Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

303 results about "Slurry reactor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Definition of 'slurry reactor'. slurry reactor in Chemical Engineering. A slurry reactor is a reactor in which contact is achieved by suspending a solid in a liquid. The solid-catalyzed reaction of a gas with a liquid can be carried out in a slurry reactor, where fine catalyst particles are suspended in the liquid.

Catalyst for production of 1,4-butynediol and preparation method of catalyst

ActiveCN102950014AHigh activityHigh selectivityPhysical/chemical process catalystsOrganic compound preparationBASIC CUPRIC CARBONATESlurry reactor

The invention discloses a catalyst for production of 1,4-butynediol and a preparation method of the catalyst, belongs to the field of catalyst research, more particularly relates to a load type catalyst for production of 1,4-butynediol in a slurry reactor and a preparation method of the catalyst. According to the method, nanosilicon dioxide which has a larger external specific surface is used as a carrier, copper and bismuth are attached to the carrier by adopting a settling and depositing method, the active components of the catalyst exist in a form of basic cupric carbonate, and the catalyst comprises the following components in percentage by mass: 20-50 percent of carrier, 35-70 percent of basic cupric carbonate and 2-15 percent of bismuth subcarbonate. The prepared catalyst has the characteristics of good activity and high selectivity and is easy to activate.

Owner:大连瑞克科技股份有限公司

Strengthened iron catalyst for slurry reactors

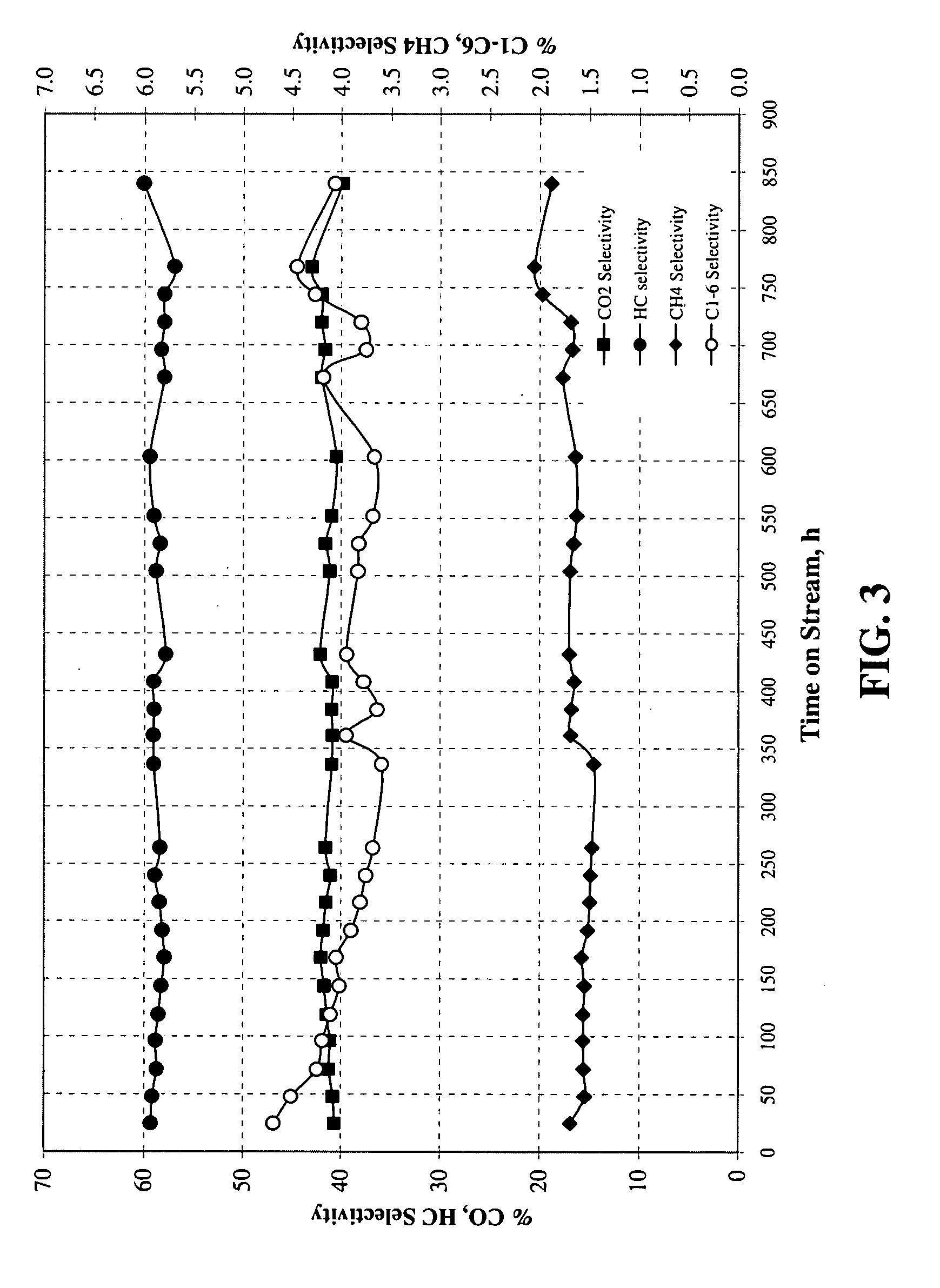

ActiveUS20090062108A1Various problemOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationSlurry reactorPotassium

A method of strengthening a precipitated unsupported iron catalyst by: preparing a precipitated unsupported iron catalyst containing copper and potassium; adding a solution comprising a structural promoter to the previously prepared catalyst; drying the mixture; and calcining the dried catalyst.A method for preparing an iron catalyst, the method comprising: precipitating a catalyst precursor comprising iron phases selected from hydroxides, oxides, and carbonates; adding a promoter to the catalyst precursor to yield a promoted precursor; drying the promoted precursor to yield dried catalyst; and calcining the dried catalyst, wherein the catalyst further comprises copper and potassium.A method of preparing a strengthened precipitated iron catalyst comprising: co-precipitating iron, copper, magnesium, and aluminum; washing the precipitate; alkalizing the precipitate; and drying the precipitate to yield a dried catalyst precursor. The dried catalyst precursor may be calcined and treated with a gas comprising carbon monoxide.

