Bearing roller of 4200 mm or above wide and thick plate rolling mill and manufacturing process of bearing roller

A technology of back-up rolls and plate rolling mills, which is applied in the direction of manufacturing tools, rolls, metal rolling, etc., can solve the problems of white spots on back-up rolls, reduced toughness at the center of back-up rolls, and short service life, and achieve good wear resistance and resistance Fatigue performance, reduce the risk of fatigue spalling, and improve the feasibility of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] Further, the preparation method of the backup roll includes the following steps:

[0057] (1) Smelting and ingot casting: molten steel is roughly smelted, refined, alloyed, and vacuum cast into ingots; wherein, the chemical composition of the steel is as above.

[0058] Preferably, the preparation method of the backup roll also includes the following steps:

[0059] (2) Forging: heating the vacuum steel ingot, cutting off the harmful part of the ingot tail, upsetting and elongating, cutting off the harmful part of the riser, and forging a back-up roll blank;

[0060] (3) Heat treatment after forging: normalizing + spheroidizing annealing + tempering;

[0061] (4) Rough machining: rough machining of the forging blank;

[0062] (5) Final heat treatment: the process form is quenching + tempering.

[0063] Preferably, the rough refining of the molten steel in step (1) adopts an electric furnace, the alloying and refining of the molten steel adopts a ladle refining furnac...

Embodiment 1

[0074] (1) Smelting and ingot casting: molten steel is initially smelted in an electric arc furnace, then poured into a ladle refining furnace for refining and alloying, and then poured into a 450t large steel ingot by dripping and degassing in a vacuum ingot casting chamber, and the hydrogen content in the steel Reduced to below 1ppm.

[0075] The mass percent of its chemical composition is as follows: C=0.59, Si=0.43, Mn=1.24, Ni=0.34, Cr=2.06, Mo=0.54, V=0.25, P=0.15, S=0.008, Cu=0.10, H= 0.8ppm, the balance is iron and other unavoidable impurities.

[0076] (2) Forging: After heating the steel ingot, cut off the harmful part of the ingot tail, upsetting and elongating, cut off the harmful part of the riser, and forge the back-up roll blank;

[0077] (3) Heat treatment after forging: normalizing + spheroidizing annealing + tempering;

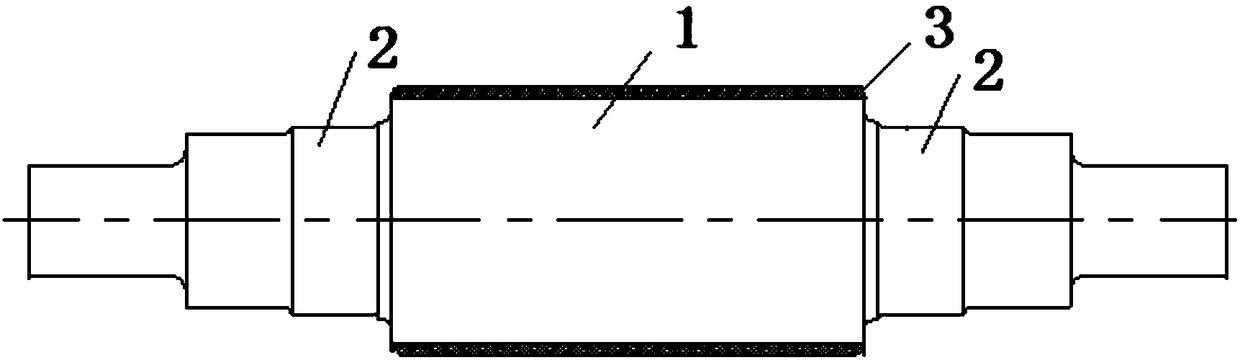

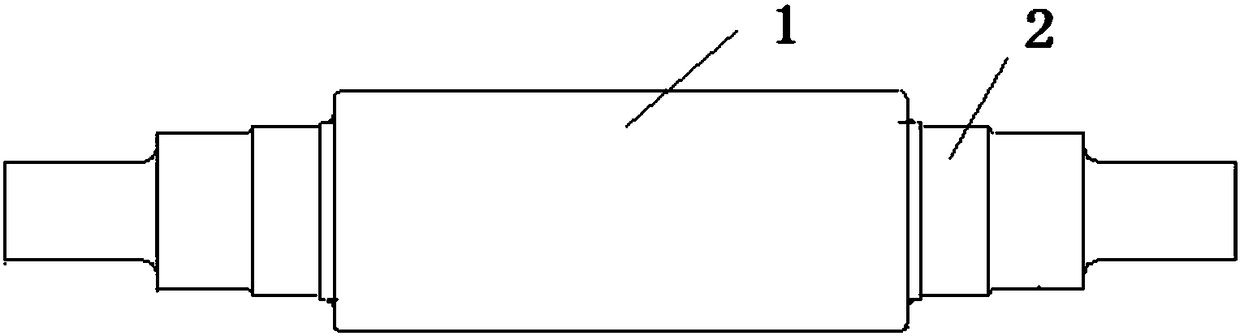

[0078] (4) Rough machining and ultrasonic flaw detection: process the forging blank according to the rough machining drawing, see the roug...

Embodiment 2

[0081] (1) Smelting and ingot casting: The molten steel is initially smelted in an electric arc furnace, then poured into a ladle refining furnace for refining and alloying, and then poured into a 340t large steel ingot by dripping and degassing in a vacuum ingot casting chamber, and the hydrogen content in the steel Reduced to below 1ppm, its chemical composition (mass percentage) is as follows: C=0.62, Si=0.38, Mn=1.18, Ni=0.34, Cr=1.96, Mo=0.49, V=0.20, P=0.016, S=0.006, Cu = 0.008, H = 0.9ppm, and the balance is other trace elements in iron and steel scrap.

[0082] (2) Forging: After heating the steel ingot, cut off the harmful part of the ingot tail, upsetting and elongating, cut off the harmful part of the riser, and forge the back-up roll blank;

[0083] (3) Heat treatment after forging: normalizing + spheroidizing annealing + tempering;

[0084] (4) Rough machining and ultrasonic flaw detection: process the forging blank according to the rough machining drawing, see ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com