Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

405 results about "Backup roll" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

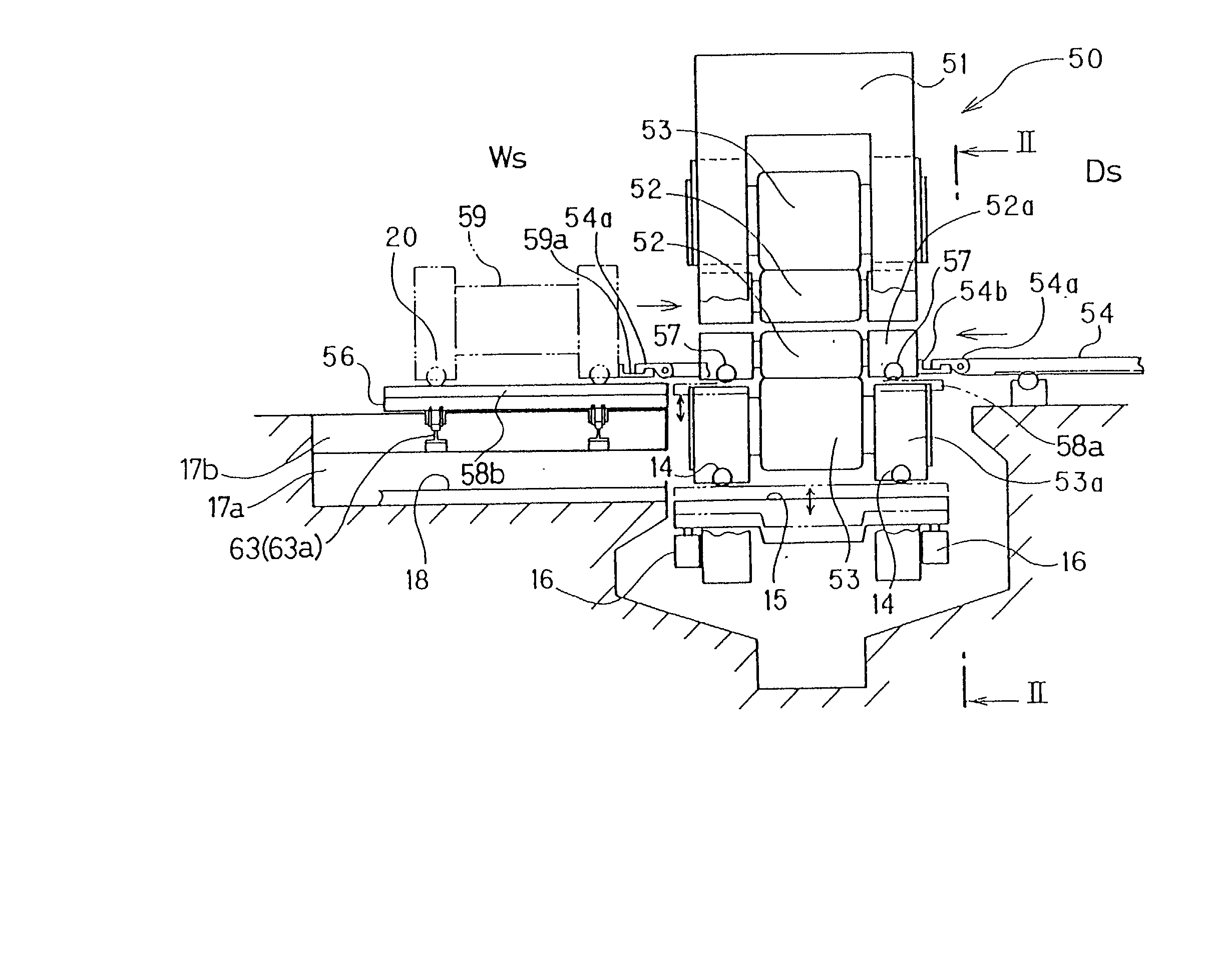

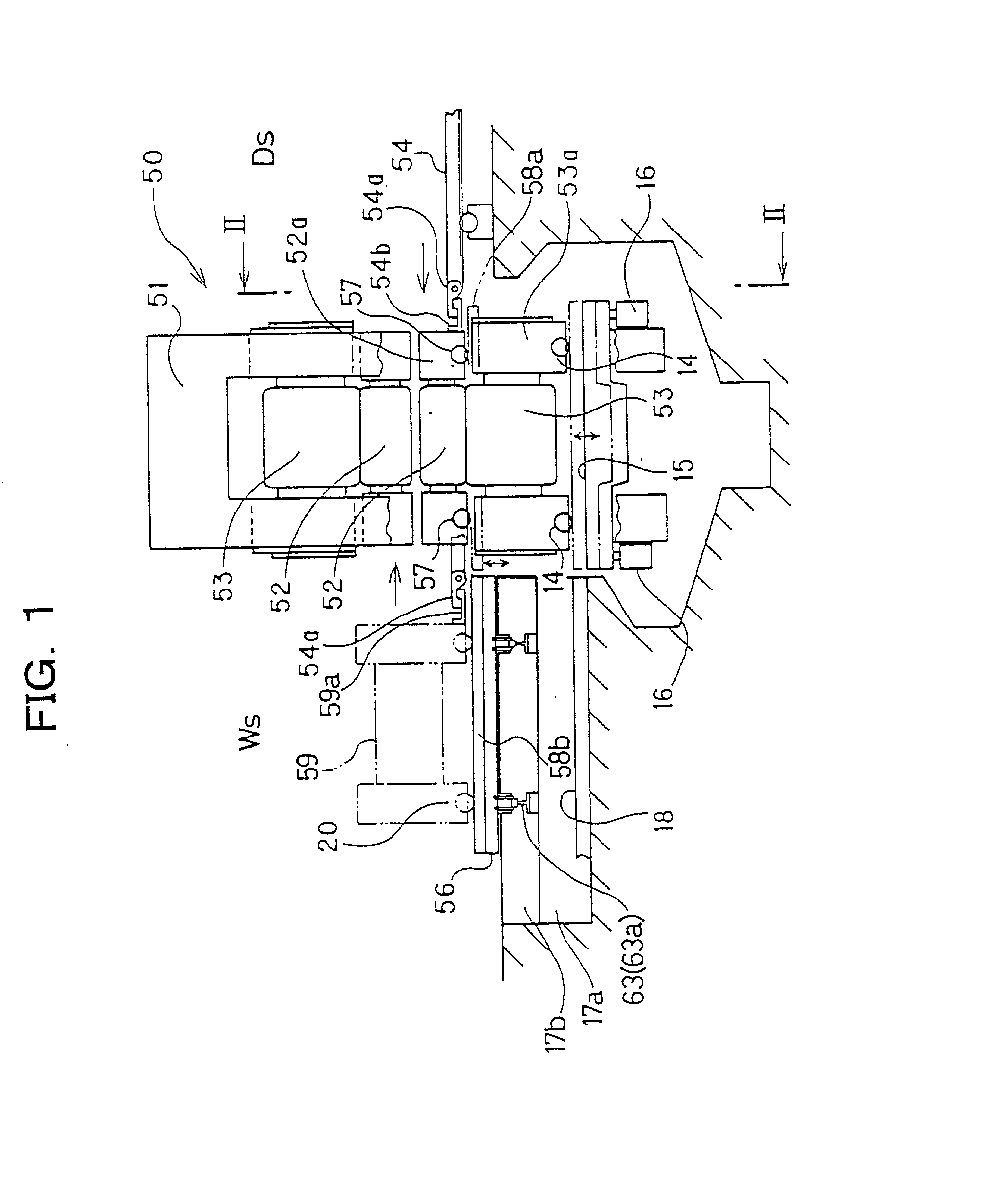

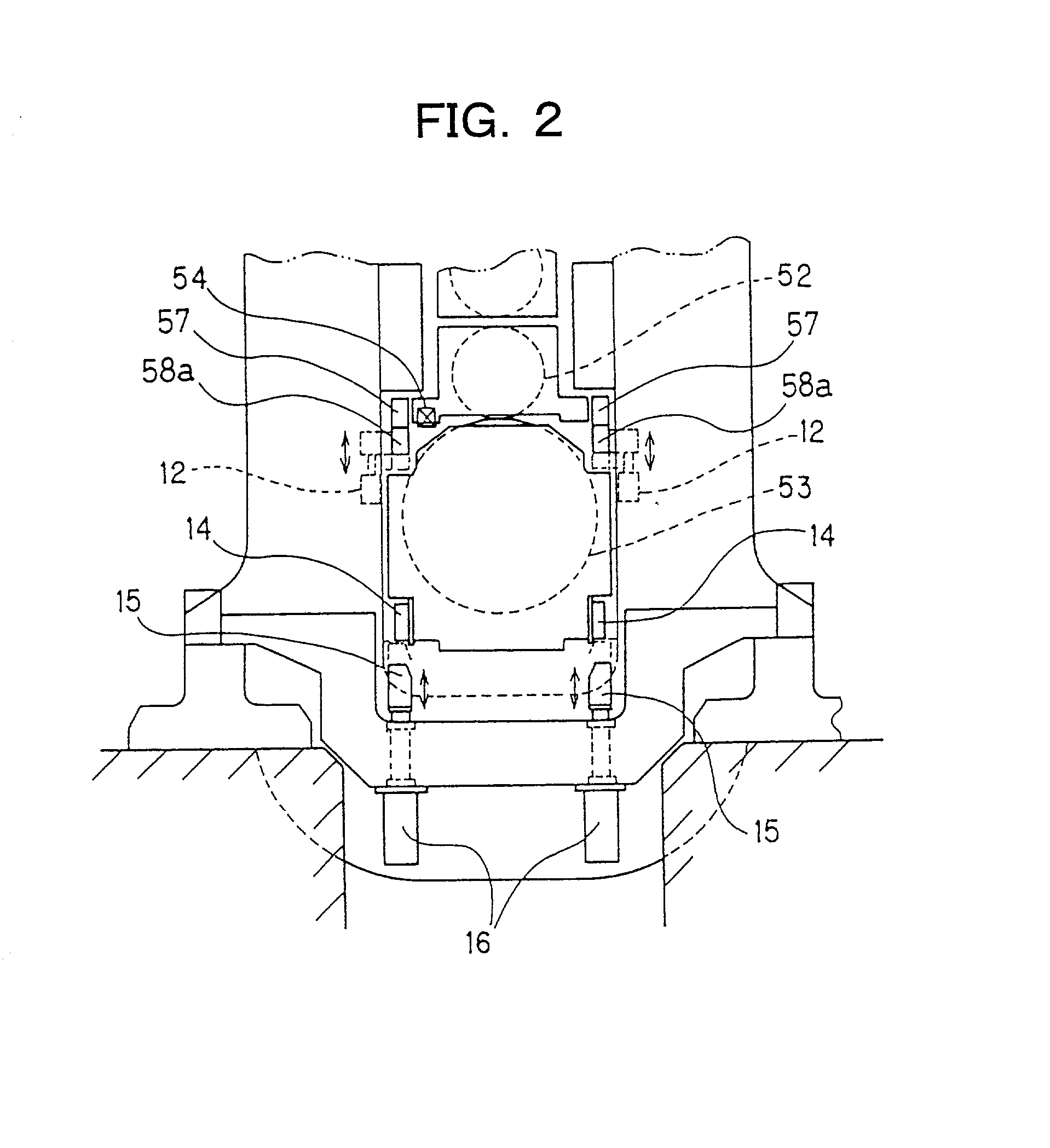

Roll changing apparatus and roll changing method for rolling mill

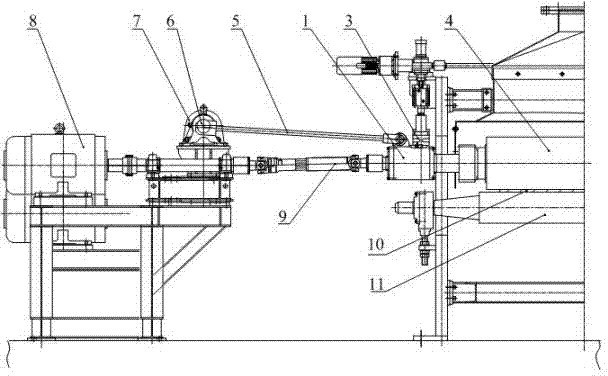

InactiveUS20020078728A1Low costReduce Fixture CostsMetal rolling stand detailsRollsWork rollEngineering

A roll changing apparatus for a four-high rolling mill comprises rails, provided in a rolling mill stand and on a work side of the rolling mill, for incoming and outgoing of a work roll assembly and a backup roll assembly, and a pusher, provided on a drive side or the work side of the rolling mill, for roll admission and withdrawal for both of work rolls and backup rolls. The roll changing apparatus can be modified into a side shift type roll changing apparatus with ease, at a low cost, and in a short time.

Owner:MITSUBISHI HEAVY IND LTD

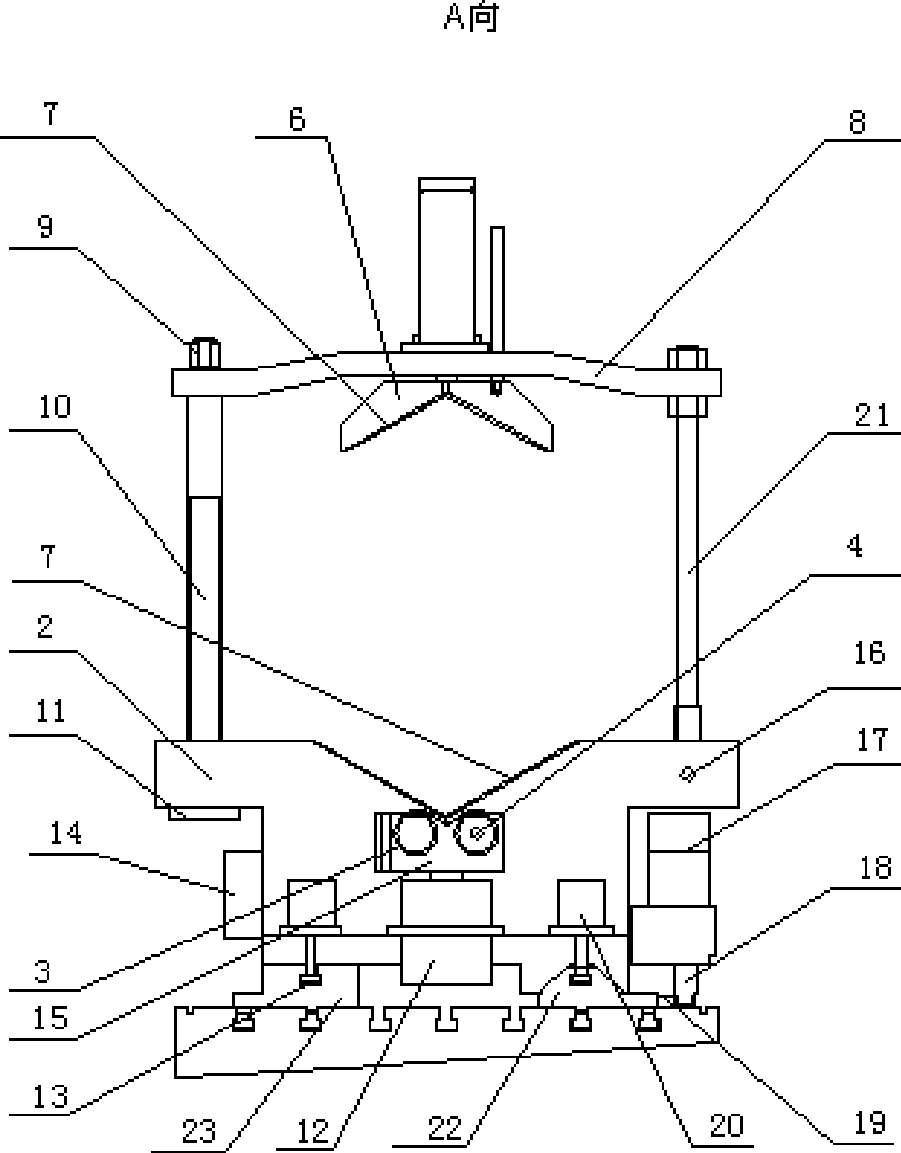

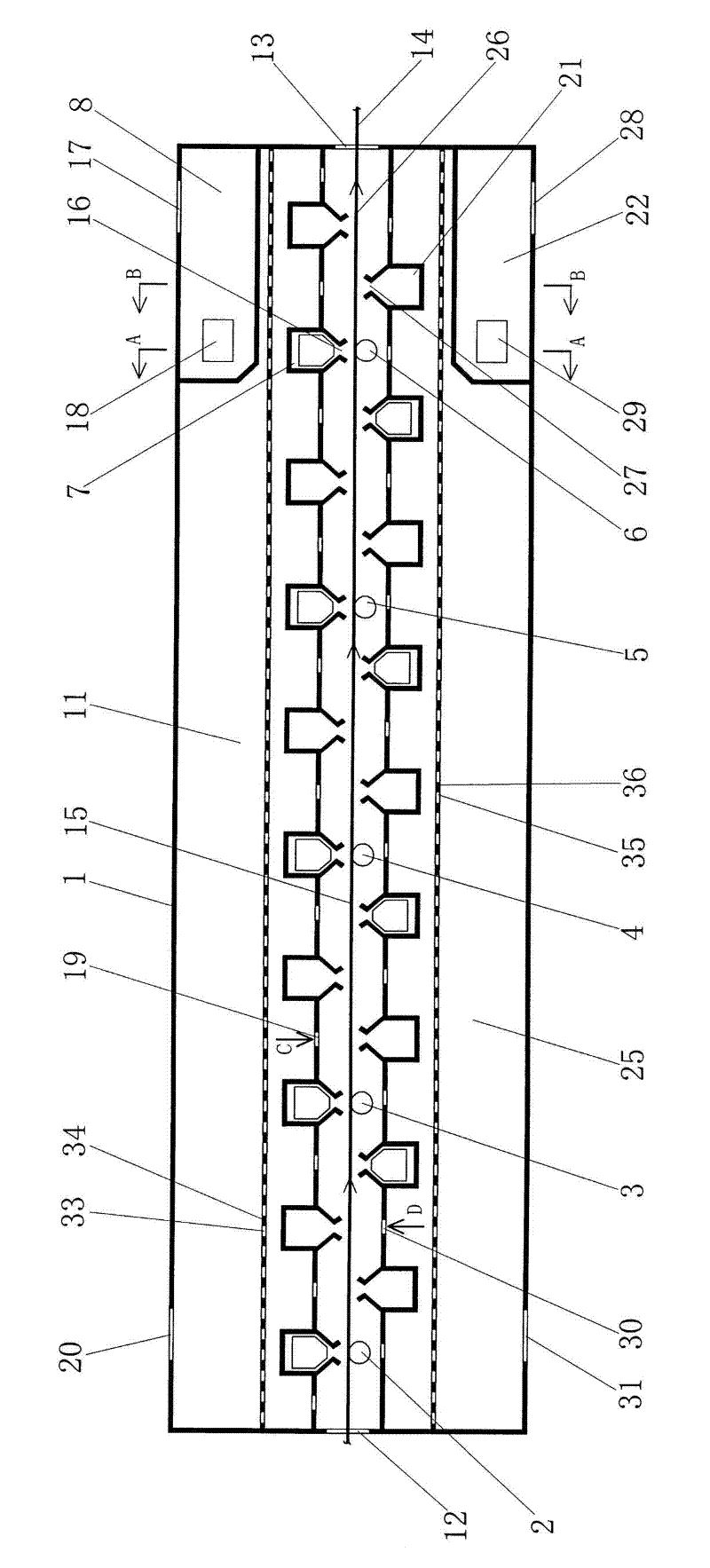

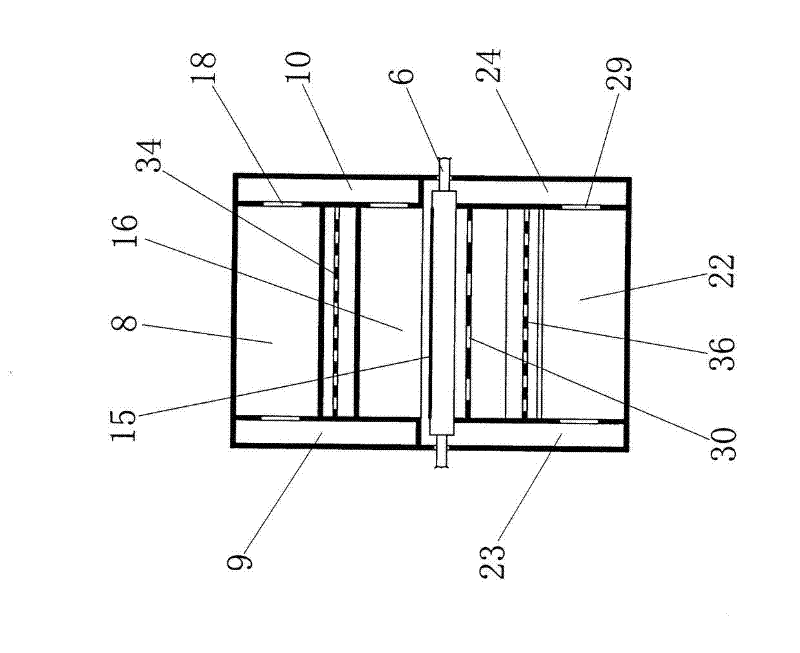

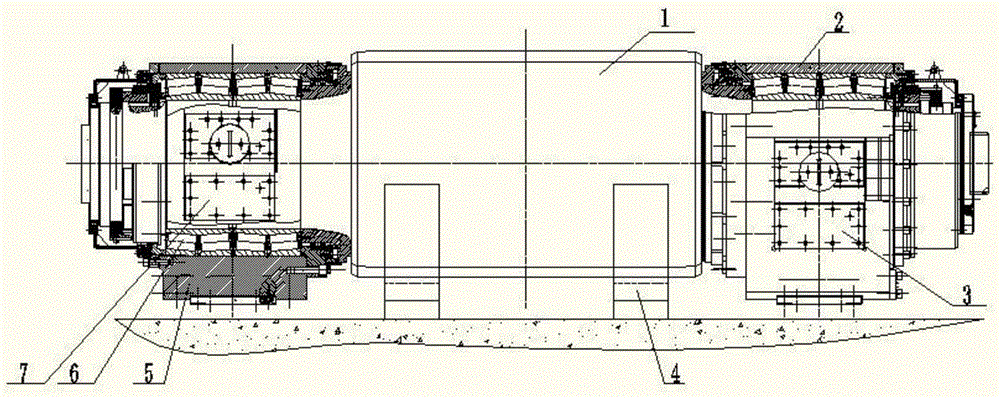

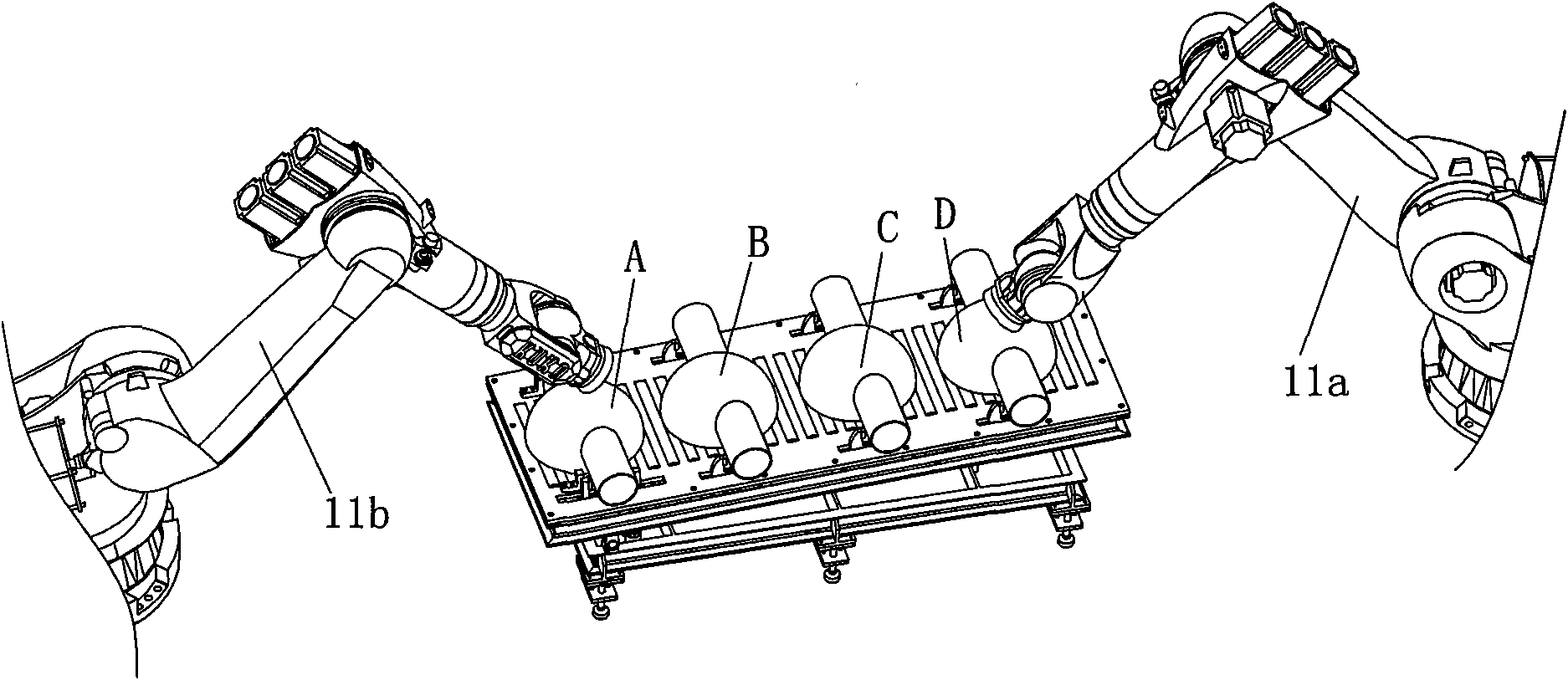

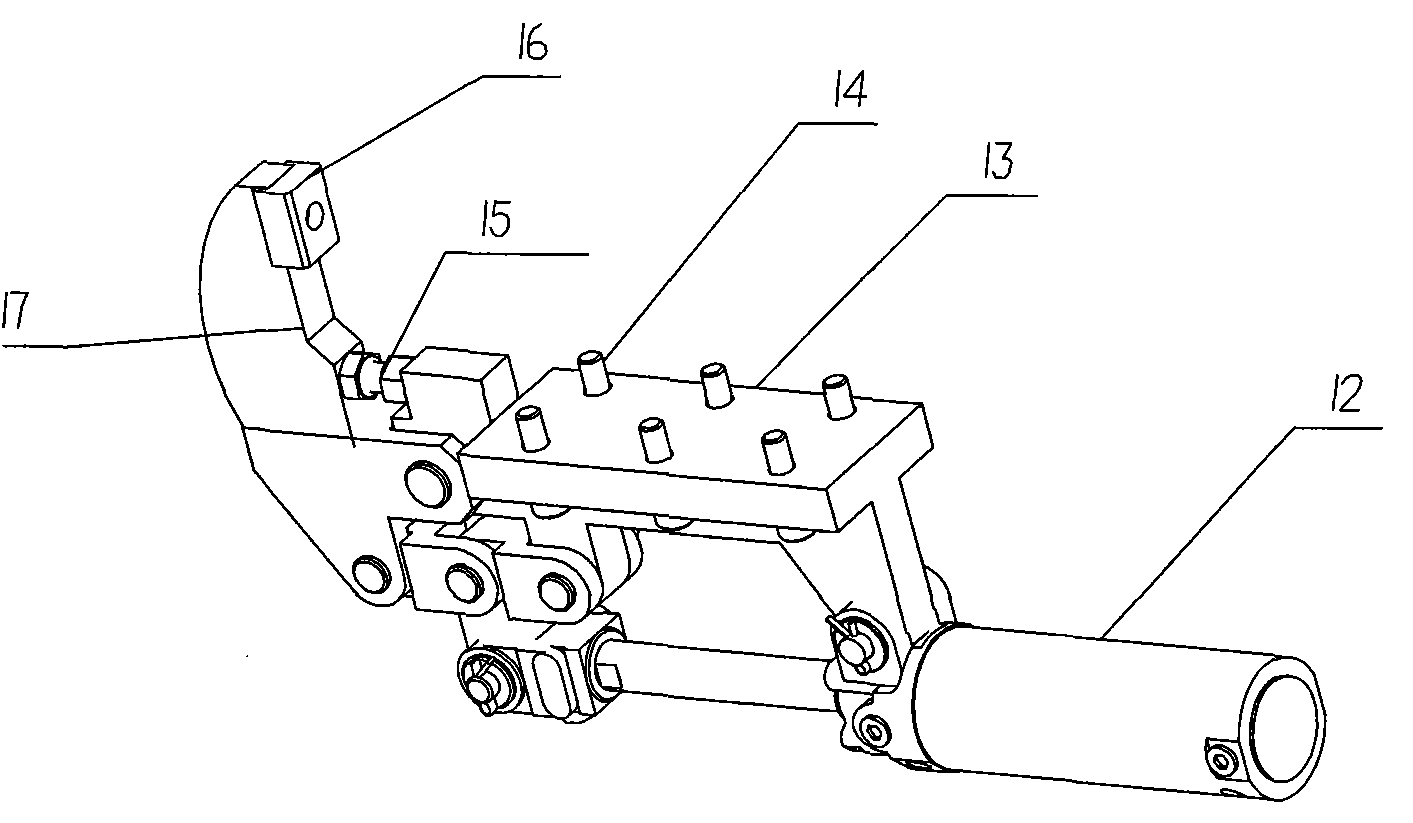

Full automatic hydraulically operated fixture device

InactiveCN101376216AReduce labor intensityIncrease productivityPositioning apparatusMetal-working holdersEngineeringAutomation

The invention relates to a fixture, in particular to a full automatic hydraulic fixture device used for a milling machine or a boring machine, which comprises at least two fixture bodies for clamping parts on a working table, a clamping mechanism arranged above a base through a support, and a guide rail fixed on a working table top. The base of each fixture body is arranged on the guide rail; and a moving mechanism for moving the base along the guide rail and a hydraulic locking mechanism for fixing the base on the guide rail are arranged on the base. The full automatic hydraulic fixture device has the advantages of wide clamping range, high mounting and positioning precision, and high automation degree, thereby greatly reducing labor intensity of operators and improving production efficiency, is particularly suitable for high strength cutting of shaft parts, and is widely applied to the manufacturing fields of various processing such as the milling of a flat head, the milling of a circular arc at the root part of the flat head, the milling of a key slot, the processing of a wabbler of a supporting roll, the beveling of a flat surface and the wabbler, the drilling and the rigid tapping processing to complete the processing of shaft parts with different diameters and different lengths through a milling machine or a boring machine.