Owner:RES USA LLC

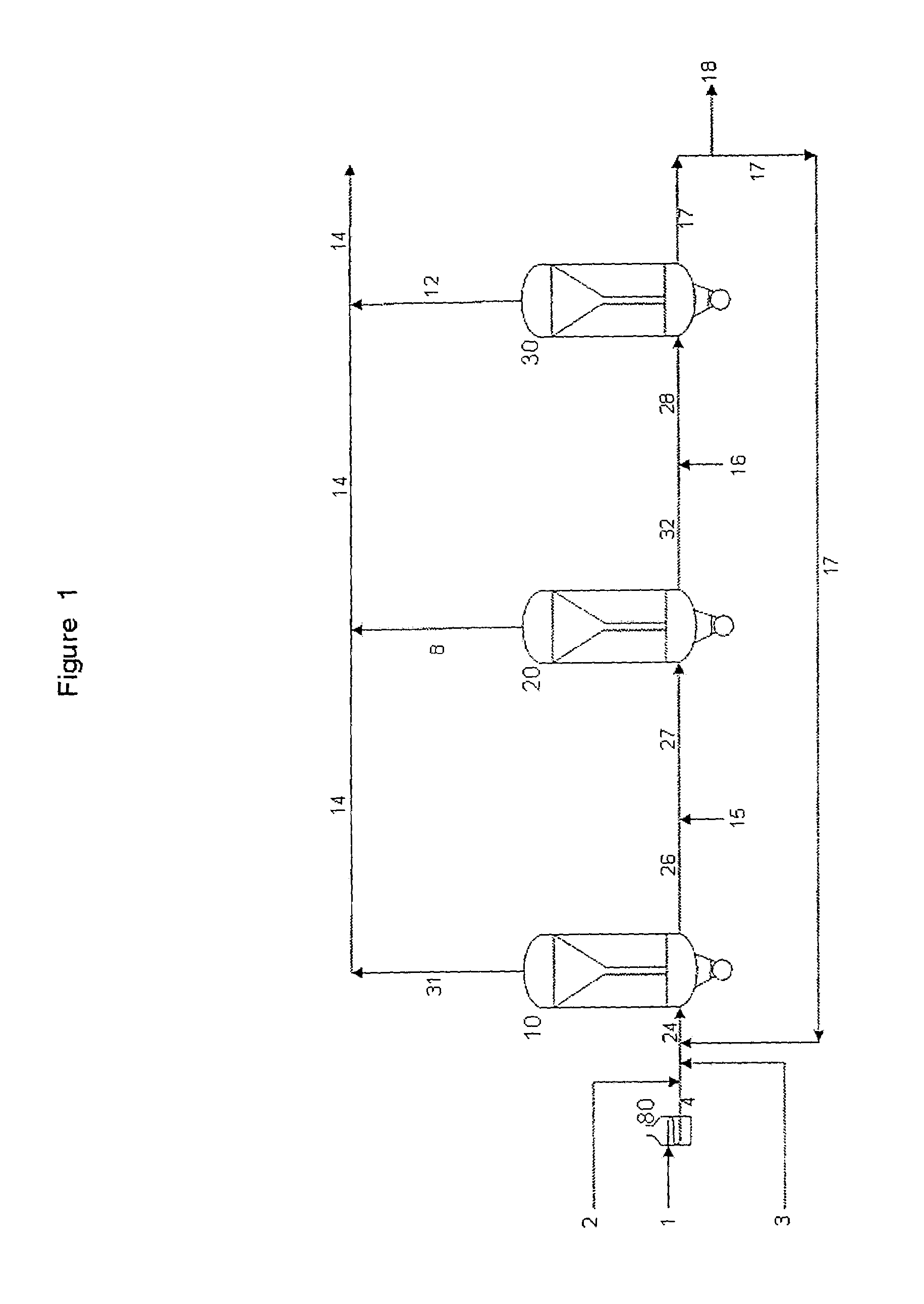

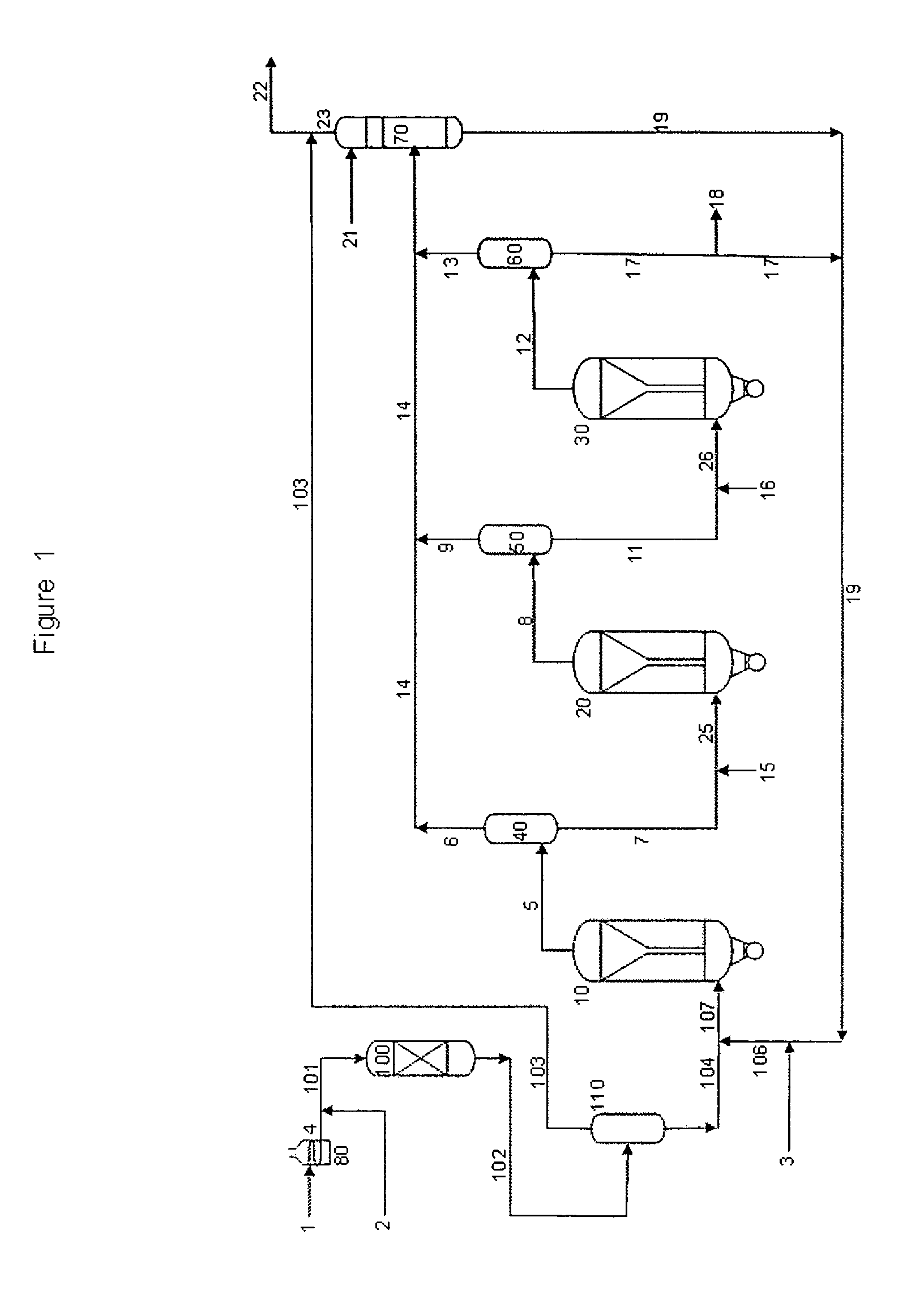

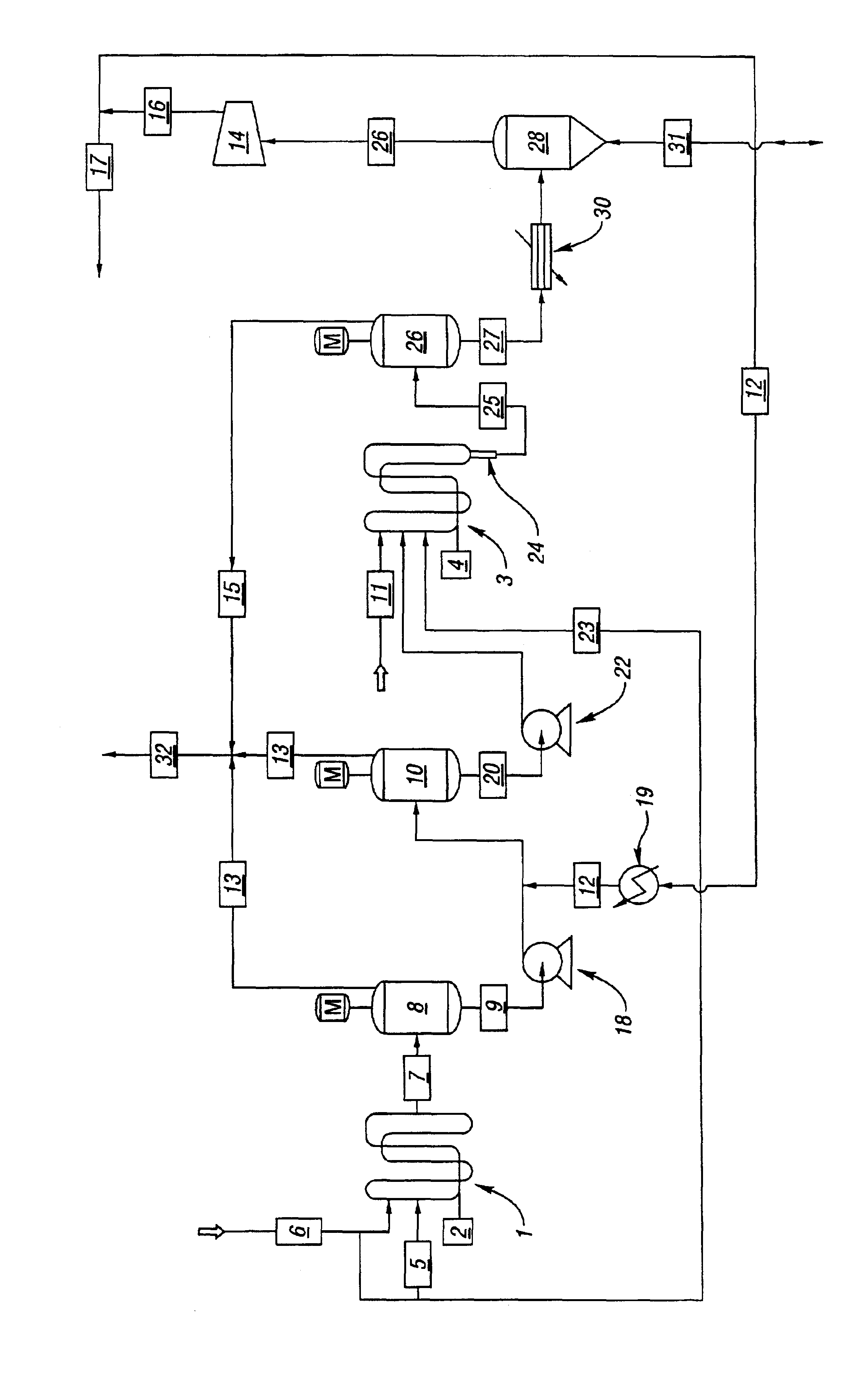

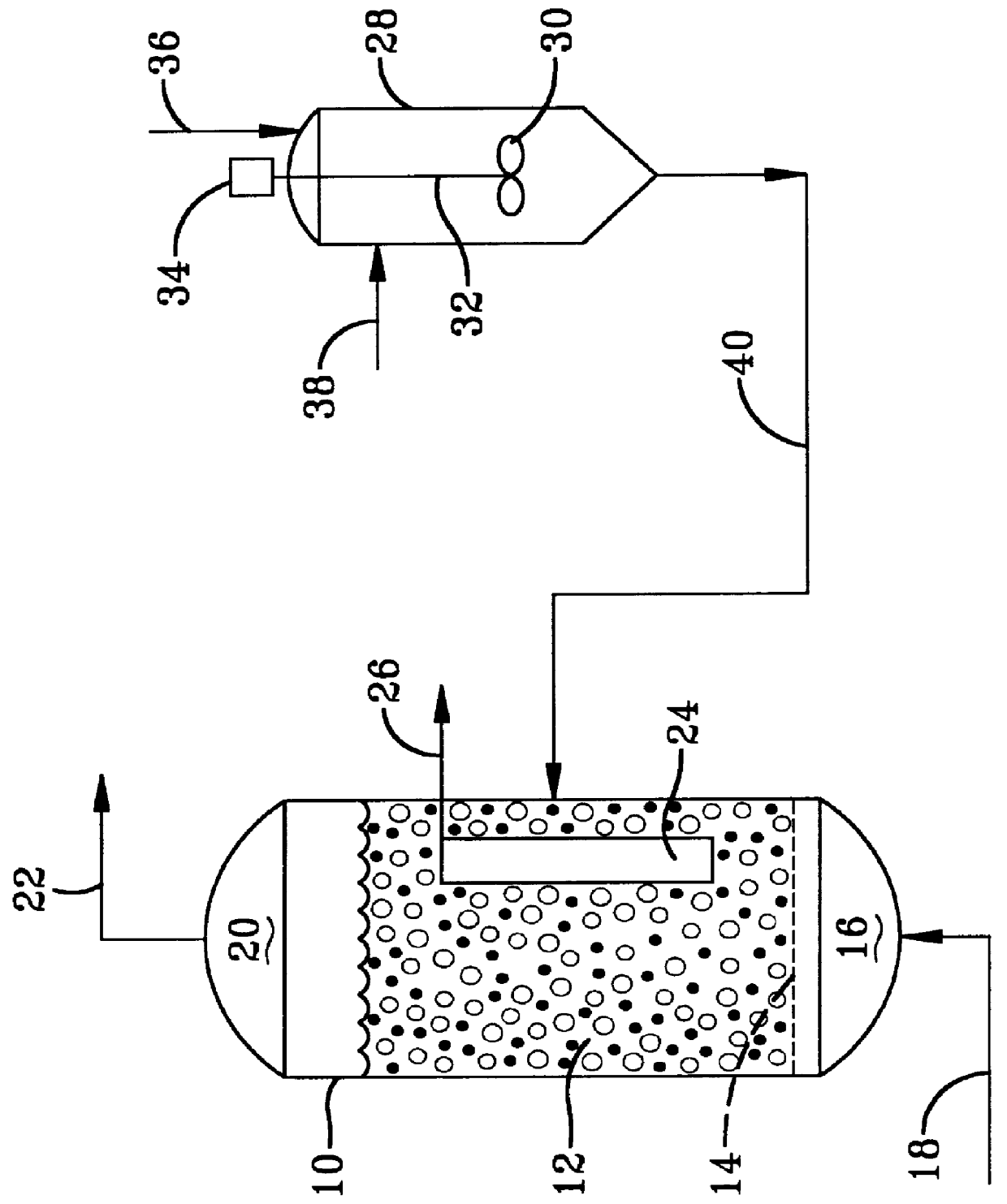

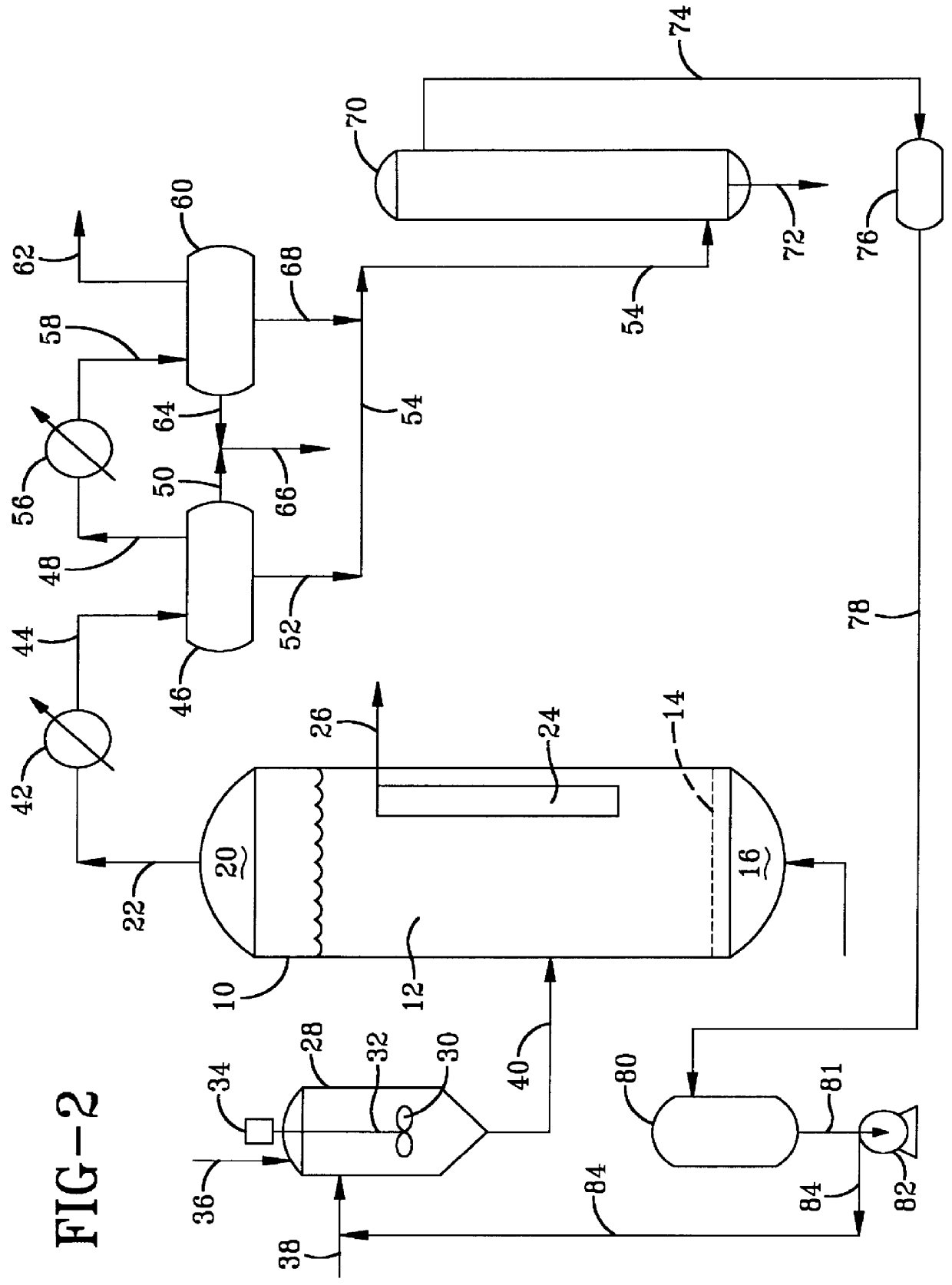

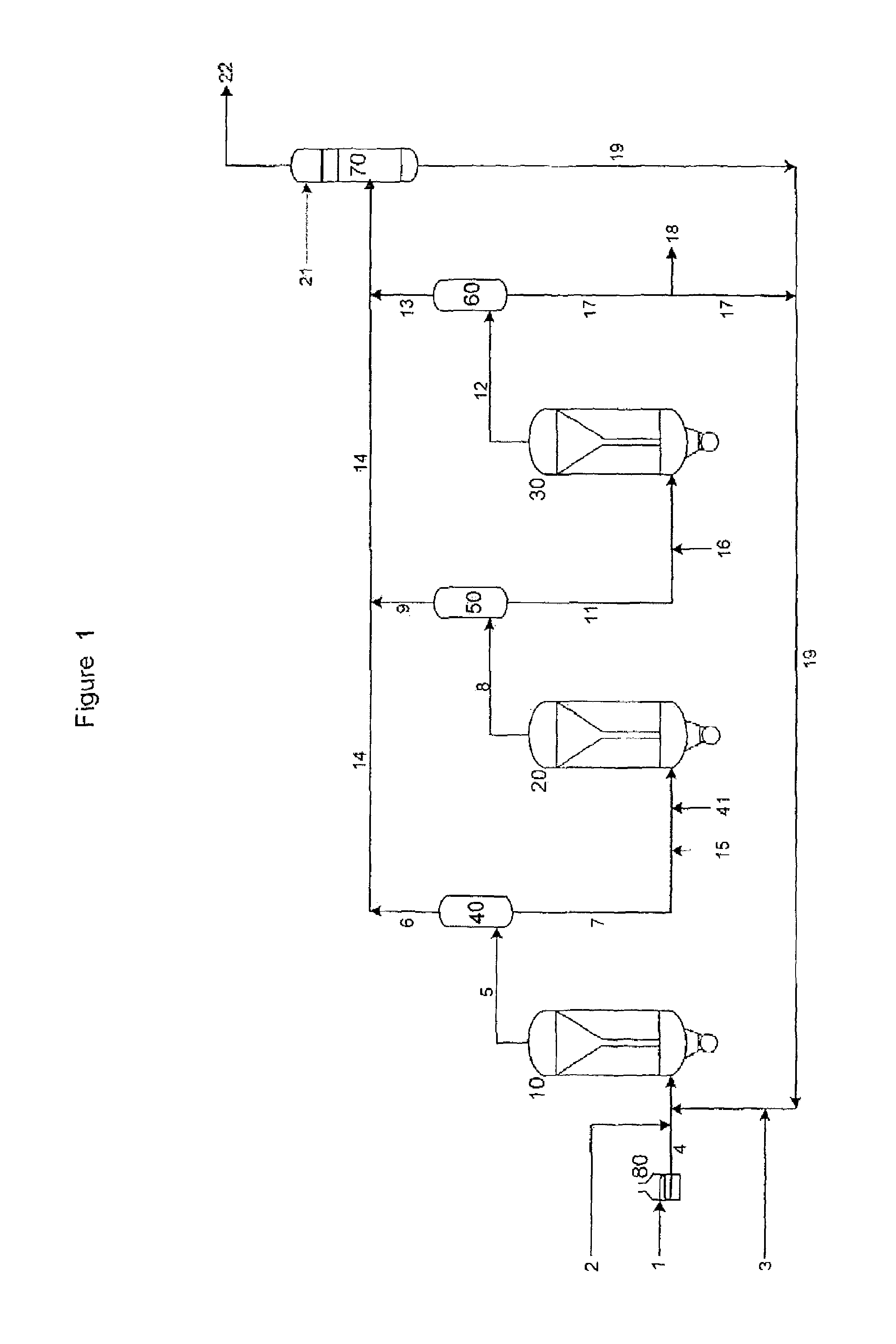

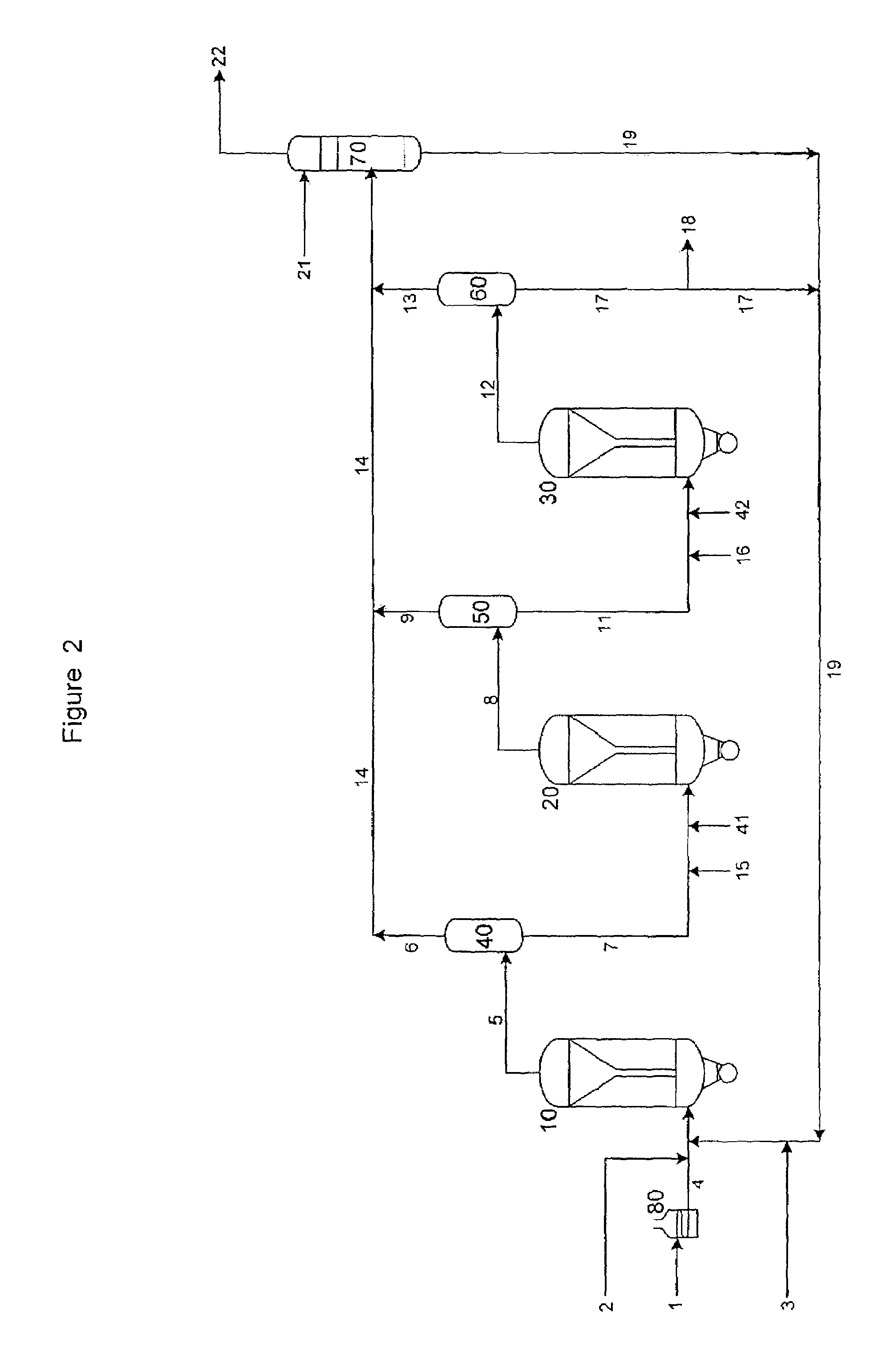

Process for upgrading heavy oil using a reactor with a novel reactor separation system

ActiveUS7431822B2Treatment with plural serial cracking stages onlyTreatment with plural parallel cracking stages onlyLiquid productHydrogen

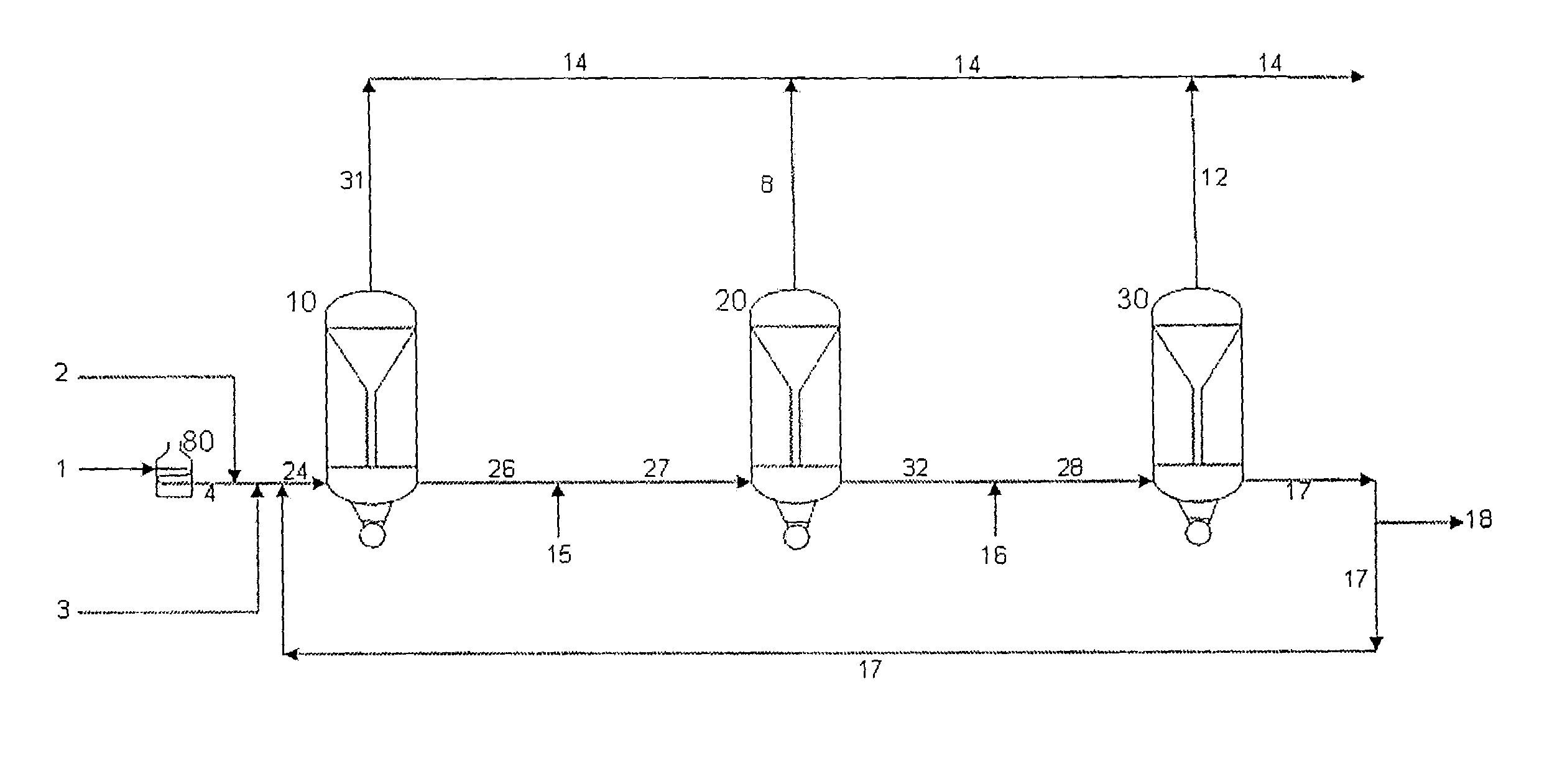

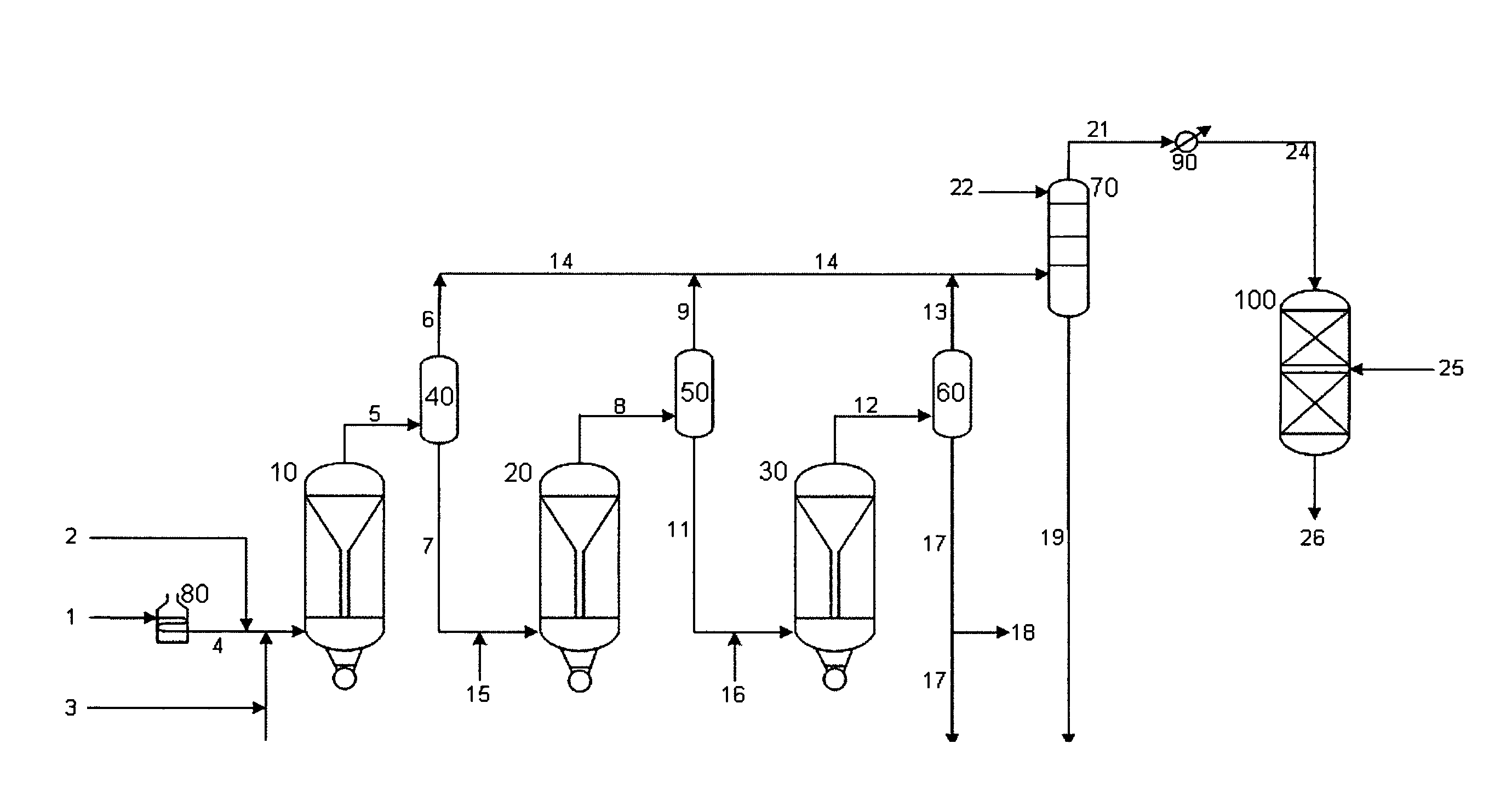

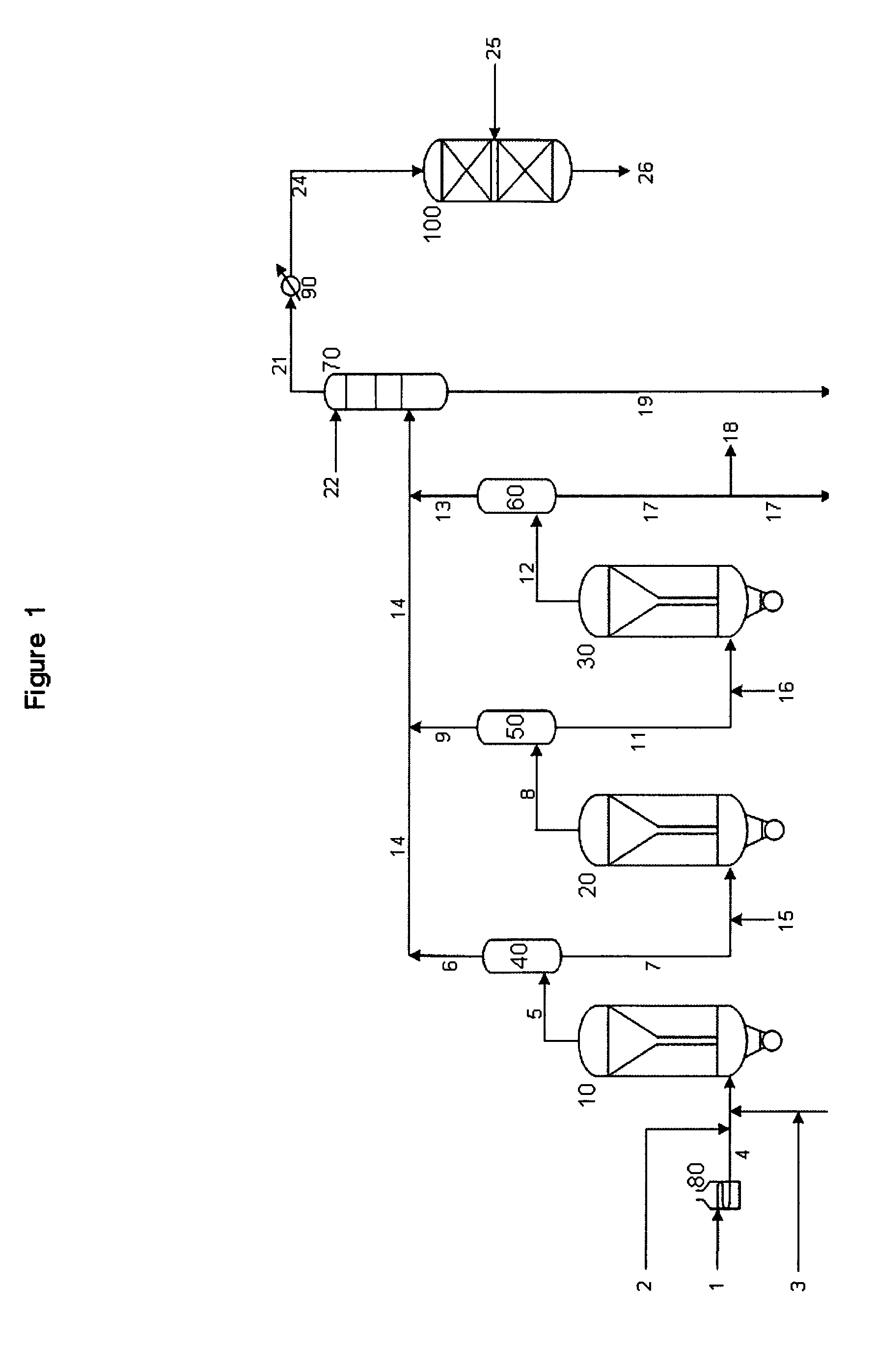

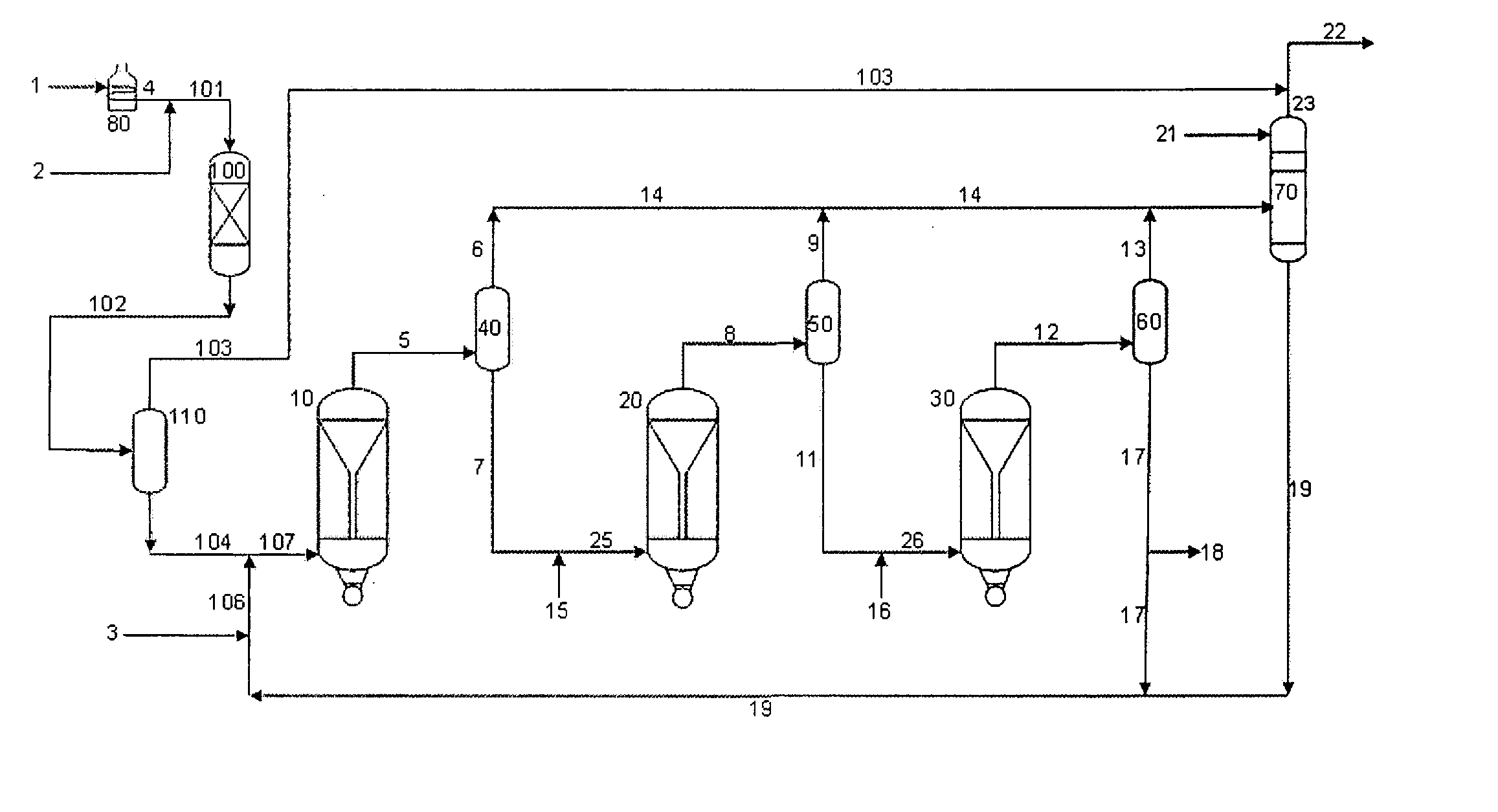

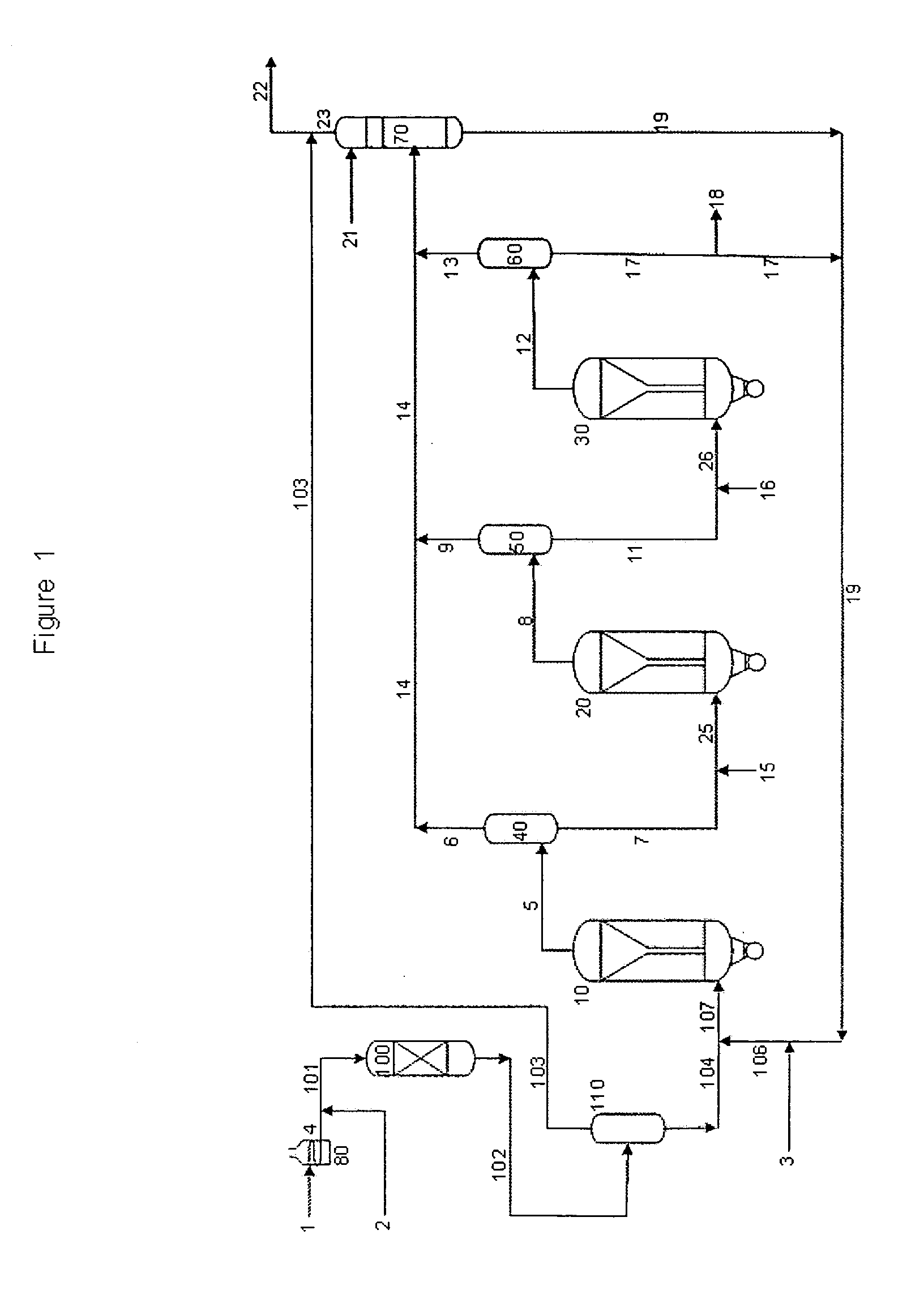

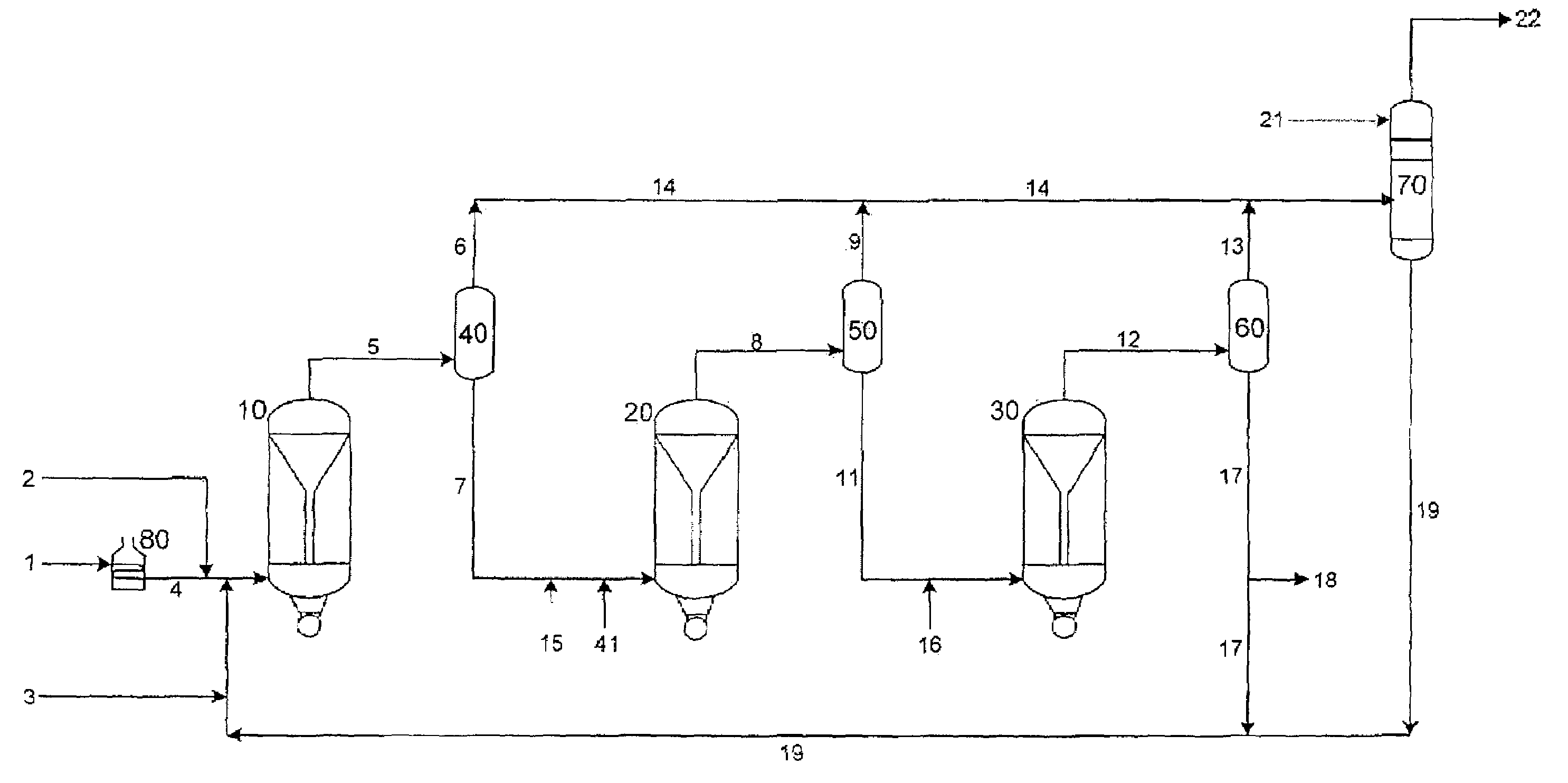

Applicants have developed a new residuum full hydroconversion slurry reactor system that allows the catalyst, unconverted oil, hydrogen, and converted oil to circulate in a continuous mixture throughout an entire reactor with no confinement of the mixture. The mixture is separated internally, within one of more of the reactors, to separate only the converted oil and hydrogen into a vapor product while permitting the unconverted oil and the slurry catalyst to continue on into the next sequential reactor as a liquid product. A portion of the unconverted oil is then converted to lower boiling point hydrocarbons in the next reactor, once again creating a mixture of unconverted oil, hydrogen, converted oil, and slurry catalyst. Further hydroprocessing may occur in additional reactors, fully converting the oil. The oil may alternately be partially converted, leaving a concentrated catalyst in unconverted oil which can be recycled directly to the first reactor.

