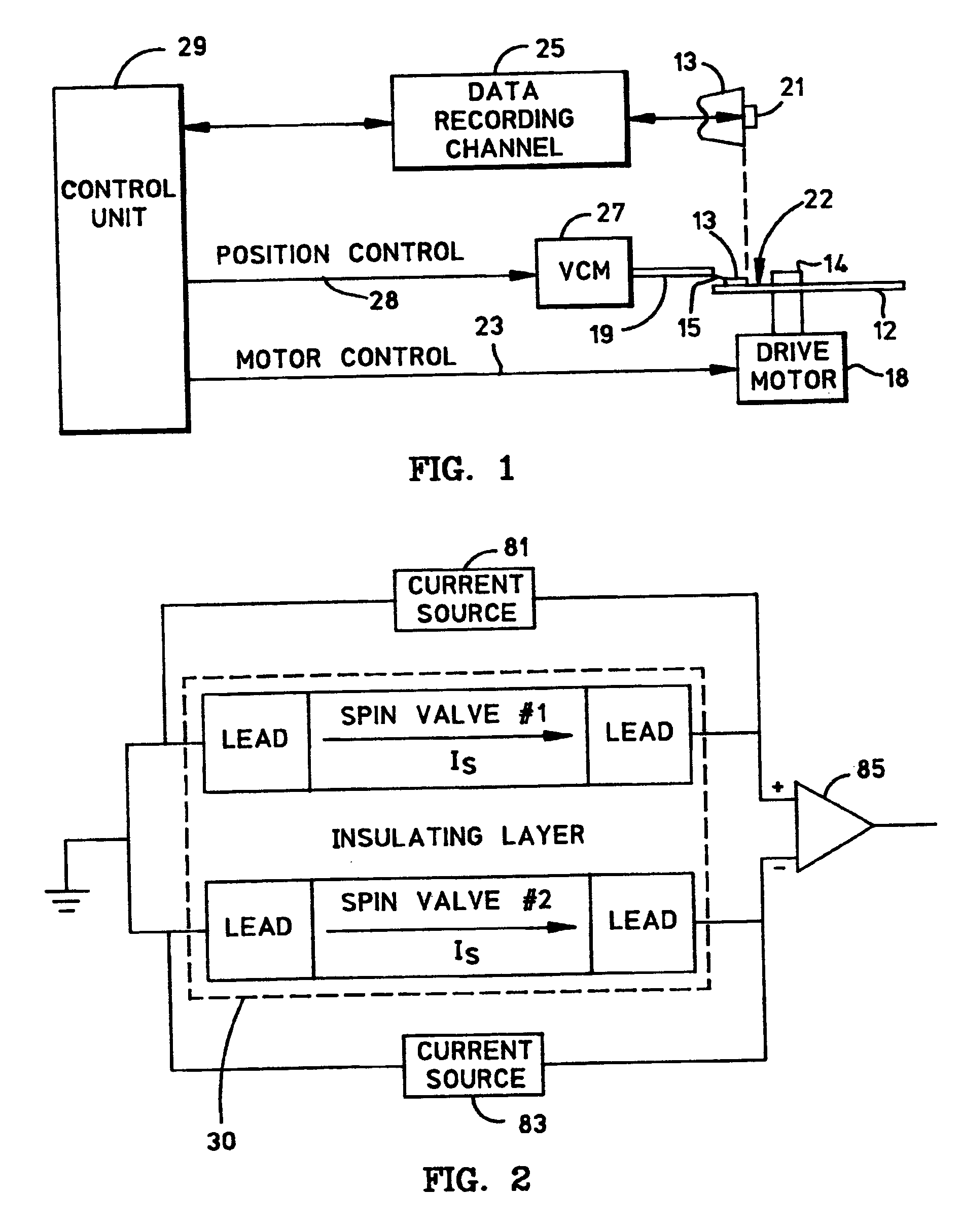

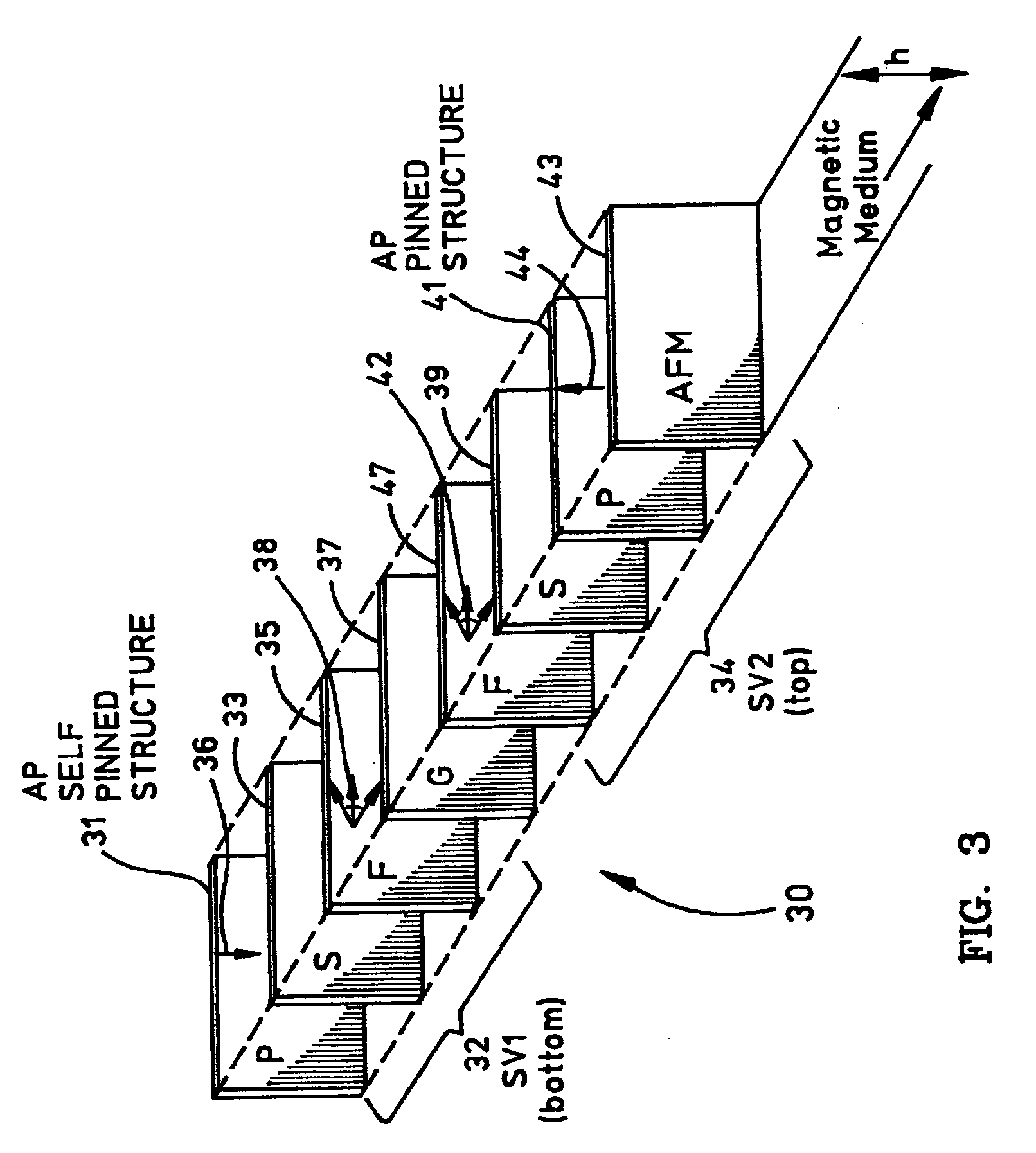

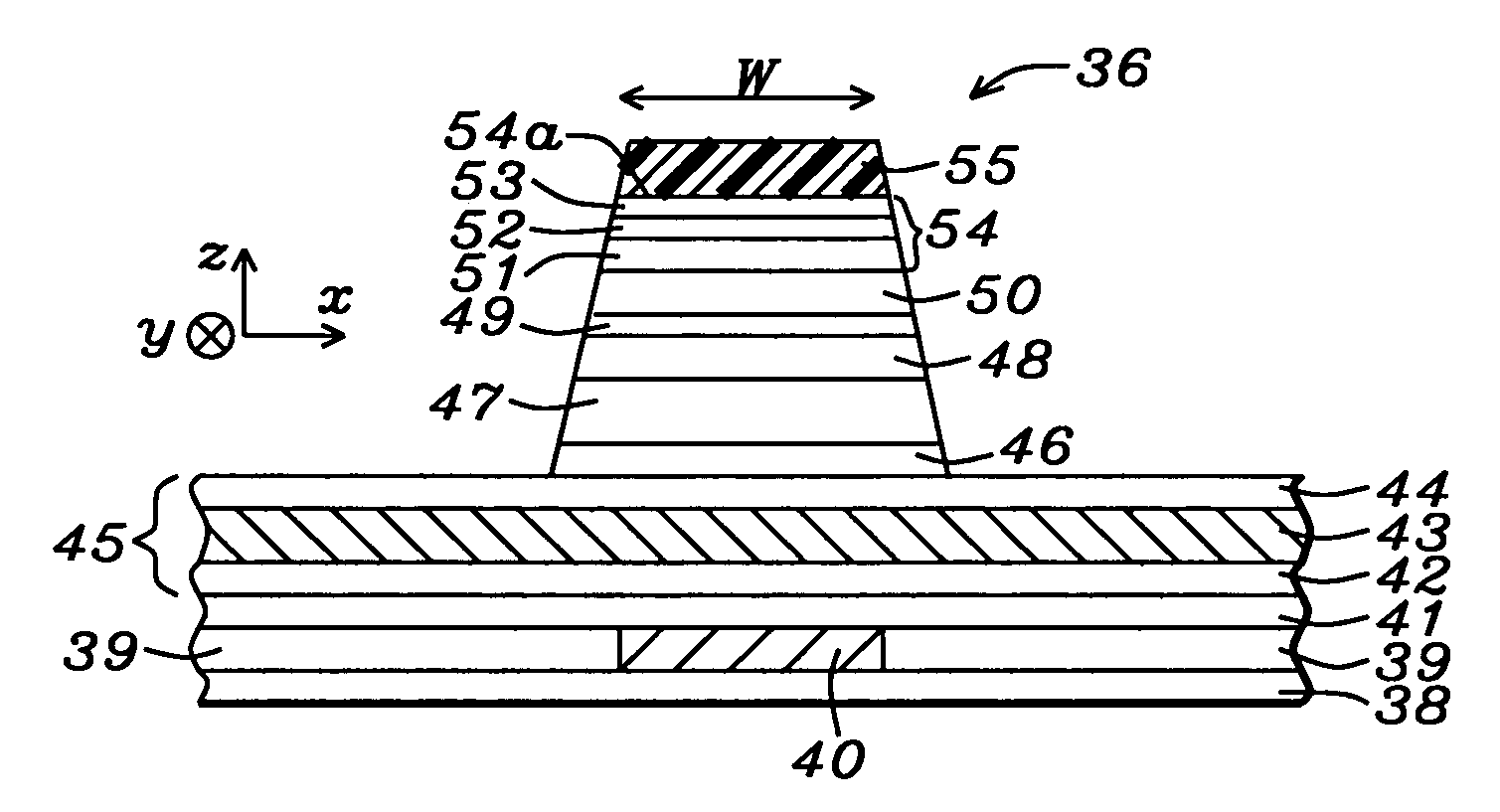

InactiveUS20050068684A1Common mode noiseHigh resolutionRecord information storageManufacture of flux-sensitive headsElectrical polaritySpin valve

A dual / differential spin valve sensor of a magnetic head includes a first spin valve having an antiparallel (AP) “pinned” layer structure and a second spin valve having an AP “self-pinned” layer structure. The AP pinned layer structure has a magnetization direction which is fixed by an adjacent antiferromagnetic (AFM) layer, whereas the AP self-pinned layer structure has a magnetization direction which is fixed by magnetostriction as well as air bearing surface (ABS) stress. The magnetization direction of the AP pinned layer structure is fixed in a direction antiparallel to the magnetization direction of the AP self-pinned layer structure. The dual / differential spin valve sensor may be configured to have either a top AP pinned layer structure and a bottom AP self-pinned layer structure, or a top AP self-pinned layer structure and a bottom AP pinned layer structure. Advantageously, the dual / differential spin valve sensor is relatively thin and overcomes the difficulties of the AFM polarity setting process when two AP pinned layer structures are utilized.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

Capping layer for a magnetic tunnel junction device to enhance dR/R and a method of making the same