Owner:GUILIN MACHINE TOOL

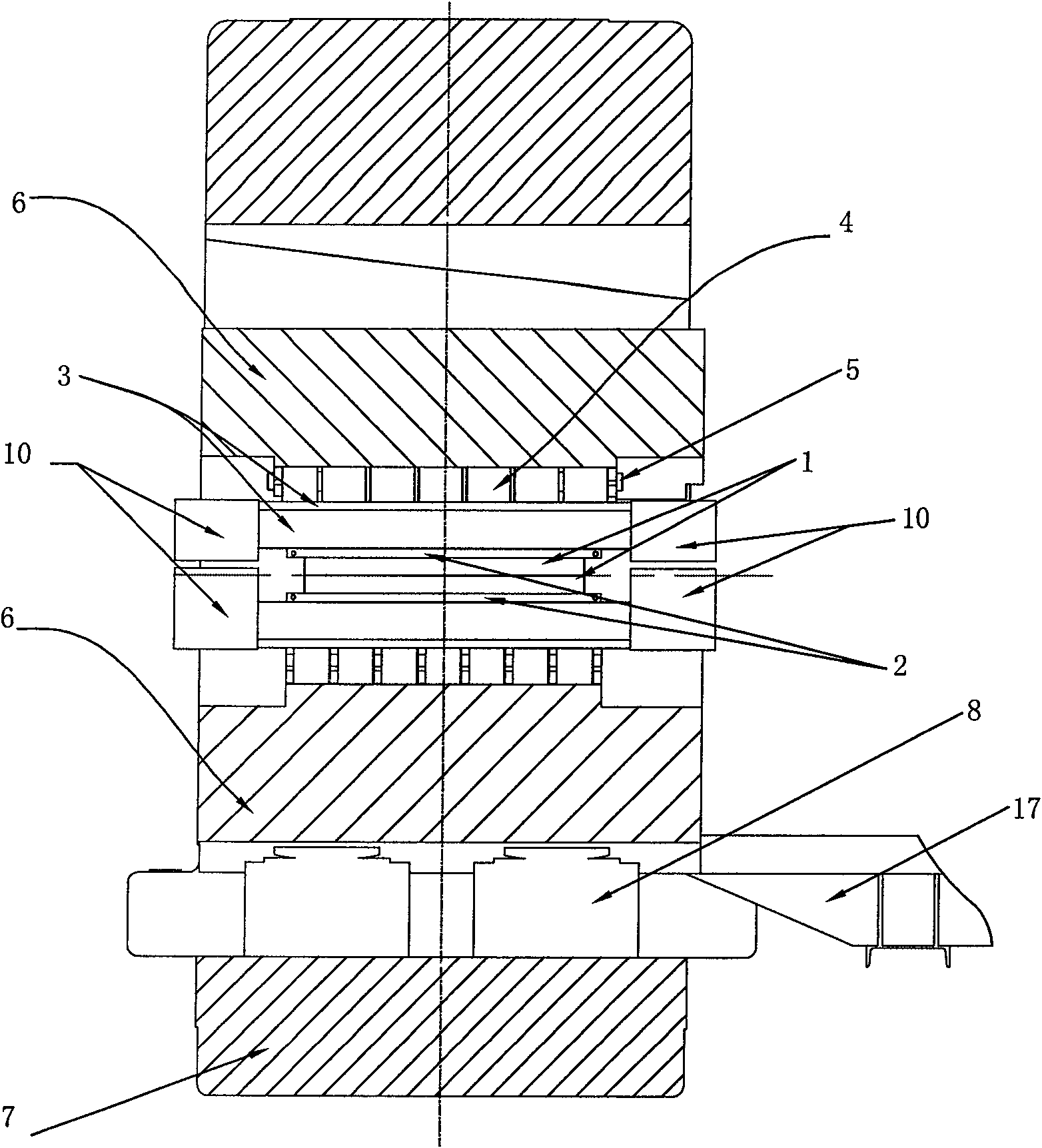

Repair method of backup roll surface of steckel mill and special repair powder used thereon

InactiveCN101358344AThe bonding strength is not lowLow costMetallic material coating processesBackup rollMachining

The invention relates to a machinery part surface repairing method in the metallurgical industry, in particular to a repairing method of steekle mill supporting roller surface and specially used repairing powder; the repairing powder contains the components with the following weight percent: 0.2 percent to 0.5 percent of C, 14 percent to 20 percent of Cr, 6 percent to 12 percent of Ni, 0 percent to 1.5 percent of Mn, 1 percent to 2.5 percent of Mo, 0.5 percent to 2.5 percent of W, 1.5 percent to 2.5 percent of Si, 2.0 percent to 3.0 percent of B, and the rest is Fe. When a supporting roller cannot be used any more because the roller surface is worn or locally falls off, areas to be repaired are molten through a laser process with the repairing powder, so that the missing and damaged parts are repaired and the performance of the repaired parts can meet the use requirements; and then, the shape of the roller surface is recovered through mechanical processing, and a reusable supporting roller can be obtained without heat treatment.

Owner:NANJING IRON & STEEL CO LTD +1

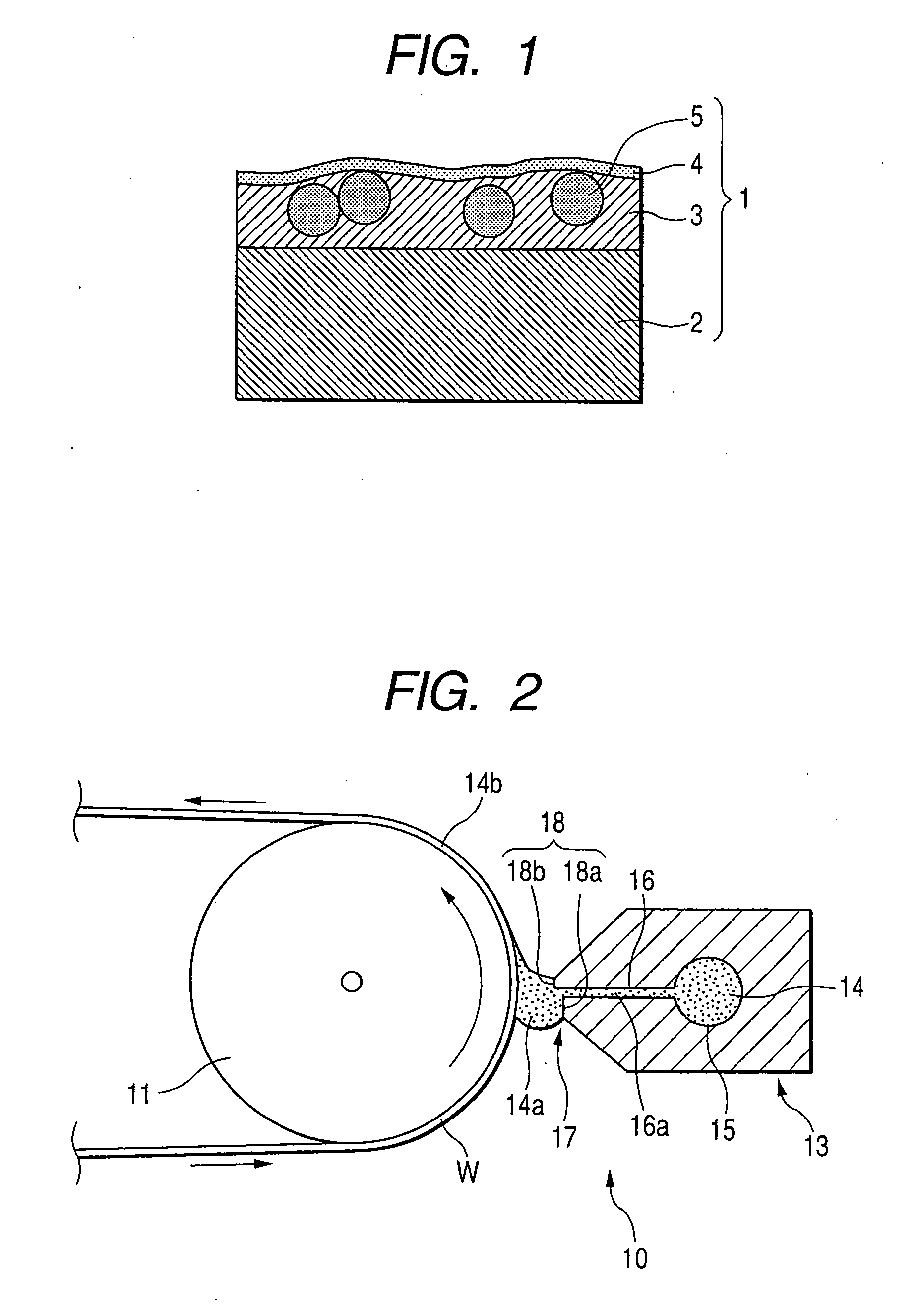

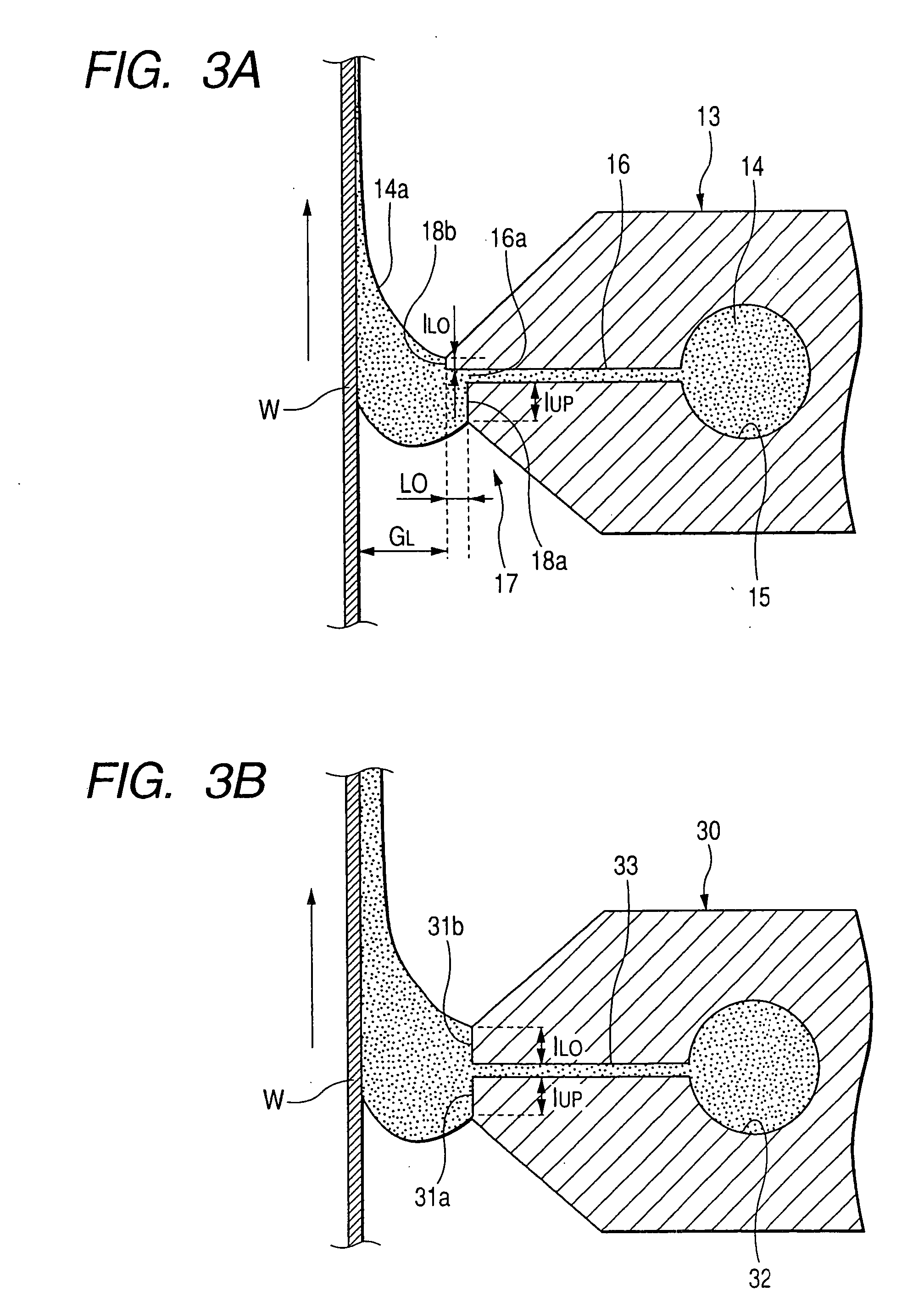

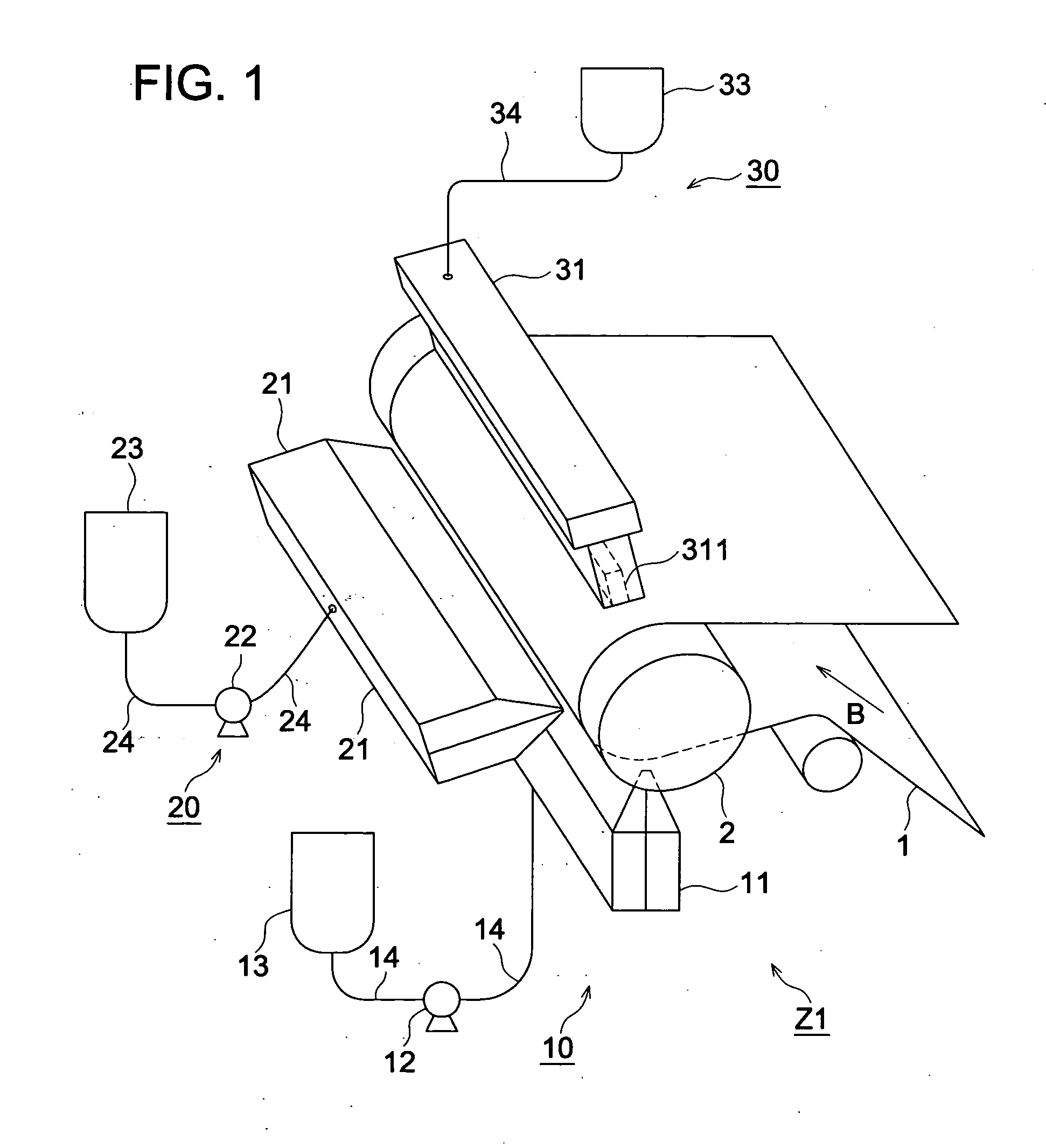

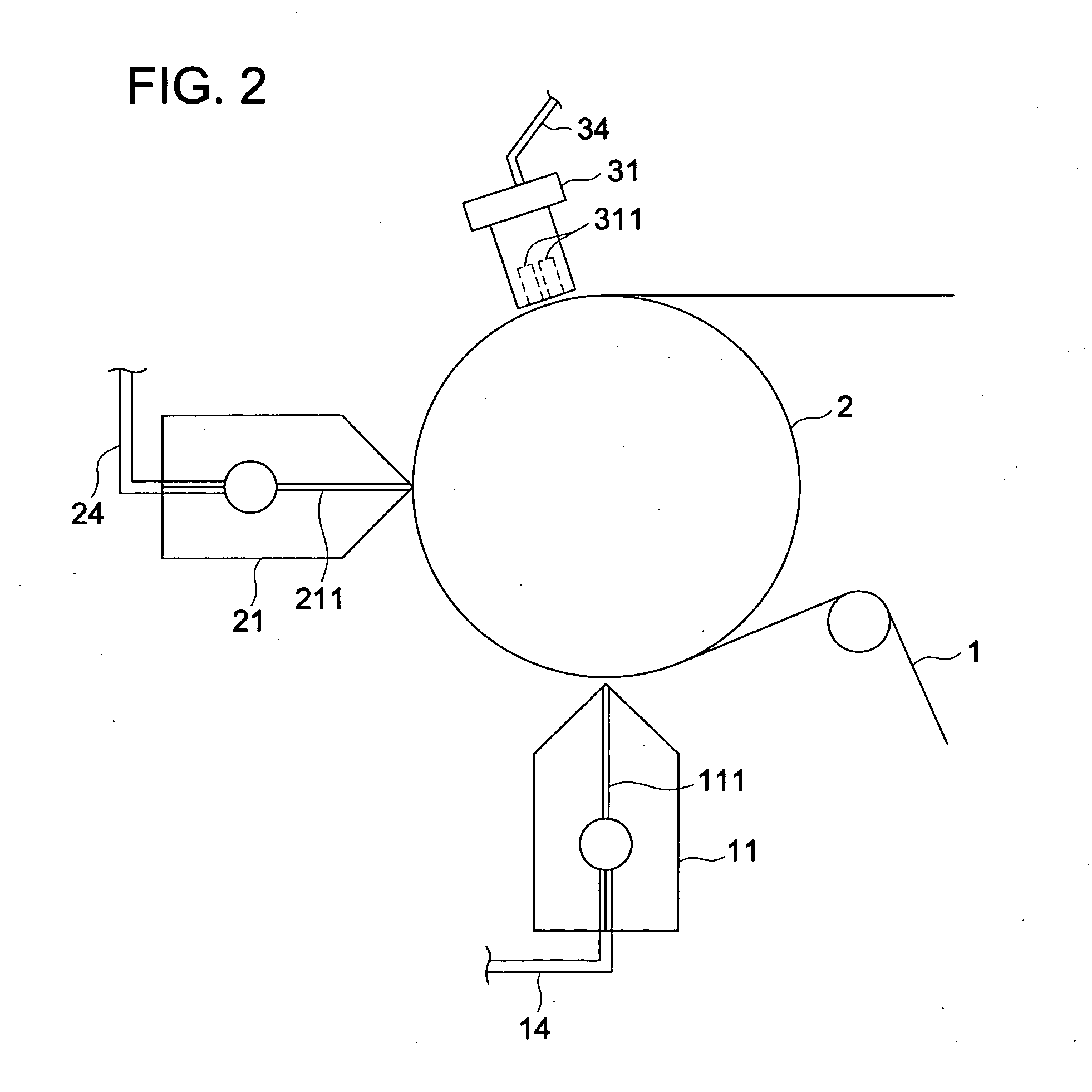

Method of Producing Light-Scattering Film, Polarizing Plate Comprising Light-Scattering Film and Liquid Crystal Display Device Comprising the Polarizing Plate

InactiveUS20070298193A1High refractive indexLower refractive indexLiquid crystal compositionsPrismsLiquid-crystal displayEngineering

A method of producing a light-scattering film, comprising: disposing a land of a forward end lip of a slot die close to a surface of a web; and applying a coating composition on the web through a slot of the forward end lip, so as to provide the coating composition directly or indirectly on the transparent support, wherein the web is being continuously running while being supported on a backup roll, and wherein the coating composition comprises a light-transmitting particulate material, a transmitting resin and a solvent, and the coating composition satisfies relationship (1) in order to control a sedimentation rate of the light-transmitting particulate material: (σ−ρ)×d2≦1.5 (1) wherein σ represents a density of the light-transmitting particulate material (g / cm2); ρ represents a density of the coating composition (g / cm2); and d represents an average particle diameter of the light-transmitting particulate material (μm).

