Alumina-loaded cobalt-based fischer-tropsch synthesis catalyst and preparation method and applications thereof

A technology of alumina loading and catalyst, which is applied in the field of preparation of Fischer-Tropsch synthesis catalysts, can solve the problems such as microwave technology has not been reported, and achieve the effect of simple and practical preparation process, easy industrialization, and simplified process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

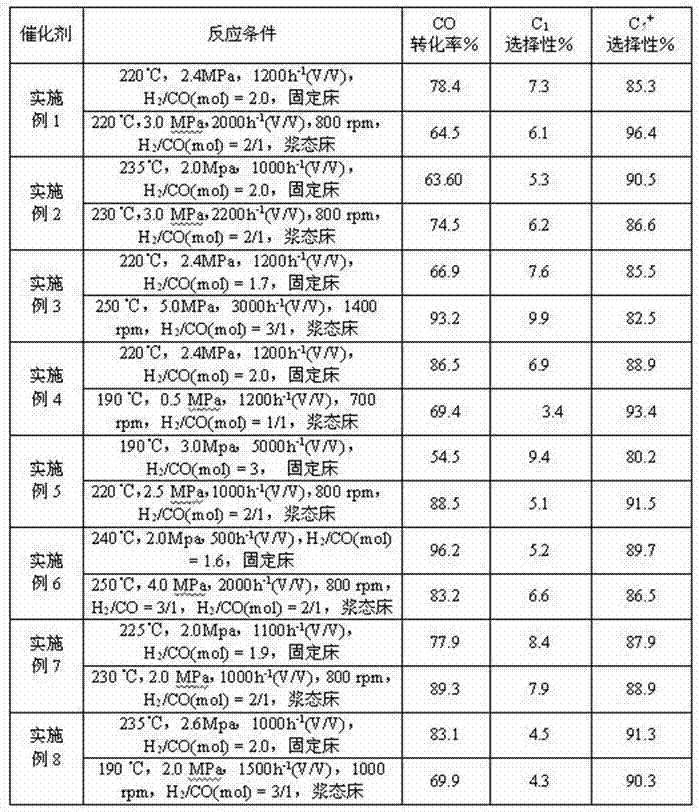

Examples

Embodiment 1

[0039] Prepare a certain amount of 1mol / L aluminum sulfate aqueous solution, and add the hydrolyzing agent NaOH into the solution by 0.05mol / L, keep the water bath temperature at 40°C, keep the time for 180min, and account for 0.1 (wt) of the final catalyst by ruthenium oxide % Weighing RuCl 3 3(H 2 O) join in this solution, be 1:1 to add peptizer H then by sol agent and aluminum source molar ratio 2 SO 4, stirred and refluxed at a microwave power of 50W until a transparent sol was maintained for 6h, and then aged at room temperature for 24h to obtain a gel. The gel was dried in a drying oven at 50°C for 2 hours, and then the dried gel was placed in a temperature-programmed microwave oven at a heating rate of 2°C / min and calcined at 550°C for 12 hours to obtain a catalyst carrier.

[0040] Weigh Co(NO 3 ) 2 6H 2 O, according to the equal-volume impregnation method, deionized water was measured, prepared into a mixed salt solution and impregnated on the above carrier for ...

Embodiment 2

[0043] Prepare a certain amount of 0.1mol / L aluminum isopropoxide aqueous solution, and the hydrolyzing agent H 2 SO 4 Add in the solution by 0.01mol / L, keep the temperature at 95°C under the microwave power of 500W, keep the time for 10min, weigh C 4 h 6 o 4 Co4H 2 O and Rh(NO 3 ) 3 2H 2 O was added to the solution, and then the peptizer HNO3 was added according to the molar ratio of the sol agent to the aluminum source at 0.01:1, stirred and refluxed to a transparent sol, kept for 3 hours, and then aged at room temperature for 6 hours to obtain a gel. The gel was dried in a microwave drying oven at 20° C. for 12 hours, and then the dry gel was placed in a temperature-programmed furnace and calcined at 200° C. for 8 hours to obtain the catalyst. The final catalyst weight is Co 3 o 4 : Rh 2 o 3 :Al 2 o 3 = 30:2:68.

[0044] Take 20 g of the above catalyst and reduce it in a fixed bed with hydrogen in nitrogen, the reduction conditions are: 400°C, 1.0 MPa, 1500 h...

Embodiment 3

[0046] Prepare a certain amount of 0.5mol / L sodium aluminate aqueous solution, and add the hydrolyzing agent NaOH into the solution at 0.2mol / L, keep the temperature at 40°C under the microwave power of 2000W, and keep the time for 180min. 0.1(wt)% of the catalyst weighed Pd(NO 3 ) 2 2H 2 O was added to the solution, and then the peptizer HCl was added according to the molar ratio of the sol agent to the aluminum source at 0.02:1, and the microwave power was 400W and stirred and refluxed to a transparent sol, kept for 6h, and then aged at room temperature for 24h to obtain a gel . The gel was dried in a drying oven at 50° C. for 2 hours, and then the dried gel was placed in a temperature-programmed microwave oven at a heating rate of 0.2° C. / min and calcined at 550° C. for 12 hours to obtain a catalyst carrier.

[0047] Account for 15 (wt)% of the final catalyst by tricobalt tetroxide 3 ) 2 6H 2 O, according to the equal-volume impregnation method, deionized water was me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com