Preparation method of graphene on diamond (111) surface

A diamond and graphene technology, applied in chemical instruments and methods, from chemically reactive gases, crystal growth and other directions, can solve the problems of insufficient research on graphene preparation, graphene can not meet practical applications, etc., and the method is simple and easy to implement. , the effect of high area controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

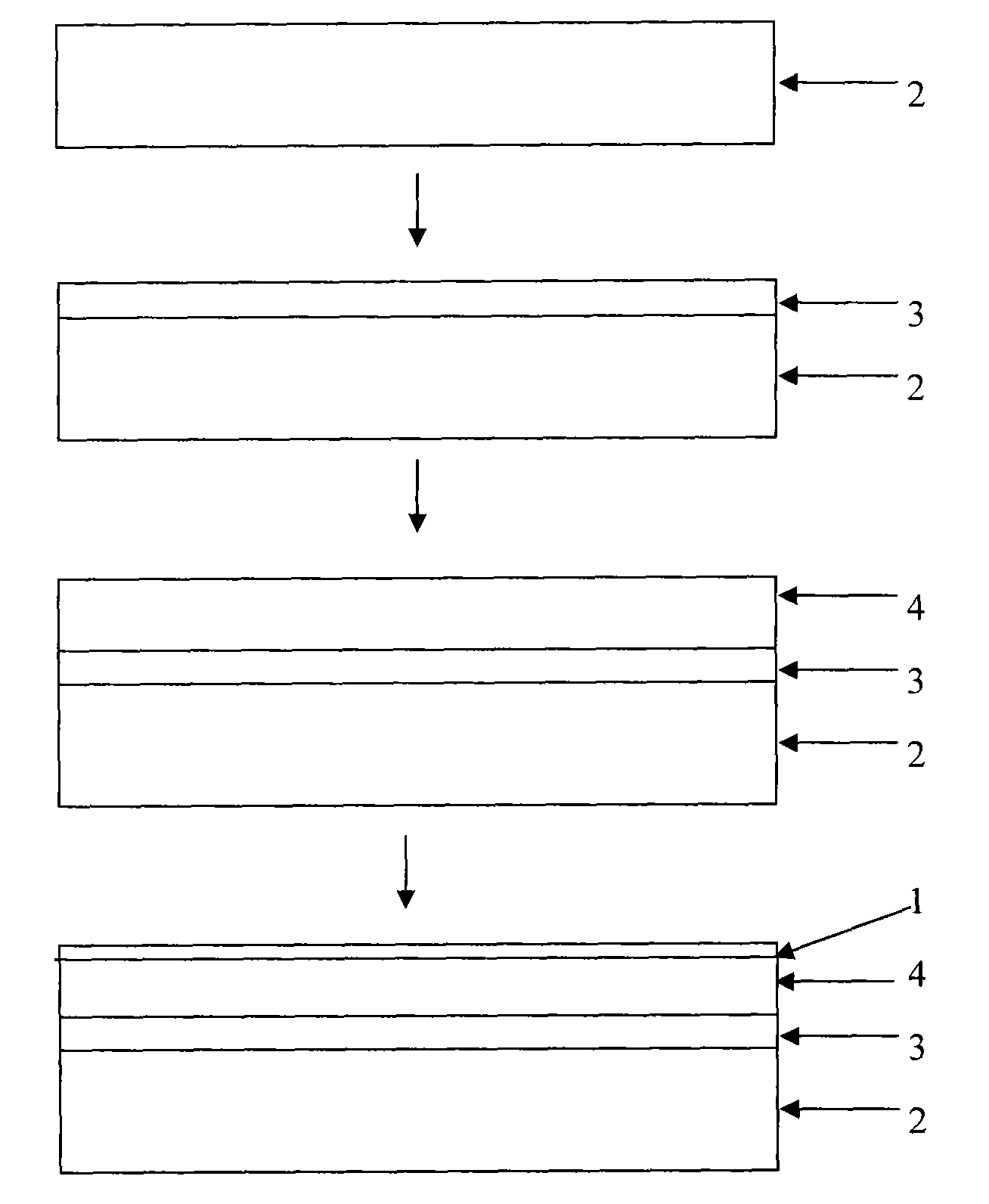

[0039] Please refer to figure 1 , carried out in a hot filament chemical vapor deposition system, the method of the present invention is described in detail through the following specific steps.

[0040] 1) Use diamond grinding paste to grind the cleaned quartz sheet to form nucleation points of diamond particles. The treatment time is 5 minutes, and then use acetone and alcohol to clean the quartz sheet for 10 minutes each.

[0041] 2) Then put the quartz plate as the substrate 2 on the substrate support, evacuate to below 5Pa, then pass methane and hydrogen into the cavity, the flow rates are 4 sccm and 100 sccm respectively, that is, the volume ratio of the two is 4:100 . When the air pressure reaches 4kPa and stabilizes, the filament is heated to about 2200°C, and the substrate temperature is kept at about 800°C to grow the diamond transition layer 3, and the growth time is set to 0.5 hours.

[0042] 3) Vacuumize to below 5 Pa, then feed methane, hydrogen, and hydrogen c...

Embodiment 2

[0045] Carried out in a hot filament chemical vapor deposition system, the method of the present invention is described in detail by the following specific steps.

[0046] 1) Use diamond powder suspension to ultrasonically treat the cleaned silicon wafer to form nucleation sites. The treatment time is 20 minutes, and then clean the silicon wafer with acetone and alcohol for 10 minutes each.

[0047] 2) Then put the silicon wafer as the substrate on the substrate holder, evacuate to below 5Pa, and then pass methane and hydrogen into the cavity with the flow rates of 4 sccm and 100 sccm respectively, that is, the volume ratio of the two is 2:100. When the pressure reaches 4kPa and stabilizes, heat the filament to about 2200°C and keep the substrate temperature at about 700°C to grow the diamond transition layer, and the growth time is set to 1 hour.

[0048] 3) Vacuumize to below 5 Pa, then feed methane, hydrogen, and hydrogen carrying trimethyl borate into the cavity, the flow ...

Embodiment 3

[0051] It is carried out in a hot filament chemical vapor deposition system, and the method of the present invention is described in detail through the following specific steps.

[0052] 1) Using the natural diamond (111) surface as a substrate, wash with acetone and alcohol for 10 minutes each.

[0053] 2) Then put the diamond substrate on the substrate support, evacuate to below 5Pa, and then pass methane and hydrogen into the cavity with the flow rates of 3 sccm and 100 sccm respectively, that is, the volume ratio of the two is 3:100. When the pressure reaches 7kPa and stabilizes, heat the filament to about 2200°C and keep the substrate temperature at about 900°C to grow the diamond transition layer, and the growth time is set to 0.5 hours.

[0054] 3) Vacuumize to below 5 Pa, then feed methane, hydrogen, and hydrogen carrying trimethyl borate into the cavity, the flow rates are 6 sccm, 100 sccm, and 1 sccm respectively, that is, the volume ratio of the three is 6:100:1. W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com