Owner:FUJIFILM CORP

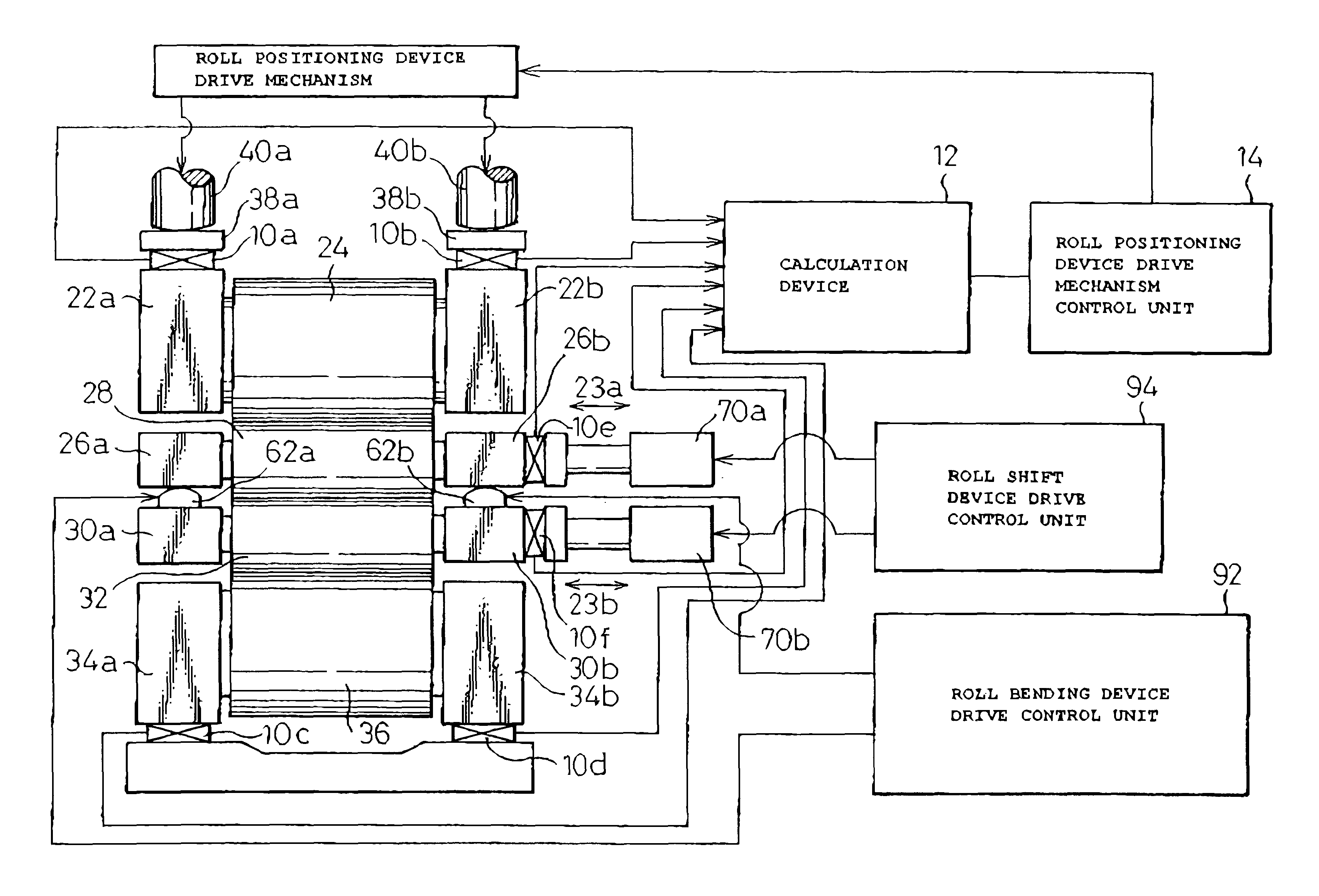

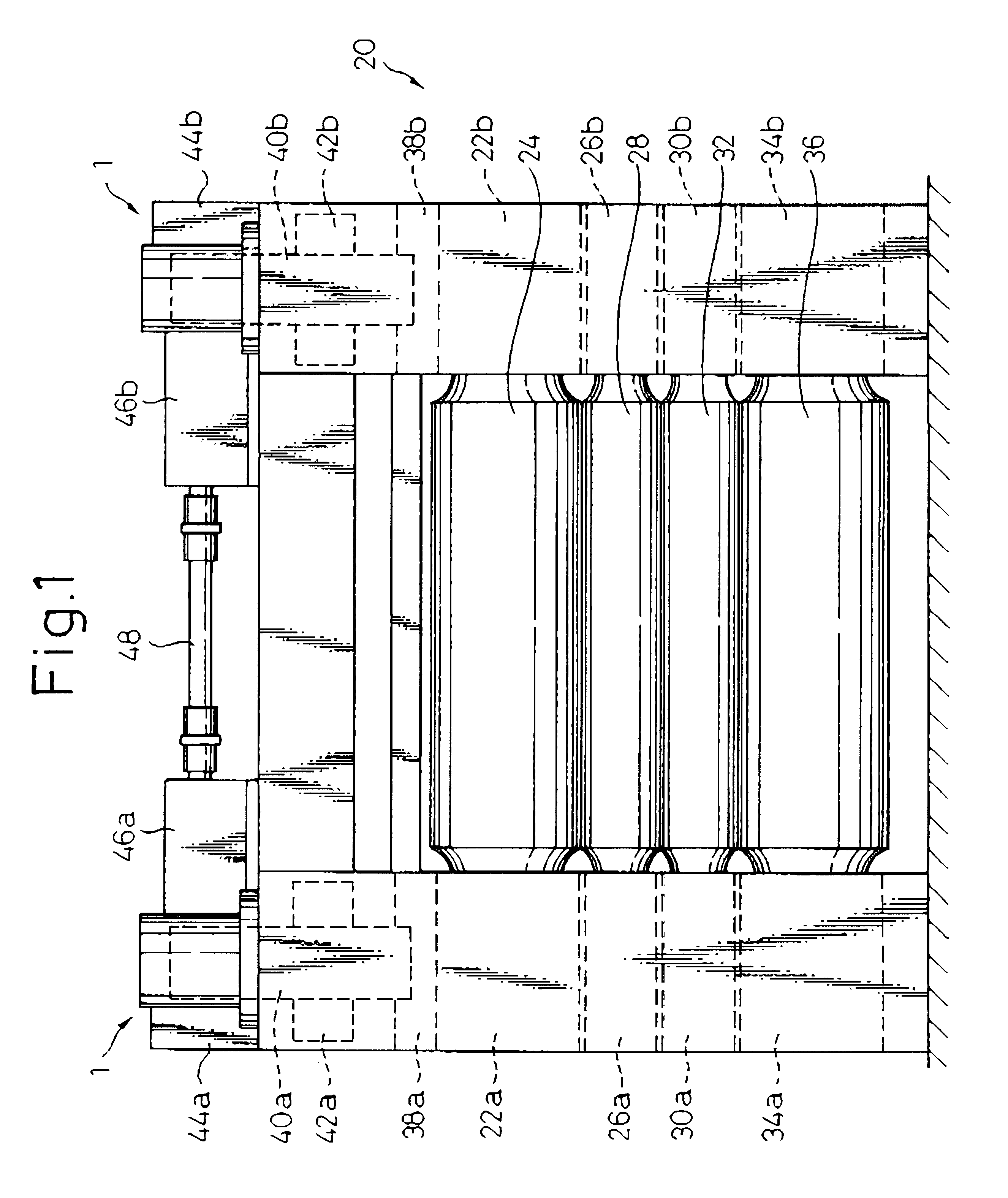

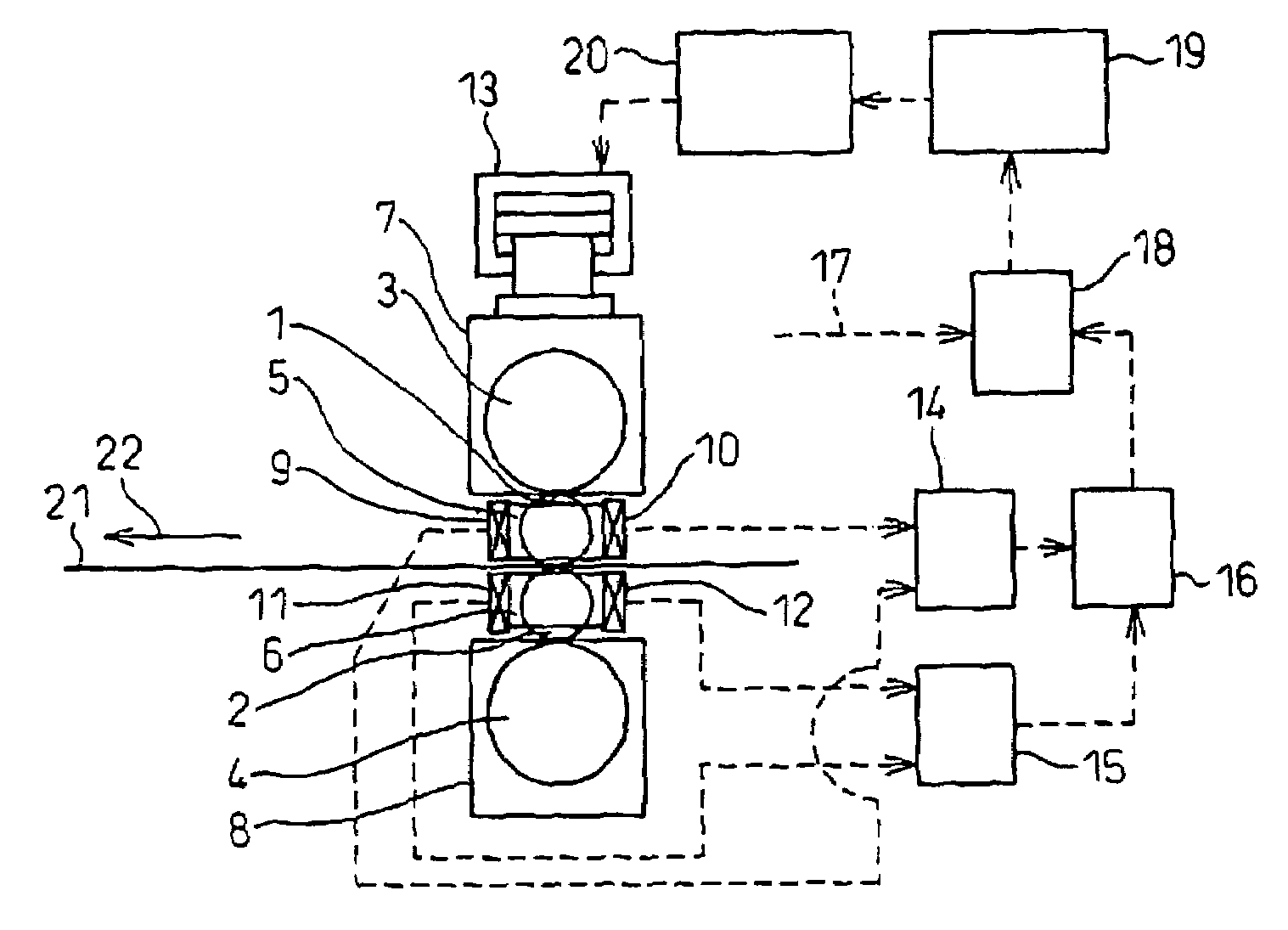

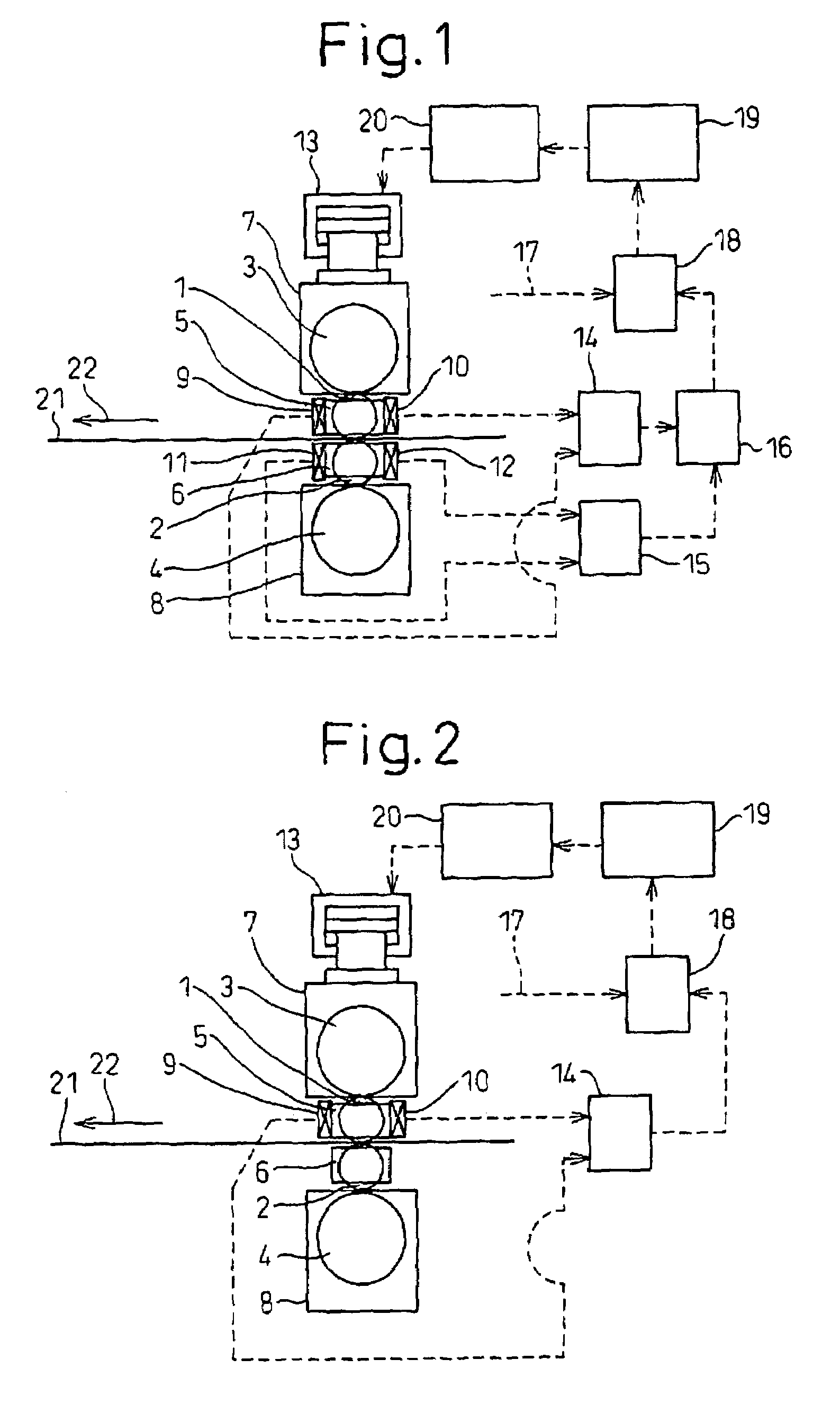

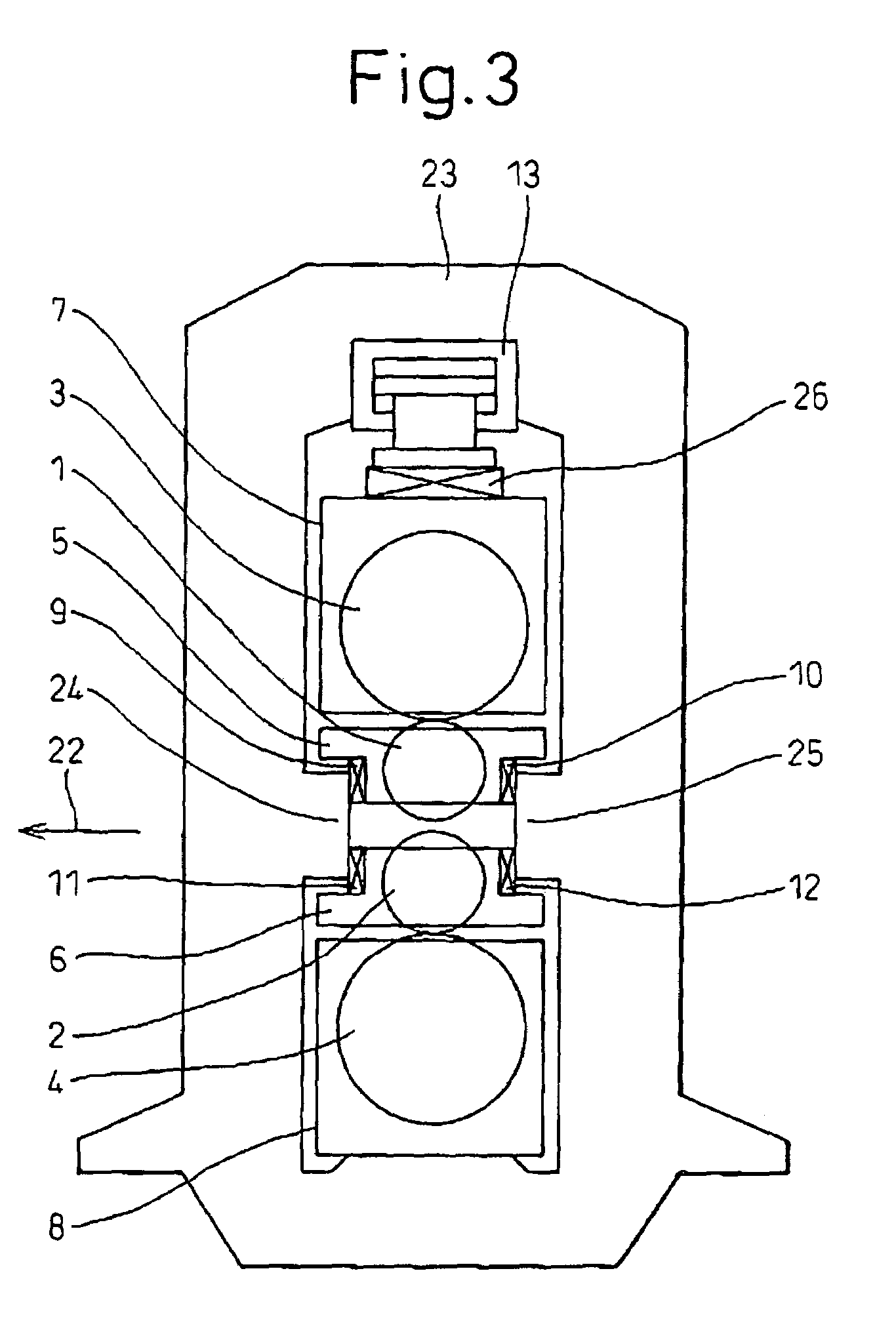

Sheet rolling method and sheet rolling mill

InactiveUS6401506B1Reduce distractionsDisturbance can be reduced negligibly smallRoll force/gap control deviceMetal rolling stand detailsStrip steelBackup roll

In a rolling method applied to a multi-roll strip rolling mill composed of not less than four rolls, one of the zero point of the roll positioning devices and the deformation characteristic of the strip rolling mill or alternatively both the zero point of the roll positioning devices and the deformation characteristic of the strip rolling mill are found from a measured value of the thrust counterforces in the axial direction of the roll acting on at least all the rolls except for the backup rolls in the kiss-roll tightening state and also from a measured value of the roll forces of the backup roll acting on the backup roll chocks of the top and the bottom backup roll in the vertival direction. According to the thus obtained zero point of the roll positioning devices or the deformation characteristic of the strip rolling mill, the setting and control of the roll forces is executed when rolling is carried out.

Owner:NIPPON STEEL CORP

High-alloy centrifugal compound cast steel supporting roll and manufacturing technology thereof

ActiveCN101480663AImprove anti-wear performanceHigh wear resistanceRollsProcess efficiency improvementManufacturing technologyMetallurgy

The invention relates to a high-alloy centrifugal compounding steelcasting support roll and a processing technique thereof. The high-alloy centrifugal compounding steelcasting support roll comprises the following chemical substances: a working layer containing 0.4-0.5 of C, 0.3-0.6 of Si, 0.4-0.8 of Mn, less than or equal to 0.035 of P, less than or equal to 0.03 of S, 3.5-4.5 of Cr, 0.2-1.0 of Ni and 0.2-0.5 of Mo, and the balance steel and impurities by weight; a core part containing 3.0-3.6 of C, 1.7-2.7 of Si, 0.2-1.0 of Mn, less than or equal to 0.08 of P, less than or equal to 0.01 of S, 0.01-0.04 of Re, 0.03-0.08 of Mg, less than or equal to 1.0 of Cr, less than or equal to 1.0 of Ni, less than or equal to 1.0of Mo, less than or equal to 1.0 of Cu, less than or equal to1.0 of V, and the balance iron and impurities by weight. Furthermore, the working layer is formed by horizontal type centrifugal pouring, the core part is formed by pouring, and the heat treatment is carried out in such a way that a trolley type high-temperature resistance furnace to heat a rough machining support roll in an austenite way and preserve the heat of the rough machining support roll. The invention has high abrasion resistance, high accident prevention and high working production ratio.

Owner:TANGSHAN XIANLONG ROLL INDAL

Rolling method and rolling apparatus for flat-rolled metal materials

ActiveUS7310982B2Roll force/gap control deviceMetal rolling stand detailsWork rollMetallic materials

The invention provides a rolling method for a flat-rolled metal material and a rolling apparatus for the method each capable of stably producing a flat-rolled metal material free from camber or having an extremely light camber. The method is a rolling method of a flat-rolled metal material executed by using a rolling mill including at least work rolls and backup rolls. The apparatus is a rolling mill for this method. A rolling direction force acting on roll chocks on the operator side and the driving, side of the work roll is measured, the difference of the rolling direction force between the operator side and the driving side is calculated and a left-right swivelling component of roll gap of the rolling mill is controlled on the basis of this difference.