Owner:CHEVROU USA INC

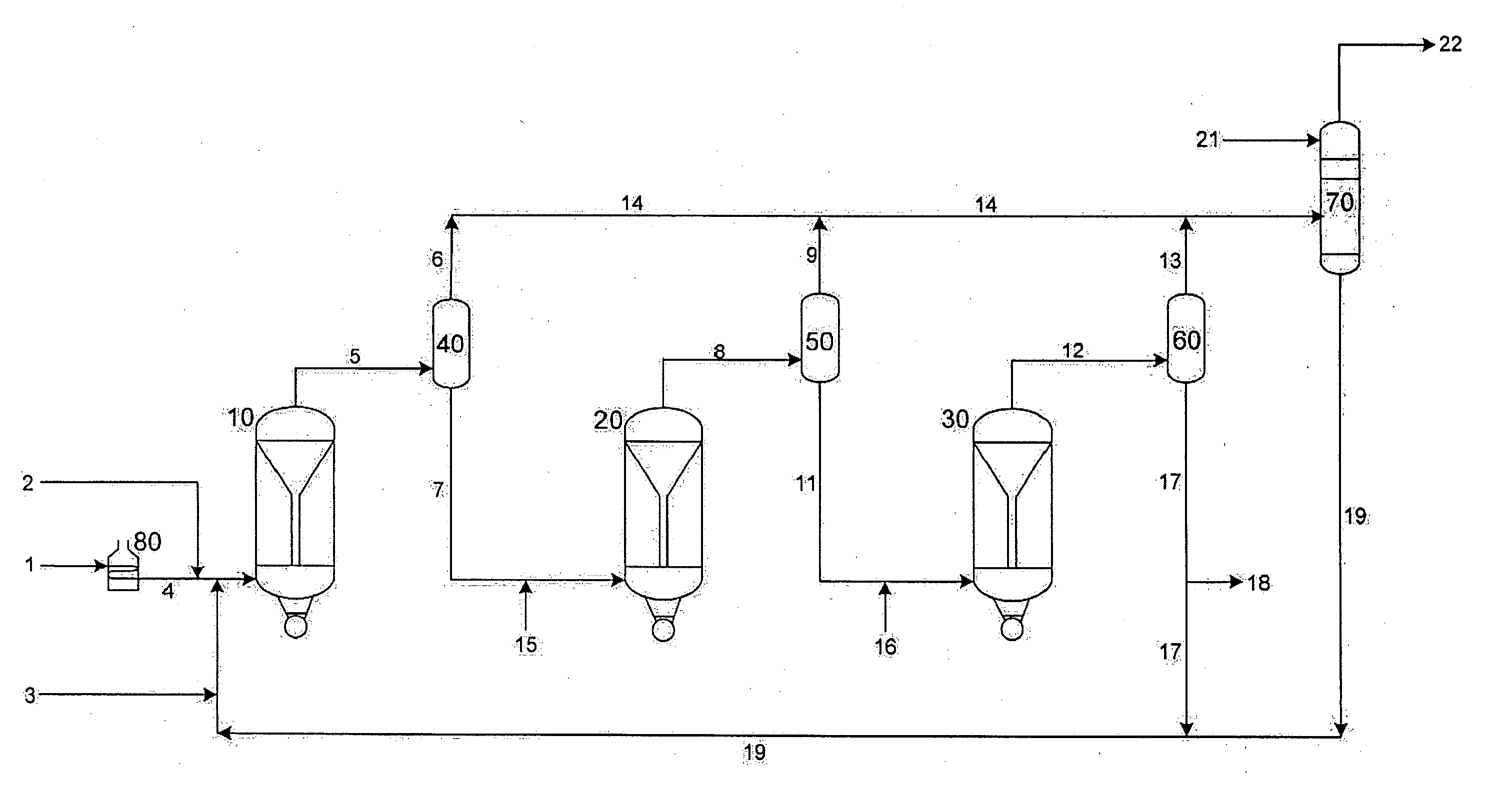

Process for upgrading heavy oil using a highly active slurry catalyst composition

ActiveUS20070138057A1Treatment with plural serial cracking stages onlyTreatment with plural parallel cracking stages onlyHydrogenSlurry reactor

The instant invention is directed to a new residuum full hydroconversion slurry reactor system that allows the catalyst, unconverted oil and converted oil to circulate in a continuous mixture throughout an entire reactor with no confinement of the mixture. The mixture is partially separated in between the reactors to remove only the products and hydrogen, while permitting the unconverted oil and the slurry catalyst to continue on into the next sequential reactor where a portion of the unconverted oil is converted to lower boiling point hydrocarbons, once again creating a mixture of unconverted oil, converted oil, and slurry catalyst. Further hydroprocessing may occur in additional reactors, fully converting the oil. The oil may alternately be partially converted, leaving a highly concentrated catalyst in unconverted oil which can be recycled directly to the first reactor.

Owner:CHEVROU USA INC

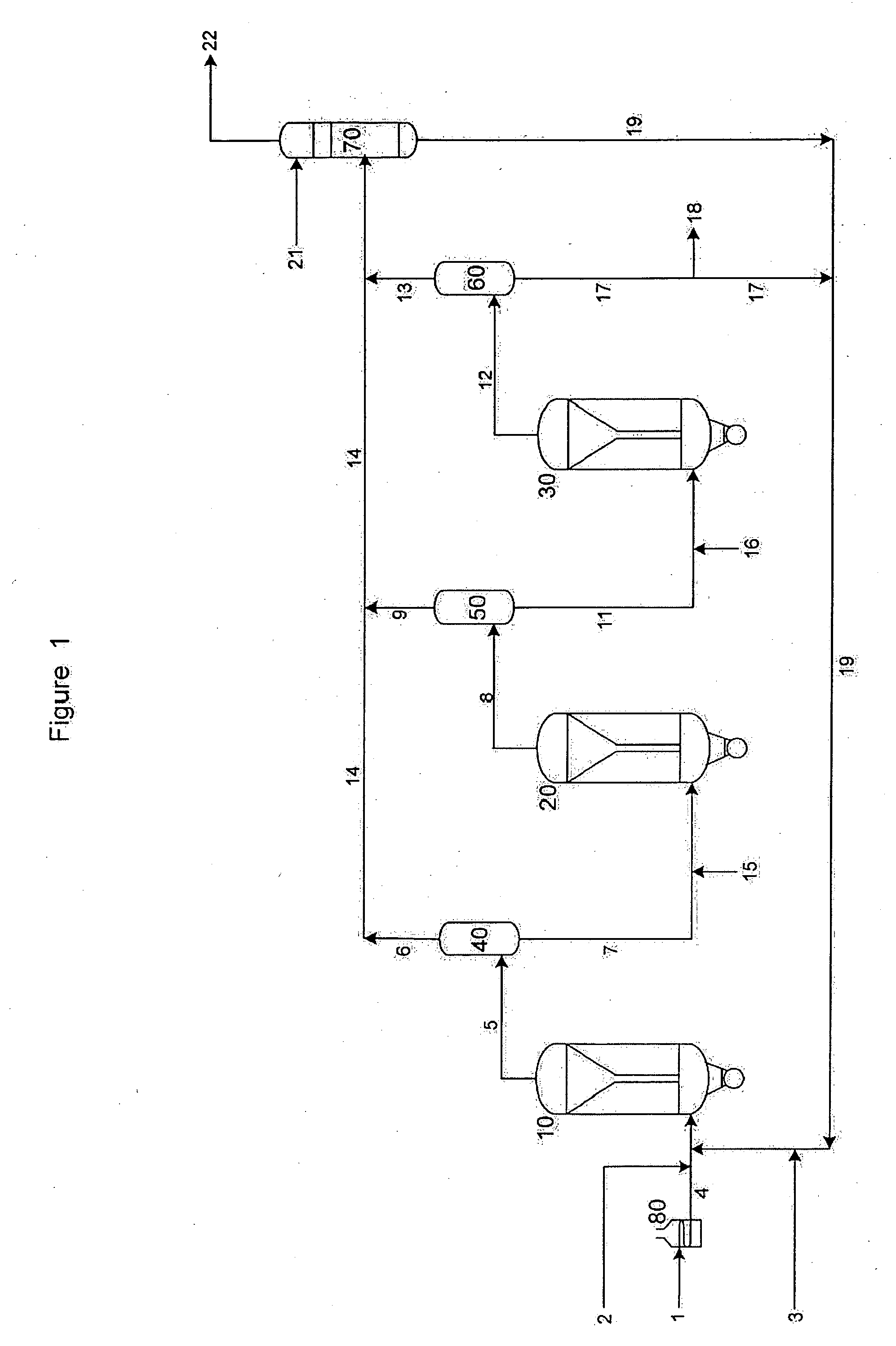

Integrated in-line pretreatment and heavy oil upgrading process

ActiveUS7431831B2Lower capital expenditureImprove product qualityTreatment with plural serial cracking stages onlyTreatment with plural parallel cracking stages onlyContinuous reactorSlurry reactor

A new residuum full hydroconversion slurry reactor system has been developed that allows the catalyst, unconverted oil, products and hydrogen to circulate in a continuous mixture throughout an entire reactor with no confinement of the mixture. The mixture is partially separated in between the reactors to remove only the products and hydrogen while permitting the unconverted oil and the slurry catalyst to continue on into the next sequential reactor. In the next reactor, a portion of the unconverted oil is converted to lower boiling point hydrocarbons, once again creating a mixture of unconverted oil, products, hydrogen and slurry catalyst. Further hydroprocessing may occur in additional reactors, fully converting the oil. The oil may alternately be partially converted, leaving a highly concentrated catalyst in unconverted oil which can be recycled directly to the first reactor. The slurry reactor system is, in this invention, preceded by an in-line pretreating step, such as hydrotreating or deasphalting. Following the slurry reactor system, fully converted oil may be subsequently hydrofinished for the removal of hetoroatoms such as sulfur and nitrogen.

Owner:CHEVROU USA INC

Catalyst for producing 1.4-butynediol and preparation method of catalyst

ActiveCN102950002AEasy to prepareSimple manufacturing methodOrganic compound preparationHydroxy compound preparationSlurry reactorPtru catalyst

The invention discloses a catalyst for producing 1.4-butynediol and a preparation method of the catalyst, belonging to the technical field of load type catalysts for a slurry reactor. The catalyst for producing 1.4-butynediol is characterized in that nanosilicon dioxide is used as a carrier, the nanosilicon dioxide has larger external specific surface area, copper and bismuth are absorbed on the carrier by adopting an impregnation and deposition-precipitation method, so that the catalyst contains 35-65 percent of copper oxide, and then a defined amount of silica sol is added, and through a specific forming method, the granularity of the catalyst is between 1micrometer and 50 micrometers. The prepared catalyst has the characteristics of good activity, high selectivity, high strength, easiness in separation, high particle uniformity, and difficulty in pulverization in a use process; and the preparation method of the catalyst is simple and easy to operate and good in repeatability.

Owner:河北瑞克新能源科技有限公司

Process for slurry phase hydroconversion of heavy hydrocarbon feeds and/or coal using a supported catalyst

InactiveUS20080149531A1Catalyst activation/preparationHydrocarbon oil crackingSlurry reactorSpherical shaped

The invention concerns a process for converting heavy feeds carried out in a slurry reactor in the presence of hydrogen and in the presence of a catalyst comprising at least one catalytic metal or a compound of a catalytic metal from group VIB and / or VIII supported on alumina, the pore structure of which is composed of a plurality of juxtaposed agglomerates each formed by a plurality of acicular platelets, the platelets of each agglomerate being generally radially oriented with respect to the others and with respect to the centre of the agglomerate, said catalyst having an irregular and non-spherical shape and being mainly in the form of fragments, obtained using a process including the following steps:a) granulation starting from an active alumina powder having a low crystallinity and / or amorphous structure, to obtain agglomerates in the form of beads;b) maturing in a moist atmosphere between 60° C. and 100° C. then drying said beads;c) sieving to recover a fraction of said beads;d) crushing said fraction;e) calcining at least a portion of said crushed fraction at a temperature in the range 250° C. to 900° C.;f) impregnating with acid and hydrothermal treatment at a temperature in the range 80° C. to 250° C.;g) drying then calcining at a temperature in the range 500° C. to 1100° C.h) depositing at least one catalytic metal or compound of a catalytic metal from group VIB and / or group VIII by impregnation.The process of the invention employs a catalyst with a specific pore texture, shape and granulometry, resulting in improved performances.

Owner:INST FR DU PETROLE

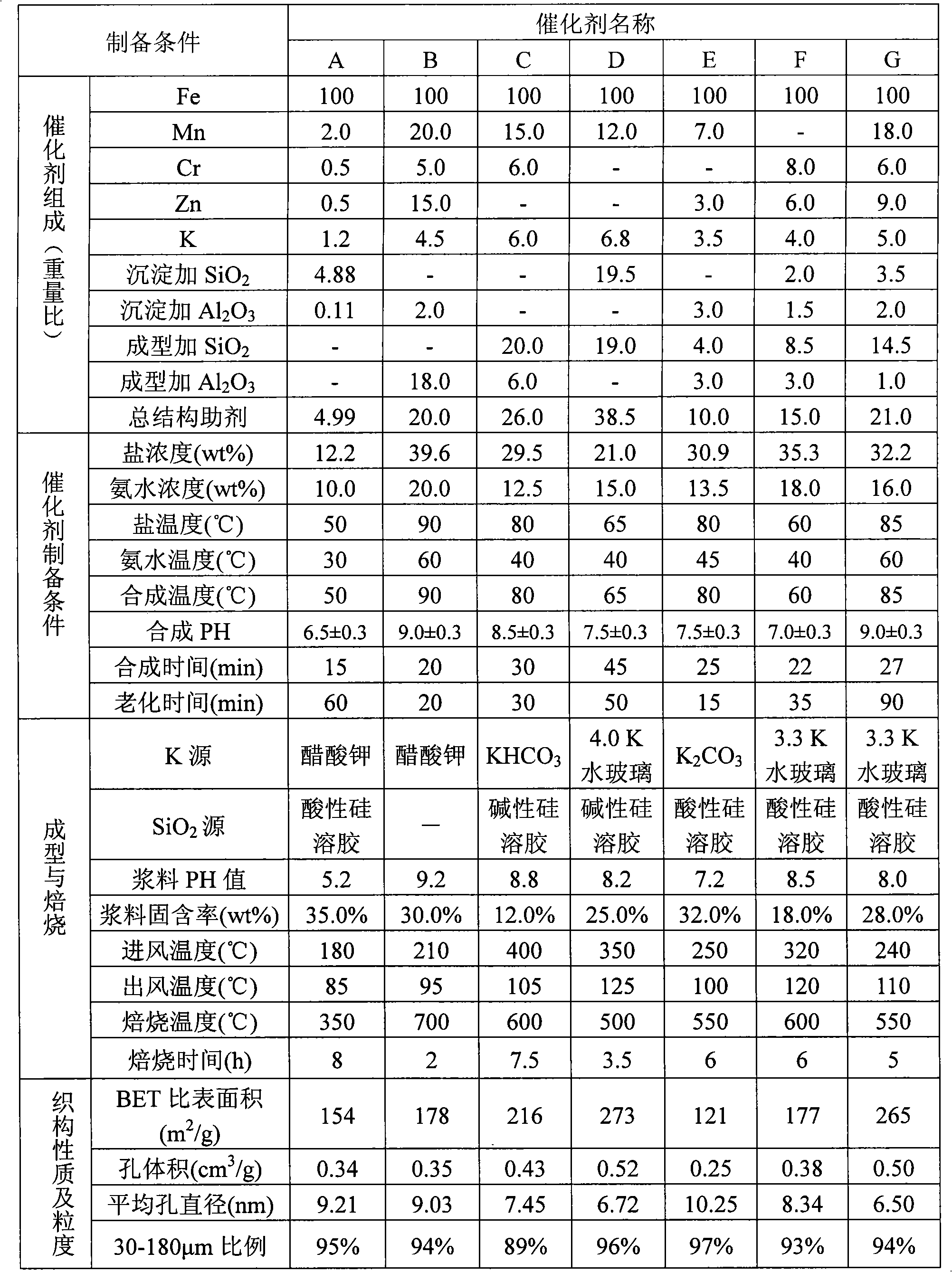

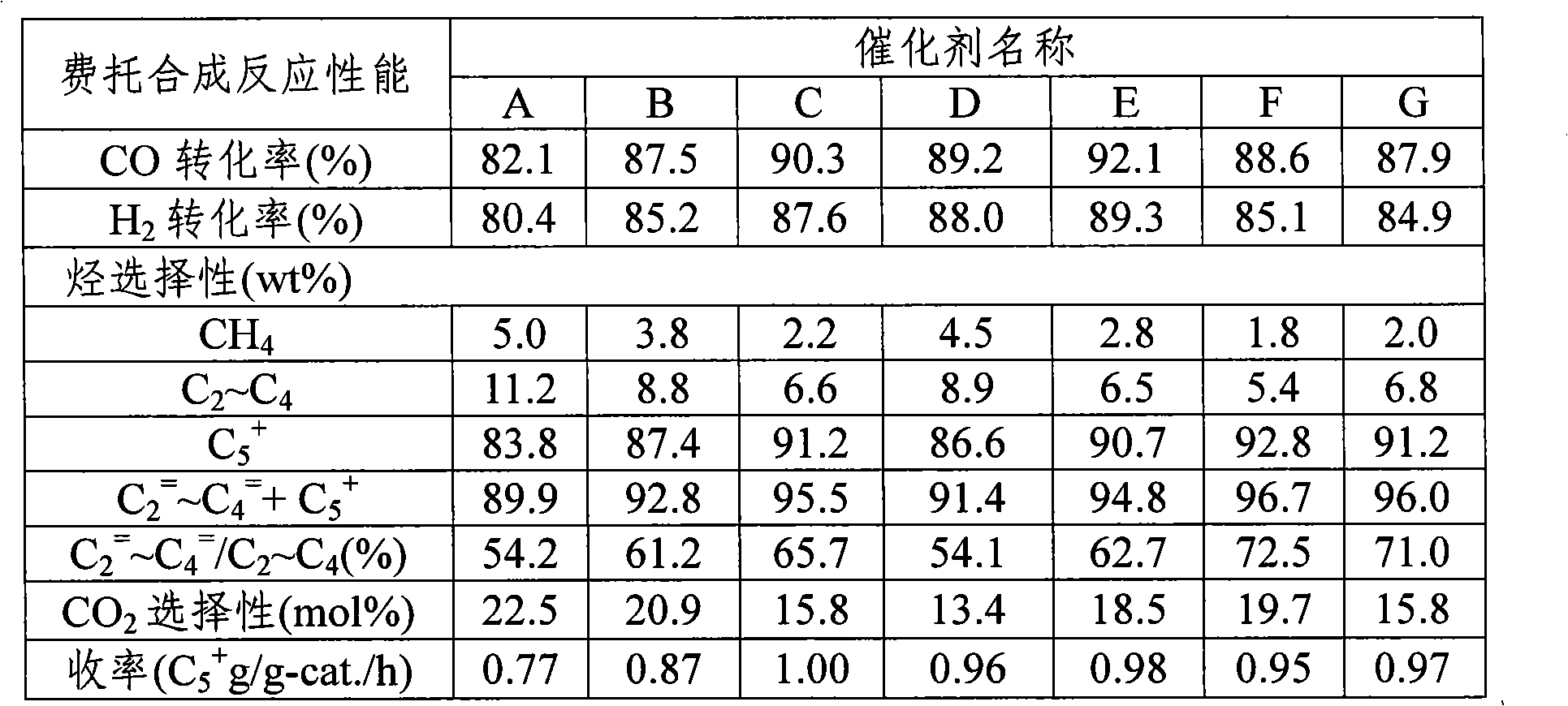

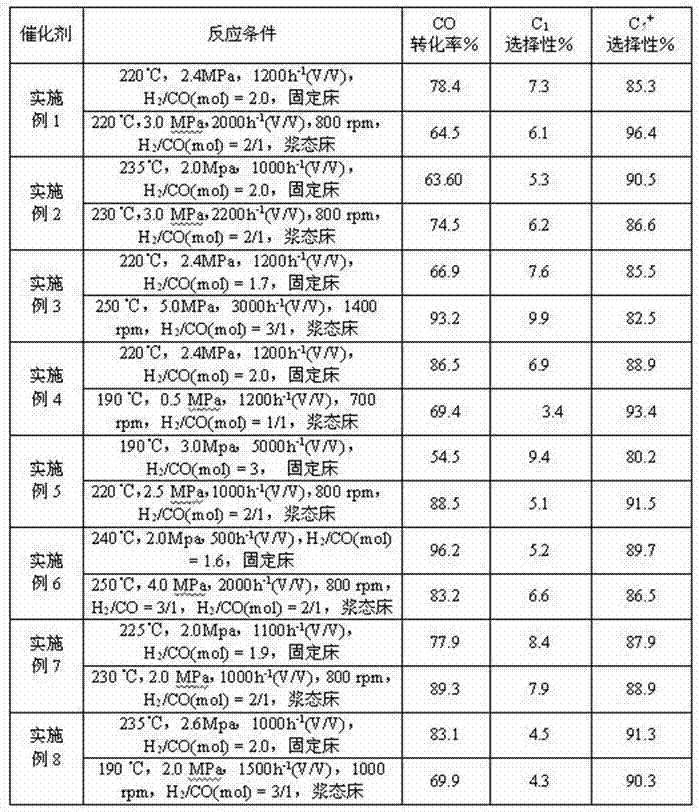

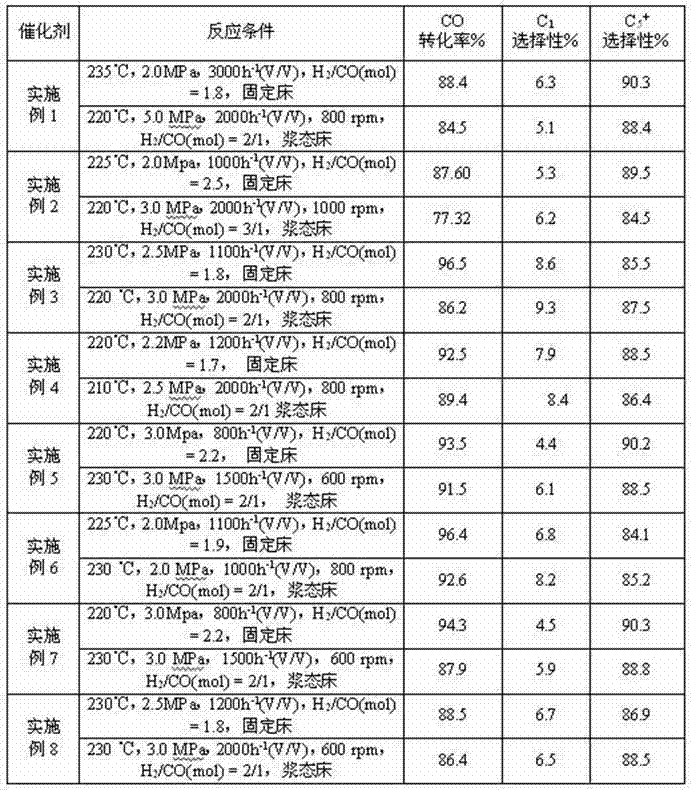

Fischer-Tropsch synthesis catalyst and preparation method and application thereof

InactiveCN101869840AHigh activityOptimize electronic structureHydrocarbon from carbon oxidesHeterogenous catalyst chemical elementsSlurry reactorPtru catalyst

The invention relates to a micro-spherical iron-based catalyst which contains transition metal additive, has high performance and is applicable to the Fischer-Tropsch synthesis of a slurry reactor, and a preparation method and the application thereof; and the weight composition of the catalyst is as follows: Fe: transition metal additive M: structural additive (SiO2 or / and Al2O3):K=100:1 to 50:1 to 50:0.5 to 10. The preparation method of the catalyst comprises the following steps: adding the structural additive into Fe / M mixed nitrate solution, co-precipitating with ammonia to prepare slurry; filtering and washing the slurry to obtain a filter cake; and adding the required amount of K additive and water into the filter cake, beating, spraying, drying and calcining to obtain the Fischer-Tropsch synthesis iron-based catalyst of the micro-spherical slurry reactor. The catalyst prepared by the method has good anti-wear performance, the distribution scope of the grain size of the catalyst is narrow, the synthesis gas conversion capability is high, the product selectivity is good and the time-space yield is high, and the Fischer-Tropsch synthesis reaction of the slurry reactor can be carried out within a wider scope of temperature simultaneously.