An MTJ in an MRAM array or TMR read head is disclosed in which a low magnetization capping layer is a composite having a NiFeHf inner layer formed on a NiFe or CoFeB / NiFe free layer, a Ta middle layer, and a Ru outer layer on the Ta layer. For example, a low magnetization NiFeHf layer is achieved by co-sputtering NiFe and Hf targets with a forward power of 400 W and 200 W, respectively. A higher Hf content increases the oxygen gettering power of the NiFeHf layer and the thickness is modified to change dR / R, RA, and magnetostriction values. A so-called dead layer between the free layer and capping layer is restored by incorporating a NiFeHf layer on the free layer to improve lattice matching. The Fe content in the NiFe target used to make the NiFeHf layer is preferably the same as in the NiFe free layer.

Owner:TAIWAN SEMICON MFG CO LTD

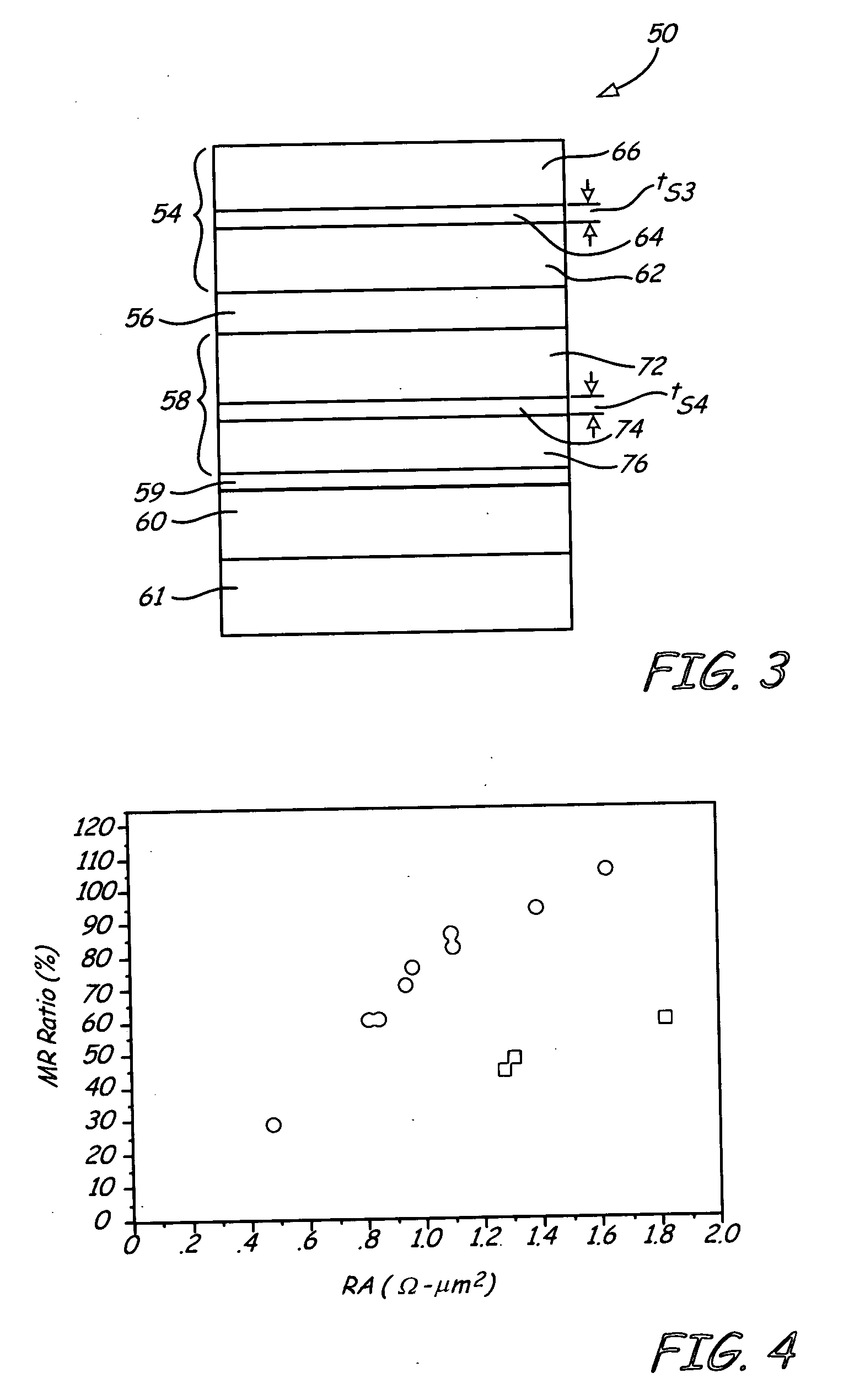

Magnetic sensing device including a sense enhancing layer

A magnetic sensor includes a sensor stack having a first magnetic portion, a second magnetic portion, and a barrier layer between the first magnetic portion and the second magnetic portion. At least one of the first magnetic portion and the second magnetic portion includes a multilayer structure having a first magnetic layer having a positive magnetostriction adjacent to the barrier layer, a second magnetic layer, and an intermediate layer between the first magnetic layer and the second magnetic layer. The magnetic sensor has an MR ratio of at least about 80% when the magnetic sensor has a resistance-area (RA) product of about 1.0 Ω·μm2.