Owner:NIPPON STEEL CORP

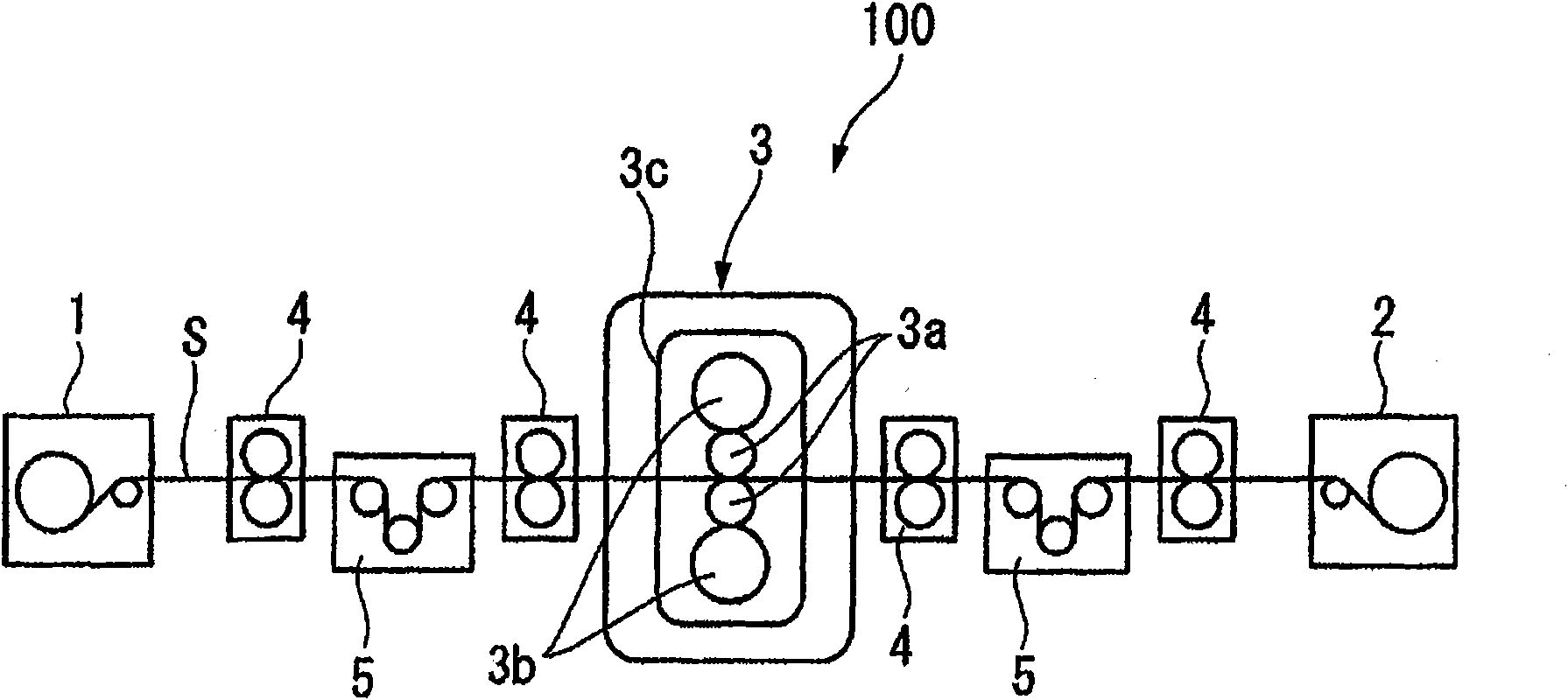

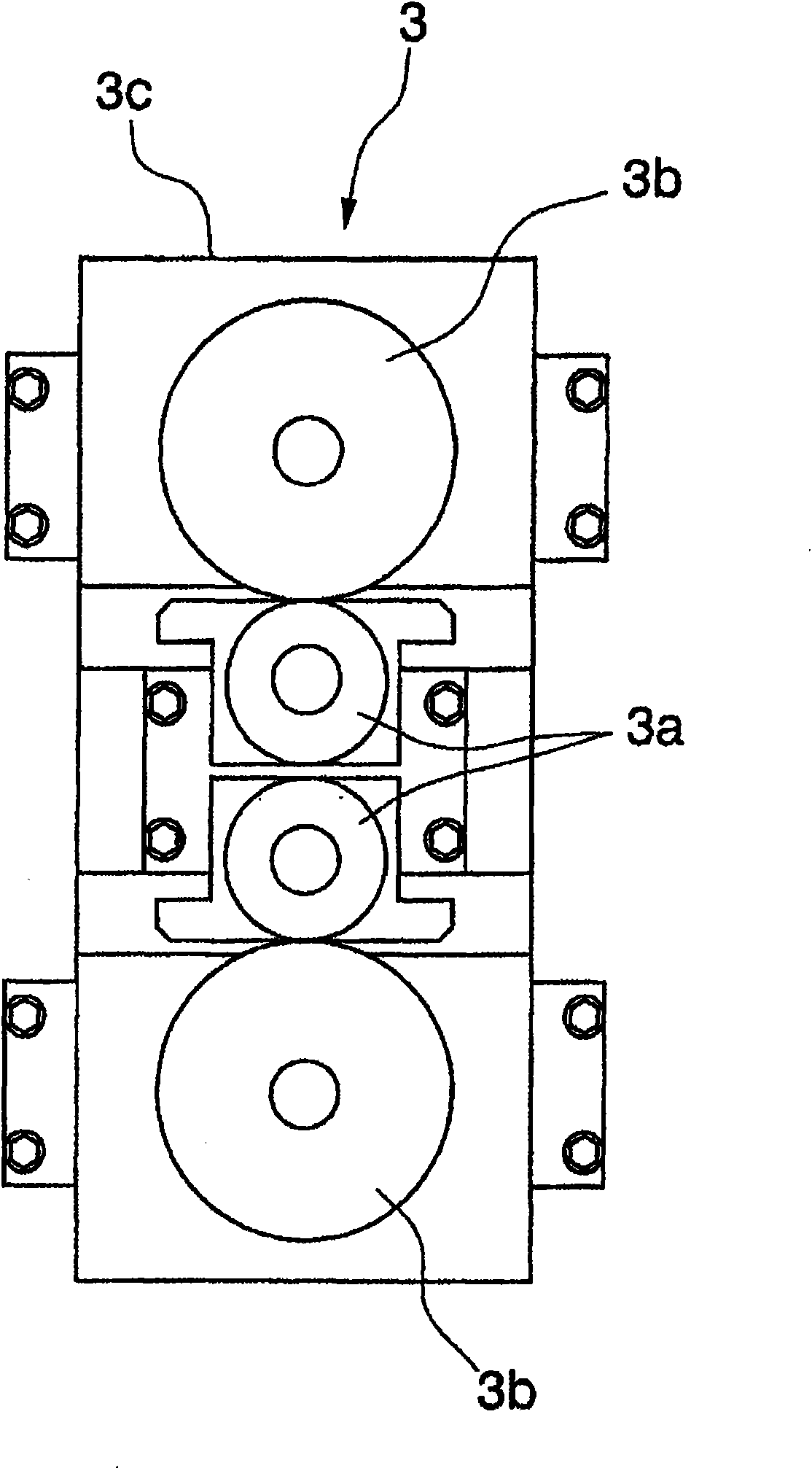

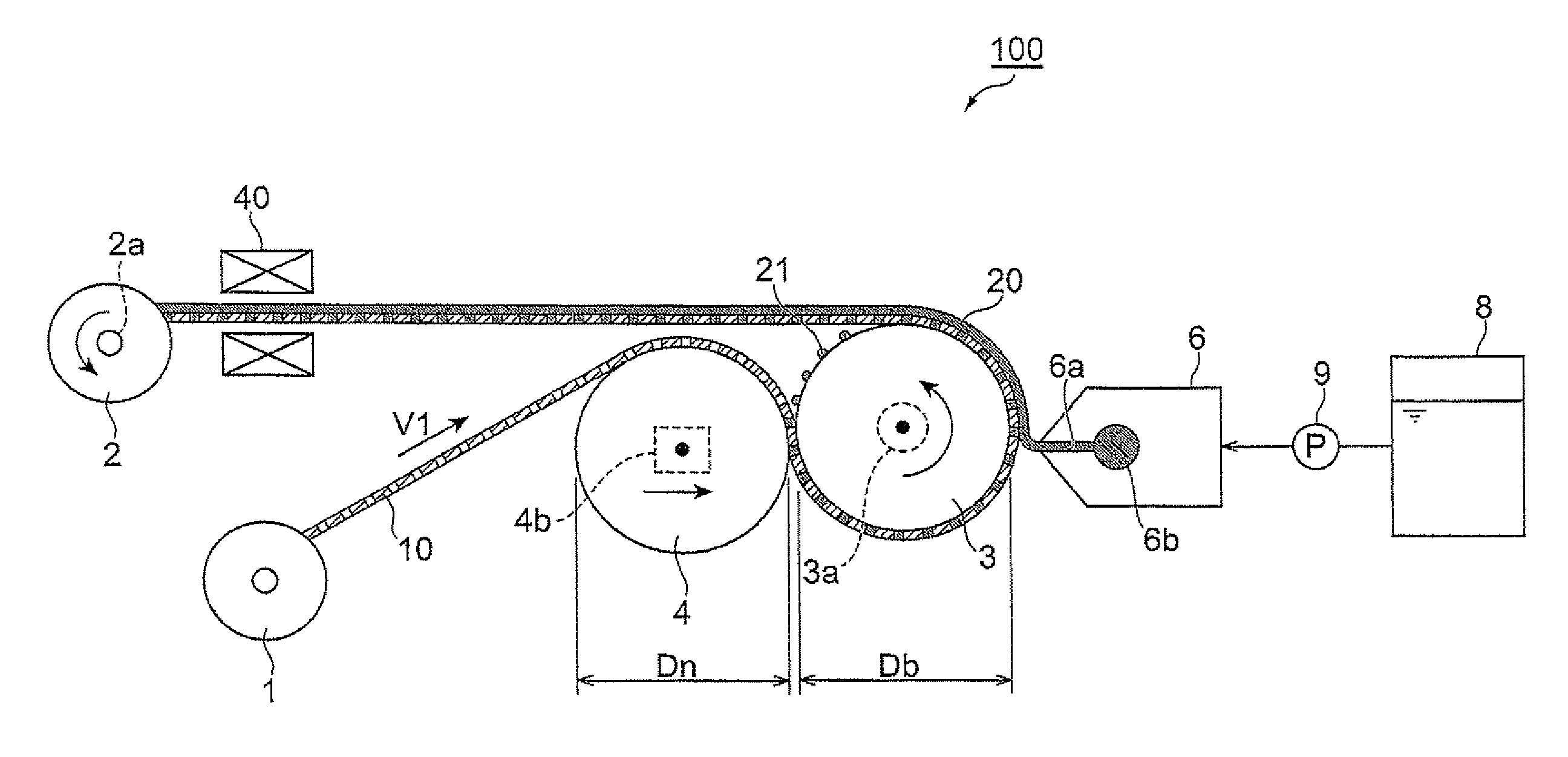

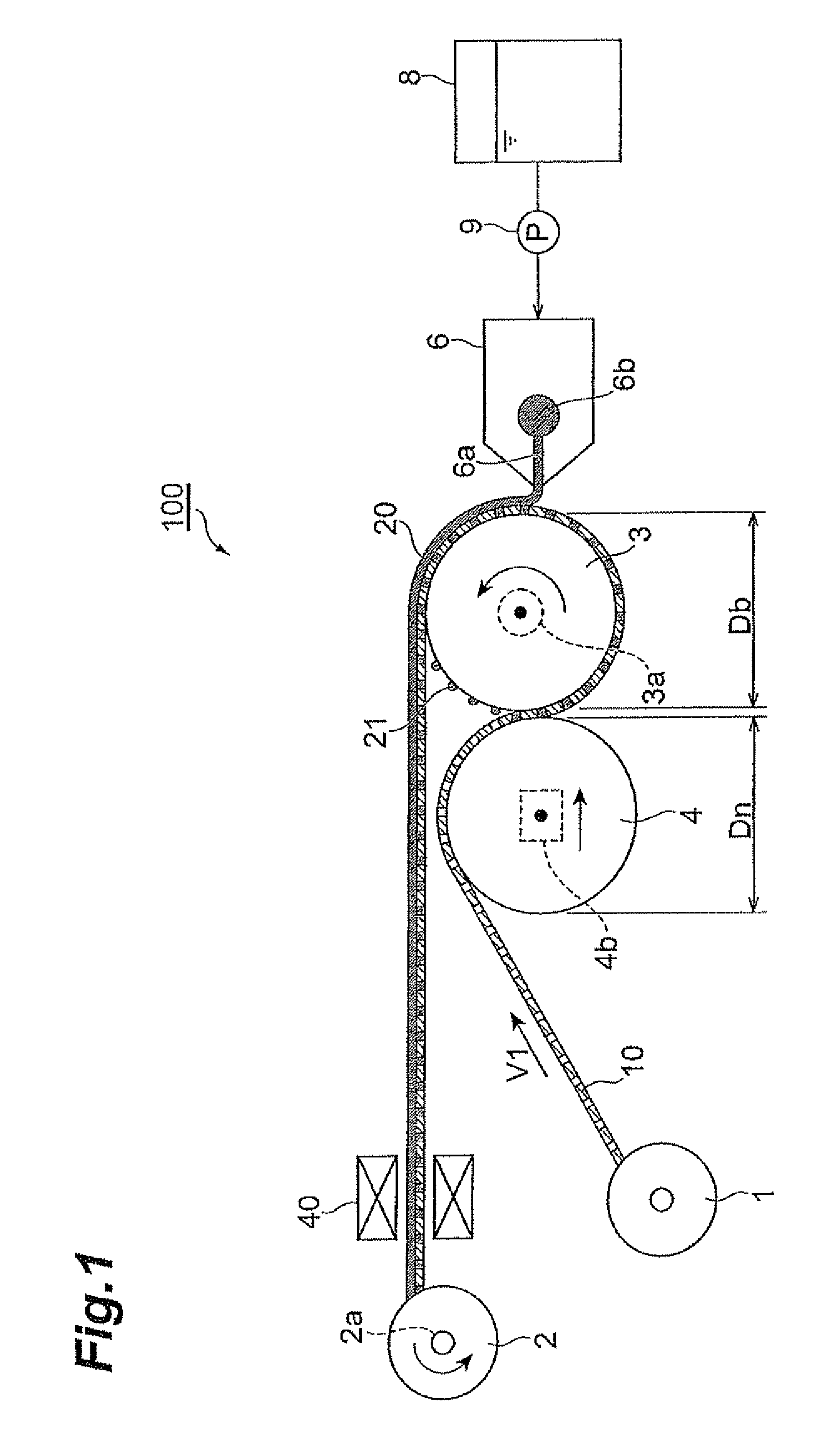

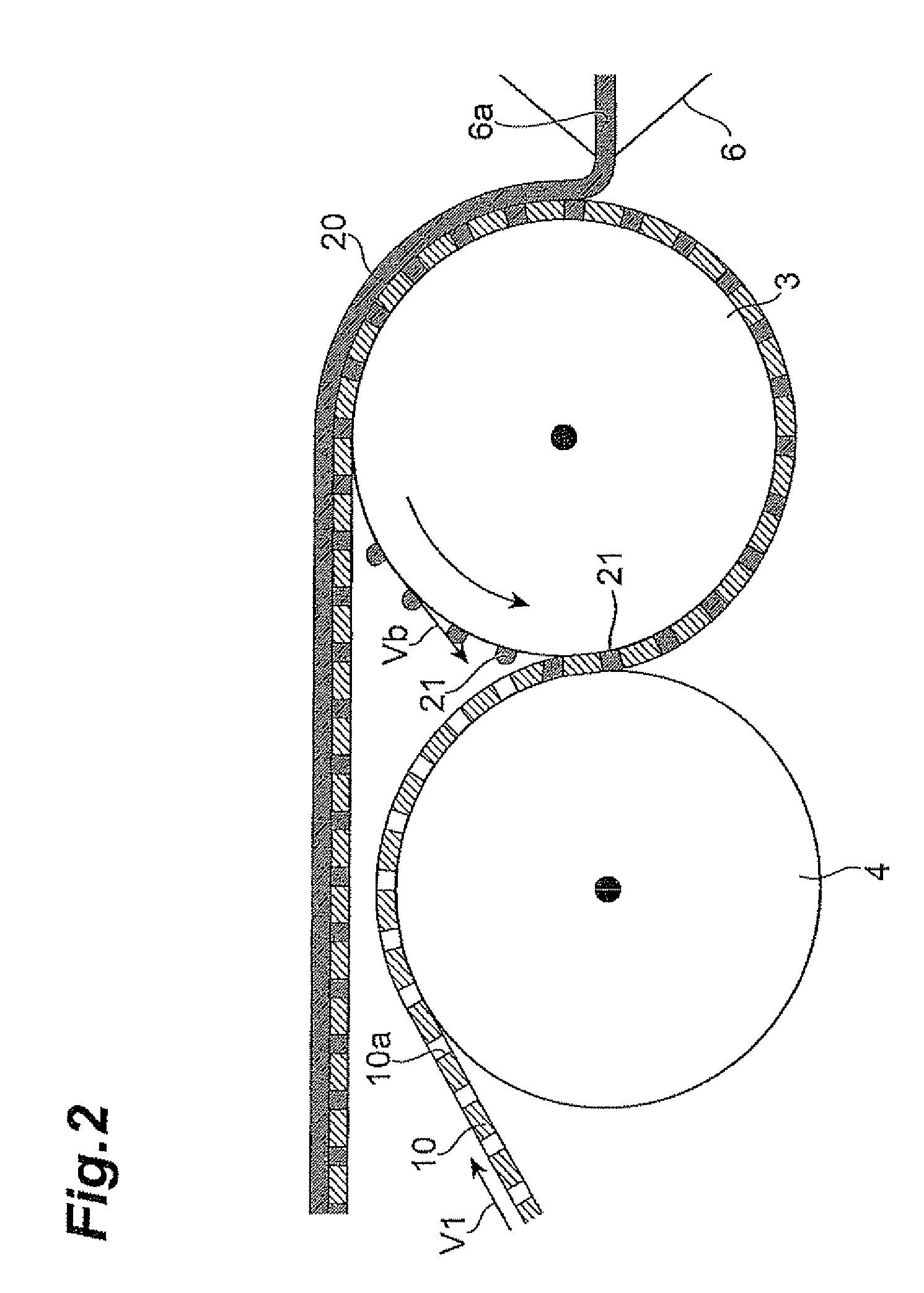

Magnesium alloy hot-rolling mill

A magnesium alloy hot-rolling mill (100), in which winders (1, 2) capable of heating and heat-retaining a magnesium alloy sheet (S) in a coiled state are installed at both input and output sides of a rolling machine (3), and the magnesium alloy sheet is sequentially pressed by multiple reverse rolling operations to gradually reduce the thickness of the sheet. The rolling machine (3) has work rolls (3a) each having a surface heatable to a predetermined temperature and also has backup rolls (3b). With the mill, degradation of the quality of products due to a temperature change during hot rolling of a magnesium alloy can be prevented, the yield of the products can be increased, and the amount of production of the products can be increased.

Owner:IHI CORP

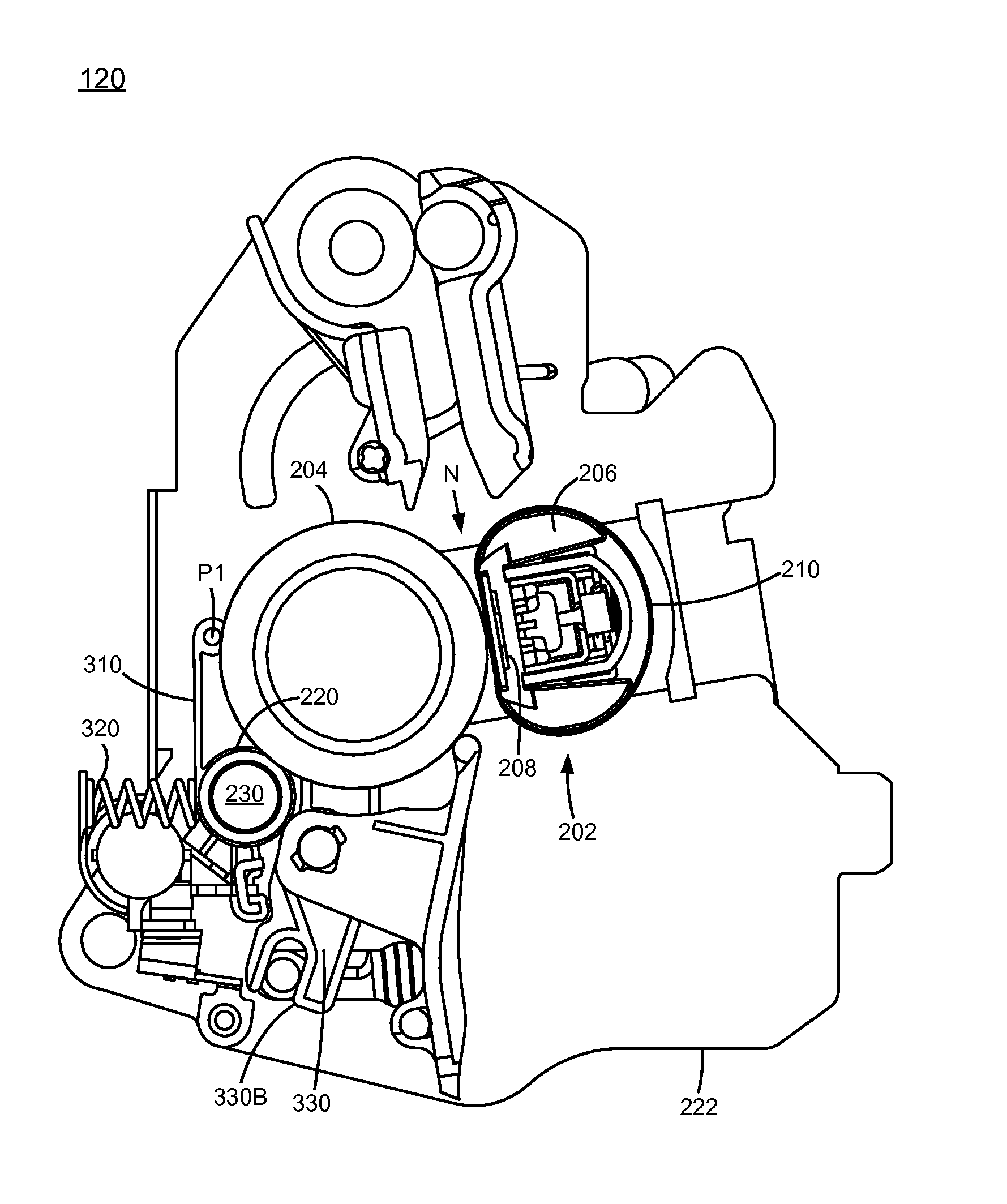

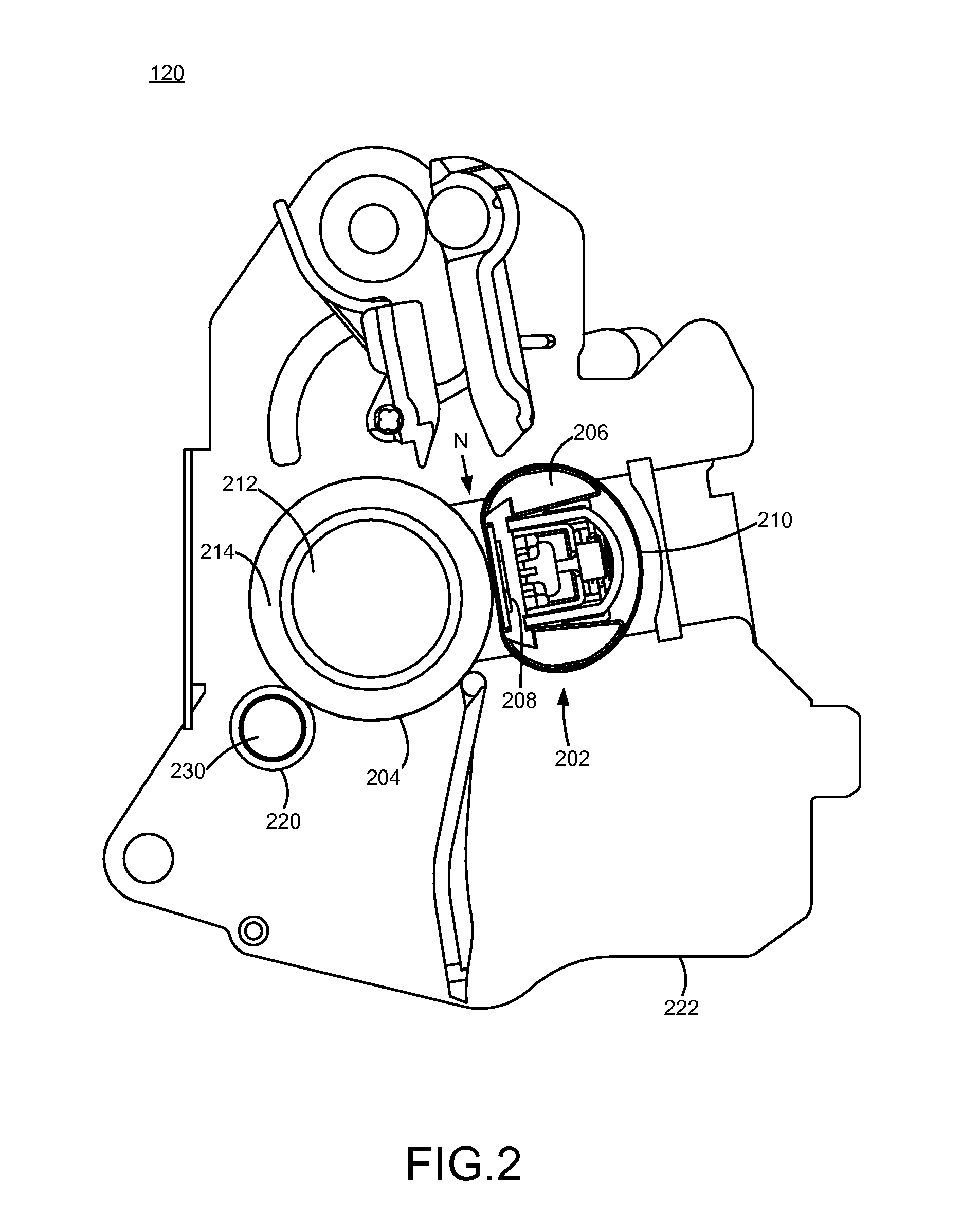

Latch Mechanism for a Fuser Assembly Having a Heat Transfer Roll

ActiveUS20140369725A1Prevent movementElectrographic process apparatusBackup rollElectrical and Electronics engineering

A fuser assembly for an electrophotographic imaging device which transfers heat from overheated portions of the fuser assembly to portions having lesser temperatures. The fuser assembly includes a heating member; a backup roll disposed proximate to the heating member so as to form a fuser nip therewith; a heat transfer device in contact with backup roll; a positioning mechanism coupled to the heat transfer device for positioning the heat transfer device in a first position in which the heat transfer device contacts the backup roll, and a second position in which the heat transfer device is spaced apart from the backup roll; and a latch mechanism for latching the heat transfer device in the second position.

Owner:LEXMARK INT INC

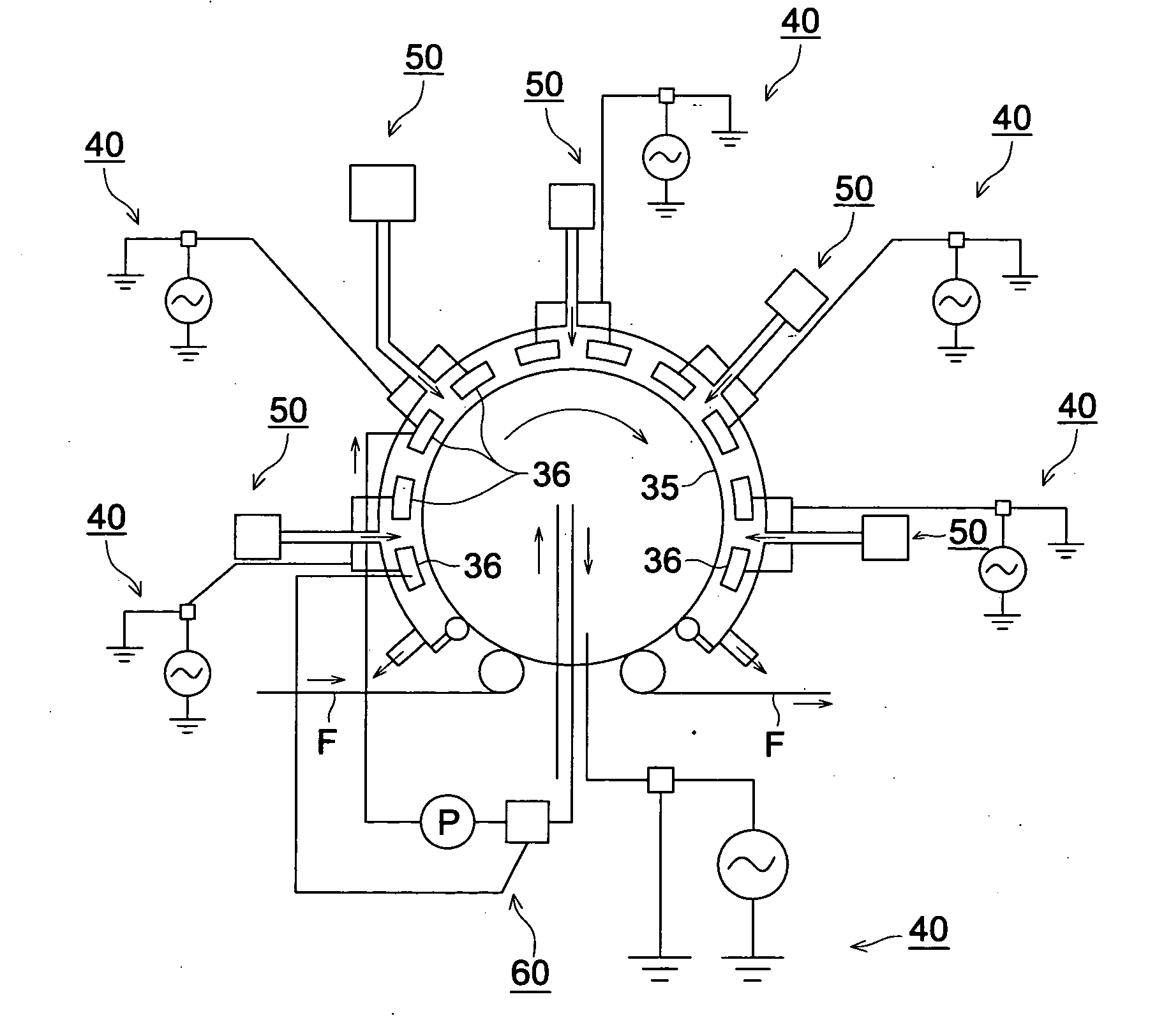

Coating method, and coating apparatus

InactiveUS20100209614A1Reduce in quantityImprove film qualitySolid-state devicesSemiconductor/solid-state device manufacturingBackup rollPhotoelectric conversion

The invention provides a coating method by which plural coating solutions of a coating solution formed from organic EL material for formation of an organic EL layer in an organic EL element and another coating solution formed from organic photoelectric conversion element material for formation of an organic photoelectric conversion element layer can be coated to prepare a multilayer film with no damage of the organic EL layer and organic photoelectric conversion element layer, and also provides a coating apparatus with the coating method. It is a feature in the coating method that plural coating units each facing a backup roll and sandwiching a long length support with the backup roll are provided, and plural coating solutions are coated onto the support by the plural coating units to form a multilayer coating film, wherein the moving support is wound up by the continuously moving backup roll supporting the support.

Owner:KONICA MINOLTA INC

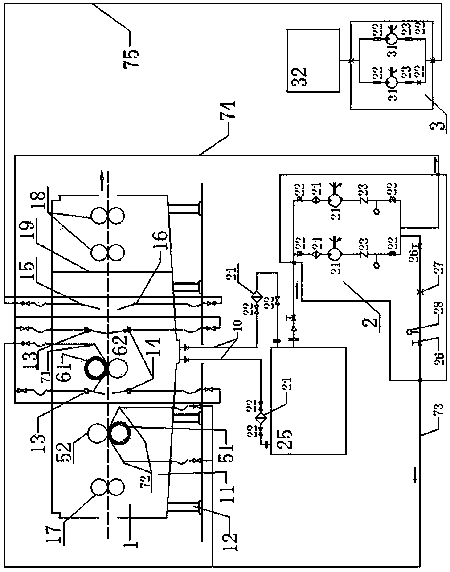

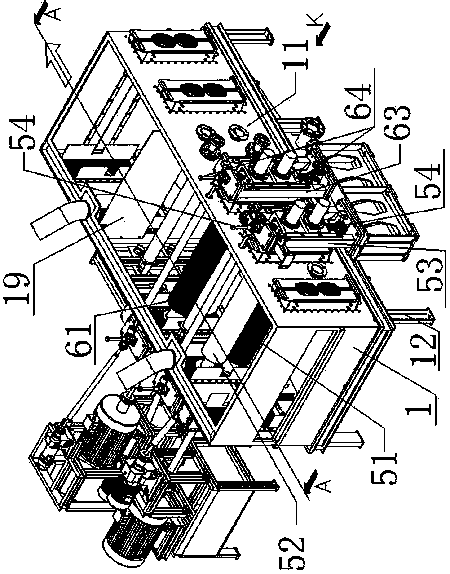

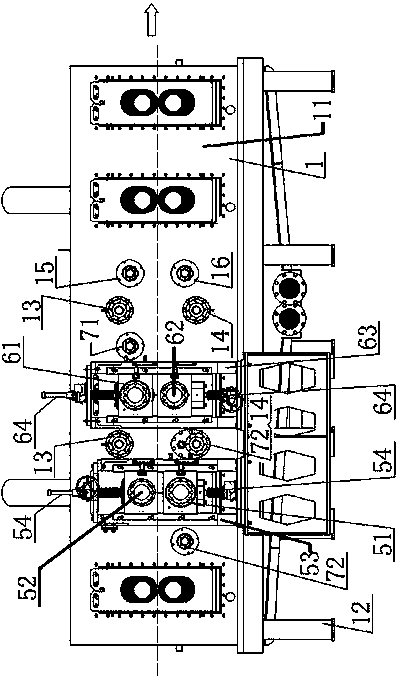

High-pressure spraying and cleaning device for cold-rolled strip steel

ActiveCN103447322AEasy to cleanPut an end to stainsWork treatment devicesMetal rolling arrangementsHigh pressureEconomic benefits

The invention relates to the field of cleaning device spraying fluids on the surface of cold-rolled strip steel, in particular to a high-pressure spraying and cleaning device for cold-rolled strip steel. The high-pressure spraying and cleaning device comprises a spraying system (1), a spraying circulating system (2) and an outlet spraying circulating system (3) and is characterized by further comprising a front brushing roll (51), a front support roll (52), a front brushing roll holder (53), a front worm gear lifting machine (54), a rear brushing roll (61), a rear support roll (62), a rear brushing roll holder (63), a rear worm gear lifting machine (64), an upper brushing roll spraying pipe (71) and a lower brushing roll spraying pipe (72). The high-pressure spraying and cleaning device is good in cleaning effect, highly adaptive, and high in economic benefit.

