Wax extraction automatic filter, backwashing system of Ft synthetic pulp bed reactor

A technology of Fischer-Tropsch synthesis and slurry bed, which is applied in the fields of filtration and separation, preparation of liquid hydrocarbon mixture, recovery of petroleum wax, etc. It can solve the difficulty of increasing liquid-solid separation and the load of gas-solid separation, catalyst particle damage, and inconvenient operation of the reactor and other problems, to achieve the effect of short flow, small catalyst wear, and reduced chance of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further elaborated below through examples and in conjunction with the accompanying drawings, but the present invention is not limited thereto.

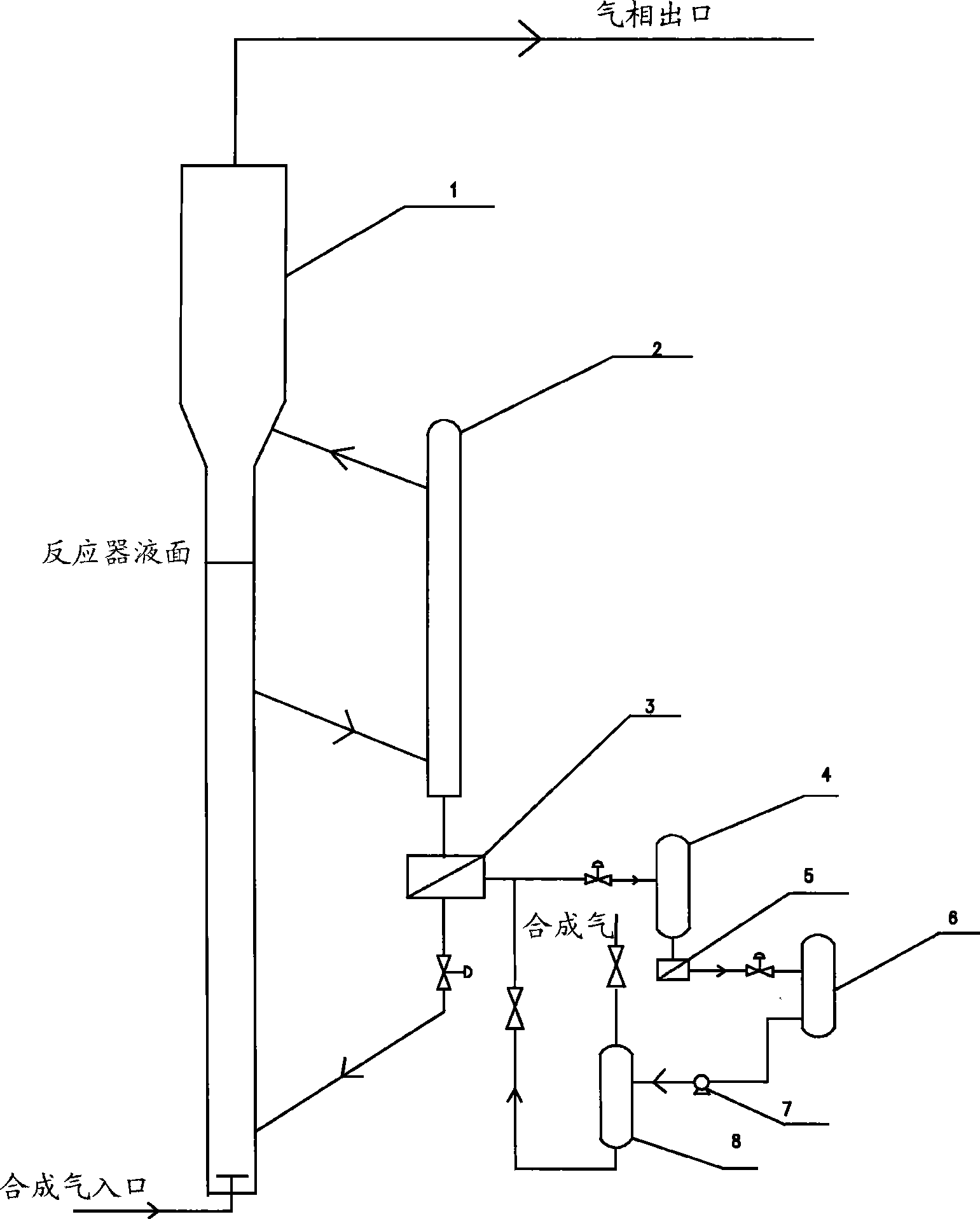

[0026] Such as figure 1As shown in the process flow chart of the wax extraction automatic filtration and backwashing system used in the Fischer-Tropsch synthesis slurry bed reactor, the synthesis gas enters the slurry bed reactor injected with a certain concentration and a certain level of catalyst slurry through the distributor in the device In 1, react at a temperature of 250°C and a pressure of 3.0 MPa, and the light oil gas produced is discharged from the top of the slurry bed reactor 1; the catalyst slurry in the slurry bed reactor 1 is drawn out from the side line into the bottom of the slurry buffer tank 2, and passed through the gas Liquid separation, the gas phase part is returned to the slurry bed reactor 1 from the upper part of the slurry buffer tank 2; the catalyst slurry enters the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com