Linkage self-balancing water lubricated thrust bearing

A thrust bearing and self-balancing technology, applied in sliding contact bearings, rotating bearings, bearings, etc., can solve problems such as reduced reliability, uneven load distribution, increased vibration, etc., to reduce tile temperature and loss, improve Running stability, increasing the effect of following function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

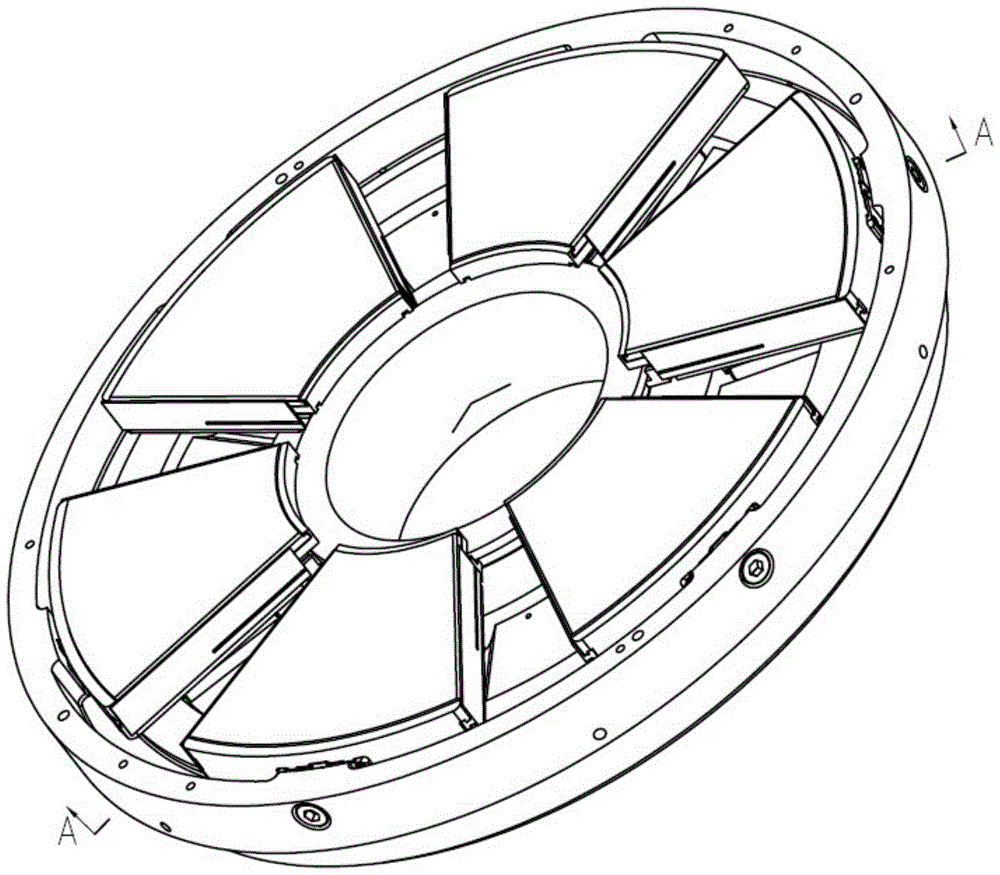

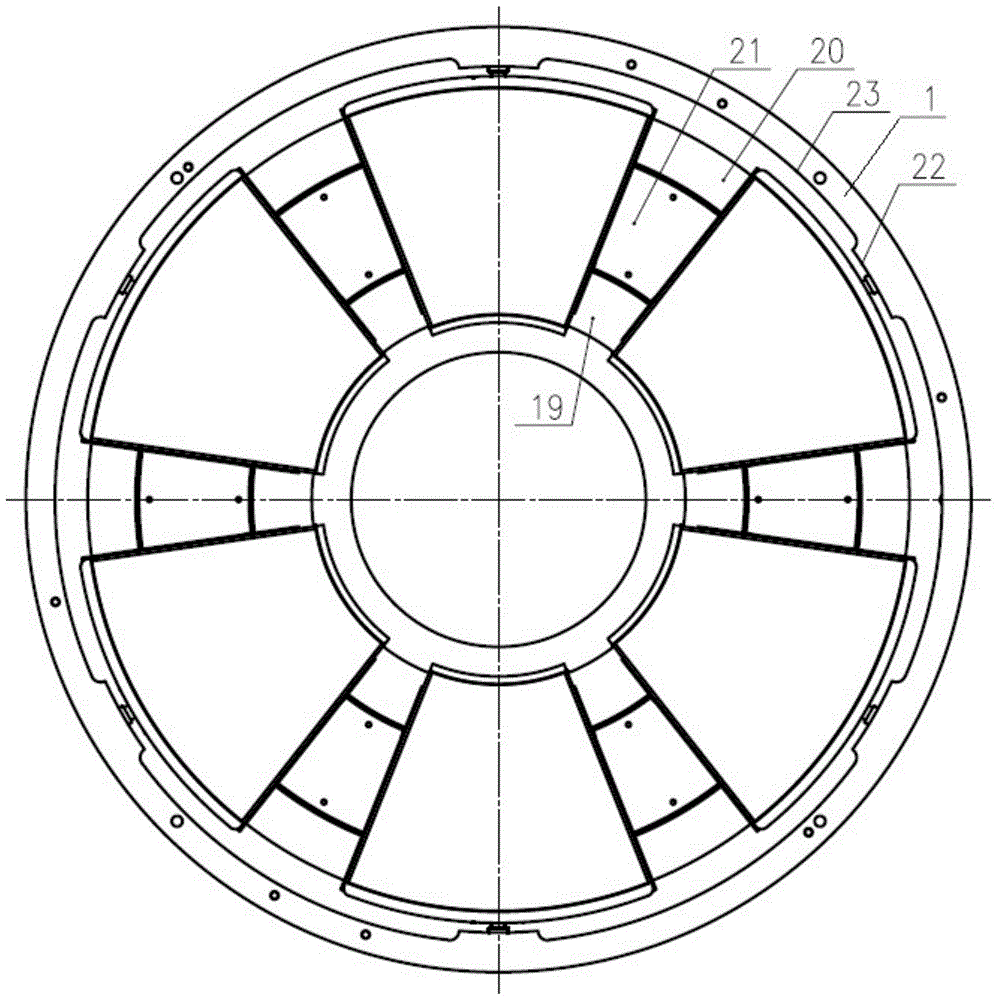

[0019] figure 1 For the linkage self-balancing water-lubricated thrust bearing suitable for the third-generation nuclear power, a special design of self-balancing and following is adopted to reduce the impact on the tile surface and increase the operating reliability. This