Owner:SEAGATE TECH LLC

TMR device with low magnetostriction free layer

InactiveUS20090122450A1Increasing TMR ratioRaise the ratioNanomagnetismNanoinformaticsSputteringMagnetostriction

Owner:HEADWAY TECH INC

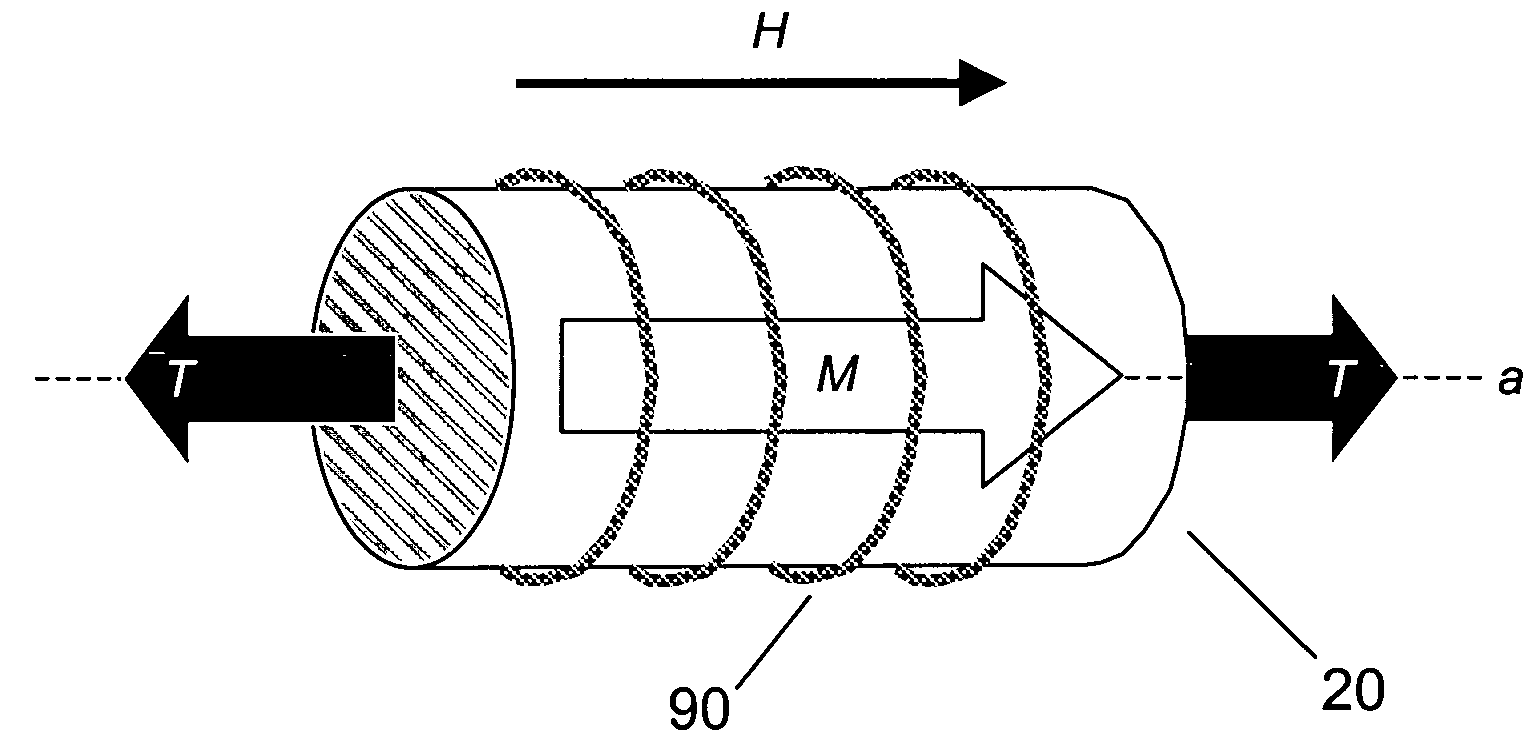

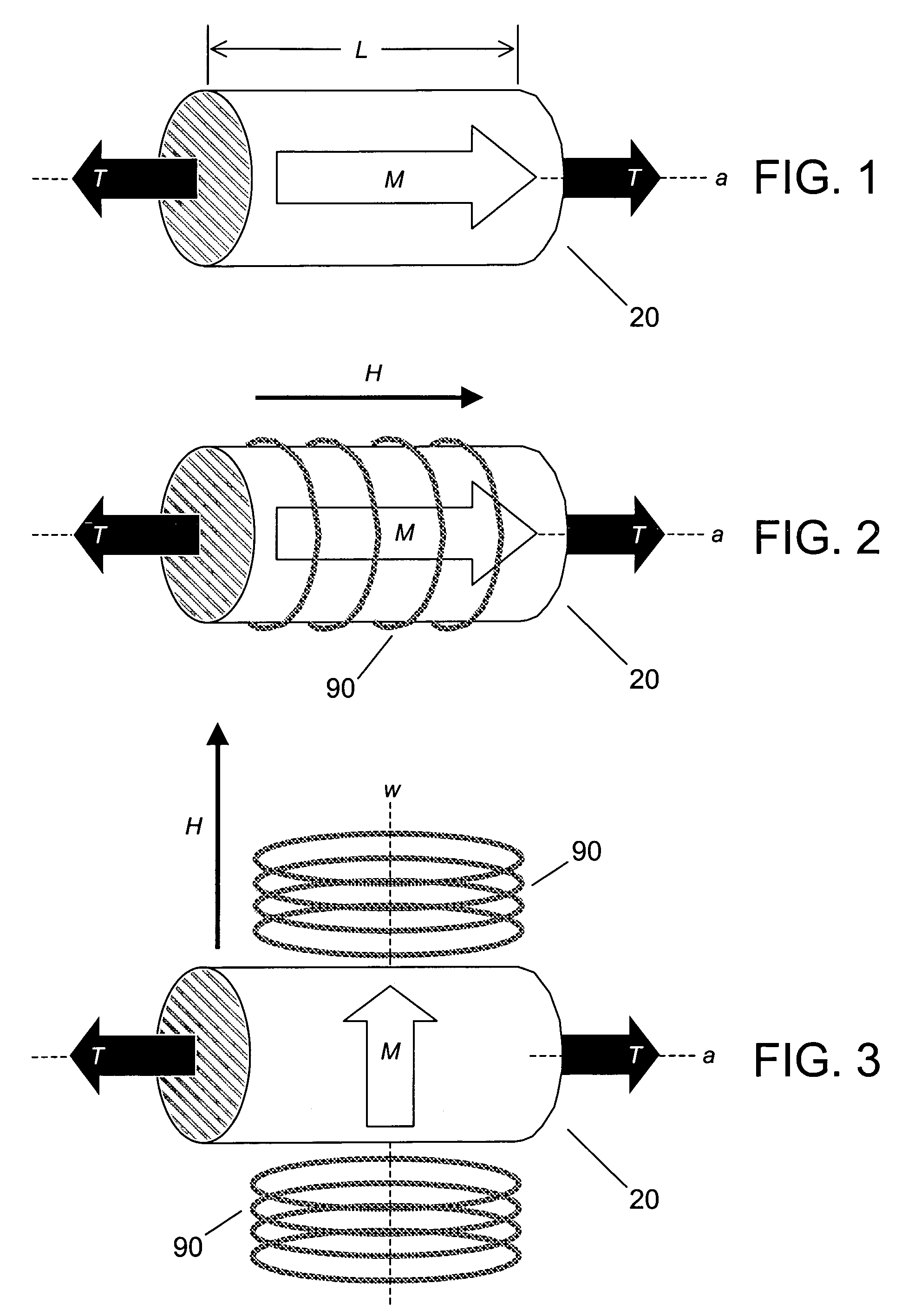

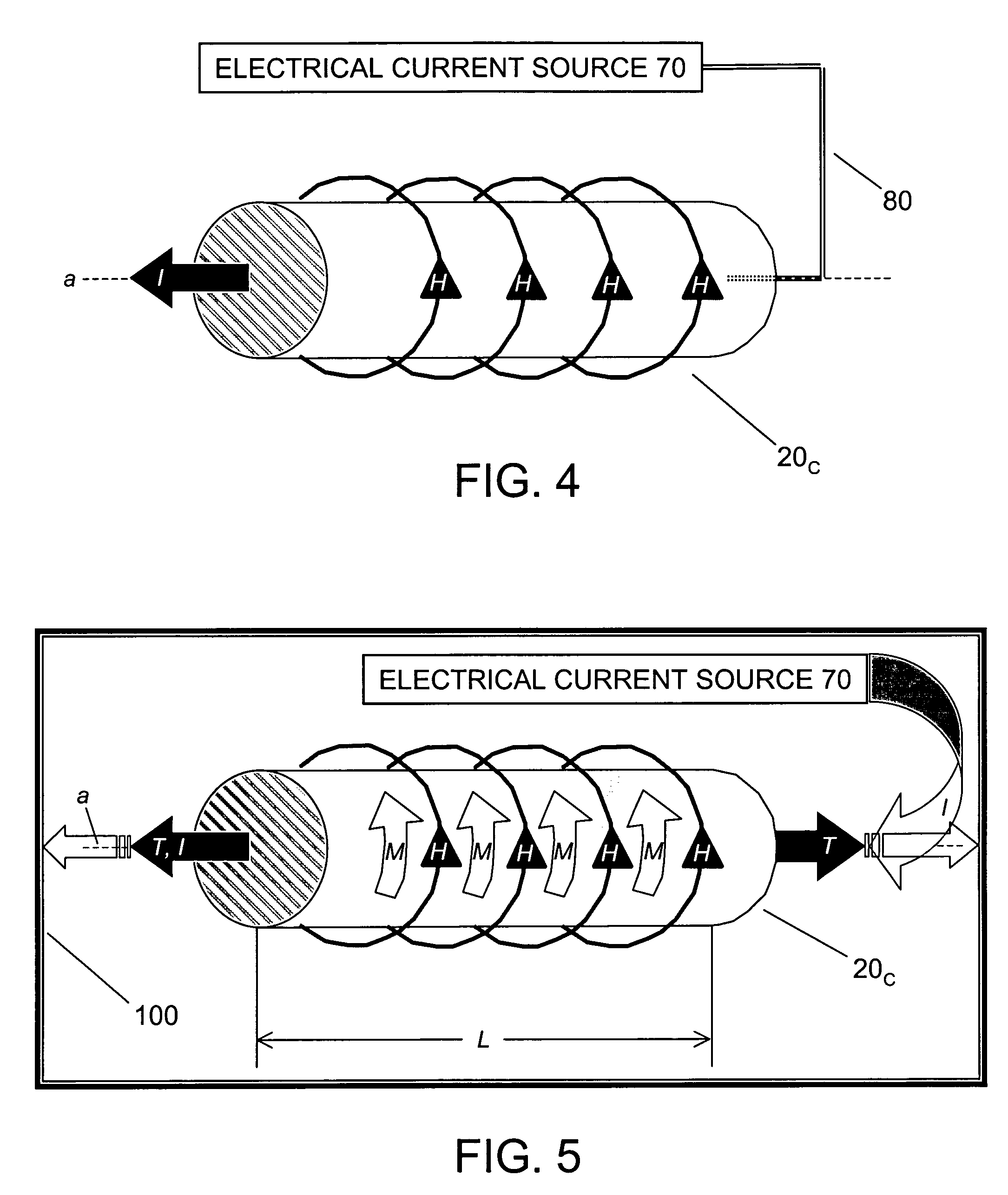

High magnetostriction of positive magnetostrictive materials under tensile load

InactiveUS7564152B1Magnetostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesElectrical conductorMagnetization

An elongate structure having a magnetostrictive material composition is subjected to tensile stress in the longitudinal-axial direction, thereby generally orienting the magnetization of the elongate structure in the longitudinal-axial direction. Electrical current is conducted through the elongate structure and / or through at least one adjacent elongate conductor, thereby generally orienting the magnetization of the elongate structure in the transverse direction, generally in parallel with the transverse direction of the magnetic field concomitant the conduction of current through the elongate structure. The elongate structure magnetostrictively contracts due to the (generally 90°) repositioning of the magnetization of the elongate structure. Examples of inventive configurational variants include: (i) an elongate structure itself conducting current; (ii) a hollow elongate structure accommodating placement therethrough of at least one elongate conductor; (iii) an elongate structure flanked by a pair of elongate conductors conducting current in opposite directions; (iv) plural elongate structures bordering a centralized elongate conductor.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