Owner:BAOSTEEL ENG & TECH GRP

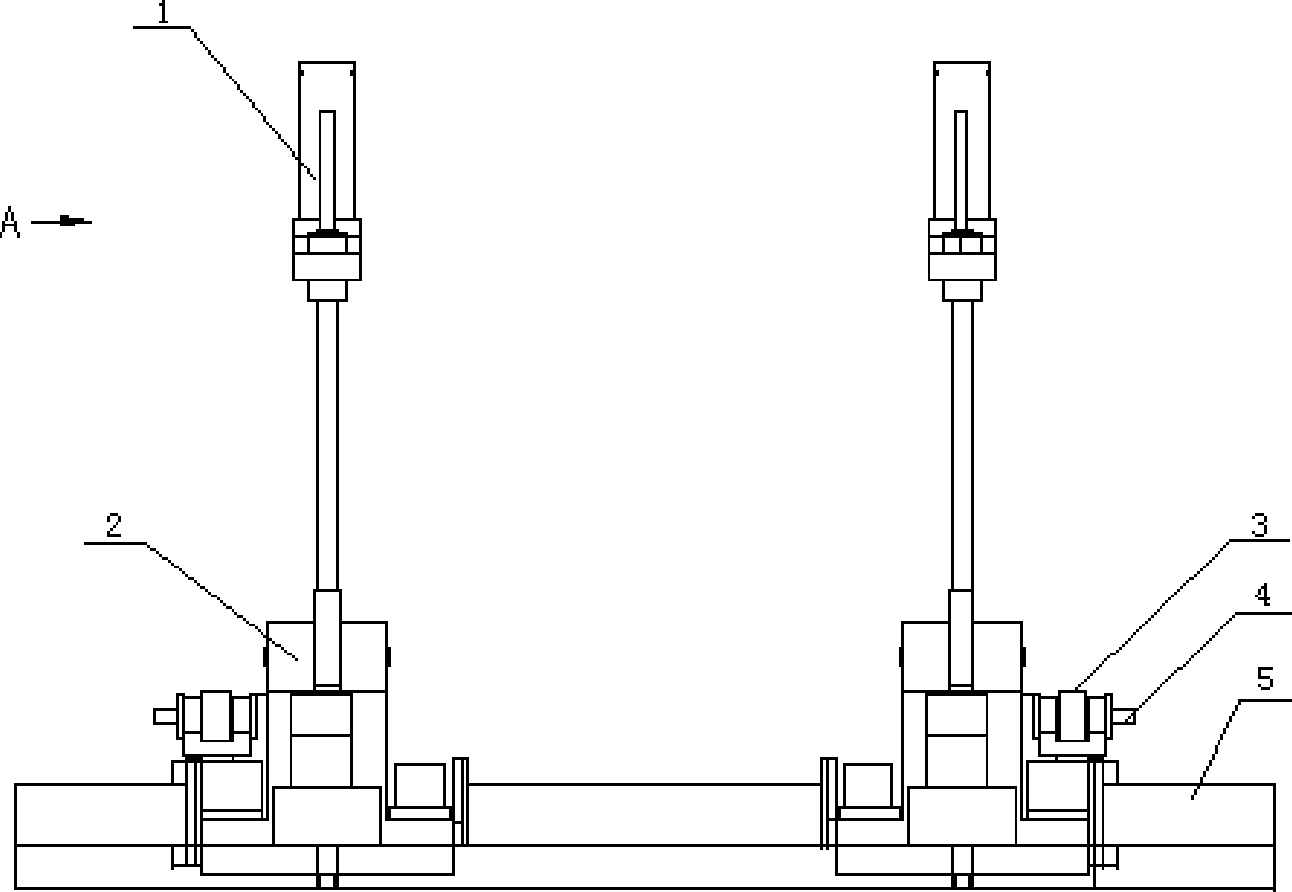

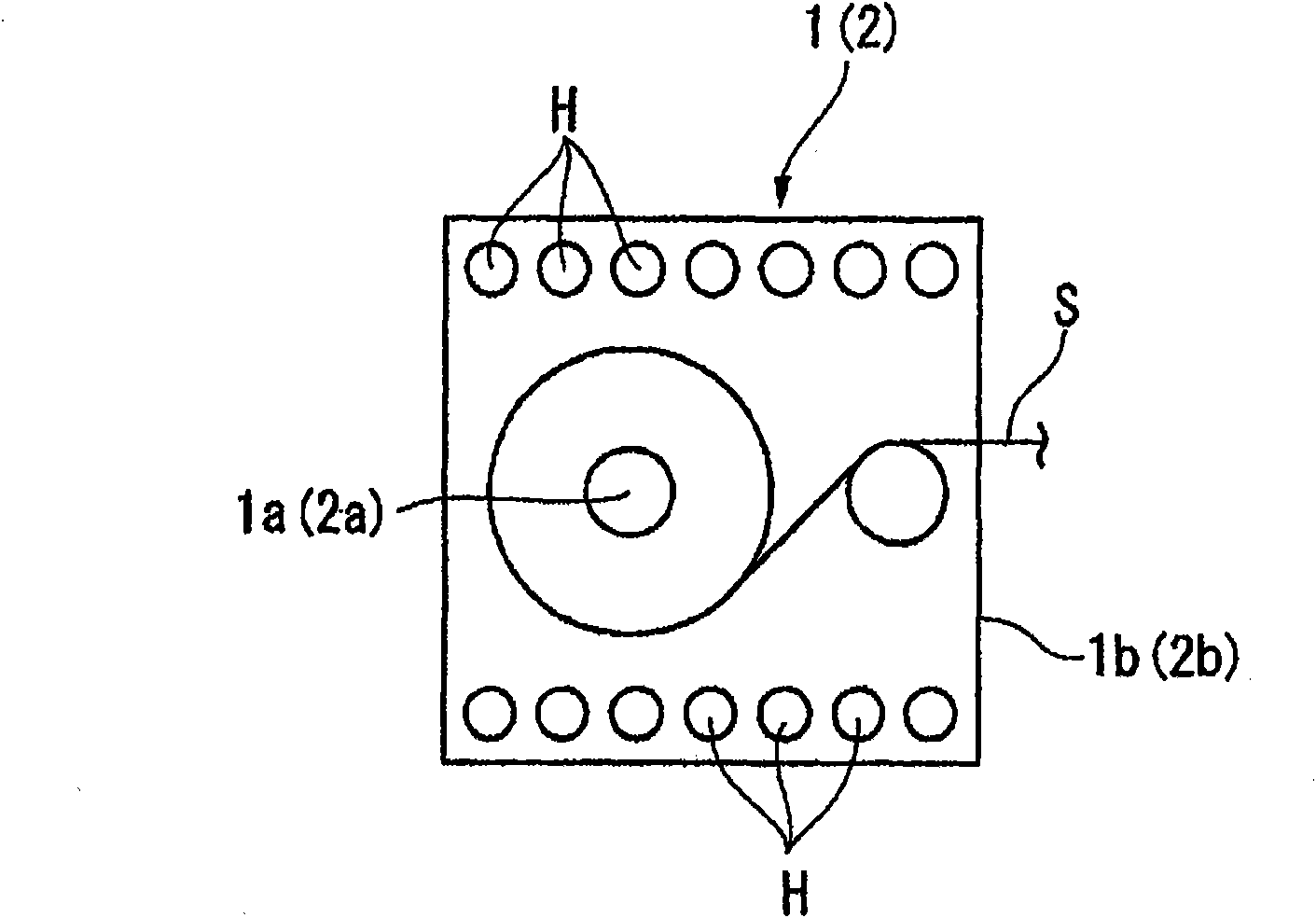

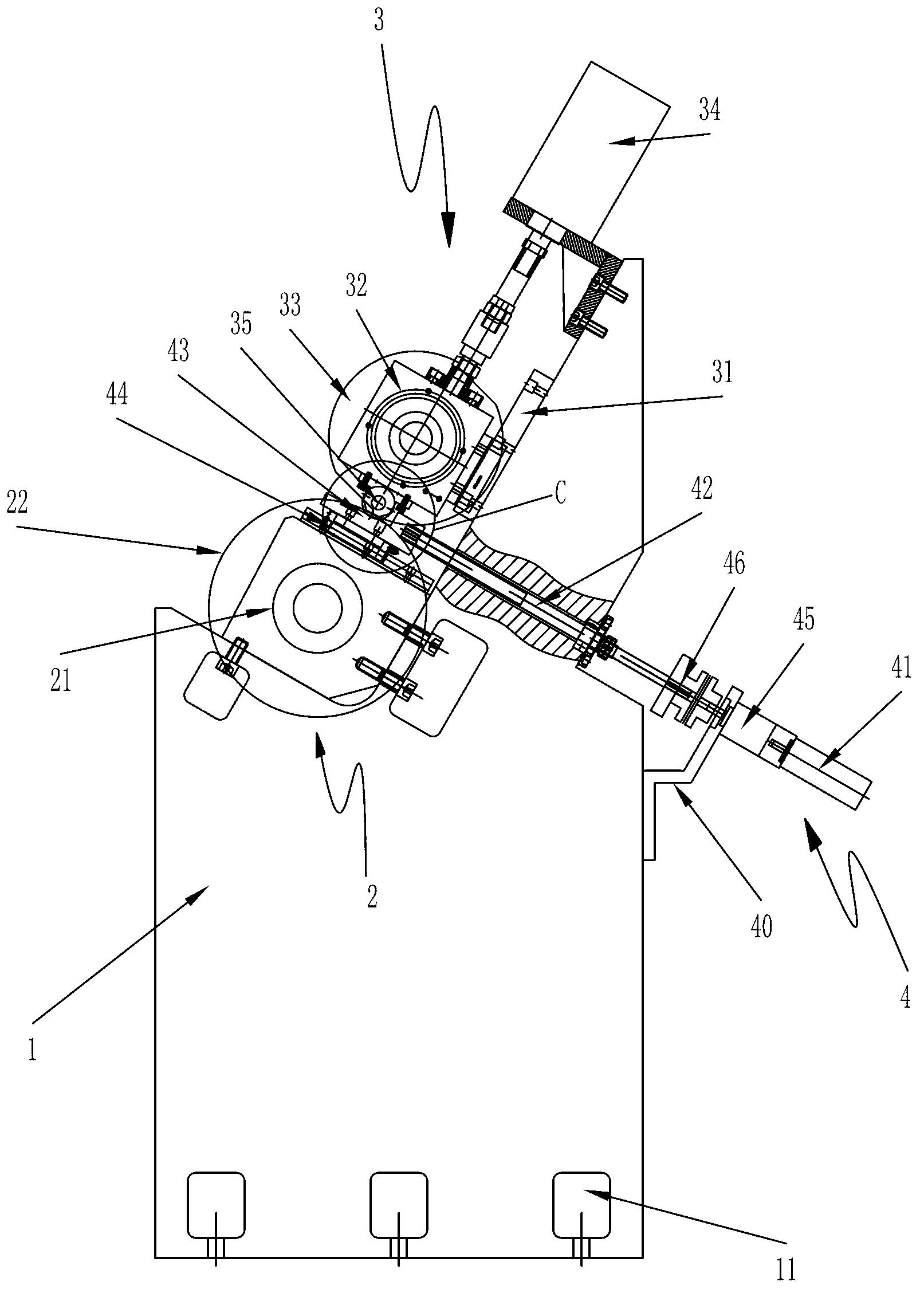

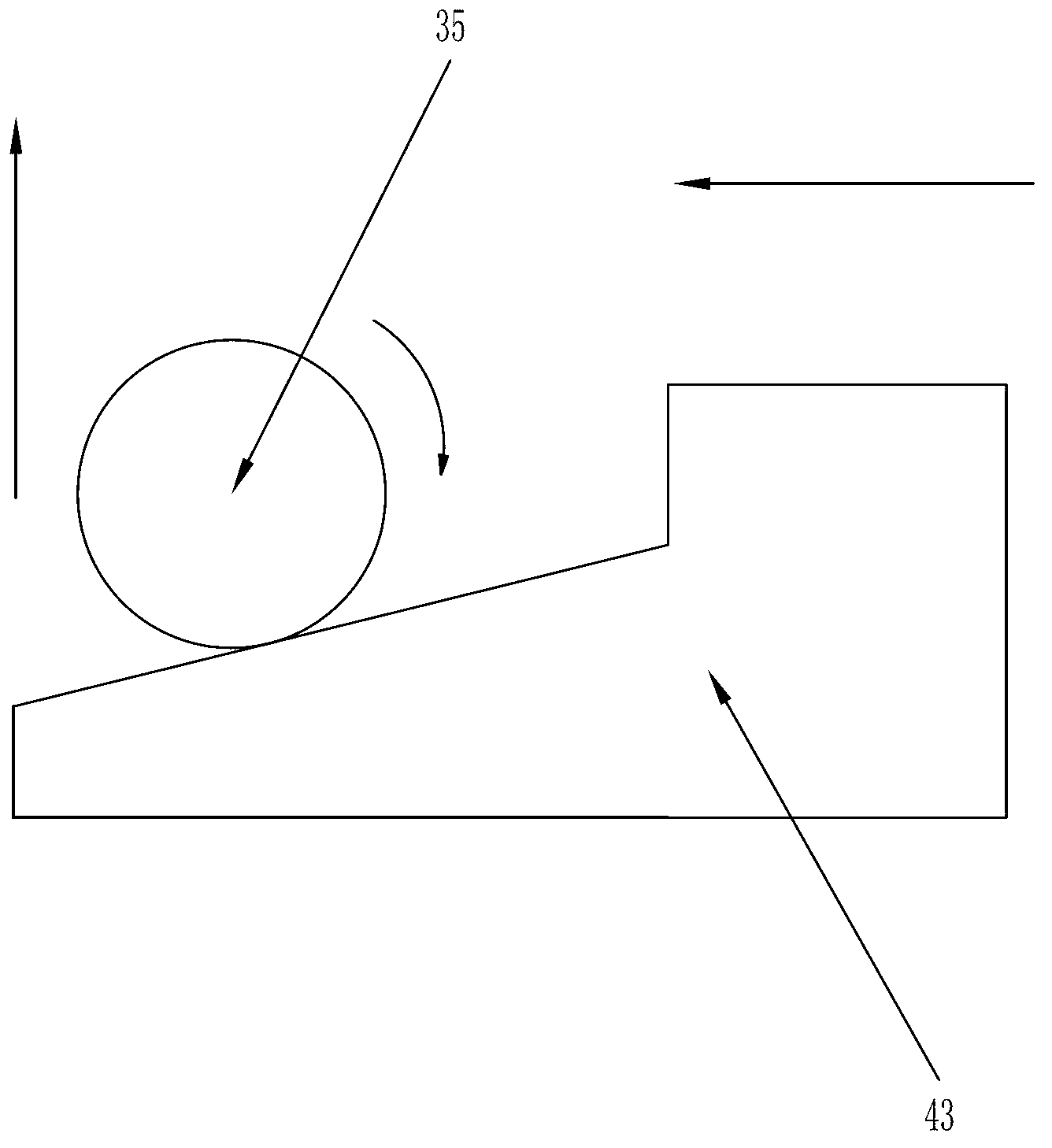

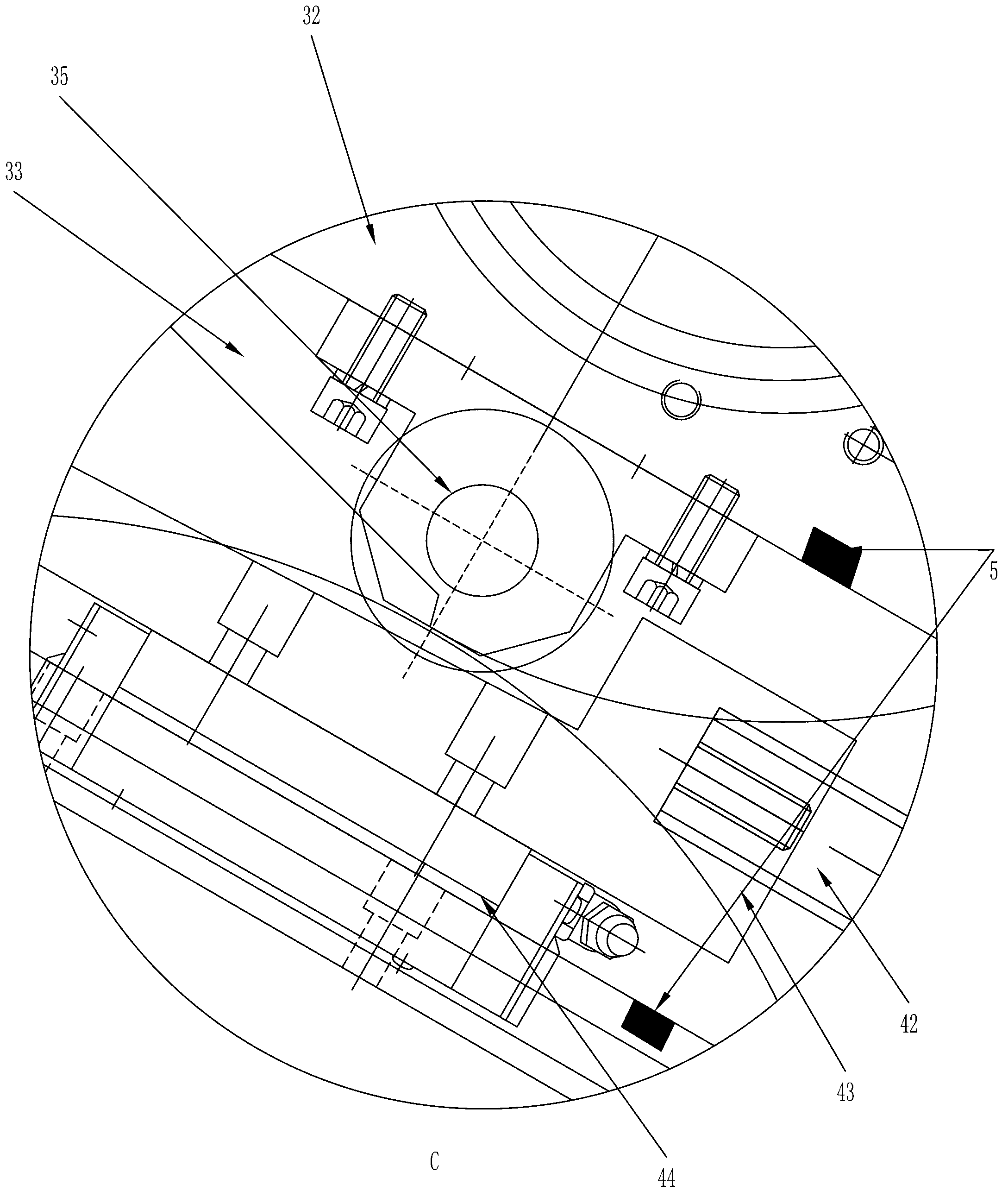

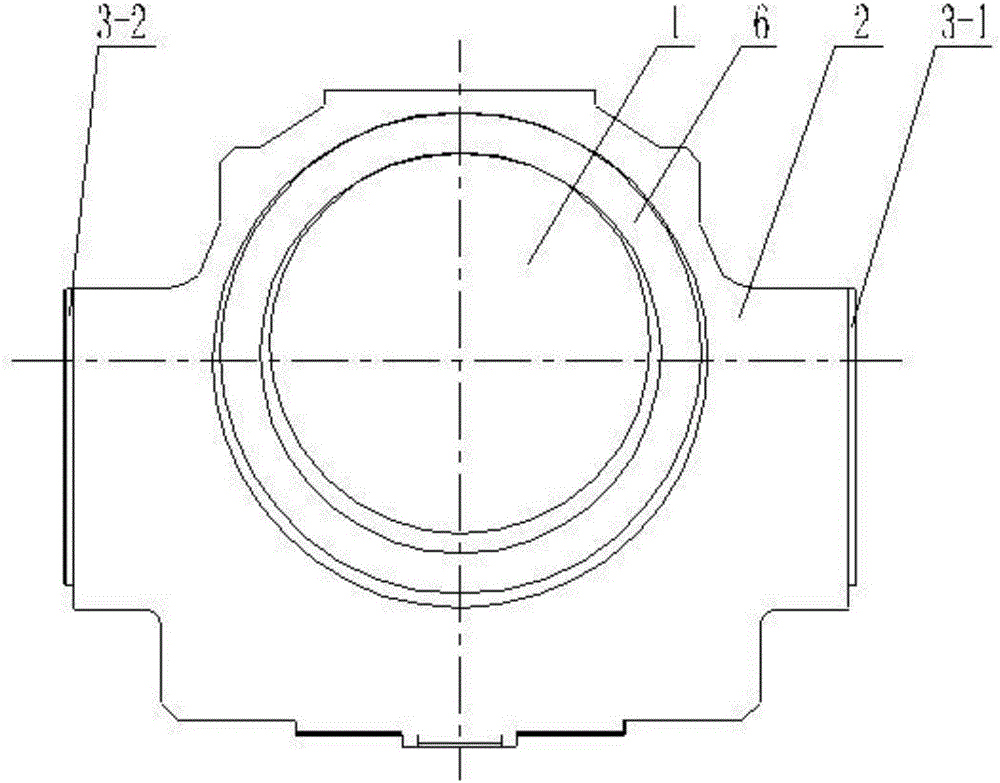

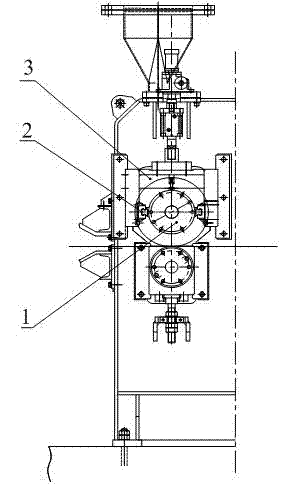

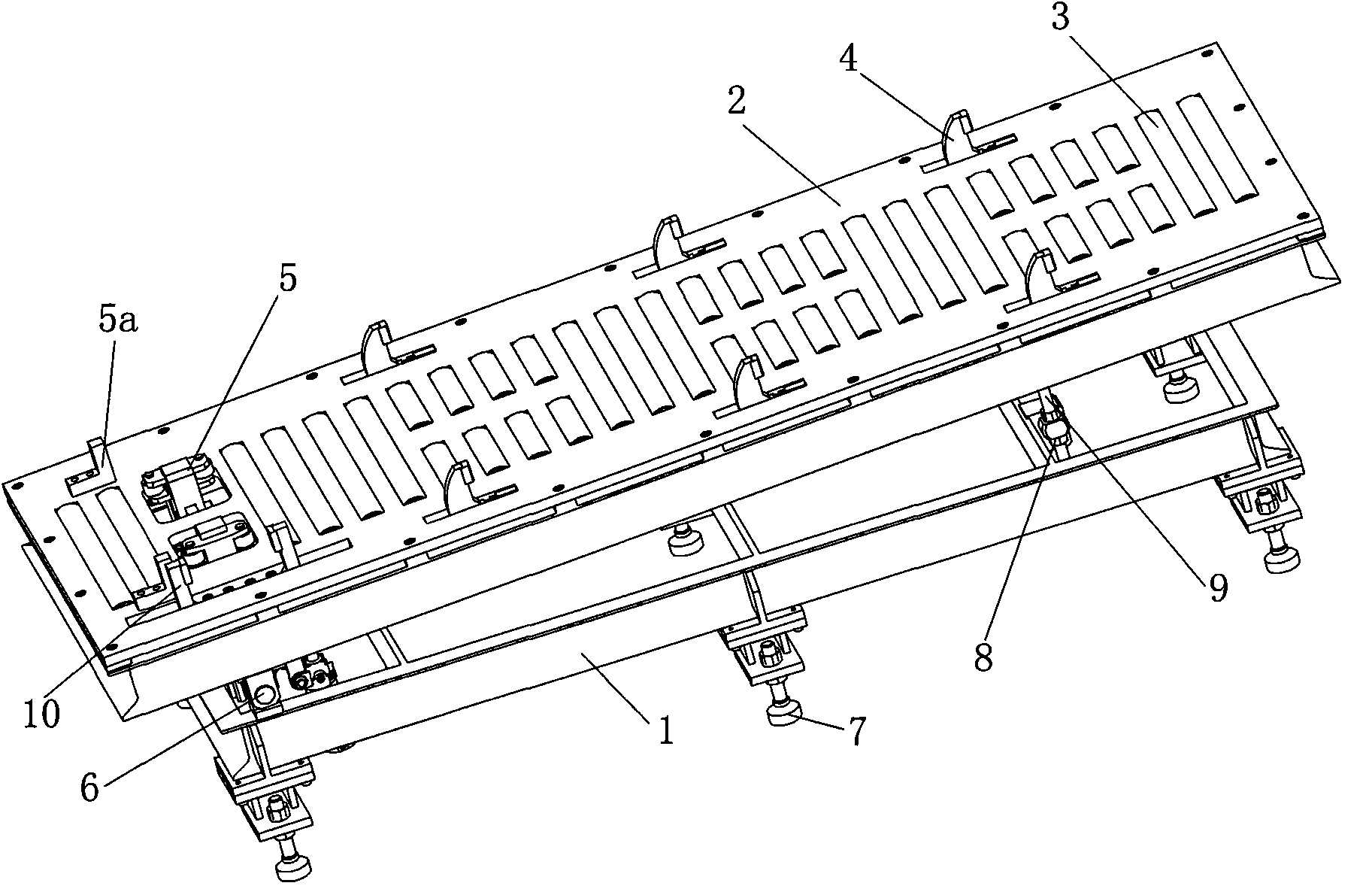

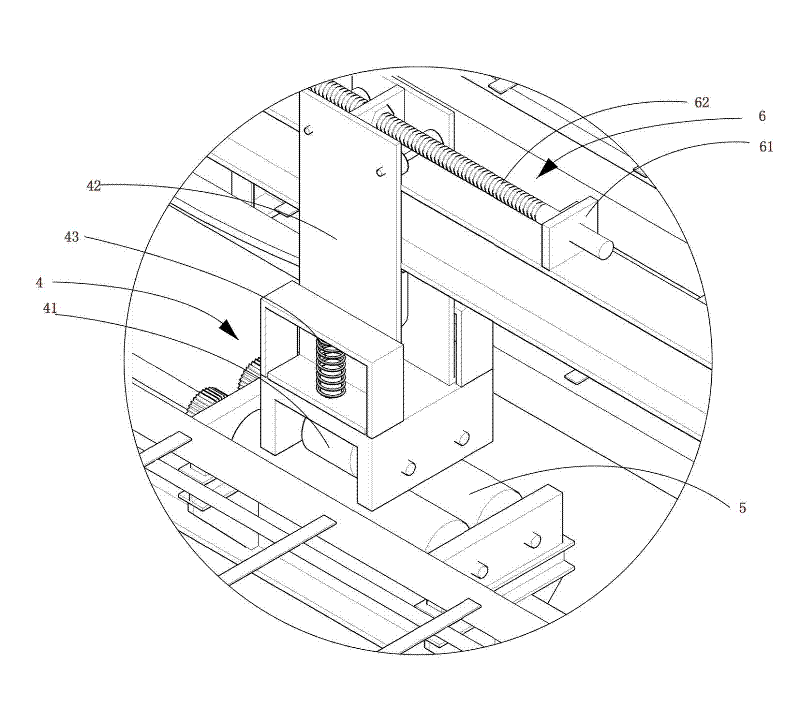

Comma scraper coating machine capable of automatically adjusting interval

InactiveCN103008180AGuaranteed adjustment accuracyLiquid surface applicatorsCoatingsEngineeringBackup roll

The invention discloses a comma scraper coating machine capable of automatically adjusting an interval. The comma scraper coating machine comprises a rack (1); a backup roll assembly (2) is mounted on the rack (1); a comma scraper assembly (3) which is matched with the backup roll assembly and is used for coating is further mounted on the rack (1); an automatic inclined block adjusting device (4) is further arranged between the backup roll assembly (2) and the comma scraper assembly (3); and the comma scraper coating machine further comprises a precision detecting device (5) which is used for detecting a size of the interval between the comma scraper assembly (3) and the backup roll assembly (2), and is capable of feeding back detection information to the automatic inclined block adjusting device (4).

Owner:SOTECH SMARTER EQUIP CO LTD

An upper and lower hot air drying oven for single-sided printing or coating

ActiveCN102294883AImprove drying efficiencyIncrease transmission speedPrinting press partsEngineeringDrying time

The invention discloses an upper and lower hot air type drying box used for single-sided printing or coating. The invention aims to solve the defects in the prior art that the drying time is long when single-sided air supply is carried out on the base material oil ink or coating layer top surface to affect the drying efficiency and transmission speed, or a drying oven is long, and an operation field is big. The technical scheme has the key point that the upper and lower hot air type drying box is composed of a box shell, a plurality of parallel base material backup rolls in the box shell, a plurality of upper hot air supply pipes above the base material backup rolls, an upper hot air equalizing chamber, an upper hot air transmission path and an upper air return chamber, wherein the slice base material enters from a feed port, is supported on the base material backup rolls to operate and is discharged from a discharge hole; and each upper hot air supply pipe is provided with an air supply outlet parallel to the top surface of the slice base material, wherein the top surface is provided with a printing or coating layer. The upper and lower hot air type drying box is characterized inthat a plurality of lower hot air supply pipes, a lower hot air equalizing chamber, a lower hot wind transmission path and a lower air return chamber are arranged below the base material backup rollsby the box shell; and each lower hot air supply pipe is provided with an air supply outlet parallel to the back surface of the slice base material, and the back surface is provided with a printing orcoating layer.

Owner:SHANTOU OLGER PACKING MACHINERY

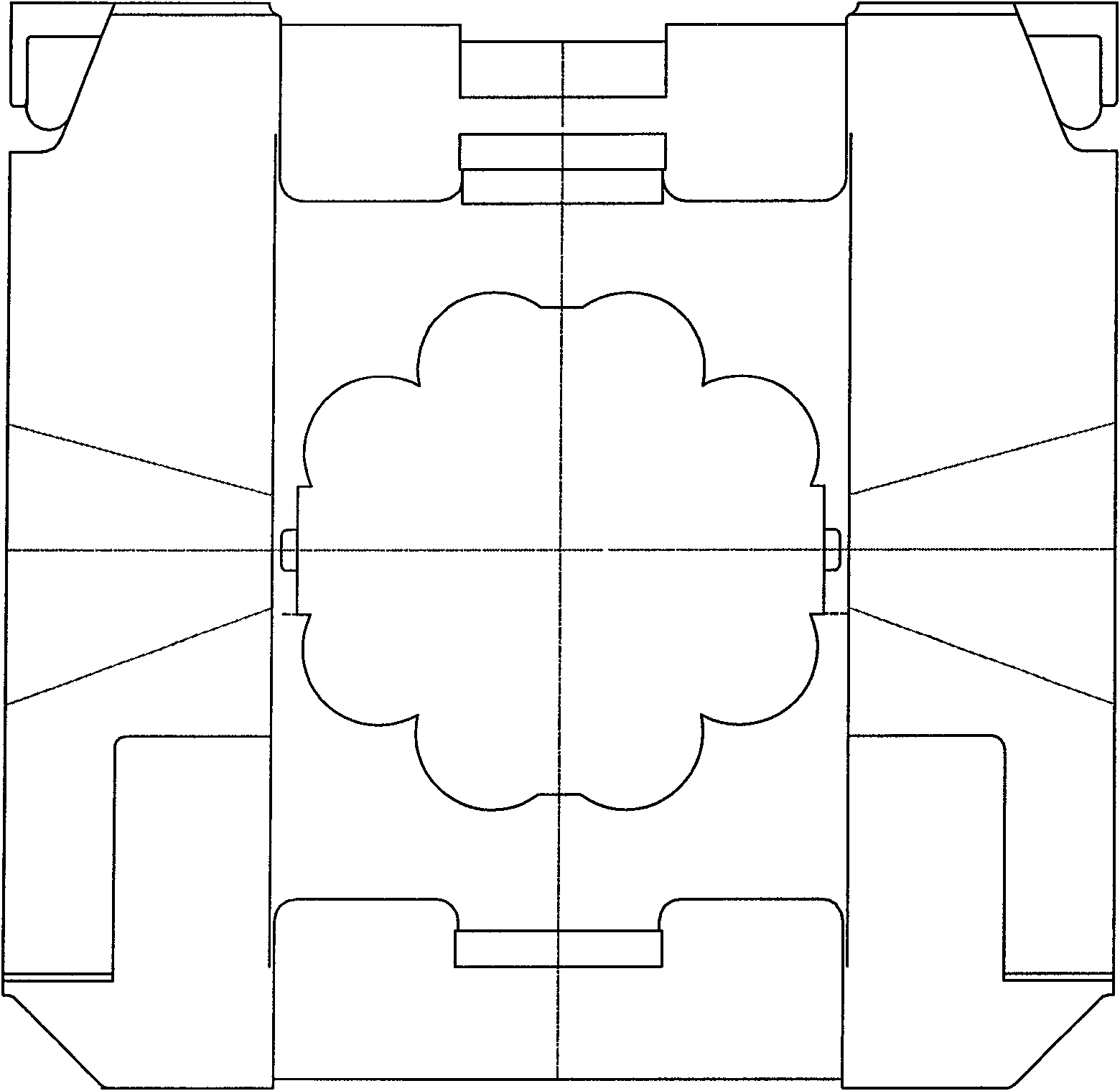

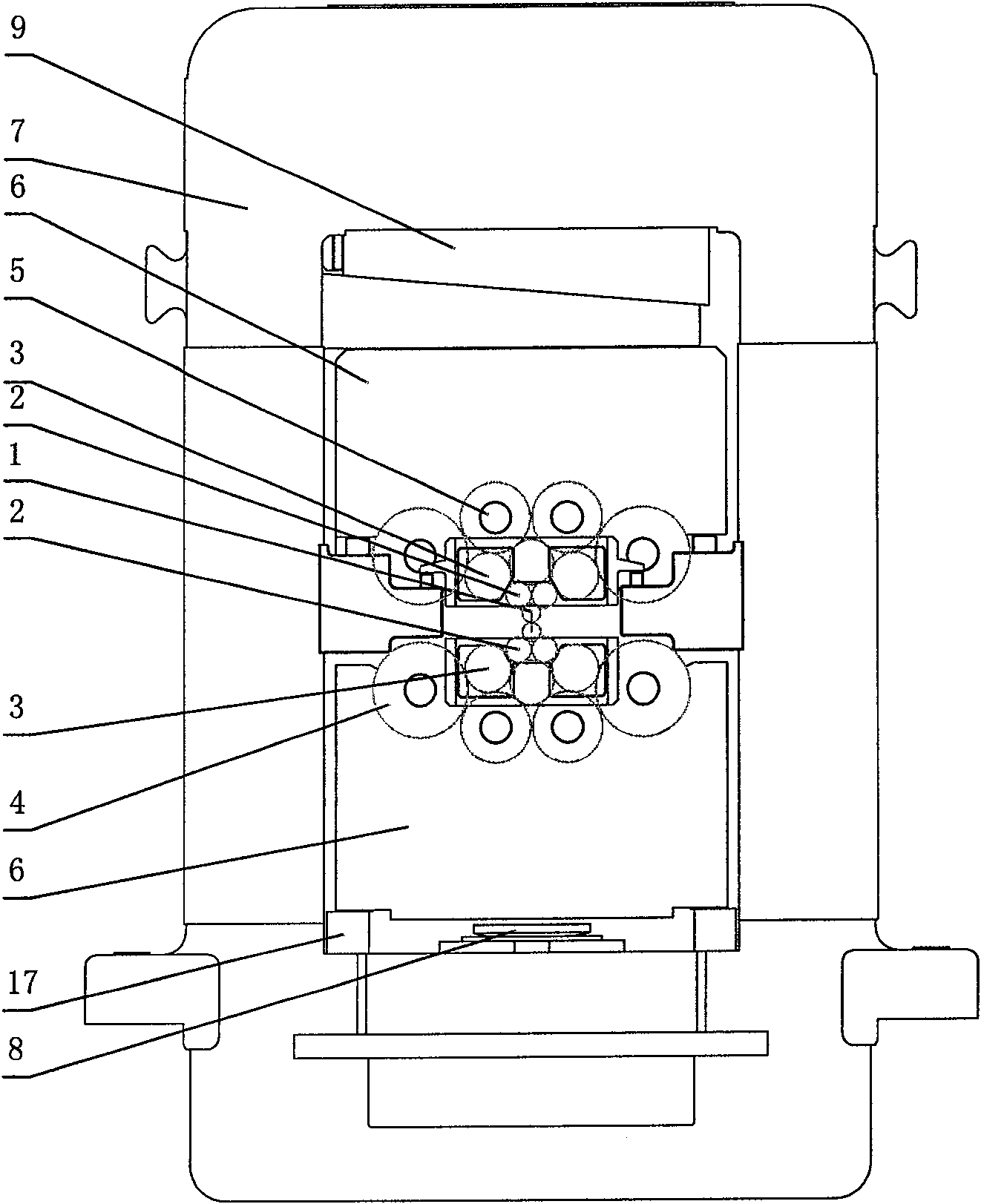

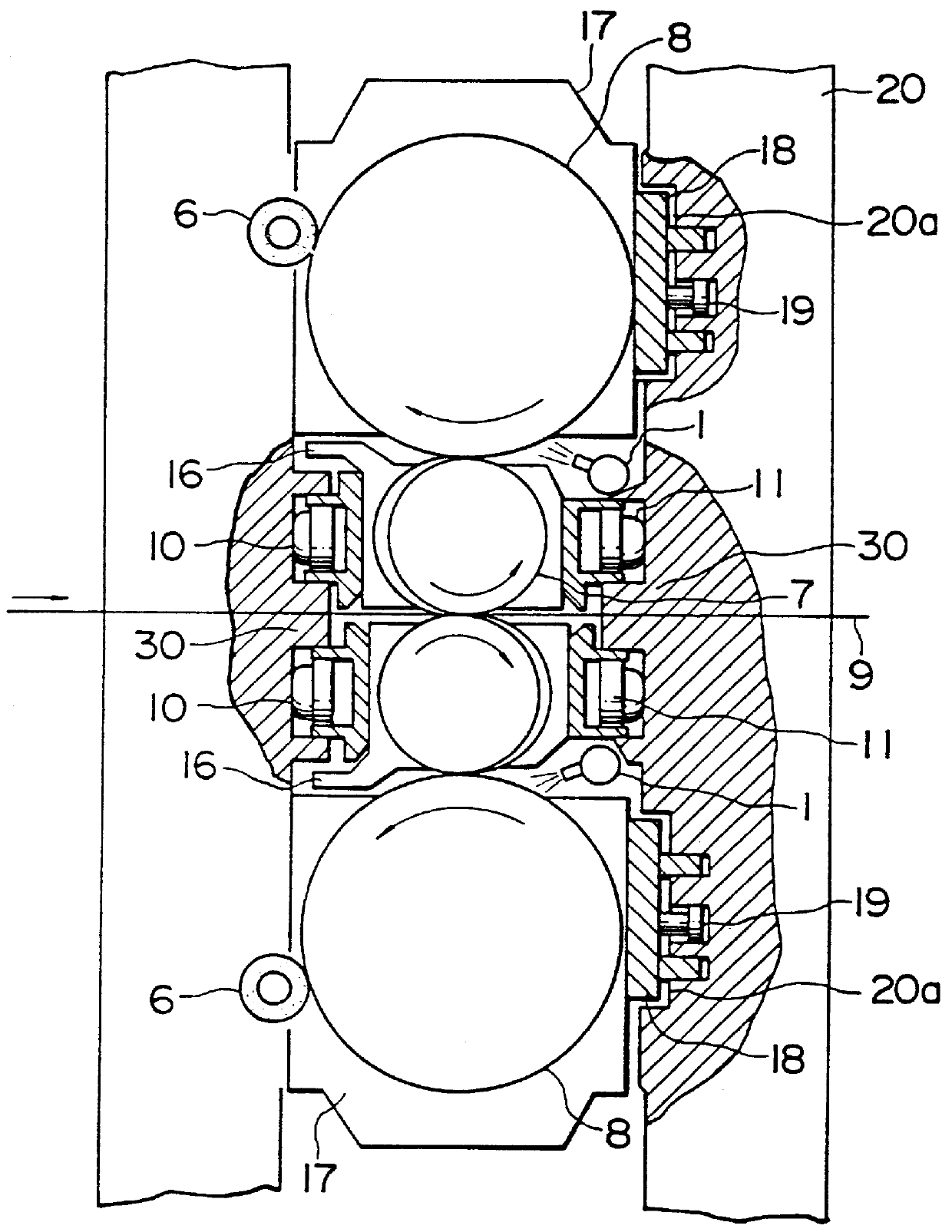

20-roll rolling mill comprising upper and lower splitting integrated roll box and method for replacing rolls thereof