self-balancing structure needs to have the function of automatically adjusting the height difference of each tile, that is, the overlapping structure of the balance weight; this overlapping structure can complete the adjustment work of adjusting the height difference of each tile under a certain pre-tightening force. When there is a certain difference in the load of each thrust pad, the height of each thrust pad can be automatically adjusted to limit the load fluctuation amplitude within ±10%.

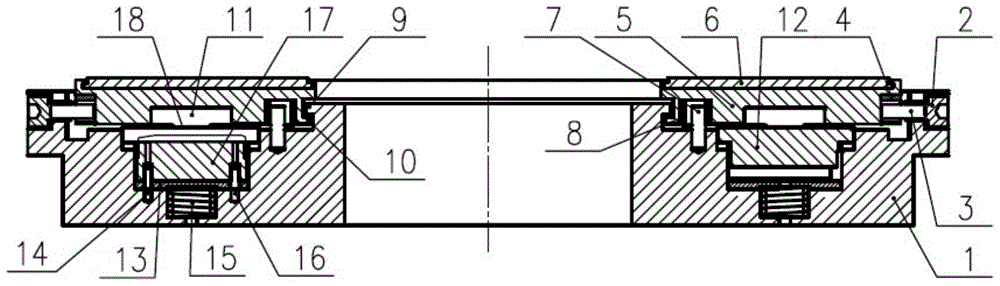

[0020] Such as figure 2 As shown, the bearing seat 1 is the main support platform, which is composed of five structures: the limit structure, the support structure, the self-balancing structure, the following struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com