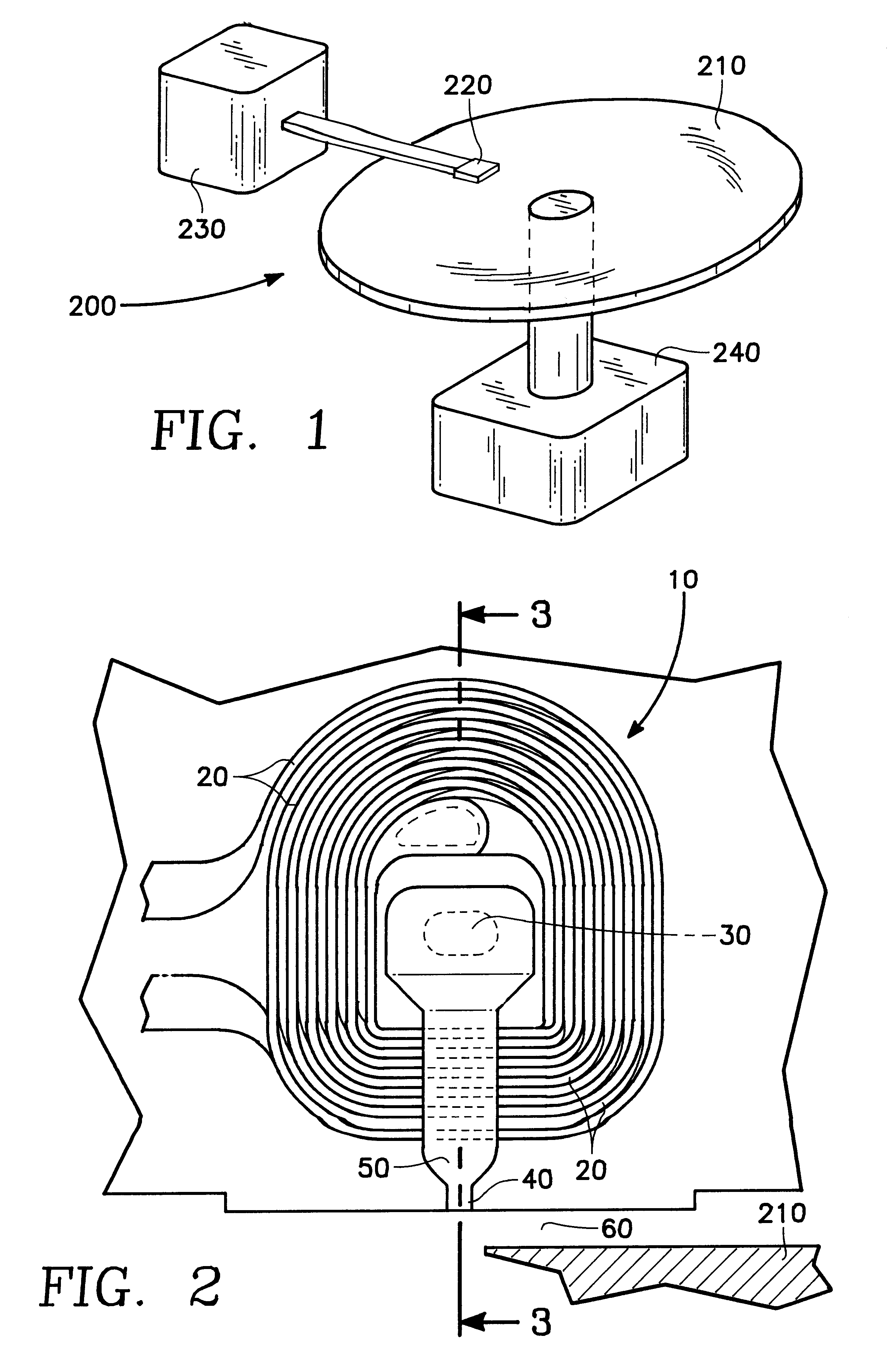

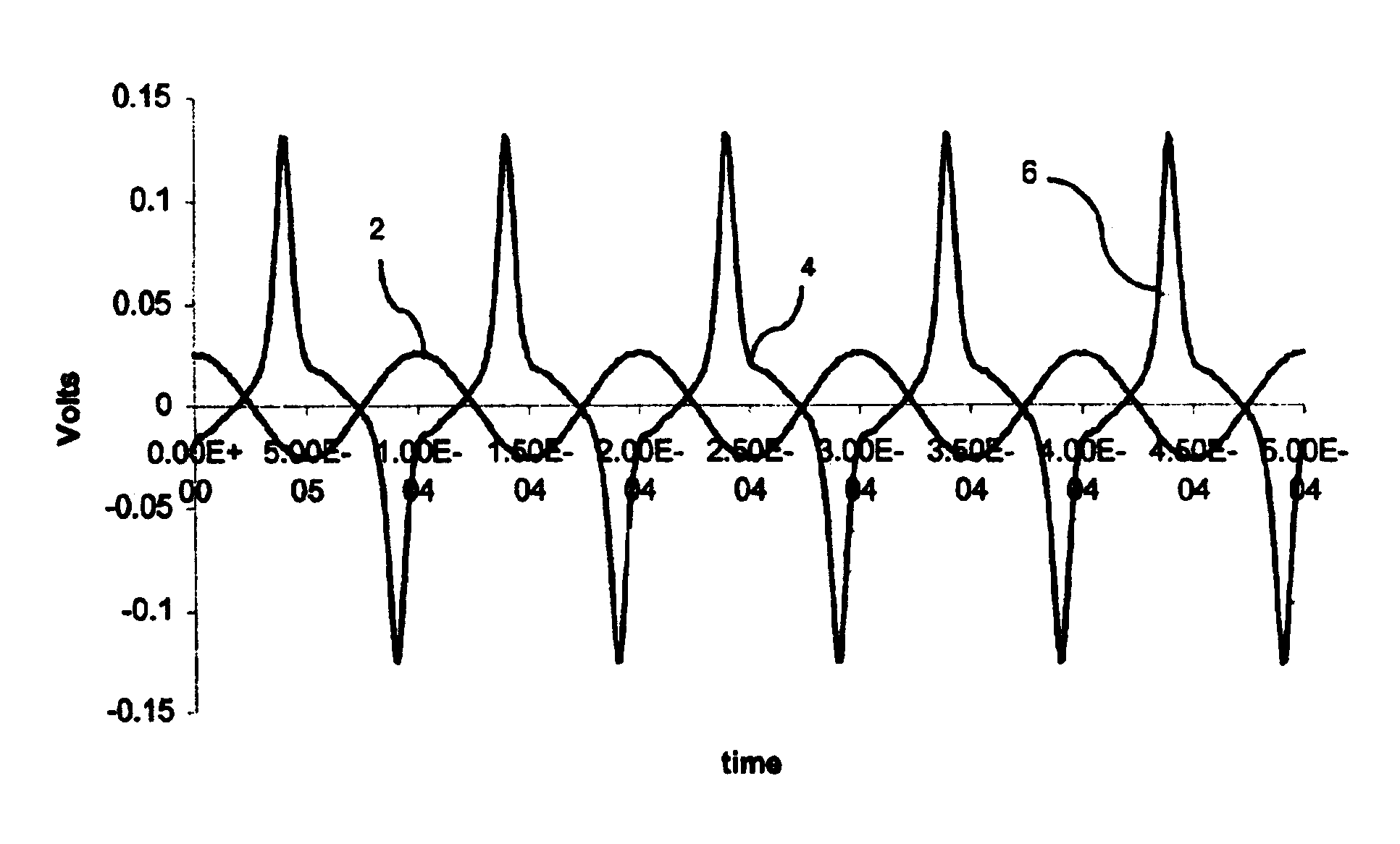

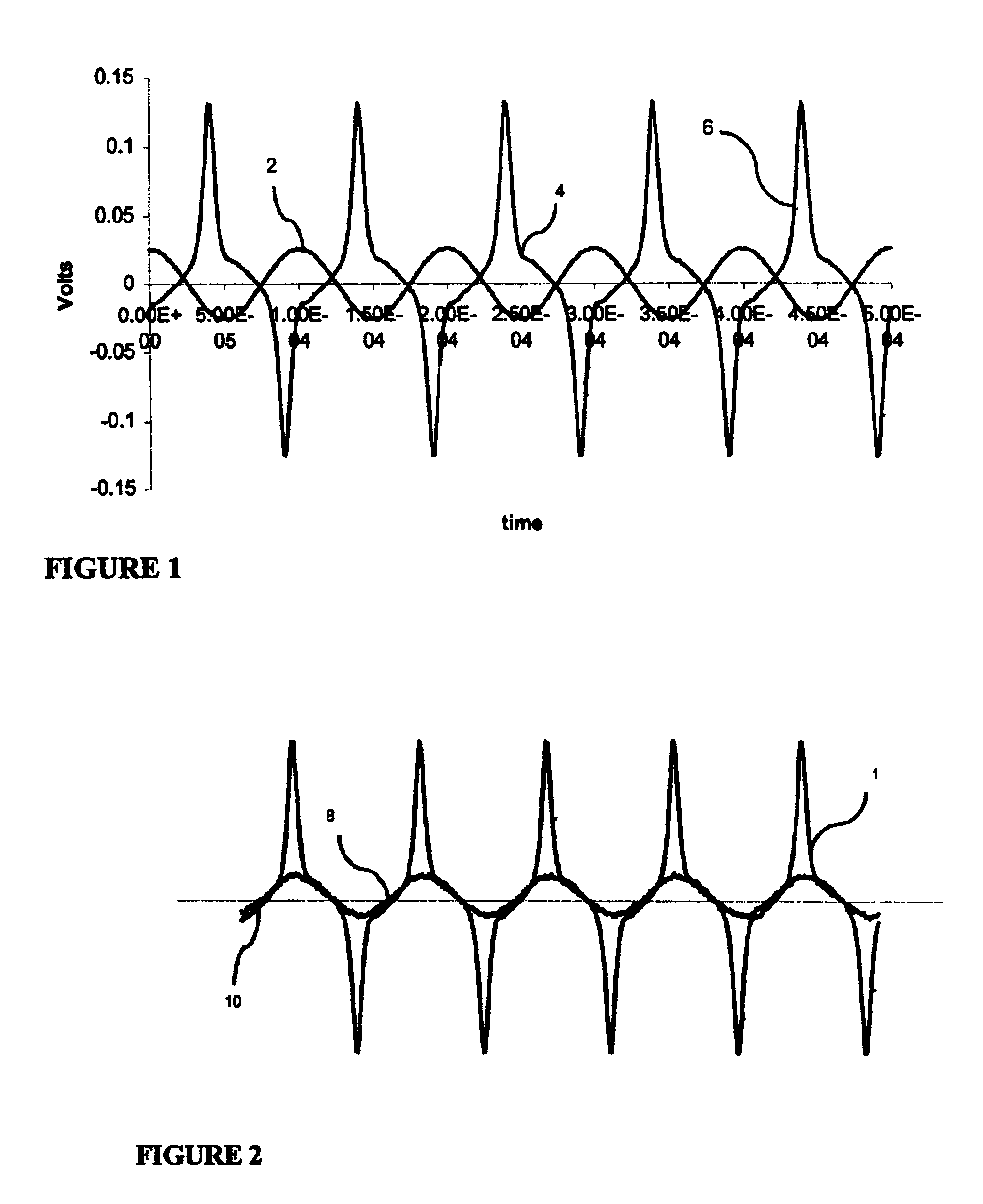

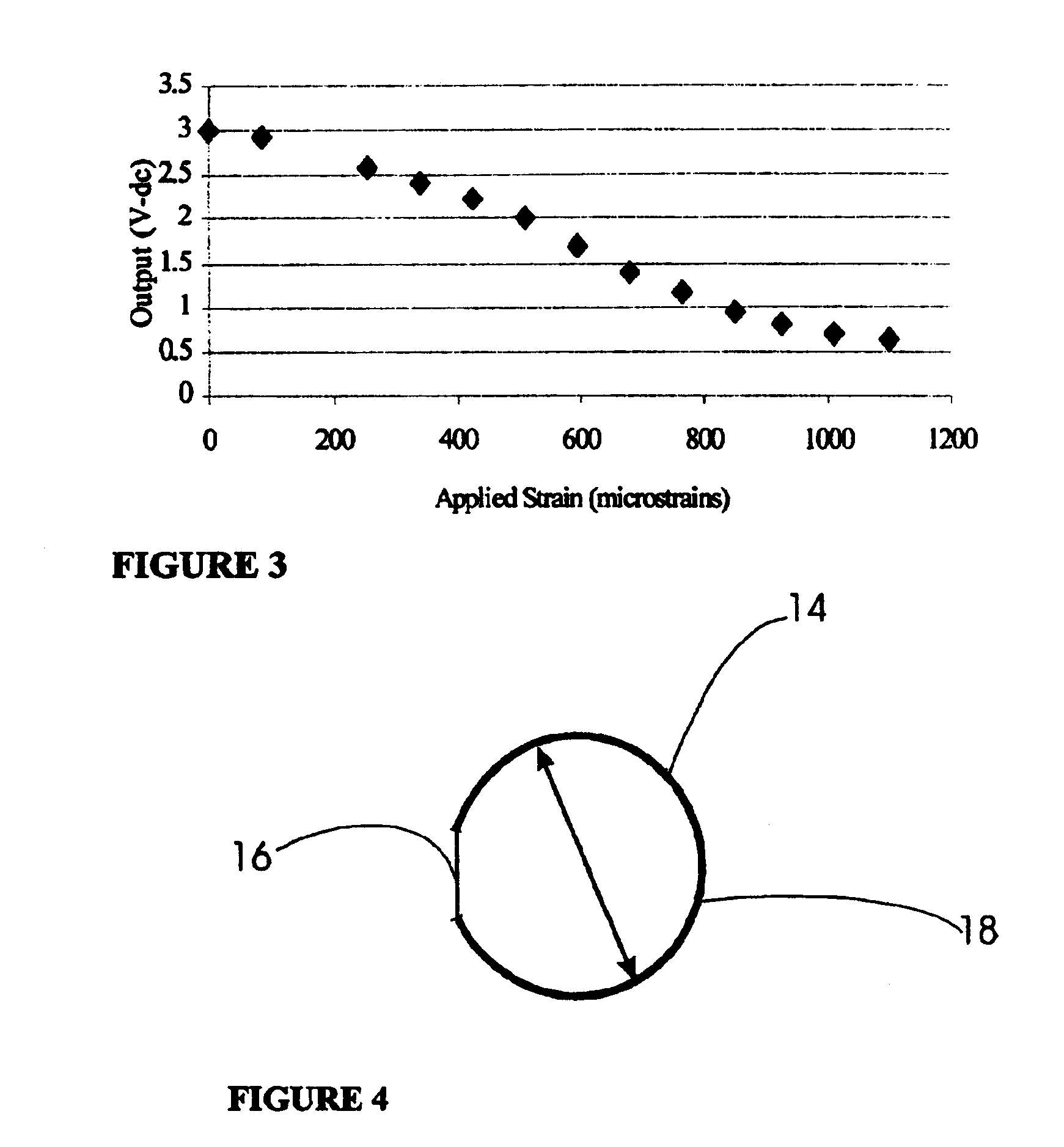

Inductively coupled stress/strain sensor

InactiveUS6912911B2Change relationshipForce measurement by measuring magnetic property varationWork measurementMagnetostrictionCouple stress

An improved method of sensing strain allows measurements of stress, torque, vibration and other loads imposed on a body without physical contact between the body / sensor and the monitoring equipment. An induction loop is at least partially comprised of a magnetostrictive material with a non-linear current-voltage relationship. An excitation device such as a coil is used to induce an AC response in the sensor. The non-linear response to the induced current is received by a sensing device such as a sensing coil, and the output thereof is filtered. The excitation device and sensing device are located in operative proximity to the sensor, but need not be in contact therewith, allowing easy measurement in small spaces, under harsh conditions, or of moving bodies such as drive shafts. The non-linear response of the sensor induces easily detectable harmonics of the base frequency of excitation. These harmonics may advantageously be measured as well.

