Exchange coupling dual-phase nano composite permanent magnet particles and preparation method thereof

A nano-composite and exchange-coupling technology, applied in the direction of magnetic materials, magnetic objects, inorganic materials, etc., can solve the problems of reducing the maximum magnetic energy product, low exchange coupling effect, and high cost, reducing rare earth content and material cost, and comprehensive magnetic properties. Can improve the effect of less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

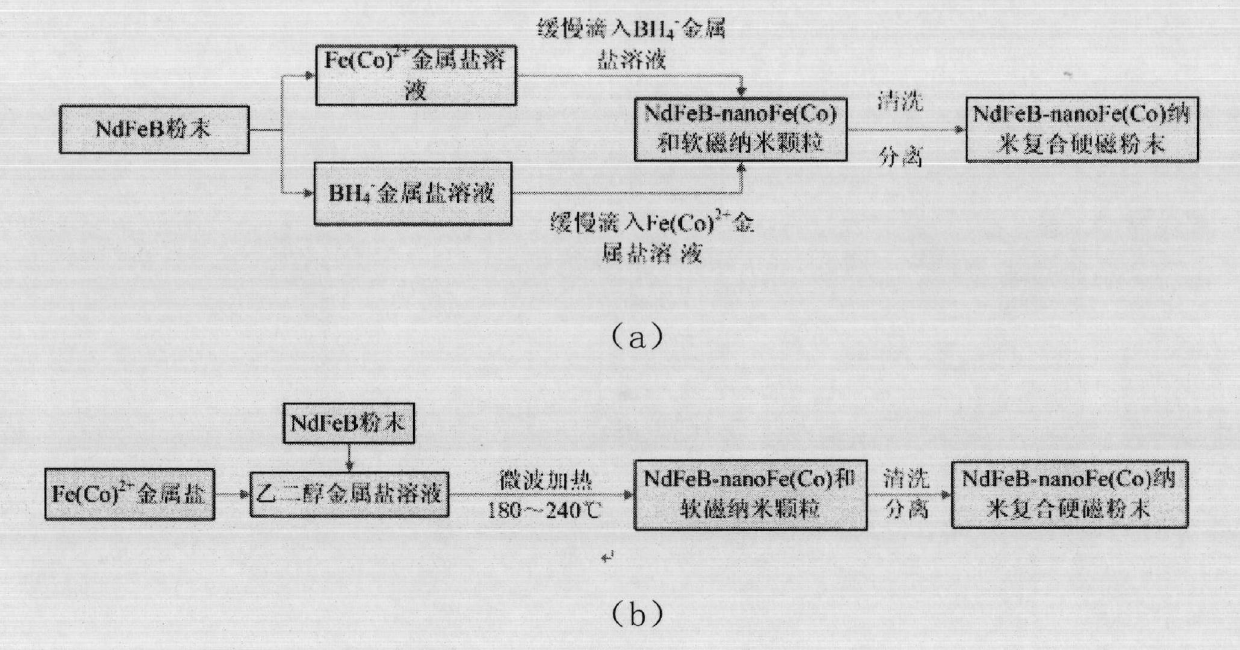

[0044] Embodiment 1 Co-precipitation method prepares NdFeB+nano-Fe nanometer composite particle (process flow chart is as follows figure 2 as shown in a)

[0045] The Fe nanoparticles were deposited on the hard magnetic particles by the chemical co-precipitation method, and the specific steps were as follows:

[0046] (1) dissolving the metal salt in distilled water and stirring evenly to obtain a metal salt solution with a total metal ion concentration of 0.085M; dissolving the reducing agent in distilled water and stirring uniformly to obtain a reducing agent solution with a concentration of 0.05M; The metal salt is FeSO 4 ; The reducing agent is sodium borohydride;

[0047] (2) In an argon atmosphere, immerse the single-phase NdFeB quenching magnetic powder in the reducing agent solution obtained in step (1), stir evenly, then add the metal salt solution dropwise and stir at a speed of 750rpm, and react for 2 minutes Magnetic particles are obtained; the molar ratio of b...

Embodiment 2

[0051] Example 2 Co-precipitation method to prepare NdFeB+nano-Fe nanocomposite particles

[0052] The Fe nanoparticles were deposited on the hard magnetic particles by the chemical co-precipitation method, and the specific steps were as follows:

[0053] (1) dissolving the metal salt in distilled water and stirring evenly to obtain a metal salt solution with a total metal ion concentration of 0.085M; dissolving the reducing agent in distilled water and stirring uniformly to obtain a reducing agent solution with a concentration of 0.0425M; The metal salt is FeSO 4 ; The reducing agent is sodium borohydride;

[0054] (2) In a nitrogen atmosphere, immerse the NdFeB powder of the single-phase component prepared by the mechanical alloying method in the reducing agent solution obtained in step (1), stir evenly, then add the metal salt solution dropwise and stir at a speed of 400rpm, Magnetic particles are obtained after reacting for 2 minutes; the molar ratio of the borohydride i...

Embodiment 3

[0058] Example 3 Co-precipitation method to prepare NdFeB+nano-Fe nanocomposite particles

[0059] The Fe nanoparticles were deposited on the hard magnetic particles by the chemical co-precipitation method, and the specific steps were as follows:

[0060] (1) dissolving the metal salt in distilled water and stirring evenly to obtain a metal salt solution with a total metal ion concentration of 0.075M; dissolving the reducing agent in distilled water and stirring uniformly to obtain a reducing agent solution with a concentration of 0.05M; The metal salt is FeSO 4 ; The reducing agent is sodium borohydride;

[0061] (2) In an argon atmosphere, immerse the NdFeB quick-quenching magnetic powder of single-phase composition in the reducing agent solution obtained in step (1), stir evenly, then add the metal salt solution dropwise and stir at a speed of 500rpm, and react for 15 minutes Magnetic particles are obtained; the molar ratio of borohydride ions in the reducing agent soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com