ActiveCN101676041APrevent slippingAchieve replacementMetal rolling stand detailsMetal rolling arrangementsTowerBackup roll

The invention provides a novel technical method for a split-type 20-roll rolling mill comprising a tower-type roll system and 8 rows of backing bearings. The invention simplifies positioning devices in upper and lower box bodies and realizes the overall positioning of same-level backup rolls, while the invention dispenses with an independent suspension device for positioning the backup rolls, so that the roll system can be dismantled rapidly and conveniently for the maintenance and services of the 20-roll rolling mill. The invention improves the process for machining the mounting part of the backing bearings of the roll box, so that the roll box can be stable and reliable in the operating process. The other improvement of the invention provides a method for rapidly changing the rolls of the 20-roll rolling mill. The method can pull out backup rolls or working rolls in each layer and adjacent backup rolls thereof at the same time, thereby greatly reducing the time for changing rolls andimproving the operating efficiency.

Owner:王宇 +1

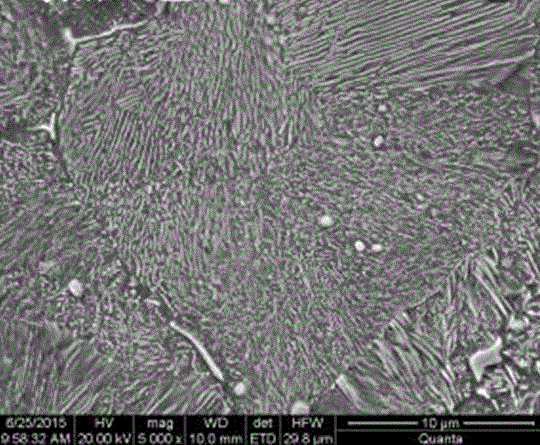

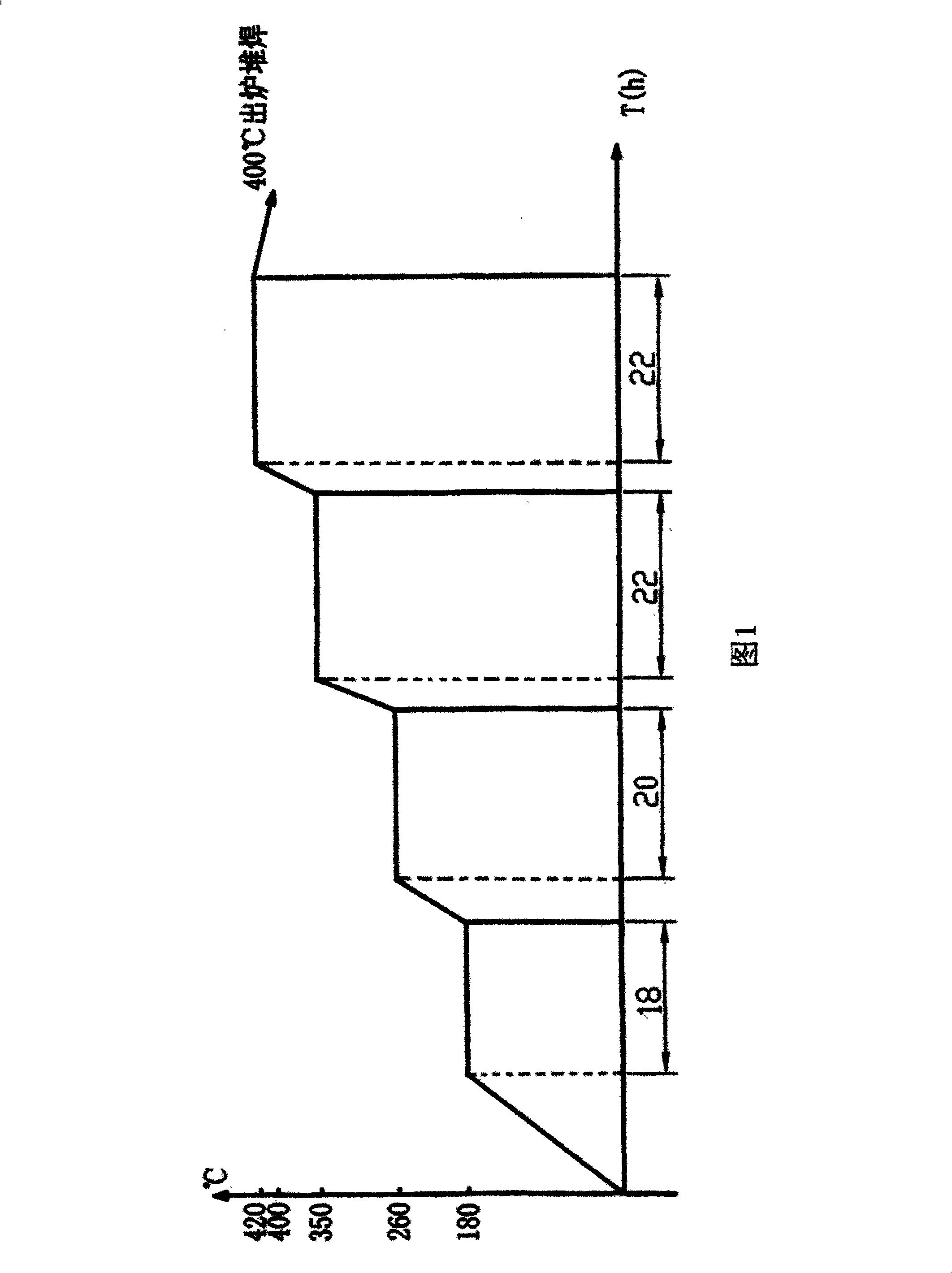

Preheat treatment method for large-size forged steel supporting roller

InactiveCN105648161AReduce spheroidization processReduce processFurnace typesHeat treatment furnacesLarge sizeQuenching

The invention discloses a preheat treatment method for a large-size forged steel supporting roller. The after-forging heat treatment process is technically characterized in that high-temperature normalizing and high-temperature tempering processes are adopted under the normalizing heating temperature of 800 to 970 DEG C and the heating rate of less than 90 DEG C / h; after the temperature is averaged, the heat insulation time is determined according to the diameter of a roller body of the supporting roller; the heat insulation time for the supporting roller with the diameter of Phi 1,000-1,700 mm is 10 to 40 hours; after the roller is cooled in air, high-temperature tempering is carried out under the tempering temperature of 500 to 750 DEG C and the heating rate of less than 60 DEG C / h; after the temperature is averaged, the heat insulation time is 40 to 90 hours. A hardening and tempering process is as follows: an oil quenching and high-temperature tempering process is adopted; the preheat temperature for the supporting roller is 550 to 700 DEG C and is insulated for 5 to 20 hours; then the supporting roller is heated to the quenching temperature of 800 to 970 DEG C under the heating rate of 80 DEG C / h; after the heat is insulated for certain time, oil quenching is carried out for cooling time of 100 to 400 min; once oil is discharged, tempering is carried out immediately under the tempering temperature of 500 to 750 DEG C and the heating rate of less than 50 DEG C / h; after being averaged, the temperature is insulated for 20 to 90 hours.

Owner:CHINA FIRST HEAVY IND

Hot rolling roller-containing bearing seat liner symmetry detection method and device

ActiveCN106247999AHigh symmetry accuracyMeet the requirement of symmetry design value 0.2mmUsing optical meansProduction lineEngineering

The invention discloses a hot rolling roller-containing bearing seat liner symmetry detection method and device. The detection method comprises a step of suspending a support roller and bearing seats when the bearing seats are in a roller-containing state, since the bearing seats are heavy (usually larger than 7t per piece) and symmetrical in the structure, line contact is formed by the bearing seats, the bearing, and the bus on the support roller, the axis of the support roller are in the symmetrical surfaces of bearing seat inner holes, then the origin of a coordinate system is established on the support roller axis, a laser tracker is used to carrying out multi-point detection on a bearing seat linear, and the symmetry numerical value after the assembly of the hot rolling roller-containing bearing seat liner is obtained. Compared with an existing roller-containing indirect detection method, the detected roller system symmetry is high, according to the a detection result, the deviation of the support roller axis from the bearing seat inner hole symmetrical surfaces is smaller than 0.05mm, the requirement of the symmetry design value 0.2mm after the assembly of the hot rolling roller-containing bearing seat liner is completely satisfied, compared with a method of removing the support roller and carrying out directly measuring by the bearing seat inner holes, the detection efficiency can be improved by more than 3 times, and the fast pace requirement of hot rolling production line roller changing is satisfied.

Owner:ANHUI MAGANG HEAVY MASCH MFG CO LTD

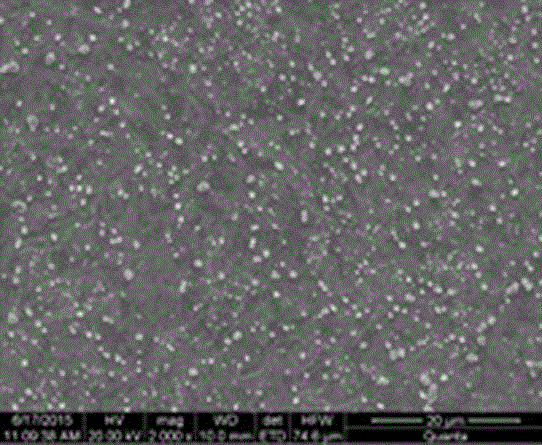

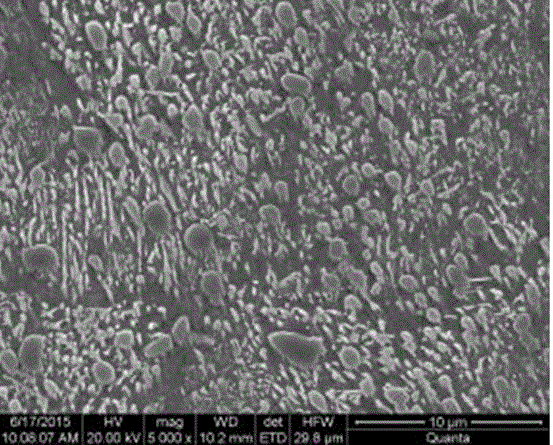

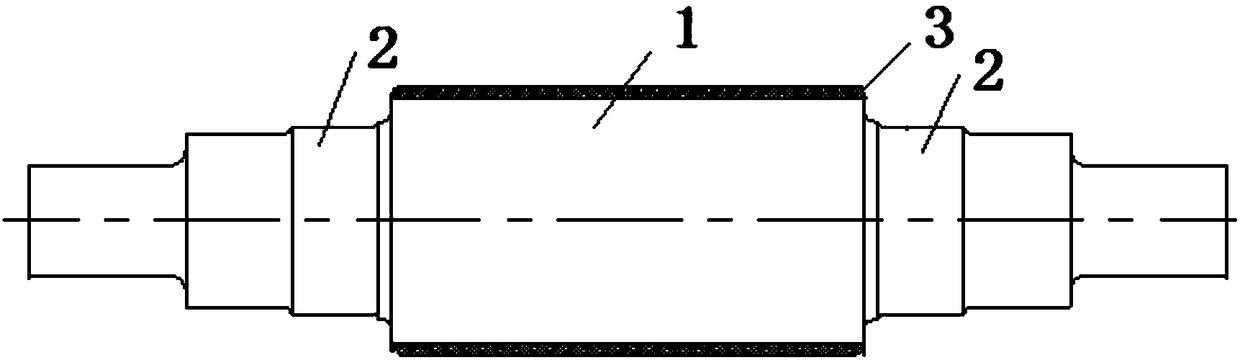

Support roll with high abrasion resistant performance and manufacturing method thereof

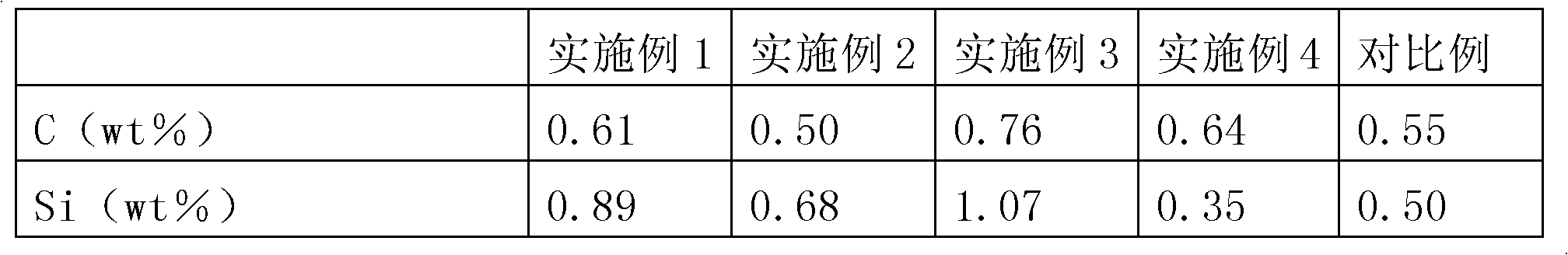

ActiveCN102618788ARich varietyIncrease particle hardnessCounter-pressure devicesMetal rolling arrangementsMetallurgyChemical constituents

The invention discloses a support roll with a high abrasion resistant performance, which comprises the following chemical constituents by weight percent: 0.38 to 0.85 percent of C, 6.1 to 10.0 percent of Cr, 0.4 to 1.5 percent of Mo, 0.15 to 0.8 percent of V, as well as one or more of 0.35 to 1.20 percent of Si, 0.35 to 1.00 percent of Mn, 0.4 to 0.8 percent of Ni, 0.4 to 0.8 percent of Co, and Fe and unavoidable impurities in balancing amount. The invention further discloses a manufacturing method of the support roll; and the rigidity and the abrasion resistance of the support roll produced according to the manufacturing method are greatly improved.

Owner:BAOSHAN IRON & STEEL CO LTD

Method and apparatus for rolling metalic plate material

ActiveUS20060230799A1Roll force/gap control deviceMetal rolling stand detailsWork rollMetallic materials

The invention provides a rolling method for a flat-rolled metal material and a rolling apparatus for the method each capable of stably producing a flat-rolled metal material free from camber or having an extremely light camber. The method is a rolling method of a flat-rolled metal material executed by using a rolling mill including at least work rolls and backup rolls. The apparatus is a rolling mill for this method. A rolling direction force acting on roll chocks on the operator side and the driving, side of the work roll is measured, the difference of the rolling direction force between the operator side and the driving side is calculated and a left-right swivelling component of roll gap of the rolling mill is controlled on the basis of this difference.

Owner:NIPPON STEEL CORP

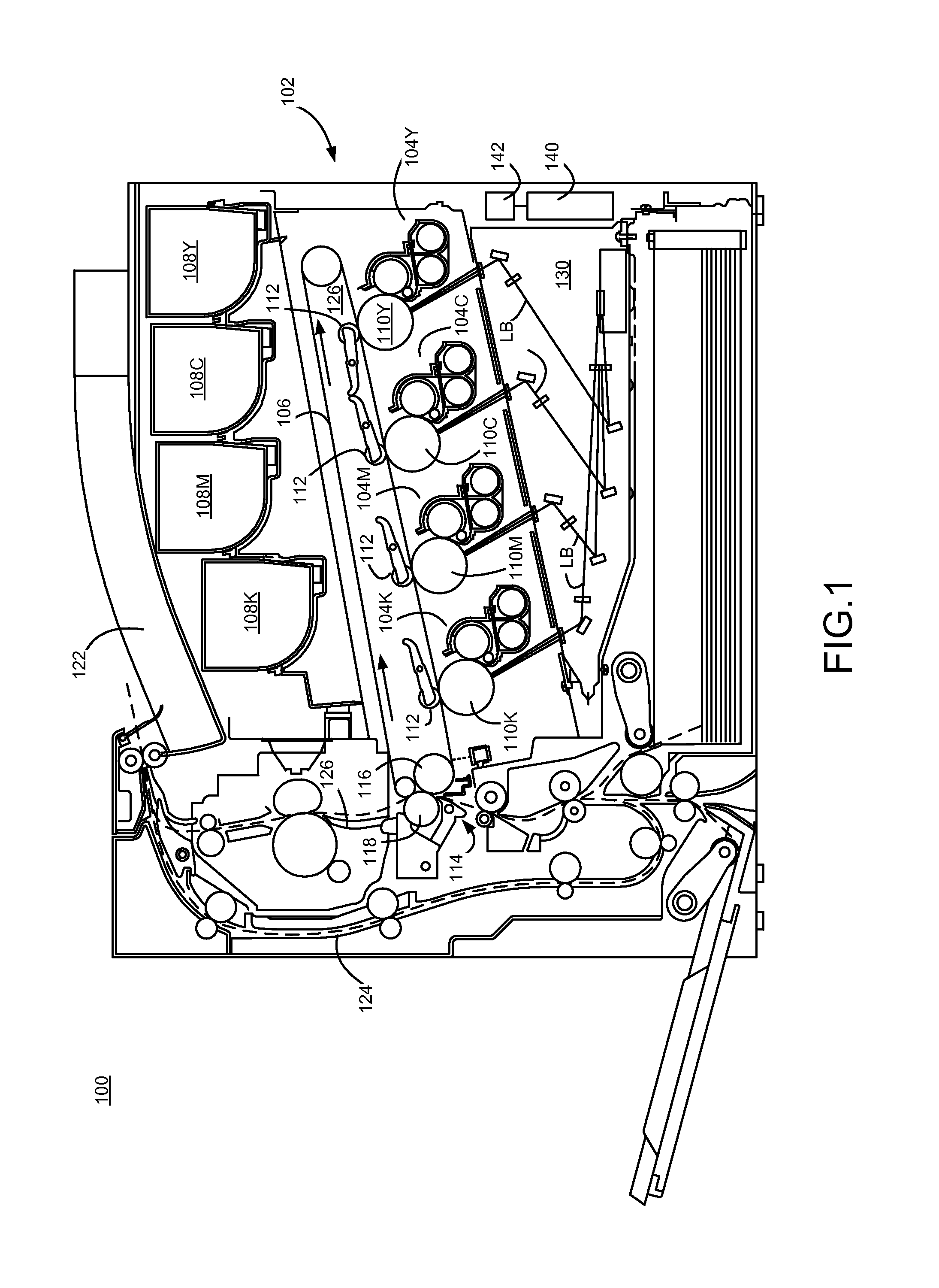

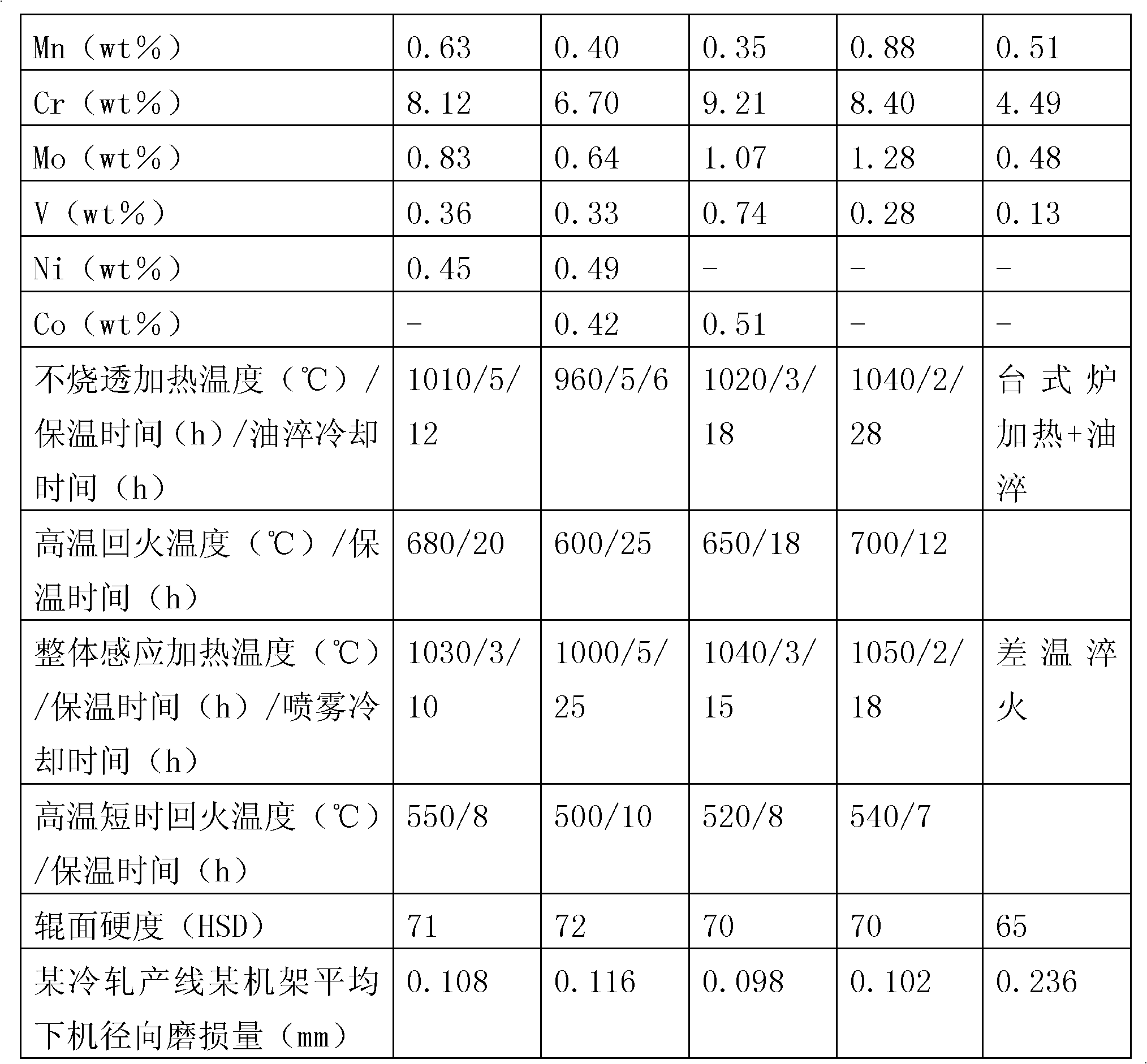

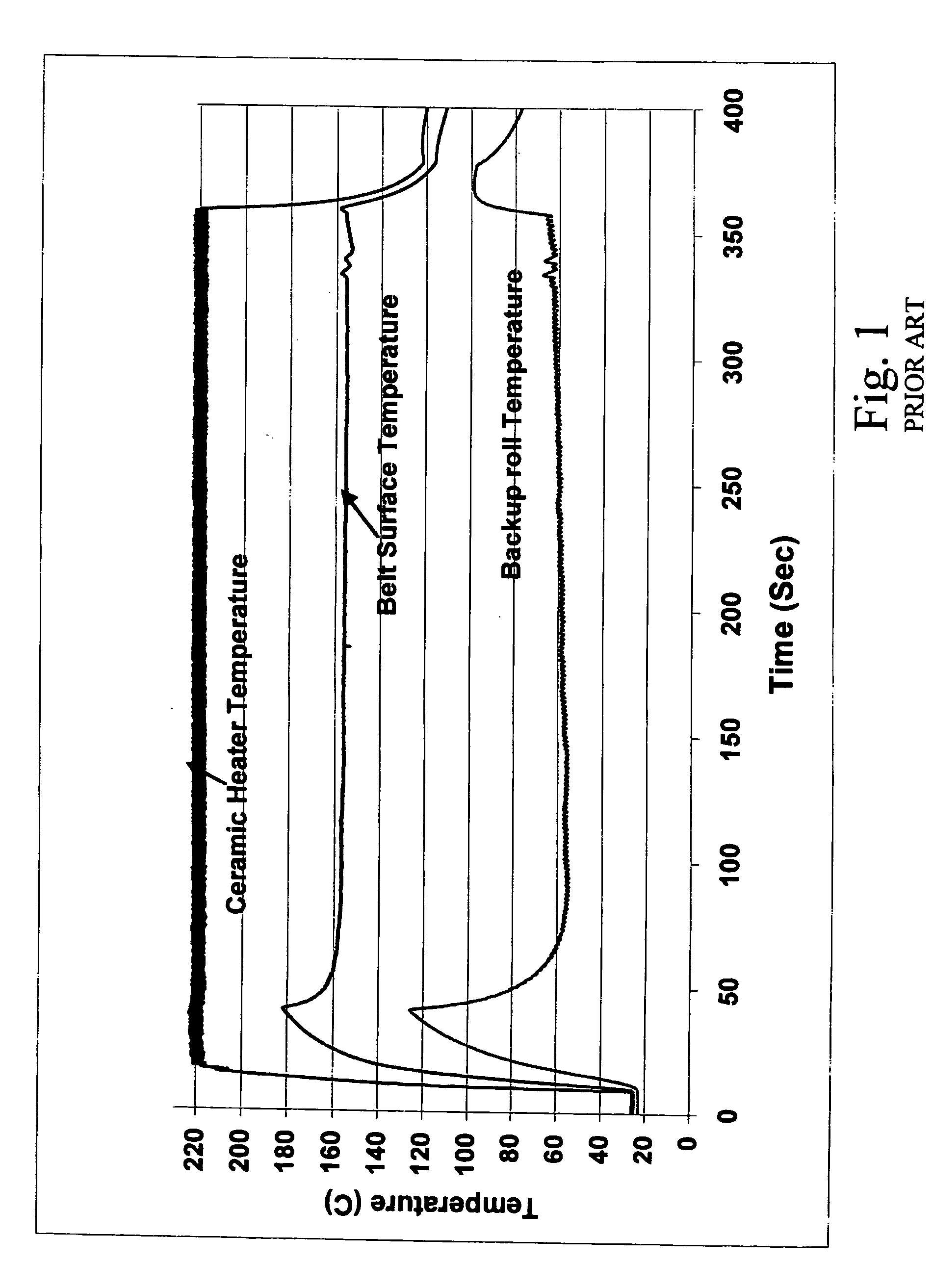

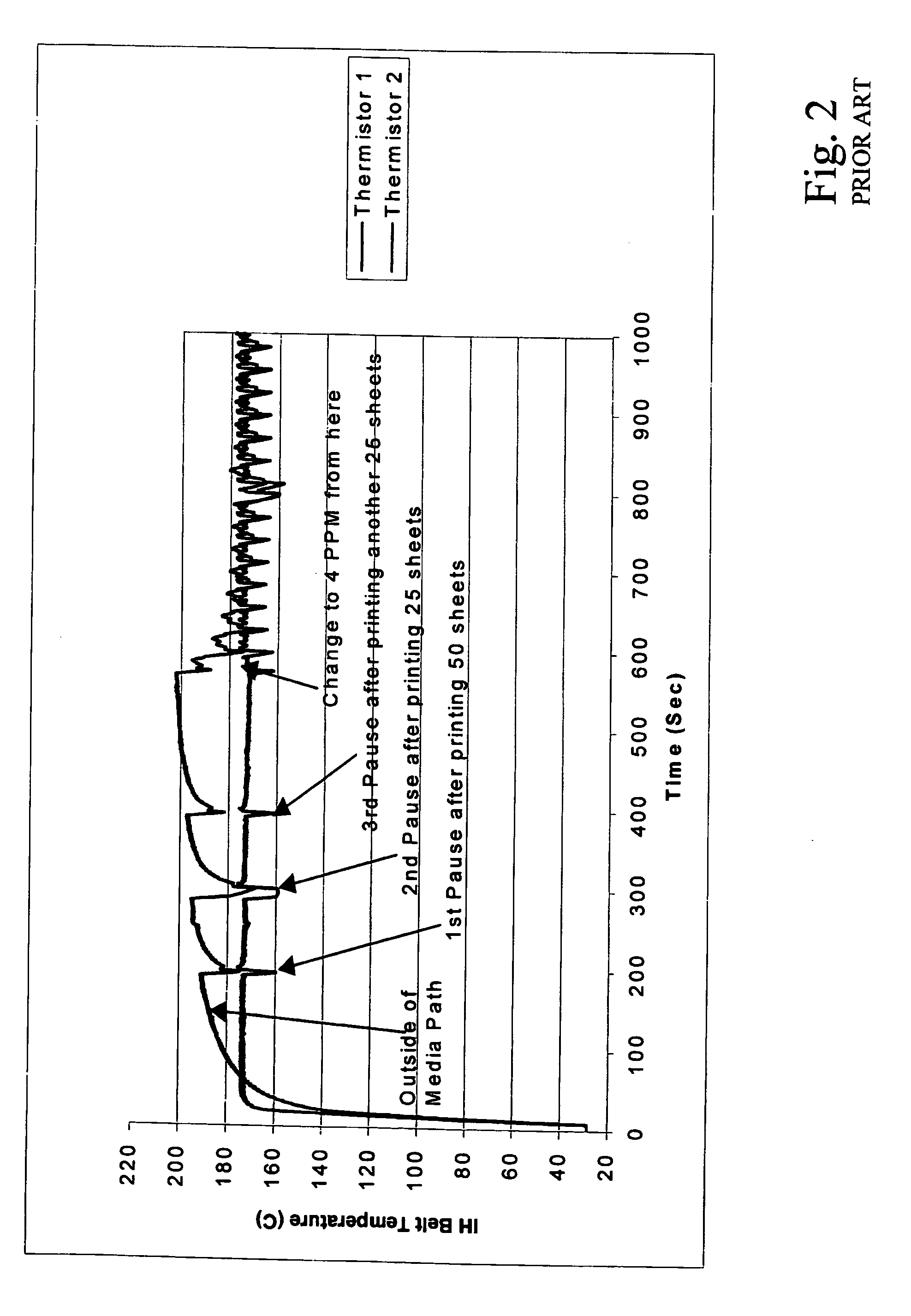

Belt fuser assembly with heated backup roll in an electrophotographic imaging device

