Method for preparing ethylene through liquid-phase selective hydrogenation of acetylene in slurry reactor

A technology of selective hydrogenation and slurry bed, applied in hydrogenation to hydrocarbons, bulk chemical production, organic chemistry, etc., can solve the problems of high energy consumption, uneconomical, complex process, etc. rate, the effect of improving selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

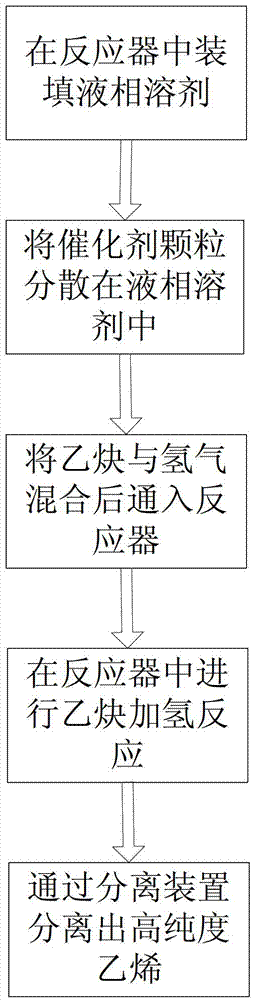

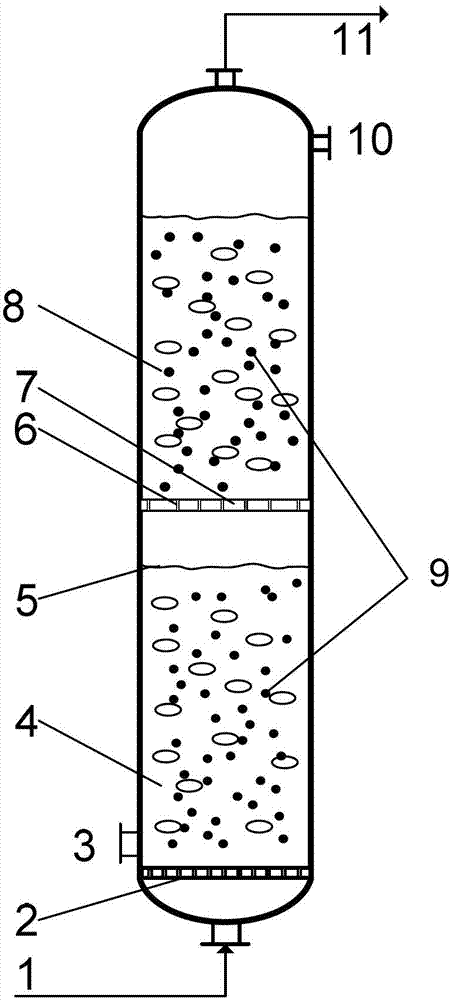

Method used

Image

Examples

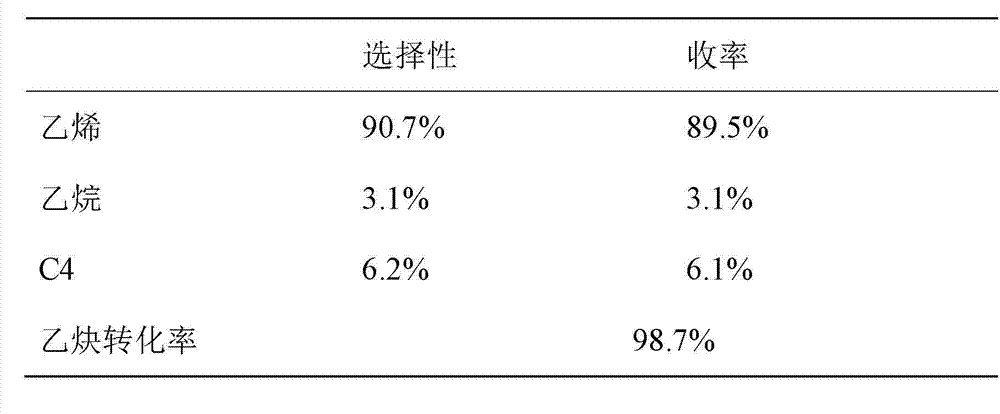

Embodiment 1

[0036] A slurry bed reactor is used, which is filled with 100 ml N-methylpyrrolidone and 0.5 g catalyst, which is Pd / SiO prepared by impregnation method 2 , where the loading of Pd was 0.01 wt%. During the reaction, the rotational speed was 700 rpm. Among them, C4 is butane, 1-butene, cis-2-butene, trans-2-butene, 1,3-butadiene.

[0037] Operating temperature: 80°C,

[0038] Operating pressure: 0.1 MPa,

[0039] Operating air speed: 3600 ml / (gcat h),

[0040] Hydrogen to acetylene volume ratio: 6,

[0041] Detection method: GC7900, FID detector, capillary column.

[0042] Table 1 Experimental data table of Example 1

[0043]

[0044] The experiment was carried out for 100 h, and there was no obvious inactivation phenomenon.

Embodiment 2

[0046] A slurry bed reactor is used, which is filled with 100 ml N-methylpyrrolidone and 0.5 g catalyst, which is Pd / SiO prepared by impregnation method 2 , where the loading of Pd was 0.01 wt%. During the reaction, the rotational speed was 700 rpm. Among them, C4 is butane, 1-butene, cis-2-butene, trans-2-butene, 1,3-butadiene.

[0047] Operating temperature: 100°C,

[0048] Operating pressure: 0.1 MPa,

[0049] Operating air speed: 3600 ml / (gcat h),

[0050] Hydrogen to acetylene volume ratio: 10,

[0051] Detection method: GC7900, FID detector, capillary column.

[0052] Table 2 Example 2 Experimental Data Table

[0053]

[0054] The experiment was carried out for 100 h, and there was no obvious inactivation phenomenon.

Embodiment 3

[0056] A slurry bed reactor is used, which is filled with 100 ml N-methylpyrrolidone and 0.5 g catalyst, which is Pd / SiO prepared by impregnation method 2 , where the loading of Pd was 0.01 wt%. During the reaction, the rotational speed was 700 rpm. Among them, C4 is butane, 1-butene, cis-2-butene, trans-2-butene, 1,3-butadiene.

[0057] Operating temperature: 100°C,

[0058] Operating pressure: 0.1 MPa,

[0059] Operating air speed: 8000 ml / (gcat h),

[0060] Hydrogen to acetylene volume ratio: 10,

[0061] Detection method: GC7900, FID detector, capillary column.

[0062] Table 3 Example 3 experimental data table

[0063]

[0064] The experiment was carried out for 100 h, and there was no obvious inactivation phenomenon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com