Owner:SYNFUELS CHINA TECH CO LTD

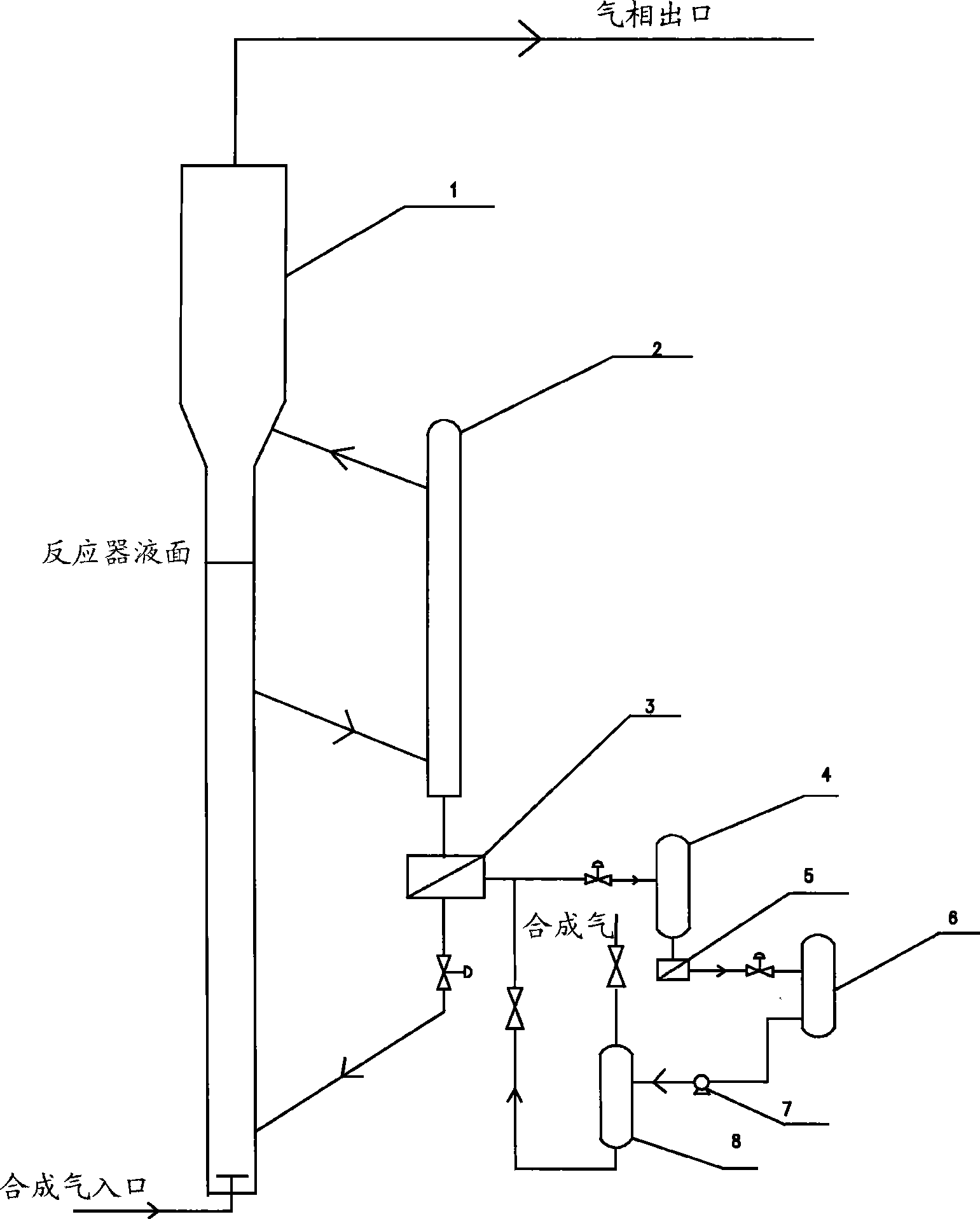

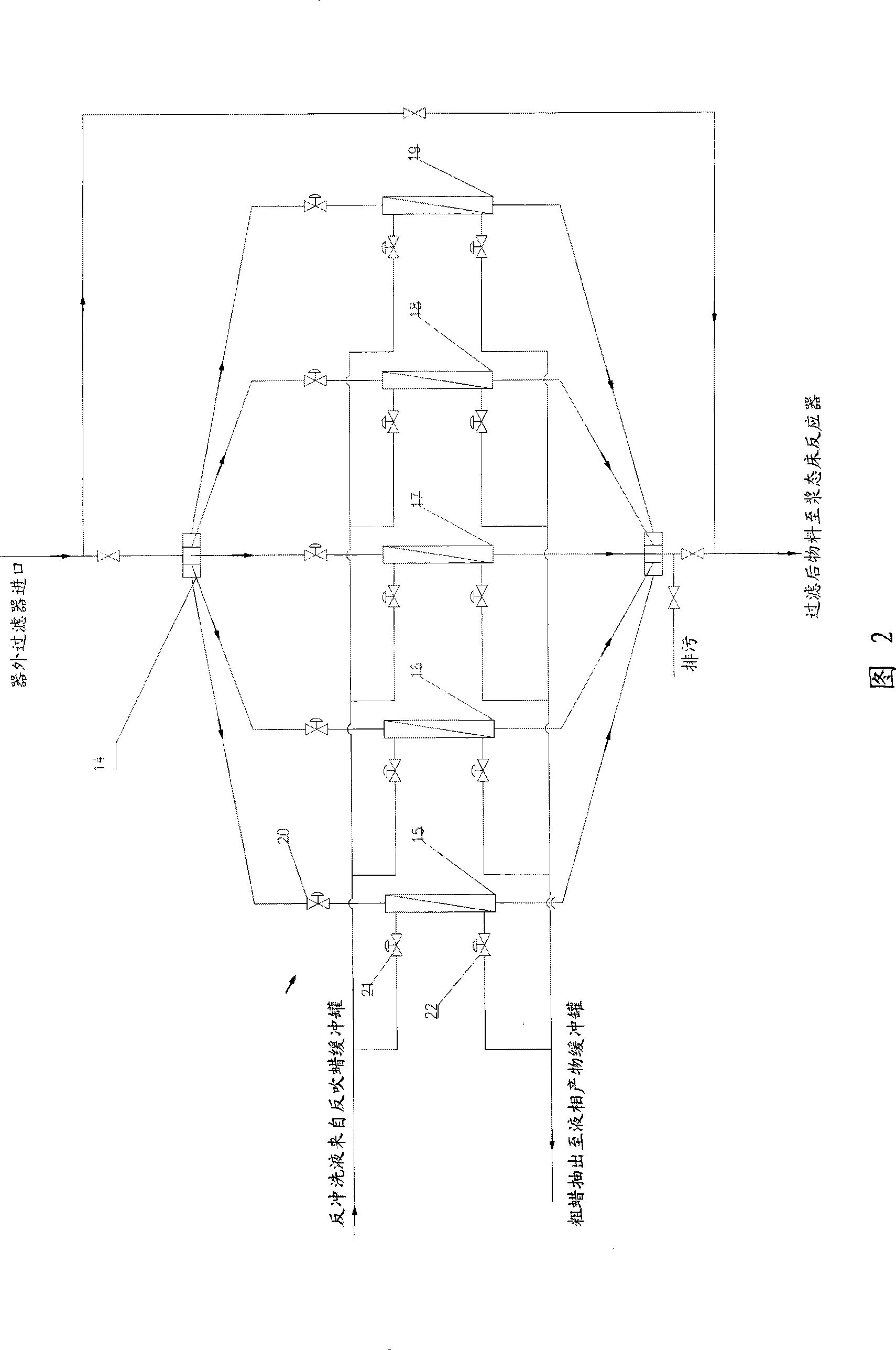

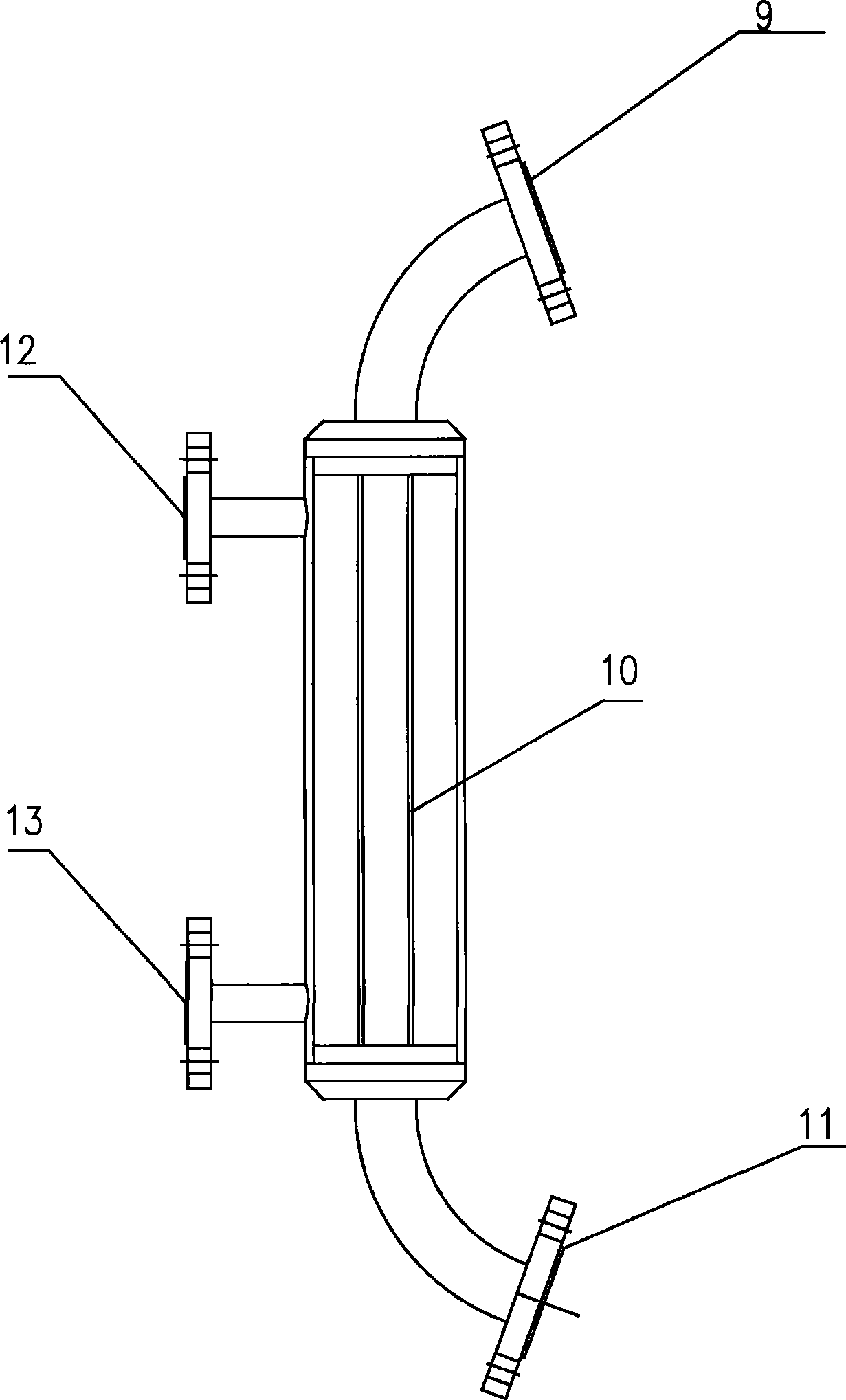

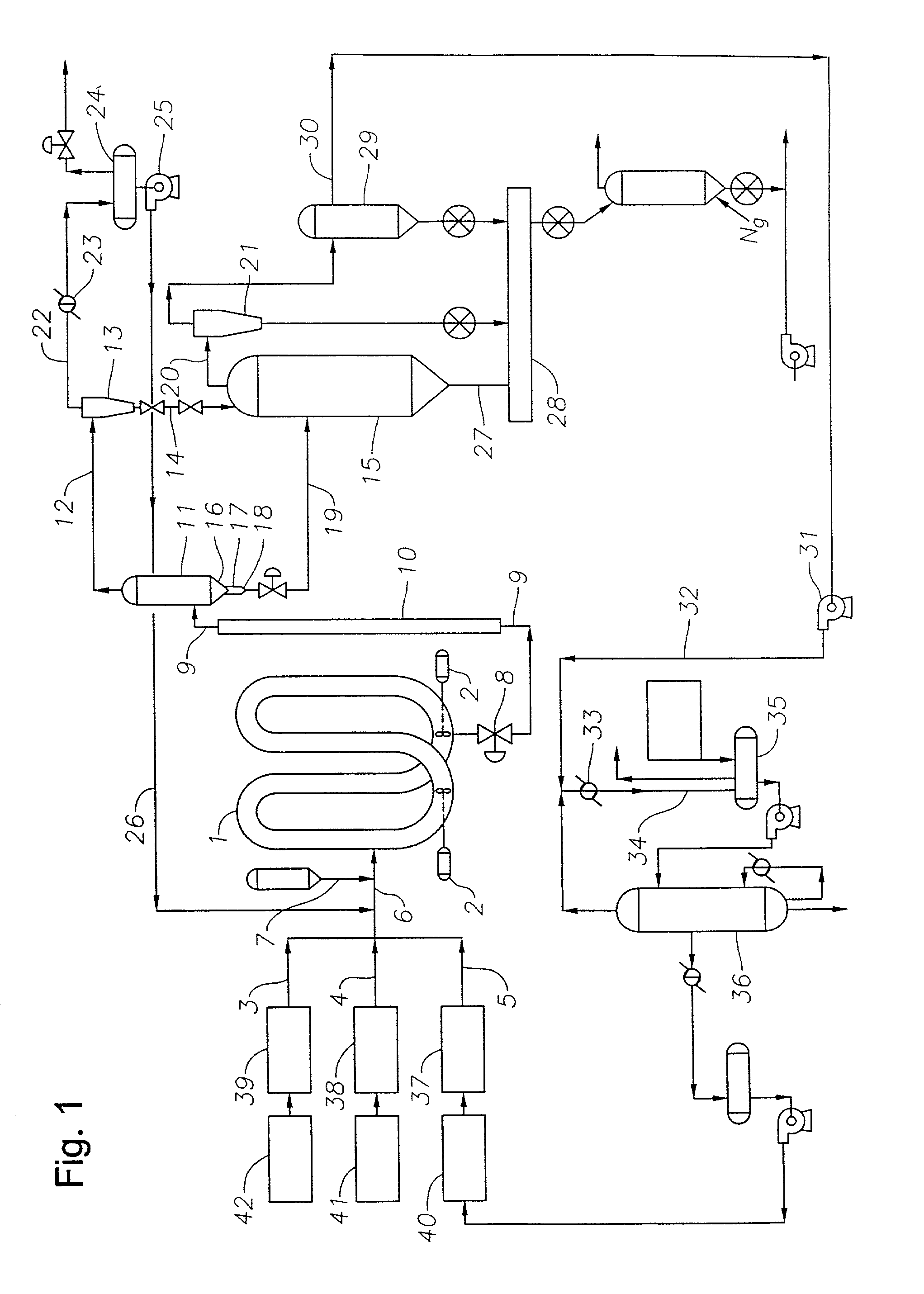

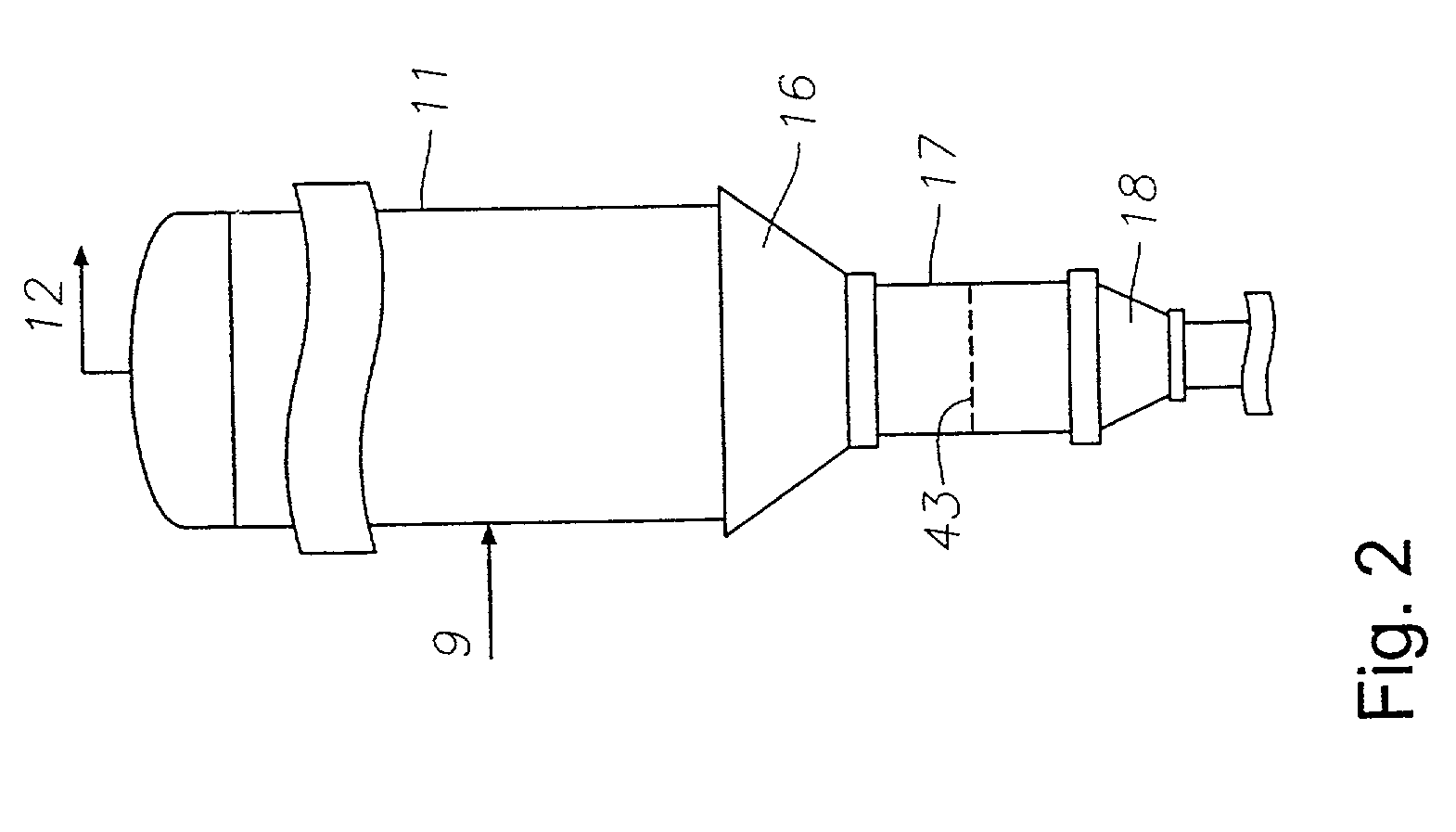

Wax extraction automatic filter, backwashing system of Ft synthetic pulp bed reactor

ActiveCN101417219AAvoid damageReduce the pressure on fine filtrationHydrocarbon from carbon oxidesLiquid hydrocarbon mixture productionWaxSlurry reactor

The invention discloses a wax extraction automatic filtration and backwashing system used for Fischer-Tropsch synthesis slurry reactor, comprising a filter unit and a backwashing unit, wherein, the filter unit comprises a slurry buffer tank, a wax device external filter (30), a coarse wave outcome buffer tank (4), a wax fine filter (5) and a wax product buffer tank (6); and the backwashing system comprises a washing wax pump (7) and a backwashing wax buffer tank (8). The wax extraction automatic filtration and backwashing system has the advantages of reasonable structure, short flow, low energy dissipation, avoiding the blocking or reverse flowing, reducing the damage of catalyst grains, and achieving the stable and continuous running of the Fischer-Tropsch synthesis slurry reactor.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

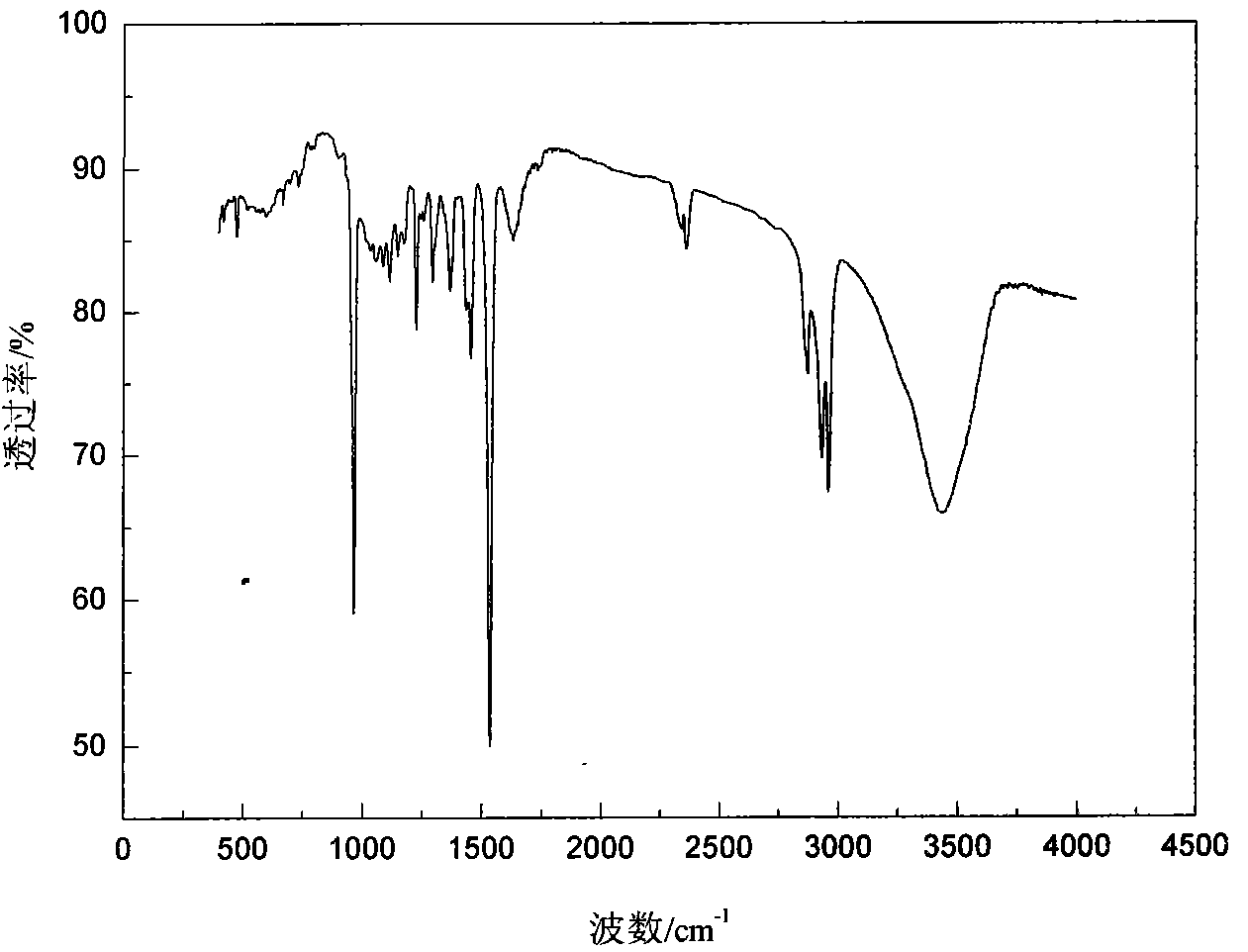

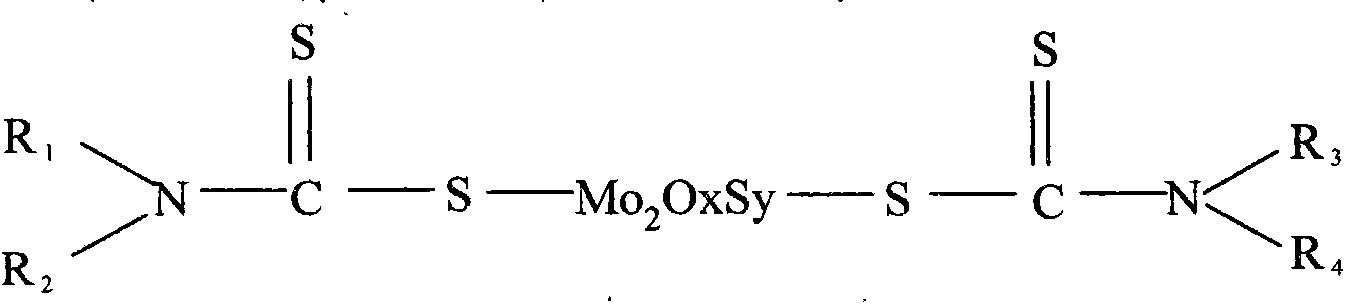

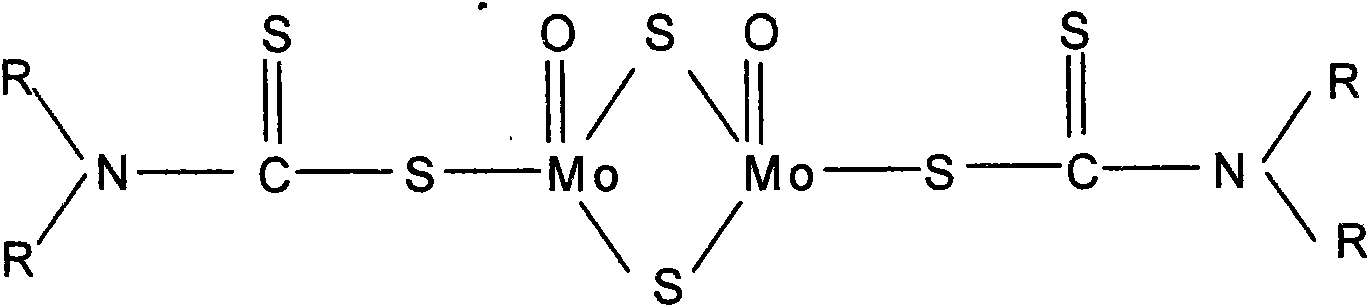

Oil-soluble self-vulcanizing molybdenum catalyst, and preparation method, use method and application of oil-soluble self-vulcanizing molybdenum catalyst

InactiveCN103349999AImprove catalytic performanceReduce yieldOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbon oil crackingSlurry reactorFiltration

The invention provides an oil-soluble self-vulcanizing molybdenum catalyst, and a preparation method, a use method and an application of the oil-soluble self-vulcanizing molybdenum catalyst. The preparation method comprises the following steps of (1) sequentially putting a molybdenum source, water, sodium sulfide, a solvent and inorganic acid in a container under the protection of nitrogen, uniformly mixing and stirring, cooling to 5-50 DEG C for reaction for 10-150min, (2) adding alkylamine and carbon disulfide, uniformly stirring, heating to 60-200 DEG C for reaction for 3-10h, and (3) after reaction, sufficiently cooling a product, performing suction filtration, sufficiently washing with methanol, and drying to obtain the oil-soluble self-vulcanizing molybdenum catalyst. The oil-soluble self-vulcanizing molybdenum catalyst can be vulcanized and decomposed to form a molybdenum disulfide active component in situ, is used for a slurry reactor hydrocracking technology for poor heavy oil with a high metal content, a high carbon residue content and a high sulfur content, can reduce the coke yield, and keeps long-period operation of a device.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

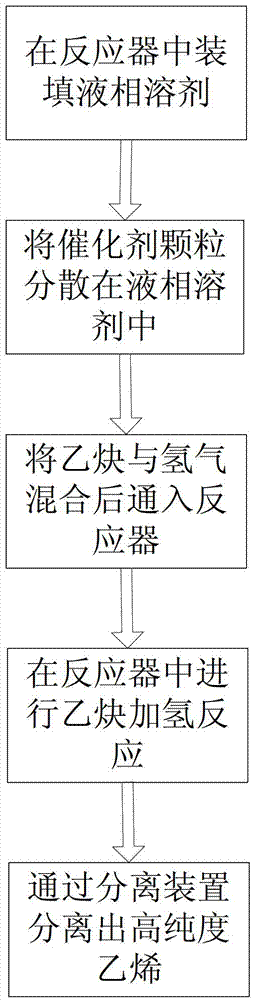

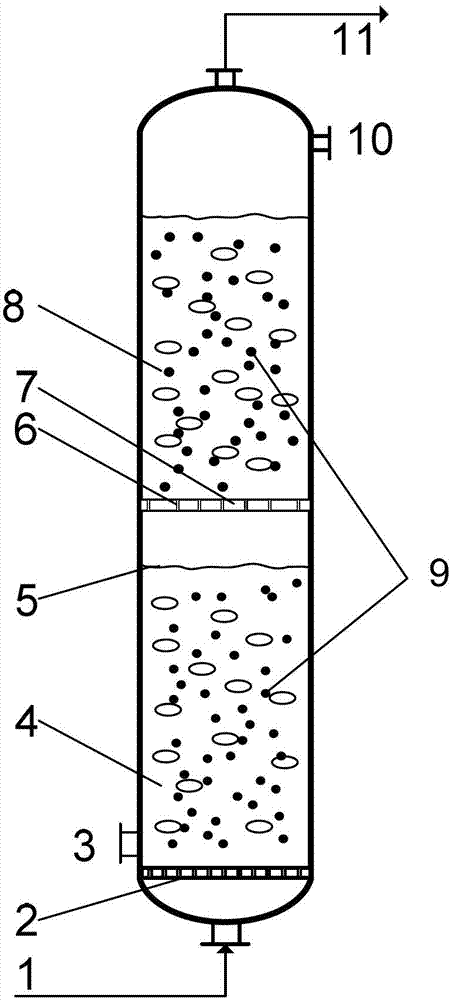

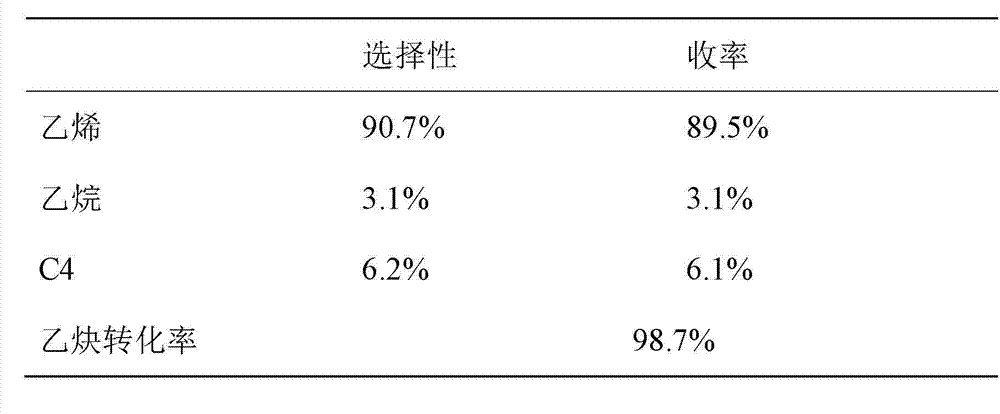

Method for preparing ethylene through liquid-phase selective hydrogenation of acetylene in slurry reactor

InactiveCN103044179AImprove conversion rateHigh yieldHydrocarbon by hydrogenationBulk chemical productionSolubilitySlurry reactor

The invention belongs to the technical field of chemical material preparing methods, and particularly relates to a method for preparing ethylene through liquid-phase selective hydrogenation of acetylene in a slurry reactor. A liquid-phase solvent with high selective solubility for acetylene and low selective solubility for ethylene is introduced into a gas-solid catalytic system, and the relative solubility coefficient of the solvent is larger than 8; a catalyst is dispersed evenly in the liquid-phase solvent, and process coupling is achieved through the high selective solubility of the liquid-phase solvent for acetylene, so that the selectivity of ethylene is improved; and ethylene is prepared and separated through an hydrogenation reaction of acetylene. According to the method, the concentration of ethylene on the surface of the catalyst is reduced through the process coupling, therefore a path of ethane generation through deep hydrogenation is blocked to a certain extent, and the selectivity of ethylene can be improved remarkably. Simultaneously, the liquid-phase dilution thermal effect can accelerate heat transfer in the slurry reactor, and temperature runaway is avoided. The method is not only used for preparing ethylene from acetylene obtained from natural gas pyrolysis, but also is an efficient method in a process for removing acetylene in ethylene.