Owner:SENSORTEX

Abutted exchange bias design for sensor stabilization

InactiveUS7283337B2Hard structureSuppresses side-lobesRecord information storageManufacture of flux-sensitive headsIn planeSelf-stabilization

A hard bias (HB) structure for biasing a free layer in a MR sensor within a magnetic read head is comprised of a main biasing layer with a large negative magnetostriction (λS) value. Compressive stress in the device after lapping induces a strong in-plane anisotropy that effectively provides a longitudinal bias to stabilize the sensor. The main biasing layer is formed between two FM layers, and at least one AFM layer is disposed above the upper FM layer or below the lower FM layer. Additionally, there may be a Ta / Ni or Ta / NiFe seed layer as the bottom layer in the HB structure. Compared with a conventional abutted junction exchange bias design, the HB structure described herein results in higher output amplitude under similar asymmetry sigma and significantly decreases sidelobe occurrence. Furthermore, smaller MRWu with a similar track width is achieved since the main biasing layer acts as a side shield.

Owner:HEADWAY TECH INC

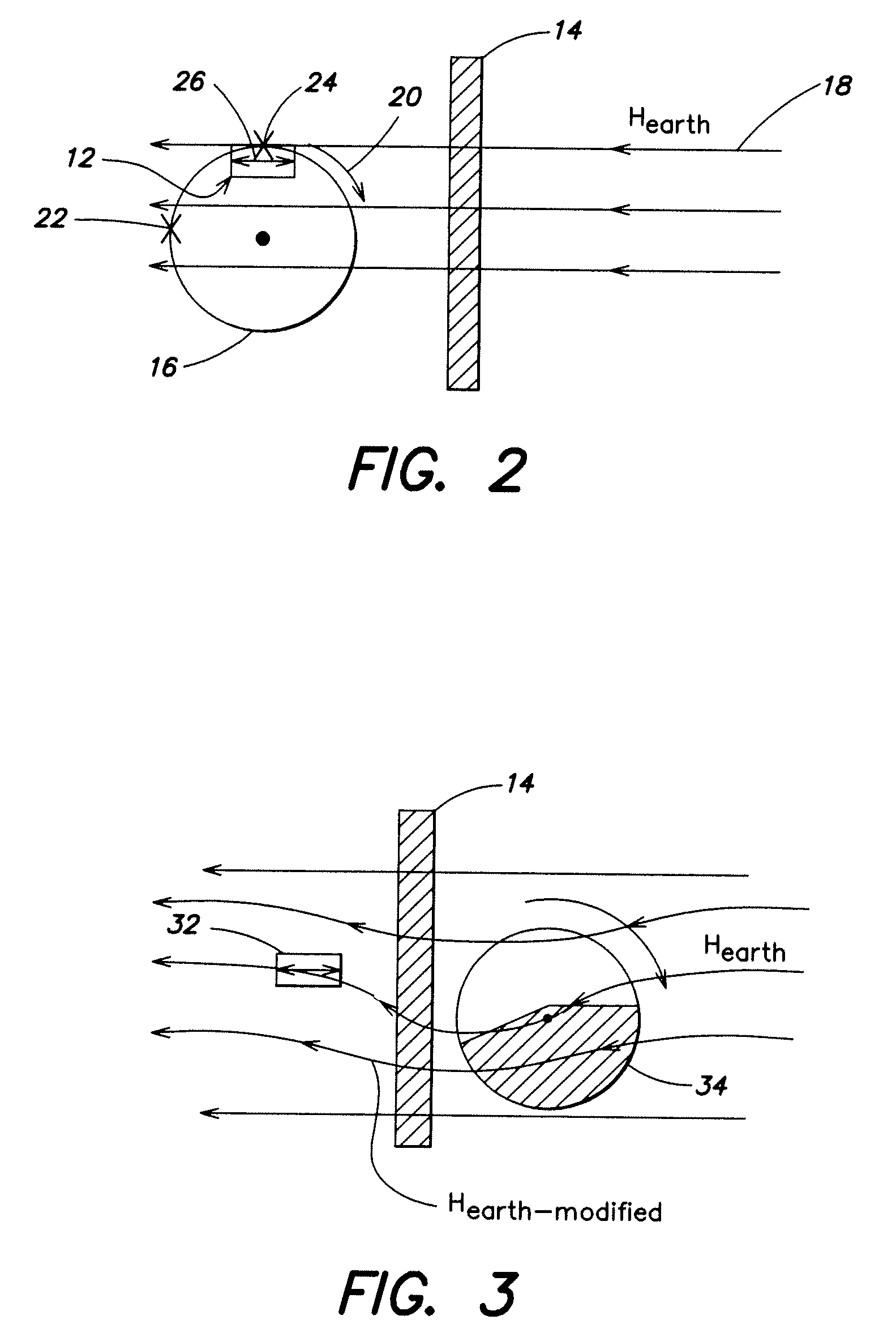

Apparatus and method utilizing magnetic field

Apparatus and method for harvesting energy from the environment and / or other external sources and converting it to useful electrical energy. The harvester does not contain a permanent magnet or other local field source but instead relies on the earth's magnetic field of another source of a magnetic field that is external to the sensing device. One advantage of these new harvesters is that they can be made smaller and lighter than energy harvesters that contain a magnet and / or an inertial mass. A small implantable stimulator(s) includes at least one passive magnetostrictive / electro-active (PME) magnetic-field sensor for delivering electrical stimulation to surrounding tissue. The PME is charged utilizing a changing magnetic field from an external alternating magnetic field source at a frequency particular to the PME. The small stimulator provides means of stimulating a nerve, tissue or internal organ with direct electrical current, such as relatively low-level direct current for temporary or as needed therapy. The field source may be a hand-held device or a small antenna affixed to the wearer's skin, clothing or accessories. The stimulator may be configured to be small enough to be implanted through a surgical needle. Open- and closed-loop systems are disclosed with measurement of current flow and therapy through PME sensor function.

