High-pressure spraying and cleaning device for cold-rolled strip steel

A high-pressure spraying, cold-rolled strip technology, applied in metal rolling, metal rolling, metal processing equipment, etc., can solve the problems of roller table scarring in the furnace, clean removal of "silicon mud", affecting product quality, etc. , to avoid economic losses, improve cleaning ability, and eliminate stains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

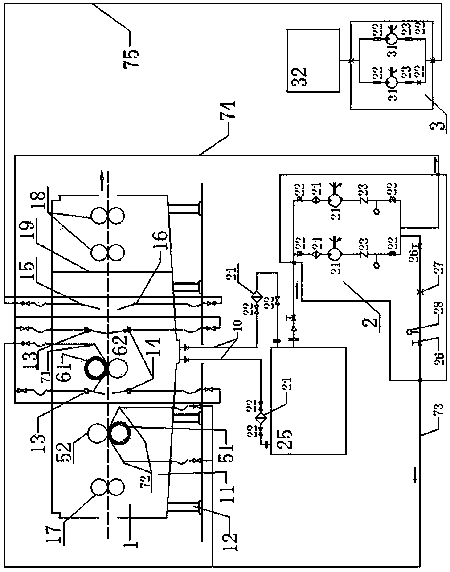

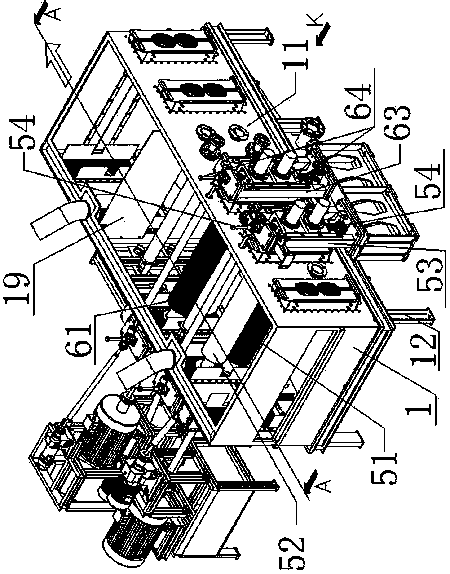

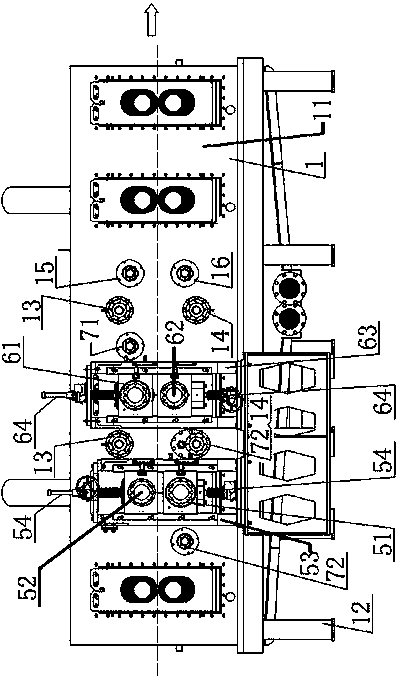

[0035] A high-pressure spraying and brushing device for cold-rolled strip steel, including spraying system 1, spraying circulation system 2 and outlet spraying circulation system 3, front brush roller 51, front backup roller 52, front brush roller frame 53, front worm gear Elevator 54, rear brush roller 61, rear backup roller 62, rear brush roller frame 63, rear worm gear elevator 64, upper brush roller nozzle 71, lower brush roller nozzle 72, such as Figure 1 to Figure 9 As shown, the specific structure is:

[0036] The spray system 1 consists of a spray tank body 11, a spray tank bracket 12, an upper spray pipe 13, a lower spray pipe 14, an upper outlet spray pipe 15, a lower outlet spray pipe 16, and a pair of front squeeze rollers 17. , The rear squeeze roller pair 18 and the partition plate 19 are composed, the spray groove body 11 is fixed on the spray groove bracket 12, and the spray groove body 11 is as shown in Figure 2 ~ Figure 4 As shown, the connection line betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com