Owner:TSINGHUA UNIV

Integrated heavy oil upgrading process and in-line hydrofinishing process

ActiveUS7708877B2Low viscosityTreatment with plural serial cracking stages onlyTreatment with plural parallel cracking stages onlySlurry reactorBoiling point

A new residuum full hydroconversion slurry reactor system has been developed that allows the catalyst, unconverted oil and converted oil to circulate in a continuous mixture throughout an entire reactor with no confinement of the mixture. The mixture is partially separated in between the reactors to remove only the converted oil while permitting the unconverted oil and the slurry catalyst to continue on into the next sequential reactor where a portion of the unconverted oil is converted to lower boiling point hydrocarbons, once again creating a mixture of unconverted oil, converted oil, and slurry catalyst. Further hydroprocessing may occur in additional reactors, fully converting the oil. The oil may alternately be partially converted, leaving a highly concentrated catalyst in unconverted oil which can be recycled directly to the first reactor. Fully converted oil is subsequently hydrofinished for the nearly complete removal of hetoroatoms such as sulfur and nitrogen.

Owner:CHEVROU USA INC

Method for activating strengthened iron catalyst for slurry reactors

InactiveUS20090111684A1Various problemOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsSlurry reactorIron catalyst

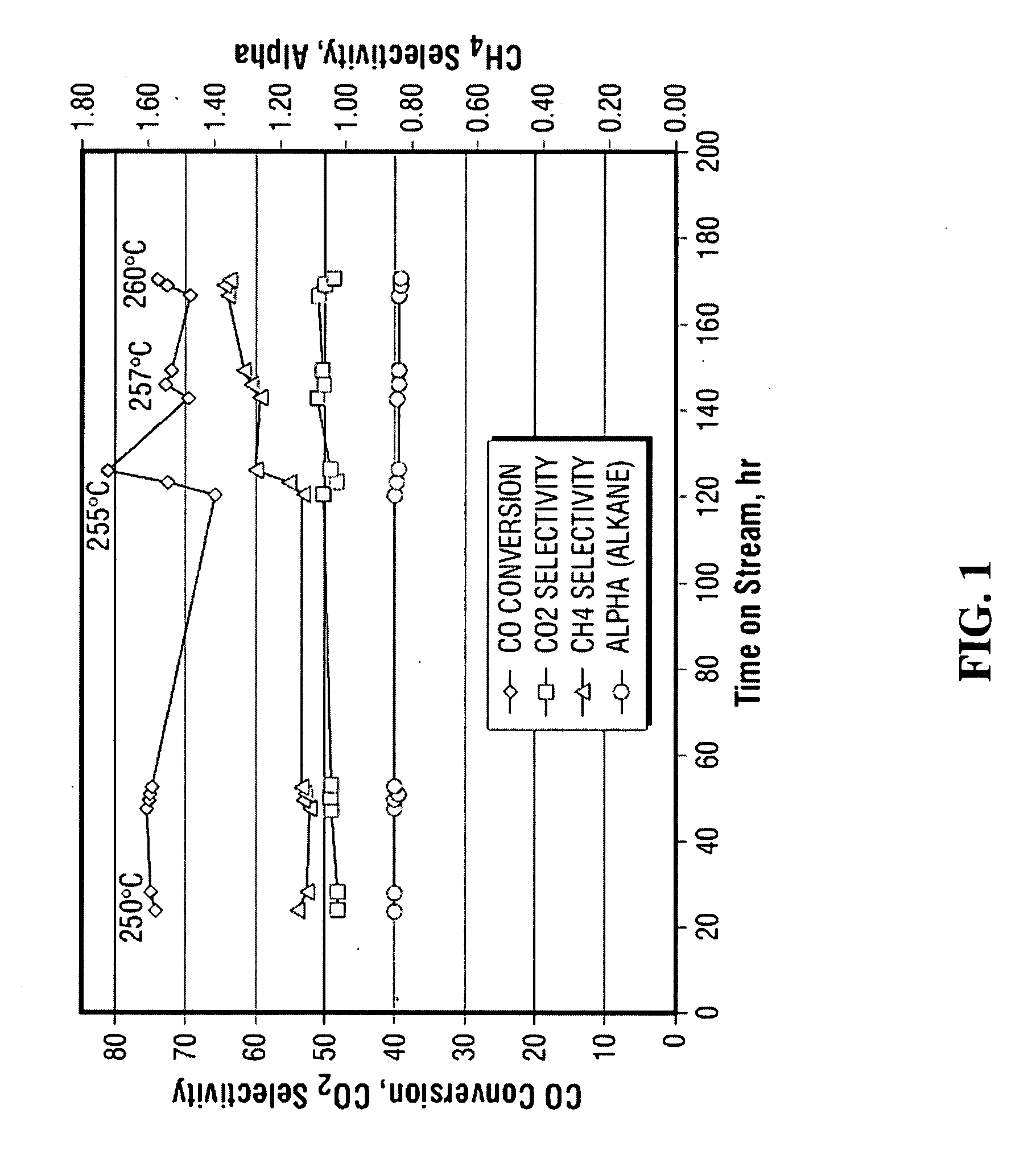

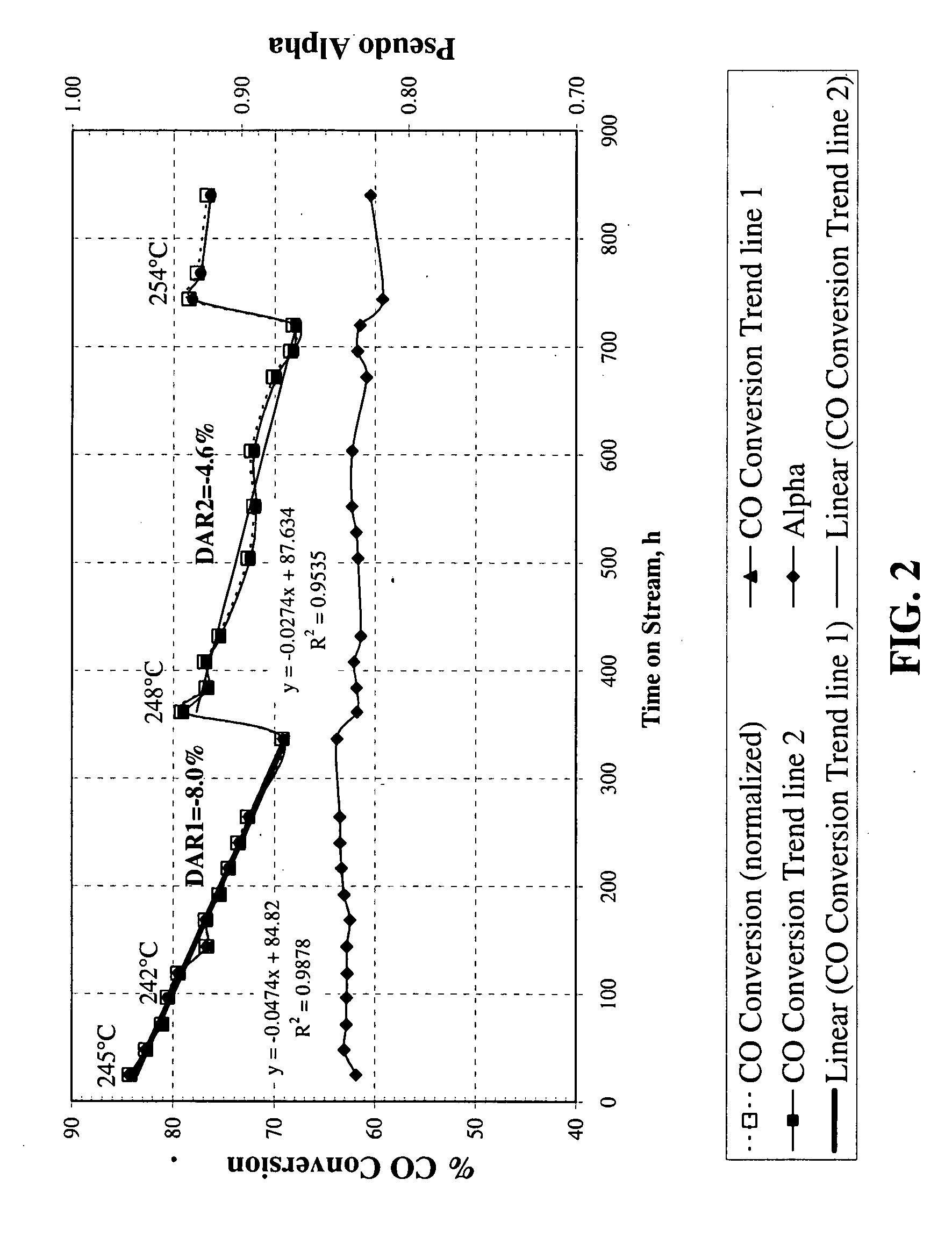

A method of activating an iron Fischer-Tropsch catalyst by introducing an inert gas into a reactor comprising a slurry of the catalyst at a first temperature, increasing the reactor temperature from the first temperature to a second temperature at a first ramp rate, wherein the second temperature is in the range of from about 150° C. to 250° C., introducing synthesis gas having a ratio of H2:CO to the reactor at a space velocity, and increasing the reactor temperature from the second temperature to a third temperature at a second ramp rate, wherein the third temperature is in the range of from about 270° C. to 300° C. The iron Fischer-Tropsch catalyst may be a precipitated unsupported iron catalyst, production of which is also provided.

Owner:RES USA LLC

Oil soluble molybdenum-based precursor of catalyst, preparation method and application thereof

InactiveCN103980320AGood oil solubilityReduce yieldPhysical/chemical process catalystsHydrocarbon oil crackingSlurry reactorDecomposition

The invention provides an oil soluble molybdenum-based precursor of a catalyst, a preparation method and application thereof, relating to the technical field of heavy oil hydrocracking catalysts and solving the problems of low catalytic hydrogenation activity and high cost of the existing catalysts. The preparation method for the precursor comprises the steps of (1) mixing a molybdenum source with water, reacting for 30-240 minutes at 70-90DEG C, and adding inorganic acid; (2) adding polycarbon alcohol into P2S5 in 5-15 minutes at 50-80DEG C, and reacting for 1-3 hours at 70-100DEG C; (3) adding the product of step (2) into the product of step (1), adding resin, and reacting for 4-8 hours at 70-110DEG C; (4) separating oil phase from the product of step (3) so as to obtain the target product. The precursor can form MoS2 active components through self sulfurization and in situ decomposition, is used in slurry reactor hydrocracking of poor heavy oil with high content of metal, carbon residue and sulfur, and can lower the yield of coke and keep a device to run for a long period.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