Owner:FERRO SOLUTIONS

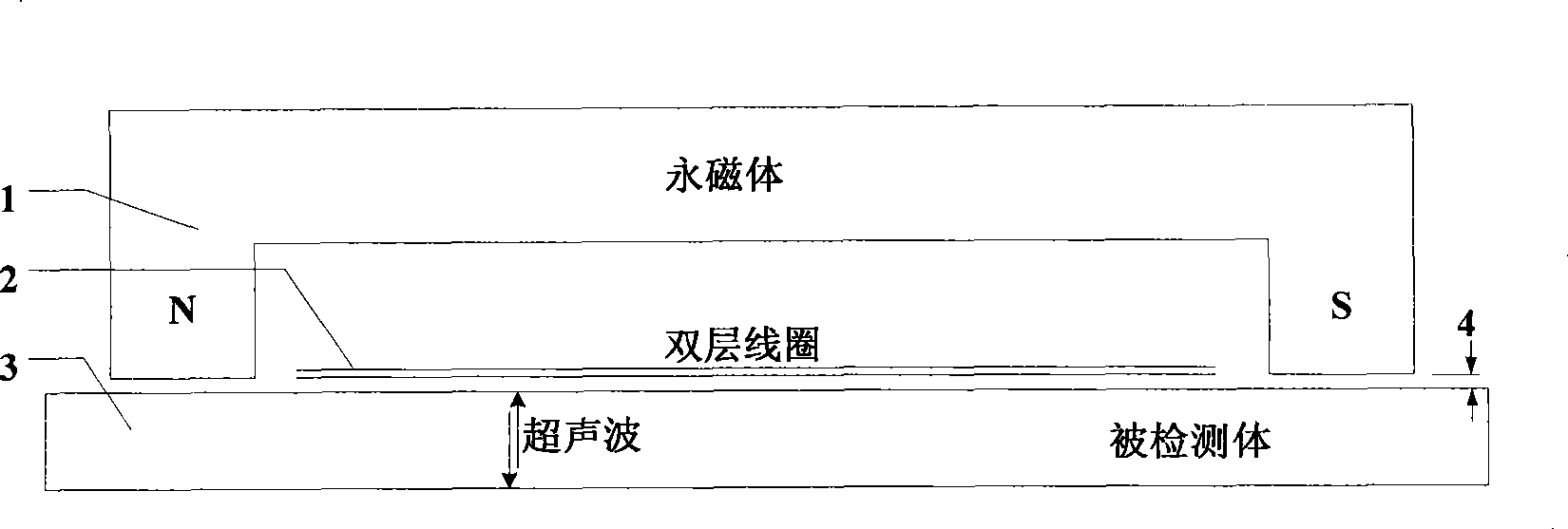

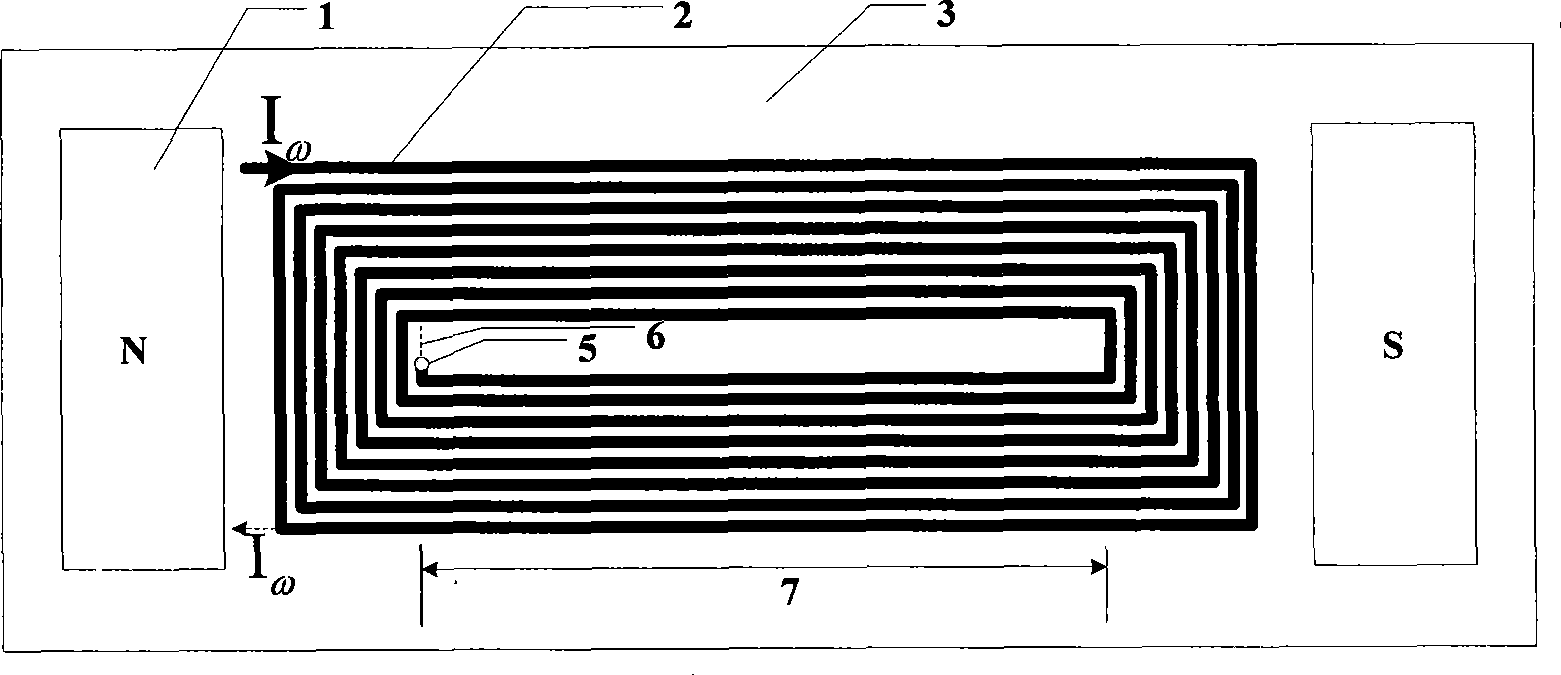

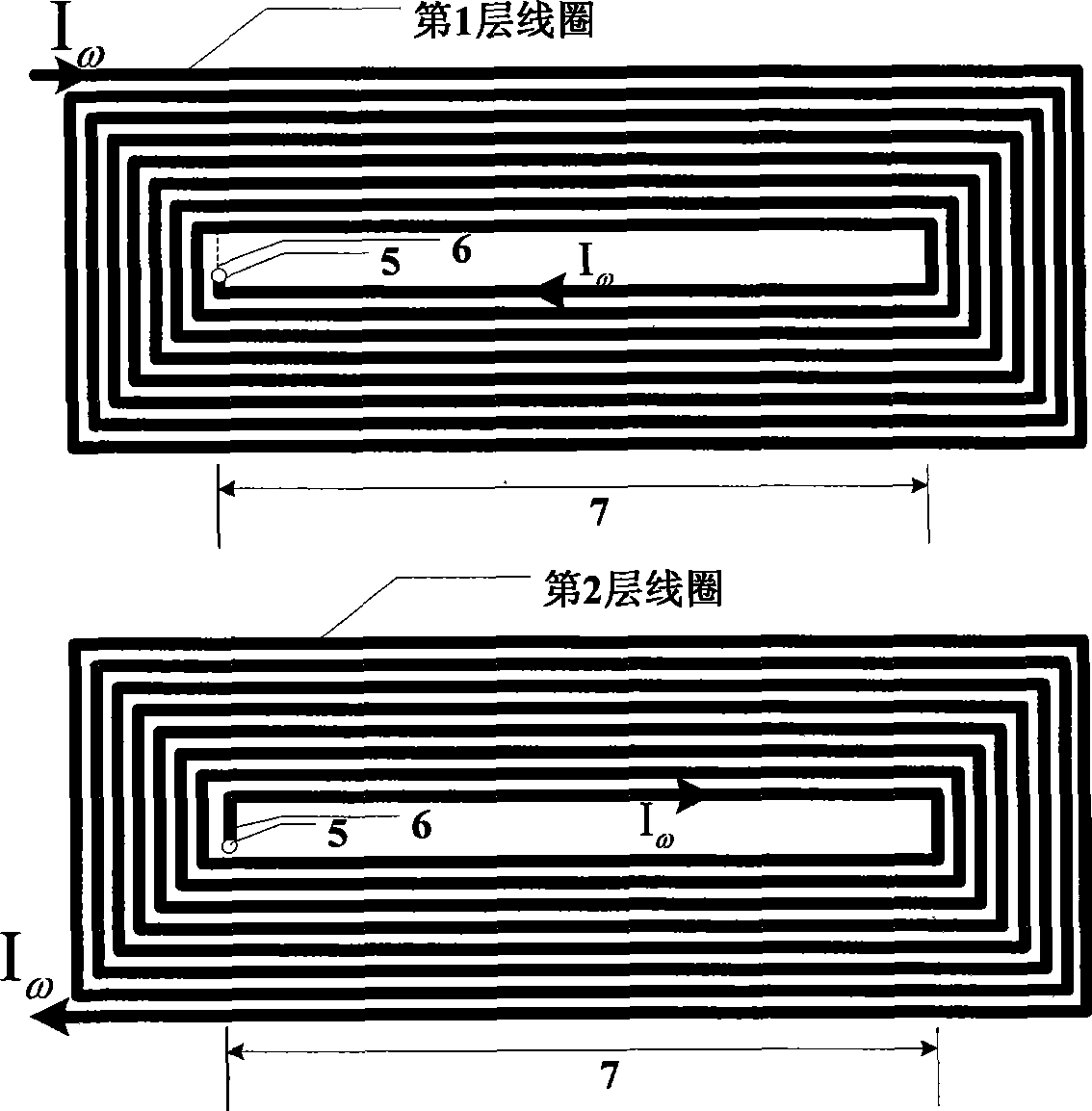

Electromagnetical ultrasonic thickness-measuring method

InactiveCN101398298AWith non-contactUsing subsonic/sonic/ultrasonic vibration meansUltrasonic sensorReflected waves

The invention discloses a method for detecting ferrous magnetic material thickness by utilizing electromagnetic ultrasound, and is characterized in that a magnet inside an electromagnetic ultrasound transducer takes a U-shaped permanent magnet, a coil takes a PCB double-layer coil that takes the shape of a Chinese character, 'Hui' and is positioned at an opening of the permanent magnet, and an effective lead part of the coil is parallel to the direction of a bias magnetic field. In thickness measurement, the electromagnetic ultrasound transducer is positioned on a detected object, high-frequency electric sinusoidal pulse current passes through the coil, according to the magnetostrictive effect, the detected object generates partial stretching deformation and oscillation, and consequently excites ultrasonic transverse wave and leads the ultrasonic transverse wave to spread downwards in a direction vertical to surfaces of the detected object. The ultrasonic wave is reflected by a lower surface of the detected object, and then the reflected wave is received by the coil. A received ultrasonic signal is collected and input into a computer after being amplified. If the ultrasonic wave spreading velocity in the detected object is v, and the spreading time is t, then the thickness of the detected object d is equal to a half of v multiplied by t. The method for detecting ferrous magnetic material thickness by realizing the thickness detection of ferrous magnetic materials, has the non-contact and couplant-free advantages, and can be used in high-temperature environment and for detecting materials with rough surfaces.