InactiveUS20060067752A1High thermal extendibilityIncrease speedElectrographic process apparatusPrint mediaMechanical engineering

An electrophotographic imaging device includes a print media transport assembly, and a fuser positioned in association with the print media transport assembly. The fuser includes a first heater assembly; a belt positioned around and adjacent to the first heater assembly; a backup roll positioned in opposition to the first heater assembly on a side of the belt opposite the first heater assembly, the belt and the backup roll defining a fusing nip therebetween; and a second heater assembly positioned in association with the backup roll.

Owner:LEXMARK INT INC

Bearing roller of 4200 mm or above wide and thick plate rolling mill and manufacturing process of bearing roller

ActiveCN108277443AReduced risk of fatigue spallingHigh hardnessRollsMetal rolling arrangementsImpurityChromium

The invention relates to a bearing roller of a 4200 mm or above wide and thick plate rolling mill and a manufacturing process of the bearing roller, and belongs to the technical field of forging. Thebearing roller comprises, by mass percent, 0.50 to 0.65% of C, 0.17 to 0.50% of Si, 0.80 to 2.0% of Mn, 0.30 to 0.70% of Ni, 1.60 to 2.5% of Cr, 0.30 to 1.00% of Mo, 0.10 to 0.35% of V, not larger than 0.020% of P, not larger than 0.010% of S, not larger than 0.15% of Cu, not large than 1.0 ppm of H, and the balance iron and inevitable impurities. The carton content of a new material of the super-huge type forged steel bearing roller is low, alloy elements of chromium, nickel and vanadium are added, the microstructure comprises bainite and pearlite, the strength and toughness of the material are improved, the solidification segregation of a large steel ingot is reduced, the comprehensive performance is good, and the service life is long.

Owner:CHINA ERZHONG GRP DEYANG HEAVY IND

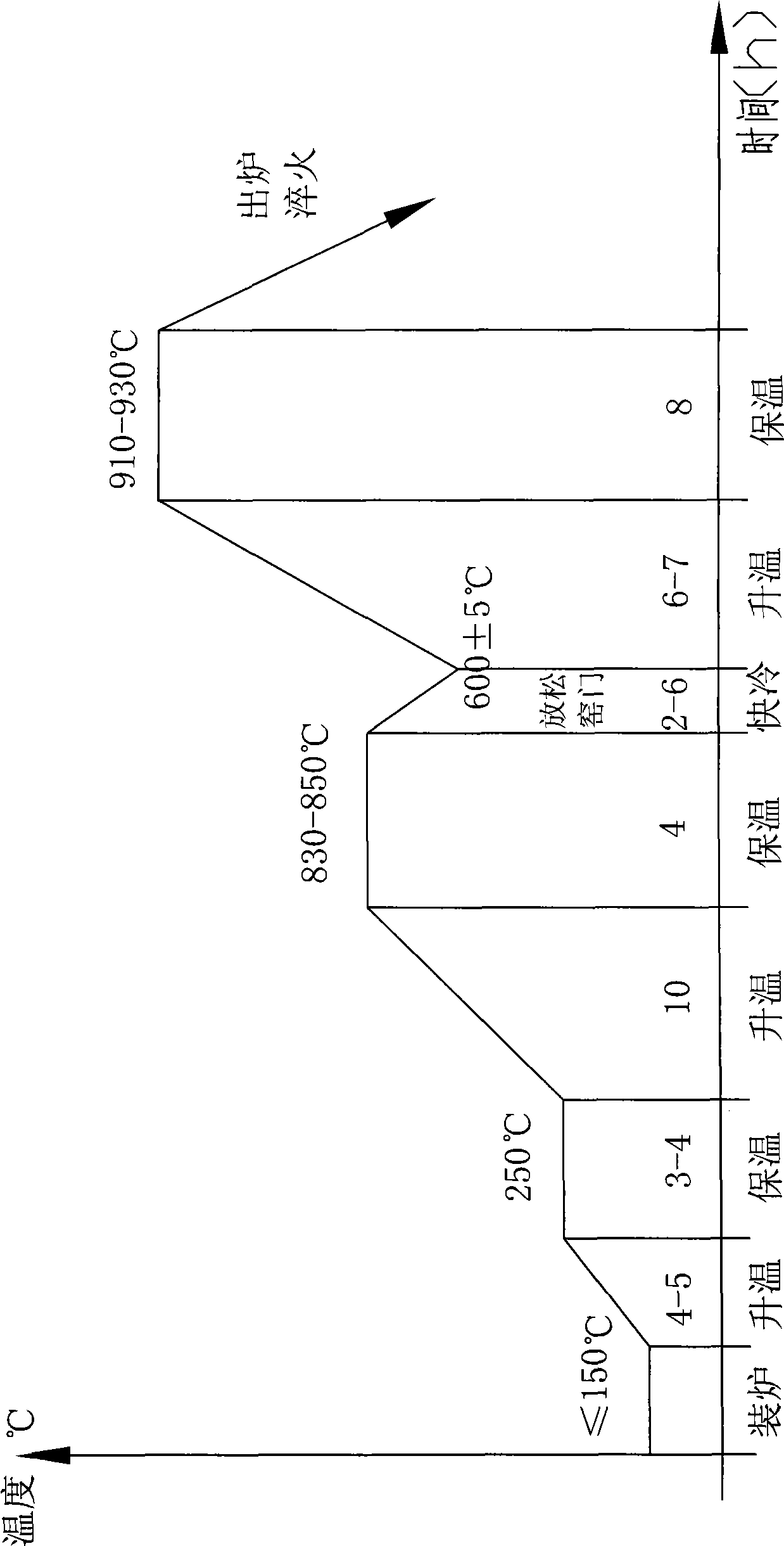

Renovation technique for phi2100í3400mm wrought steel support roll

InactiveCN101293300AEnsure homogeneityPreserve the quality of restorationCounter-pressure devicesArc welding apparatusHeat-affected zoneEngineering

The invention relates to the technical field for repairing an ultra-large type backup roll, in particular to a repair process of a forging steel backup roll with Phi2100* 3400mm. Firstly, welding is carried out on the rib of the backup roll: the roll body of the backup roll which needs to be welded is preheated to 250 DEG C, and the temperature is preserved for 10 hours; then the door of a furnace is opened, rib welding is carried out, zigzag welding is carried out every 100mm, and the length of the weld pass is 50-60mm; oxygen is used on the welded part immediately, and ethyne is used for warming the welded part until the welded part becomes blue. After the rib welding is finished, preheating treatment, temperature preservation treatment and destressing treatment are carried out respectively according to a heat treatment curve when the roll body of the backup roll is overlaid for making a bottom layer, a transition layer and a working layer. Compared with the prior art, in the technology of the invention, the influence on the service performance caused by the temperature circulation and change of a heat influencing region during the overlaying is considered, uniformity and penetration of preheating workpieces and uniformity of temperature between layers are guaranteed in the repair process, the blank in the repair rebirth field of the domestic ultra-large type backup roll is filled in. The time for repair is short, the service life is prolonged, and the cost is saved.

Owner:SHANGHAI SHIWEI WELDING IND

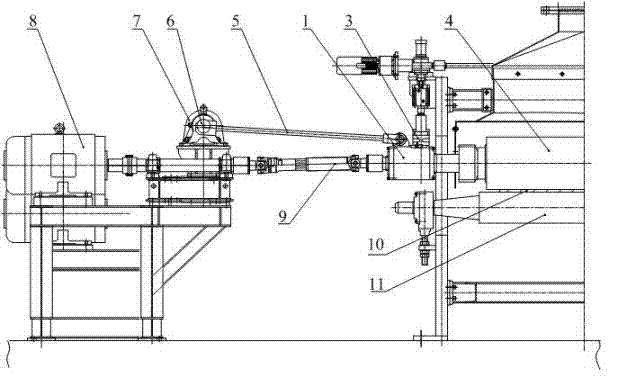

Moving mechanism of brush of dry brushing machine

InactiveCN102581046AHighlight substantive featuresSignificant progressWork treatment devicesMetal rolling arrangementsFixed bearingEngineering

The invention relates to a moving mechanism of a brush of a dry brushing machine. The moving mechanism comprises a fixed bearing block, a movable bearing block, a guide track, a brush rotation motor and a brush linear moving motor, the brush is positioned above a backup roll, the guide track consists of a track and a slider mounted in the track, the slider is fixed onto the fixed bearing block, the track is fixed onto the movable bearing block, a rotating shaft of the brush is supported on the movable bearing block and is in transmission connection with an output shaft of the brush rotation motor by a retractable coupler, the movable bearing block is connected with an eccentric wheel by a connecting rod, and the eccentric wheel is mounted on an output shaft of the linear moving motor. By the aid of the moving mechanism, the brush not only can rotate, but also can linearly move along the direction of a brush shaft. The brush rotates while reciprocating axially, accordingly, capability of removing oxide scales and impurities on surfaces of strips is remarkably improved, the surface of the brush is worn uniformly due to axial reciprocation of the brush, and abrasion grinding maintenance period of the brush is prolonged.

Owner:生田(苏州)精密机械有限公司

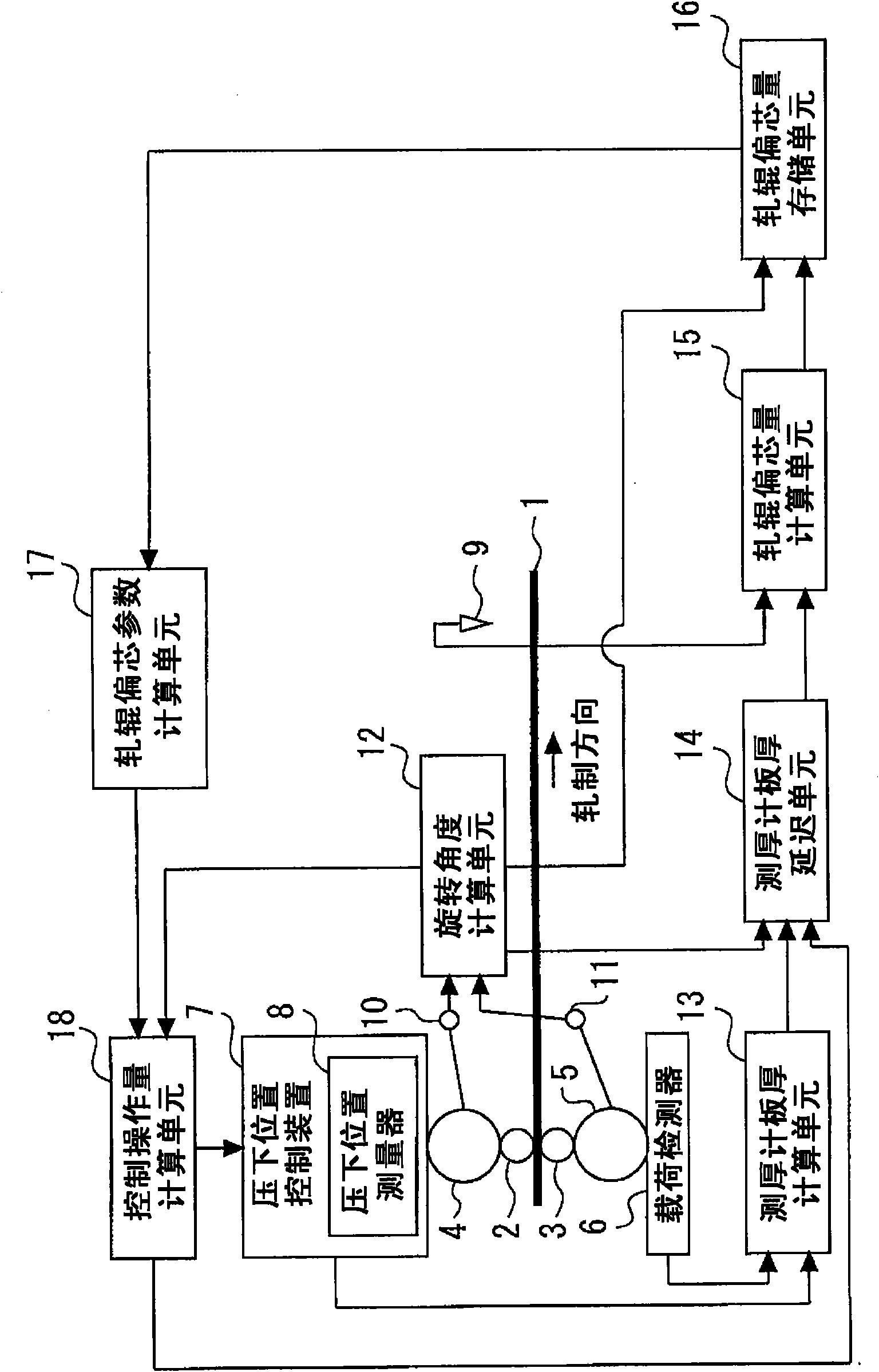

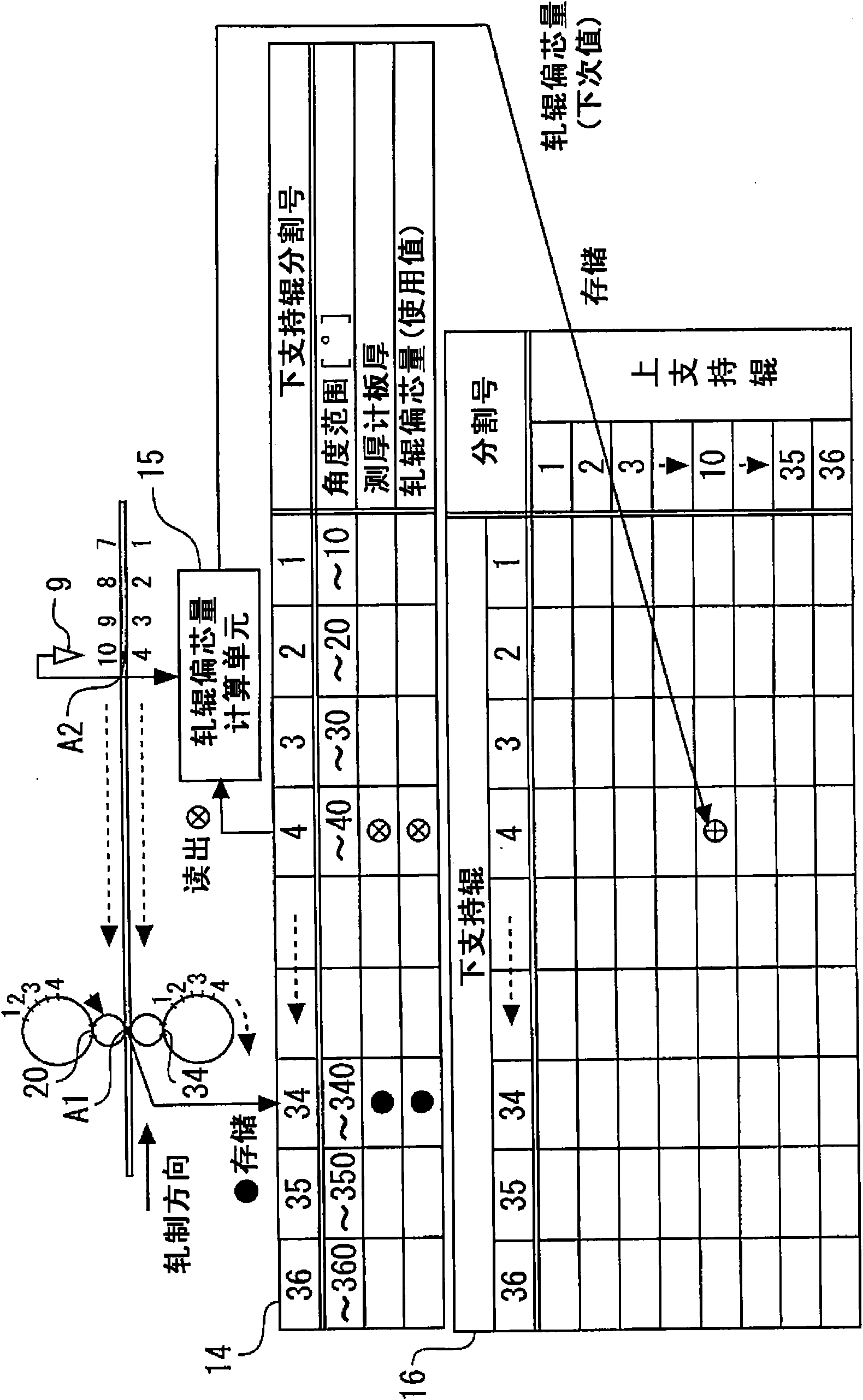

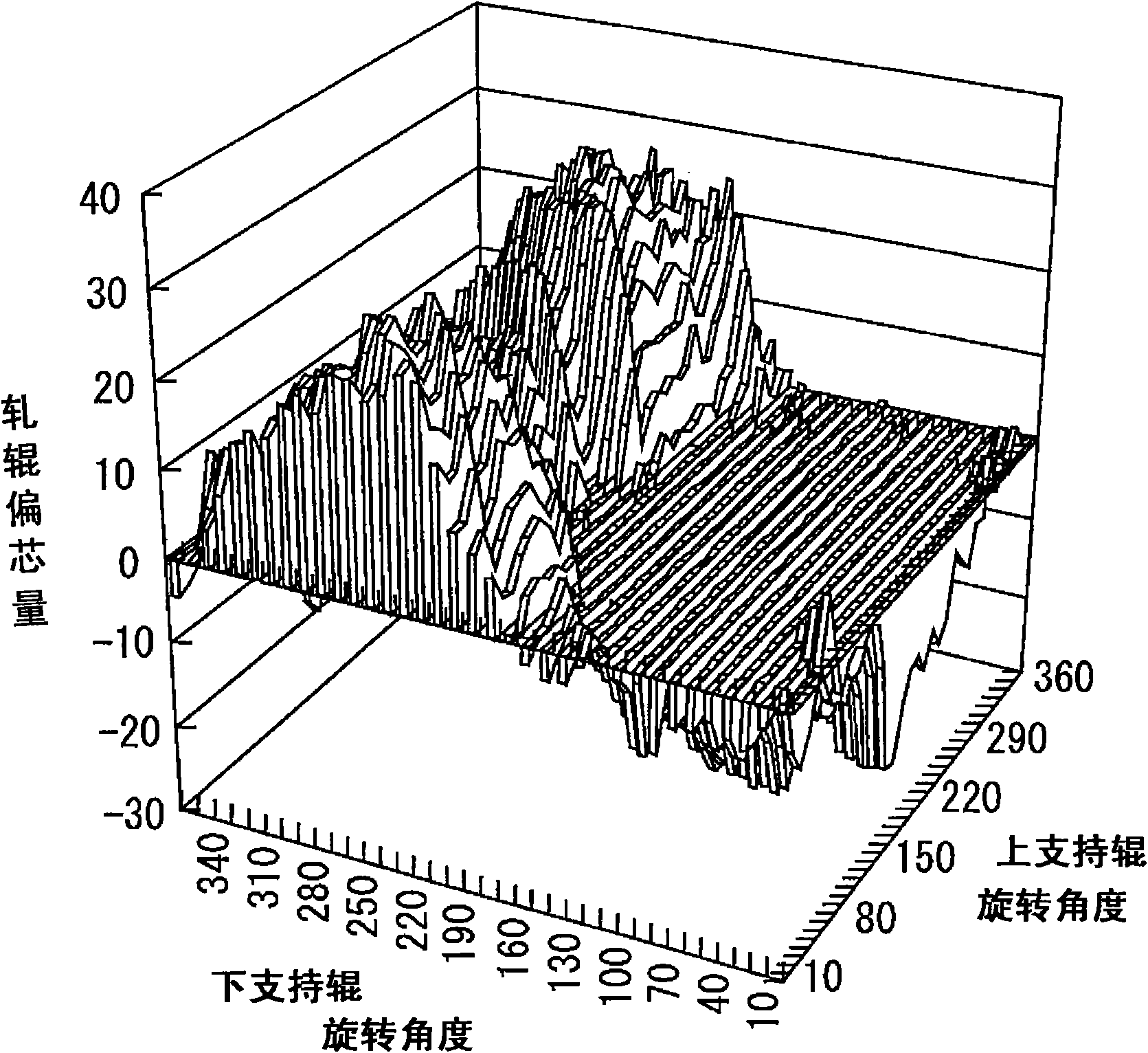

Board thickness controller for rolling machine

ActiveCN102015136ASuppress plate thickness variationRoll force/gap control deviceMetal rolling arrangementsBackup rollEngineering

A board thickness controller for a rolling machine which can fully reduce variation in board thickness arising from roll core eccentricity even in the event of deterioration over time of roll core eccentricity parameters or in any other cases. For such a purpose, the amount of roll core eccentricity is first determined from gauge meter board thickness and actual board thickness. Secondly, a curved surface corresponding to a distribution curve for the determined amount of roll core eccentricity is depicted to identify the curved surface using the Fourier analysis, thereby computing a phase and an amplitude of the roll core eccentricity for each of the upper and lower backup rolls. Subsequently, roll gaps are controlled in accordance with the computation result to reduce variation components in board thickness of an rolled material arising from the roll core eccentricity.

Owner:TOSHIBA MITSUBISHI-ELECTRIC IND SYST CORP

Rolling mill, hot rolling system, rolling method and rolling mill revamping method

InactiveUS6076388AImprove abilitiesReduce thrustMetal rolling stand detailsRolling equipment maintainenceWork rollEngineering

A work roll crossing type rolling mill has back-up rolls arranged in such a manner that their axes are not inclined in a horizontal plane. Work rolls are constructed in such a manner that their axes can be inclined in a horizontal plane relative to the backup rolls such that the axes of the work rolls cross the axes of the back-up rolls and such that the axes of the work rolls cross each other. A lubricant supply device is provided for supplying a lubricant between each work roll and each back-up roll combination to greatly reduce the thrust exerted to the work rolls, whereby the rolling mill is given an excellent ability of controlling the crown of the material to be rolled.