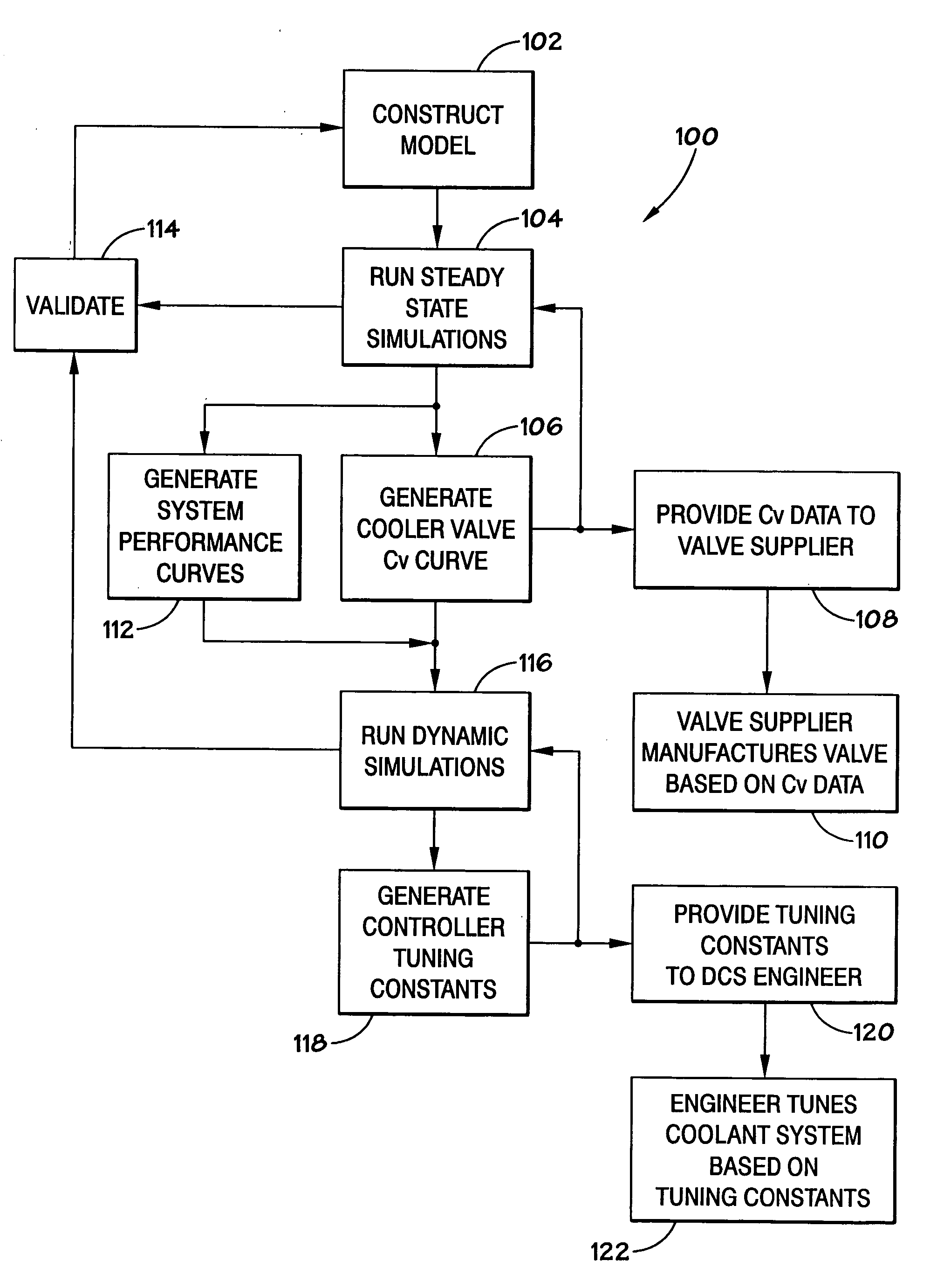

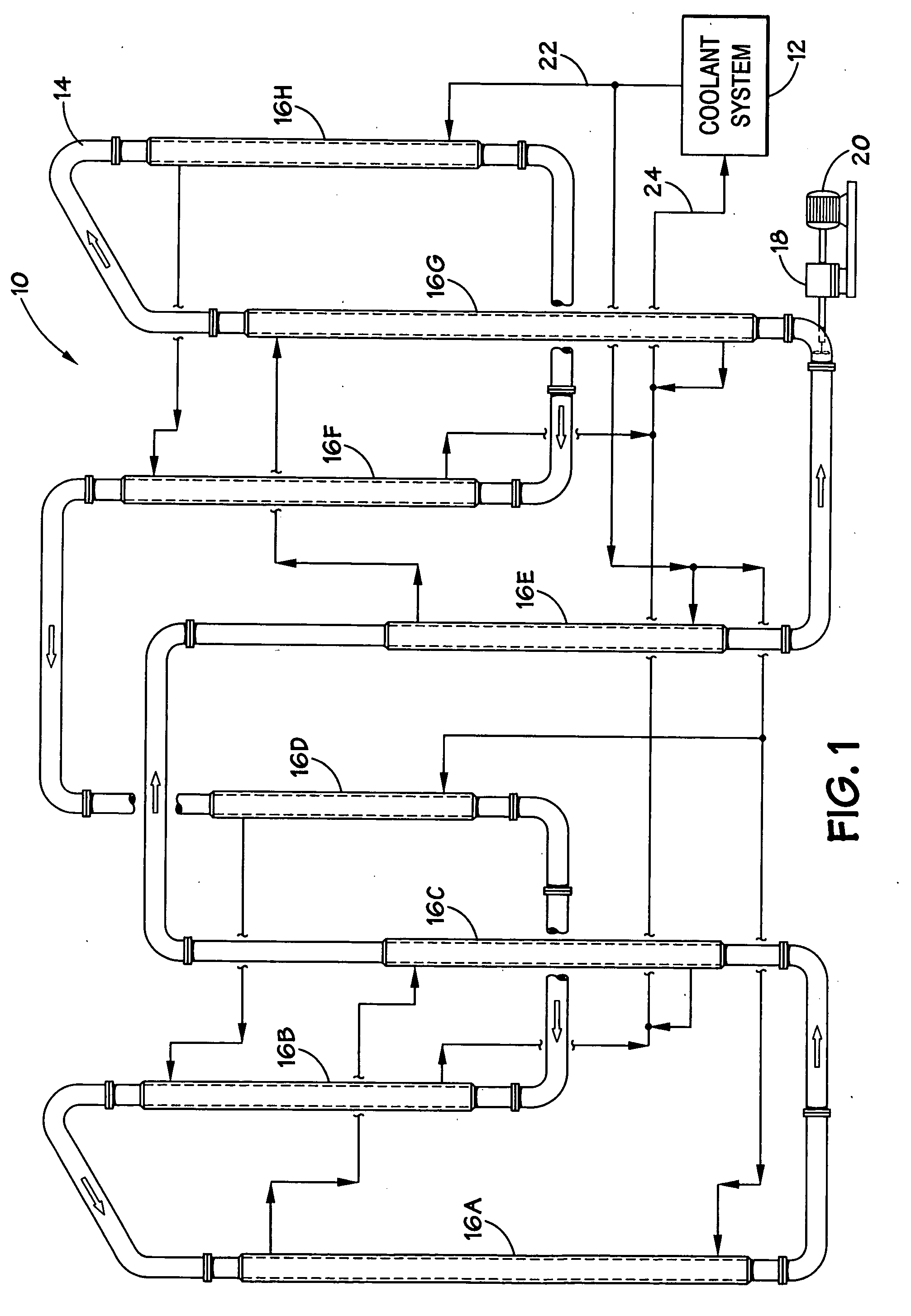

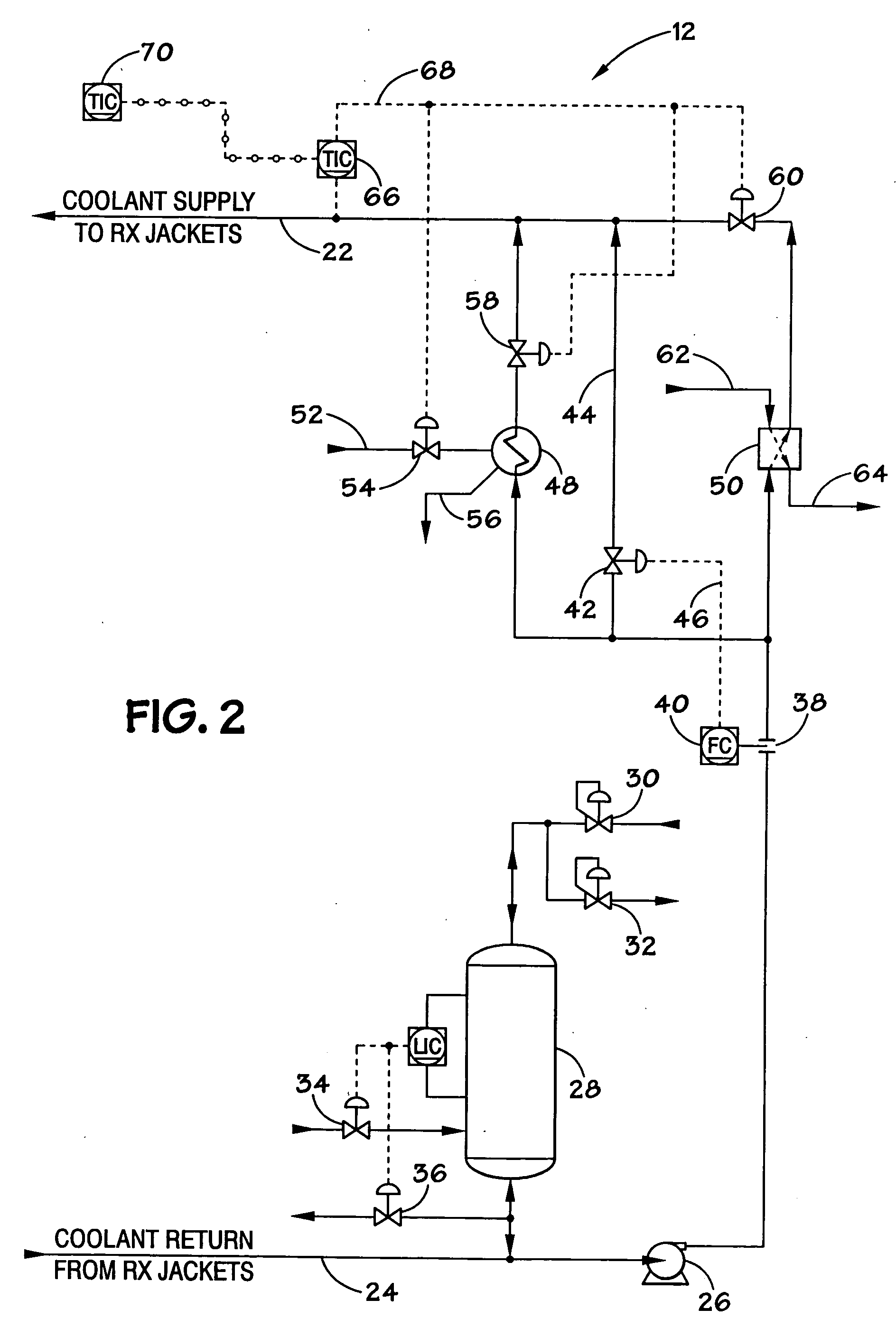

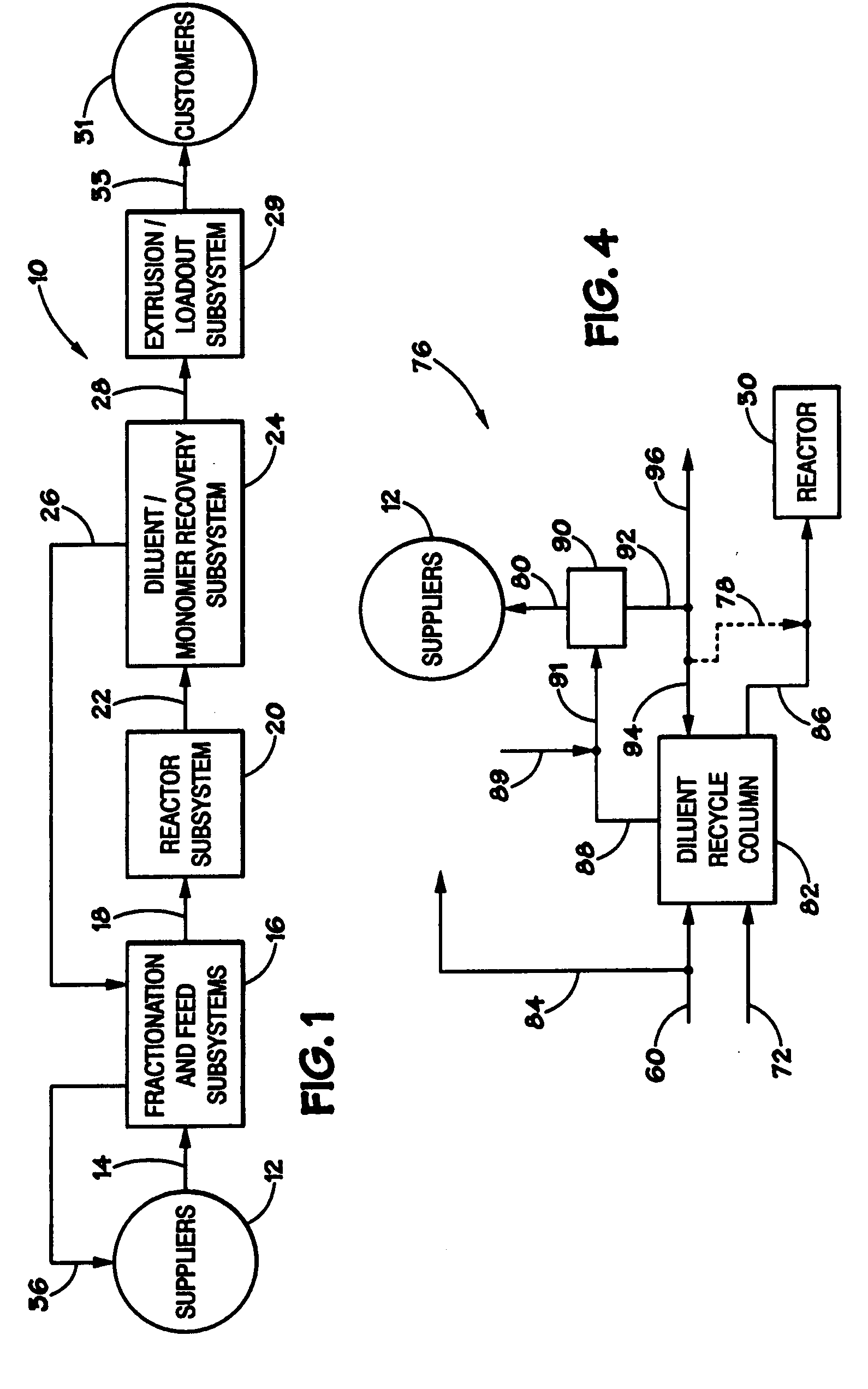

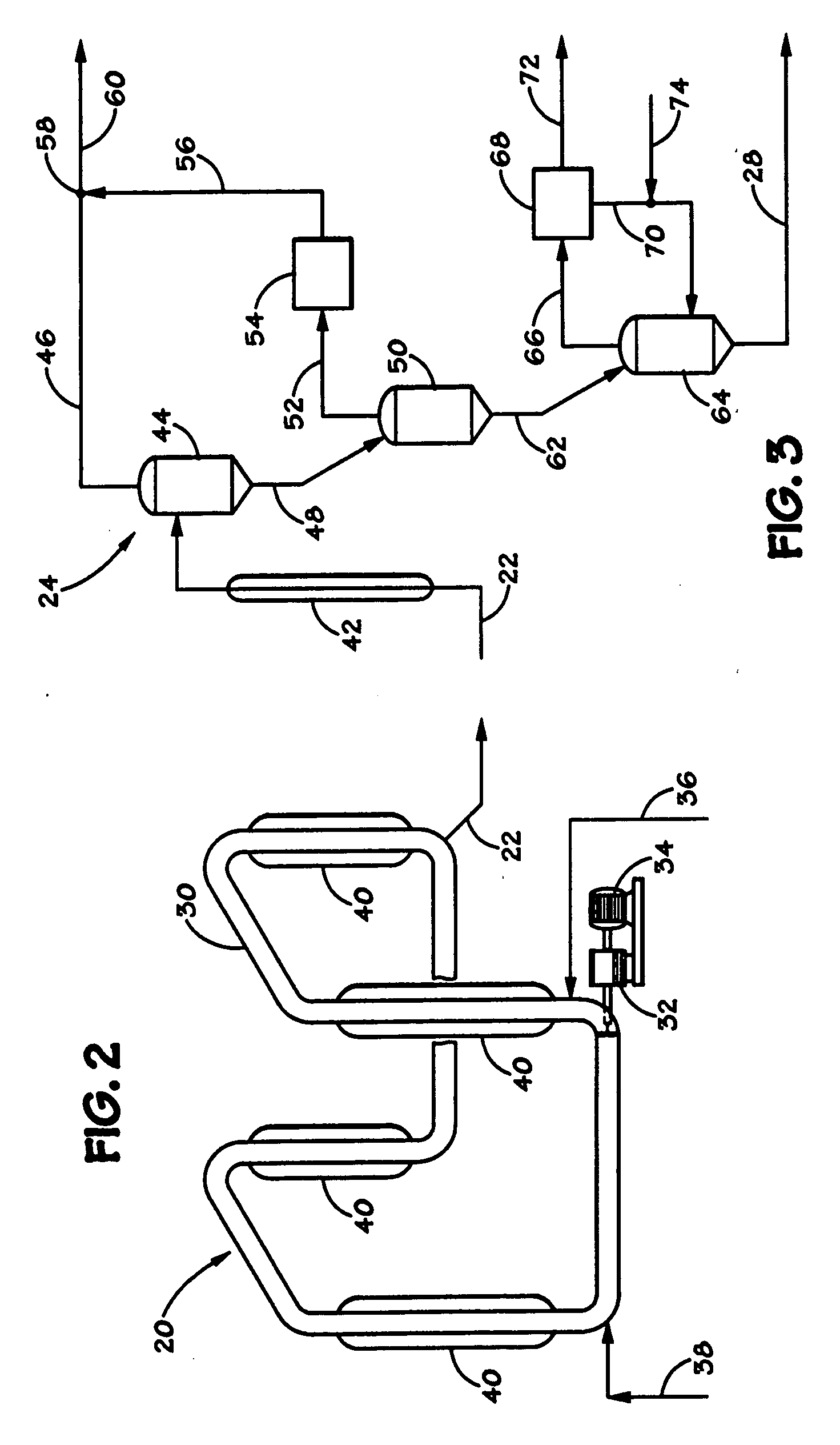

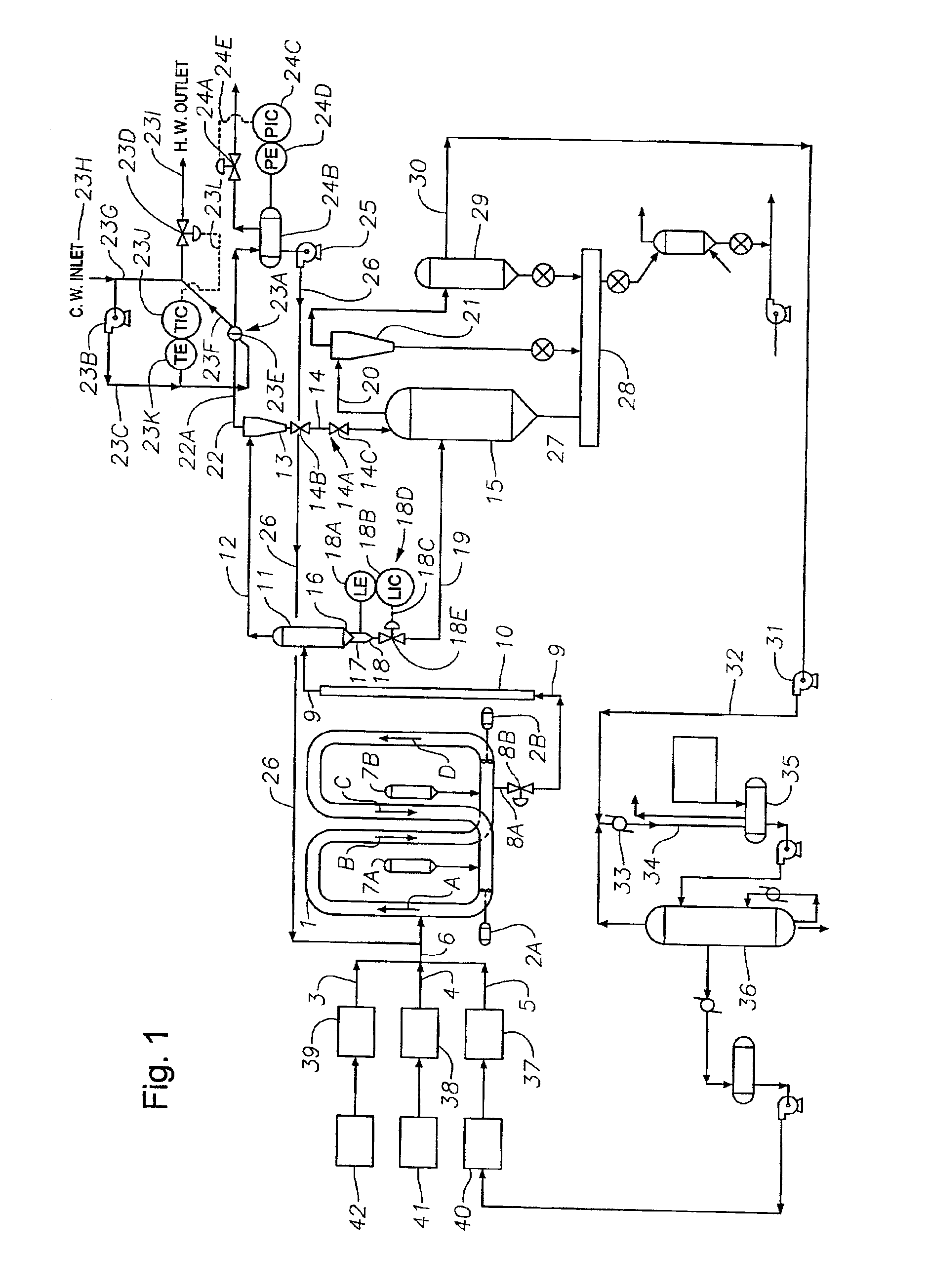

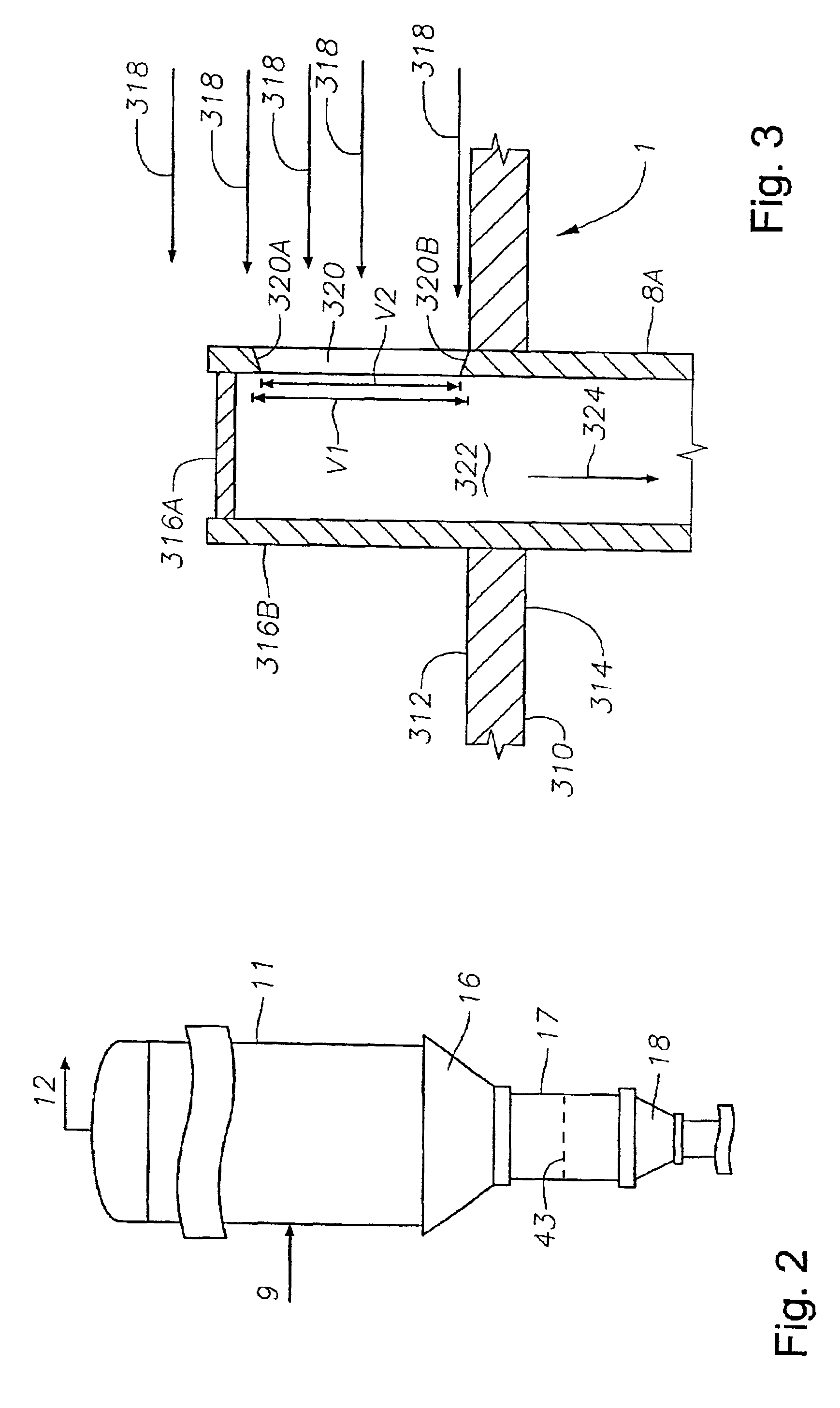

Method and apparatus for controlling polyolefin reactor temperature

InactiveUS20050091021A1Sampled-variable control systemsAnalogue computers for chemical processesTemperature controlSlurry reactor

Methods and apparatus for controlling polyolefin reactor temperature. In one embodiment, a simulation model is constructed for improving control of polymerization temperature in a polyethylene loop slurry reactor. The model is used to design the reactor coolant system to capacity and to improve tuning of system controllers, such as the reactor temperature controller and coolant temperature controller. A coolant control valve is sized having a bilinear flow characteristic which improves Cv reproducibility at low coolant flow rates and thus improves reactor temperature control.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

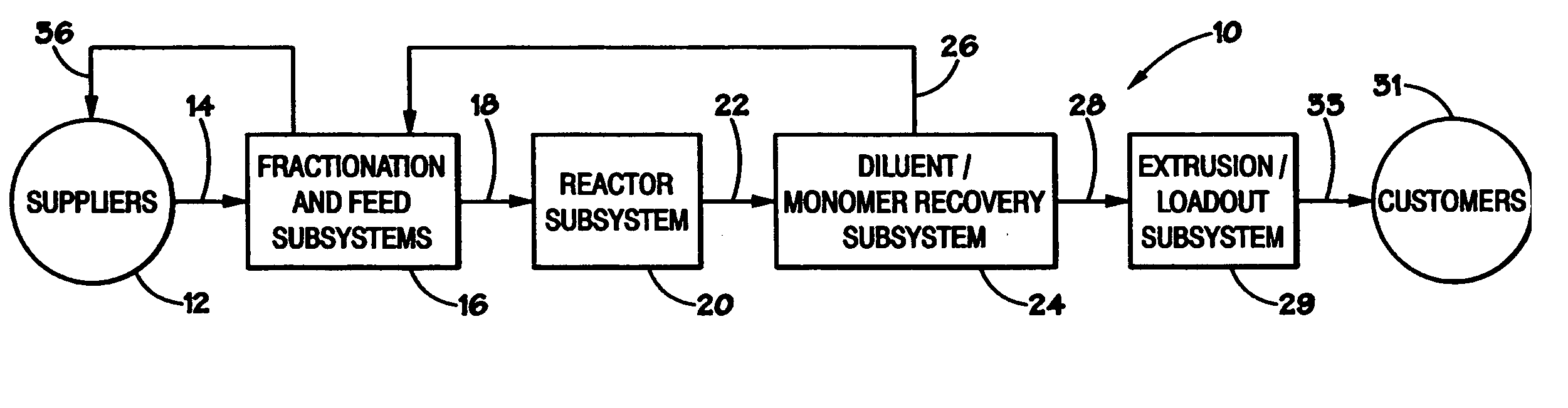

Monomer recovery by returning column overhead liquid to the reactor

InactiveUS20070142576A1Vacuum distillation separationChemical/physical/physico-chemical processesPolyolefinSlurry reactor

A polyolefin production system, comprising a polymerization reactor (such as a polyethylene loop slurry reactor) and a fractionation system that receives reactor effluent processed in a diluent / monomer recovery system for recycle to the reactor and to suppliers. A conduit diverts a portion of a reflux flow comprising monomer, such as ethylene, from within the fractionation system to the polymerization reactor, providing for less venting of monomer, such as ethylene, to the supplier. Accordingly, monomer yield is advantageously increased, as the monomer returned to the reactor displaces monomer feedstock to the reactor. The reflux flow may originate from a condensed overhead lights from a diluent recycle column disposed in the fractionation subsystem. The diluent recycle column may receive a stream comprising diluent and monomer as feed from the diluent / monomer recovery subsystem, and may receive the non-diverted portion of the reflux flow as reflux.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

Process for removal of intermediate hydrogen from cascaded polyolefin slurry reactors

Multimodal polyolefin polymers may be prepared in series-connected polymerization reactors where a prior reactor is a slurry reactor employing light solvent as the slurry medium and hydrogen to limit polymer molecular weight, the polymer product from the prior reactor being substantially freed of hydrogen prior to entry into a subsequent polymerization reactor operating at low hydrogen pressure to produce a high molecular weight olefin. The economics and operating performance of such a series slurry reactor polyethylene process can be significantly improved through the use of an intermediate slurry transfer system and hydrogen removal apparatus that employs flash drums in series in conjunction with a warm recycle solvent slurry diluent.

Owner:EQUSR CHEM LP

Alumina-loaded cobalt-based fischer-tropsch synthesis catalyst and preparation method and applications thereof

ActiveCN102962066ASimple manufacturing processEasy to industrializeCatalyst activation/preparationLiquid hydrocarbon mixture productionIridiumSlurry reactor

Owner:中科潞安能源技术有限公司

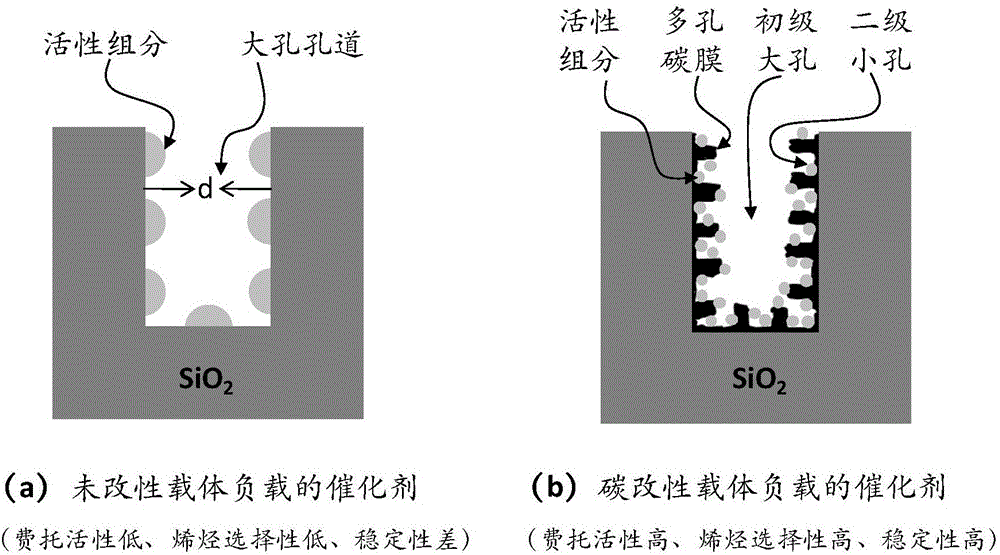

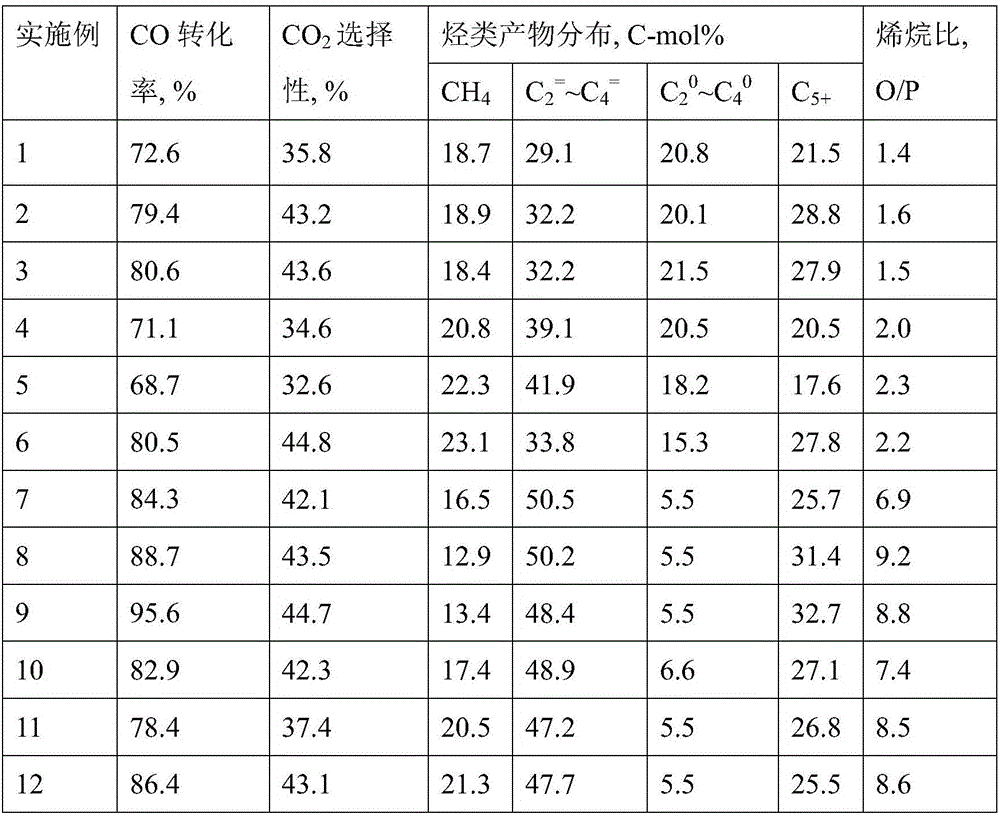

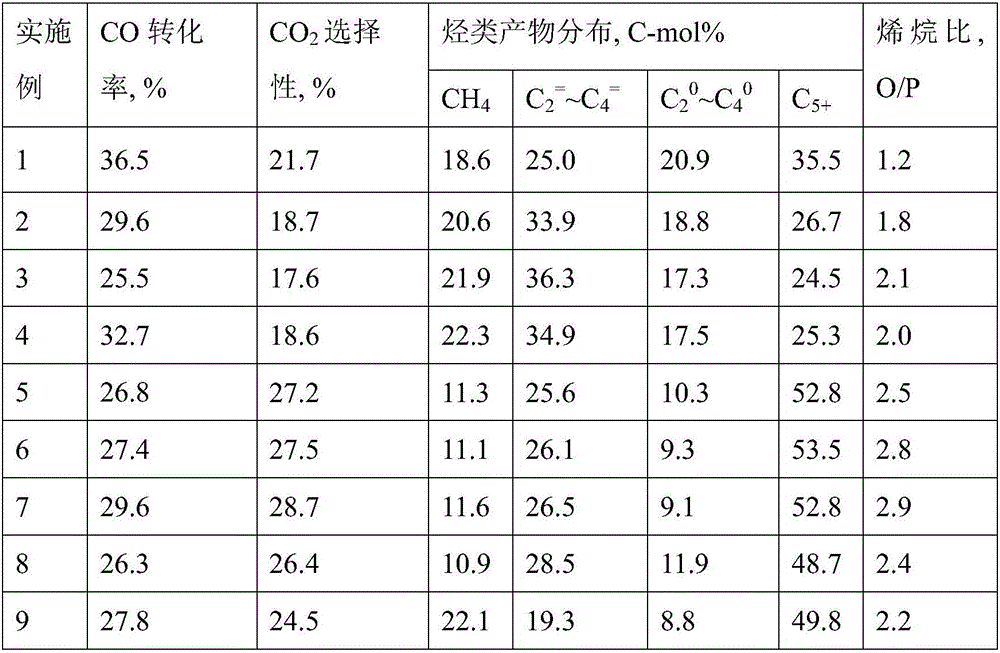

Preparation and application of carbon modified silicon dioxide carrier loaded iron-based catalyst for Fischer-Tropsch synthesis

ActiveCN106000404ALarge specific surface areaGood dispersionHydrocarbon from carbon oxidesCatalystsCarbon filmSlurry reactor

The invention discloses a preparation and an application of a carbon modified silicon dioxide carrier loaded iron-based catalyst for Fischer-Tropsch synthesis. The carbon modified silicon dioxide with second-level hole structure is taken as a carrier of the carrier provided by the invention and iron is taken as a main catalyst and auxiliaries are added; the second-level hole structure is composed of a primary silicon dioxide macro-porous structure and a carbon film layer modified small-porous structure; the second-level hole structure is beneficial to the promotion of the dispersion of active component iron, can prevent iron and silicon dioxide carrier from forming unreducible ferrosilite, can boost the carbonization and activation of iron and can effectively restrain the secondary hydrogenation of Fischer-Tropsch primary product so as to acquire high Fischer-Tropsch reaction activity and selectivity of olefin products. Besides, the catalyst provided by the invention has excellent mechanical strength and hydrothermal stability and is fit for the Fischer-Tropsch synthesis of slurry reactor and fluidized bed; the raw materials for preparing the catalyst are low in cost; the preparation method is simple; the repeatability is excellent; the catalyst is fit for industrial production application.