Owner:TSINGHUA UNIV

TMR device with novel free layer structure

ActiveUS20100073827A1Reduce noiseSolution value is not highNanomagnetismMagnetic measurementsNoise reductionLayer thickness

Owner:HEADWAY TECH INC

Magnetoresistive sensor having improved synthetic free layer

InactiveUS7130167B2Large physical thicknessSmall thicknessNanomagnetismMagnetic measurementsMagnetic layerPhysics

A magnetoresistive sensor having employing a synthetic free layer having a first magnetic layer that contributes strongly to the GMR effect and a second magnetic layer that does not contribute to GMR effect, but has a negative magnetostriction to compensate for a positive magnetostriction of the first ferromagnetic layer.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

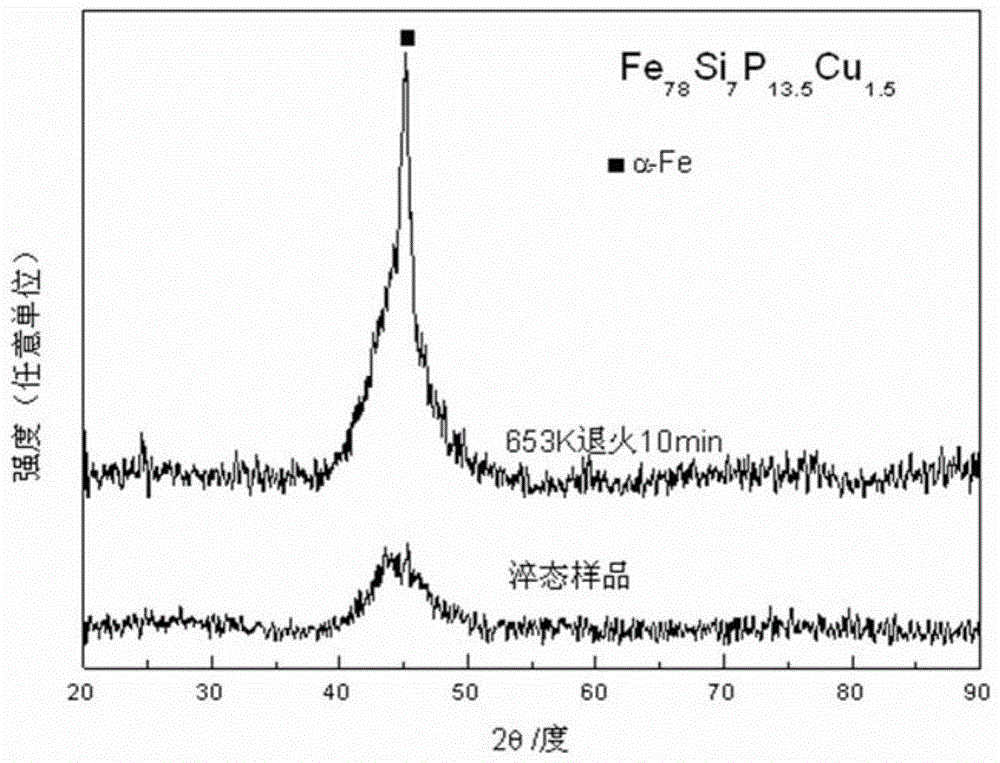

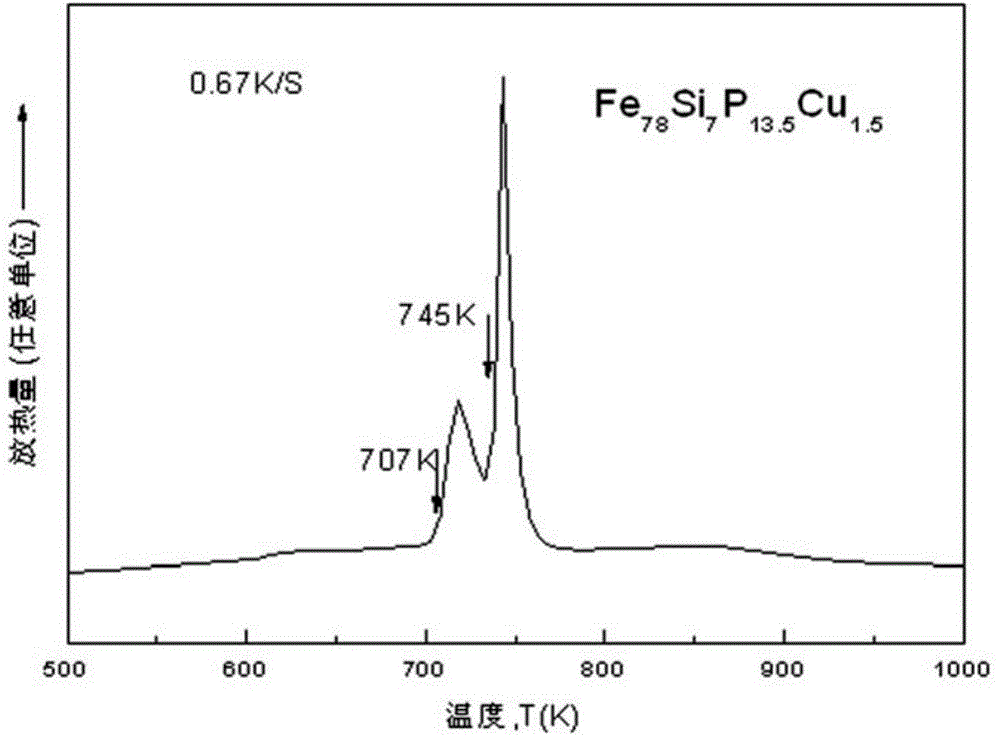

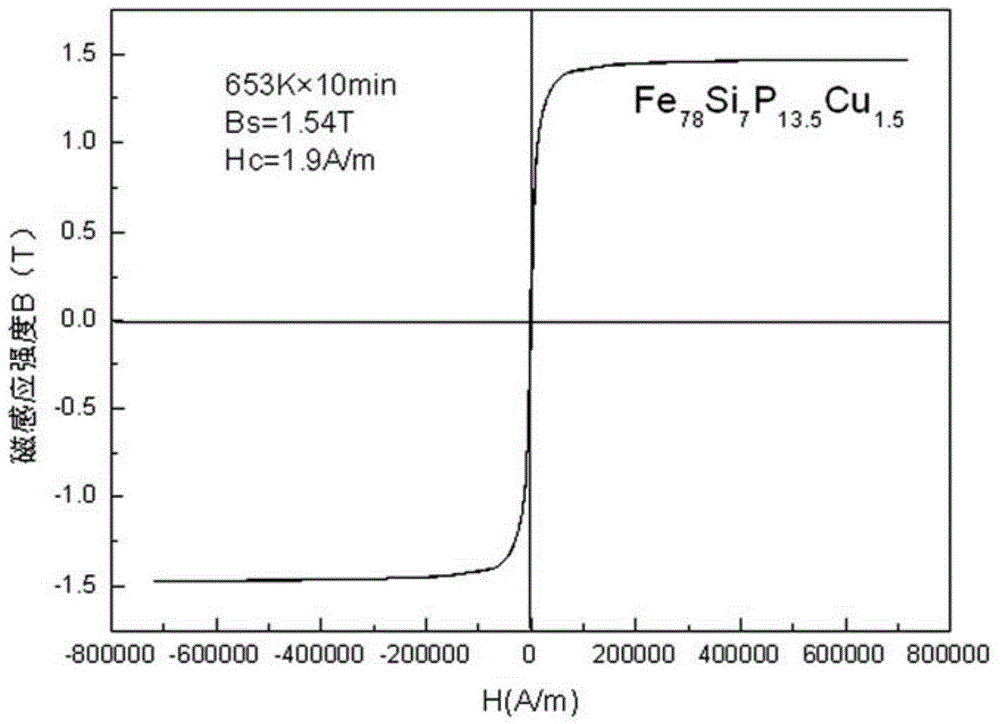

Iron-based nanocrystalline soft-magnetic alloy with excellent high-frequency performance and preparation method thereof

ActiveCN104087833AHigh saturation magnetic inductionImprove thermal stabilityMagnetic materialsRare-earth elementNanocrystalline silicon

The invention discloses iron-based nanocrystalline soft-magnetic alloy with excellent high-frequency performance and a preparation method thereof. The expression of the alloy is FeaSibPcCuxMy, wherein a, b, c, x and y respectively represent the atomic percent content of corresponding compositions and satisfy the following conditions: 70<=a<=85, 5<=b<=15, 5<=c<=18, 0.0001<=x<=3, 0<=y<=5, a+b+c+x+y=100%, and M is one or more of Zr, Ti, Ta, Hf, Nb, V, W, Mo, Mn, Cr, Re, Zn, In, As, Sb, Bi, Ca, platinum group elements, rare earth elements, N, Sn, Ge, Ga and Al. The alloy is a nanocrystalline soft-magnetic alloy band prepared by employing a single-roller quick-cooling method under the conditions of high vacuum and argon protection. The alloy does not contain B elements, is good in soft magnetic property, high in thermal stability, low in high-frequency loss and low in magnetostriction coefficient.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com