An upper and lower hot air drying oven for single-sided printing or coating

A drying box and hot air technology, which is applied to the general parts of printing machinery, printing, printing machines, etc., can solve the problems of occupying a large work space, long drying time, and lengthening of the drying box, so as to avoid work space and reduce Effect of drying time, improvement of drying efficiency and conveying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

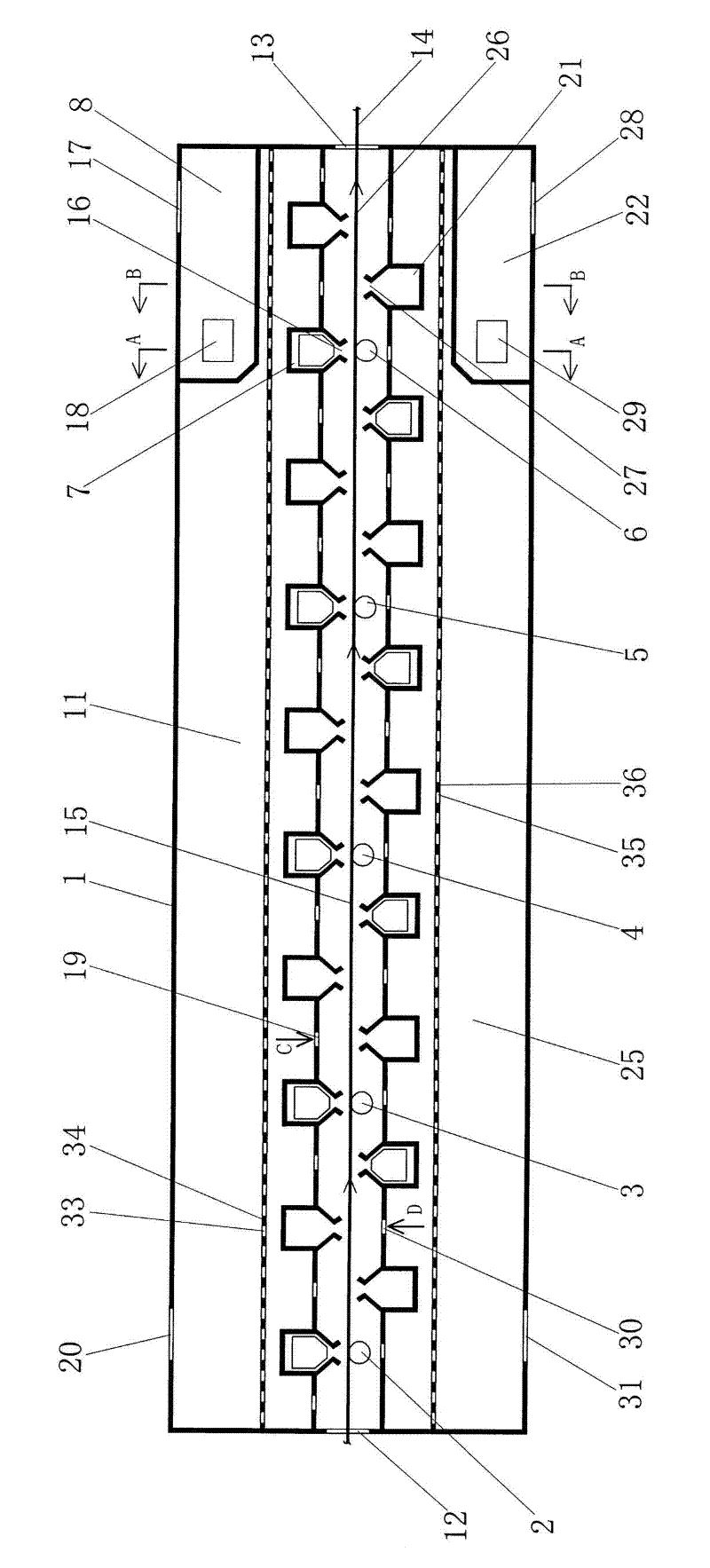

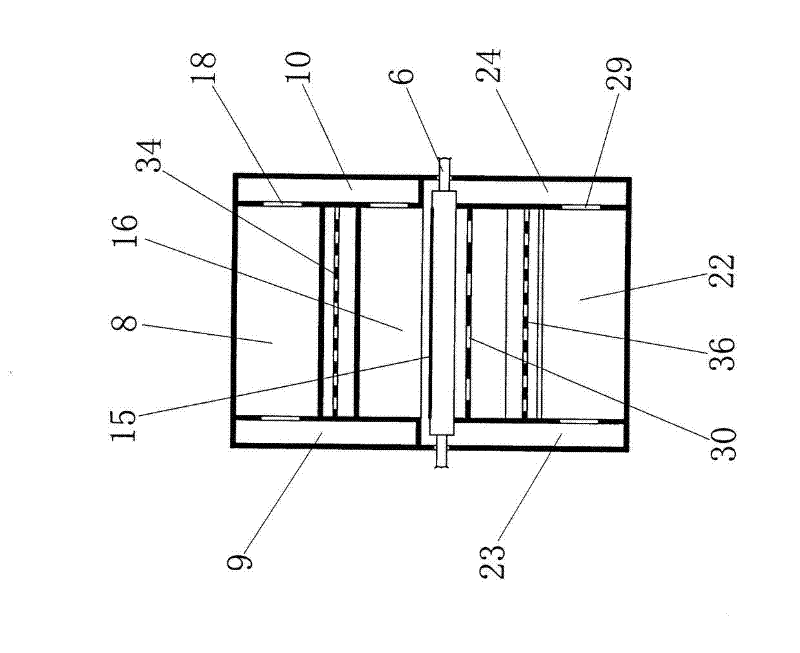

[0021] refer to Figure 1 ~ Figure 4 , the upper and lower hot air drying box for single-sided printing or coating is supported by the box shell 1 and several parallel substrate support rollers 2, 3, 4, 5 and 6 arranged in the substrate. Several upper hot air supply pipes 7 above the rollers, upper hot air equalizing chamber 8, upper hot air conveying passages 9, 10 and upper return air chamber 11, in which the box shell 1 is provided with a material inlet 12 and a material outlet 13. The thin sheet substrate 14 enters from the feed port 12 and is supported on the substrate support rollers 2, 3, 4, 5 and 6 to run and then comes out from the discharge port 13. The upper hot air supply pipe 7 and the like are equipped with Thin sheet substrate 14 has the elongated air supply port 16 etc. that the top surface 15 of printing or coating layer is arranged in parallel, has some air supply port 16 etc. to be positioned at the top of base material supporting roller 2,3,4,5 and 6, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com