Owner:JIANGNAN UNIV

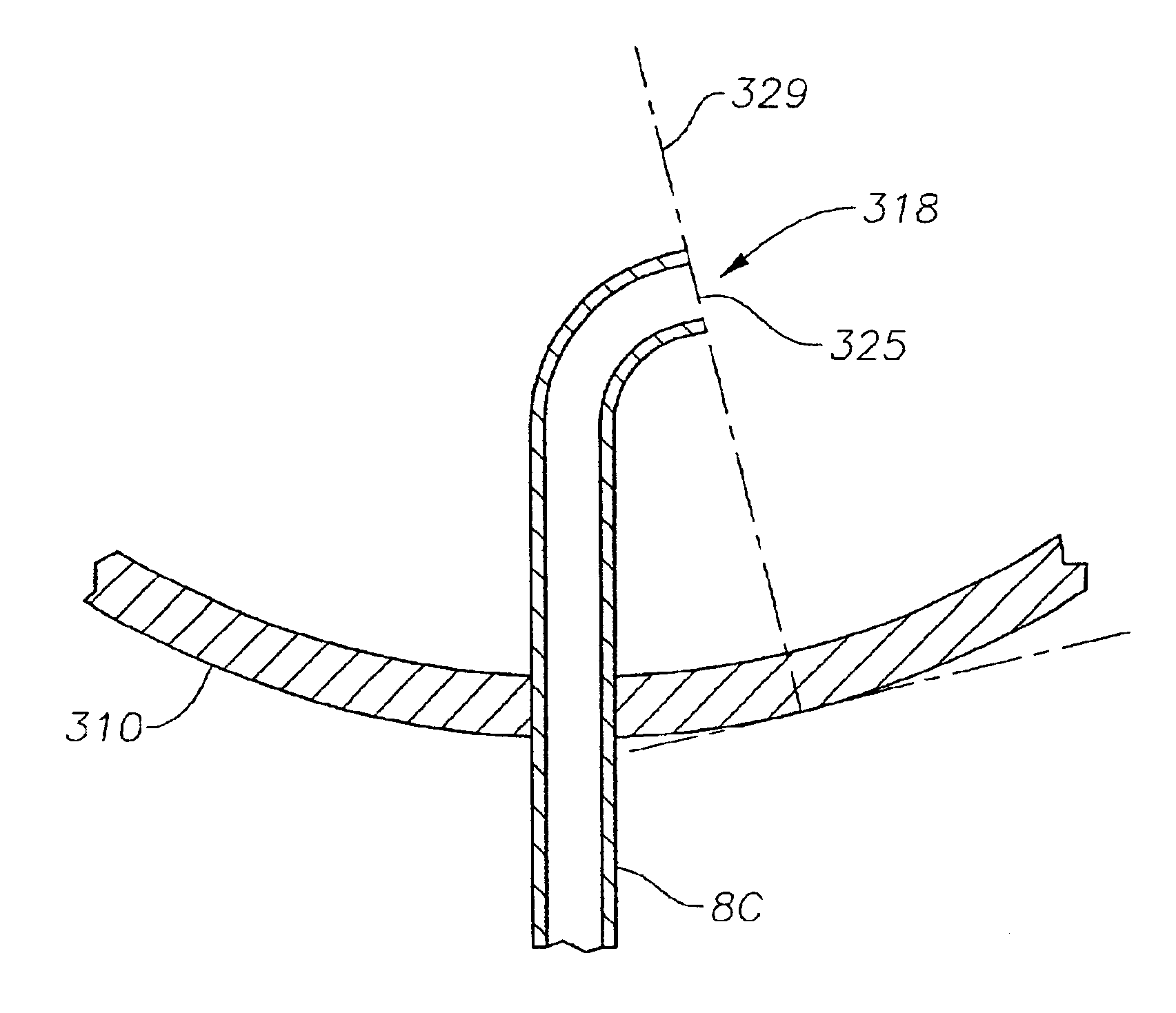

Continuous slurry polymerization volatile removal

InactiveUS6926868B2Increase contentSmall sizeChemical/physical/physico-chemical stationary reactorsFluidised-bed furnacesLiquid mediumSlurry reactor

A process / apparatus is disclosed for continuously separating a liquid medium comprising diluent and unreacted monomers from a polymerization effluent of a slurry loop reactor containing a flow of slurry therein, comprising a discharge conduit extending a distance into the loop reactor; the conduit having a longitudinal axis and an opening inside the loop reactor; at least a portion of the conduit being curved along its longitudinal axis inside the loop reactor; and the opening substantially facing the flow of the slurry, wherein the discharge conduit is located within a lower leg of the loop reactor such that a continuous discharge of the polymerization effluent from a slurry reactor through a discharge valve and transfer conduit into a first intermediate pressure flash tank wherein volatile inert diluent and unreacted monomers are removed and the polymer solids which remain after removal of about 50 to 100% of the inert diluent therefrom to a second flash tank at a lower pressure.

Owner:EXXONMOBIL CHEM PAT INC

Integrated in-line pretreatment and heavy oil upgrading process

ActiveUS20070138058A1Lower capital expenditureImprove product qualityTreatment with plural serial cracking stages onlyTreatment with plural parallel cracking stages onlyHydrogenSlurry reactor

A new residuum full hydroconversion slurry reactor system has been developed that allows the catalyst, unconverted oil, products and hydrogen to circulate in a continuous mixture throughout an entire reactor with no confinement of the mixture. The mixture is partially separated in between the reactors to remove only the products and hydrogen while permitting the unconverted oil and the slurry catalyst to continue on into the next sequential reactor. In the next reactor, a portion of the unconverted oil is converted to lower boiling point hydrocarbons, once again creating a mixture of unconverted oil, products, hydrogen and slurry catalyst. Further hydroprocessing may occur in additional reactors, fully converting the oil. The oil may alternately be partially converted, leaving a highly concentrated catalyst in unconverted oil which can be recycled directly to the first reactor. The slurry reactor system is, in this invention, preceded by an in-line pretreating step, such as hydrotreating or deasphalting. Following the slurry reactor system, fully converted oil may be subsequently hydrofinished for the removal of hetoroatoms such as sulfur and nitrogen.

Owner:CHEVROU USA INC

Continuous slurry polymerization volatile removal

InactiveUS7034090B2Increasing ethylene concentrationReduce energy consumptionChemical/physical/physico-chemical stationary reactorsFlash distillationLiquid mediumSlurry reactor

A process / apparatus is disclosed for continuously separating a liquid medium comprising diluent and unreacted monomers from a polymerization effluent comprising diluent, unreacted monomers and polymer solids, comprising a continuous discharge of the polymerization effluent from a slurry reactor through a discharge valve and transfer conduit into a first intermediate pressure flash tank with a conical bottom defined by substantially straight sides inclined at an angle to that of horizontal equal to or greater than the angle of slide of the slurry / polymer solids and an exit seal chamber of such diameter (d) and length (l) as to maintain a desired volume of concentrated polymer solids / slurry in the exit seal chamber such as to form a pressure seal while continuously discharging a plug flow of concentrated polymer solids / slurry bottom product of said first flash tank from the exit seal chamber through a seal chamber exit reducer with inclined sides defined by substantially straight sides inclined at an angle to that of horizontal equal to or greater than the angle of slide of the polymer solids which remain after removal of about 50 to 100% of the inert diluent therefrom to a second flash tank at a lower pressure.

Owner:EXXONMOBIL CHEM PAT INC

Cobalt-based Fischer-Tropsch synthetic catalyst as well as preparation method and application thereof

ActiveCN102962077ASimple manufacturing processEasy to industrializeLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsSlurry reactorCobalt(II,III) oxide

The invention discloses a cobalt-based Fischer-Tropsch synthetic catalyst which comprises the following components by weight: 15-30% of cobaltosic oxide, 0.5-15% of oxide of non-noble metal in transitional metal, 0.01-2% of noble metal oxide and the balance of carrier gamma-Al2O3. The cobalt-based Fischer-Tropsch synthetic catalyst has the advantages of high activity and stability, and can be used for the Fischer-Tropsch synthetic reaction in slurry reactors and static beds.

Owner:中科潞安能源技术有限公司

Small catalyst particle addition to slurry reactor (Law749)

InactiveUS6090859ARefining to change hydrocarbon structural skeletonHydroxy compound preparationAlcoholSlurry reactor

Small particle size catalysts having an average particle size of less than 20 or 10 microns, which agglomerate when contacted with a hydrocarbon liquid, are easily dispersed in the hydrocarbon liquid by first forming a mixture comprising the catalyst particles and one or more non-acidic, liquid polar oxygenates, such as an alcohol, ketone, ester, ether or mixture thereof. The mixture is contacted with the hydrocarbon liquid in which the particles then readily disperse. This process is useful for adding fresh or regenerated small particle size catalyst to catalytic hydroprocessing process slurries, including a reactive Fischer-Tropsch hydrocarbon synthesis slurry. One to four carbon atom alcohols are preferred oxygenates for use with a Fischer-Tropsch slurry.

Owner:EXXON RES & ENG CO

Fischer-Tropsch synthesizing catalyst prepared by carrying cobalt with porous aluminum oxide, preparation method and application

ActiveCN105618052ARich landing siteImprove synthetic catalytic activityCatalyst carriersHeterogenous catalyst chemical elementsSlurry reactorCobalt(II,III) oxide

A Fischer-Tropsch synthesizing catalyst prepared by carrying cobalt with porous aluminum oxide is prepared from cobaltosic oxide, metal additive oxide and aluminum oxide at the weight ratio of (25-50):(1-10):100.The catalyst has the advantages of being high in activity and stability and capable of being used for Fischer-Tropsch synthesizing reactions with a slurry reactor and a static bed.

Owner:中科潞安能源技术有限公司

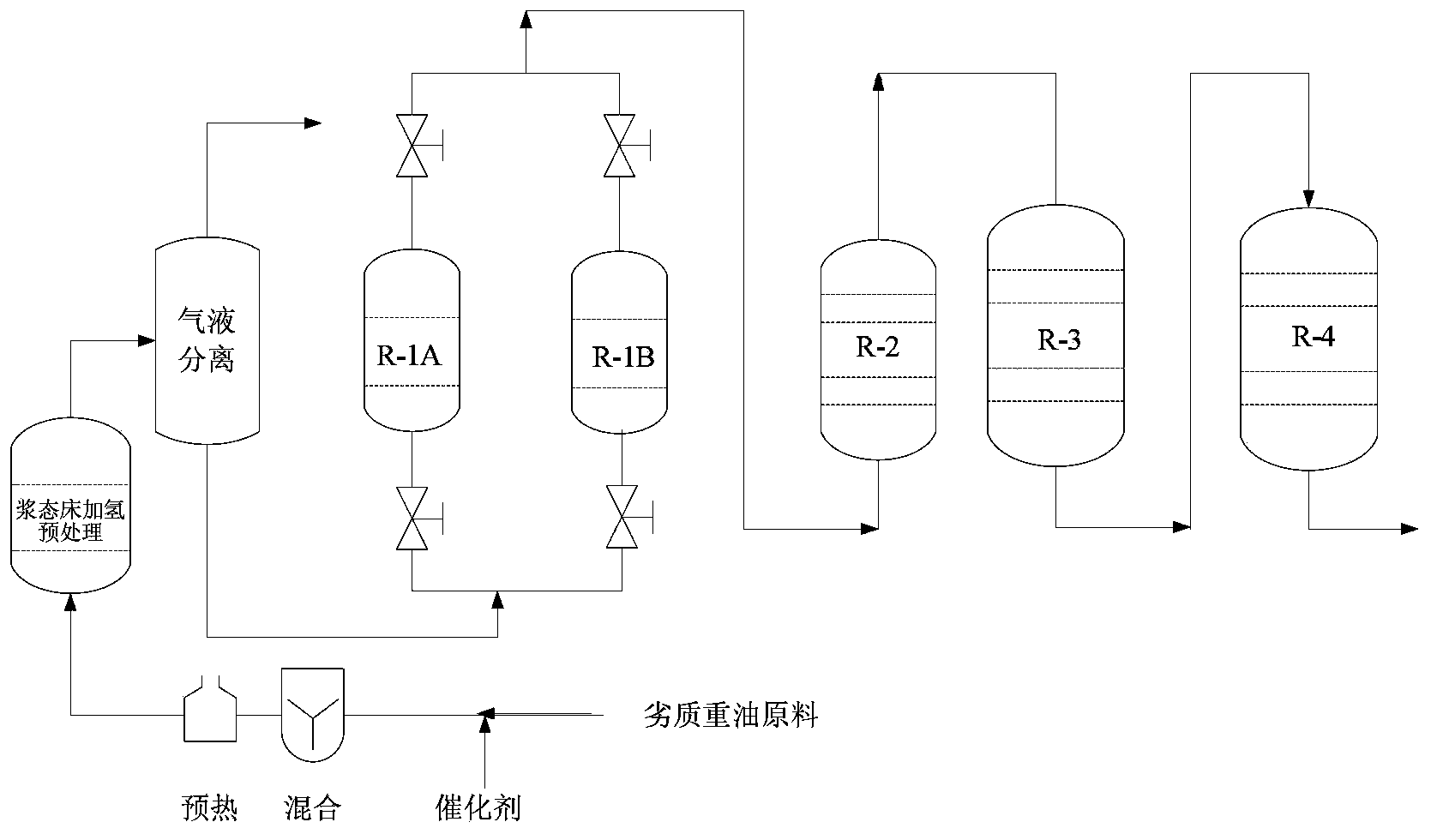

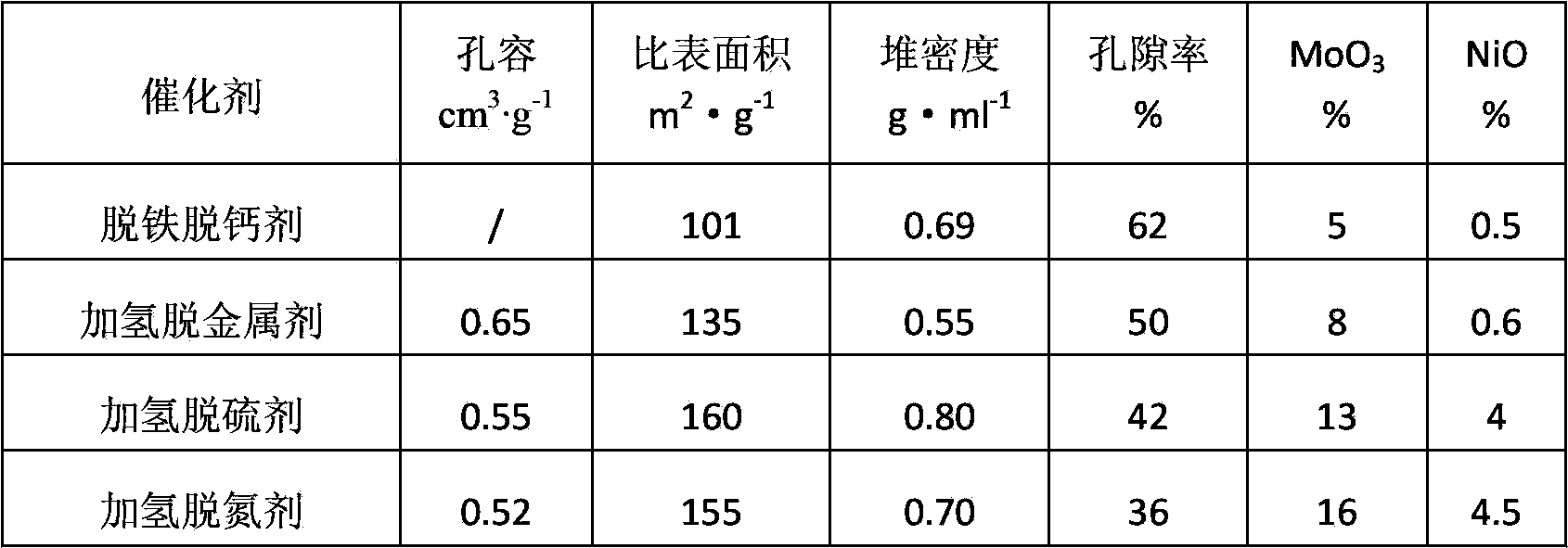

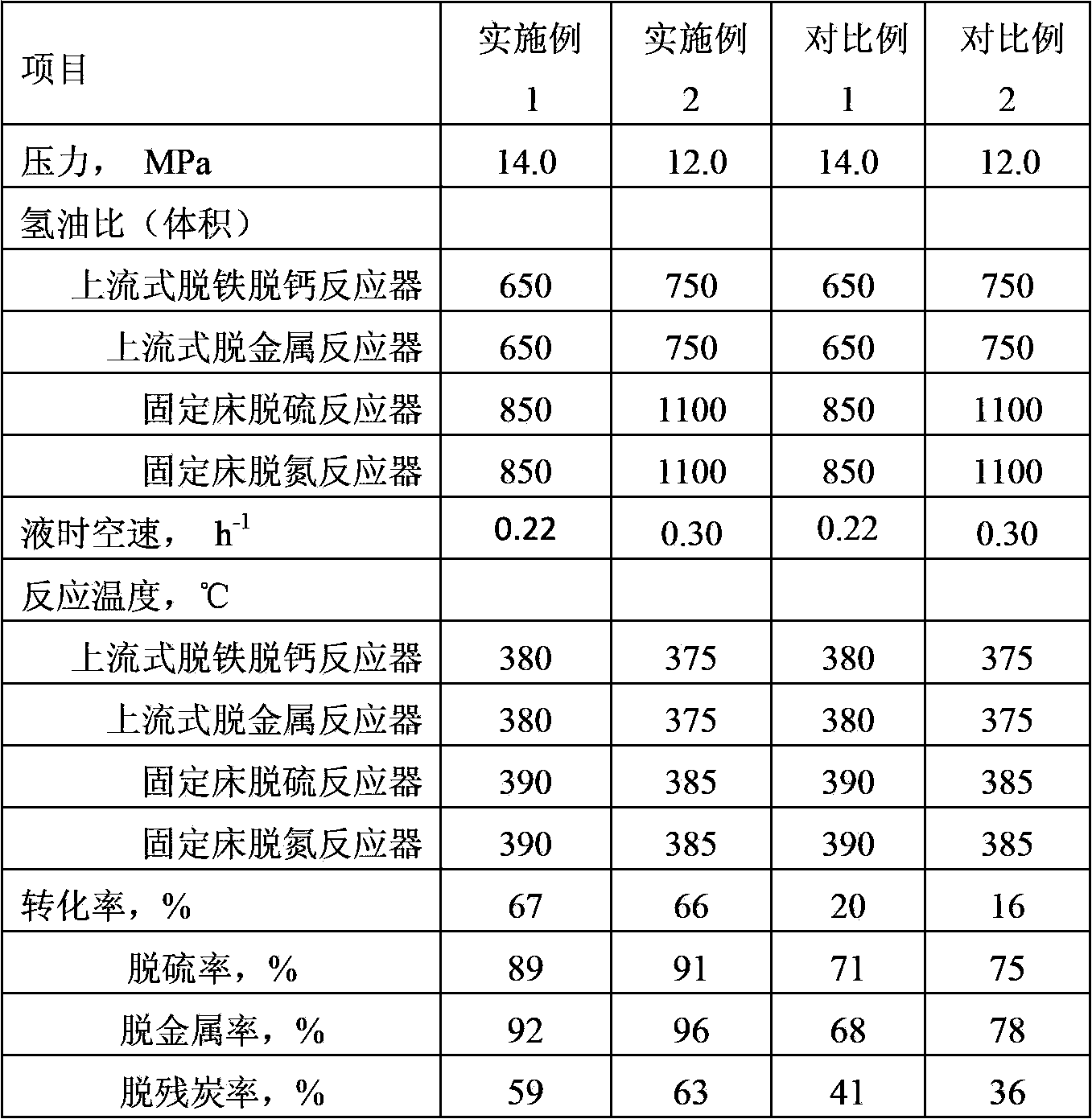

Hydrotreating combined process for inferior heavy oil and residual oil

ActiveCN103540350AHigh demetallizationImprove desulfurizationTreatment with hydrotreatment processesSlurry reactorFuel oil

The invention relates to a hydrotreating combined process for inferior heavy oil and residual oil. The hydrotreating combined process comprises the following steps of: firstly pretreating the heavy oil and / or residual oil raw material in a slurry reactor; carrying out gas-liquid separation, and hydro-upgrading the liquid-phase product in a fixed bed, wherein the hydro-pretreating part of the slurry reactor comprises a straight cylinder type slurry reactor pretreatment reactor and a slurry reactor hydro-catalyst, and the reactors used in the fixed bed hydro-upgrading part sequentially and mainly include two parallel up-flow type deferrization-decalcification reactors, one up-flow type demetalization reactor, one fixed bed desulfurization reactor and one fixed bed denitrification reactor. By adopting the hydrotreating combined process provided by the invention, not only are the hydrotreating and impurity removal capacities of the catalyst improved, but also the running cycle of the device is prolonged. The hydrotreating combined process provided by the invention can be applied to treating the inferior heavy oil and residual oil, which are high in sulfur content, metal content, and asphalt content; the conversion ratio is 30-80%; the raising rate of the pressure drop of the reactors can be effectively reduced so as to achieve the long-period running of the device.