Owner:HITACHI LTD

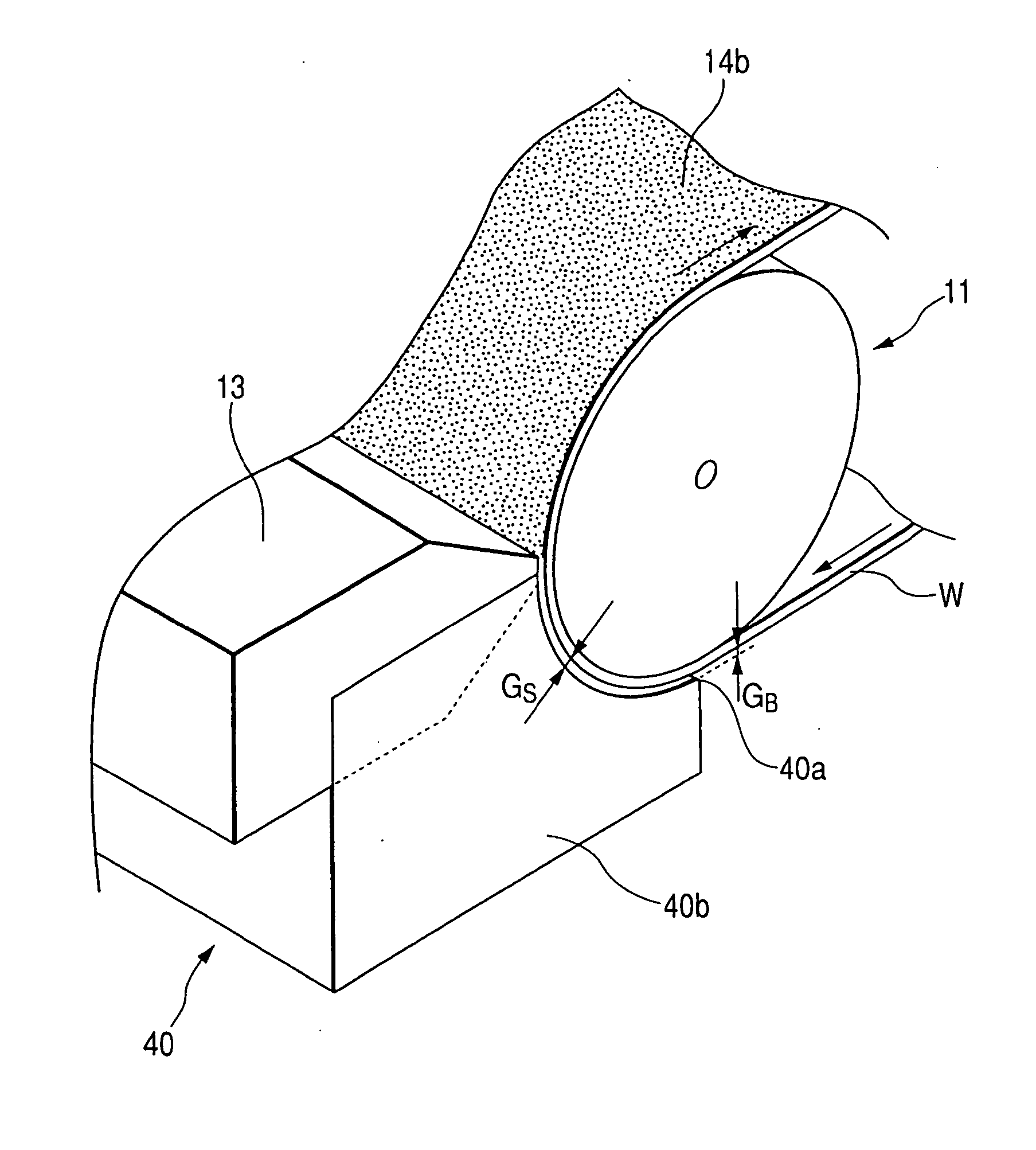

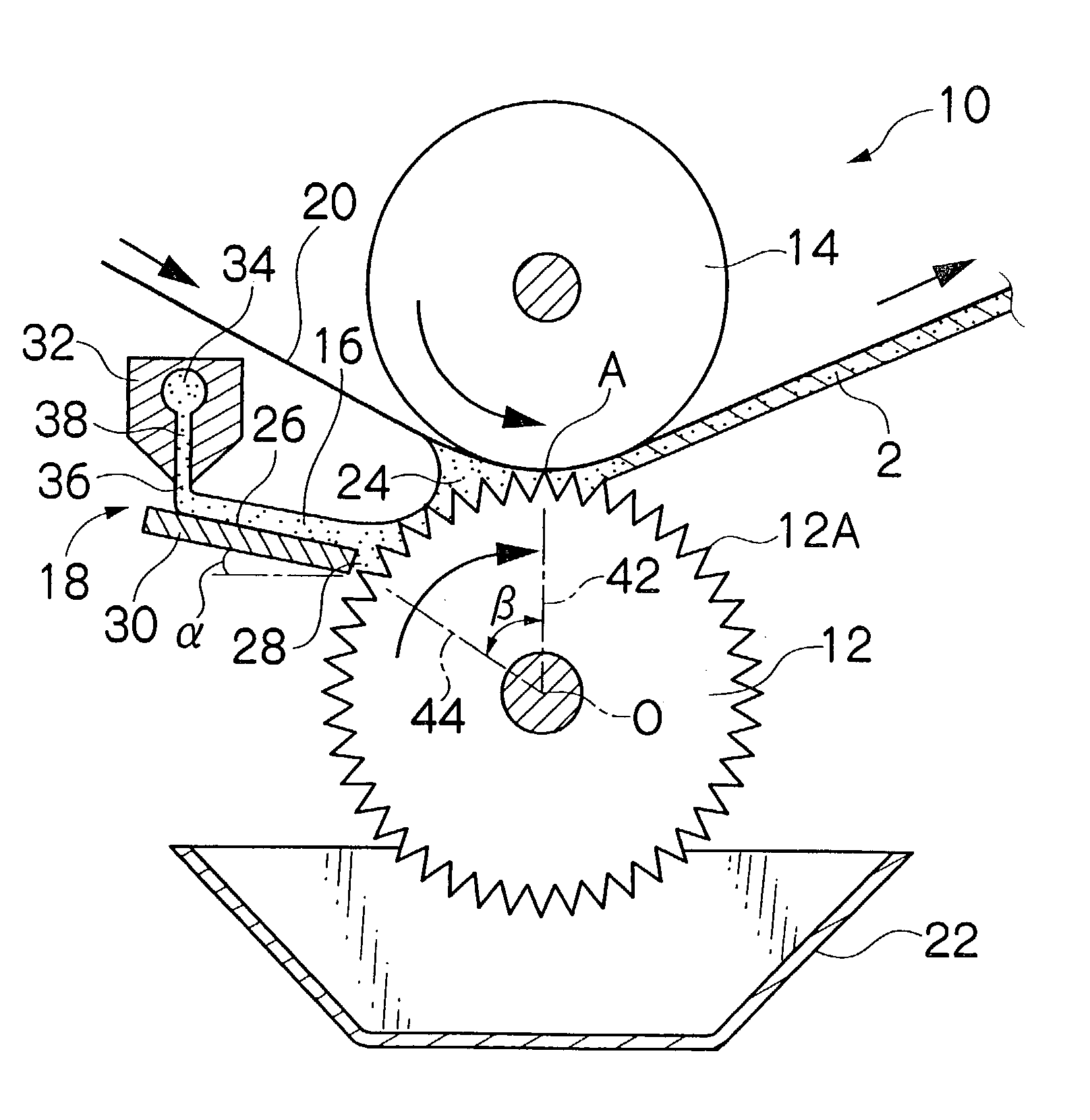

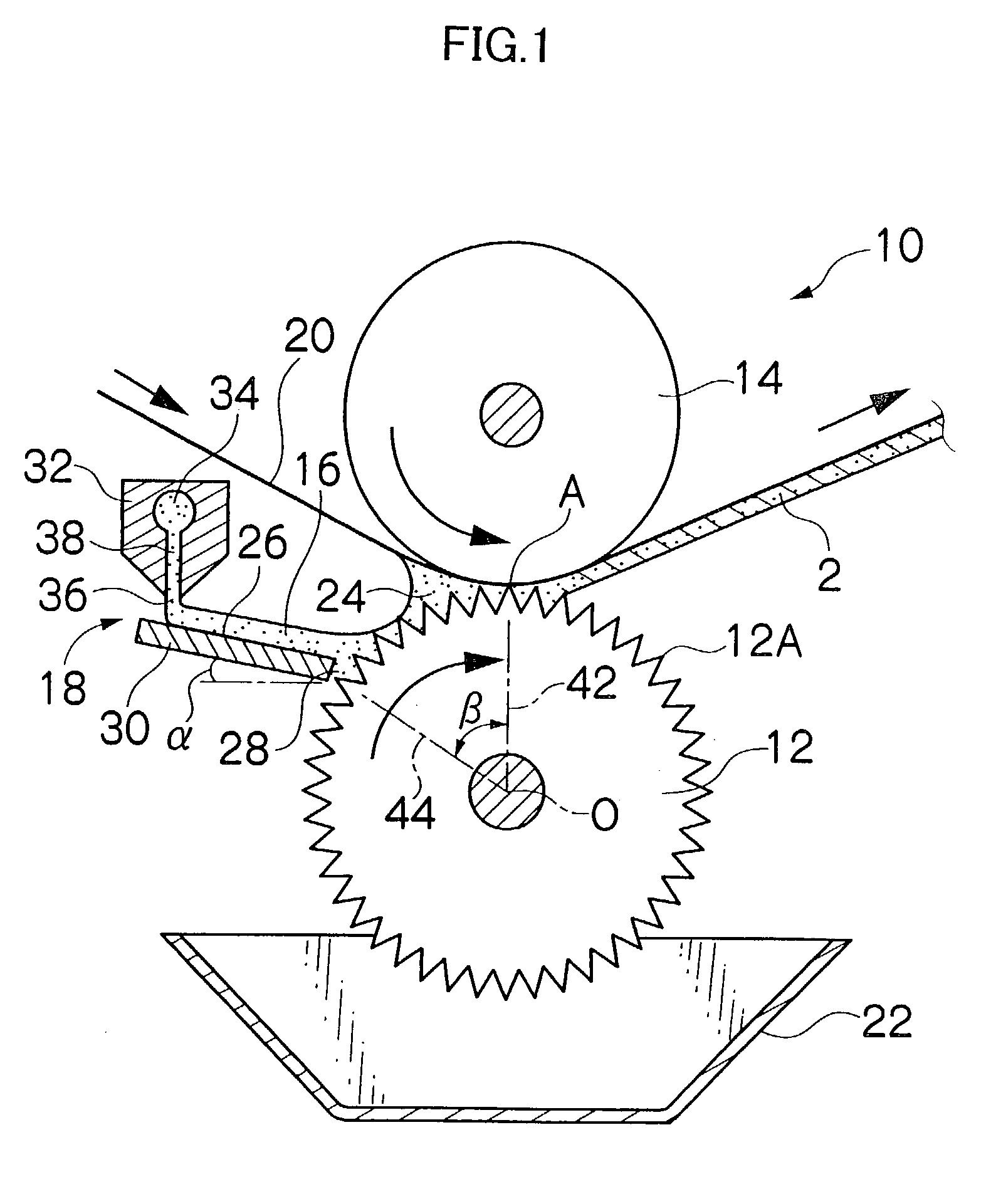

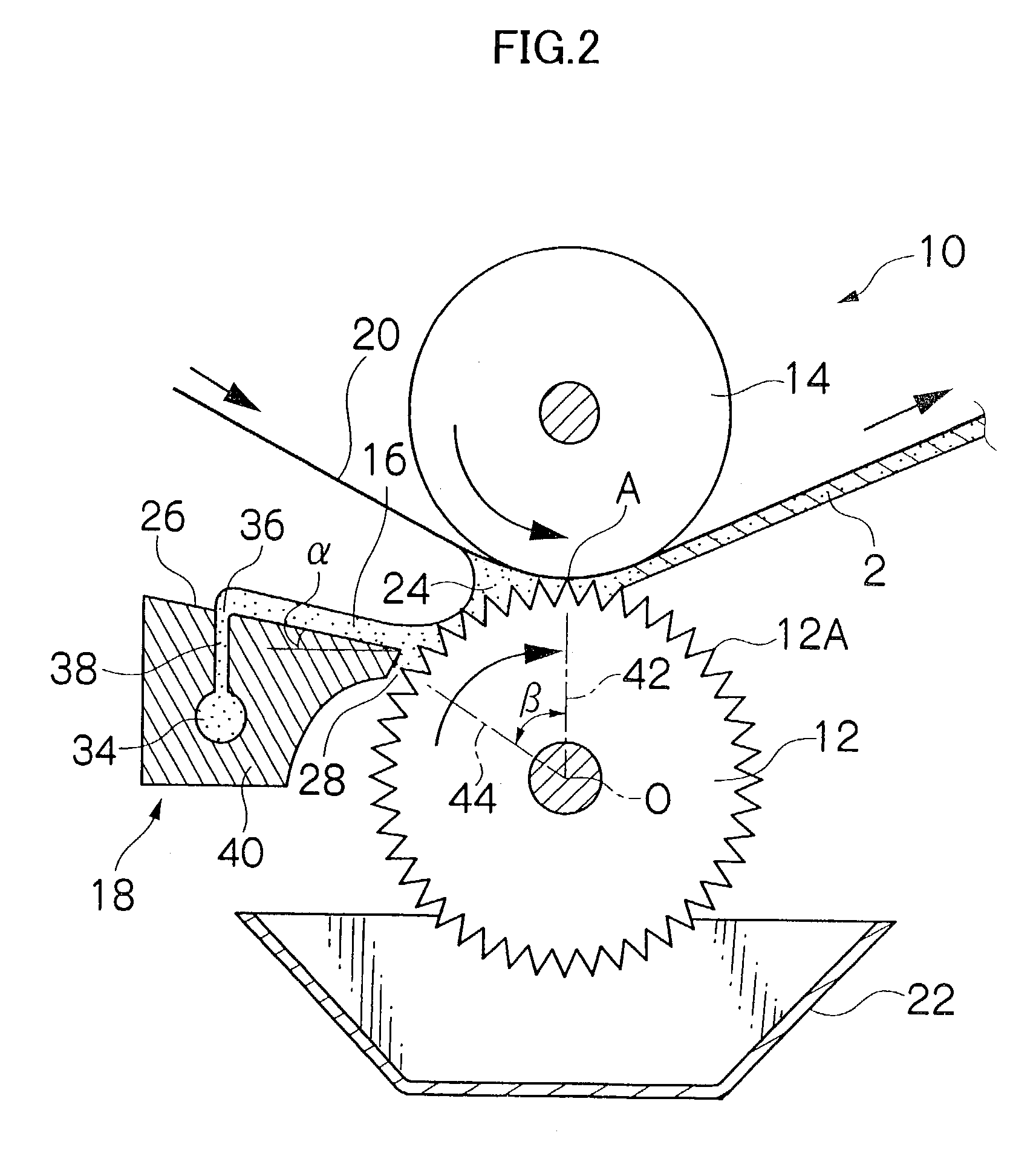

Gravure coating apparatus

InactiveUS20030121471A1Liquid surface applicatorsRotary intaglio printing pressCoated surfaceEngineering

In the gravure coating apparatus, while a bead portion of a coating liquid is formed between a roll surface of a gravure roll to which the coating liquid is excessively supplied and a web that runs continuously, the web is pressed on the gravure roll by using a backup roll, whereby a desired amount of the coating liquid is applied to the web, a liquid supply device having an inclined surface that is inclined downward toward the roll surface and a gap too narrow for the coating liquid to flow down between the roll surface and the inclined surface is provided at a position near the bead portion on the upstream side in the direction of rotation of the gravure roll so that the coating liquid flows down on the inclined surface and is supplied to the gravure roll. A liquid return of an excess coating liquid that is not used for coating in the bead portion is less liable to occur, so that a streak trouble on a coating surface formed on the web can be prevented from occurring.

Owner:FUJIFILM CORP +1

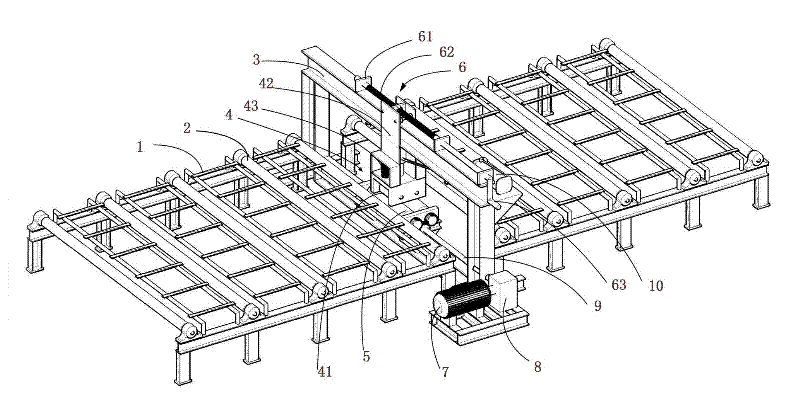

Automatic conveyor

ActiveCN101798014ANo pollution in the processMeet delivery requirementsConveyor partsVehiclesProper timeEngineering

The invention relates to an automatic conveyor, which is characterized in that a conveying platform is arranged by taking a base as a support, the conveying platform is obliquely arranged along the conveying direction in a way that the part loading end of the conveying platform is high and the part unloading end of the conveying platform is low, and backup rolls which can rotate on the conveying platform form a conveying plane; and limiting mechanisms which can be lifted up or lowered down at proper time are respectively arranged at different positions on the conveying platform. The invention has the advantages that the structure is simple, the use is convenient, the application scope is wide for different parts to be conveyed and the logistic conveying method by using the gravity of the parts to be conveyed is not limited by the automation level.

Owner:ANHUI JEE AUTOMATION EQUIP CO LTD

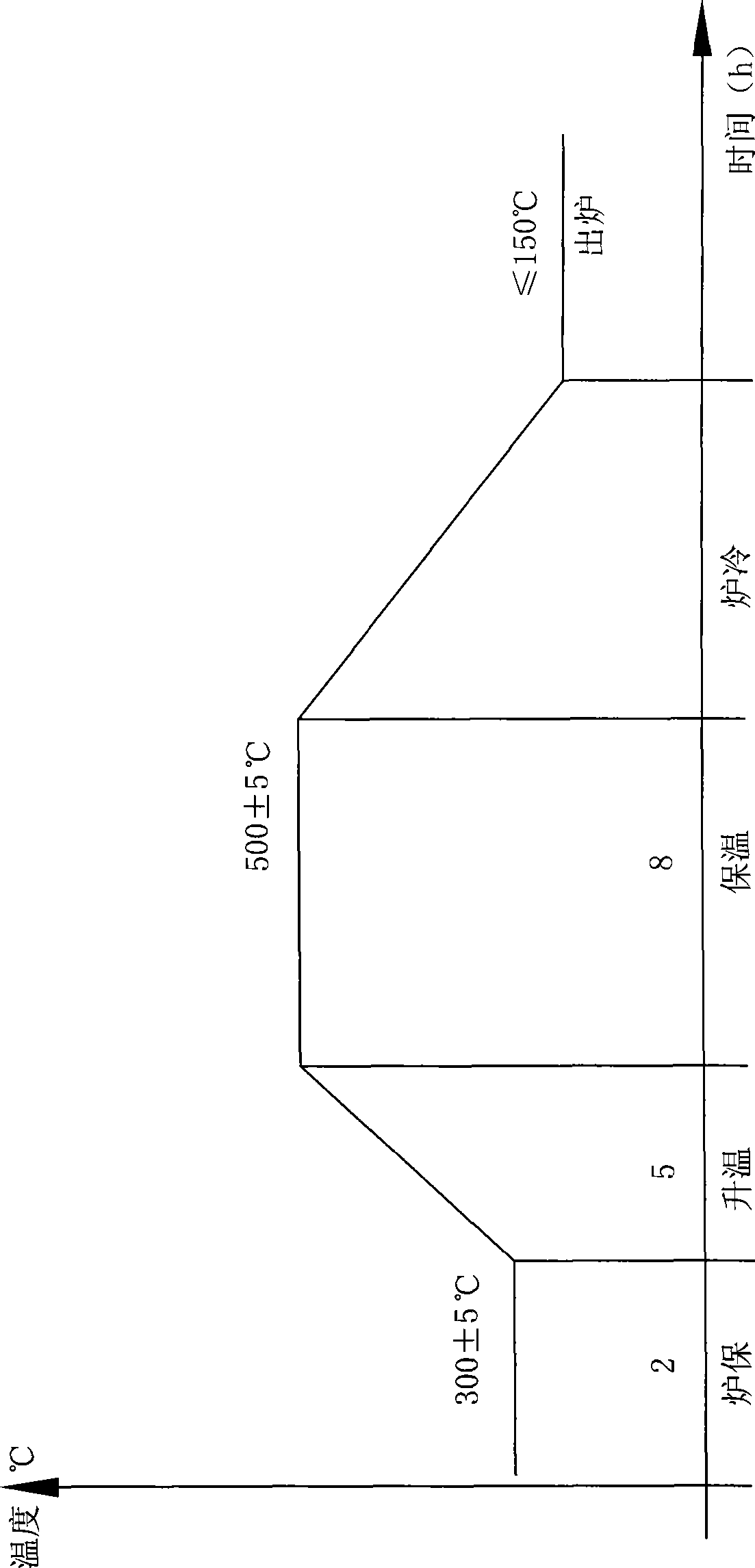

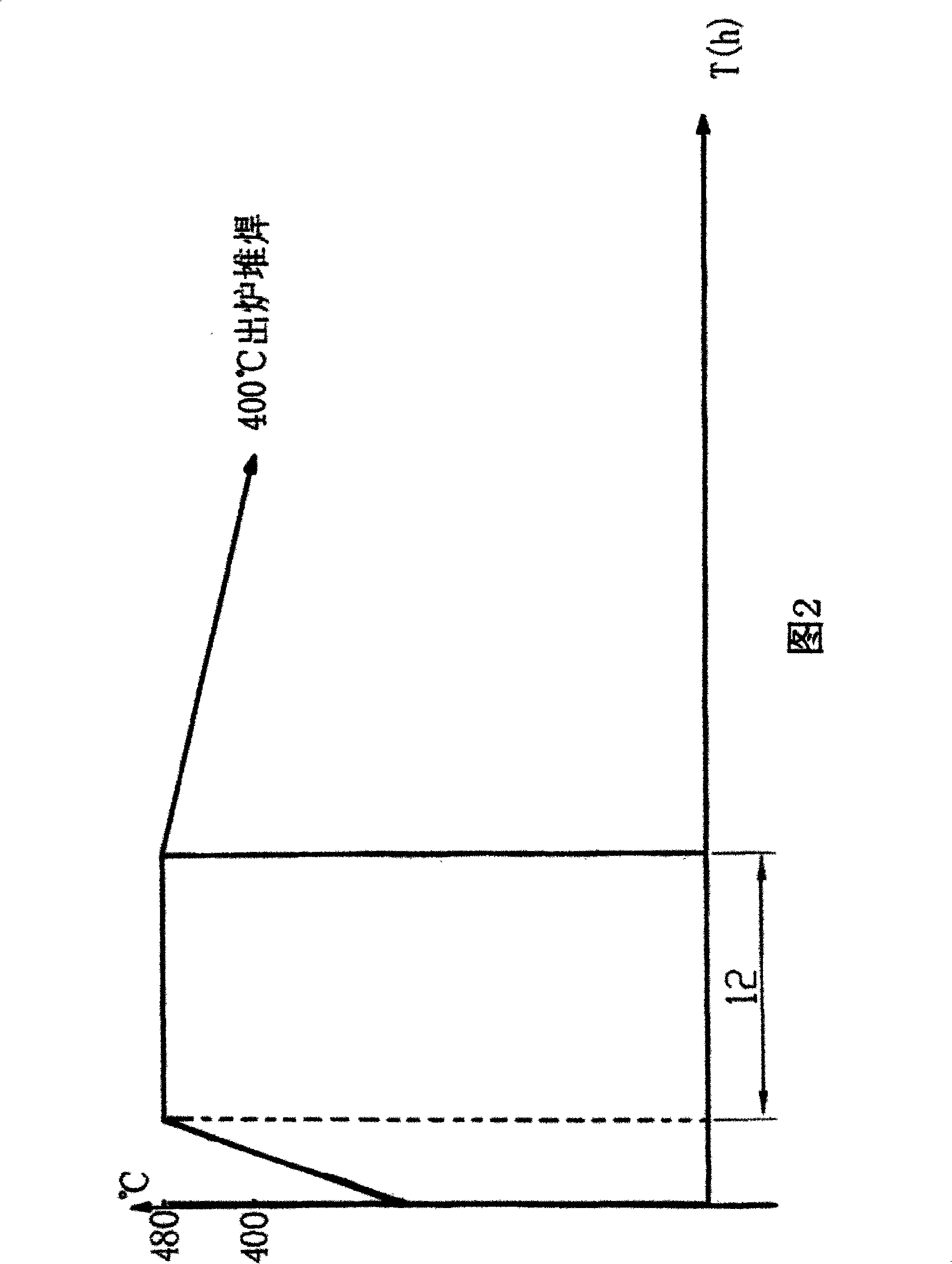

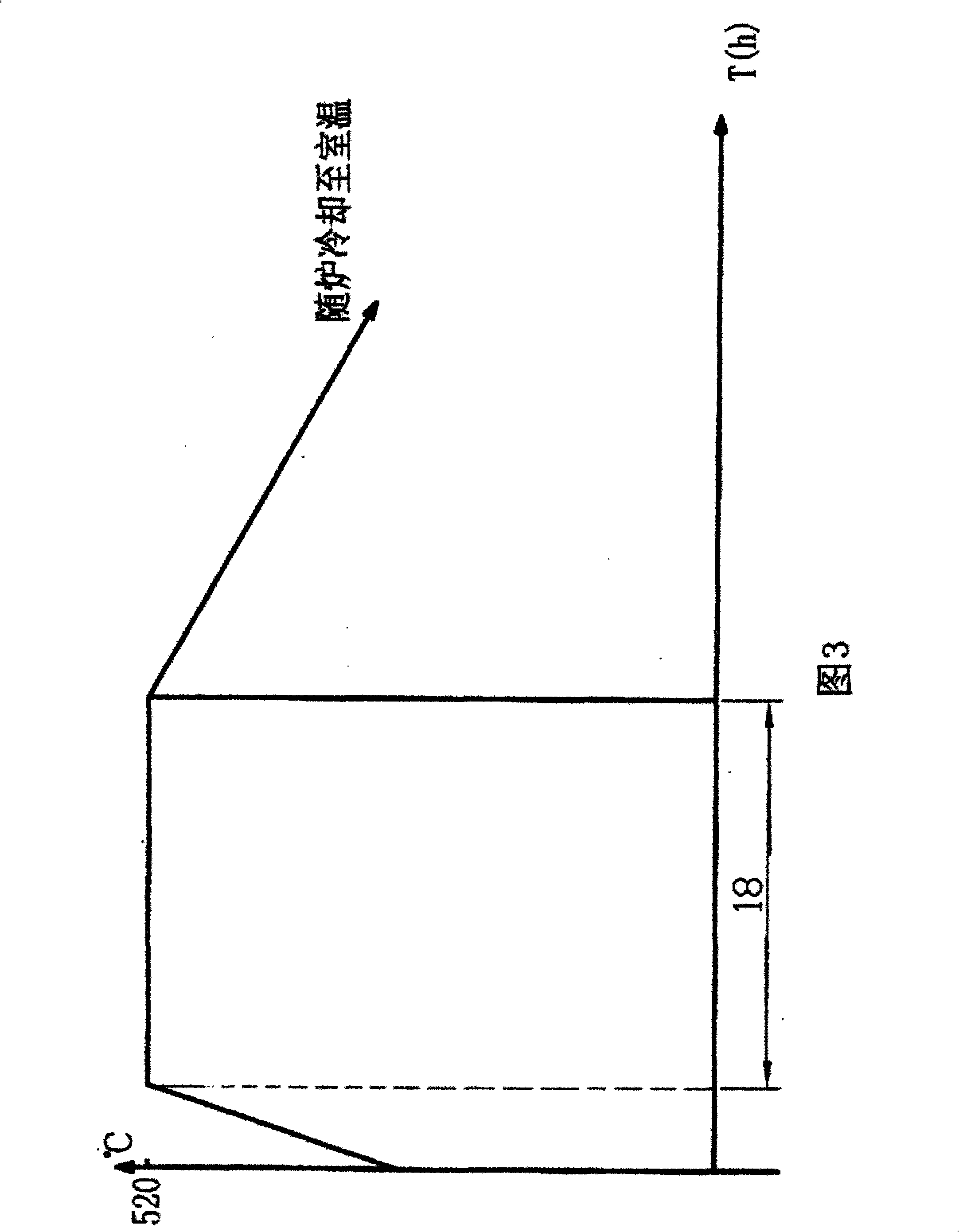

Backup roll reparation technique

InactiveCN101758359AGuaranteed uniformityThe process steps are simpleFurnace temperatureSurface layer

The invention relates to the technical field of roll reparation techniques, in particular to a backup roll reparation technique. The backup roll reparation technique includes the following steps: (a) rough turning: rolls with the diameter of 500mm are turned to the diameter of 530mm, rolls with the diameter of 450mm are turned to the diameter of 430mm, and oil stains are cleaned up; (b) preheating; (c) intermediate layer surfacing; (d) hard surface layer surfacing: when the last roll is surfaced with an intermediate layer and mounted into a furnace, the furnace temperature is increased to 380 DEG C to 400 DEG C, and is kept for 2 hours, meanwhile, a welding wire and flux are replaced, the flux is also baked, the welding wire is deoiled and derusted, and a 324 welding wire with the diameter of 3.2mm and HJ107 flux are used; (e) tempering; (f) semi-finishing turning to the grinding allowance; (g) grinding; (h) secondary tempering. Compared with the prior art, the invention has the following advantages that: the technique steps are simple, the uniformity of rigidity of rolls can be ensured, and moreover, the machining cost is reduced.

Owner:SHANGHAI HEXIN METAL PRODS

Full-automatic digital control roll grinder backup roll belt box grinding device

ActiveCN101856795AAvoid injury hazardGuaranteed grinding accuracyRevolution surface grinding machinesRadial positionFuel tank

The invention discloses a full-automatic digital control roll grinder backup roll belt box grinding device, comprising an installation precision regulating device, an oil supplying device and an oil temperature controlling device, wherein the installation precision regulating device comprises a bearing box pushing cylinder, limit blocks, an inching device and a clamping plate, the bearing box pushing cylinder and the limit blocks are arranged on the box seat and used for locating the position of the bearing box relative to the box seat, the clamping plate is used for driving the box seat to slide in a radial direction relative to a bed body of a workpiece, and the inching device and the lamping plate are used for regulating the radial position of the box seat at one end of the bed body of the workpiece so as to parallel a space axial line between the two box seats with the axial line of a grinding wheel, thereby ensuring grinding precision; the oil temperature controlling device comprises a temperature sensor and an oil temperature controller, which is used for ensuring that the temperature of the supplied oil in the oil supplying device is proper; and the oil supplying device comprises an oil inlet pipeline, a cylinder and an oil outlet pipeline with an overflow valve and a throttle valve, which is used for supplying the oil meeting the requirements of temperature, oil pressure and flow to a bearing box so as to ensure that a oil film bearing forms an effective dynamic pressure, thereby effectively avoiding hidden troubles of damaging a bearing and ensuring grinding efficiency. In all, the invention ensures grinding, and can be convenient and reliable in use.

Owner:HIECISE PRECISION EQUIP (KUNSHAN) CO LTD

Machine for strengthening welding deformation of steel plate

InactiveCN102397914AImprove flatnessImprove appearance qualityClassical mechanicsStructural engineering

Owner:江苏利柏特股份有限公司

Electrode manufacturing apparatus and electrode manufacturing method

ActiveUS8163332B2Improve flatnessGood effectElectrode carriers/collectorsActive material electrodesManufactured apparatusEngineering

An electrode manufacturing apparatus comprises a conveying section for conveying a current collector sheet having a plurality of through holes; a backup roll for guiding the conveyed current collector sheet; an applicator for supplying a coating liquid to the current collector sheet on the backup roll; and a nip roll for pressing a part of the current collector sheet where the coating liquid is not supplied yet from the applicator against the backup roll.

Owner:TDK CORPARATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com