Owner:PETROCHINA CO LTD

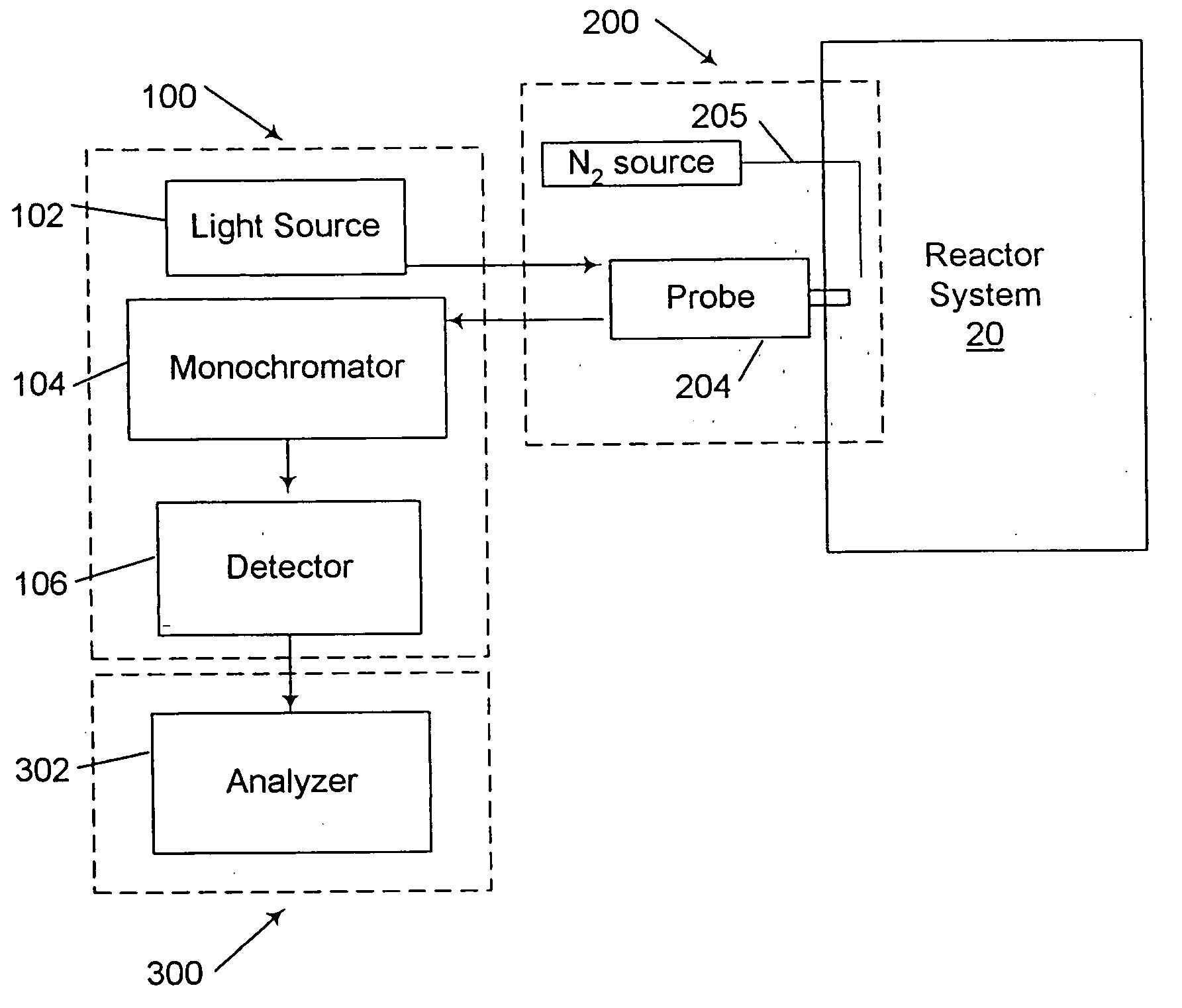

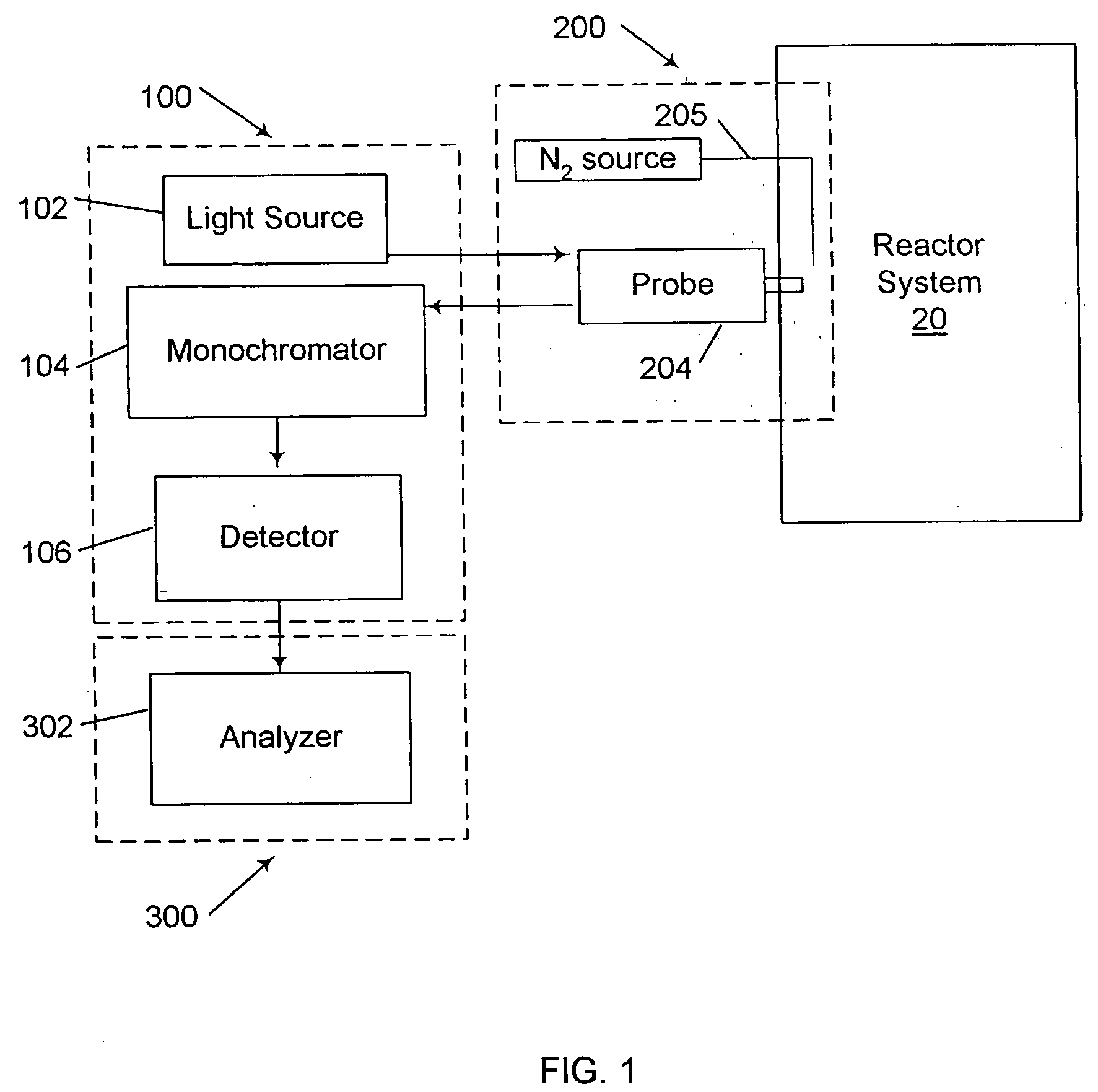

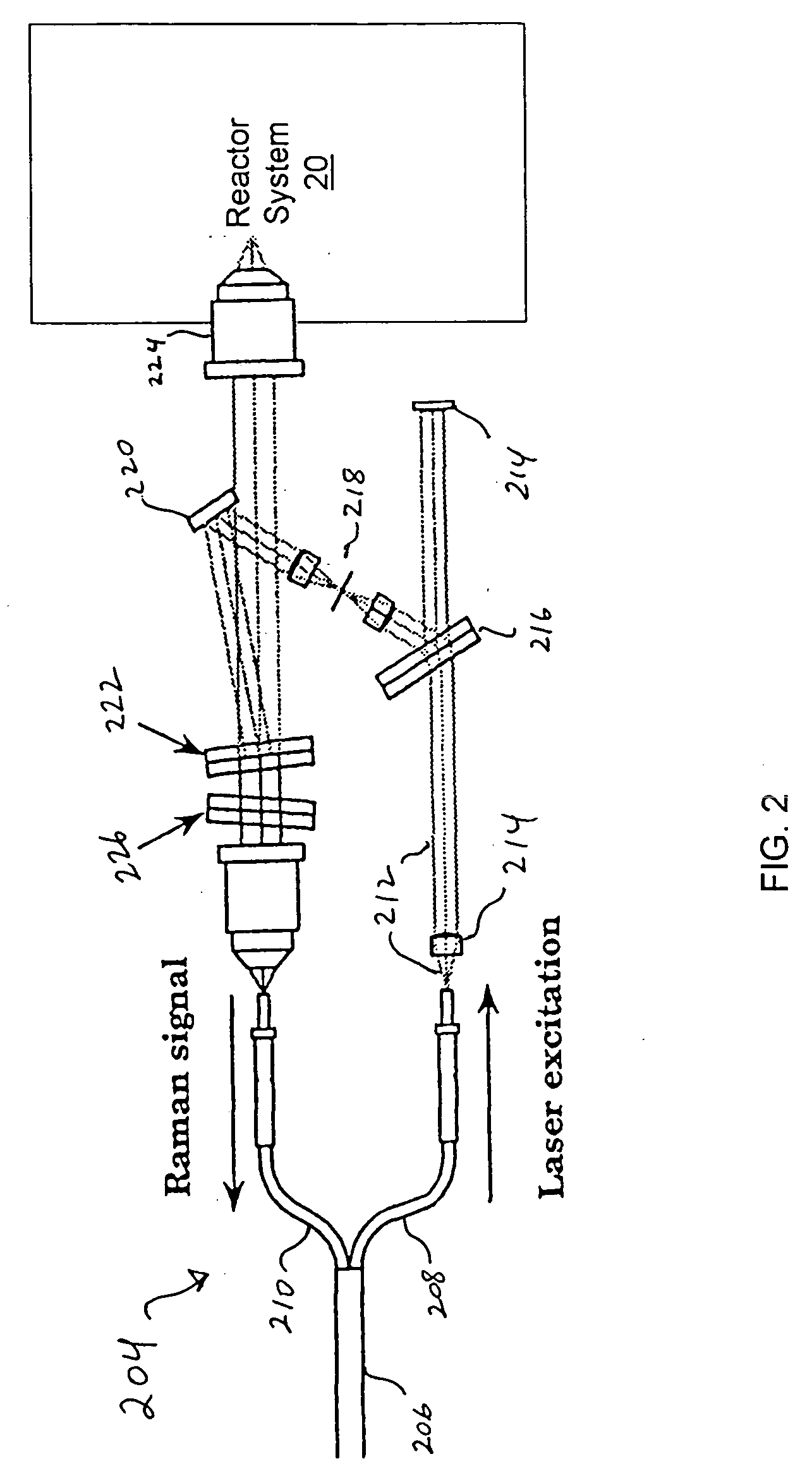

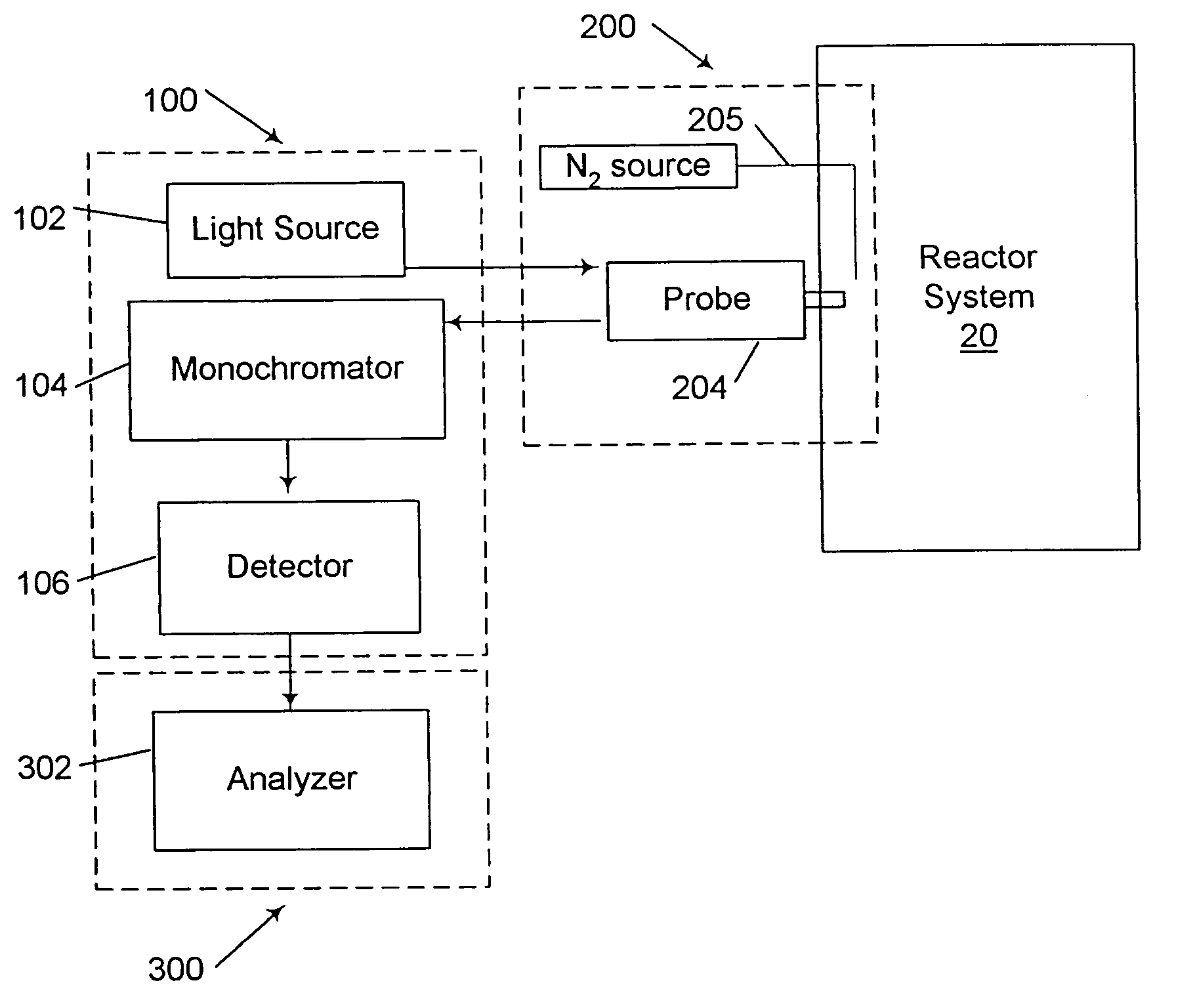

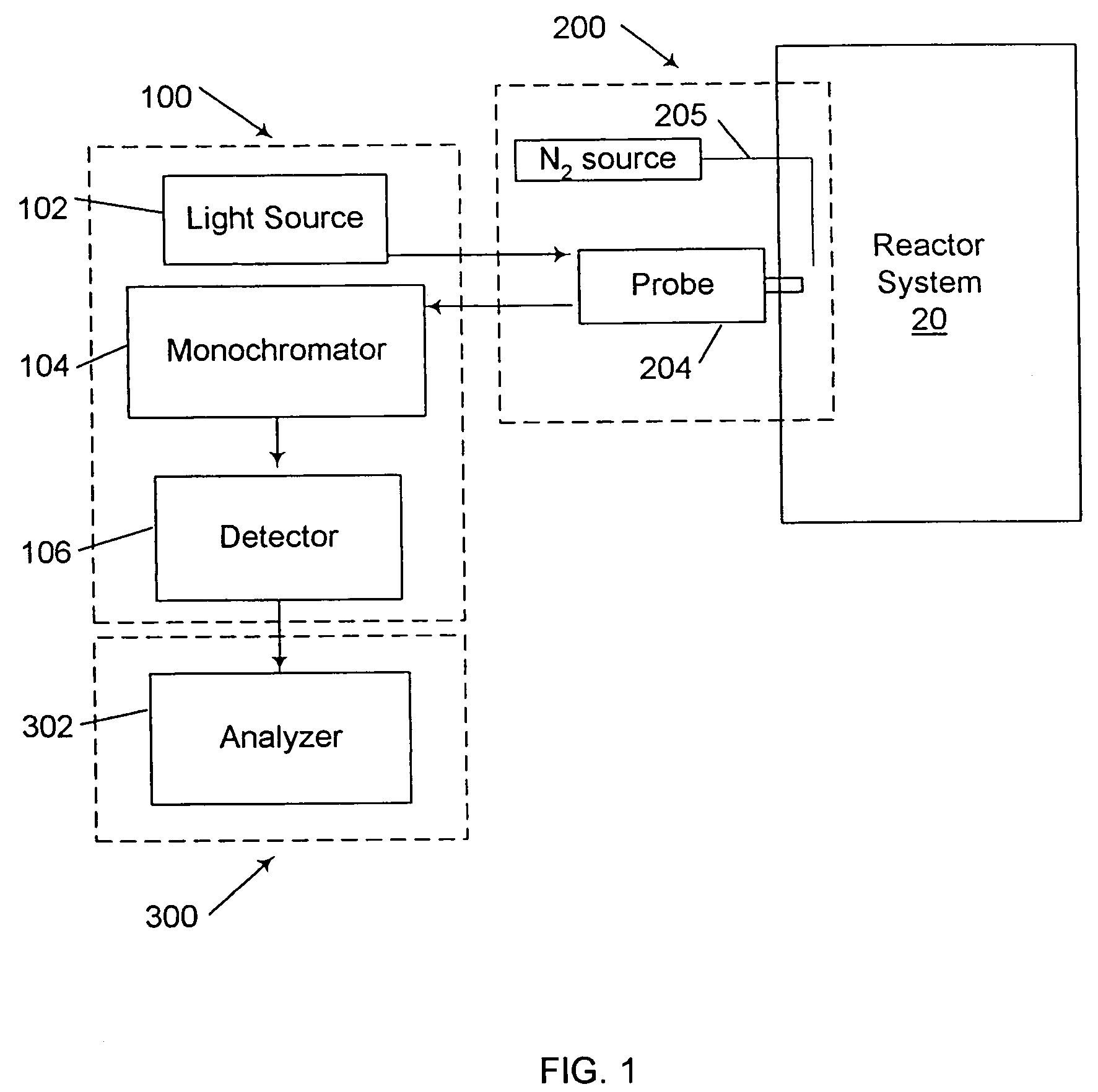

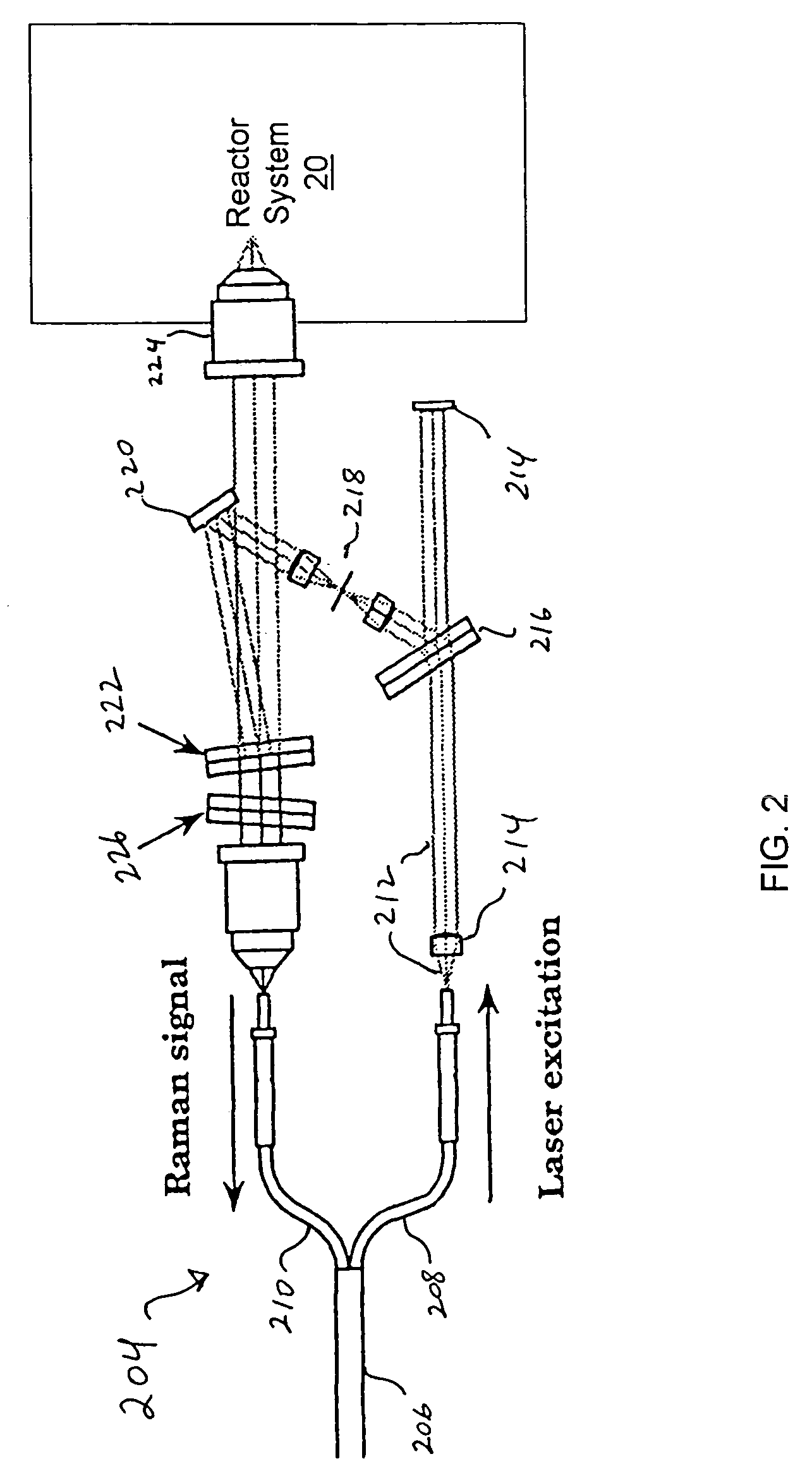

On-line measurement and control of polymer product properties by Raman spectroscopy

InactiveUS20040133364A1Radiation pyrometryChemical/physical/physico-chemical processesSlurry reactorPolymerization

Methods are provided for determining and controlling polymer product properties on-line in a slurry reactor system, such as a stirred slurry or slurry loop reactor. The methods include obtaining a regression model for determining a polymer product property, the regression model including principal component loadings and principal component scores, acquiring a Raman spectrum of polymer product in the slurry reactor system, calculating a new principal component score from at least a portion of the Raman spectrum and the principal component loadings, and calculating the polymer product property by applying the new principal component score to the regression model. The property can be controlled by adjusting at least one polymerization parameter based on the calculated polymer product property.

Owner:EXXONMOBIL CHEM PAT INC

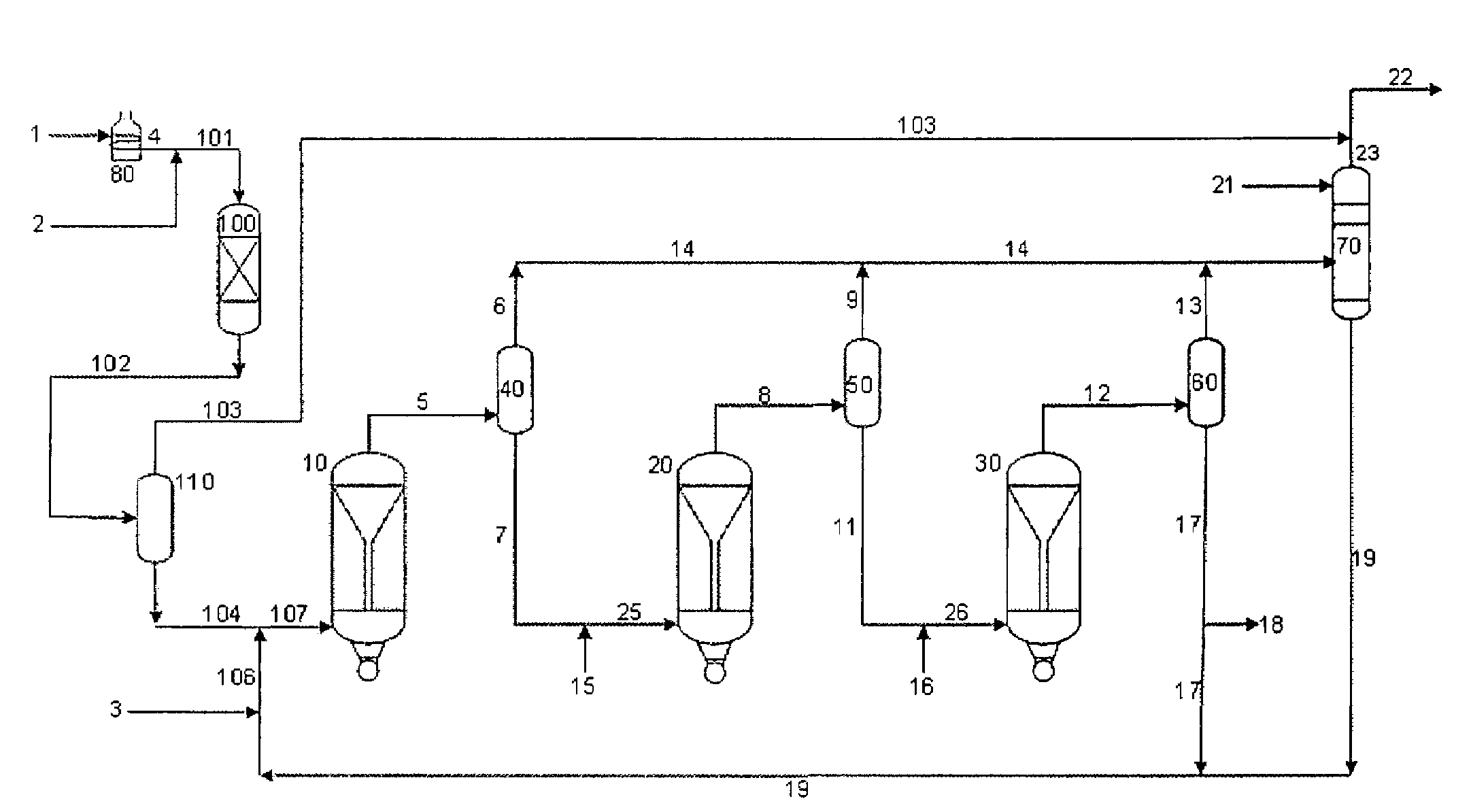

Process for upgrading heavy oil using a highly active slurry catalyst composition

ActiveUS7390398B2Treatment with plural serial cracking stages onlyCoke ovensContinuous reactorHydrogen

Applicants have developed a new residuum full hydroconversion slurry reactor system that allows the catalyst, unconverted oil and converted oil to circulate in a continuous mixture throughout an entire reactor with no confinement of the mixture. The mixture is partially separated in between the reactors to remove only the products and hydrogen gas, while permitting the unconverted oil and the slurry catalyst to continue on into the next sequential reactor. A portion of the unconverted oil is then converted to lower boiling point hydrocarbons, once again creating a mixture of unconverted oil, products, hydrogen, and slurry catalyst. Further hydroprocessing may occur in additional reactors, fully converting the oil. Additional oil may be added at the interstage feed inlet, possibly in combination with slurry. The oil may alternately be partially converted, leaving a highly concentrated catalyst in unconverted oil which can be recycled directly to the first reactor.

Owner:CHEVROU USA INC

On-line measurement and control of polymer product properties by Raman spectroscopy

Owner:EXXONMOBIL CHEM PAT INC

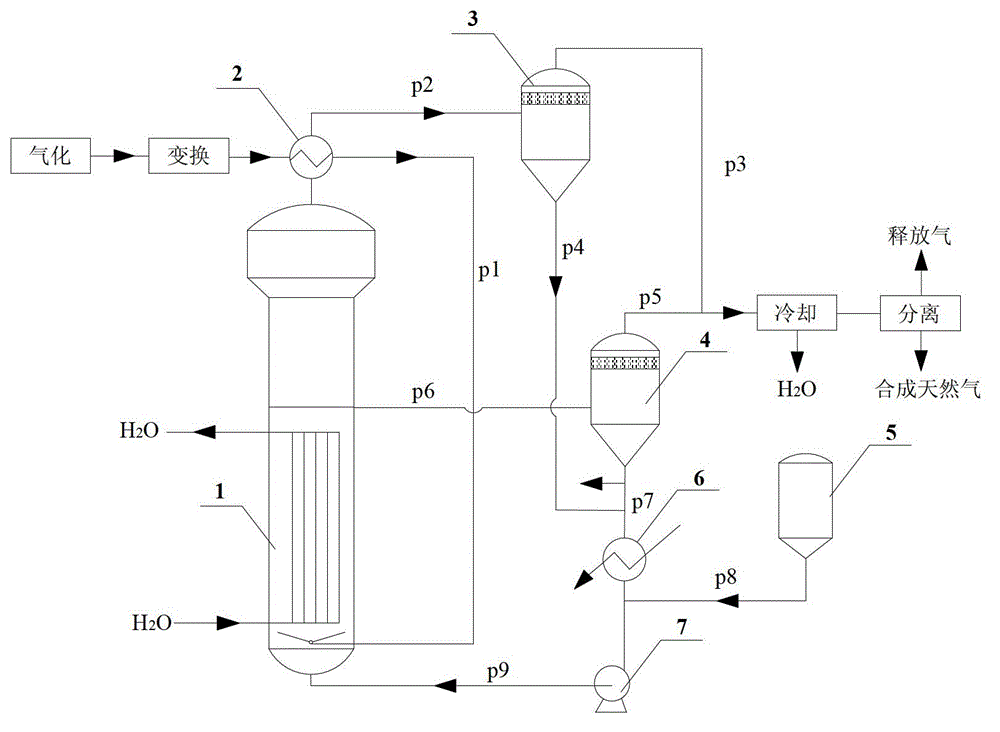

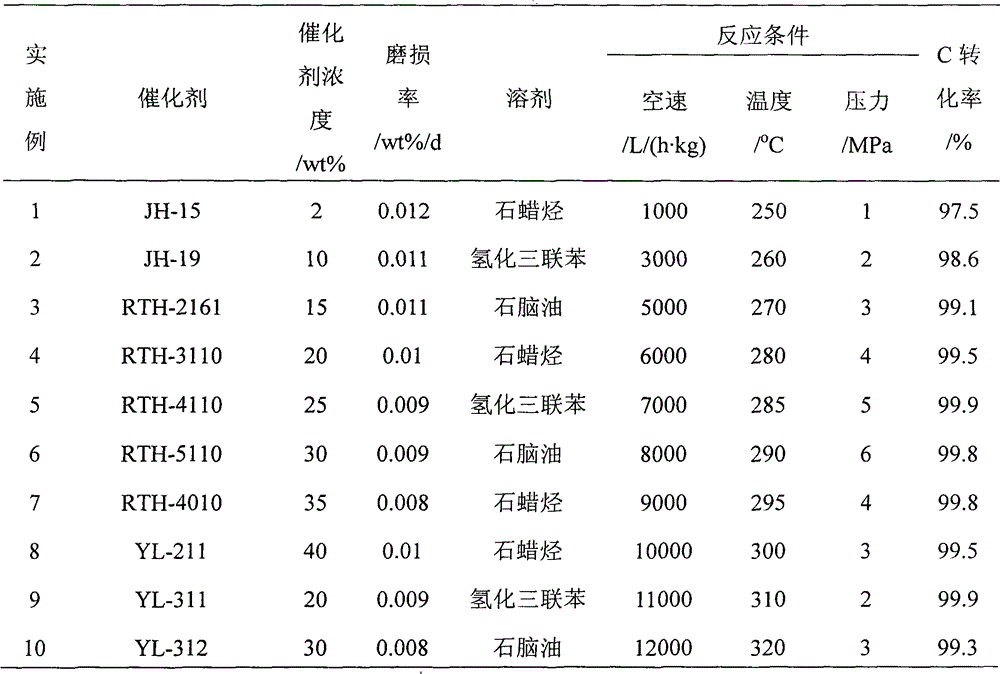

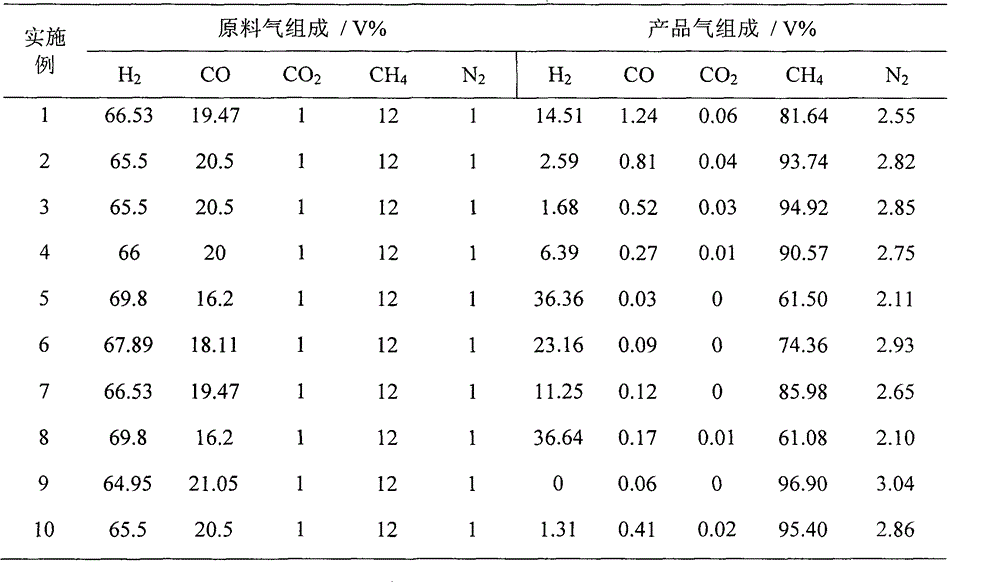

Application of raney nickel as slurry reactor to synthesize methane catalyst

InactiveCN102942971AWith characteristicsHave made significant progressGaseous fuelsLiquid mediumSlurry reactor

The invention provides the application of raney nickel as a slurry reactor to synthesize a methane catalyst, including: adding a raney nickel catalyst dispersed in an inert liquid medium to a reactor for a methanation reaction, feeding product gas and raw material gas to a separator, discharging a liquid phase component I composed of the liquid phase component and the catalyst component in the product gas from the bottom of the separator I, discharging gas phase I from the top of the separator, discharging a part of the inert liquid medium containing the catalyst from the middle of the reactor into a separator II, discharging gas phase II from the top of the separator II, mixing the gas phase II with the gas phase I to get a natural gas product, discharging the inert liquid medium of the catalyst from the bottom of the separator II to mix with the liquid phase component I to get a mixture, and feeding the mixture and the fresh methanation catalyst dispersed in the inert liquid medium together into the reactor for the methanation reaction. The application has the advantages that the raney nickel catalyst does not need reduction, has high mechanical strength and good wear resistance, and can satisfy the requirement of slurry reactor methanation process for low temperature activity.

Owner:TAIYUAN UNIV OF TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com